1. Introduction

Due to advantages such as energy conservation, environmental protection, and low charging cost, EVs have been gradually accepted by the market [

1,

2]. EVs have been considered as a good approach to reduce carbon dioxide emissions, for EVs can overcome the shortcomings of traditional fuel vehicle exhaust pollution. At the same time, EVs can save energy because they can be charged when the power consumption of the power grid is low [

3]. The

BT is one of the most expensive components of the EV and has a decisive impact on EV’s price and some of their performance [

4]. In current EVs, the BTs are always oversized in order to improve power performance and acceleration capability. Such challenges as power performance, running range, lifetime of the

BT, and cost of the EV with a sole energy storage system limit the EV’s wider use.

The SC has the advantages of high-power density, short charge and discharge time, and long service life and is less affected by the temperature, but the energy density is small [

5]. The Li-ion

BT and SC HESS can make up for the advantages of both sides while avoiding their disadvantages [

6].

The

BT and SC HESS is widely used in different objects and occasions. The

BT and SC HESS in smart phones extends the service life of Li-ion BTs [

7]. The lead-acid

BT and SC HESS in trucks reduces carbon dioxide emissions [

8,

9,

10]. The

BT and SC HESS reduces the power fluctuation of fuel cell and wind energy in the HESS with fuel cell and wind energy [

11,

12,

13,

14,

15,

16].

The performance of

BT and SC HESS depends on an appropriate energy management strategy. The wavelet analysis method is used to identify the road conditions; then, the neural network is used to learn the conditions data, and the fuzzy energy management strategy is used to distribute the power of the HESS, which improves vehicle performance [

17]. The HESS real-time energy management strategy based on SC voltage detection has achieved good results. By improving the topology of HESS, flexible control of lithium

BT current is realized, and the effect of energy management is improved. The power performance of HESS is improved by the fuzzy predictive control method [

18]. A HESS energy management strategy based on dynamic programming considering lithium

BT degradation is proposed [

19].

Compared with the BT, the HESS not only improves the performance but also leads to the increase of system complexity and cost. Therefore, the evaluation and optimization of HESS should be carried out with multiple objectives. The purpose of HESS EV is to improve the performances of the EV while taking into account the economy of the EV.

The GA algorithm is widely used in the field of EV optimization [

20,

21,

22,

23,

24]. The GA algorithm is used to optimize the multi objectives of fuel cell current, lithium

BT current, lithium

BT’s

SOC change, SC’s

SOC change, and hydrogen consumption cost by the control of the powers of the

BT and SC and the load in the fuel cell,

BT, and SC hybrid EV [

20]. The multi-objective GA algorithm is used to optimize the automotive electric transmission [

21]. The GA algorithm is used to optimize the location and power of EV charging stations [

22,

23]. The multi-objective GA algorithm is used to optimize the driving paths and powers of multi depot vehicle [

24].

The above studies focus on comparing HESS performance with

BT or SC performance or, for specific HESS, using an intelligent control method to optimize the energy management strategy and improve the HESS performance, with less consideration of the influence of the sizing parameters of components in HESS and less consideration of the optimal design based on the EV’s specific performance indicators in the optimization. At the same time, how to get the real time performances of the HESS EV is a difficulty. In this paper, a multiobjective optimization on a

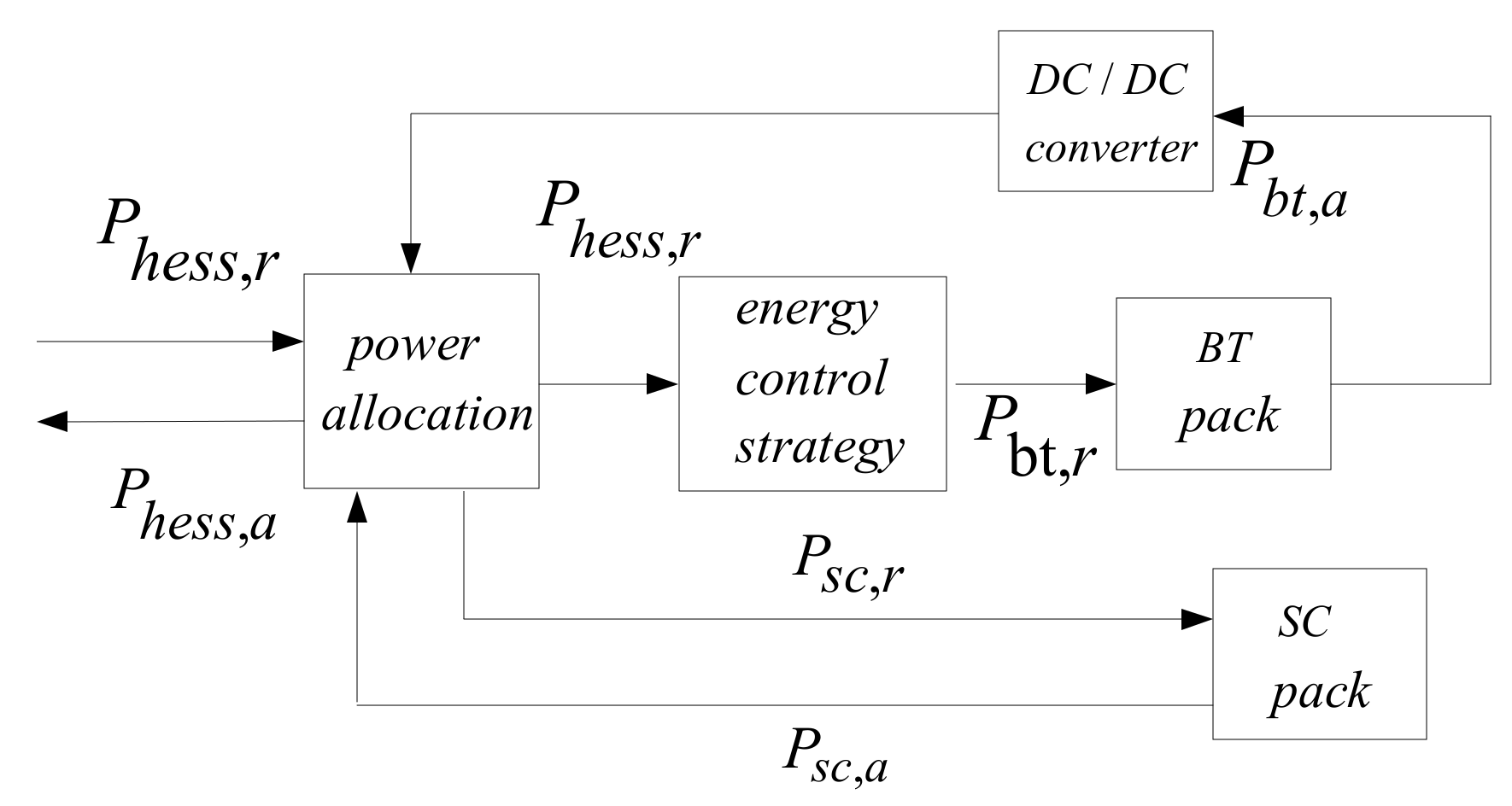

BT and SC HESS EV using both GA algorithm and ADVISOR software will be studied. The real time performances of the HESS EV are obtained by the ADVISOR software. The EV’s energy consumption over 100 km, acceleration time from 0–100 km per hour, maximum speed, HESS cost, and running range are considered in the objective function. The structure of the paper is as follows: The fundamentals of a

BT semi-active HESS EV, the scheme of the multiobjective optimization and an optimal energy management strategy are designed in

Section 2.

Section 3 focuses on the multiobjective problem analysis. In

Section 4 the GA algorithm optimization based on ADVISOR software and MATLAB software is carried out. The study discussion is also presented in

Section 4. The conclusions are presented in

Section 5.

3. Multiobjective Optimization Analysis

The HESS EV performance simulation results [

26] of the HESS EV in the ADVISOR software show that both the sizing parameters of the HESS components and the control strategy parameters have a certain impact on EV’s performances, energy consumption rate, running range, and HESS cost. When

kbt increases,

t100,

Q100,

l, and

Chess increases, and

Vveh,max decreases. When

Nbt,s increases,

Vveh,max,

t100, l, and

Chess increase, and

Q100 increases or decreases. When

Nsc,s increases,

Vveh,max,

Q100, and

Chess increase, and

t100 and

l decrease. When

Nsc,p increases,

Vveh,max,

l, and

Chess increase, and

Q100 and

t100 decrease. When

Pcharge increases,

Vveh,max and

Q100 increase, and

t100,

l and

Chess decrease. Therefore, the relationships between the sizing parameters of the HESS components and the control strategy parameters and EV’s performances, energy consumption rate, running range, and the HESS cost are nonlinear and strong coupling.

The HESS EV performance simulation results show that, among the sizing parameters of HESS’s components and the control strategy parameters, the scaled factors of BT capacity kbt, Nbt,s, Nsc,s, Nsc,p, and Pcharge have a greater impact on the five objectives, while other parameters have less impact on the five objectives. Therefore, kbt, Nbt,s, Nsc,s, Nsc,p, and Pcharge are selected as the optimization variables.

The semi-active HESS EV evaluation focuses on the energy consumption over 100 km

Q100, the acceleration time from 0–100 km per hour

t100, the maximum speed

Vveh,max, the running range

l, and the HESS cost

Chess, which are essentially contradictory. The variables of the multiobjective optimization problem for the HESS EV contain

kbt,

Nbt,s,

Nsc,s,

Nsc,p, and

Pcharge, as shown in Equation (10).

The HESS EV performance simulation results and the HESS EV performance constraints reduce the amount of calculations during the optimization. The varied ranges of the variables are described in Equation (11).

The multiobjective function is given by Equation (12). The optimization objective is to maximize the value of F(x).

t100,norm,Vveh,max,norm, lnorm, Q100,norm, and Chess,norm are the normalization value of t100, Vveh,max, l, Q100, and Chess, between zero and one, based on the maximum and minimum values obtained.

t100,norm is shown in Equation (13).

t100,min is the reference minimum value of t100, and t100,max is the reference maximum value of t100.

Vveh,max,norm is shown in Equation (14).

Vveh,max,min is the reference minimum value of Vveh,max, and Vveh,max,max is the maximum value of Vveh,max.

lnorm is shown in Equation (15).

lmin is the reference minimum value of l, and lmax is the reference maximum value of l.

Q100,norm is shown in Equation (16).

Q100,min is the reference minimum value of Q100, and Q100,max is the reference maximum value of Q100.

Chess,norm is shown in Equation (17).

Chess,min is the reference minimum value of Chess. Chess,max is the reference maximum value of Chess.

The optimization constraints parameters are shown in

Table 6.

mveh is the weight of the HESS EV.

The weights w1, w2, w3, w4, and w5 are chosen to indicate the importance of the five objectives. The sum of w1, w2, w3, w4, and w5 is 1.

4. Optimization Results

The GA algorithm has been shown to be an effective strategy to solve complex and non-linear engineering optimization problems. The GA algorithm is written in the ADVISOR software in the MATLAB environment. The GA algorithm parameters are as in

Table 7.

The HESS optimization flowchart diagram based on the ADVISOR software and GA algorithm is as in

Figure 4. The optimized variables

kbt,

Nbt,s,

Nsc,s,

Nsc,p, and

Pcharge are encoded by binary method.

w1,

w2,

w3, w4, and

w5 are 0.2, 0.2, 0.2, 0.2, and 0.2, respectively. The equivalent fuel economy of the HESS EV under UDDS driving condition is good. Therefore, two consecutive UDDS (Urban Dynamometer Driving Schedule) drive cycles are used in the simulation.

The HESS cost is evaluated by considering a BACP3000 super-capacitor cost as USD 50 and a SAFT VL45E Li-ion

BT cost as USD 40. The Li-ion

BT packs are replaced once in the cycle lifetime, so the cost of a

BT is USD 80.

Chess is presented as Equation (18).

The objection function

F(x) convergence process is as in

Figure 5, basically stable after nearly 15 generations.

The

t100 convergence process is as in

Figure 6, basically stable after near 20 generations.

The

Vveh,max convergence process is as in

Figure 7, basically stable after near 25 generations.

The

Q100 convergence process is as in

Figure 8, basically stable after near 25 generations.

The

Chess convergence process is as in

Figure 9, basically stable after near 30 generations.

The

l convergence process is as in

Figure 10, basically stable after near 30 generations.

The simulation results are as in

Table 8. It is clear that the optimization results meet the constraints of the optimization. The GA algorithm can find the optimal value. The optimization results are reasonable taking into account the five objectives, such as

t100,

Vveh,max,

l,

Q100, and

Chess.

Two sets of weights are used to study their influences on the results of multiobjective optimization. The two sets of weights are as in

Table 9. The five weights of the five objectives are the same in the first set of weights. This means that these five objectives are equally important. In the second set of weights,

w1,

w2, and

w5 change, but

w3 and

w4 remain unchanged comparing the first set of weights. The results are shown in

Table 10. It can be seen from

Table 9 and

Table 10 that when

w1 decreases from 0.2 to 0.15, the corresponding objective

t100 increases from 8.2 to 9.5. When

w2 decreases from 0.2 to 0.15, the corresponding objective

Vveh,max decreases from 133.28 to 108.85. When w

5 increases from 0.2 to 0.3, the corresponding objective

Chess decreases from 30,800 to 19,800. Some of the multi objectives are sensitive to their weights. The weight of each objective can be selected according to the importance of each objective.

The optimization of HESS EV in ADVISOR software is realized by the direct optimization algorithm, which directly uses a large number of simulations and compares the results, so as to obtain the optimal solution or approximate optimal solutions. Compared with GA algorithm optimization, the direct optimization algorithm of the HESS EV takes longer time, but the optimization effect is poor, and it is difficult to find a better solution. Compared with direct optimization algorithm, the GA algorithm has a stronger optimization ability, and the single objective is more sensitive to its corresponding weight.