Utilization of Window System as Exhaust Air Heat Recovery Device and Its Energy Performance Evaluation: A Comparative Study

Abstract

:1. Introduction

2. Methodology

2.1. Framework of Heat Recovery Assessment

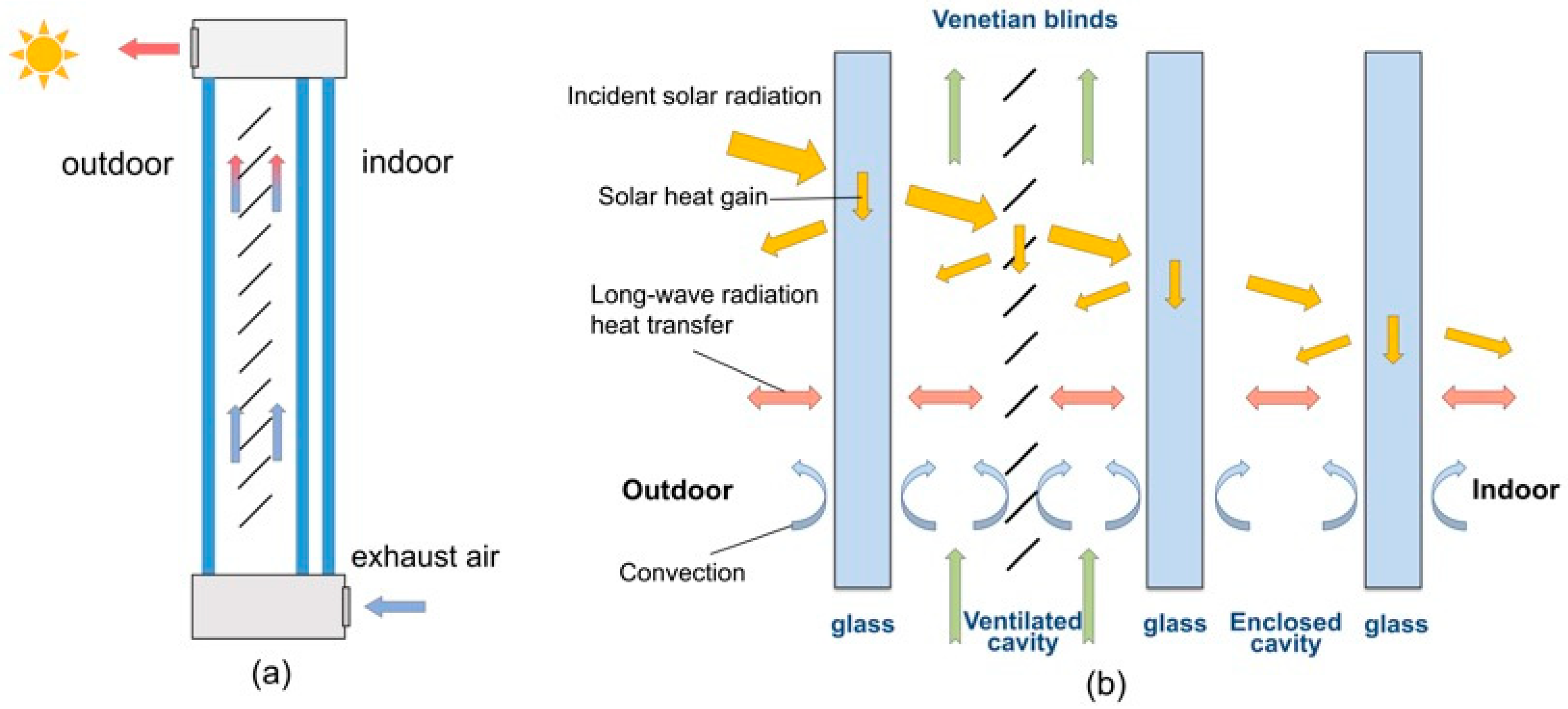

2.2. Numerical Model of EAGU

2.2.1. Energy Balance Equations

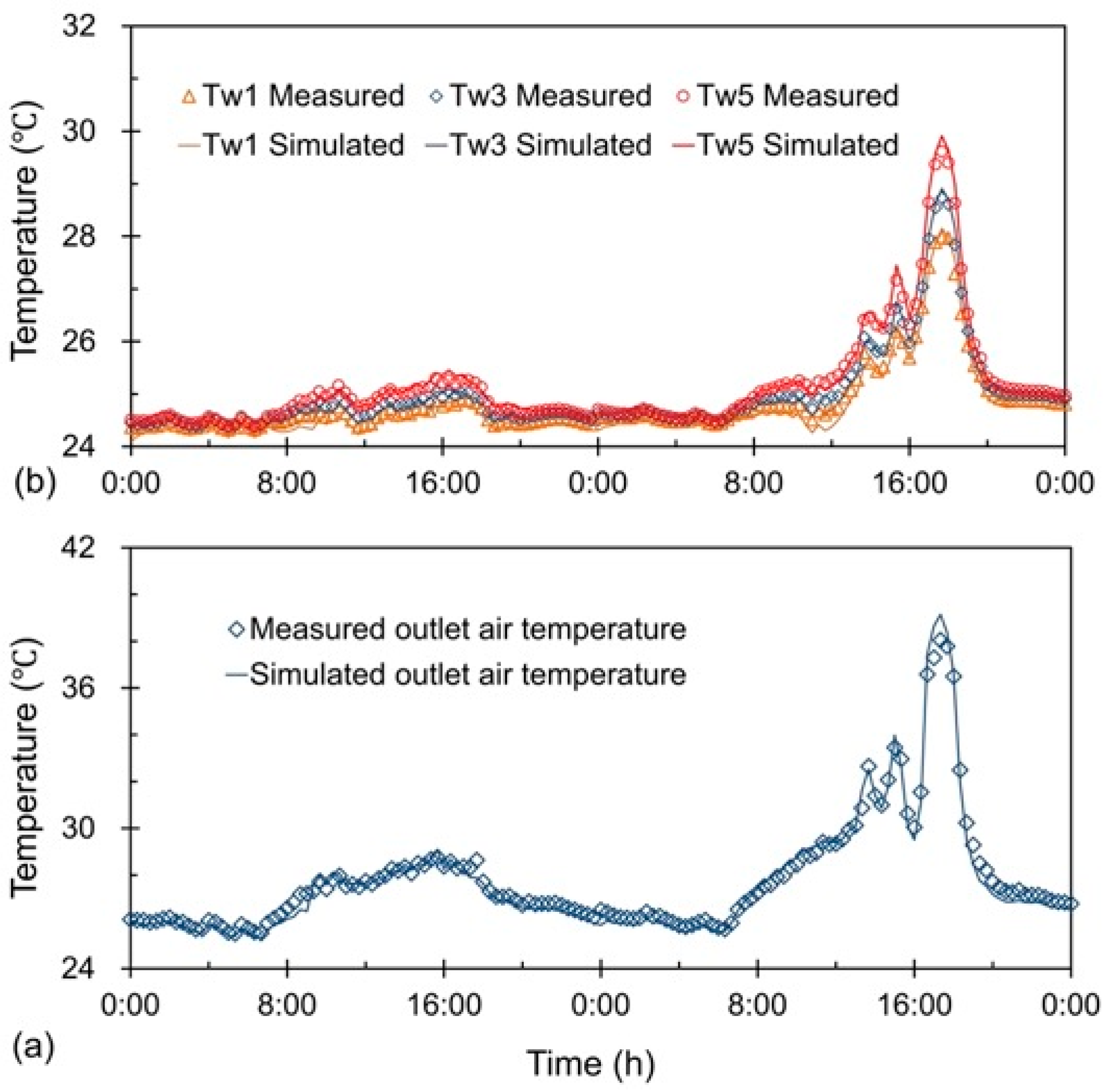

2.2.2. Model Validation

2.3. Energy Requirement of Ventilation Fresh Air

3. Case Studies in Different Climate Conditions

4. Results and Discussion

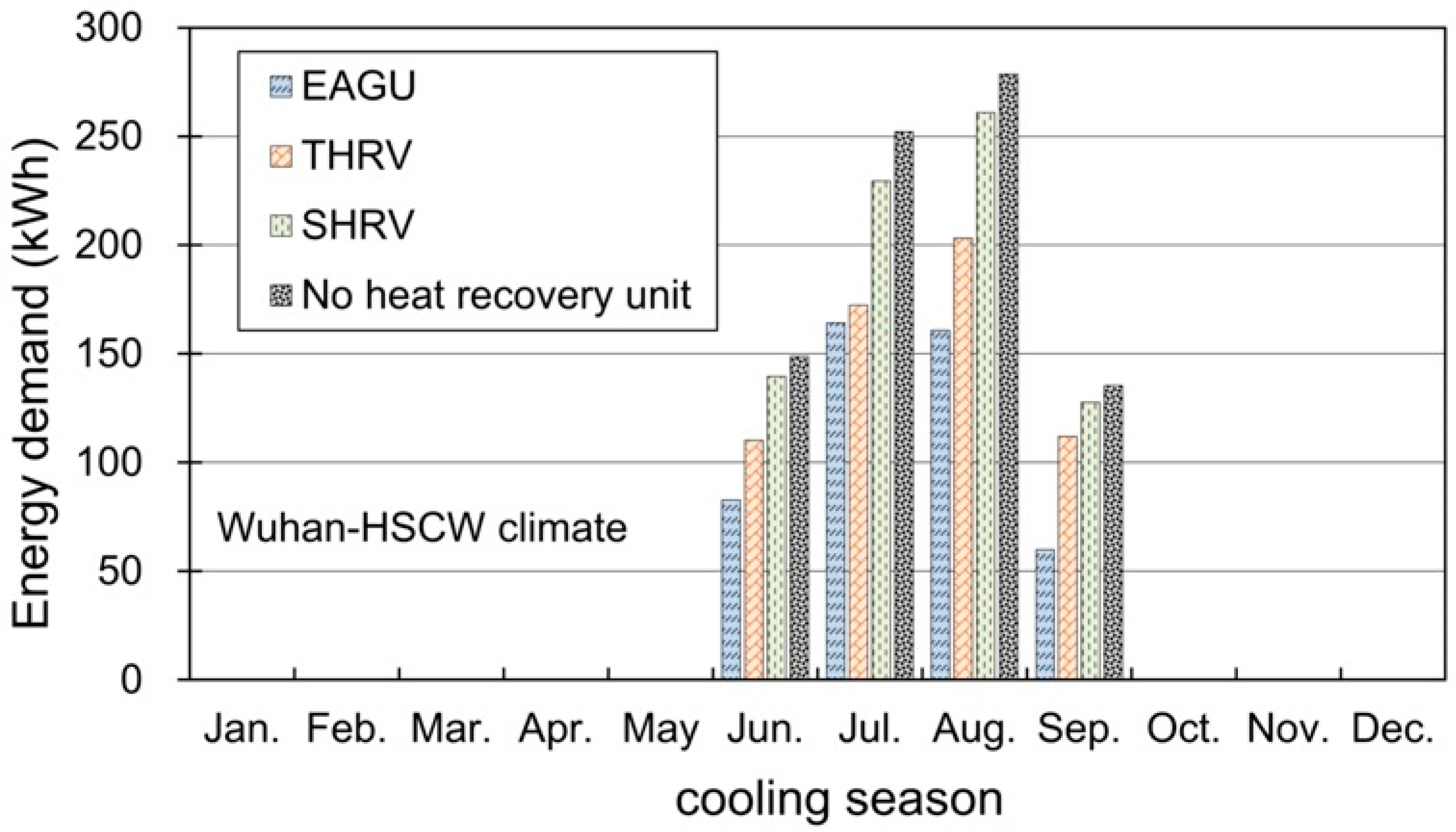

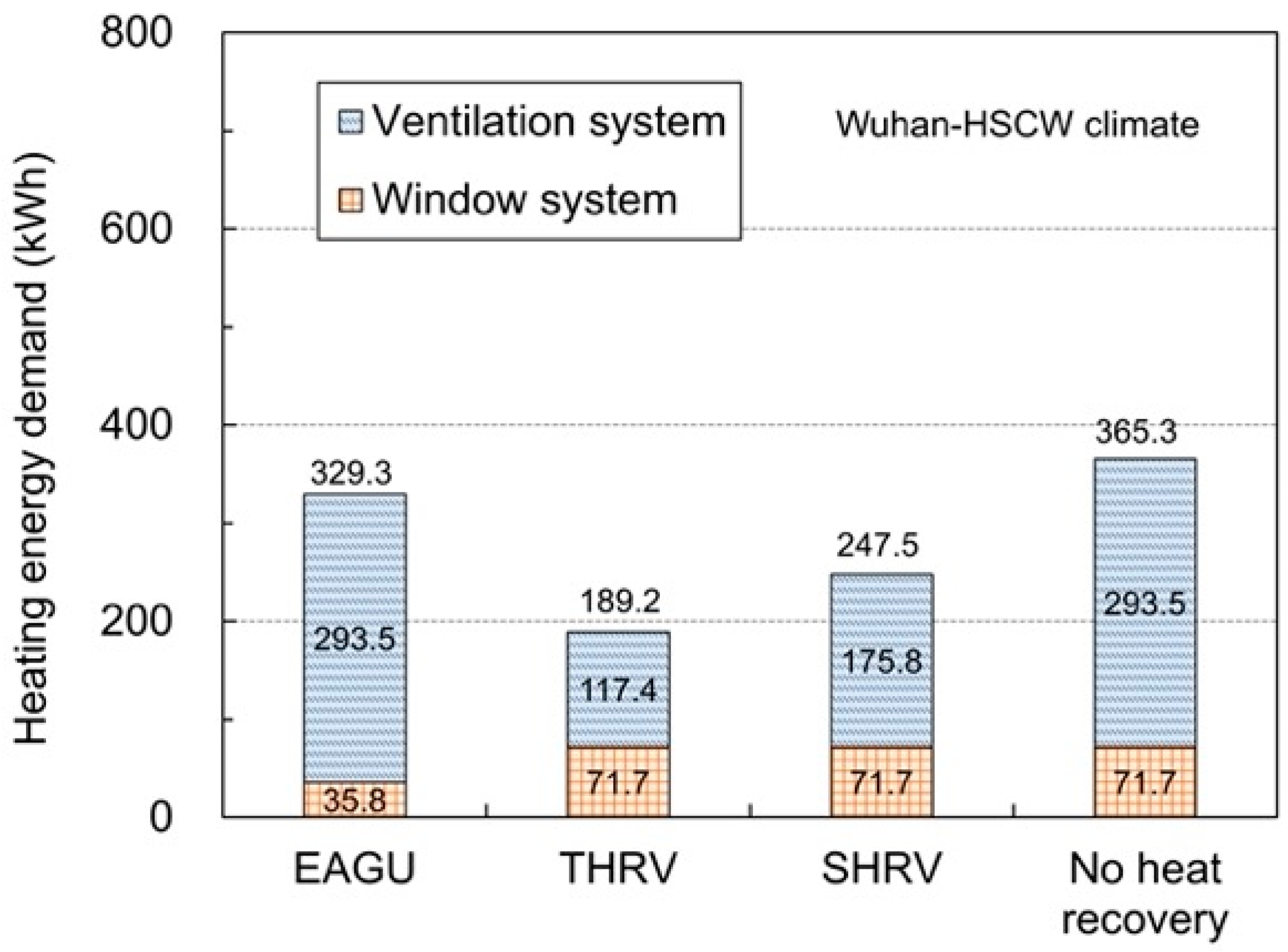

4.1. Year-Round Energy Performance Comparison

4.2. Comparison Results in Different Climate Conditions

4.3. Influence of Ventilation Fresh Air Rate

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Chen, S.; Jiang, K.; Kaghembega, W.S.H. The gaps and pathways to carbon neutrality for different type cities in China. Energy 2022, 244, 122596. [Google Scholar] [CrossRef]

- Lemmet, S. Buildings and Climate Change: Summary for Decision Makers; United Nations Environment Programme—Sustainable Buildings & Climate Initiative: Paris, France, 2009; pp. 1–62. [Google Scholar]

- Berardi, U.; Sprengard, C. An overview of and introduction to current researches on super insulating materials for high-performance buildings. Energy Build. 2020, 214, 109890. [Google Scholar] [CrossRef]

- Li, A.; Xiao, F.; Zhang, C.; Fan, C. Attention-based interpretable neural network for building cooling load prediction. Appl. Energy 2021, 299, 117238. [Google Scholar] [CrossRef]

- Boahen, S.; Anka, S.K.; Lee, K.H.; Choi, J.M. Performance characteristics of a cascade multi-functional heat pump in the winter season. Energy Build. 2021, 253, 111511. [Google Scholar] [CrossRef]

- Lyu, W.; Li, X.; Yan, S.; Jiang, S. Utilizing shallow geothermal energy to develop an energy efficient HVAC system. Renew. Energy 2020, 147, 672–682. [Google Scholar] [CrossRef]

- Jelle, B.P.; Hynd, A.; Gustavsen, A.; Arasteh, D.; Goudey, H.; Hart, R. Fenestration of today and tomorrow: A state-of-the-art review and future research opportunities. Sol. Energy Mater. Sol. Cells 2012, 96, 1–28. [Google Scholar] [CrossRef] [Green Version]

- Arıcı, M.; Tükel, M.; Yıldız, Ç.; Li, D.; Karabay, H. Is the thermal transmittance of air-filled inclined multi-glazing windows similar to that of vertical ones? Energy Build. 2020, 229, 110515. [Google Scholar] [CrossRef]

- Somasundaram, S.; Thangavelu, S.R.; Chong, A. Improving building efficiency using low-e coating based retrofit double glazing with solar films. Appl. Therm. Eng. 2020, 171, 115064. [Google Scholar] [CrossRef]

- Arıcı, M.; Kan, M. An investigation of flow and conjugate heat transfer in multiple pane windows with respect to gap width, emissivity and gas filling. Renew. Energy 2015, 75, 249–256. [Google Scholar] [CrossRef]

- Chen, Y.M.; Xiao, Y.L.; Zheng, S.Q.; Liu, Y.; Li, Y.P. Dynamic heat transfer model and applicability evaluation of aerogel glazing system in various climates of China. Energy 2018, 163, 1115–1124. [Google Scholar] [CrossRef]

- Son, H.; Song, T.H. Heat transfer and stress distribution in the central part of vacuum glazing. Appl. Therm. Eng. 2019, 159, 113926. [Google Scholar] [CrossRef]

- Baetens, R.; Jelle, B.P.; Gustavsen, A. Properties, requirements and possibilities of smart windows for dynamic daylight and solar energy control in buildings: A state-of-the-art review. Sol. Energy Mater. Sol. Cells 2010, 94, 87–105. [Google Scholar] [CrossRef] [Green Version]

- Li, D.; Zhang, C.J.; Li, Q.; Liu, C.Y.; Arıcı, M.; Wu, Y.Y. Thermal performance evaluation of glass window combining silica aerogels and phase change materials for cold climate of China. Appl. Therm. Eng. 2020, 165, 114547. [Google Scholar] [CrossRef]

- Wieprzkowicz, A.; Heim, D. Modelling of thermal processes in a glazing structure with temperature dependent optical properties-An example of PCM-window. Renew. Energy 2020, 160, 653–662. [Google Scholar] [CrossRef]

- Rezaie, B.; Esmailzadeh, E.; Dincer, I. Renewable energy options for buildings: Case studies. Energy Build. 2011, 43, 56–65. [Google Scholar] [CrossRef]

- Shen, C.; Li, X.T. Thermal performance of double skin façade with built-in pipes utilizing evaporative cooling water in cooling season. Sol. Energy 2016, 137, 55–65. [Google Scholar] [CrossRef]

- Li, L.; Zhang, C.; Xu, X.; Yu, J.; Wang, F.; Gang, W.; Wang., J. Simulation study of a dual-cavity window with gravity-driven cooling mechanism. Build. Simul. 2022, 15, 1339–1352. [Google Scholar] [CrossRef]

- Shen, C.; Li, X.T.; Yan, S. Numerical study on energy efficiency and economy of a pipe-embedded glass envelope directly utilizing ground-source water for heating in diverse climates. Energy Convers. Manag. 2017, 150, 878–889. [Google Scholar] [CrossRef]

- Huang, J.C.; Chen, X.; Yang, H.X.; Zhang, W.L. Numerical investigation of a novel vacuum photovoltaic curtain wall and integrated optimization of photovoltaic envelope systems. Appl. Energy 2018, 229, 1048–1060. [Google Scholar] [CrossRef]

- Michaux, G.; Greffet, R.; Salagnac, P.; Ridoret, J.B. Modelling of an airflow window and numerical investigation of its thermal performances by comparison to conventional double and triple-glazed windows. Appl. Energy 2019, 242, 27–45. [Google Scholar] [CrossRef]

- Li, C.Y.; Lyu, Y.L.; Li, C.M.; Qiu, Z.Z. Energy performance of water flow window as solar collector and cooling terminal under adaptive control. Sustain. Cities Soc. 2020, 59, 102152. [Google Scholar] [CrossRef]

- Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Berardi, U.; Tookey, J.; Li, D.H.W.; Kariminia, S. Exploring the advantages and challenges of double-skin façades (DSFs). Renew. Sustain. Energy Rev. 2016, 60, 1052–1065. [Google Scholar] [CrossRef]

- Wang, Y.J.; Chen, Y.M.; Li, C. Airflow modeling based on zonal method for natural ventilated double skin façade with Venetian blinds. Energy Build. 2019, 191, 211–223. [Google Scholar] [CrossRef]

- Srisamranrungruang, T.; Hiyama, K. Balancing of natural ventilation, daylight, thermal effect for a building with double-skin perforated facade (DSPF). Energy Build. 2020, 210, 109765. [Google Scholar] [CrossRef]

- Akbarpoor, A.M.; Poshtiri, A.H.; Biglari, F. Performance analysis of domed roof integrated with earth-to-air heat exchanger system to meet thermal comfort conditions in buildings. Renew. Energy 2021, 168, 1265–1293. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, J.B.; Xu, X.H.; Zou, F.X.; Yu, J.H. Modeling and thermal performance evaluation of a switchable triple glazing exhaust air window. Appl. Therm. Eng. 2016, 92, 8–17. [Google Scholar] [CrossRef]

- Zanghirella, F.; Perino, M.; Serra, V. A numerical model to evaluate the thermal behaviour of active transparent façades. Energy Build. 2011, 43, 1123–1138. [Google Scholar] [CrossRef]

- Takemasa, Y.; Togari, S.; Miura, K.; Katoh, M.; Hiraoka, M.; Owada, J. Evaluation of calculation models for predicting thermal performance of various window systems. ASHRAE Trans. 2013, 119, 1B. [Google Scholar]

- Zhang, C.; Gang, W.J.; Wang, J.B.; Xu, X.H.; Du, Q.Z. Numerical and experimental study on the thermal performance improvement of a triple glazed window by utilizing low-grade exhaust air. Energy 2019, 167, 1132–1143. [Google Scholar] [CrossRef]

- Skaff, M.C.; Gosselin, L. Summer performance of ventilated windows with absorbing or smart glazings. Sol. Energy 2014, 105, 2–13. [Google Scholar] [CrossRef]

- Chow, T.T.; Li, C.Y.; Lin, Z.; Fong, K.F.; Pei, G. Experimental evaluation of ventilated glazing performance in Hong Kong. Int. J. Energy Res. 2009, 33, 526–537. [Google Scholar] [CrossRef]

- Kim, M.H.; Oh, C.Y.; Hwang, J.H.; Choi, H.W.; Yang, W.J. Thermal performance of the exhausting and the semi-exhausting triple-glazed airflow windows. Int. J. Energy Res. 2006, 30, 177–190. [Google Scholar] [CrossRef]

- Ismail, K.A.R.; Henriquez, J.R. Simplified model for a ventilated glass window under forced air flow conditions. Appl. Therm. Eng. 2006, 26, 295–302. [Google Scholar] [CrossRef]

- Zhang, C.; Gang, W.J.; Wang, J.B.; Xu, X.H.; Du, Q.Z. Experimental investigation and dynamic modeling of a triple-glazed exhaust air window with built-in venetian blinds in the cooling season. Appl. Therm. Eng. 2018, 140, 73–85. [Google Scholar] [CrossRef]

- Khalvati, F.; Omidvar, A. Summer study on thermal performance of an exhausting airflow window in evaporatively-cooled buildings. Appl. Therm. Eng. 2019, 153, 147–158. [Google Scholar] [CrossRef]

- Bao, L.L.; Wang, J.G.; Yang, H.X. Investigation on the performance of a heat recovery ventilator in different climate regions in China. Energy 2016, 104, 85–98. [Google Scholar] [CrossRef] [Green Version]

- Gil-Baez, M.; Barrios-Padura, A.; Molina-Huelva, M.; Chacartegui, R. Natural ventilation systems in 21st-century for near zero energy school buildings. Energy 2017, 137, 1186–1200. [Google Scholar] [CrossRef]

- Shahsavar, A.; Khanmohammadi, S. Feasibility of a hybrid BIPV/T and thermal wheel system for exhaust air heat recovery: Energy and exergy assessment and multi-objective optimization. Appl. Therm. Eng. 2019, 146, 104–122. [Google Scholar] [CrossRef]

- Zhang, C.; Xiao, F.; Wang, J.B. Design optimization of multi-functional building envelope for thermal insulation and exhaust air heat recovery in different climates. J. Build. Eng. 2021, 43, 103151. [Google Scholar] [CrossRef]

- US Department of Energy. Lawrence Berkeley National Laboratory. WINDOW 7.4. Available online: https://windows.lbl.gov/software/window (accessed on 21 April 2022).

- China Meteorological Bureau, Climate Information Center, Climate Data Office and Tsinghua University, Department of Building Science and Technology. China Standard Weather Data for Analyzing Building Thermal Conditions; China Architecture and Building Press: Beijing, China, 2005. [Google Scholar]

- Wei, J.; Zhao, J.; Chen, Q. Energy performance of a dual airflow window under different climates. Energy Build. 2010, 42, 111–122. [Google Scholar] [CrossRef] [Green Version]

- Zhong, K.; Kang, Y. Applicability of air-to-air heat recovery ventilators in China. Appl. Therm. Eng. 2009, 29, 830–840. [Google Scholar] [CrossRef]

- Ministry Housing and Urban-Rural Development of People’s Republic of China. Design Standard for Energy Efficiency of Public Buildings (GB50189-2015); Architecture & Building Press: Beijing, China, 2015.

| Type of Heat Recovery | Window System | Heat Recovery Ventilator | |

|---|---|---|---|

| Case 1 | EAGU | EAGU | without |

| Case 2 | SHRV | Double glazed unit | SHRV |

| Case 3 | THRV | Double glazed unit | THRV |

| Case 4 | without | Double glazed unit | without |

| Climate Condition | Cold Climate | Hot-Summer and Cold-Winter (HSCW) Climate | Hot-Summer and Warm-Winter (HSWW) Climate |

|---|---|---|---|

| Representative city | Beijing | Wuhan | Guangzhou |

| Cooling season | 15 June to 15 September | 1 June to 30 September | 1 May to 30 September |

| Heating season | 15 November to 15 March | 15 December to 15 March | 1 December to 28 February |

| Location | 39°56′ N, 116°20′ E | 30°36′ N, 114°17′ E | 23°06′ N, 113°16′ E |

| Season | Overall Absorptance | Transmittance | Reflectance | |||

|---|---|---|---|---|---|---|

| Exterior Glass | Venetian Blinds | Mid-Glass | Interior Glass | |||

| Summer | 0.134 | 0.3137 | 0.0375 | 0.0263 | 0.2215 | 0.2668 |

| Winter | 0.1134 | NA | 0.0853 | 0.0638 | 0.5761 | 0.1614 |

| Climate Condition | Annual Total Energy Demand (kWh) | Energy Saving Potential Compared with No Heat Recovery Unit | |||||

|---|---|---|---|---|---|---|---|

| EAGU | THRV | SHRV | No Heat Recovery Unit | EAGU | THRV | SHRV | |

| Cold | 939.9 | 801.2 | 1033 | 1284.5 | 26.8% | 37.6% | 19.6% |

| Hot-summer and cold-winter (HSCW) | 796.9 | 786.8 | 1005 | 1180.1 | 32.5% | 33.3% | 14.8% |

| Hot-summer and warm-winter (HSWW) | 714.2 | 809.2 | 1060.6 | 1156 | 38.2% | 30.0% | 8.3% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, J.; Zhang, C. Utilization of Window System as Exhaust Air Heat Recovery Device and Its Energy Performance Evaluation: A Comparative Study. Energies 2022, 15, 3116. https://doi.org/10.3390/en15093116

Guo J, Zhang C. Utilization of Window System as Exhaust Air Heat Recovery Device and Its Energy Performance Evaluation: A Comparative Study. Energies. 2022; 15(9):3116. https://doi.org/10.3390/en15093116

Chicago/Turabian StyleGuo, Jue, and Chong Zhang. 2022. "Utilization of Window System as Exhaust Air Heat Recovery Device and Its Energy Performance Evaluation: A Comparative Study" Energies 15, no. 9: 3116. https://doi.org/10.3390/en15093116

APA StyleGuo, J., & Zhang, C. (2022). Utilization of Window System as Exhaust Air Heat Recovery Device and Its Energy Performance Evaluation: A Comparative Study. Energies, 15(9), 3116. https://doi.org/10.3390/en15093116