Concept for Biomass and Organic Waste Refinery Plants Based on the Locally Available Organic Materials in Rural Areas of Poland

Abstract

:1. Introduction

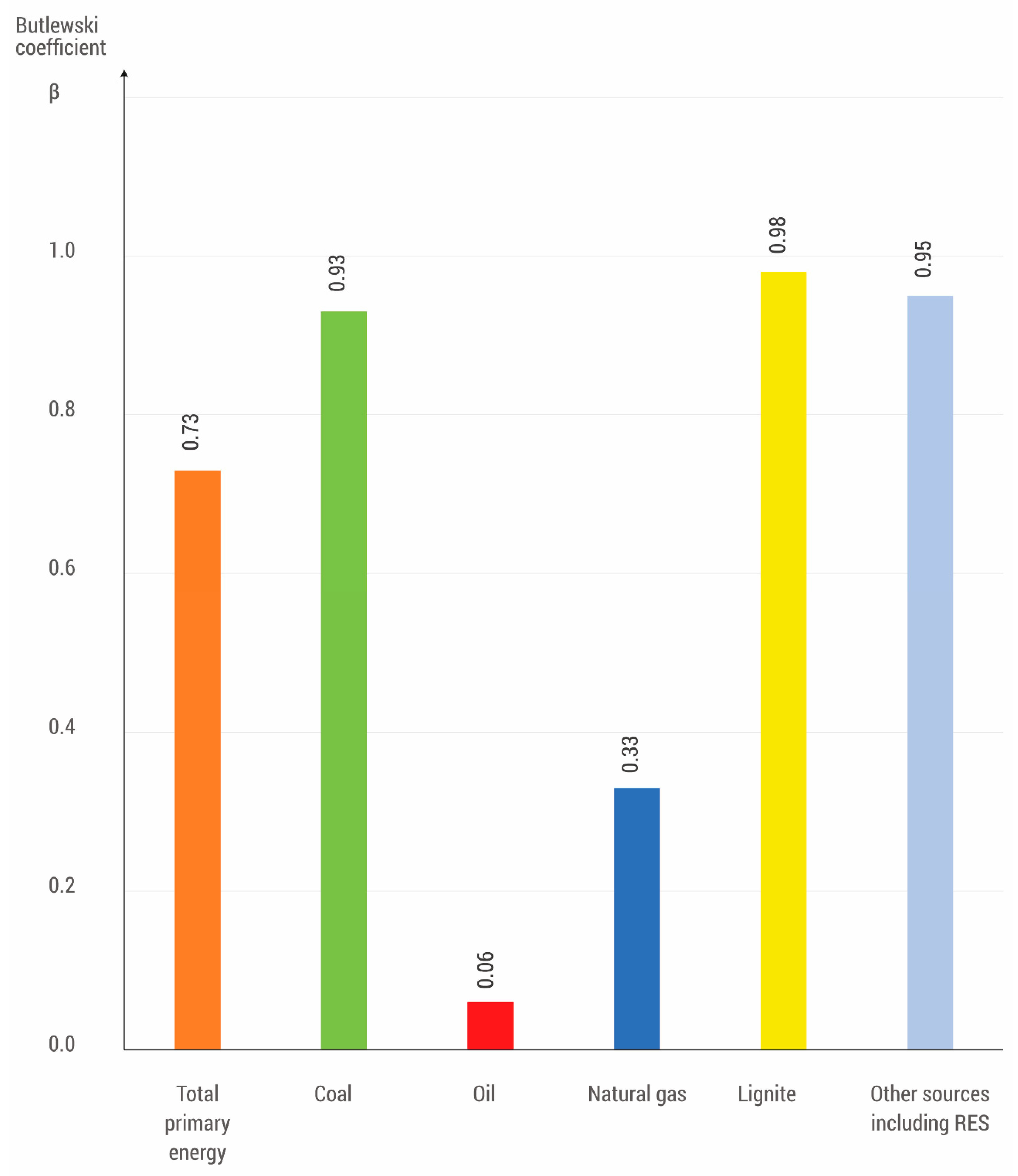

2. Biomass Resources for Energy Production in Poland

2.1. Forestry Resources

2.2. Straw

2.3. Biogas Production

2.3.1. Biogas from Livestock Manure

2.3.2. Biogas from Maize Silage

2.4. Energy Crops

2.5. Grasses from Meadows and Pastures

2.6. Communal Waste

2.7. Potential Energy Production from Biomass in Poland

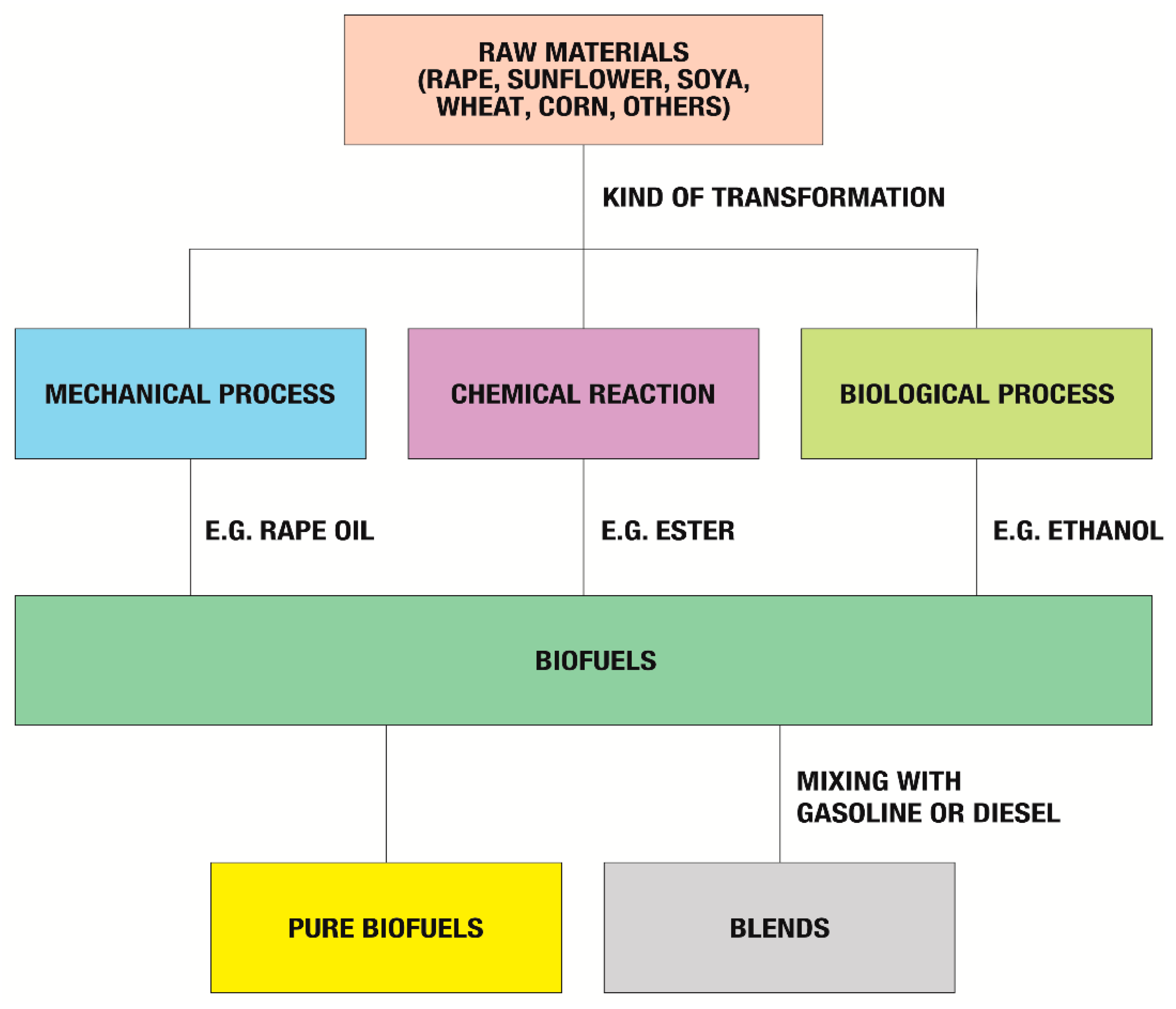

3. Biofuel Production in Poland

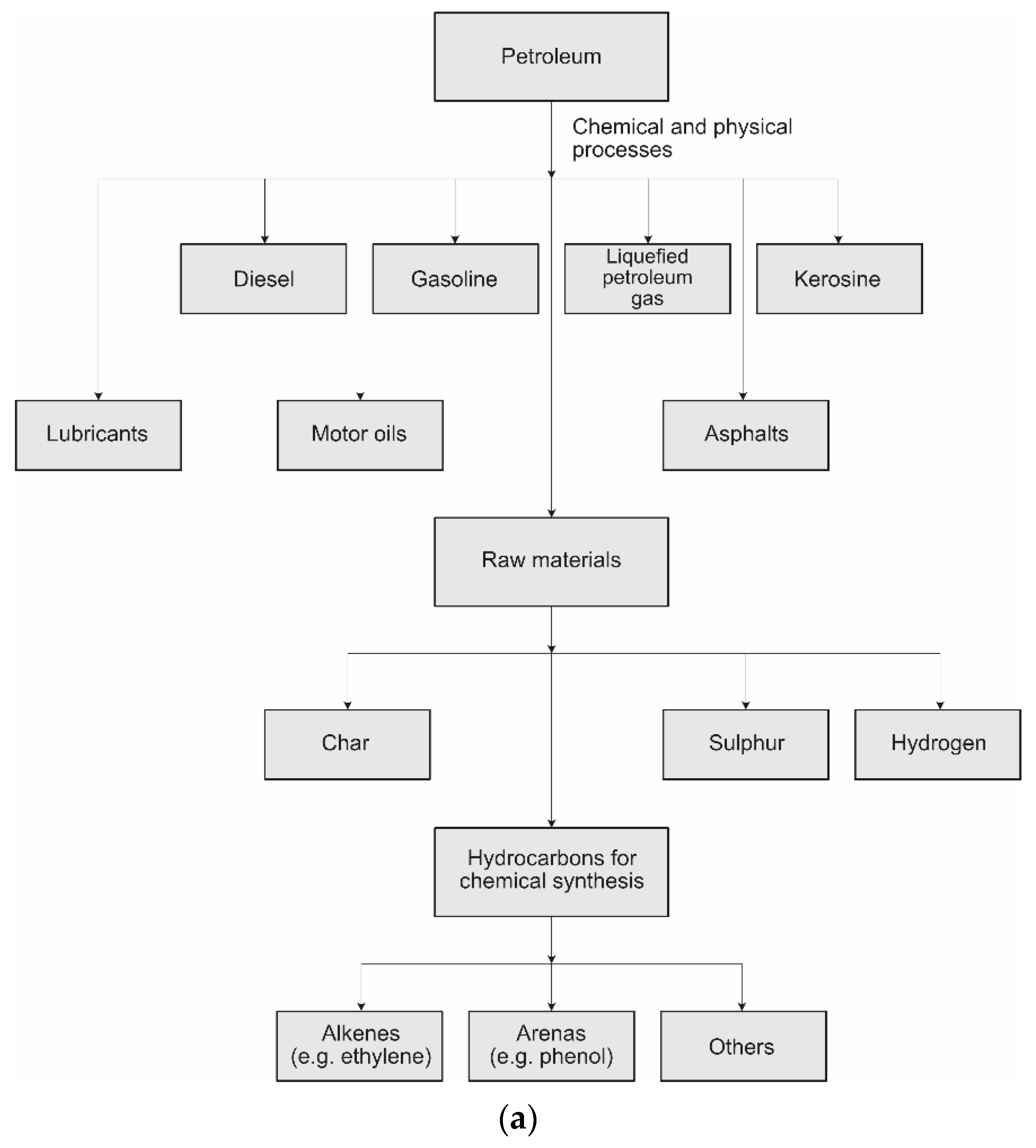

4. New Energy and Biofuel Units

5. Refinery Plant Concept for Locally Available Organic Materials in Rural Areas in Poland

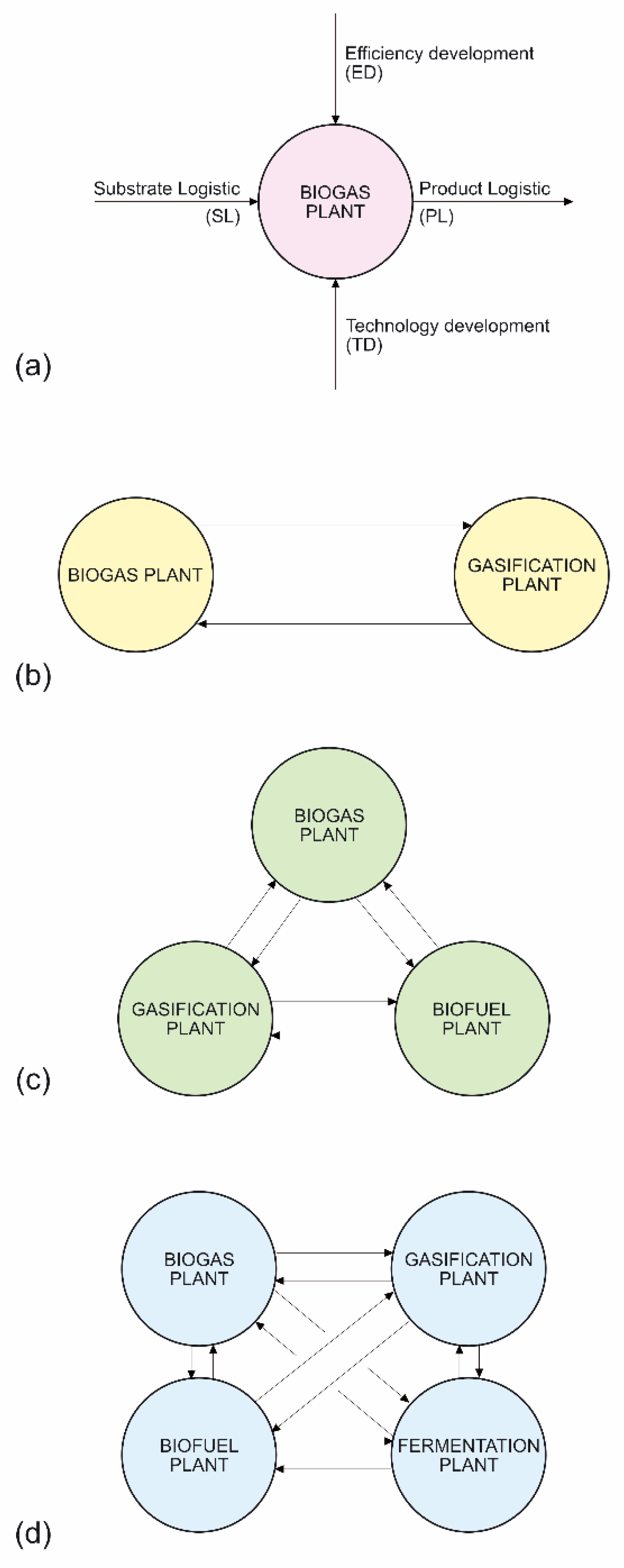

5.1. Biomass Refinery Models

5.1.1. Input/Output Model of Biomass Refineries

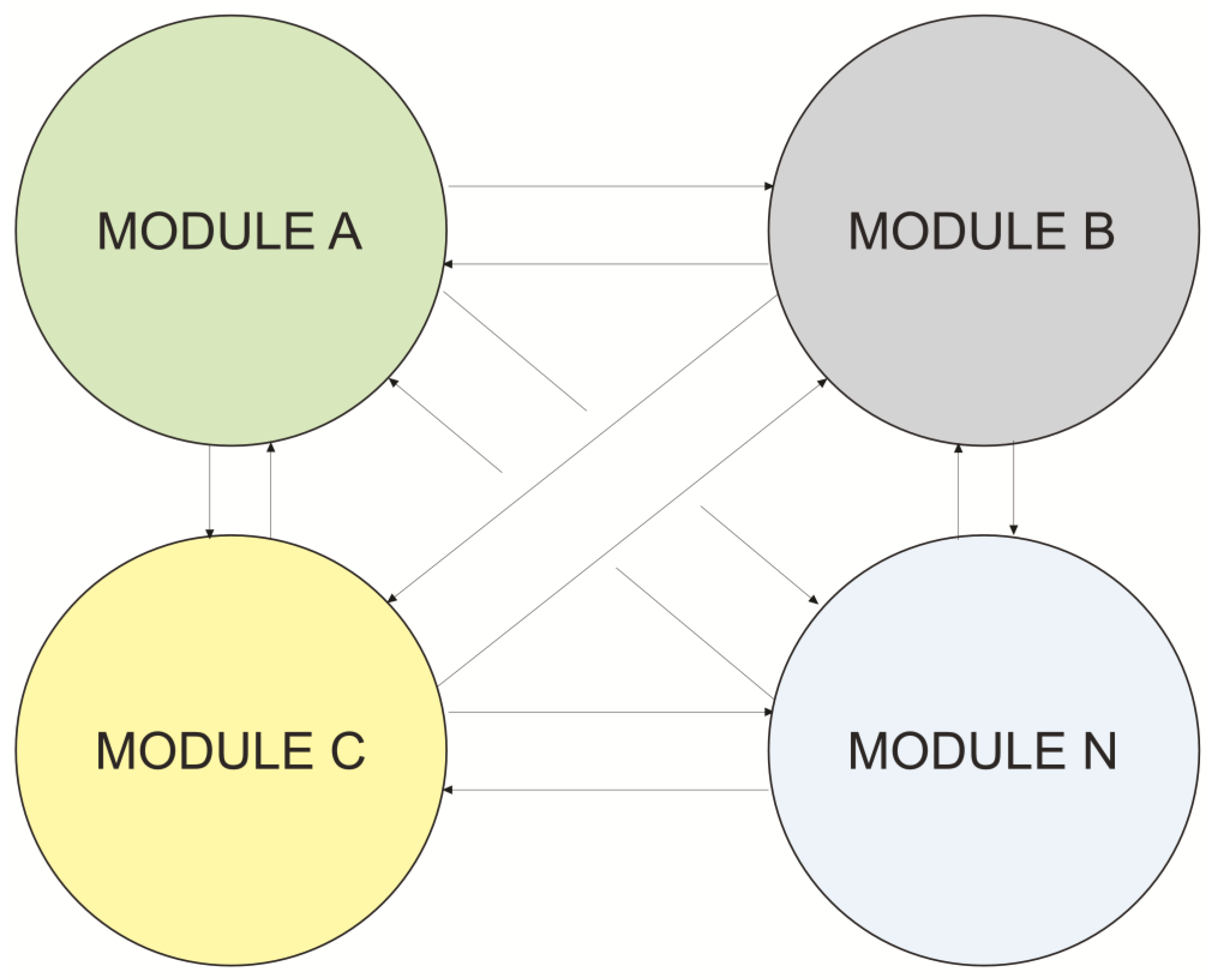

5.1.2. Modular Model of Biomass Refineries

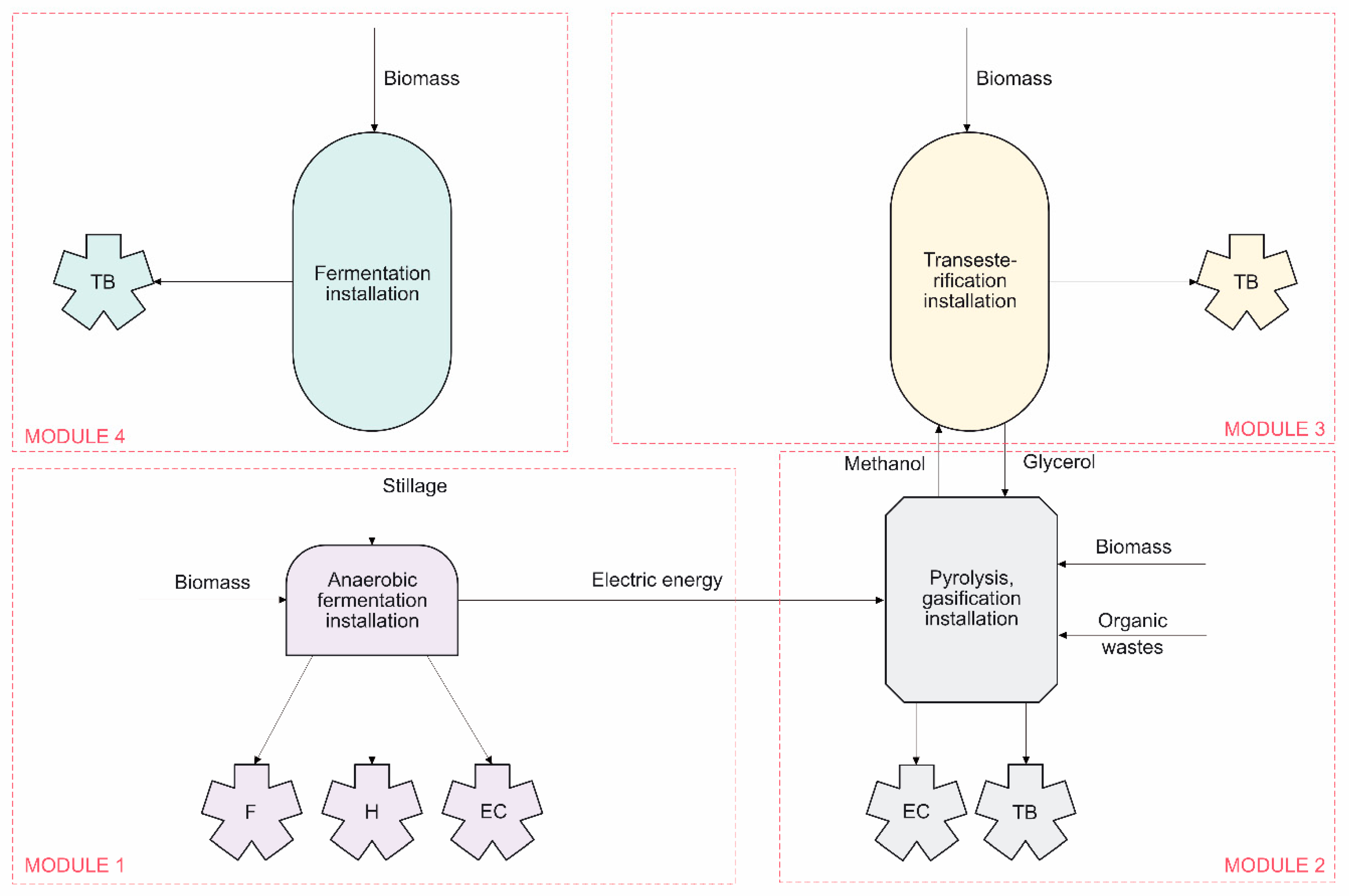

6. Four-Module Concept of Biomass Refinery Plants

7. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Statistical Yearbook of the Republic of Poland, Statistics Poland (GUS). 2021. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-rzeczypospolitej-polskiej-2021,2,21.html (accessed on 21 March 2022).

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Rather, R.A.; Wani, A.W.; Mumtaz, S.; Padder, S.A.; Khan, A.H.; Almohana, A.I.; Almojil, S.F.; Alam, S.S.; Baba, T.R. Bioenergy: A foundation to environmental sustainability in a changing global climate scenario. J. King Saud Univ.—Sci. 2022, 34, 101734. [Google Scholar] [CrossRef]

- Central Statistical Office (GUS). Statistical Yearbook of Agriculture. 2020. Available online: https://stat.gov.pl/en/topics/statistical-yearbooks/statistical-yearbooks/statistical-yearbook-of-agriculture-2020,6,15.html (accessed on 21 March 2022).

- National Agricultural Support Centre Public Information Bulletin. Data on Biocomponent Production in 2020. Warsaw, Poland. 2021. Available online: https://bip.kowr.gov.pl/informacje-publiczne/odnawialne-zrodla-energii/informacje-dotyczace-rynku-biokomponentow (accessed on 21 March 2022).

- Central Statistical Office (GUS). Energy Statistics in 2018 and 2019. Available online: https://stat.gov.pl/en/topics/environment-energy/energy/energy-statistics-in-2018-and-2019,4,15.html (accessed on 21 March 2022).

- Central Statistical Office (GUS). Energy Statistics in 2019 and 2020. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/energia/gospodarka-paliwowo-energetyczna-w-latach-2019-i-2020,4,16.html (accessed on 21 April 2022).

- Butlewski, K. Evaluation of the Present State and Prospects for Energy and Energy Carrier Production from Biomass in Poland. In Proceedings of the 25th European Biomass Conference and Exhibition, Stockholm, Sweden, 12–15 June 2017. [Google Scholar] [CrossRef]

- Energy Regulatory Office (URE), Renewable Energy Sources, Installed Power. Available online: https://www.ure.gov.pl/pl/oze/potencjal-krajowy-oze (accessed on 1 April 2022).

- Central Statistical Office (GUS). Statistical Yearbook of Forestry in 2019. Available online: https://stat.gov.pl/files/gfx/portalinformacyjny/en/defaultaktualnosci/3328/12/2/1/statistical_yearbook_of_forestry_2019.pdf/ (accessed on 21 March 2022).

- Iglinski, B.; Cichosz, M.; Skrzatek, M.; Buczkowski, R. Technical potential of waste biomass for energy in Poland. Eng. Protec. Environ. 2018, 22, 109–118. [Google Scholar] [CrossRef]

- Ray, C.D. Calculating the Green Weight of Wood Species. PennState Extension 2014. Available online: https://extension.psu.edu/calculating-the-green-weight-of-wood-species (accessed on 21 March 2022).

- Aniszewska, M.; Gendek, A. Comparison of heat of combustion and calorific value of the cones and wood of selected forest trees species. For. Res. Pap. 2014, 75, 231–236. [Google Scholar] [CrossRef] [Green Version]

- Kurowska, A. Waste wood supply structure in Poland. Sylwan 2016, 160, 187–196. [Google Scholar]

- Central Statistical Office (GUS). Statistical Yearbook of Agriculture in 2019. Available online: https://stat.gov.pl/obszary-tematyczne/rolnictwo-lesnictwo/rolnictwo/ (accessed on 21 March 2022).

- Dai, J.; Bean, B.; Brown, B.; Bruening, W.; Edwards, J.; Flowers, M.; Karow, R.; Lee, C.; Morgan, G.; Ottman, M.; et al. Harvest index and straw yield of five classes of wheat. Biomass Bioenergy 2016, 85, 223–227. [Google Scholar] [CrossRef] [Green Version]

- Zhu, J.H.; Pan, X.J. Woody biomass pretreatment for cellulosic ethanol production: Technology and energy consumption evaluation. Bioresour. Technol. 2010, 13, 4992–5002. [Google Scholar] [CrossRef]

- National Agricultural Support Centre (KOWR). 2020. Available online: https://www.kowr.gov.pl/odnawialne-zrodla-energii/biogaz-rolniczy/wytworcy-biogazu-rolniczego/rejestr-wytworcow-biogazu-rolniczego (accessed on 21 March 2022).

- Strzalka, R.; Schneider, D.; Eicker, U. Current status of bioenergy technologies in Germany. Renew. Sustain. Energy Rev. 2017, 72, 801–820. [Google Scholar] [CrossRef]

- Iglinski, B.; Buczkowski, R.; Iglinska, A.; Cichosz, M.; Piechota, G.; Kujawski, W. Agricultural biogas plant in Poland: Investment process, economical and environmental aspects, biogas potential. Renew. Sustain. Energy Rev. 2012, 16, 4890–4900. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biotechnol. 2010, 85, 849–860. [Google Scholar] [CrossRef]

- Igliński, B.; Buczkowski, R.; Cichosz, M. Biogas production in Poland–Current state, potential and perspectives. Renew. Sustain. Energy Rev. 2015, 50, 686–695. [Google Scholar] [CrossRef]

- Comino, E.; Reggio, V.A.; Rosso, M. Biogas production by anaerobic co-digestion of cattle slurry and cheese whey. Bioresour. Technol. 2012, 114, 46–53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Piwowar, A.; Dzikuć, M.; Adamczyk, J. Agricultural biogas plants in Poland—Selected technologies, market and environmental aspects. Renew. Sustain. Energy Rev. 2016, 58, 69–74. [Google Scholar] [CrossRef]

- Central Statistical Office (GUS). Agriculture in 2019. Available online: https://stat.gov.pl/obszary-tematyczne/rolnictwo-lesnictwo/rolnictwo/rolnictwo-w-2019-roku,3,16.html (accessed on 21 March 2022).

- Central Statistical Office (GUS). Production of Agricultural and Horticultural Crops in 2018. Available online: https://stat.gov.pl/obszary-tematyczne/rolnictwo-lesnictwo/uprawy-rolne-i-ogrodnicze/produkcja-upraw-rolnych-i-ogrodniczych-w-2018-roku,9,17.html (accessed on 21 March 2022).

- Jezierska-Thole, A.; Rudnicki, R.; Kluba, M. Development of energy crops cultivation for biomass production in Poland. Renew. Sustain. Energy Rev. 2016, 62, 534–545. [Google Scholar] [CrossRef]

- Central Statistical Office (GUS). Environment 2019. Warsaw, Poland. 2019. Available online: https://stat.gov.pl/obszary-tematyczne/srodowisko-energia/srodowisko/ochrona-srodowiska-2019,1,20.html (accessed on 21 March 2022).

- Worldometer. Largest Countries in the World (by Area). Available online: https://www.worldometers.info/geography/largest-countries-in-the-world/2022 (accessed on 21 March 2022).

- Eurostat. Final Energy Consumption by Product. Available online: https://ec.europa.eu/eurostat/databrowser/view/ten00123/default/table?lang=en (accessed on 21 March 2022).

- Statista. Biofuels Production in Selected Countries in Europe in 2019. Available online: https://www.statista.com/statistics/332510/biofuels-production-in-selected-countries-in-europe/ (accessed on 21 March 2022).

- Huang, C.; Jiang, X.; Shen, X.; Hu, J.; Tang, W.; Wu, X.; Ragauskas, A.; Jameel, H.; Meng, X.; Yong, Q. Lignin-enzyme interaction: A roadblock for efficient enzymatic hydrolysis of lignocellulosics. Renew. Sustain. Energy Rev. 2022, 154, 111822. [Google Scholar] [CrossRef]

- Butlewski, K. Combined Biomass Gasification and Anaerobic Digestion for the Synergic Effect in Power Production for the Local Application. In Proceedings of the European Biomass Conference and Exhibition, Amsterdam, The Netherlands, 6–9 June 2016; pp. 884–885. [Google Scholar] [CrossRef]

- Butlewski, K. Anaerobic digestion and microwave pyrolysis techniques for recycling organic wastes. Polimery 2019, 64, 811–817. [Google Scholar] [CrossRef]

- Feroskhan, M.; Thangavel, V.; Subramanian, B.; Sankaralingam, R.K.; Ismail, S.; Chaudhary, A. Effects of operating parameters on the performance, emission and combustion indices of a biogas fuelled HCCI engine. Fuel 2021, 298, 120799. [Google Scholar] [CrossRef]

- Czekala, W.; Gawrych, K.; Smurzynska, A.; Mazurkiewicz, J.; Pawlisiak, A.; Chelkowski, D.; Brzoski, M. The possibility of functioning micro-scale biogas plant in selected farm. J. Water Land Develop. 2017, 35, 19–25. [Google Scholar] [CrossRef] [Green Version]

- Butlewski, K. Biogas upgrading methods including possibilities of thermal integration with the biomass fermentation process. Probl. Agric. Eng. 2016, 24, 67–83. Available online: https://www.itp.edu.pl/old/wydawnictwo/pir/zeszyt_92_2016/Butlewski%20K%20%20Metody%20uzdatniania%20biogazu.pdf (accessed on 21 March 2022).

- Carranza-Abaid, A.; Wanderley, R.R.; Knuutila, H.K.; Jakobsen, J.P. Analysis and selection of optimal solvent-based technologies for biogas upgrading. Fuel 2021, 303, 121327. [Google Scholar] [CrossRef]

- Cavaignac, R.S.; Ferreira, N.L.; Guardani, R. Techno-economic and environmental process evaluation of biogas upgrading via amine scrubbing. Renew. Energy 2021, 171, 868–880. [Google Scholar] [CrossRef]

- Khan, M.U.; Lee, J.T.E.; Bashir, M.A.; Dissanayake, P.D.; Ok, Y.S.; Tong, Y.W.; Shariati, M.A.; Wu, S.; Ahring, B.K. Current status of biogas upgrading for direct biomethane use: A review. Renew. Sustain. Energy Rev. 2021, 149, 111343. [Google Scholar] [CrossRef]

- Fu, S.; Angelidaki, I.; Zhang, Y. In situ Biogas Upgrading by CO2-to-CH4 Bioconversion. Trends Biotechnol. 2021, 39, 336–347. [Google Scholar] [CrossRef] [PubMed]

- Goulding, D.; Power, N. Which is the preferable biogas utilization technology for anaerobic digestion of agricultural crops in Ireland: Biogas to CHP or biomethane as a transport fuel? Renew. Energy 2013, 53, 121–131. [Google Scholar] [CrossRef]

- Patrizio, P.; Leduc, S.; Chinese, D.; Dotzauer, E.; Kraxner, F. Biomethane as transport fuel—A comparison with other biogas utilization pathways in northern Italy. Appl. Energy 2015, 157, 25–34. [Google Scholar] [CrossRef]

- Fernandez-Gonzalez, J.M.; Martin-Pascual, J.; Zamorano, M. Biomethane injection into natural gas network vs. composting and biogas production for electricity in Spain: An analysis of key decision factors. Sustain. Cities Soc. 2020, 60, 102242. [Google Scholar] [CrossRef]

- Rosha, P.; Rosha, A.K.; Ibrahim, H.; Kumar, S. Recent advances in biogas upgrading to value-added products: A review. Int. J. Hydrog. Energy 2021, 46, 21318–21337. [Google Scholar] [CrossRef]

- Yousef, A.M.; El-Maghlany, W.M.; Eldrainy, Y.A.; Attia, A. Upgrading biogas to biomethane and liquid CO2: A novel cryogenic process. Fuel 2019, 251, 611–628. [Google Scholar] [CrossRef]

- Pellegrini, L.A.; De Guido, G.; Lange, S. Biogas to liquified biomethane via cryogenic upgrading technologies. Renew. Energy 2018, 124, 75–83. [Google Scholar] [CrossRef]

- Thirusevi, D.; Kumar, P.S.; Kumar, M.A.; Lay, C.H.; Aathika, S.; Mani, Y.; Jagadiswary, D.; Dhanasekaran, A.; Shanmugam, P.; Sivanesan, S.; et al. A critical review on global trends in biogas scenario with its up-gradation techniques for fuel cell and future perspectives. Int. J. Hydrogen Energy 2021, 46, 16734–16750. [Google Scholar] [CrossRef]

- Butlewski, K. Fuel cells in agricultural heat and power generating plants. Probl. Agric. Eng. 2013, 3, 109–125. Available online: https://www.itp.edu.pl/old/wydawnictwo/pir/zeszyt_81_2013/K_Butlewski%20%20Ogniwa%20paliwowe%20.pdf (accessed on 21 March 2022).

- Zhou, N.; Zhou, J.; Dai, L.; Guo, F.; Wang, Y.; Li, H.; Deng, W.; Lei, H.; Chen, P.; Liu, Y.; et al. Syngas production from biomass pyrolysis in a continuous microwave assisted pyrolysis system. Bioresour. Technol. 2020, 314, 123756. [Google Scholar] [CrossRef] [PubMed]

- Liu, L.; Lin, Z.; Lin, S.; Chen, Y.; Zhang, L.; Chen, S.; Zhang, X.; Lin, J.; Zhang, Z.; Wan, S.; et al. Conversion of syngas to methanol and DME on highly selective Pd/ZnAl2O4 catalyst. J. Energy Chem. 2021, 58, 564–572. [Google Scholar] [CrossRef]

- De Jesus, S.S.; Ferreira, G.F.; Moreira, L.S.; Filho, R.M. Biodiesel production from microalgae by direct transesterification using green solvents. Renew. Energy 2020, 160, 1283–1294. [Google Scholar] [CrossRef]

- Ansari, S.H.; Ahmed, A.; Razzaq, A.; Hildebrandt, X.L.; Park, Y.K. Incorporation of solar-thermal energy into gasification process to co-produce bio-fertilizer and power. Environ. Pollut. 2020, 266, 115103. [Google Scholar] [CrossRef]

- Patra, T.K.; Mukherjee, S.; Sheth, P.N. Process simulation of hydrogen-rich gas production from producer gas using HTS catalysis. Energy 2019, 173, 1130–1140. [Google Scholar] [CrossRef]

- Okolie, J.A.; Patra, B.R.; Mukherjee, A.; Nanda, S.; Dalai, A.K.; Kozinski, J.A. Futuristic applications of hydrogen in energy, biorefining, aerospace, pharmaceuticals and metallurgy. Int. J. Hydrogen Energy 2021, 46, 8885–8905. [Google Scholar] [CrossRef]

- Asomaning, J.; Haupt, S.; Chae, M.; Bressler, D.C. Recent developments in microwave-assisted thermal conversion of biomass for fuels and chemicals. Renew. Sustain. Energy Rev. 2018, 92, 642–657. [Google Scholar] [CrossRef]

- Suriapparao, D.V.; Vinu, R. Biomass waste conversion into value-added products via microwave-assisted Co-Pyrolysis platform. Renew. Energy 2021, 170, 400–409. [Google Scholar] [CrossRef]

- Caligiuri, C.; Renzi, M.; Bietresato, M.; Baratieri, M. Experimental investigation on the effects of bioethanol addition in diesel-biodiesel blends on emissions and performances of a micro-cogeneration system. Energy Convers. Manag. 2019, 185, 55–65. [Google Scholar] [CrossRef]

- Park, S.H.; Cha, J.; Lee, C.S. Impact of biodiesel in bioethanol blended diesel on the engine performance and emissions characteristics in compression ignition engine. Appl. Energy 2012, 99, 334–343. [Google Scholar] [CrossRef]

- O’Shea, R.; Lin, R.; Wall, D.M.; Browne, J.D.; Murphy, J.D. Using biogas to reduce natural gas consumption and greenhouse gas emissions at a large distillery. Appl. Energy 2020, 279, 115812. [Google Scholar] [CrossRef]

- Singh, N.; Basu, S.; Balakrishnan, M. Comprehensive treatment scheme for distillery wastewater targeting recovery of water, antioxidant compounds and biogas. J. Water Process Eng. 2020, 38, 101663. [Google Scholar] [CrossRef]

- Mofijur, M.; Siddiki, S.Y.; Shuvho, M.B.; Djavanroodi, F.; Fattah, I.M.; Ong, H.C.; Chowdhury, M.A.; Mahlia, T.M.I. Effect of nanocatalysts on the transesterification reaction of first, second and third-generation biodiesel sources—A mini-review. Chemosphere 2021, 270, 128642. [Google Scholar] [CrossRef] [PubMed]

- Ng, M.H.; Yung, C.L. Nuclear magnetic resonance spectroscopic characterisation of palm biodiesel and its blends. Fuel 2019, 257, 116008. [Google Scholar] [CrossRef]

- Sajid, M.; Ayoub, M.; Uemura, Y.; Yusup, S.; Saleem, M.; Abdullah, B.; Khan, A.U. Comparative study of glycerol conversion to polyglycerol via conventional and microwave irradiation reactor. Mater Today Proc. 2019, 16, 210–217. [Google Scholar] [CrossRef]

- Ogwang, I.; Kasedde, H.; Nabuuma, B.; Kirabira, J.B.; Lwanyaga, J.D. Characterization of Biogas Digestate for Solid Biofuel Production in Uganda. Sci. Afr. 2021, 12, e00735. [Google Scholar] [CrossRef]

- Valentinuzzi, F.; Cavani, L.; Porfido, C.; Terzano, R.; Pii, Y.; Cesco, S.; Marzadori, C.; Mimmo, T. The fertilising potential of manure-based biogas fermentation residues: Pelleted vs. liquid digestate. Heliyon 2020, 6, e03325. [Google Scholar] [CrossRef]

- Skibko, Z.; Romaniuk, W.; Borusiewicz, A.; Porwisiak, H.; Lisowski, A. Use of pellets from agricultural plants in fertilization of oxytrees in Podlasie, Poland. J. Water Land Develop. 2021, 51, 124–128. [Google Scholar] [CrossRef]

- Kwan, T.H.; Shen, Y.; Pei, G. Recycling fuel cell waste heat to the thermoelectric cooler for enhanced combined heat, power and water production. Energy 2021, 223, 119922. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butlewski, K. Concept for Biomass and Organic Waste Refinery Plants Based on the Locally Available Organic Materials in Rural Areas of Poland. Energies 2022, 15, 3392. https://doi.org/10.3390/en15093392

Butlewski K. Concept for Biomass and Organic Waste Refinery Plants Based on the Locally Available Organic Materials in Rural Areas of Poland. Energies. 2022; 15(9):3392. https://doi.org/10.3390/en15093392

Chicago/Turabian StyleButlewski, Krystian. 2022. "Concept for Biomass and Organic Waste Refinery Plants Based on the Locally Available Organic Materials in Rural Areas of Poland" Energies 15, no. 9: 3392. https://doi.org/10.3390/en15093392