Investigation of the Bearing Characteristics of Bolts on a Coal–Rock Combined Anchor Body under Different Pull-Out Rates

Abstract

:1. Introduction

2. Materials and Methods

2.1. Pull-Out Test of Bolts on the Coal–Rock Combined Anchor Body

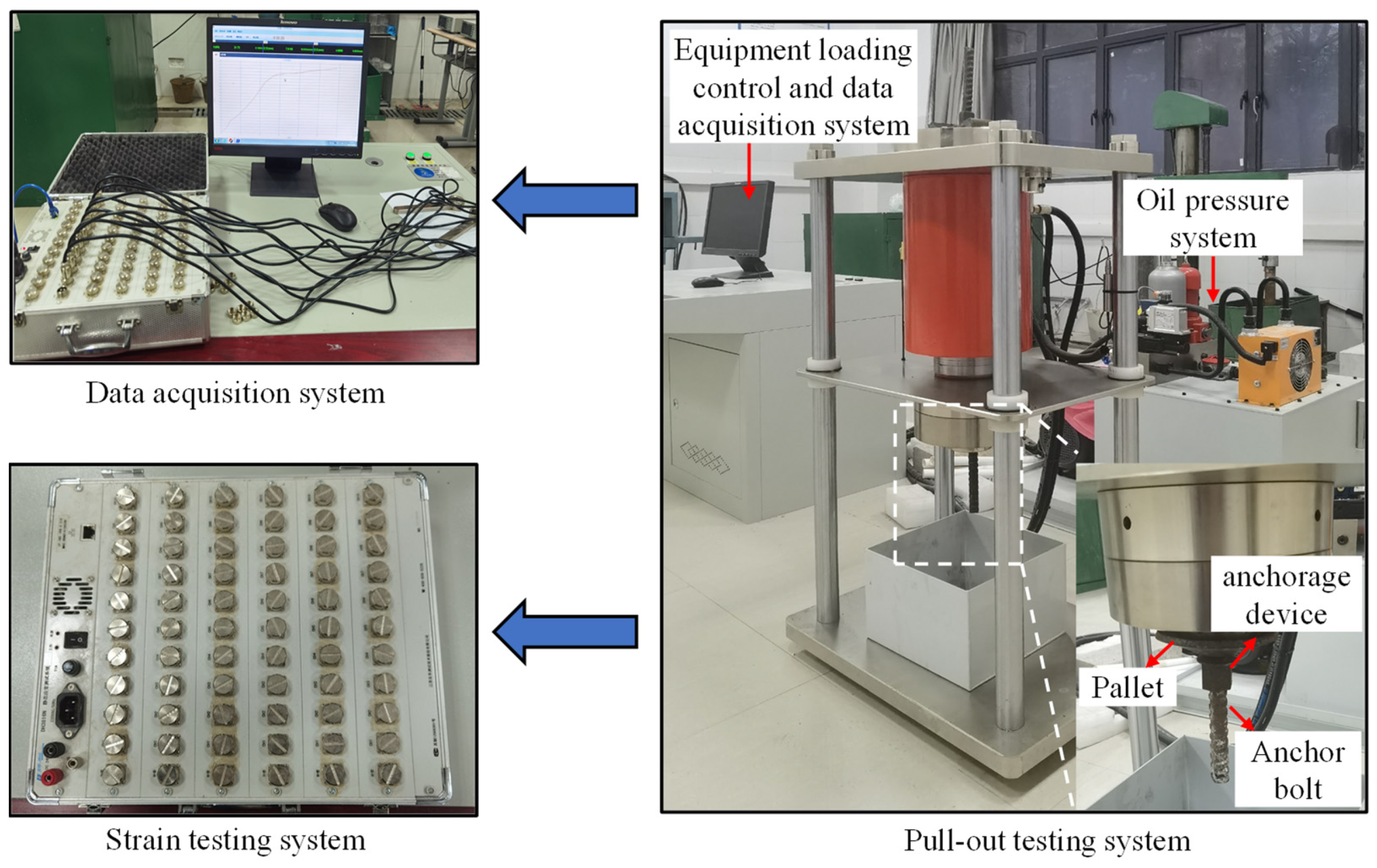

2.1.1. Test Equipment and Materials

- 1.

- Pull-out system

- 2.

- Strain testing system

- 3.

- Borehole camera

- 4.

- Test material

2.1.2. Preparation of Anchorage Specimen

- 1.

- Determination of ratio of similar materials for anchoring the surrounding rock

- 2.

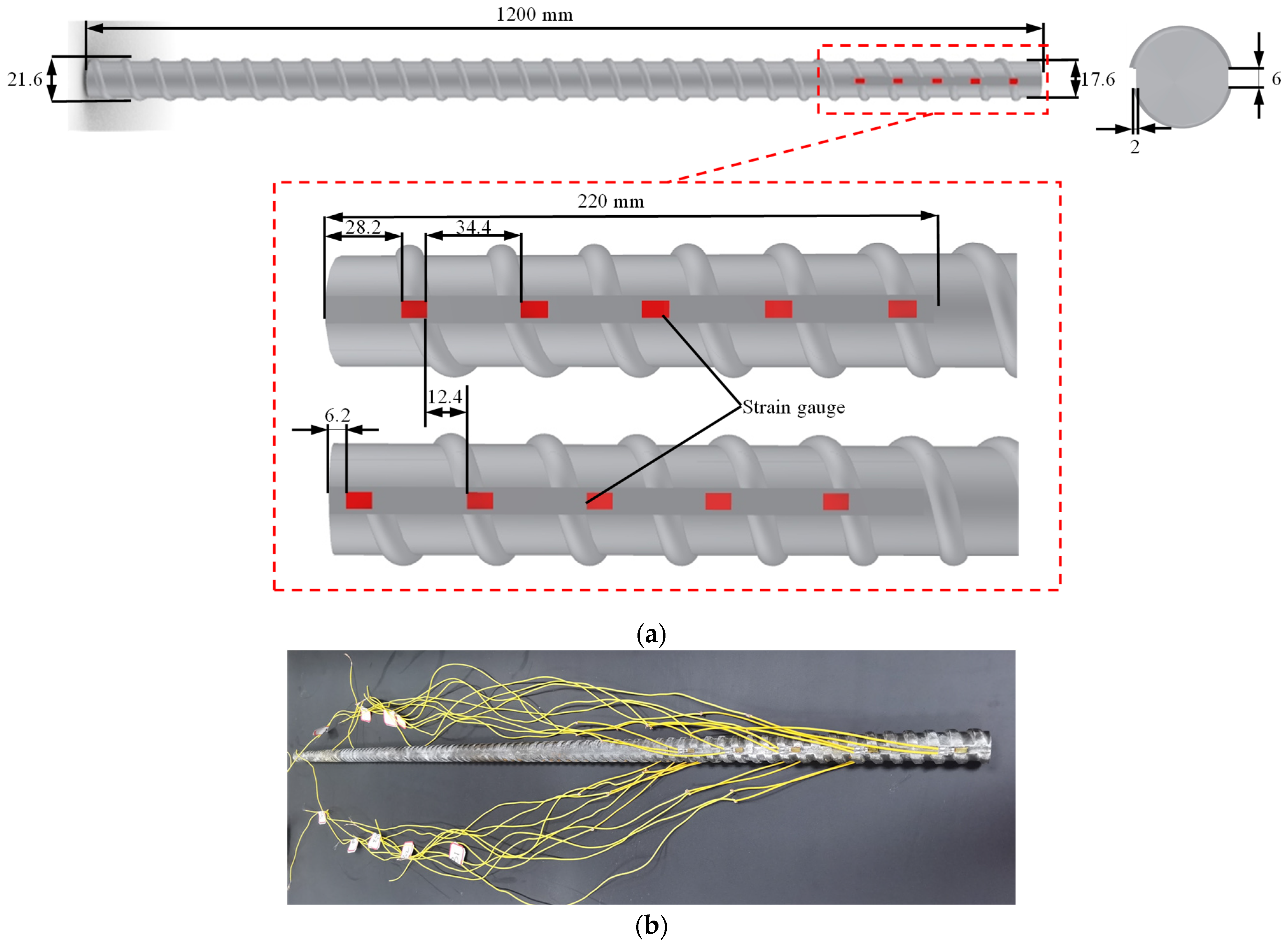

- Preparation of force-measuring bolt

- 3.

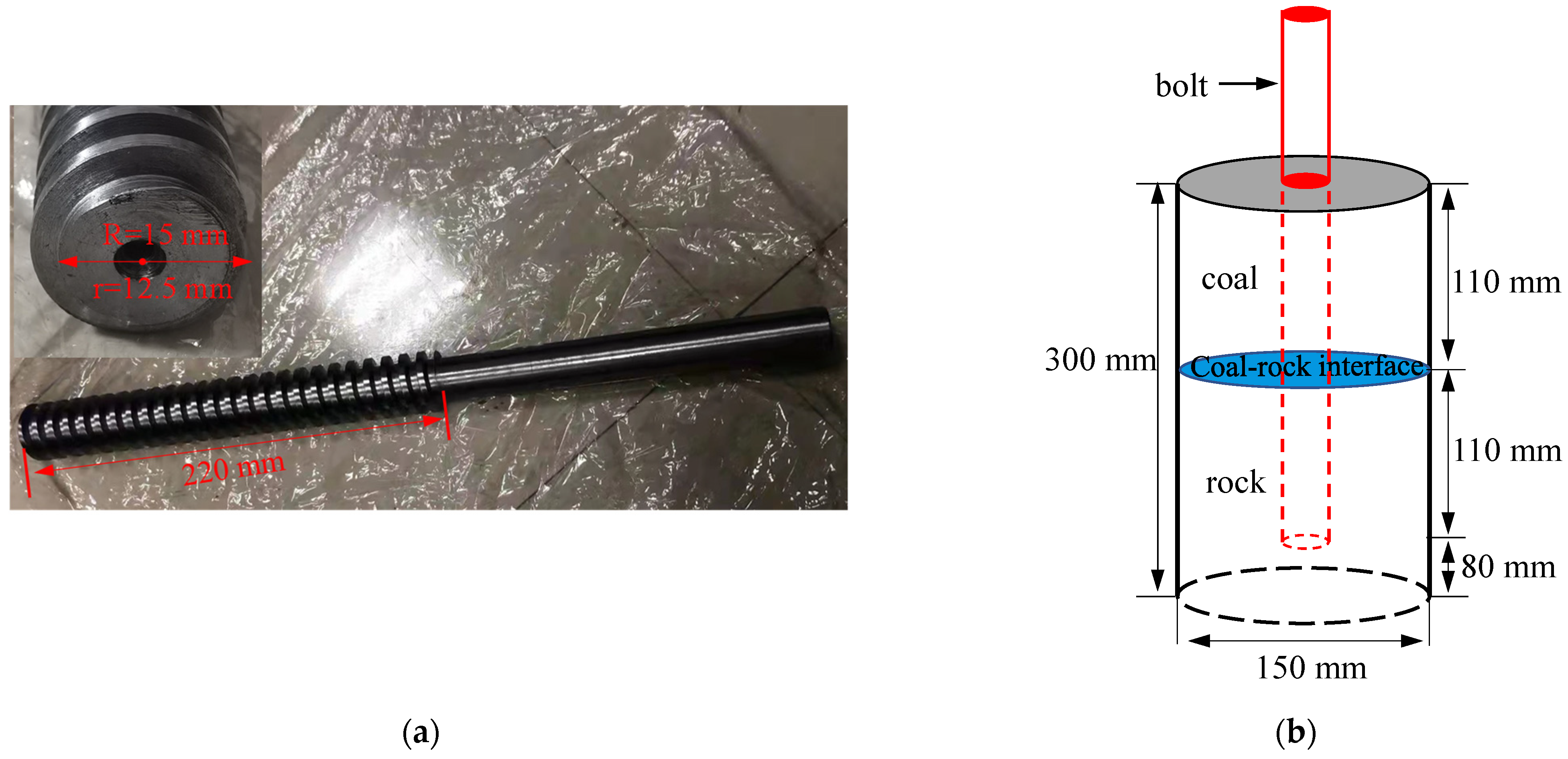

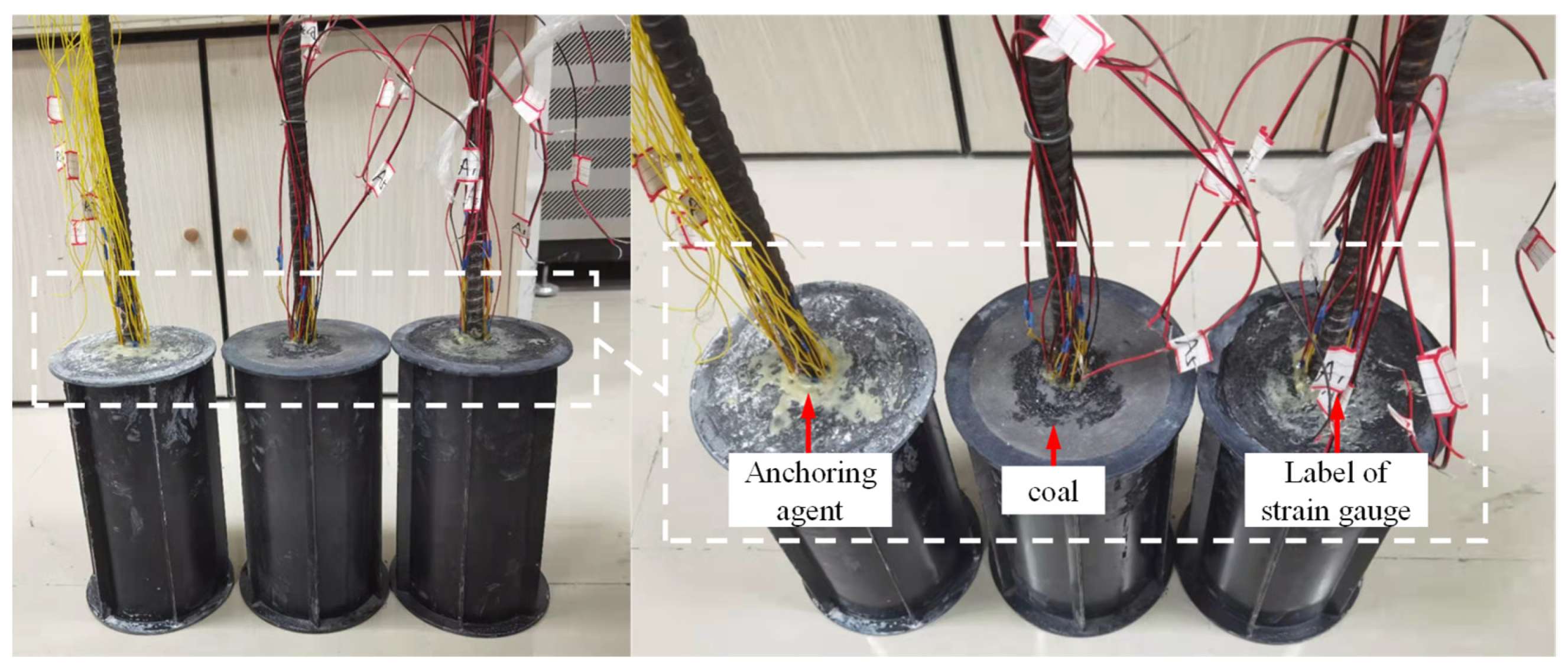

- Pull-out specimen preparation

2.1.3. Test Process

3. Results

3.1. Effect on Pull-Out Load

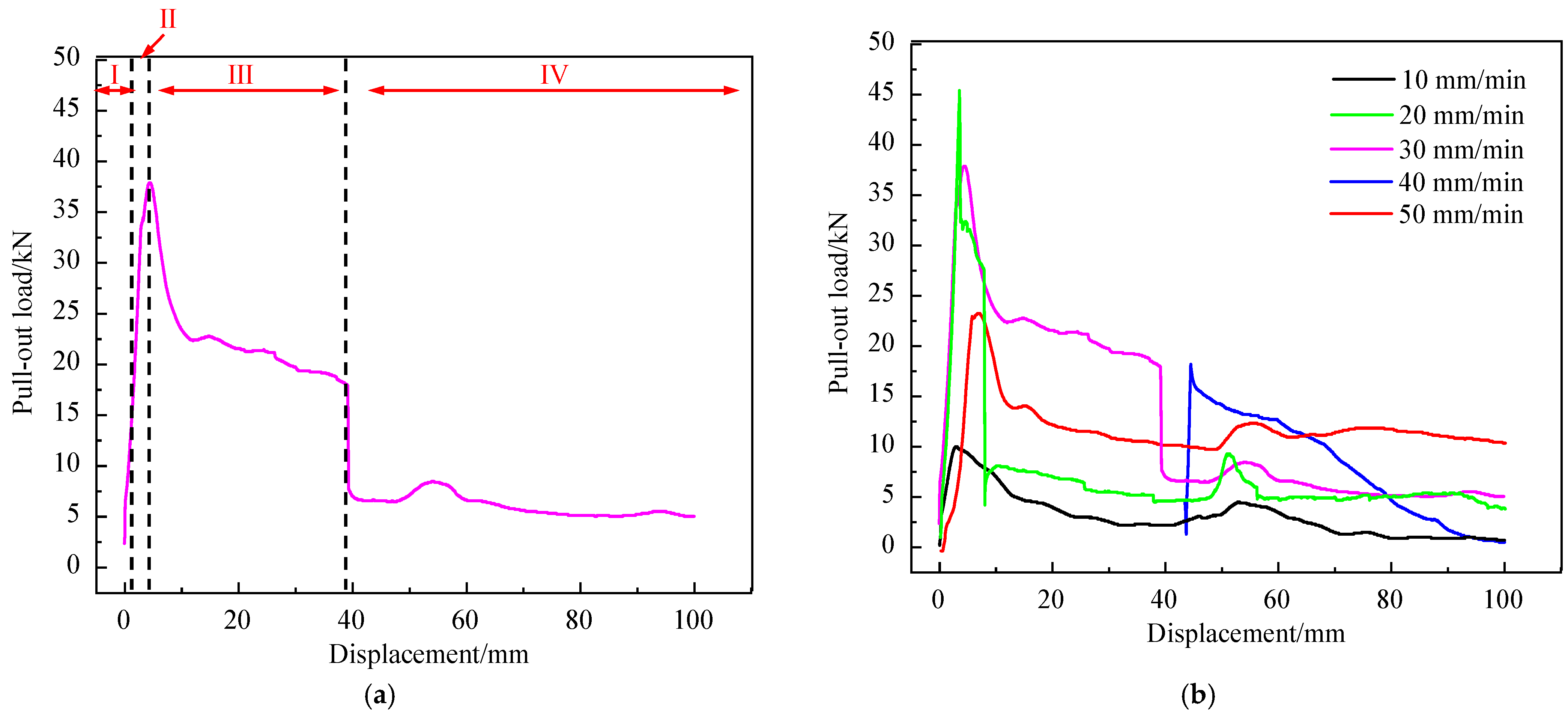

- The general trend in the curve between the pull-out load and displacement at different pull-out rates is basically the same. As shown in Figure 6, it can be divided into four stages [33]: I chemical debonding stage; II microcrack development stage; III shear slip stage; and IV friction slip stage. In the chemical debonding stage, the pull-out bearing capacity of the bolt mainly depends on the chemical bonding force between the bolt and the resin grout, and the pull-out load increases nonlinearly. In the stage of microcrack development, microcracks gradually appear in the anchoring agent and surrounding rock. With the development of microcracks, the bolt pull-out load increases approximately linearly and gradually reaches the maximum pull-out load. In the shear slip stage, shear failure occurs at the anchoring interface, the pull-out load decreases nonlinearly, and the mechanical interlocking effect of the anchorage interface gradually disappears. In the friction slip stage, the pull-out load decreases steadily and the microcracks develop rapidly. When enough microcracks are formed, the anchorage interface is damaged and invalid. At this time, the bolt pull-out load mainly depends on the sliding friction force at the anchorage interface, which is the residual pull-out load of the bolt.

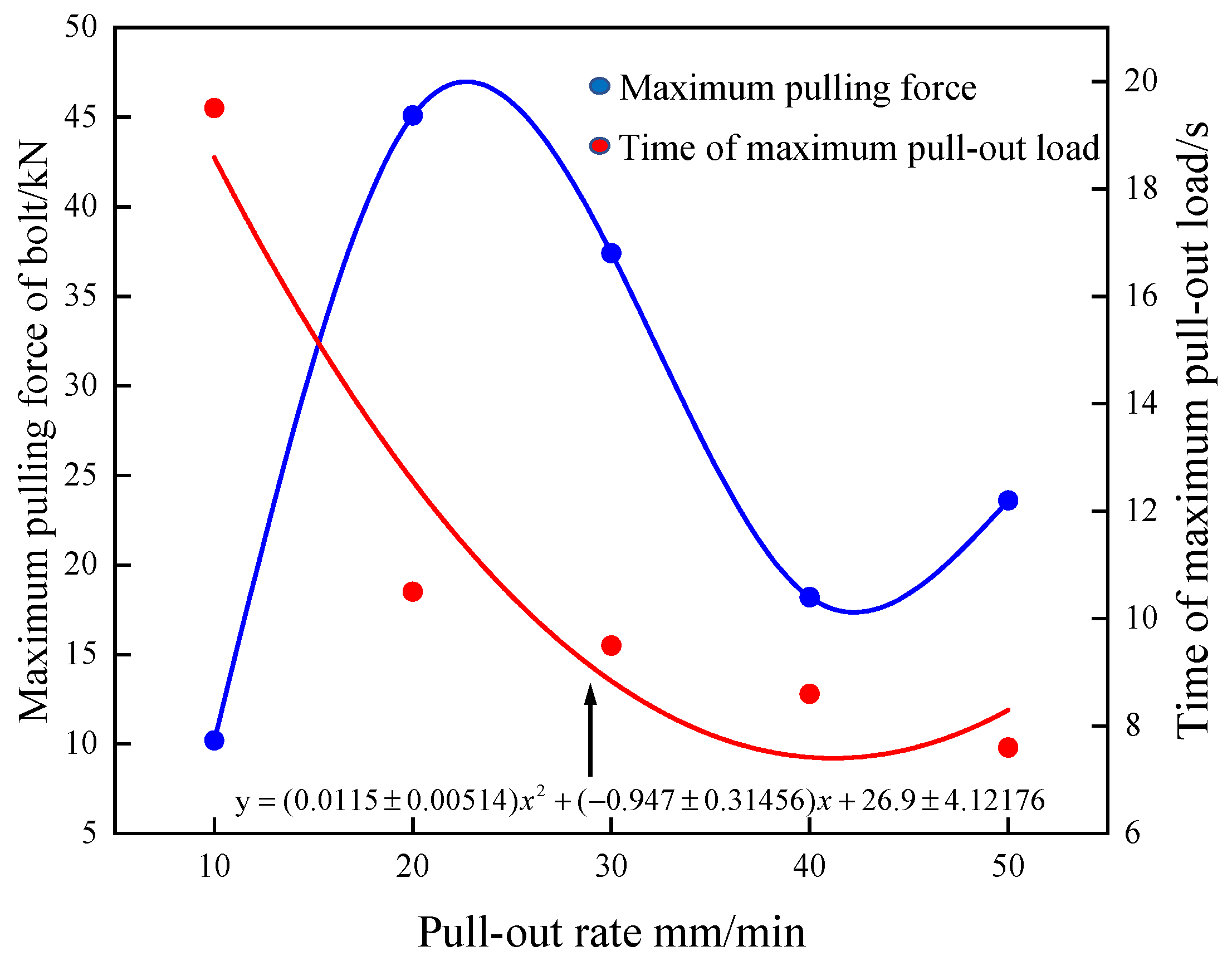

- With the increase in the pull-out rate, the maximum pull-out load of the bolt first increases, then decreases, and finally tends to be stable. The time to reach the maximum pull-out load decreases gradually with the increase in the pull-out rate, and finally tends to be stable. As shown in Figure 7, when the pull-out rate is 10~20 mm/min, it is at the growth stage. Due to the increase in the pull-out rate, the time is insufficient for the release of the load at the anchorage interface; energy accumulates rapidly and accelerates the failure of the anchorage interface. The pull-out load increases approximately linearly. When the pull-out rate is 20~40 mm/min, it is at the decline stage. Due to the existence of the coal–rock interface and the different media of coal and rock, the coal–rock combined anchor body shows heterogeneity and different strengths [27], resulting in the phenomenon where its elastic modulus and strength gradually decrease with the increase in the pull-out rate, and the pull-out load of the bolt decreases. When the pull-out rate is 40~50 mm/min, the influence of the increase in the pull-out rate on the pull-out load of the bolt is weakened, and the pull-out load of the bolt tends to be stable, which indicates that there is a critical pull-out rate for the coal–rock combined anchor body.

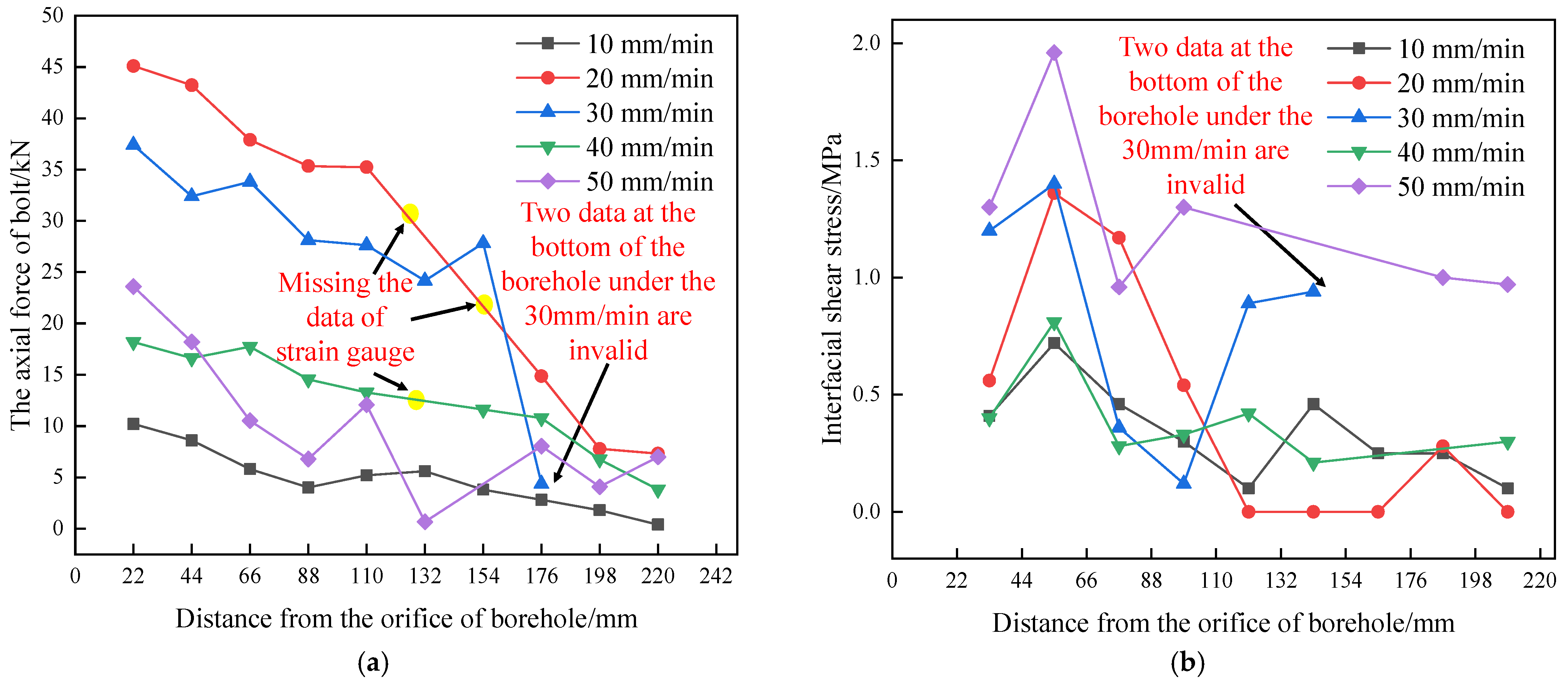

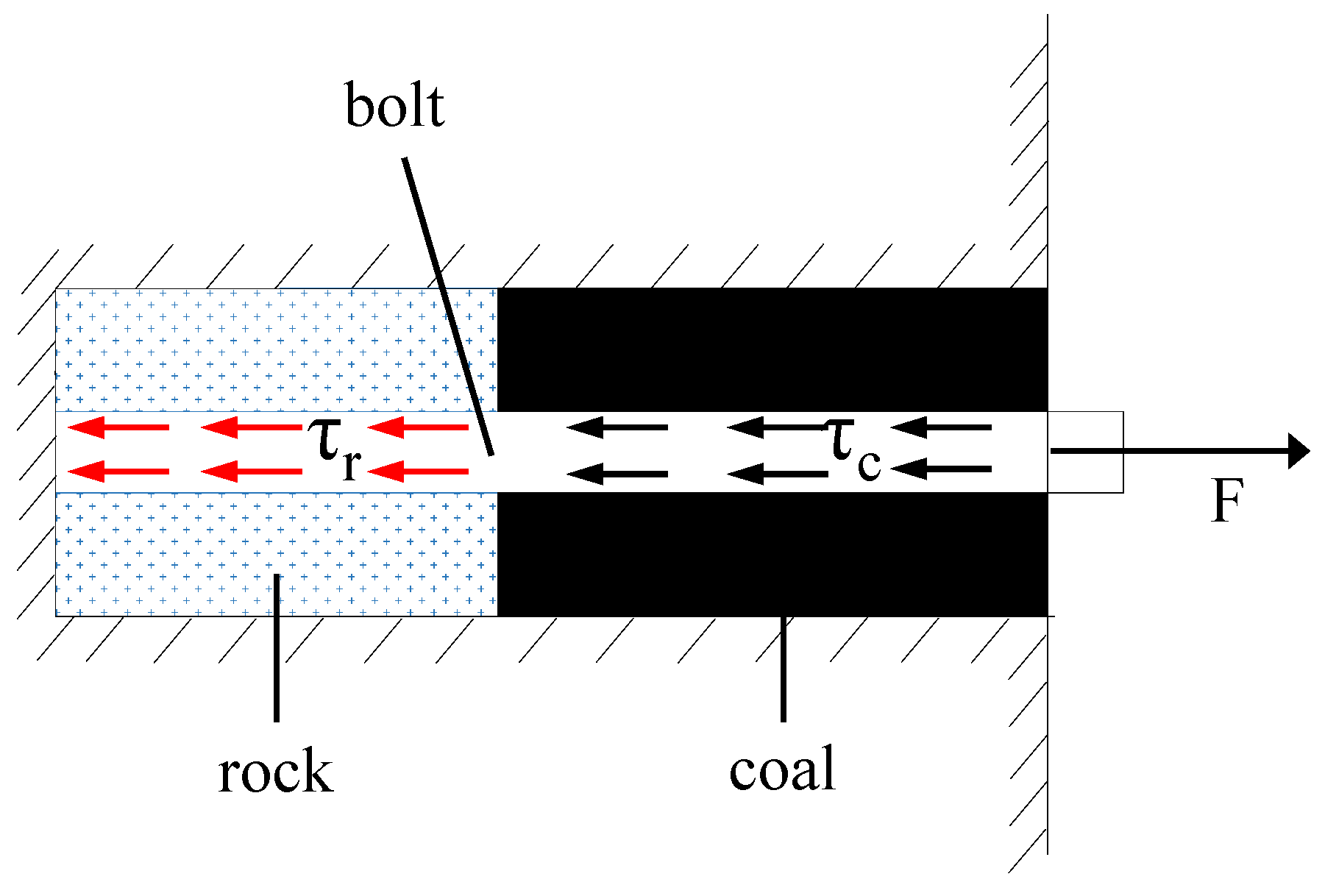

3.2. Effect on Axial Force and Shear Force

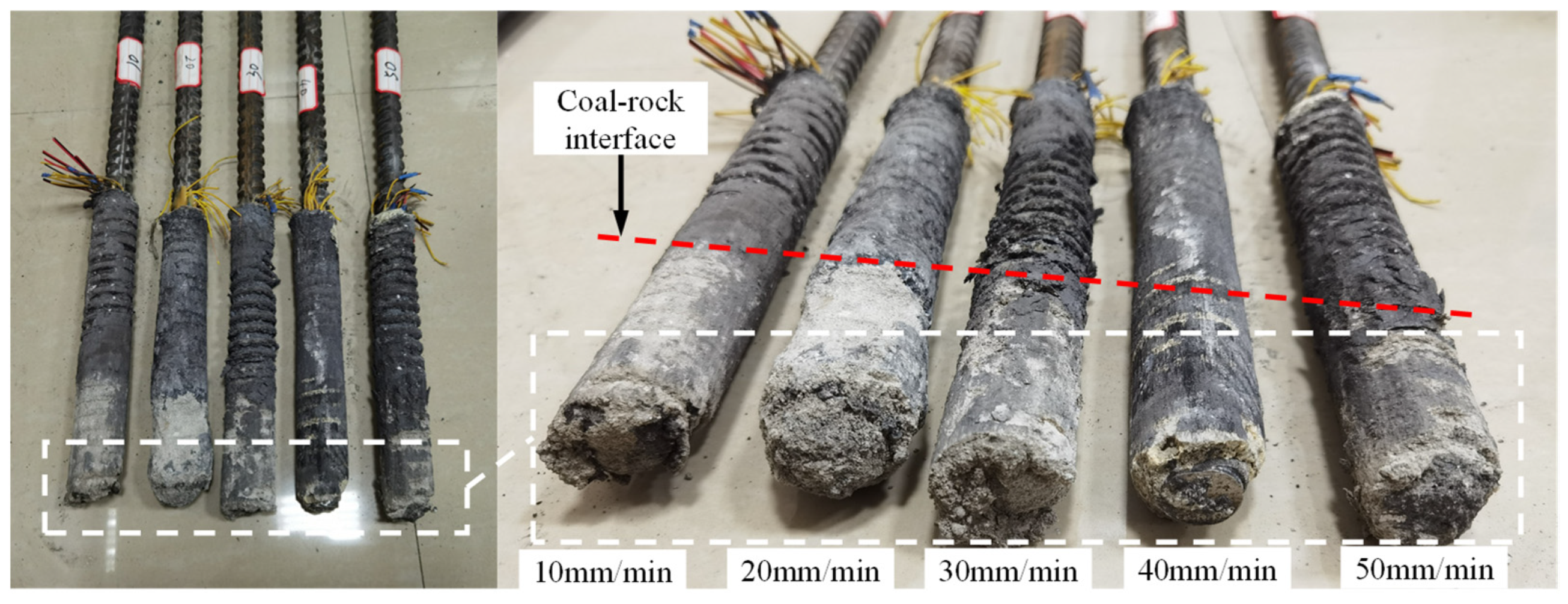

3.3. Damage Characteristics of the Coal–Rock Combined Anchor Body

4. Discussion

4.1. Time Differential Development of Cracks on the Coal–Rock Combined Anchor Body

4.2. Mechanical Properties of the Coal–Rock Combined Anchor Body under Different Pull-Out Rates

5. Conclusions

- Under the condition of a dynamic load, the bearing characteristics of the coal–rock combined anchor body are different from those of rock. With the increase in the pull-out rate, the maximum pull-out load of a bolt passing through the coal–rock interface increases first, then decreases, and finally tends to be stable. A low pull-out rate can greatly improve the bearing capacity of the anchorage system. Across the coal–rock interface, the bearing capacity of the coal–rock combined anchor system can be greatly improved, but when the pull-out rate exceeds 20 mm/min, the bearing capacity of the anchor system will be reduced.

- Under different pull-out rates, the debonding process of a bolt passing through the coal–rock interface is the same as that in rock. The debonding process of the anchoring section of the coal–rock combined anchor body gradually expands from the beginning section of the anchor to the bottom of the borehole. Increasing the anchoring length and the friction coefficient between the borehole wall and the anchoring agent interface is an effective way to improve the dynamic load resistance of a bolt passing through the coal–rock interface.

- The coal–rock combined anchor body undergoes time differential development of cracks, and the failure of the coal and rock mass occurs at different times. The failure process can be divided into three stages: (1) the coal anchor and rock anchor act together; (2) the rock anchor acts alone; and (3) the coal anchor and rock anchor have residual action.

- In this test, the anchor-surrounding rock was equivalent to the test model constraint, and the interfacial effect of the coal–rock interface was not considered. In the future, the bearing performance of the bolt on the coal–rock combined anchor body under conditions approaching the real confining pressure should be further studied.

- In the current work, the bearing performance of the bolt under different pull-out rates was studied, and it was found that the coal–rock combined anchor body underwent time differential development of cracks. In the future, combined with different coal rock interface inclinations and differences in the coal rock height ratio, it would help to propose a theoretical basis for the anchorage support of the coal–rock roadway under the influence of dynamic pressure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, L.X.; Zhang, H.; Jiang, P.F.; Cai, R.C.; Li, B.B. Mechanical properties and experimental study on reaming anchor in soft coal and rock mass. J. Min. Saf. Eng. 2019, 36, 1153–1160. [Google Scholar]

- Yu, W.J.; Feng, T.; Wang, W.J.; Wang, P.; Yuan, C.; Guo, G.Y.; Du, S.H. Support problems and solutions of roadway surrounding rock for thin coal seams under complex conditions in Southern China. J. China Coal Soc. 2015, 40, 2370–2379. [Google Scholar]

- Yu, W.J.; Wu, G.S.; Liu, H.; Wang, P.; An, B.F.; Liu, Z.; Huang, Z.; Liu, F.F. Deformation characteristics and stability control of soft coal-rock mining roadway in thin coal seam. J. China Coal Soc. 2018, 43, 2668–2678. [Google Scholar]

- Aghchai, M.H.; Maarefvand, P.; Rad, H.S. Analy-tically determining bond shear strength of fully grouted rock bolt based on pullout test results. Period. Polytech.-Civ. Eng. 2020, 64, 212–222. [Google Scholar]

- Liu, C.C.; Li, Y.Z. Research progress in bolting mechanism and theories of fully grouted bolts in jointed rock masses. Chin. J. Rock Mech. Eng. 2018, 37, 1856–1872. [Google Scholar]

- Kang, H.P.; Lin, J.; Wu, Y.Z.; Cheng, P.; Meng, X.Z.; Ren, S. Mechanical performances and compatibility of rock bolt components. J. China Coal Soc. 2015, 40, 11–23. [Google Scholar]

- Xiao, T.Q.; Li, H.M.; Li, H.Y.; Wang, M. Pull-out properties of bolt with different anchorage length. J. Min. Saf. Eng. 2017, 34, 1075–1080. [Google Scholar]

- Wang, H.T.; Wang, Q.; Wang, F.Q.; Li, S.C.; Wang, D.C.; Ren, Y.X.; Guo, N.B.; Zhang, S.G. Mechanical effect analysis of bolts in roadway under different anchoring lengths and its application. J. China Coal Soc. 2015, 40, 509–515. [Google Scholar]

- Du, Y.L.; Feng, G.R.; Kang, H.P.; Zhang, Y.J.; Zhang, X.H. Investigation on the pull-out bearing characteristics of bolts with different bond lengths. J. Min. Strat. Control Eng. 2021, 3, 5–12. [Google Scholar]

- Li, C.C.; Kristjansson, G.; Høien, A.H. Critical embedment length and bond strength of fully encapsulated rebar rockbolts. Tunn. Undergr. Space Technol. 2016, 59, 16–23. [Google Scholar] [CrossRef] [Green Version]

- Thenevin, I.; Blanco-Martin, L.; Hadj-Hassen, F.; Schleifer, J.; Lubosik, Z.; Wrana, A. Laboratory pull-out tests on fully grouted rock bolts and cable bolts: Results and lessons learned. J. Rock Mech. Geotech. Eng. 2017, 9, 843–855. [Google Scholar] [CrossRef]

- Hoien, A.H.; Li, C.C.; Zhang, N. Pull-out and Critical Embedment Length of Grouted Rebar Rock Bolts-Mechanisms When Approaching and Reaching the Ultimate Load. Rock Mech. Rock Eng. 2021, 54, 1431–1447. [Google Scholar] [CrossRef]

- Hu, B.; Kang, H.P.; Lin, J.; Cai, J.F. Influence of Water on Anchorage Properties of resin Bolt. J. Min. Saf. Eng. 2013, 18, 44–47,51. [Google Scholar]

- Zhou, H.J.; Li, G.C.; Cui, G.J.; He, J.T.; Sun, C.L.; Du, L.L. Research on Weakening Performance of Anchor Bolt by Drilling Water. Saf. Coal Mines 2018, 49, 54–57. [Google Scholar]

- Kim, H.J.; Kim, K.H.; Kim, H.M.; Shin, J.H. Anchorage mechanism and pullout resistance of rock bolt in water-bearing rocks. Geomech. Eng. 2018, 15, 841–849. [Google Scholar]

- Hu, B.; Kang, H.P.; Lin, J.; Cai, J.F.; Jing, P.F. Study on Influence of Temperature on Anchorage Performance of Resin Anchored Bolt. J. Min. Saf. Eng. 2012, 29, 644–649. [Google Scholar]

- Wang, J.Y.; Guo, J.M.; Mi, J.F.; Zhang, Y.; Shi, E.R. Influence of the temperature on the gel time of the capsules in rock bolting system. J. China Coal Soc. 2008, 06, 619–622. [Google Scholar]

- Du, Y.L.; Feng, G.R.; Kang, H.P.; Zhang, Y.J.; Zhang, X.H. Effects of different pull-out loading rates on mechanical behaviors and acoustic emission responses of fully grouted bolts. J. Cent. South Univ. 2021, 28, 2052–2066. [Google Scholar] [CrossRef]

- Wei, S.J.; Wu, Y.F.; Zhao, S.N.; Li, H.H. Mechanics response of anchorage body under different pullout velocity tests. J. Henan Polytech. Univ., Nat. Sci. 2018, 37, 17–23. [Google Scholar]

- Kong, L.F.; Guo, W.Y.; Zhao, T.B. Experimental study on impact of loading rate on bolt and anchoring effect. J. Heilongjiang Univ. Sci. Technol. 2014, 24, 553–557. [Google Scholar]

- Wang, Z.Y.; Dou, L.M.; Wang, G.F. Failure mechanism of anchored bolt supporting structure of circular roadway under dynamic load. Chin. J. Geotech. Eng. 2015, 37, 1901–1909. [Google Scholar]

- Zhang, Z.C.; Zhang, X.D.; Liu, Y.H.; Li, Q.W. Experimental research of anchors bonding mechanical properties under transverse harmonic loads. J. China Coal Soc. 2016, 41, 1407–1415. [Google Scholar]

- Tahmasebinia, F.; Zhang, C.G.; Canbulat, I.; Vardar, O.; Saydam, S. Numerical and analytical simulation of the structural behaviour of fully grouted cable bolts under impulsive loading. Int. J. Min. Sci. Technol. 2018, 28, 807–811. [Google Scholar] [CrossRef]

- Zhao, T.B.; Guo, W.Y.; Yin, Y.C.; Tan, Y.L. Bolt pull-out tests of anchorage body under different loading rates. Shock Vib. 2015, 2015, 121673. [Google Scholar] [CrossRef]

- Chen, C.F.; Liang, G.T.; Tang, Y.; Xu, Y.L. Anchoring solid-soil interface behavior using a novel laboratory testing technique. Chin. J. Geotech. Eng. 2015, 37, 1115–1122. [Google Scholar]

- Chen, G.B.; Teng, P.C.; Zhang, G.H.; Yang, L.; Li, T.; Lv, P.F. Fractal characteristics and energy transfer mechanism of coal-rock combined body fragments under different loading rates. J. Chongqing Univ. 2021, 44, 1–13. Available online: http://kns.cnki.net/kcms/detail/50.1044.N.20210516.1420.002.html (accessed on 4 April 2022).

- Yin, D.W.; Chen, S.J.; Xing, W.B.; Huang, D.M.; Liu, X.Q. Experimental study on mechanical behavior of roof-coal pillar structure body under different loading rates. J. China Coal Soc. 2018, 43, 1249–1257. [Google Scholar]

- Gong, F.Q.; Ye, H.; Luo, Y. Rate effect on the burst tendency of coal-rock combined body under low loading rate range. J. China Coal Soc. 2017, 42, 2852–2860. [Google Scholar]

- Yang, K.; Liu, W.J.; Ma, Y.K.; Dou, L.T.; Liu, S.; Wei, Z.; Xu, R.J. Experimental research on energy dissipation and failure characteristics of coal-rock combined body under impact loading. J. China Coal Soc. 2021, 46, 1–16. Available online: https://doi.org/10.13225/j.cnki.jccs.2021.1279 (accessed on 4 April 2022).

- Ma, Q.; Tan, Y.L.; Liu, S.S.; Zhao, Z.H.; Fan, D.Y.; PUREV, L. Experimental and numerical simulation of loading rate effects on failure and strain energy characteristics of coal-rock composite samples. J. Cent. South Univ. 2021, 28, 3207–3222. [Google Scholar] [CrossRef]

- Zhang, P.D.; Gao, L.; Liu, P.Z.; Wang, Y.Y.; Liu, P.; Kang, X.T.; Cheng, Z.B. Study on the Influence of Borehole Water Content on Bolt Anchoring Force in Soft Surrounding Rock. Shock Vib. 2022, 2022, 2384626. [Google Scholar] [CrossRef]

- Zhao, T.B. Rock Creep Properties Test in Deep Mine and Deformation Mechanism of Anchored Surrounding Rock; Shandong University of Science and Technology: Shandong, China, 2009. [Google Scholar]

- Du, Y.L.; Feng, G.R.; Kang, H.P.; Zhang, X.H.; Zhang, Y.J.; Shi, X.D.; Wen, X.Z. Investigation on the mechanical behavior and failure characteristics of fully grouted bolts under tension. Energy Sources Part A—Recovery Util. Environ. Eff. 2020, 1–15. Available online: https://doi.org/10.1080/15567036.2020.1829194 (accessed on 4 April 2022). [CrossRef]

- You, C.N.; Zhan, Y.B.; Liu, Q.Y.; Sun, L.L.; Wang, K.B. Shear Lag-debonding model for anchorage section of prestressed anchor cable. Chin. J. Rock Mech. Eng. 2013, 32, 800–806. [Google Scholar]

- Ma, S.Q.; Nemcik, J.; Aziz, N. An analytical model of fully grouted rock bolts subjected to tensile load. Chin. Constr. Build. Mater. 2013, 49, 519–526. [Google Scholar] [CrossRef]

| Name | Length/mm | Diameter/mm | Remark |

|---|---|---|---|

| bolt | 1100 | 21.6 | — |

| epoxy resin glue | — | — | A and B glue 1∶1 |

| Surrounding Rock | Cement Mark | Water: Cement: Sand: Stone (Mass Ratio) |

|---|---|---|

| coal | 42.5 | 0.8∶0∶0.5∶2.5 |

| rock | 42.5 | 0.49∶1∶1.47∶1.68 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Gao, L.; Zhan, X.; Liu, P.; Kang, X.; Ma, Z.; Wang, Y.; Liu, P.; Han, S. Investigation of the Bearing Characteristics of Bolts on a Coal–Rock Combined Anchor Body under Different Pull-Out Rates. Energies 2022, 15, 3313. https://doi.org/10.3390/en15093313

Zhang P, Gao L, Zhan X, Liu P, Kang X, Ma Z, Wang Y, Liu P, Han S. Investigation of the Bearing Characteristics of Bolts on a Coal–Rock Combined Anchor Body under Different Pull-Out Rates. Energies. 2022; 15(9):3313. https://doi.org/10.3390/en15093313

Chicago/Turabian StyleZhang, Pandong, Lin Gao, Xinyu Zhan, Pengze Liu, Xiangtao Kang, Zhenqian Ma, Yongyin Wang, Ping Liu, and Sen Han. 2022. "Investigation of the Bearing Characteristics of Bolts on a Coal–Rock Combined Anchor Body under Different Pull-Out Rates" Energies 15, no. 9: 3313. https://doi.org/10.3390/en15093313

APA StyleZhang, P., Gao, L., Zhan, X., Liu, P., Kang, X., Ma, Z., Wang, Y., Liu, P., & Han, S. (2022). Investigation of the Bearing Characteristics of Bolts on a Coal–Rock Combined Anchor Body under Different Pull-Out Rates. Energies, 15(9), 3313. https://doi.org/10.3390/en15093313