Performance Evaluation of 1.1 MW Grid-Connected Solar Photovoltaic Power Plant in Louisiana

Abstract

:1. Introduction

2. Background and Literature Review

| Reference | Location | Climate Classification | Size | Studied Technology | Main Contribution/Findings |

|---|---|---|---|---|---|

| [14] | India | Tropical, savannah | 10 MW | poly-Si | The actual performance closely matches with the simulated performance of PVsyst and solar GIS over the study period. |

| [17] | Kuwait | Arid | 11.15 MW | poly-Si and thin film | Comparison between the thin film and poly-Si PV subsystems reveals no significant difference between the two technologies regarding performance ratios (80.0% for thin film and 80.2% for poly-Si) |

| [21] | Europe | NA | 20 modules | bifacial | Use of panels with 92% bifaciality resulted in a higher yield of up to 3% compared to panels with 70% bifaciality |

| [18] | Spain | NA | Six power plants of different sizes | poly-Si, mono-Si, a-Si | Fixed tilt, single-axis, and dual-axis tracking systems are studied |

| [20] | Kuwait | Arid desert | 16 modules | eight PV technology mono-Si, poly-Si (2 types), HIT, CdTe, CIGS (2 types), a-Si | A-Si and CdTe performed significantly lower than other technologies |

| [22] | Singapore | Tropical | 190 kW | mono-Si, poly-Si, a-Si, CdTe, CIGS | Simulation predictions shows that east façade and panel slope of 30° and 40° are the most suitable location and inclination in Singapore |

| Current study | Louisiana, USA | Humid, subtropical | 1.1 MW | poly-Si, mono-Si, and CIGS | CIGS performs well in these conditions |

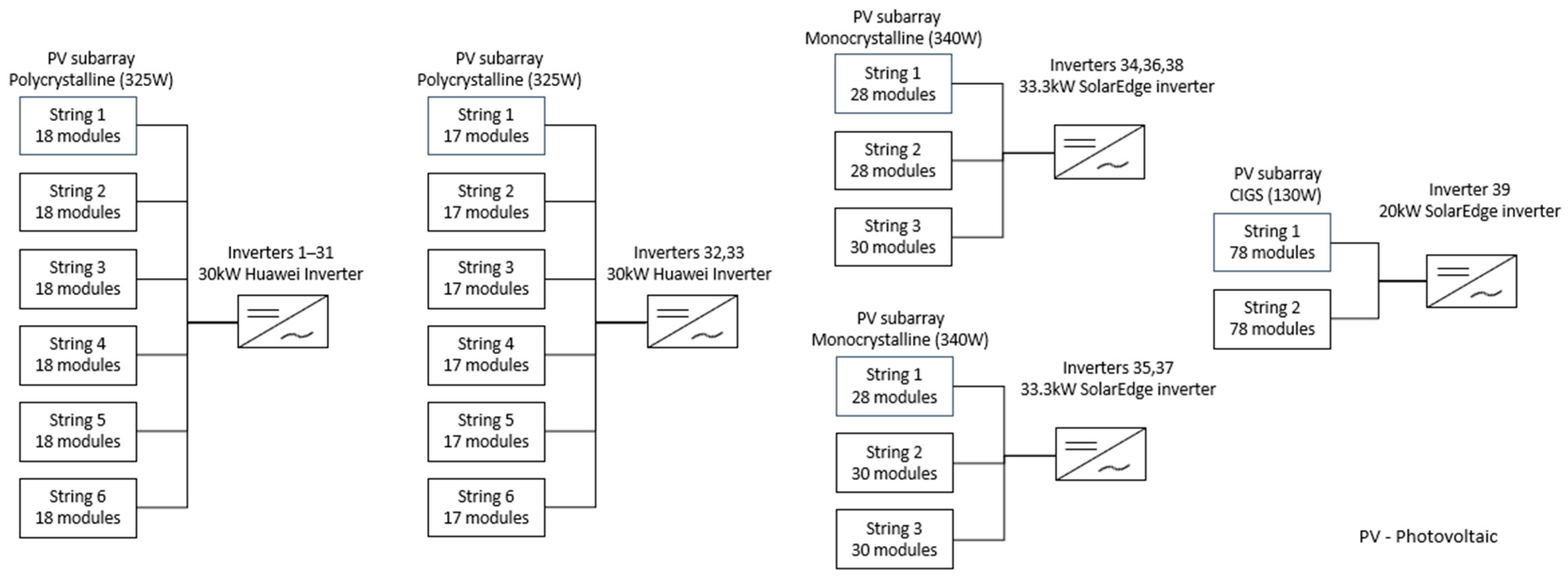

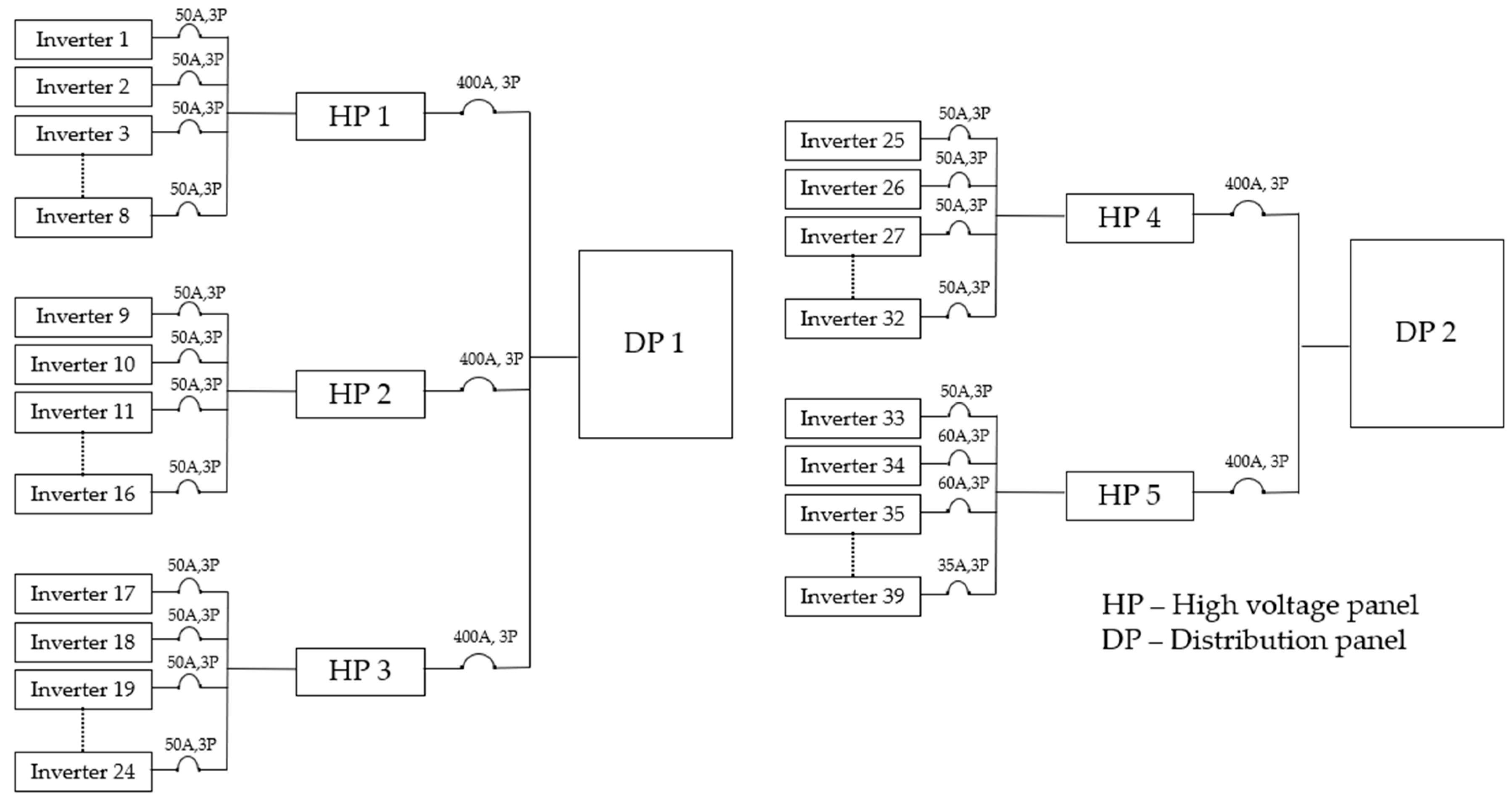

3. Description of the Power Plant

4. Methodology

4.1. Final Yield

4.2. Reference Yield

4.3. Performance Ratio

4.4. Capacity Factor

4.5. System Efficiency

4.6. Levelized Cost of Energy

4.7. Simulation Using SAM and PVsyst

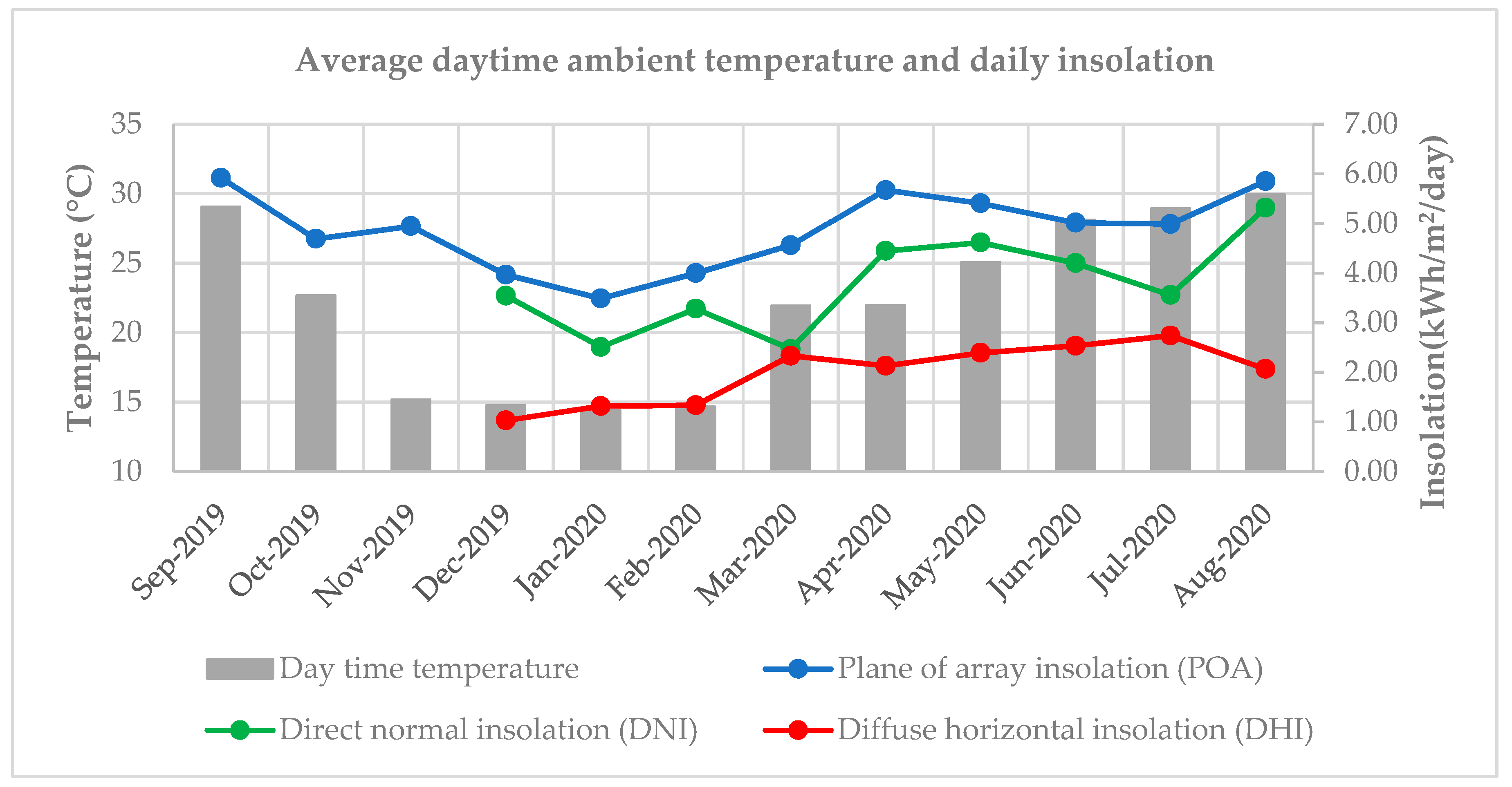

5. Results and Discussion

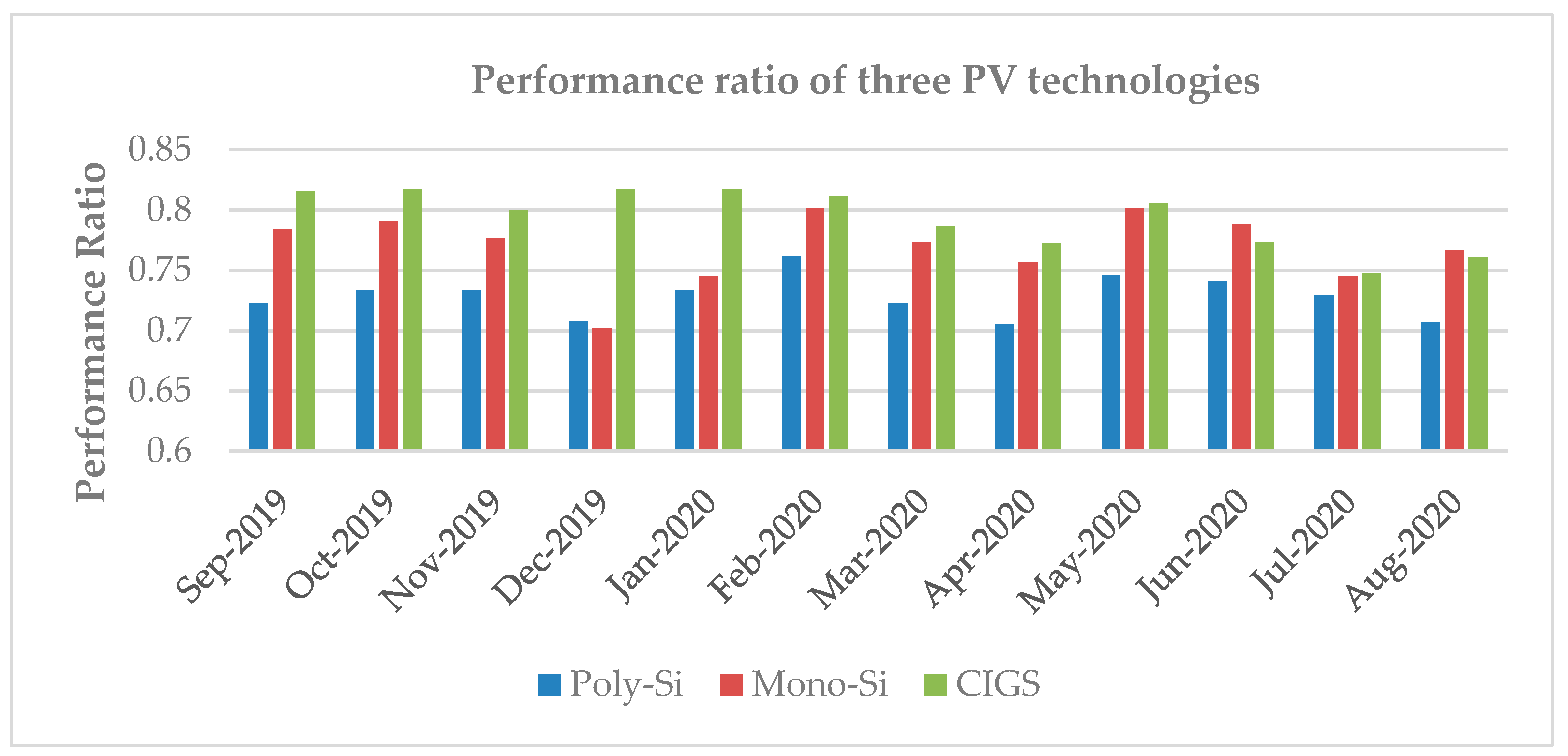

5.1. Final Yield and Performance Ratio

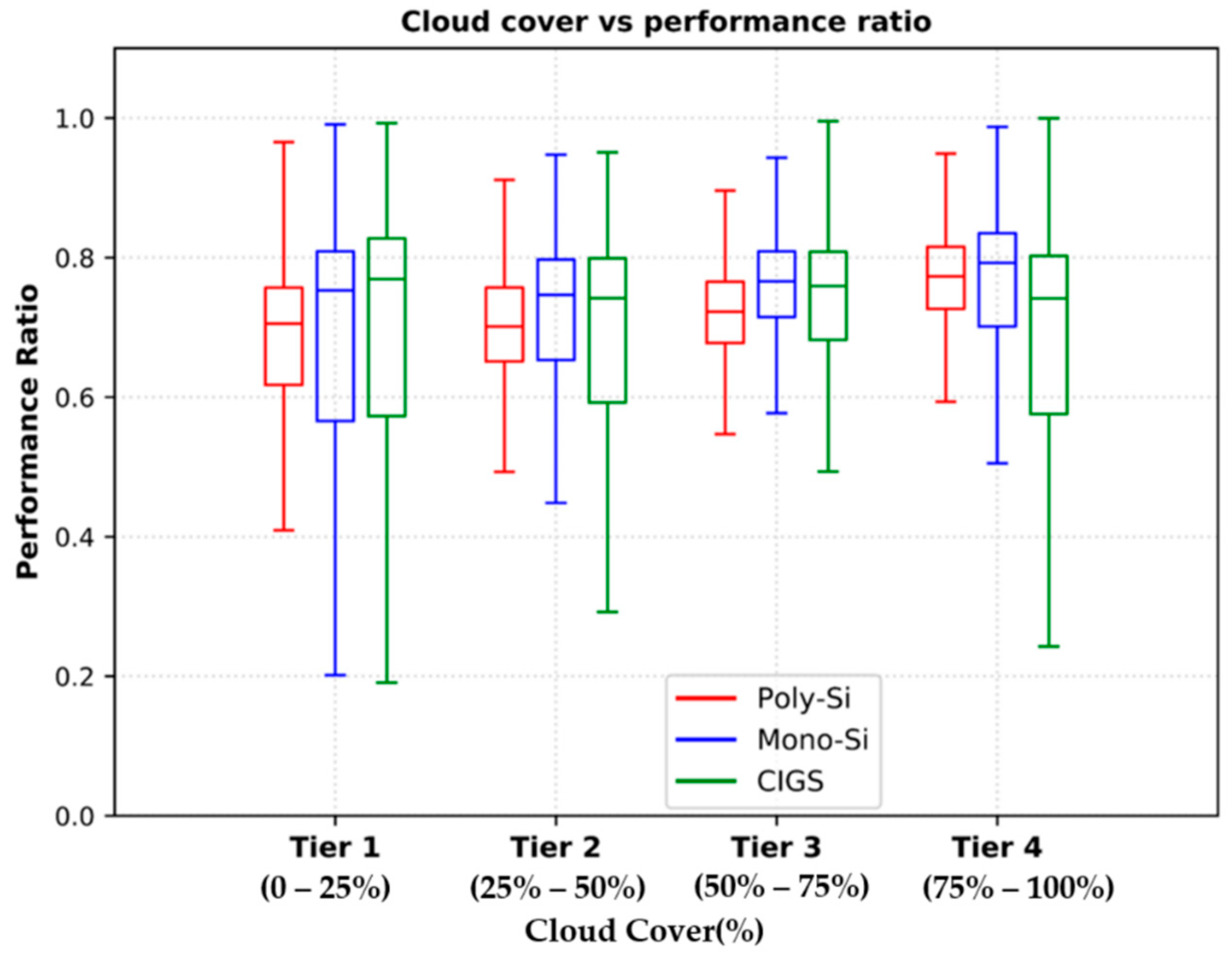

5.2. Comparison of Cloud Cover to Performance Ratio

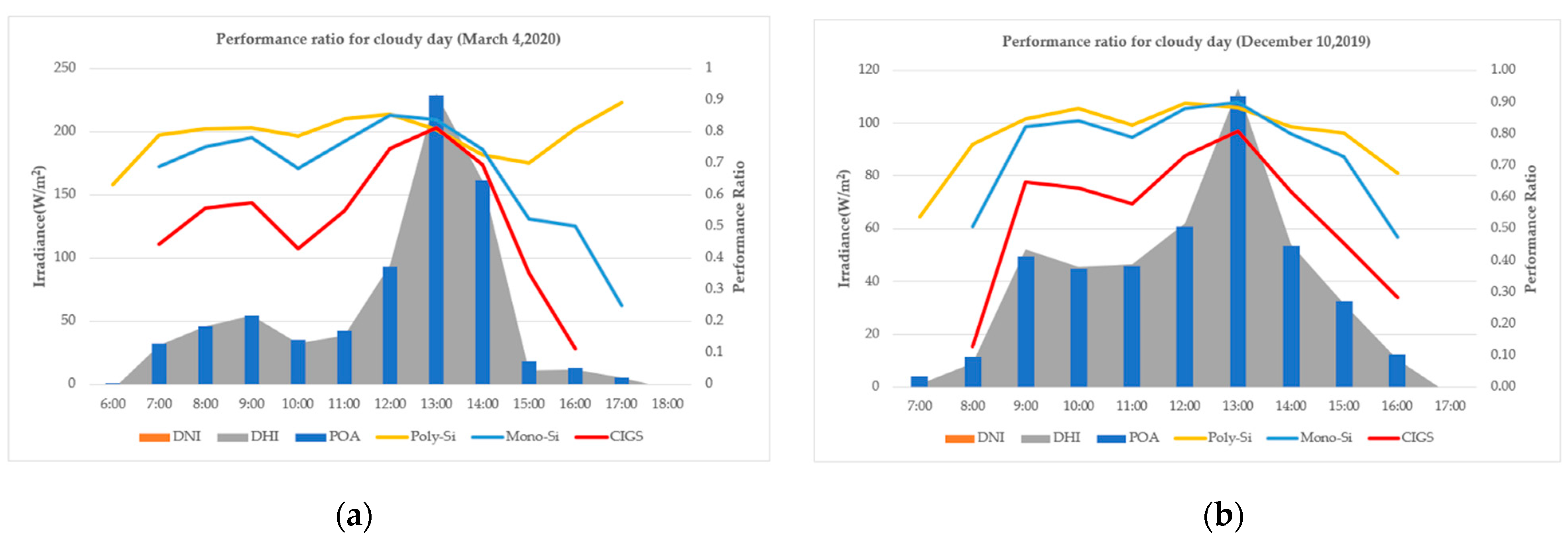

5.2.1. Performance Ratio for Clear Day and Cloudy Day

5.2.2. Distribution of Clear and Cloudy Sky Hours for a Year

5.2.3. Performance Ratio for December 2019 and January 2020

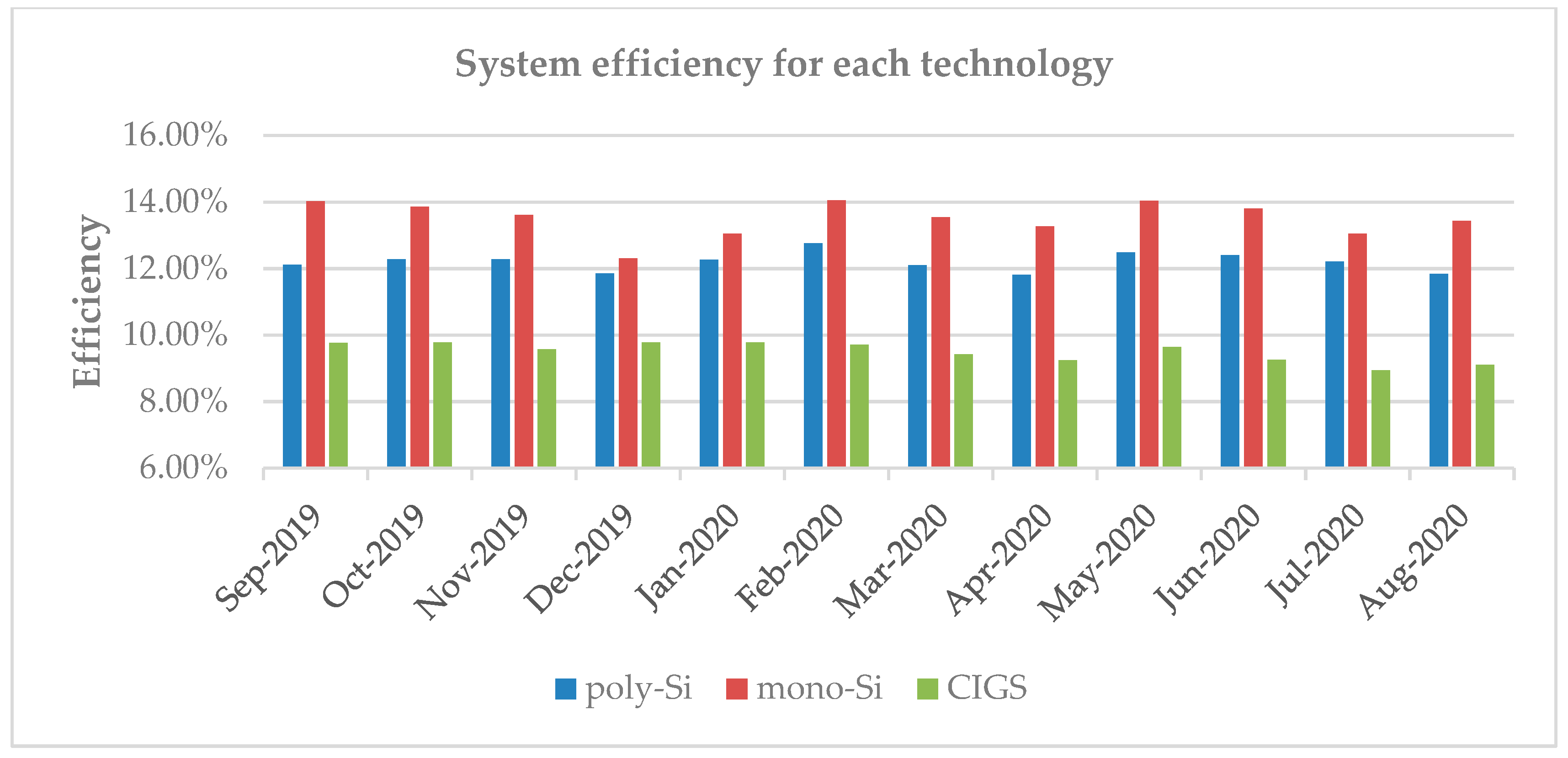

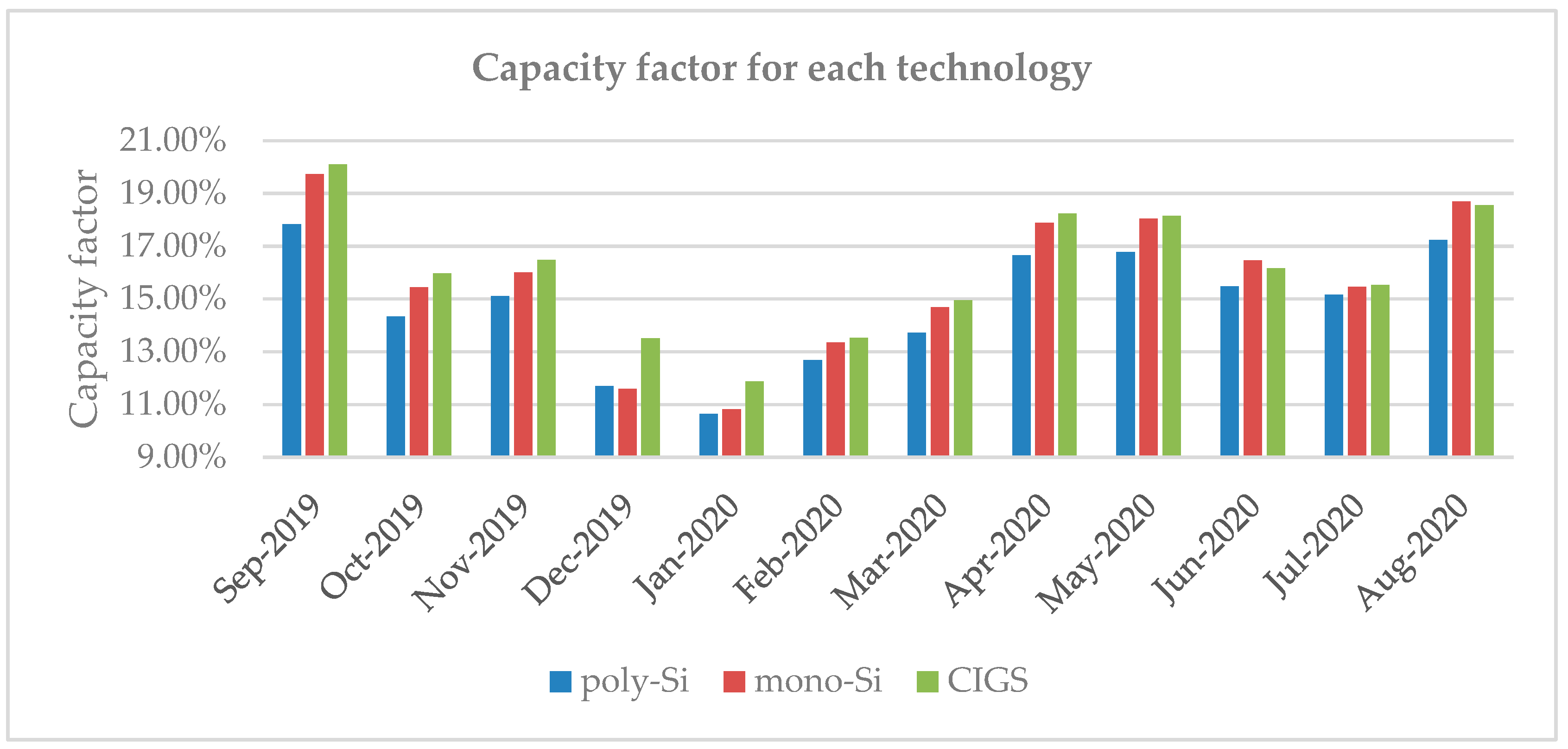

5.3. System Efficiency and Capacity Factor

5.4. Economic Analysis

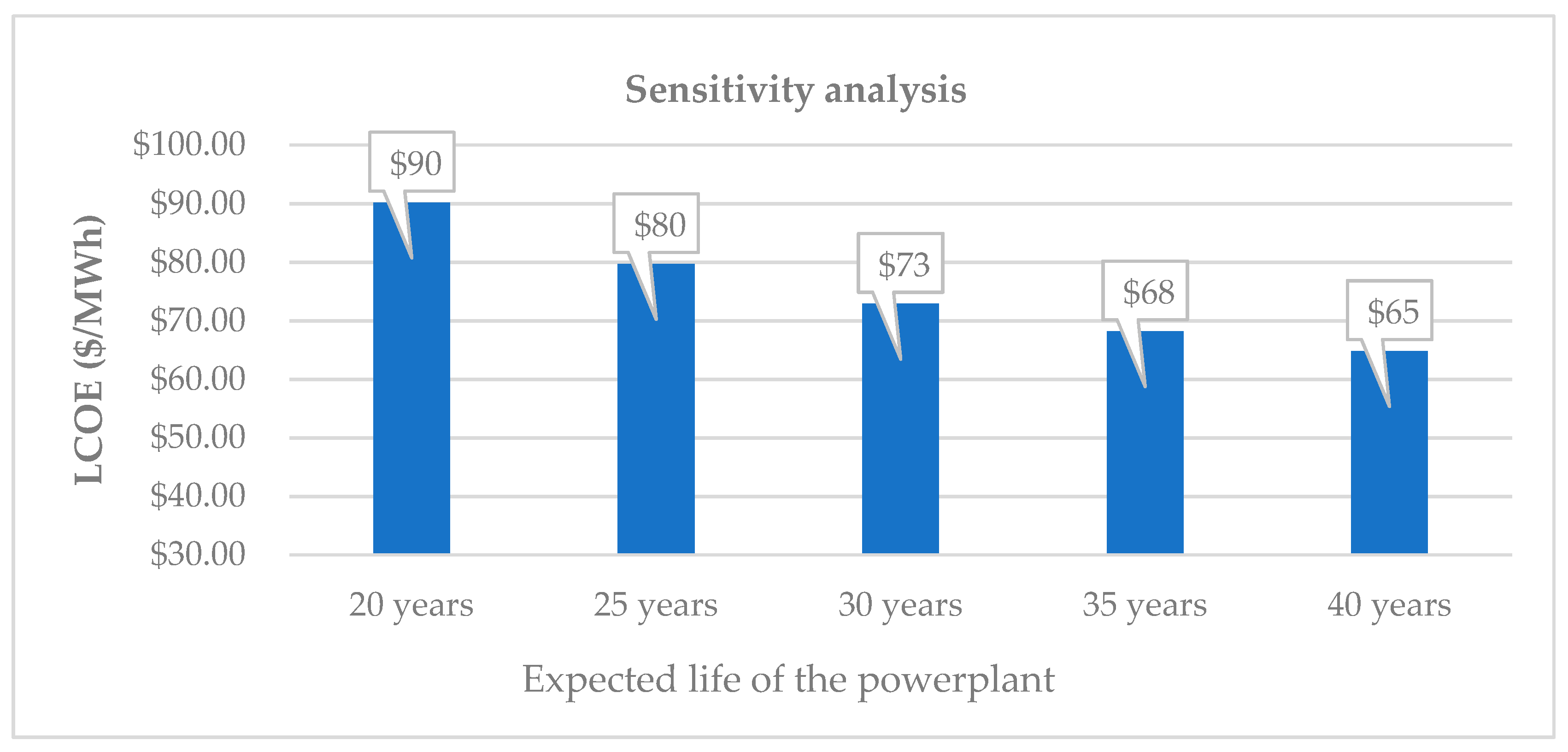

5.5. Sensitivity Analysis

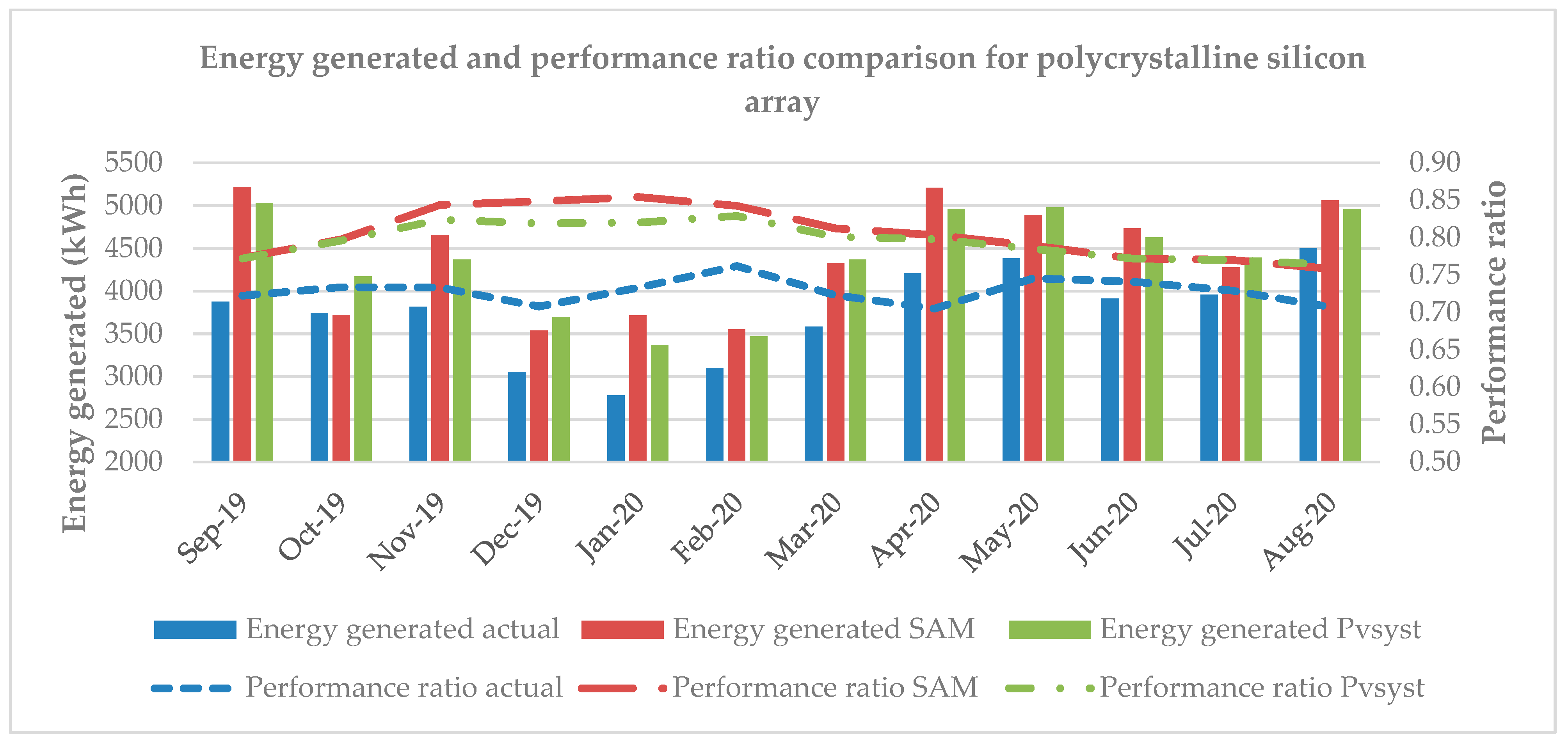

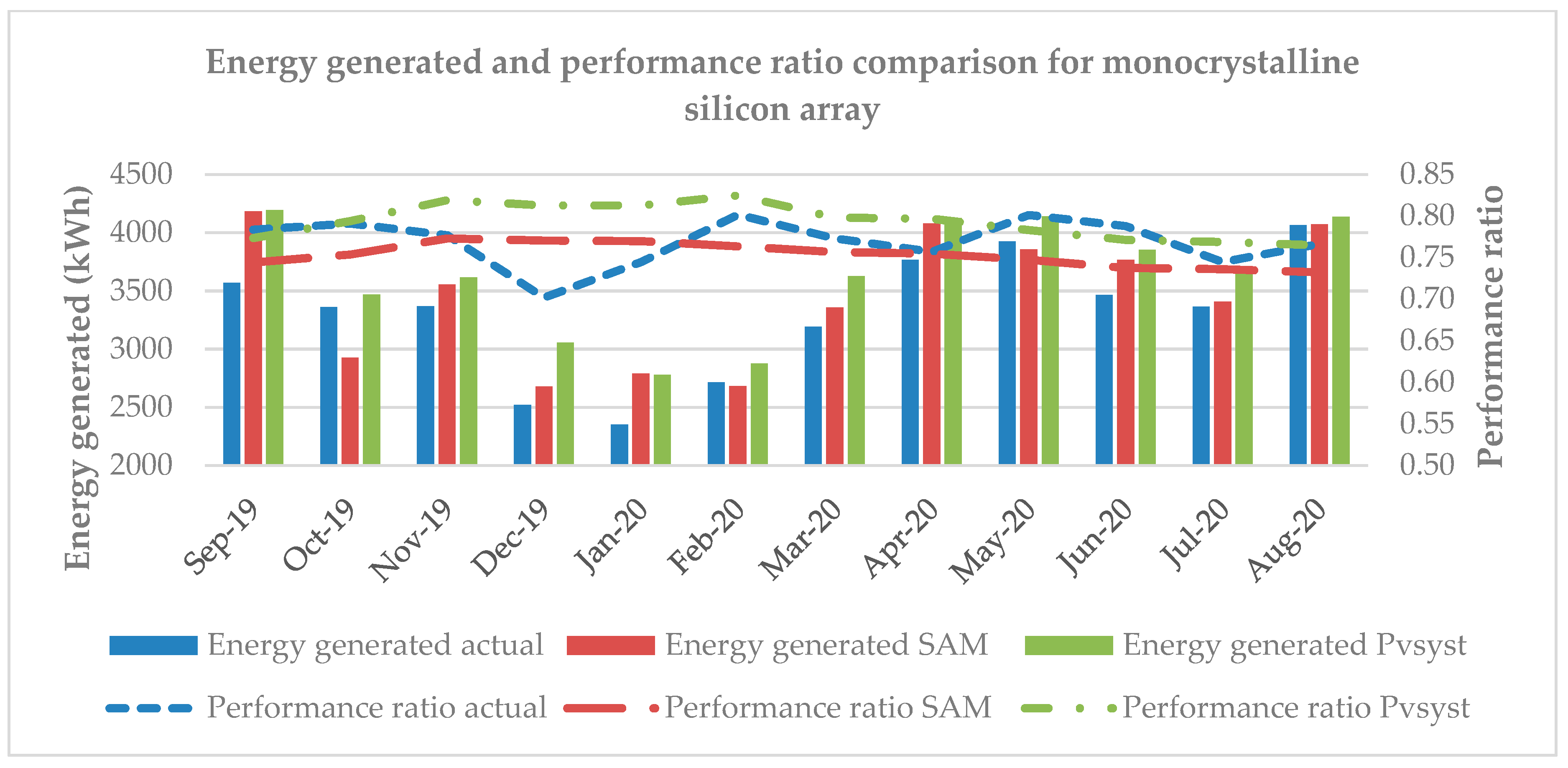

5.6. Comparison of Actual Data to Simulation Results

5.7. Comparison with Other Studies

6. Conclusions

- The plant has produced 3.1 GWh of energy as of August 2020, which is equivalent to saving 1.4 million gallons of water; it has also generated a CO2 offset equivalent of planting 54,764 trees.

- The CIGS has a PR of 0.79 in this period, which is better than the other two technologies.

- It was also found that the CIGS has better PR than the crystalline silicon technology on clear days.

- In terms of system efficiency, the mono-Si array has better efficiency (13.50%) than the poly-Si array (12.20%), and the CIGS array (9.50%).

- Poly-Si has the lowest LCOE of 79$/MWh compared to other technologies.

- Simulation results for the mono-Si and CIGS are much closer to actual values, whereas actual values are lower than the simulation for poly-Si.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| A-Si | Amorphous silicon |

| AC | Alternating current |

| BIPV | Building integrated photovoltaics |

| Cf or CUF | Capacity utilization factor |

| CdTe | Cadmium telluride |

| CIGS | Copper indium gallium selenide |

| DHI | Diffuse horizontal irradiance |

| EAc | AC energy |

| Go | Global irradiance at standard test condition |

| HPOA | Total plane of array insolation (kWh/m2) |

| HIT | Heterojunction with intrinsic layer |

| Mono-Si | Monocrystalline silicon |

| POA | Plane of array irradiance |

| Poly-Si | Polycrystalline silicon |

| PPV,Rated | Rated power of the module |

| PV | Photovoltaic |

| PR | Performance ratio |

| SAM | System Advisor Model |

| STC | Standard test conditions |

| TMY | Typical meteorological year |

| YF | Final yield |

| YR | Reference yield |

| ηPV | System efficiency |

References

- Solar Market Insight Report 2018 Year in Review|SEIA. Available online: https://www.seia.org/research-resources/solar-market-insight-report-2018-year-review (accessed on 23 March 2021).

- Solar Market Insight Report 2019 Year in Review|SEIA. Available online: https://www.seia.org/research-resources/solar-market-insight-report-2019-year-review (accessed on 23 March 2021).

- Louisiana Solar|SEIA. Available online: https://www.seia.org/state-solar-policy/louisiana-solar (accessed on 23 March 2021).

- Memiche, M.; Bouzian, C.; Benzahia, A.; Moussi, A. Effects of dust, soiling, aging, and weather conditions on photovoltaic system performances in a Saharan environment—Case study in Algeria. Glob. Energy Interconnect. 2020, 3, 60–67. [Google Scholar] [CrossRef]

- Kurnik, J.; Jankovec, M.; Brecl, K.; Topic, M. Outdoor testing of PV module temperature and performance under different mounting and operational conditions. Sol. Energy Mater. Sol. Cells 2011, 95, 373–376. [Google Scholar] [CrossRef]

- Marion, B.; Adelstein, J.; Boyle, K.; Hayden, H.; Hammond, B.; Fletcher, T.; Canada, B.; Narang, D.; Kimber, A.; Mitchell, L.; et al. Performance parameters for grid-connected PV systems. In Proceedings of the IEEE Conference Record of the Thirty-First IEEE Photovoltaic Specialists Conference, Lake Buena Vista, FL, USA, 3–7 January 2005; pp. 1601–1606. [Google Scholar] [CrossRef] [Green Version]

- Magare, D.; Sastry, O.S.; Gupta, R.; Betts, T.R.; Gottschalg, R.; Kumar, A.; Bora, B.; Singh, Y.K. Effect of seasonal spectral variations on performance of three different photovoltaic technologies in India. Int. J. Energy Environ. Eng. 2016, 7, 93–103. [Google Scholar] [CrossRef] [Green Version]

- Jamil, I.; Zhao, J.; Zhang, L.; Jamil, R.; Rafique, S.F. Evaluation of Energy Production and Energy Yield Assessment Based on Feasibility, Design, and Execution of 3 × 50 MW Grid-Connected Solar PV Pilot Project in Nooriabad. Int. J. Photoenerg. 2017, 2017, 6429581. [Google Scholar] [CrossRef] [Green Version]

- Durisch, W.; Bitnar, B.; Mayor, J.C.; Kiess, H.; Lam, K.H.; Close, J. Efficiency model for photovoltaic modules and demonstration of its application to energy yield estimation. Sol. Energy Mater. Sol. Cells 2007, 91, 79–84. [Google Scholar] [CrossRef]

- Padmavathi, K.; Daniel, S.A. Performance analysis of a 3MWp grid connected solar photovoltaic power plant in India. Energy Sustain. Dev. 2013, 17, 615–625. [Google Scholar] [CrossRef]

- Verma, S.; Yadav, D.K.; Sengar, N. Performance Evaluation of Solar Photovoltaic Power Plants of Semi-Arid Region and Suggestions for Efficiency Improvement. Int. J. Renew. Energy Res. 2021, 11, 762–775. [Google Scholar]

- Sharma, V.; Chandel, S. Performance analysis of a 190 kWp grid interactive solar photovoltaic power plant in India. Energy 2013, 55, 476–485. [Google Scholar] [CrossRef]

- Malvoni, M.; Kumar, N.M.; Chopra, S.S.; Hatziargyriou, N. Performance and degradation assessment of large-scale grid-connected solar photovoltaic power plant in tropical semi-arid environment of India. Sol. Energy 2020, 203, 101–113. [Google Scholar] [CrossRef]

- Kumar, B.S.; Sudhakar, K. Performance evaluation of 10 MW grid connected solar photovoltaic power plant in India. Energy Rep. 2015, 1, 184–192. [Google Scholar] [CrossRef] [Green Version]

- Sundaram, S.; Babu, J.S.C. Performance evaluation and validation of 5MWp grid connected solar photovoltaic plant in South India. Energy Convers. Manag. 2015, 100, 429–439. [Google Scholar] [CrossRef]

- Bansal, N.; Pany, P.; Singh, G. Visual degradation and performance evaluation of utility scale solar photovoltaic power plant in hot and dry climate in western India. Case Stud. Therm. Eng. 2021, 26, 101010. [Google Scholar] [CrossRef]

- Al-Rasheedi, M.; Gueymard, C.A.; Al-Khayat, M.; Ismail, A.; Lee, J.A.; Al-Duaj, H. Performance evaluation of a utility-scale dual-technology photovoltaic power plant at the Shagaya Renewable Energy Park in Kuwait. Renew. Sustain. Energy Rev. 2020, 133, 110139. [Google Scholar] [CrossRef]

- Martín-Martínez, S.; Cañas-Carretón, M.; Honrubia-Escribano, A.; Gómez-Lázaro, E. Performance evaluation of large solar photovoltaic power plants in Spain. Energy Convers. Manag. 2019, 183, 515–528. [Google Scholar] [CrossRef]

- Schweiger, M.; Herrmann, W.; Gerber, A.; Rau, U. Understanding the energy yield of photovoltaic modules in different climates by linear performance loss analysis of the module performance ratio. IET Renew. Power Gener. 2017, 11, 558–565. [Google Scholar] [CrossRef]

- Adouane, M.; Al-Qattan, A.; Alabdulrazzaq, B.; Fakhraldeen, A. Comparative performance evaluation of different photovoltaic modules technologies under Kuwait harsh climatic conditions. Energy Rep. 2020, 6, 2689–2696. [Google Scholar] [CrossRef]

- Muehleisen, W.; Loeschnig, J.; Feichtner, M.; Burgers, A.; Bende, E.; Zamini, S.; Yerasimou, Y.; Kosel, J.; Hirschl, C.; Georghiou, G. Energy yield measurement of an elevated PV system on a white flat roof and a performance comparison of monofacial and bifacial modules. Renew. Energy 2021, 170, 613–619. [Google Scholar] [CrossRef]

- Saber, E.; Lee, S.E.; Manthapuri, S.; Yi, W.; Deb, C. PV (photovoltaics) performance evaluation and simulation-based energy yield prediction for tropical buildings. Energy 2014, 71, 588–595. [Google Scholar] [CrossRef]

- Wittkopf, S.K.; Valliappan, S.; Liu, L.; Ang, K.S.; Cheng, S.C.J. Analytical performance monitoring of a 142.5kWp grid-connected rooftop BIPV system in Singapore. Renew. Energy 2012, 47, 9–20. [Google Scholar] [CrossRef]

- Romero-Fiances, I.; Muñoz-Cerón, E.; Espinoza-Paredes, R.; Nofuentes, G.; De la Casa, J. Analysis of the Performance of Various PV Module Technologies in Peru. Energies 2019, 12, 186. [Google Scholar] [CrossRef] [Green Version]

- Chimtavee, A.; Ketjoy, N. PV Generator Performance Evaluation and Load Analysis of the PV Microgrid System in Thailand. Procedia Eng. 2012, 32, 384–391. [Google Scholar] [CrossRef] [Green Version]

- Nascimento, L.R.D.; Braga, M.; Campos, R.A.; Naspolini, H.F.; Rüther, R. Performance assessment of solar photovoltaic technologies under different climatic conditions in Brazil. Renew. Energy 2020, 146, 1070–1082. [Google Scholar] [CrossRef]

- De Lima, L.C.; Ferreira, L.D.A.; de Lima Morais, F.H.B. Performance analysis of a grid connected photovoltaic system in northeastern Brazil. Energy Sustain. Dev. 2017, 37, 79–85. [Google Scholar] [CrossRef]

- Ameur, A.; Sekkat, A.; Loudiyi, K.; Aggour, M. Performance evaluation of different photovoltaic technologies in the region of Ifrane, Morocco. Energy Sustain. Dev. 2019, 52, 96–103. [Google Scholar] [CrossRef]

- Banda, M.H.; Nyeinga, K.; Okello, D. Performance evaluation of 830 kWp grid-connected photovoltaic power plant at Kamuzu International Airport-Malawi. Energy Sustain. Dev. 2019, 51, 50–55. [Google Scholar] [CrossRef]

- Malvoni, M.; Leggieri, A.; Maggiotto, G.; Congedo, P.M.; de Giorgi, M.G. Long term performance, losses and efficiency analysis of a 960 kW P photovoltaic system in the Mediterranean climate. Energy Convers. Manag. 2017, 145, 169–181. [Google Scholar] [CrossRef]

- Abdullah, G.; Nishimura, H. Techno-Economic Performance Analysis of a 40.1 kWp Grid-Connected Photovoltaic (GCPV) System after Eight Years of Energy Generation: A Case Study for Tochigi, Japan. Sustainability 2021, 13, 7680. [Google Scholar] [CrossRef]

- Dahbi, H.; Aoun, N.; Sellam, M. Performance analysis and investigation of a 6 MW grid-connected ground-based PV plant installed in hot desert climate conditions. Int. J. Energy Environ. Eng. 2021, 12, 577–587. [Google Scholar] [CrossRef]

- Tozzi, P.; Jo, J.H. A comparative analysis of renewable energy simulation tools: Performance simulation model vs. system optimization. Renew. Sustain. Energy Rev. 2017, 80, 390–398. [Google Scholar] [CrossRef]

- De Souza Silva, J.L.; Costa, T.S.; de Melo, K.B.; Sako, E.Y.; Moreira, H.S.; Villalva, M.G. A Comparative Performance of PV Power Simulation Software with an Installed PV Plant. In Proceedings of the 2020 IEEE International Conference on Industrial Technology (ICIT), Buenos Aires, Argentina, 26–28 February 2020; pp. 531–535. [Google Scholar] [CrossRef]

- Ayompe, L.M.; Duffy, A.; McCormack, S.J.; Conlon, M. Measured performance of a 1.72kW rooftop grid connected photovoltaic system in Ireland. Energy Convers. Manag. 2011, 52, 816–825. [Google Scholar] [CrossRef] [Green Version]

- Mondol, J.D.; Yohanis, Y.G.; Norton, B. The effect of low insolation conditions and inverter oversizing on the long-term performance of a grid-connected photovoltaic system. Prog. Photovolt. Res. Appl. 2007, 15, 353–368. [Google Scholar] [CrossRef]

- Mensah, L.D.; Yamoah, J.O.; Adaramola, M.S. Performance evaluation of a utility-scale grid-tied solar photovoltaic (PV) installation in Ghana. Energy Sustain. Dev. 2019, 48, 82–87. [Google Scholar] [CrossRef]

- Dahmoun, M.E.-H.; Bekkouche, B.; Sudhakar, K.; Guezgouz, M.; Chenafi, A.; Chaouch, A. Performance evaluation and analysis of grid-tied large scale PV plant in Algeria. Energy Sustain. Dev. 2021, 61, 181–195. [Google Scholar] [CrossRef]

- Texas Real Estate Research Center. Rural Land Prices for Louisiana. Available online: https://www.recenter.tamu.edu/data/rural-land/#!/state/Louisiana (accessed on 2 May 2022).

- Lavappa, P.D.; Kneifel, J.D. Energy Price Indices and Discount Factors for Life-Cycle Cost Analysis—2018 Annual Supplement to NIST Handbook 135; National Institute of Standards and Technology: Gaithersburg, MD, USA, 2018; NIST IR 85-3273-33. [Google Scholar] [CrossRef]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic Degradation Rates-an Analytical Review: Photovoltaic degradation rates. Prog. Photovolt. Res. Appl. 2013, 21, 12–29. [Google Scholar] [CrossRef] [Green Version]

- King, B.H.; Stein, J.S.; Riley, D.; Jones, C.B.; Robinson, C.D. Degradation Assessment of Fielded CIGS Photovoltaic Arrays. In Proceedings of the 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017; pp. 3155–3160. [Google Scholar] [CrossRef]

- Lazard. Levelized Cost of Energy and Levelized Cost of Storage. 2018. Available online: https://www.lazard.com/perspective/levelized-cost-of-energy-and-levelized-cost-of-storage-2018/ (accessed on 23 March 2021).

- Sidi, C.E.B.E.; Ndiaye, M.L.; El Bah, M.; Mbodji, A.; Ndiaye, A.; Ndiaye, P.A. Performance analysis of the first large-scale (15 MWp) grid-connected photovoltaic plant in Mauritania. Energy Convers. Manag. 2016, 119, 411–421. [Google Scholar] [CrossRef]

- Kymakis, E.; Kalykakis, S.; Papazoglou, T.M. Performance analysis of a grid connected photovoltaic park on the island of Crete. Energy Convers. Manag. 2009, 50, 433–438. [Google Scholar] [CrossRef]

| Module Manufacturer | Peimar | Seraphim Solar | Stion |

|---|---|---|---|

| Model | SG325P | SRP-340-6MA | STO-130 |

| Framed/frameless | Framed | Framed | Frameless |

| Technology | Poly-Si | Mono-Si | CIGS * (thin film) |

| Max power output (Pmax) | 325 | 340 | 130 |

| Max voltage (Vmp) | 36.3 | 37.7 | 57 |

| Max current (Imp) | 9.03 | 9.02 | 2.28 |

| Open circuit voltage (Voc) | 44.6 | 46.6 | 76.7 |

| Short circuit current (Isc) | 9.74 | 9.32 | 2.6 |

| Rated efficiency (%) | 16.74 | 17.52 | 12 |

| Temperature coefficient for power (%/°C) | −0.43% | −0.40% | −0.26% |

| Temperature coefficient for voltage (%/°C) | −0.32% | −0.32% | −0.24% |

| Temperature coefficient for current (%/°C) | 0.047% | 0.05% | 0.004% |

| Poly-Si | Mono-Si | CIGS | |

|---|---|---|---|

| Tier_1 (0–25%) | 0.71 | 0.70 | 0.83 |

| Tier_2 (25–50%) | 0.73 | 0.76 | 0.82 |

| Tier_3 (50–75%) | 0.74 | 0.79 | 0.81 |

| Tier_4 (75–100%) | 0.76 | 0.79 | 0.79 |

| Average | 0.72 | 0.73 | 0.82 |

| Poly-Si | Mono-Si | CIGS | POA Insolation | |

|---|---|---|---|---|

| Tier_1 (0–25%) | 103.01 | 102.55 | 120.93 | 145.86 (64%) |

| Tier_2 (25–50%) | 5.86 | 6.09 | 6.59 | 8.05 (3%) |

| Tier_3 (50–75%) | 16.48 | 17.60 | 18.05 | 22.39 (10%) |

| Tier_4 (75–100%) | 38.90 | 40.44 | 40.60 | 51.32 (23%) |

| Total | 164.25 | 166.68 | 186.17 | 277.62 (100%) |

| Error Values in AC Energy Calculation for Simulation Using SAM | Error Values in AC Energy Calculation for Simulation Using PVsyst | |||||

|---|---|---|---|---|---|---|

| Technology | NMBE (%) | NMAE (%) | R2 | NMBE (%) | NMAE (%) | R2 |

| Poly-Si | 14.76 | 14.84 | 0.70 | 13.85 | 13.85 | 0.87 |

| Mono-Si | 3.46 | 5.65 | 0.78 | 7.91 | 7.91 | 0.90 |

| CIGS | −7.23 | 8.41 | 0.39 | 2.91 | 3.40 | 0.90 |

| Location | Climate Classification | PV Type a | Installed Capacity (kW) | Final Yield (kWh/kW) | System Efficiency (%) | Performance Ratio (%) | Capacity Factor (%) | Reference |

|---|---|---|---|---|---|---|---|---|

| Mauritania | Arid (B) | Micromorph-Si (Array 1) | 954.72 kW | 4.29 | NA b | 67.90% | 17.75% | [44] |

| Kuwait | Arid subtropical (B) | Poly-Si | 5.6 MW | 5.18 | 13.02% | 80.20% | 20.66% | [17] |

| Kuwait | Arid subtropical (B) | Thin film | 5.5 MW | 5.16 | 10.42% | 80% | 20.61% | [17] |

| India | Desert, semi arid (B) | Mono-Si | 3 MW | 3.73 | NA | 70% | NA | [10] |

| Algeria | Hot desert (bwh) | Poly-Si | 6 MW | 5.15 | 11.39% | 73.70% | 21.44% | [32] |

| Greece | Temperate | Poly-Si | 171.36 kW | 3.66 | NA | 67.40% | 15.30% | [45] |

| Italy (42 months) | Temperate | Mono-Si | 960 kW | 3.8 | 14.90% | 84.40% | 15.66% | [30] |

| Malawi (4 years) | Temperate | HIT | 830 kW | 4.25 | 14.60% | 79.50% | 17.70% | [29] |

| India | Temperate (humid subtropical) | Poly-Si | 10 MW | NA | NA | 86.10% | 17.70% | [14] |

| India | Temperate (humid, subtropical) | Poly-Si | 190 kW | 2.23 | 8.30% | 74% | 9.27% | [12] |

| Aratiba, RS, Brazil | Temperate (humid, subtropical) | Poly-Si, mono-Si, CIGS, | 54 kW | NA | NA | 79%, 79%, 76% | NA | [26] |

| Capivari de Baixo, SC, Brazil | Temperate (humid, subtropical) | Poly-Si, mono-Si, CIGS | 54 kW | NA | NA | 75%, 79%, 76% | NA | [26] |

| Louisiana, USA c | Temperate (humid, subtropical) | CIGS d | 20.28 kW | 3.81 | 9.50% | 79% | 16.08% | Current research |

| Louisiana, USA c | Temperate (humid, subtropical) | mono-Si | 147.56 kW | 3.72 | 13.50% | 77% | 15.68% | Current research |

| Louisiana, USA c | Temperate (humid, subtropical) | Poly-Si | 1.15 MW | 3.5 | 12.20% | 73% | 14.78% | Current research |

| Ghana (3 years) | Tropical | Poly-Si | 2.5 MW | NA | NA | 70.60% | 16.20% | [37] |

| India | tropical | A-Si | 5 MW | 4.81 | 5.08% | 89.20% | NA | [15] |

| India (four years) | Tropical semiarid | Mono-Si | 1 MW | 4.64 | 11.02% | 74.73% | 19.33% | [13] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Veerendra Kumar, D.J.; Deville, L.; Ritter, K.A., III; Raush, J.R.; Ferdowsi, F.; Gottumukkala, R.; Chambers, T.L. Performance Evaluation of 1.1 MW Grid-Connected Solar Photovoltaic Power Plant in Louisiana. Energies 2022, 15, 3420. https://doi.org/10.3390/en15093420

Veerendra Kumar DJ, Deville L, Ritter KA III, Raush JR, Ferdowsi F, Gottumukkala R, Chambers TL. Performance Evaluation of 1.1 MW Grid-Connected Solar Photovoltaic Power Plant in Louisiana. Energies. 2022; 15(9):3420. https://doi.org/10.3390/en15093420

Chicago/Turabian StyleVeerendra Kumar, Deepak Jain, Lelia Deville, Kenneth A. Ritter, III, Johnathan Richard Raush, Farzad Ferdowsi, Raju Gottumukkala, and Terrence Lynn Chambers. 2022. "Performance Evaluation of 1.1 MW Grid-Connected Solar Photovoltaic Power Plant in Louisiana" Energies 15, no. 9: 3420. https://doi.org/10.3390/en15093420

APA StyleVeerendra Kumar, D. J., Deville, L., Ritter, K. A., III, Raush, J. R., Ferdowsi, F., Gottumukkala, R., & Chambers, T. L. (2022). Performance Evaluation of 1.1 MW Grid-Connected Solar Photovoltaic Power Plant in Louisiana. Energies, 15(9), 3420. https://doi.org/10.3390/en15093420