Effects of Bulk Flow Pulsation on Film Cooling Involving Compound Angle

Abstract

:1. Introduction

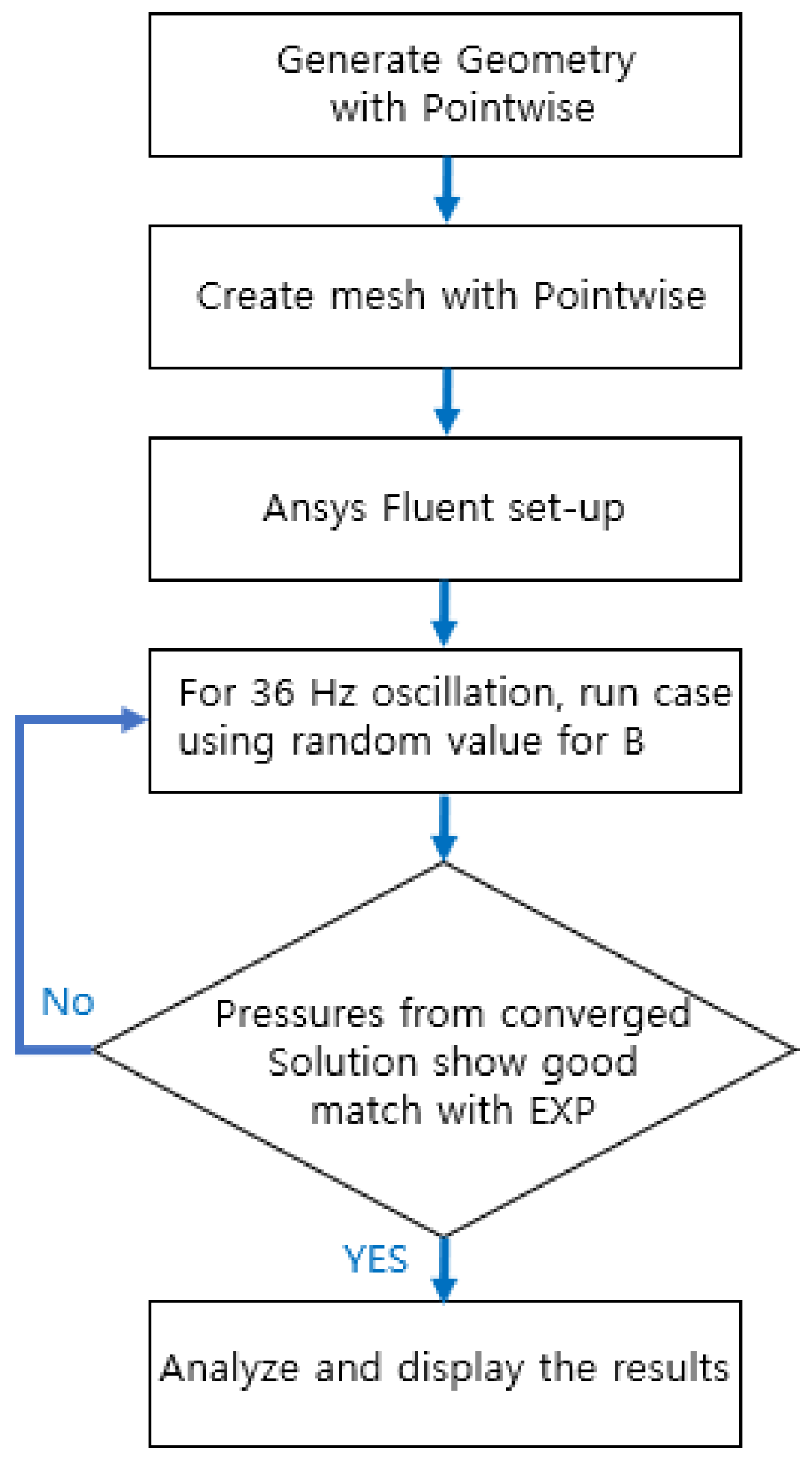

2. Numerical Method

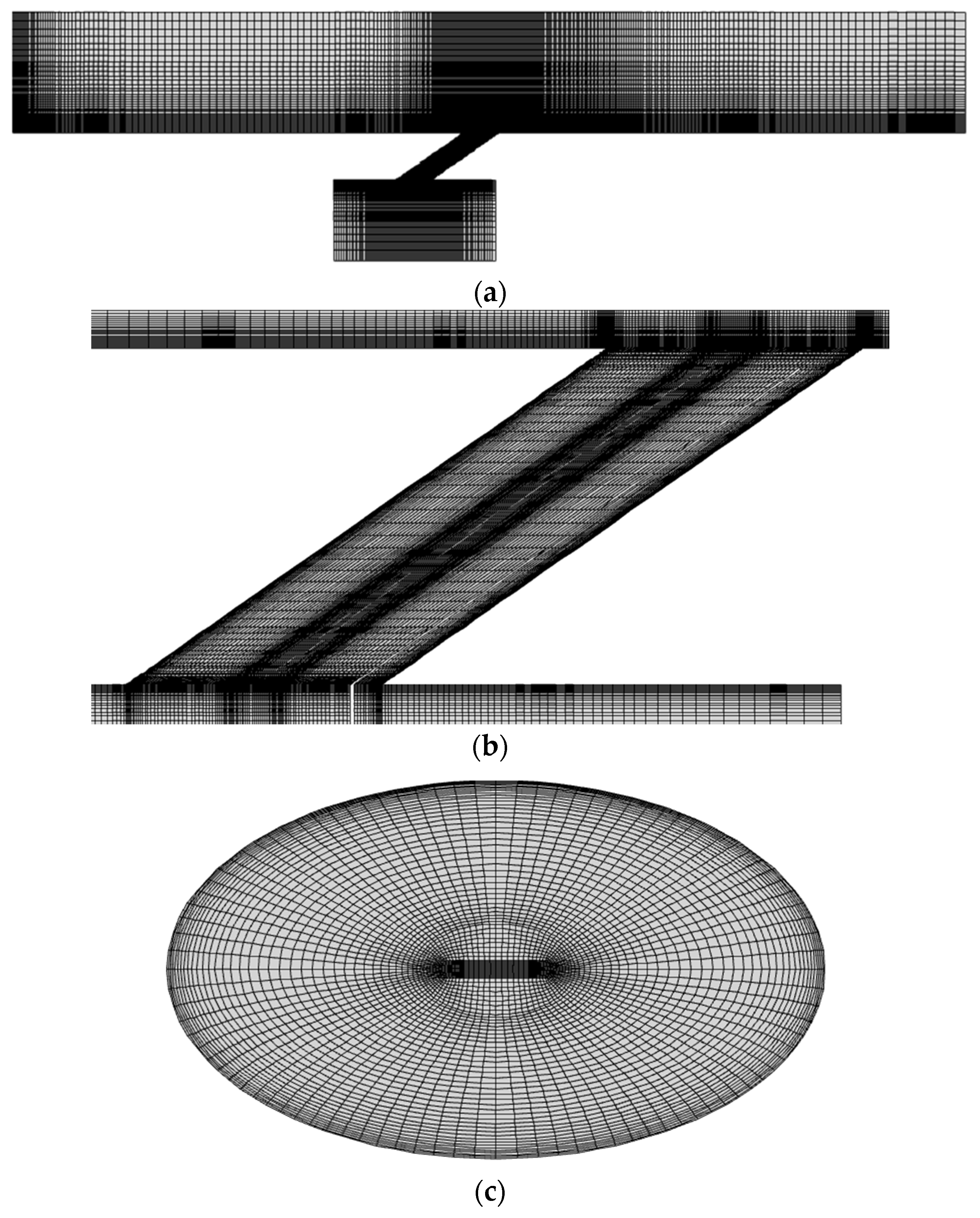

2.1. Computational Domain and CFD Mesh

2.2. Governing Equations and Boundary Conditions

2.2.1. Unsteady RANS Approach

2.2.2. LES Approach

2.2.3. Boundary Conditions

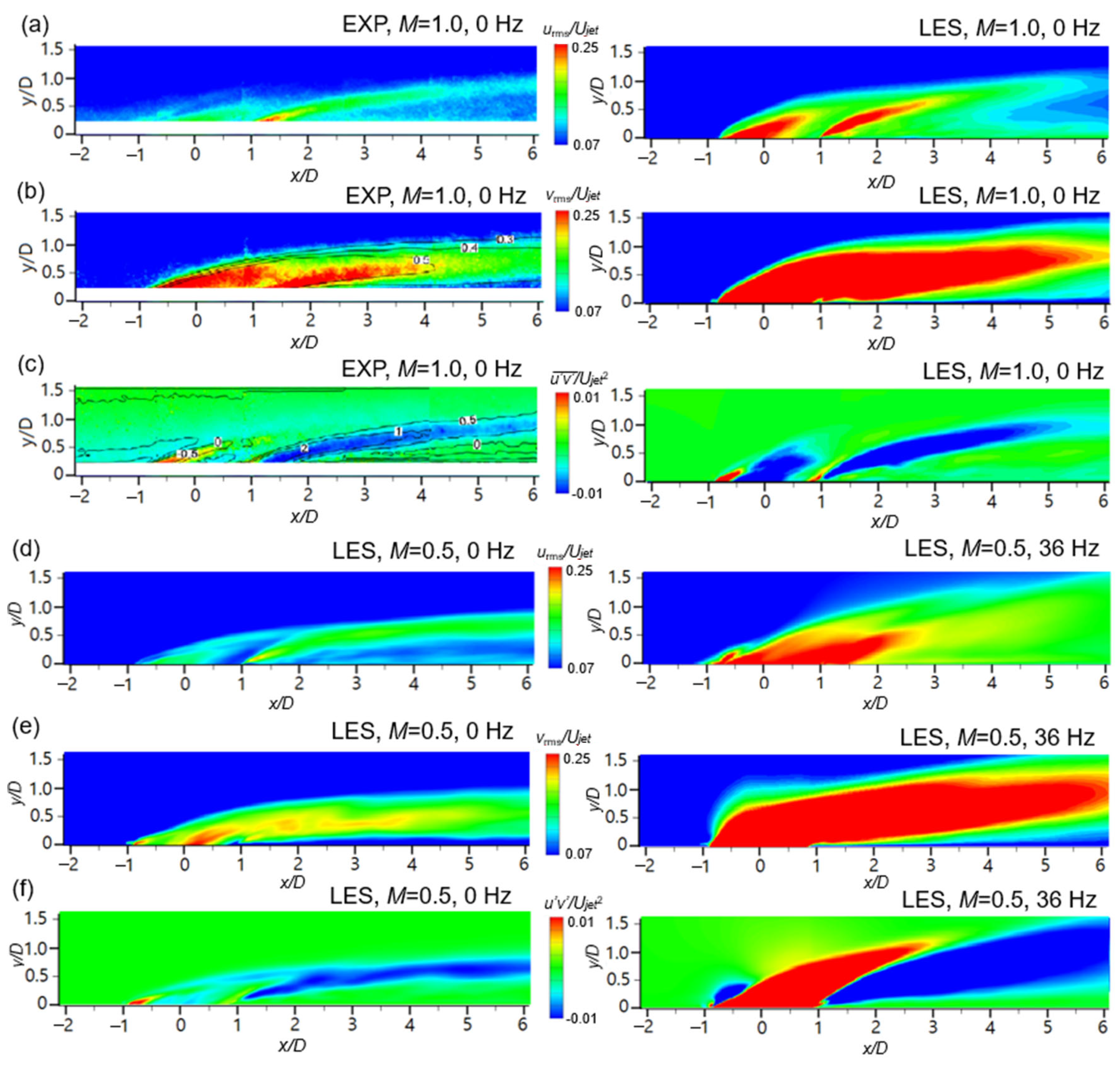

2.3. Validation of Numerical Methods

3. Results and Discussion

3.1. Contours of the Time-Averaged Effectiveness on the Wall

3.2. Time-Averaged Temperature Contours on the Streamwise-Normal Planes

3.3. Time-Averaged Streamwise Velocity Contour

3.4. Turbulence Statistics

3.5. Temperature Fluctuations

4. Conclusions

- The contours of the time-averaged effectiveness and the dimensionless temperatures of the coolant on the streamwise-normal plane obtained by the LES show a better agreement with the experimental data than with the contours at steady state.

- The streamwise velocity gradients in the shear layer predicted by the LES and URANS are smaller than those at steady state because of the intensive mixing between the coolant and the main flow.

- The URANS results predict a weaker streamwise velocity of the coolant jet that blocks the main flow compared with the LES.

- The values of urms around the coolant core, the center of the hole and the trailing edge of the hole increase as well as the values of wrms around the wall, while the contour of vrms increased along the trajectory of the injected coolant. Additionally, in the contour of uv, the secondary peaks became stronger while the main peaks weakened.

- The dimensionless temperature fluctuations increase in the region of the core of the coolant compared with those at steady state.

- For the orientation angle of 30°, the secondary peaks became stronger, similar to those for the simple angle, although the main blue streak weakened.

- This paper only covered the cylindrical hole, however, the effects of the main flow pulsations on film cooling for the shaped hole such as the forward expansion hole will be covered in future studies. Moreover, the effects for the two sister holes positioned more downstream of the primary hole and the optimized length between the sister hole and the primary hole will be investigated to obtain the best film cooling performance. For the parametric study, the CFD results of this study could be used as the baseline.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| D = hole diameter | |

| L = hole length | |

| M = blowing ratio = | |

| P = pitch between holes [mm] | |

| Sr = Strouhal number = | |

| T = temperature [K] | |

| t = time [s] | |

| U = flow velocity [m/s] | |

| u = fluctuating velocity [m/s] | |

| x = streamwise coordinate | |

| y = wall-normal coordinate | |

| z = spanwise coordinate | |

| Greek symbols | |

| β | = orientation angle |

| = angle between the streamwise direction and projected injection vector on the x–z plane | |

| κ = von Karman’s universal constant = 0.41 | |

| = adiabatic film cooling effectiveness | |

| = spanwise-averaged film cooling effectiveness | |

| = density [kg/m3] | |

| τij = sub-grid scale turbulent stress | |

| μt = sub-grid scale turbulent viscosity [kg/(m·s)] | |

| μ = dynamic viscosity | |

| Θ = dimensionless temperature | |

| Subscripts | |

| C = coolant | |

| G = mainstream gas | |

| m = spanwise-averaged | |

| rms = root mean squared | |

References

- Moran, M.; Shapiro, H.; Boettner, D.; Bailey, M. Fundamentals of Engineering Thermodynamics, 8th ed.; Wiley: Hoboken, NJ, USA, 2014; p. 532. [Google Scholar]

- Leedom, D.H.; Acharya, S. Large eddy simulations of film cooling flow fields from cylindrical and shaped holes. In Proceedings of the ASME Turbo Expo 2008, Berlin, Germany, 9–13 June 2008; pp. 865–877. [Google Scholar]

- Baek, S.; Ryu, J.; Ahn, J. Large Eddy Simulation of Film Cooling with Forward Expansion Hole: Comparative Study with LES and RANS Simulations. Energies 2021, 14, 2063. [Google Scholar] [CrossRef]

- Walters, D.K.; Leylek, J.H. Impact of film-cooling jets on turbine aerodynamic losses. ASME J. Turbomach. 2000, 122, 537–545. [Google Scholar] [CrossRef]

- Tyagi, M.; Acharya, S. Large eddy simulation of film cooling flow from an inclined cylindrical jet. ASME J. Turbomach. 2003, 125, 734–742. [Google Scholar] [CrossRef]

- Rozati, A.; Tafti, D. Large eddy simulation of leading edge film cooling: Part II—Heat transfer and effect of blowing ratio. In ASME Turbo Expo 2007; ASME: Montreal, QC, Canada, 2007. [Google Scholar]

- Na, S.; Shih, T. Increasing adiabatic film cooling effectiveness by using an upstream ramp. J. Heat Transfer. 2007, 129, 464–471. [Google Scholar] [CrossRef]

- Johnson, P.; Shyam, V.; Hah, C. Reynolds-Averaged Navier-Stokes Solutions to Flat Plate Film Cooling Scenarios; NASA/TM-2011-217025; NASA: Washington, DC, USA, 1 May 2011. [Google Scholar]

- Bianchini, C.; Andrei, L.; Andreini, A.; Facchini, B. Numerical Benchmark of Nonconventional RANS Turbulence Models for Film and Effusion Cooling. J. Turbomach. 2013, 135, 041026. [Google Scholar] [CrossRef]

- Yu, F.; Yavuzkurt, S. Near-Field Simulations of Film Cooling with a Modified DES Model. Inventions 2020, 5, 13. [Google Scholar] [CrossRef] [Green Version]

- Zamiri, A.; You, S.; Chung, J. Large eddy simulation in the optimization of laidback fan-shaped hole geometry to enhance film-cooling performance. Int. J. Heat Mass Transf. 2020, 158, 120014. [Google Scholar] [CrossRef]

- Lee, S.W.; Kim, Y.B.; Lee, J.S. Flow Characteristics and Aerodynamic Losses of Film-Cooling Jets with Compound Angle Orientations. J. Turbomach. 1997, 119, 310–319. [Google Scholar] [CrossRef]

- Jung, I.S.; Lee, J.S. Effects of Orientation Angles on Film Cooling over a Flat Plate: Boundary Layer Temperature Distributions and Adiabatic Film Cooling Effectiveness. J. Turbomach. 1999, 122, 153–160. [Google Scholar] [CrossRef]

- Seo, H.; Lee, J.; Ligrani, P. The effect of injection hole length on film cooling with bulk flow pulsations. Int. J. Heat Mass Transf. 1998, 41, 3515–3528. [Google Scholar] [CrossRef]

- Coulthard, S.M.; Volino, R.J.; Flack, K.A. Effect of Jet Pulsing on Film Cooling-Part I: Effectiveness and Flow-Field Temperature Results. J. Turbomach. 2006, 129, 232–246. [Google Scholar] [CrossRef]

- Nikitopoulos, D.E.; Acharya, S.; Oertling, J.; Muldoon, F.H. On Active Control of Film-Cooling Flows. In Proceedings of the ASME Turbo Expo, Barcelona, Spain, 8–11 May 2006. GT2006-90051. [Google Scholar]

- Jung, I.S.; Ligrani, P.M.; Lee, J.S. Effects of bulk flow pulsations on phase-averaged and time-averaged film-cooled boundary layer flow structure. J. Fluids Eng. 2001, 123, 559–566. [Google Scholar] [CrossRef]

- El-Gabry, L.A.; Rivir, R.B. Effect of Pulsed Film Cooling on Leading Edge Film Effectiveness. ASME J. Turbomach. 2012, 134, 041005. [Google Scholar] [CrossRef]

- Behrendt, T.; Gerendas, M. Characterization of the influence of moderate pressure fluctuations on the cooling performance of advanced combustor cooling concepts in a reacting flow. In Turbo Expo: Power for Land, Sea, and Air; GT2012-68845; American Society of Mechanical Engineers: New York, NY, USA, 2012. [Google Scholar]

- Baek, S.; Ahn, J. Large Eddy Simulation of Film Cooling Involving Compound Angle Hole with Bulk Flow Pulsation. Energies 2021, 14, 7659. [Google Scholar] [CrossRef]

- ANSYS Fluent Theory Guide Version 19. Available online: https://www.ansys.com/products/fluids/ansys-fluent (accessed on 21 January 2022).

- Pointwise Version 18. Available online: http://www.pointwise.com/ (accessed on 10 October 2021).

- Baek, S.I.; Yavuzkurt, S. Effects of Flow Oscillations in the Mainstream on Film Cooling. Inventions 2018, 3, 73. [Google Scholar] [CrossRef] [Green Version]

- Renze, P.; Schröder, W.; Meinke, M. Large-eddy Simulation of Film Cooling Flows with Variable Density Jets. Flow Turbul. Combust. 2007, 80, 119–132. [Google Scholar] [CrossRef]

- Iourokina, I.; Lele, S. Towards large eddy simulation of film cooling flows on a model turbine blade leading edge. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, USA, 10–13 January 2005. No. 2005-0670. [Google Scholar]

- Jung, I.S. Effects of bulk flow pulsations on film cooling with compound angle injection holes. Ph.D. Thesis, Seoul National University, Seoul, Korea, 1998. [Google Scholar]

- Han, J.; Dutta, S.; Ekkad, S. Gas Turbine Heat Transfer and Cooling Technology, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Farhadi-Azar, R.; Ramezanizadeh, M.; Taeibi-Rahni, M.; Salimi, M. Compound Triple Jets Film Cooling Improvements via Velocity and Density Ratios: Large Eddy Simulation. J. Fluids Eng. 2011, 133, 031202. [Google Scholar] [CrossRef]

- Cengel, Y.; Cimbala, J. Fluid Mechanics, 3rd ed.; McGrawHill: New York, NY, USA, 2014. [Google Scholar]

- Acharya, S.; Leedom, D.H. Large Eddy Simulations of Discrete Hole Film Cooling with Plenum Inflow Orientation Effects. J. Heat Transf. 2012, 135, 011010. [Google Scholar] [CrossRef]

- White, F. Fluid Mechanics, 8th ed.; McGraw-Hill: New York, NY, USA, 2015. [Google Scholar]

- Kaszeta, R.; Simon, T. Measurement of Eddy Diffusivity of Momentum in Film Cooling Flows with Streamwise Injection. J. Turbomach. 2000, 122, 178–183. [Google Scholar] [CrossRef]

- Baek, S.; Ahn, J. Large Eddy Simulation of Film Cooling Involving Compound Angle Holes: Comparative Study of LES and RANS. Processes 2021, 9, 198. [Google Scholar] [CrossRef]

- Burd, S.W.; Kaszeta, R.W.; Simon, T.W. Measurements in Film Cooling Flows: Hole L/D and Turbulence Intensity Effects. J. Turbomach. 1998, 120, 791–798. [Google Scholar] [CrossRef] [Green Version]

- Coletti, F.; Benson, M.; Ling, J.; Elkins, C.; Eaton, J. Turbulent transport in an inclined jet in crossflow. Int. J. Heat Fluid Flow 2013, 43, 149–160. [Google Scholar] [CrossRef]

| Surface | Boundary Condition |

|---|---|

| Main inlet | Velocity inlet |

| Plenum inlet | Velocity inlet |

| Top | Symmetry |

| Test plate | Adiabatic wall |

| Outflow | Pressure outlet |

| Main sides | Periodic |

| Sides of plenum | Wall |

| Blowing ratio, M | 1.0 | 0.5 | ||||

| Frequency, f (Hz) | 0 | 0 | 36 | |||

| Sr | 0 | 0 | 3.62 | |||

| β | 0° | 30° | 0° | 30° | 0° | 30° |

| A | 0 | 0 | 0.54 | |||

| Blowing ratio, M | 1.0 | 0.5 | ||||

| Frequency, f (Hz) | 0 | 0 | 36 | |||

| Sr | 0 | 0 | 3.62 | |||

| β | 0° | 30° | 0° | 30° | 0° | 30° |

| B | 0 | 0 | 0.3 | |||

| C | 0.328 | 0.164 | 0.164 | |||

| Grid | Number of Cells in the x-Direction | Number of Cells in the y-Direction | Number of Cells in the z-Direction | Number of Cells in the Main Block (Million) | Total Number of Cells (Million) |

|---|---|---|---|---|---|

| First | 242 | 52 | 34 | 0.5 | 1.14 |

| Second | 248 | 62 | 52 | 0.96 | 1.60 |

| Third | 276 | 80 | 56 | 1.41 | 2.04 |

| Fourth | 298 | 94 | 60 | 1.93 | 2.56 |

| Fifth | 312 | 110 | 68 | 2.76 | 3.40 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baek, S.-I.; Ahn, J. Effects of Bulk Flow Pulsation on Film Cooling Involving Compound Angle. Energies 2022, 15, 2643. https://doi.org/10.3390/en15072643

Baek S-I, Ahn J. Effects of Bulk Flow Pulsation on Film Cooling Involving Compound Angle. Energies. 2022; 15(7):2643. https://doi.org/10.3390/en15072643

Chicago/Turabian StyleBaek, Seung-Il, and Joon Ahn. 2022. "Effects of Bulk Flow Pulsation on Film Cooling Involving Compound Angle" Energies 15, no. 7: 2643. https://doi.org/10.3390/en15072643

APA StyleBaek, S.-I., & Ahn, J. (2022). Effects of Bulk Flow Pulsation on Film Cooling Involving Compound Angle. Energies, 15(7), 2643. https://doi.org/10.3390/en15072643