Experimental Research on the Dynamic Characteristics and Voltage Uniformity of a PEMFC Stack under Subzero Temperatures

Abstract

:1. Introduction

2. Experimental Procedure

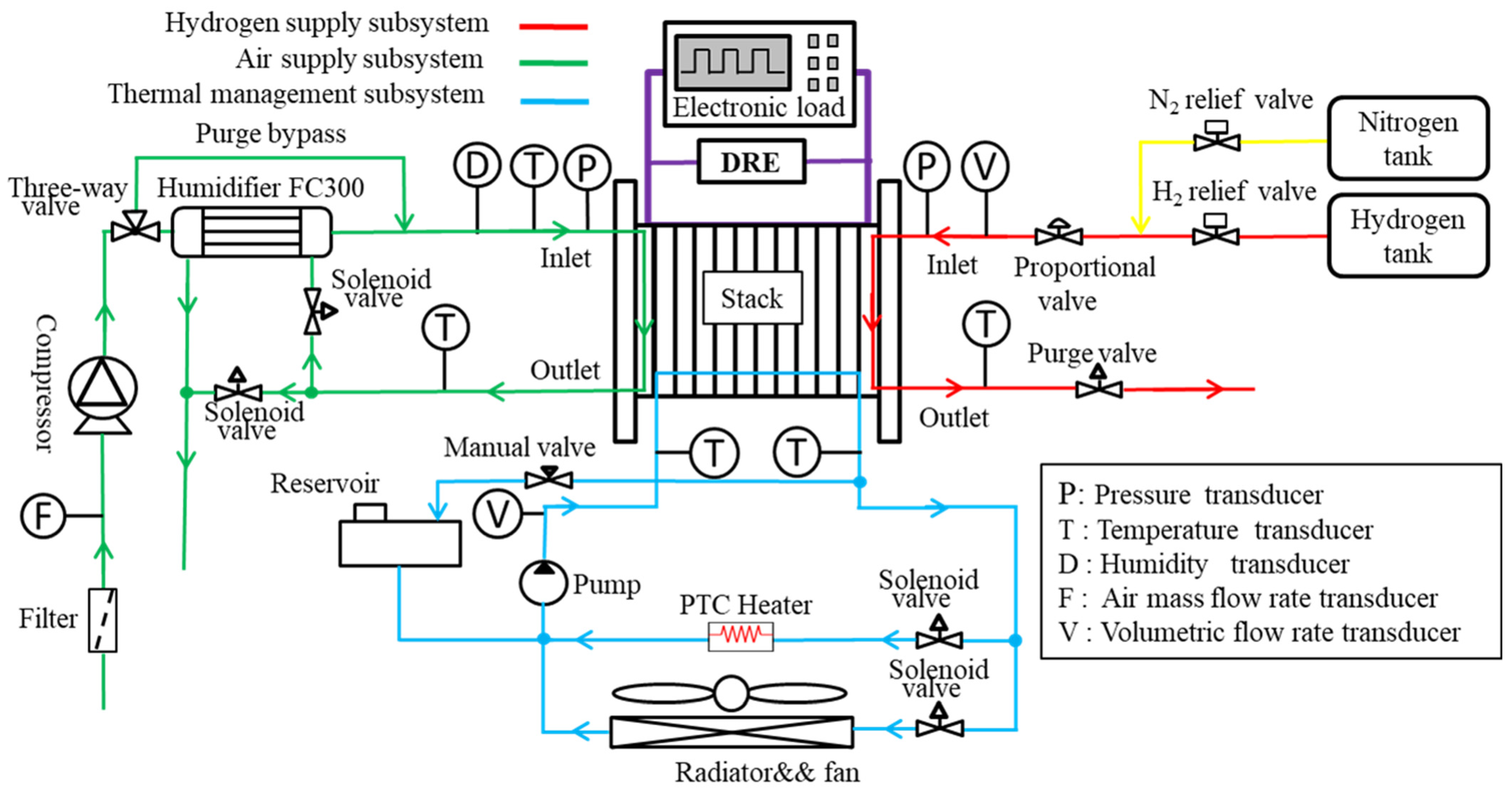

2.1. Experimental Setup

2.2. Experimental Procedure

3. Results

3.1. Effect of Different Step Sizes

3.2. Effect of Different Stack Temperatures

3.3. Comparisons of Different Loading Strategies

3.4. Comparisons of Two Increasing Loading Rate Strategies

- I2 = I1 + K0 × t Constant loading rate strategy (I);

- I2 = I1 + K1 × t2 Square increasing loading rate strategy (II);

- I2 = I1 + K2 × t3 Cure increasing loading rate strategy (III).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, A.R.; Vinothkannan, M.; Yoo, D.J. Sulfonated fluorinated multi-block copolymer hybrid containing sulfonated(poly ether ether ketone) and graphene oxide: A ternary hybrid membrane architecture for electrolyte applications in proton exchange membrane fuel cells. J. Energy Chem. 2018, 27, 1247–1260. [Google Scholar] [CrossRef]

- Ryu, S.K.; Vinothkannan, M.; Kim, A.R.; Yoo, D.J. Effect of type and stoichiometry of fuels on performance of polybenzimidazole-based proton exchange membrane fuel cells operating at the temperature range of 120–160 °C. Energy 2021, 238, 121791. [Google Scholar] [CrossRef]

- Luo, Y.; Jiao, K. Cold start of proton exchange membrane fuel cell. Prog. Energy Combust. Sci. 2018, 64, 29–61. [Google Scholar] [CrossRef]

- Lin, R.; Jiang, Z.H.; Ren, Y.S.; Shi, W. Performance degradation and strategy optimization of PEMFCs under subfreezing temperature. J. Tongji Univ. (Nat. Sci.) 2018, 46, 658–666. [Google Scholar]

- Lin, R.; Zhu, Y.; Ni, M.; Jiang, Z.; Lou, D.; Han, L.; Zhong, D. Consistency analysis of polymer electrolyte membrane fuel cell stack during cold start. Appl. Energy 2019, 241, 420–432. [Google Scholar] [CrossRef]

- Dai, C.H.; Shi, Q.; Chen, W.Q.; Li, Y.; Li, Q. A Review of the Single Cell Voltage Uniformity in Proton Exchange Membrane Fuel Cells. Proc. CSEE 2016, 36, 1289–1302. [Google Scholar]

- Mishler, J.; Wang, Y.; Mukherjee, P.P.; Mukundan, R.; Borup, R.L. Subfreezing operation of polymer electrolyte fuel cells: Ice formation and cell performance loss. Electrochim. Acta 2012, 65, 127–133. [Google Scholar] [CrossRef] [Green Version]

- Zhong, D.; Lin, R.; Jiang, Z.; Zhu, Y.; Liu, D.; Cai, X.; Chen, L. Low temperature durability and consistency analysis of proton exchange membrane fuel cell stack based on comprehensive characterizations. Appl. Energy 2020, 264, 114626. [Google Scholar] [CrossRef]

- Huang, Y. Research on Proton Exchange Membrane Fuel Cell Start-Up at Subzero Temperature. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2015. [Google Scholar]

- Lin, R.; Lin, X.; Weng, Y.; Ren, Y. Evolution of thermal drifting during and after cold start of proton exchange membrane fuel cell by segmented cell technology. Int. J. Hydrog. Energy 2015, 40, 7370–7381. [Google Scholar] [CrossRef]

- Wang, X.; Tajiri, K.; Ahluwalia, R. Water transport during startup and shutdown of polymer electrolyte fuel cell stacks. J. Power Sources 2010, 195, 6680–6687. [Google Scholar] [CrossRef]

- Song, K.-Y.; Kim, H.-T. Effect of air purging and dry operation on durability of PEMFC under freeze/thaw cycles. Int. J. Hydrogen Energy 2011, 36, 12417–12426. [Google Scholar] [CrossRef]

- Gavello, G.; Zeng, J.; Francia, C.; Icardi, U.; Graizzaro, A.; Specchia, S. Experimental studies on Nafion® 112 single PEM-FCs exposed to freezing conditions. Int. J. Hydrog. Energy 2011, 36, 8070–8081. [Google Scholar] [CrossRef]

- Cho, E.A.; Ko, J.J.; Ha, H.Y.; Hong, S.A.; Lee, K.Y.; Lim, T.W.; Oh, I.H. Effects of Water Removal on the Performance Deg-radation of PEMFCs Repetitively Brought to <0 °C. J. Electrochem. Soc. 2004, 151, A661–A665. [Google Scholar] [CrossRef]

- Knorr, F.; Sanchez, D.G.; Schirmer, J.; Gazdzicki, P.; Friedrich, K.A. Methanol as antifreeze agent for cold start of automotive polymer electrolyte membrane fuel cells. Appl. Energy 2019, 238, 1–10. [Google Scholar] [CrossRef]

- Amamou, A.; Boulon, L.; Kelouwani, S. Comparison of self cold start strategies of automotive Proton Exchange Membrane Fuel Cell. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 19–22 February 2018; pp. 904–908. [Google Scholar] [CrossRef]

- Luo, Y.; Jiao, K.; Jia, B. Elucidating the constant power, current and voltage cold start modes of proton exchange membrane fuel cell. Int. J. Heat Mass Transf. 2014, 77, 489–500. [Google Scholar] [CrossRef]

- Amamou, A.; Kandidayeni, M.; Boulon, L.; Kelouwani, S. Real time adaptive efficient cold start strategy for proton exchange membrane fuel cells. Appl. Energy 2018, 216, 21–30. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Dai, C.; Guo, A.; Chen, W. Experimental study on dynamic voltage uniformity of a 2-kW air-cooled PEMFC. Electr. Eng. 2018, 100, 2725–2735. [Google Scholar] [CrossRef]

- Liu, P.C.; Zhang, B.T.; Xu, S.C. Experimental Research on Voltage Uniformity of a PEMFC Stack under Dynamic Step Loading. In Proceedings of the SAE WCX Digital Summit, Detroit, MI, USA, 13–15 April 2021. [Google Scholar]

- Li, Y.K. Research on Voltage Uniformity and Control Strategy of Proton Exchange Membrane Fuel Cell Stack. Ph.D. Thesis, Southwest Jiao Tong University, Wuhan, China, 2015. [Google Scholar]

- Zhao, Y.Q. Research on Dynamic Response of Air-Cooled PEMFC Considering Uniformity. Master’s Thesis, Southwest Jiao Tong University, Wuhan, China, 2016. [Google Scholar]

- Li, Y.; Zhao, X.; Liu, Z.; Li, Y.; Chen, W.; Li, Q. Experimental study on the voltage uniformity for dynamic loading of a PEM fuel cell stack. Int. J. Hydrog. Energy 2015, 40, 7361–7369. [Google Scholar] [CrossRef]

- Migliardini, F.; Di Palma, T.; Gaele, M.; Corbo, P. Cell voltage analysis of a 6 kW polymeric electrolyte fuel cell stack designed for hybrid power systems. Mater. Today Proc. 2019, 10, 393–399. [Google Scholar] [CrossRef]

- Corbo, P.; Migliardini, F.; Veneri, O. Dynamic behavior of hydrogen fuel cells for automotive application. Renew. Energy 2009, 34, 1955–1961. [Google Scholar] [CrossRef]

- Corbo, P.; Migliardini, F.; Veneri, O. Experimental analysis of a 20 kWe PEM fuel cell system in dynamic conditions representative of automotive applications. Energy Convers. Manag. 2008, 49, 2688–2697. [Google Scholar] [CrossRef]

- Xu, P.; Zhang, J.; Guo, X.; Gao, Y.; Xu, S.C. An experimental investigation into gas purge after shutdown and cold start performance of proton exchange membrane fuel cell. J. Tongji Univ. (Nat. Sci.) 2017, 45, 126–131. [Google Scholar]

- Xu, P. Research on Thermal and Water Transport Mechanism in Subfreezing Temperature for Proton Exchange Membrane Fuel Cell. Ph.D. Thesis, Tongji University, Shanghai, China, 2019. [Google Scholar]

- Chen, P.; Chen, X.S. Experimental investigation on −10 °C start performance of a PEM fuel cell power system for automotive application. J. Automot. Saf. Energy 2016, 7, 427–432. [Google Scholar]

- Kota, M.; Yoshiaki, N.; Yasuhiro, N.; Mikio, K.; Tomoya, O. Development of Fuel Cell Hybrid Vehicle Rapid Start-up from Sub-Freezing Temperatures. In Proceedings of the SAE WCX Digital Summit, Detroit, MI, USA, 13–15 April 2021. [Google Scholar]

- Liu, P.; Xu, S.; Fu, J.; Liu, C. Experimental investigation on the voltage uniformity for a PEMFC stack with different dynamic loading strategies. Int. J. Hydrog. Energy 2020, 45, 26490–26500. [Google Scholar] [CrossRef]

- Jiao, K.; Li, X. Cold start analysis of polymer electrolyte membrane fuel cells. Int. J. Hydrogen Energy 2010, 35, 5077–5094. [Google Scholar] [CrossRef]

- Pinton, E.; Fourneron, Y.; Rosini, S.; Antoni, L. Experimental and theoretical investigations on a proton exchange membrane fuel cell starting up at subzero temperatures. J. Power Sources 2009, 186, 80–88. [Google Scholar] [CrossRef]

- Cho, J.; Kim, H.-S.; Min, K. Transient response of a unit proton-exchange membrane fuel cell under various operating conditions. J. Power Sources 2008, 185, 118–128. [Google Scholar] [CrossRef]

- Chen, H.C. Analysis of the Dynamic Response Affecting the Fuel Cell Lifetime and Economic Evaluation of the Fuel Cell. Ph.D. Thesis, Tsinghua University, Beijing, China, 2015. [Google Scholar]

- Jia, L.; Tan, Z.; Kang, M.; Zhang, Z. Experimental investigation on dynamic characteristics of proton exchange membrane fuel cells at subzero temperatures. Int. J. Hydrog. Energy 2014, 39, 11120–11127. [Google Scholar] [CrossRef]

- Frano, B.; Li, D.H.; Lian, X.F. PEM fuel cell: Theory and practice. In The 2nd Edition of the Original Book; China Machine Press: Beijing, China, 2016; pp. 31–32. [Google Scholar]

- Nguyen, T.-T.; Fushinobu, K. Effect of operating conditions and geometric structure on the gas crossover in PEM fuel cell. Sustain. Energy Technol. Assess. 2020, 37, 100584. [Google Scholar] [CrossRef]

- Baik, K.D.; Hong, B.K.; Kim, M.S. Effects of operating parameters on hydrogen crossover rate through Nafion® membranes in polymer electrolyte membrane fuel cells. Renew. Energy 2013, 57, 234–239. [Google Scholar] [CrossRef]

- Qi, J. Study on Individual Cell Voltage Uniformity of PEMFC Stack. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2011. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Xu, S. Experimental Research on the Dynamic Characteristics and Voltage Uniformity of a PEMFC Stack under Subzero Temperatures. Energies 2022, 15, 3062. https://doi.org/10.3390/en15093062

Liu P, Xu S. Experimental Research on the Dynamic Characteristics and Voltage Uniformity of a PEMFC Stack under Subzero Temperatures. Energies. 2022; 15(9):3062. https://doi.org/10.3390/en15093062

Chicago/Turabian StyleLiu, Pengcheng, and Sichuan Xu. 2022. "Experimental Research on the Dynamic Characteristics and Voltage Uniformity of a PEMFC Stack under Subzero Temperatures" Energies 15, no. 9: 3062. https://doi.org/10.3390/en15093062