Comparison of the Carbon Payback Period (CPP) of Different Variants of Insulation Materials and Existing External Walls in Selected European Countries

Abstract

:1. Introduction

- −

- life-cycle thinking and circularity, to minimize the footprint of buildings;

- −

- respect for aesthetics and architectural quality;

- −

- renovation must respect design, craftsmanship, heritage and public space conservation principles.

- −

- insulation of external walls—93%;

- −

- installing windows—36.5%;

- −

- modernization of the internal heating system—25.2%;

- −

- modernization of the hot water installation—13.3%;

- −

- modernization/replacement of the ventilation system—5.6%.

2. Materials and Methods

2.1. Goal and Scope

- −

- comparison of the carbon footprint of the most popular thermal insulation materials in Europe;

- −

- comparison of operating energy savings using the analyzed insulation materials for typical building partitions and the resulting savings in carbon dioxide emissions;

- −

- comprehensive comparison and calculation of the CPP for insulation materials used in the modernization of typical building partitions in various locations.

2.2. Functional Unit (FU)

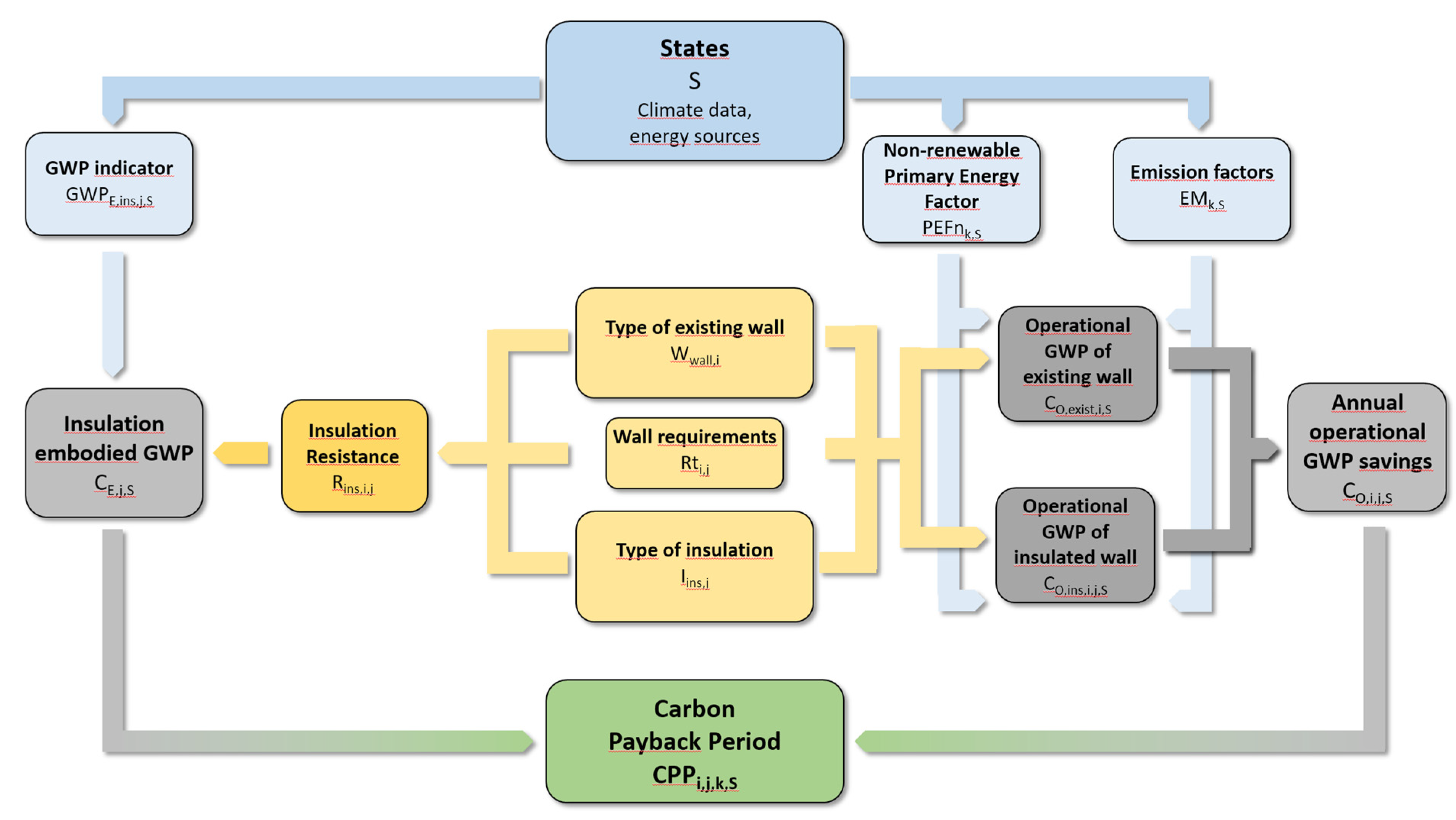

2.3. Carbon Payback Period (CPP)

2.4. System Boundaries

2.4.1. Life-Cycle Inventory Analysis of Product Stage

2.4.2. Life-Cycle Inventory Analysis of Use Stage

2.4.3. Life-Cycle Inventory Analysis for End of Life (EoL) Stage

2.4.4. Life-Cycle Inventory Analysis for Reuse, Recovery, Recycling and Potential stage

2.5. Insulation Materials

- −

- the most popular on the construction market;

- −

- the ones whose information on environmental impact is available in the form of EPD.

- −

- typology of the insulation materials (blown/expanding/loose material, panel itp.);

- −

- manufacturing methods and technologies;

- −

- energy mix of the countries where manufacturing processes happen;

- −

- percentage of recycled material introduced in the production chain;

- −

- origin of the raw material and distance from the manufacturing site.

2.6. Existing External Walls

- −

- (Wwall.1): a massive wall, built of full ceramic bricks joined with lime or cement-lime mortars. It is one of the most popular type of walls in historical buildings. Walls with the thickness of 1.5 bricks were assumed for the analysis (Table 5, number 1). The assumed width of a brick commonly used in Europe equals 13 cm. Stone masonry walls used in earlier historical periods were omitted because their number among existing buildings is small;

- −

- (Wwall.2): perforated brick wall with the thickness of 1.5 bricks (Table 5, number 2). The brick is characterized by holes with rhomboid shapes perpendicular to the base and is widely used to this day;

- −

- (Wwall.3): cavity wall (Table 5, number 3). An air gap is used in the brick wall, which increases the thermal resistance of the wall, but it requires making connections between the layers of the wall;

- −

- (Wwall.4): slag concrete wall (Table 5, number 4). These types of walls, made of blast furnace slag formed during iron ore smelting or coal slag, were particularly popular after World War II;

- −

- (Wwall.5): aerated concrete wall (Table 5, number 5). Popular in Poland after 1954, but known in Europe since the beginning of the 20th century. Aerated concrete blocks are characterized by high thermal resistance and are still very popular today (in Poland, their market share at the end of the 20th century was approx. 40%),

- −

- (Wwall.6): prefabricated curtain wall from large panel systems (LPS) in the WWP system (Table 5, number 6). Precast concrete buildings were very popular from the 1960s to the 1990s, especially in Central and Eastern Europe (170 million apartments were built). Many different systems have been developed, mostly consisting of two layers of reinforced concrete (bearing and texture layer) with insulation between them. Due to the low thermal resistance of these walls and various manufacturing defects, they require comprehensive modernization [73]. The wall in the WWP system consists of a load-bearing layer of reinforced concrete with 15 cm thickness, insulation made of polystyrene or mineral wool of 6 cm thickness and a reinforced concrete textured layer of 6 cm thickness;

- −

- (Wwall.7): half-timbered wall (Table 5, number 7). This is a type of wooden frame wall, the filling of which is a mix of clay with chaff, sawdust or shavings, or a brick (half-timbered work). This type of wall was historically very popular in northern Europe until the 17th century, but also later in Alpine construction, in Sudetenland and in the Baltic Pomerania.

2.7. Calculation Methodology

- −

- Emk,S is the CO2 emission factor for the selected energy source (k) in the selected location (S);

- −

- PEFnk,S is the non-renewable primary energy factor for the selected energy source (k) in the selected location (S) according to Table 1;

- −

- Rwall,i is the thermal resistance of the selected wall (i) without insulation;

- −

- Rwall,i,j is the thermal resistance of the selected wall (i) with insulation;

- −

- HDDS—means the number of the heating degree days with the base temperature equal to 18 °C in capitals of the selected location (S): Europe—2671, Poland—3220, Germany—2962, Czech Republic—3328, Austria—2685, Finland—4318 [74].

2.8. Limitations of the Study

3. Results

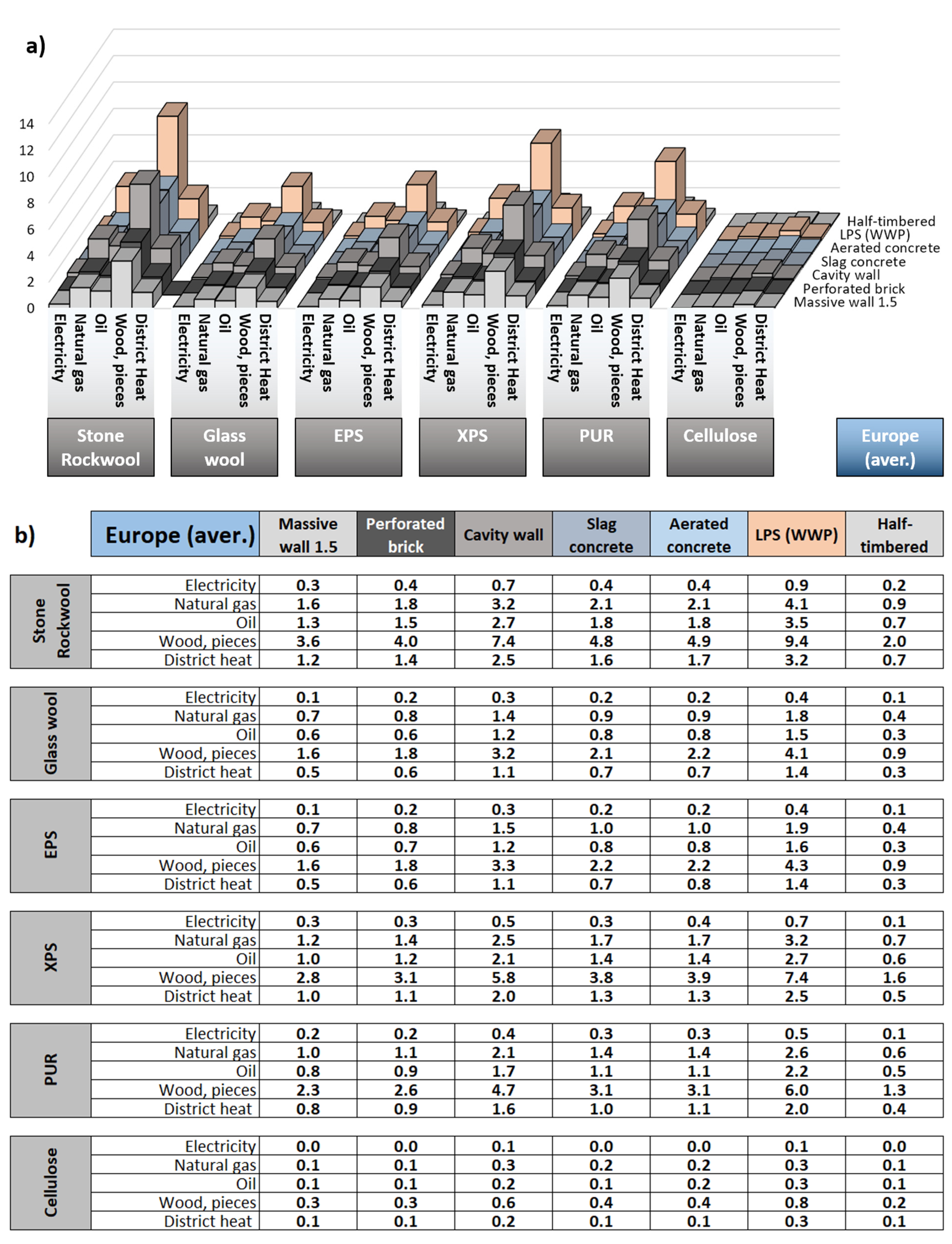

3.1. CPP for Europe (Aver.)

- −

- for existing walls with higher resistance (Rwall) such as LPS (Wwall,6,) or cavity wall (Wwall,3), CPP values are higher;

- −

- in the case of space heating with biomass, the CPP values are much higher than the others;

- −

- the lowest CPP values are achieved for cases of space heating with electricity due to the high value of non-renewable primary energy factors (PEFnk,S) for electricity in all countries and high emission factors of gCO2∙kWh−1 (Emk,S);

- −

- materials with lower density, such as glasswool or EPS, and lower embodied carbon (CE) per 1R∙m−2 are characterized by lower CPP values (from 0.1 to 4.1 years for glass wool, from 0.1 to 4.3 years for EPS);

- −

- XPS and PUR due to the high value of embodied Carbon (CE) are characterized by a higher CPP value (from 0.1 to 7.4 years for XPS and from 0.1 to 6.0 years for PUR);

- −

- CPP values depend to a large extent on the energy source used for space heating: for electricity they are the lowest (from 0.1 to 0.9 years), for biomass they are the highest (from 0.2 to 9.4 years);

- −

- the lowest CPP values are achieved by Cellulose insulation due to the lowest embodied carbon (CE) values.

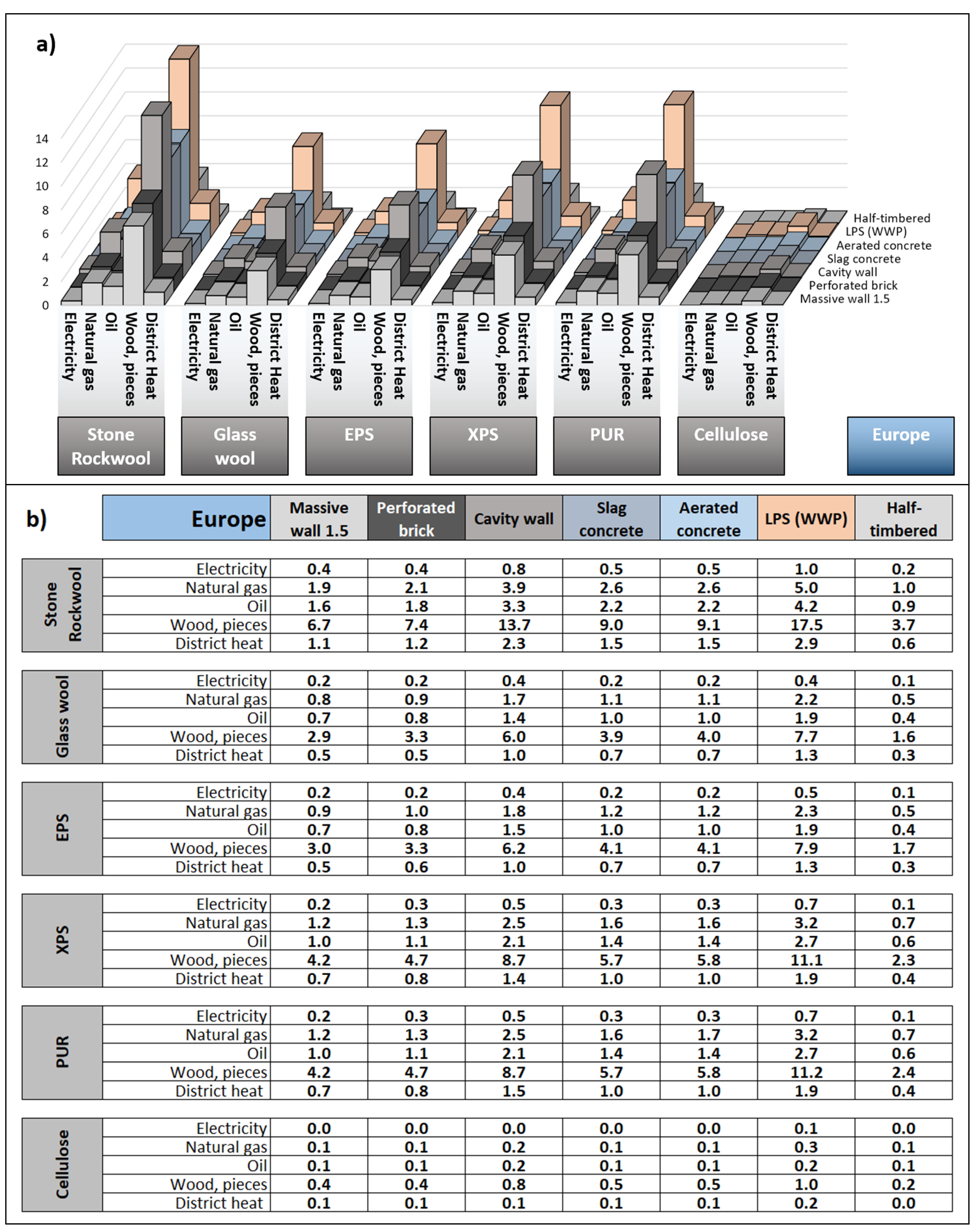

3.2. CPP for Europe

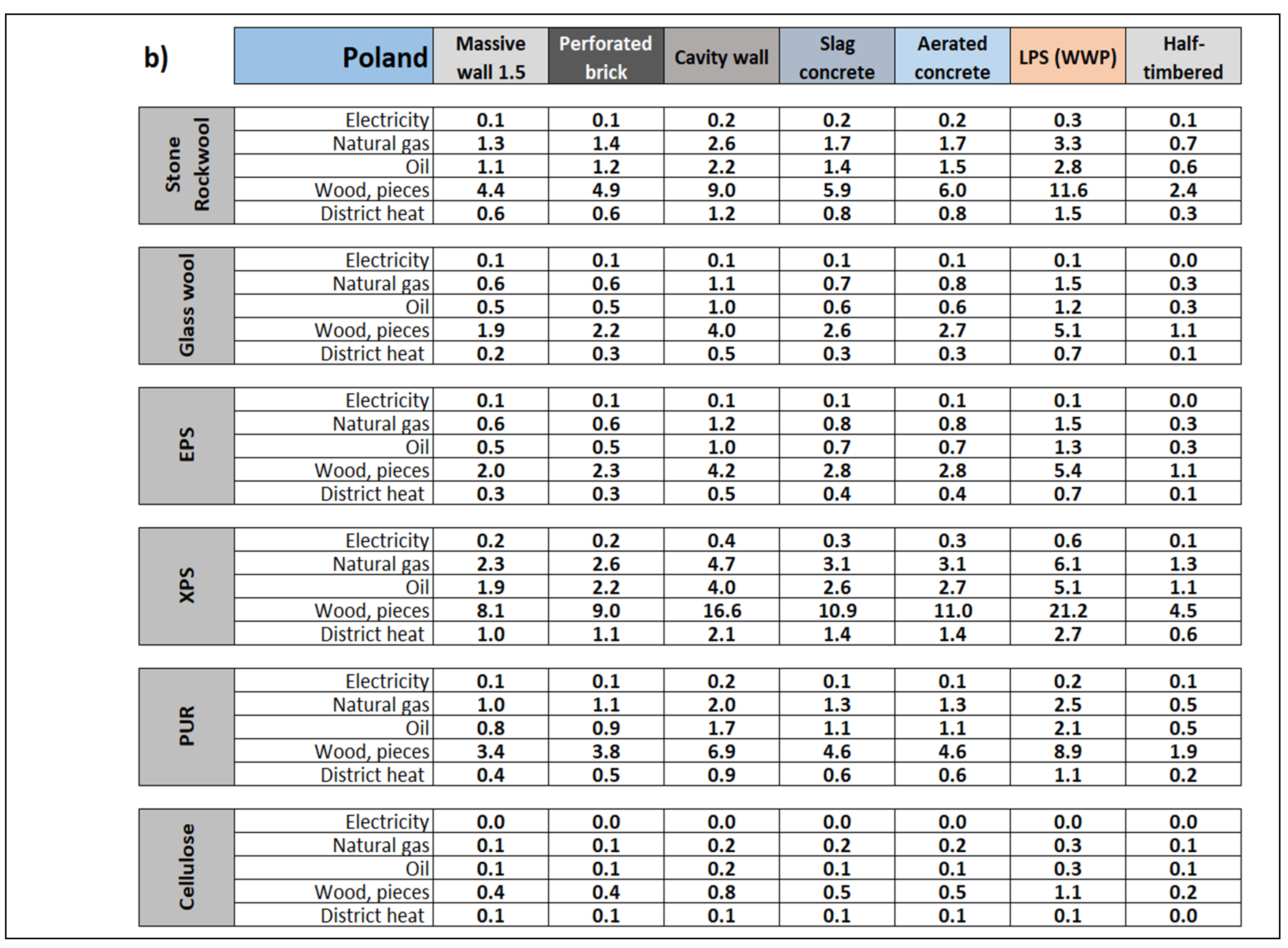

3.3. PCC for Poland

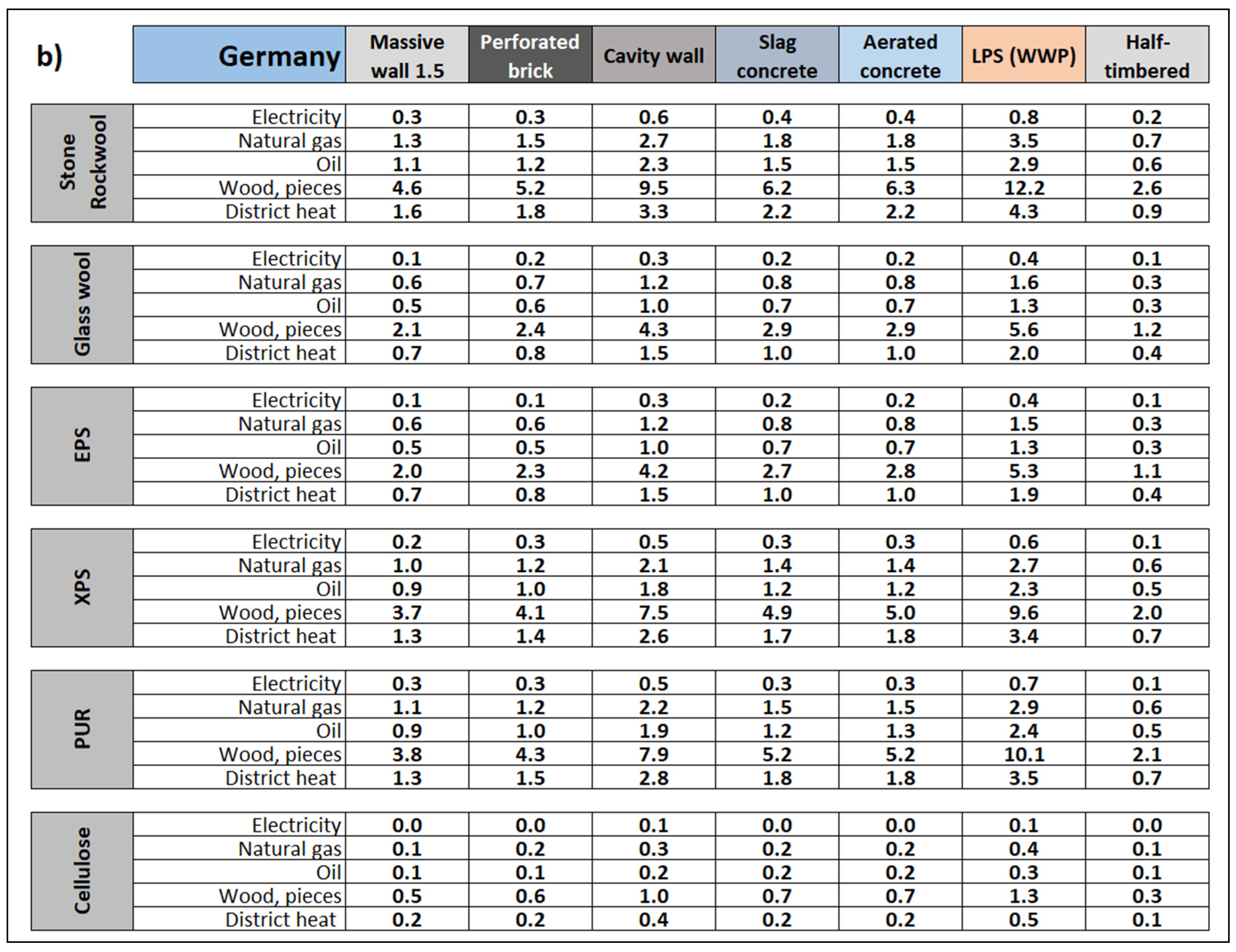

3.4. CPP for Germany

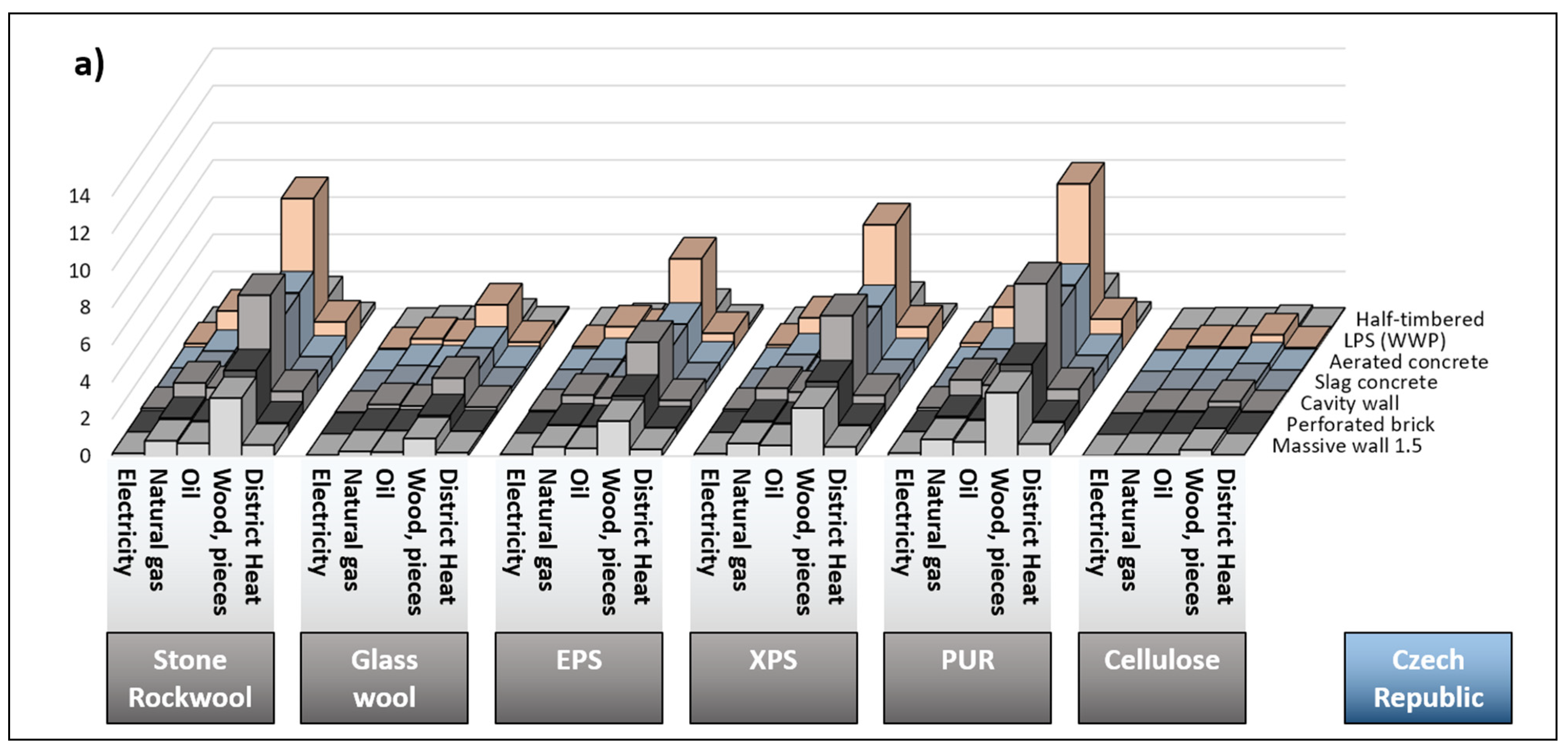

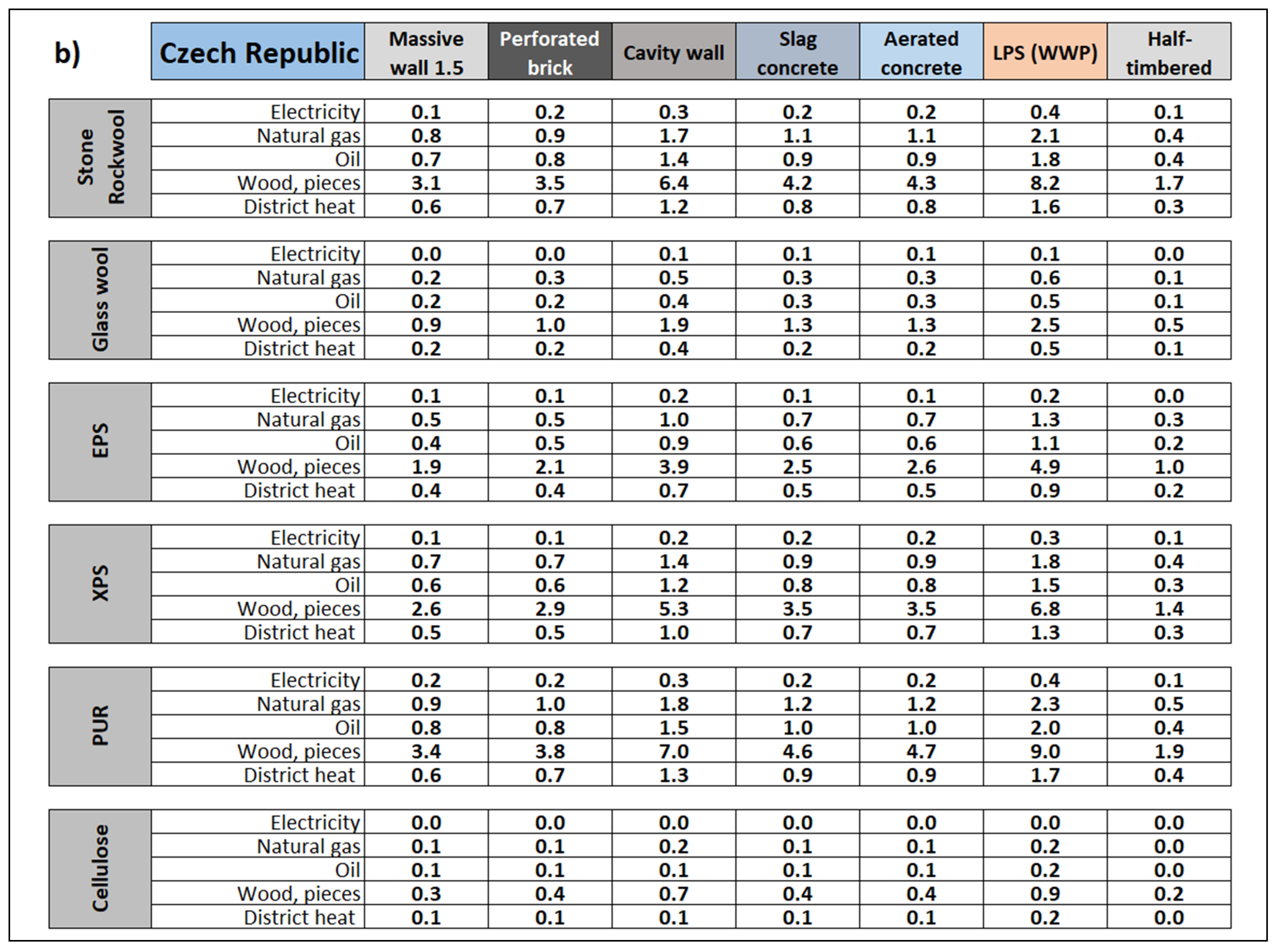

3.5. CPP for Czech Republic

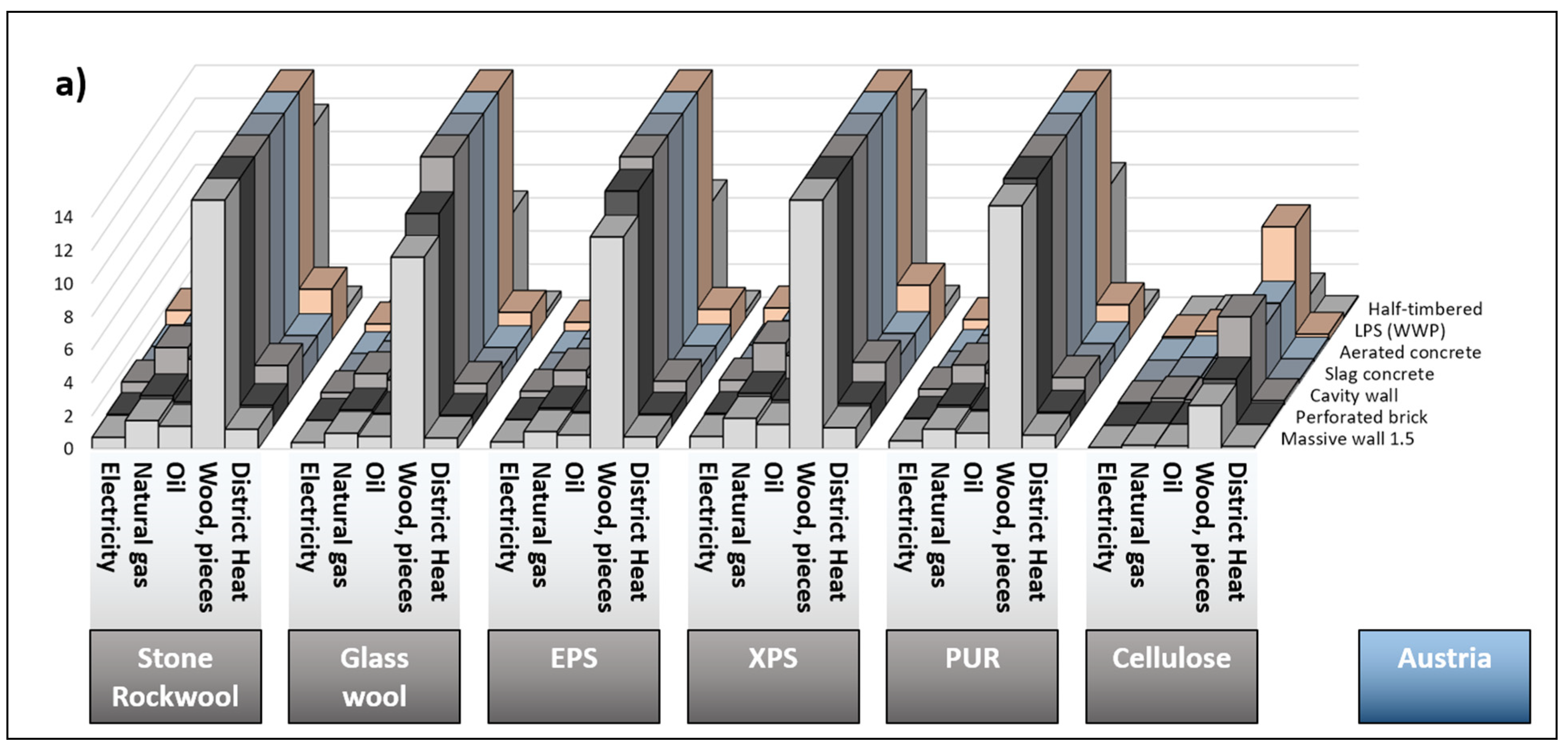

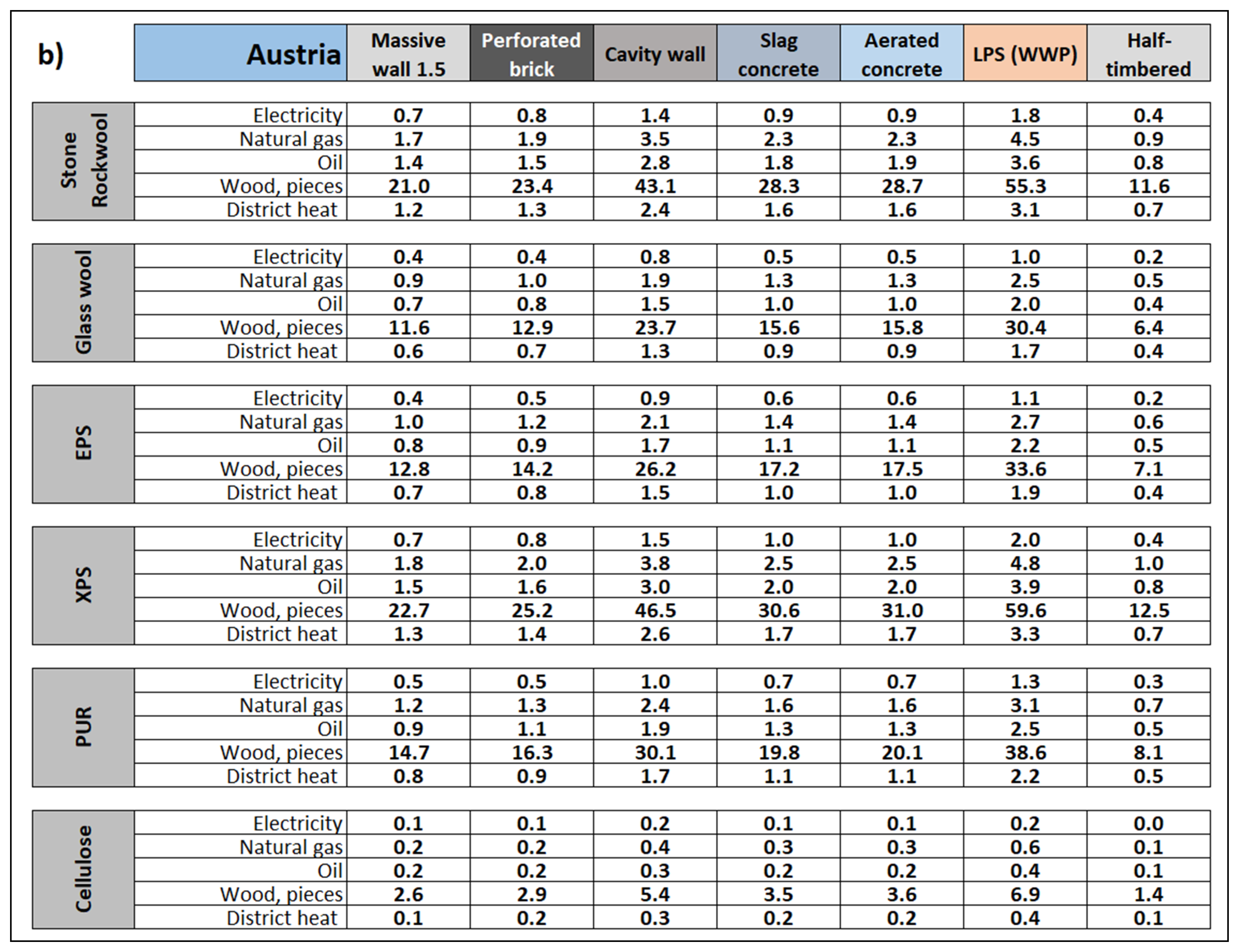

3.6. CPP for Austria

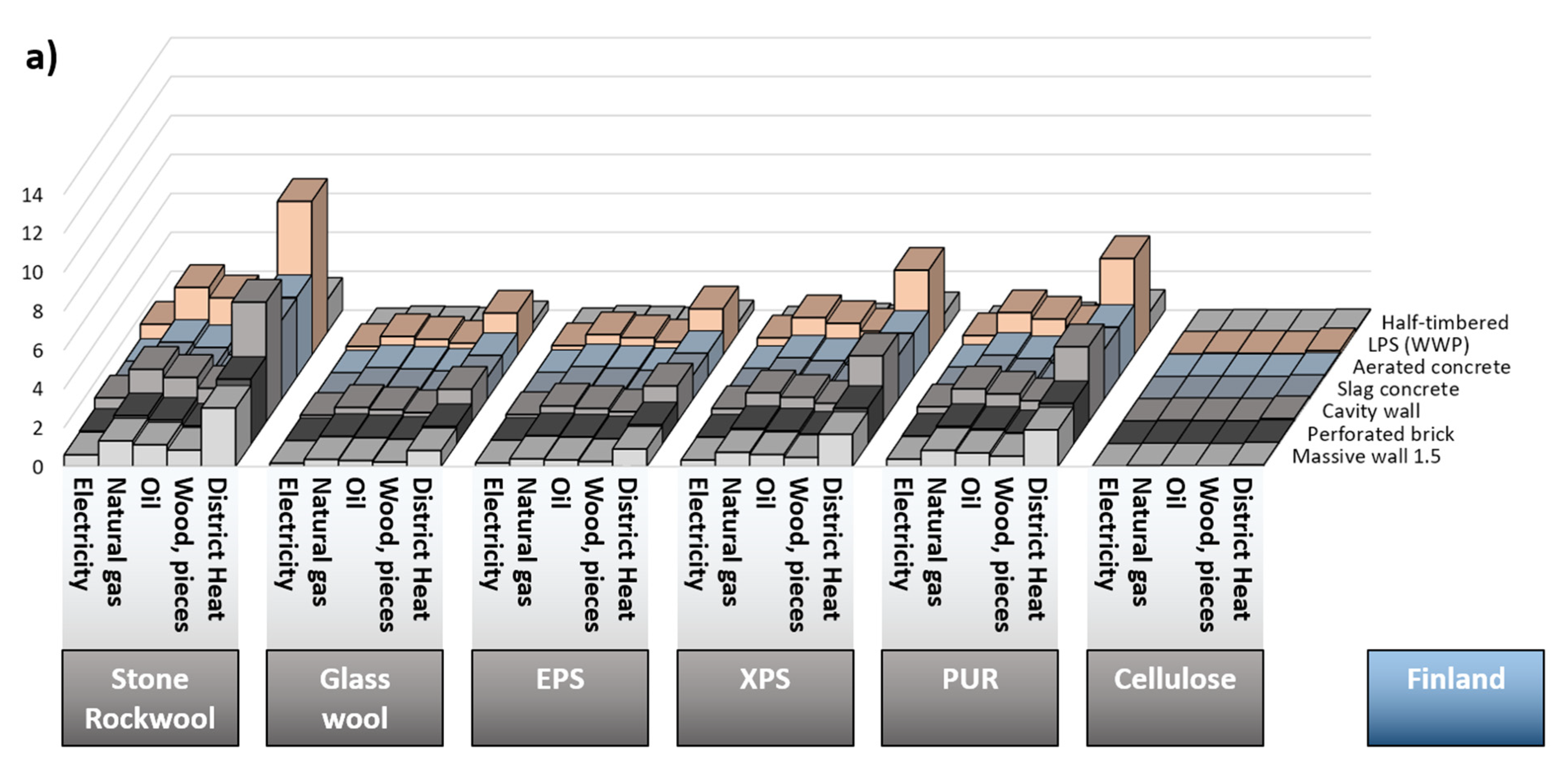

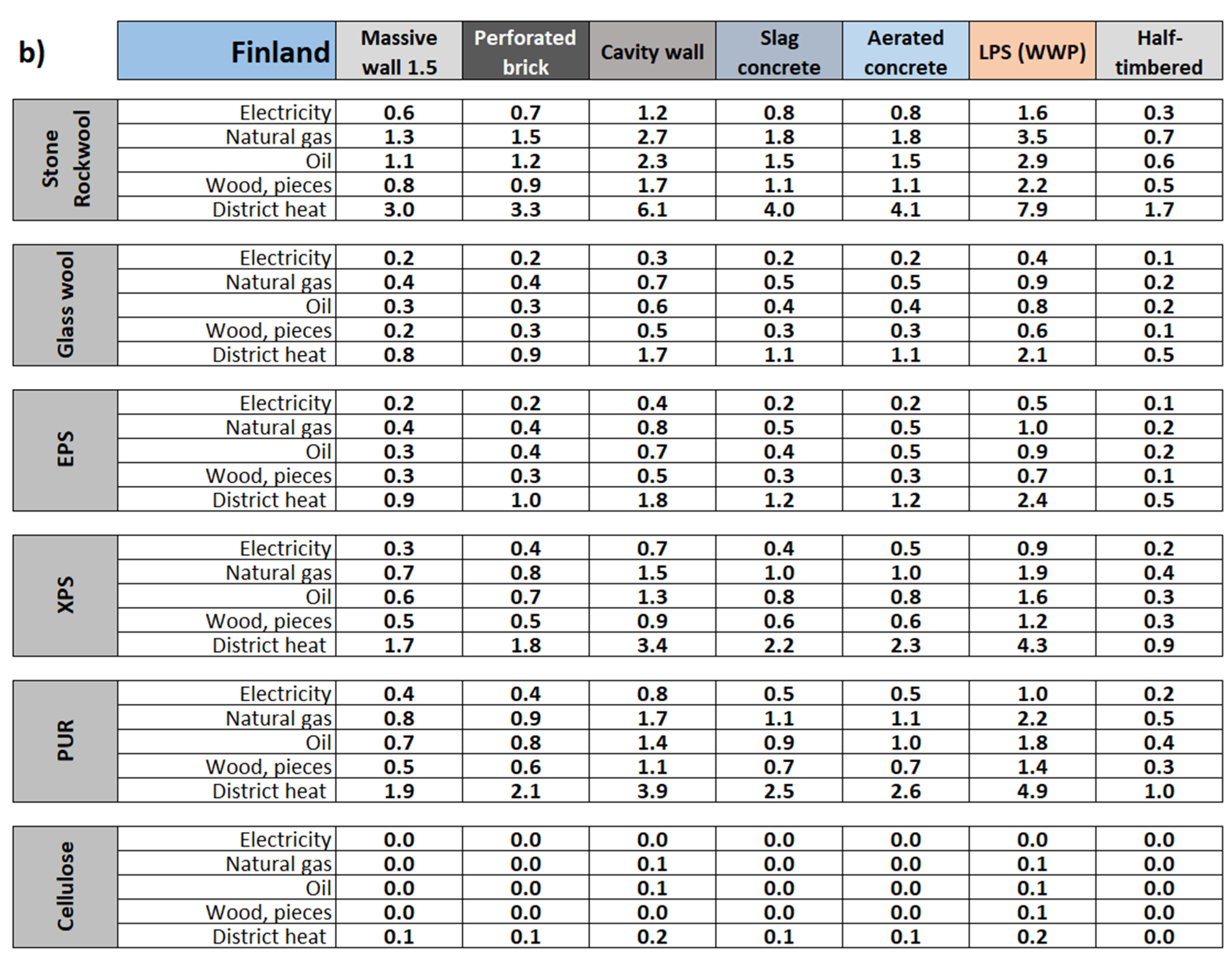

3.7. CPP for Finland

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| CE,j,S | embodied carbon reported as GWP for the selected insulation material (j) in the selected location (S), [kgCO2-eq] |

| CO,i,j,S | annual operational CO2 savings for the selected wall (i) insulated with the selected material (j) in selected location (S), [kgCO2-eq] |

| CO,ins,i,j,S | annual operational CO2 emissions of the selected wall (i) insulated with the selected insulation material (j) in the selected location (S), [kgCO2-eq] |

| CO,exist,i,S | annual operational CO2 emission of non-insulated, selected wall (i) in the selected location (S), [kgCO2-eq] |

| CPPi,j,k,S | Carbon Payback Period for the selected wall (i) insulated with the selected material (j) in selected location (S) and for the selected heat source (k), [years] |

| di,j | insultation thickness, [m] |

| EE | Embodied Energy |

| EIFS | External Insulation Finishing System |

| EMk,S | CO2 emissions for selected heat sources (k) in selected location (S), [gCO2∙kWhdelivered−1] |

| EPBD | Energy Performance of Building Directive |

| EPD | Environmental Product Declaration |

| EPP | Energy Payback Period, [years] |

| EPS | expanded polystyrene |

| ETICS | External Thermal Insulation Composite System |

| FU | functional unit |

| GWP | Global Warming Potential [kgCO2-eq] |

| GWPE,ins,j,S | value of GWP for A1-A3 substages for 1 m2 of selected insulation material (j) with resistance R = 1 (m2∙K∙W−1) in selected location (S), [kgCO2-eq] |

| GHG | greenhouse gases |

| HDDS | number of the heating degree days with the base temperature equal to 18 °C in capitals of the selected location (S) |

| IPP | Investment Payback Period, [years] |

| λj | thermal conductivity coefficient of insulation (j), [W∙m−1∙K−1] |

| LCA | Life-Cycle Assessment |

| LCIA | Life-Cycle Impact Assessment |

| LCC | Life-Cycle Cost |

| LPS | Large Panel System |

| NZEB | Nearly Zero Energy Buildings |

| PCR | Product Category Rules |

| PEFnk,S | Non-renewable Primary Energy Factors, for selected heat souces (k) in selected location (S), [kWhprimary/kWhdelivered] |

| PENR | non-Renewable Primary Energy |

| PER | Primary Renewable Energy |

| PIR | polyisocyanurate |

| PUR | polyurethane |

| Rins,i,j | expected thermal resistance of the given insulation (j) on a given wall (i), [m2∙K∙W−1] |

| Rsi | thermal resistance on the internal surface, [m2∙K∙W−1] |

| Rse | thermal resistance on the external surface, [m2∙K∙W−1] |

| Rti,j | total thermal resistance of an insulated wall, [m2∙K∙W−1] |

| Rwall.i | thermal resistance of the existing wall, [m2∙K∙W−1] |

| Uc | heat transfer coefficient, [W1∙m−2∙K−1] |

| XPS | extruded polystyrene |

| ZEB | Zero Emmisopn Buildings |

References

- European Parliament and the Council Directive (EU) 2010/31 of the European Parliament and of the Council of 19 May 2010 on the Energy Performance of Buildings (Recast). Available online: http://data.europa.eu/eli/dir/2010/31/oj (accessed on 29 August 2022).

- European Parliament and the Council Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 Amending Directive 2010/31/EU on the Energy Performance of Buildings and Directive 2012/27/EU on Energy Efficiency. Available online: http://data.europa.eu/eli/dir/2018/844/oj/eng (accessed on 29 August 2022).

- United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector; Communication Division, United Nations Environment Programme: Nairobi, Kenya, 2020. [Google Scholar]

- COM(2011) 571 Final, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and Committee of the Regions, the Roadmap to a Resource Efficient Europe. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52011DC0571 (accessed on 29 August 2022).

- European Commission. 2050 Long-Term Strategy. Available online: https://ec.europa.eu/clima/policies/strategies/2050_en (accessed on 29 August 2022).

- Rousselot, M.; Pinto Da Rocha, F. Energy Efficiency Trends in Buildings in the EU, Odyssee-Mure, Policy Brief. 2021. Available online: https://www.odyssee-mure.eu/publications/policy-brief/buildings-energy-efficiency-trends.html (accessed on 30 August 2022).

- COM (2021) 802 Final, Proposal for a Directive 2010/31/EU of the European Parliamen and of the Council on the Energy Performance of Buildings (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex:52021PC0802 (accessed on 29 August 2022).

- COM(2020) 662 Final, Communication from the Commission to the European Parliament, the Council, the European Social and Economic Committee and the Committee of the Regions, A Renovation Wave for Europe—Greening Our Buildings, Creating Jobs, Improving Lives. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A52020DC0662 (accessed on 30 August 2022).

- European Commission. Directorate-General for Energy, Comprehensive Study of Building Energy Renovation Activities and the Uptake of Nearly Zero-Energy Buildings in the EU: Final Report, Publications Office. 2019. Available online: https://data.europa.eu/doi/10.2833/14675 (accessed on 30 August 2022).

- European Commission. Renovation Wave: Doubling the Renovation Rate to Cut Emissions, Boost Recovery and Reduce Energy Poverty. Available online: https://ec.europa.eu/commission/presscorner/detail/en/ip_20_1835 (accessed on 30 August 2022).

- COM (2021) 558, Proposal for a Directive 2012/27/EU of the European Parliament and the Council on Energy Efficiency (Recast). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:52021PC0558 (accessed on 31 August 2022).

- The American Institute of Architects. 10 Steps to Reducing Embodied Carbon. Available online: https://www.aia.org/articles/70446-10-steps-to-reducing-embodied-carbon:2976 (accessed on 10 August 2022).

- BPIE. Factsheet 97% of Buildings in the EU Need to Be Upgraded. 2017. Available online: http://bpie.eu/wp-content/uploads/2017/12/State-of-the-building-stock-briefing_Dic6.pdf (accessed on 1 September 2022).

- Ramesh, T.; Prakash, R.; Shukla, K.K. Life cycle energy analysis of buildings: An overview. Energy Build 2010, 42, 1592–1600. [Google Scholar] [CrossRef]

- Ibn-Mohammed, T.; Greenough, R.; Taylor, S.; Ozawa-Meida, L.; Acquaye, A. Operational vs. embodied emissions in buildings—A review of current trends. Energy Build 2013, 66, 232–245. [Google Scholar] [CrossRef]

- Ürge-Vorsatz, D.; Khosla, R.; Bernhardt, R.; Chan, Y.; Vérez, D.; Hu, S.; Cabeza, L.F. Advances Toward a Net-Zero Global Building Sector. Annu. Rev. Environ. Resour. 2020, 45, 227–269. [Google Scholar] [CrossRef]

- Thormark, C. A low energy building in a life cycle—Its embodied energy, energy need for operation and recycling potential. Build. Environ. 2022, 37, 429–435. [Google Scholar] [CrossRef]

- Blengini, G.A.; Di Carlo, T. Energy-saving policies and low-energy residential buildings: An LCA case study to support decision makers in piedmont (Italy). Int. J. Life Cycle Assess. 2010, 15, 652–665. [Google Scholar] [CrossRef]

- Chastas, P.; Theodosiou, T.; Bikas, D. Embodied energy in residential buildings towards the nearly zero energy building: A literature review. Build. Environ. 2016, 105, 267–282. [Google Scholar] [CrossRef]

- Kjendseth, W. Marianne & Fufa, Selamawit & Kristjansdottir, Torhildur & Andresen, Inger, Lessons learnt from embodied GHG emission calculations in zero emission buildings (ZEBs) from the Norwegian ZEB research centre. Energy Build. 2018, 165, 25–34. [Google Scholar] [CrossRef]

- Statistics Poland. Development of Methodology and Realisation of a Survey of a Thermo-Modernization Activity Scale in Multi-Dwelling Residential Buildings. 2018. Available online: https://stat.gov.pl/download/gfx/portalinformacyjny/pl/defaultaktualnosci/6336/1/1/1/przeprowadzenie_badania_skali_dzialan_termomodernizacyjnych_budynkow_mieszkalnych.pdf (accessed on 2 September 2022).

- 2017. Available online: https://www.visiongain.com/report/building-thermal-insulation-market-analysis-forecasts-2017-2027/ (accessed on 2 September 2022).

- Luo, Z.; Yang, L.; Liu, J. Embodied carbon emissions of office building: A case study of China’s 78 office buildings. Build. Environ. 2016, 95, 365–371. [Google Scholar] [CrossRef] [Green Version]

- Aditya, L.; Mahlia, T.M.I.; Rismanchi, B.; Ng, H.M.; Hasan, M.H.; Metselaar, H.S.C.; Muraza, O.; Aditiya, H.B. A review on insulation materials for energy conservation in buildings. Renew. Sustain. Energy Rev. 2017, 73, 1352–1365. [Google Scholar] [CrossRef]

- Mohsen, M.S.; Akash, B.A. Some prospects of energy savings in buildings. Energy Convers. Manag. 2001, 42, 1307–1315. [Google Scholar] [CrossRef]

- Filate, S.S. Investigation of an Energy Refurbishment Concept for Office Building Using Nanogel/Aerogel Insulation Plaster and Replaced Windows by Building Simulation. Master Programme in Energy Technology; Uppsala Universitet: Uppsala, Sweden, 2014; Available online: https://www.diva-portal.org/smash/get/diva2:772909/ATTACHMENT01.pdf (accessed on 14 September 2016).

- Evola, G.; Margani, G. Energy retrofit towards net zeb, Application of BIPV on an Apartment Block in Southern Italy. In Proceedings of the Architectural Research through to Practice: 48th International Conference of the Architectural Science Association, Genoa, Italy, 10–13 December 2014. [Google Scholar]

- Hoxha, E.; Habert, G.; Lasvaux, S.; Chevalier, J.; Le Roy, R. Influence of construction material uncertainties on residential building LCA reliability. J. Clean. Prod. 2017, 144, 33–47. [Google Scholar] [CrossRef]

- Passer, A.; Kreiner, H.; Maydl, P. Assessment of the environmental performance of buildings: A critical evaluation of the influence of technical building equipment on residential buildings. Int. J. Life Cycle Assess. 2012, 17, 1116–1130. [Google Scholar] [CrossRef]

- Hoxha, E.; Jusselme, T. On the necessity of improving the environmental impacts of furniture and appliances in net-zero energy buildings. Sci. Total Environ. 2017, 596–597, 405–416. [Google Scholar] [CrossRef] [PubMed]

- Kunič, R. Carbon footprint of thermal insulation materials in building envelopes. Energy Effic. 2017, 10, 1511–1528. [Google Scholar] [CrossRef]

- Grazieschi, G.; Asdrubali, F.; Thomas, G. Embodied energy and carbon of building insulating materials: A critical review. Clean Environ. Syst. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Hill, C.; Norton, A.; Dibdiakova, J. A comparison of the environmental impacts of different categories of insulation materials. Energy Build. 2018, 162, 12–20. [Google Scholar] [CrossRef]

- Su, X.; Luo, Z.; Li, Y.; Huang, C. Life cycle inventory comparison of different building insulation materials and uncertainty analysis. J. Clean. Prod. 2016, 112, 275–281. [Google Scholar] [CrossRef]

- Pargana, N.; Pinheiro, M.D.; Silvestre, J.D.; de Brito, J. Comparative environmental life cycle assessment of thermal insulation materials of buildings. Energy Build. 2014, 82, 466–481. [Google Scholar] [CrossRef]

- Casini, M. Insulation materials for the building sector: A review and comparative analysis. In Encyclopedia of Renewable and Sustainable Materials; Elsevier: Amsterdam, The Netherlands, 2020; pp. 121–132. [Google Scholar] [CrossRef]

- Biswas, K.; Shrestha, S.S.; Bhandari, M.S.; Desjarlais, A.O. Insulation materials for commercial buildings in North America: An assessment of lifetime energy and environmental impacts. Energy Build. 2016, 112, 256–269. [Google Scholar] [CrossRef]

- Yard, S. Developments of the payback method. Int. J. Prod. Econ. 2000, 67, 155–167. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, M.; Cellura, M.; Mistretta, M. Energy and environmental benefits in public buildings as a result of retrofit actions. Renew. Sustain. Energy Rev. 2011, 15, 460–470. [Google Scholar] [CrossRef]

- Asdrubali, F.; Ballarini, I.; Corrado, V.; Evangelisti, L.; Grazieschi, G.; Guattari, C. Energy and environmental payback times for an NZEB retrofit. Build Environ. 2019, 147, 461–472. [Google Scholar] [CrossRef]

- Berggren, B.; Hall, M.; Wall, M. LCE analysis of buildings—Taking the step towards net zero energy buildings. Energy Build 2013, 62, 381–391. [Google Scholar] [CrossRef]

- Lu, L.; Yang, H.X. Environmental payback time analysis of a roof-mounted building-integrated photovoltaic (BIPV) system in Hong Kong. Appl Energy 2010, 87, 3625–3631. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J.L.; Chung, T.M. Energy and carbon emission payback analysis for energy-efficient retrofitting in buildings-overhang shading option. Energy Build 2012, 44, 94–103. [Google Scholar] [CrossRef]

- Zhang, C.; Hu, M.; Laclau, B.; Garnesson, T.; Yang, X.; Tukker, A. Energy-carbon-investment payback analysis of prefabricated envelope-cladding system for building energy renovation: Cases in Spain, the Netherlands, and Sweden. Renew. Sustain. Energy Rev. 2021, 145, 111077. [Google Scholar] [CrossRef]

- Beccali, M.; Cellura, M.; Fontana, M.; Longo, S.; Mistretta, M. Energy retrofit of a single-family house: Life cycle net energy saving and environmental benefits. Renew. Sustain. Energy Rev. 2013, 27, 283–293. [Google Scholar] [CrossRef]

- Dylewski, R.; Adamczyk, J. 12—Life cycle assessment (LCA) of building thermal insulation materials. Eco-efficient Construction and Building Materials; Pacheco-Torgal, F., Cabeza, L.F., Labrincha, J., de Magalhães, A., Eds.; Woodhead Publishing: Sawston, UK, 2014; pp. 267–286. ISBN 9780857097675. [Google Scholar] [CrossRef]

- EN 15804:2012; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. The European Committee for Standardization: Brussels, Belgium, 2012.

- ISO 14040; Environmental Management–Life Cycle Assessment–Principles and Framework. International Organisation for Standardisation: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 10 September 2022).

- Passive House Requirements, Passive House Institute. Available online: https://passivehouse.com/02_informations/02_passive-house-requirements/02_passive-house-requirements.htm (accessed on 12 September 2022).

- Singh, U.; Colosi, L.M. The case for estimating carbon return on investment (CROI) for CCUS platforms. Appl. Energy 2021, 285, 116394. [Google Scholar] [CrossRef]

- ISO 14044; Environmental management—Life cycle assessment—Requirements and guidelines. International Organisation for Standardisation: Geneva, Switzerland, 2006. Available online: https://www.iso.org/standard/38498.html (accessed on 10 September 2022).

- EN 15978:2011; Sustainability of construction works—Assessment of environmental performance of buildings—Calculation method. The European Committee for Standardization: Geneva, Switzerland. Available online: https://www.oneclicklca.com/ (accessed on 10 September 2022).

- European Commission. Commission Delegated Regulation (EU) No 811/2013 of 18 February 2013 Supplementing Directive 2010/30/EU of the European Parliament and of the Council with Regard to the Energy Labelling of Space Heaters, Combination Heaters, Packages of Space Heater, Temperature Control and Solar Device and Packages of Combination Heater, Temperature Control and Solar Device. Available online: http://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32013R0811&from=E (accessed on 10 September 2022).

- Sartori, I.; Napolitano, A.; Voss, K. Net zero energy buildings: A consistent definition framework. Energy Build. 2012, 48, 220–232. [Google Scholar] [CrossRef] [Green Version]

- EN 52000-1:2017-10; Energy Performance of Buildings—Overarching EPB assessment—Part 1: General Framework and Procedures. International Organization for Standardization: Geneva, Switzerland, 2017.

- Regulation of the Minister of Infrastructure and Development of 27 February 2015 on the Methodology for Determining the Energy Performance of a Building or Part of a Building and Energy Performance Certificates. J. Laws 2015, 376, 6.

- DIN V 18599:2007-02; Energy efficiency of buildings - Calculation of the net, final and primary energy demand for heating, cooling, ventilation, domestic hot water and lighting - Part 1: General balancing procedures, terms and definitions, zoning and evaluation of energy sources. Beuth: Berlin, Germany, 2009. Available online: https://www.beuth.de/en/pre-standard/din-v-18599-1/96921476 (accessed on 10 September 2022).

- Ministry of the Environment of Czech Republic. National Greenhouse Gas Inventory Report of the Czech Republic (reported inventories 1990–2018), Table 3-11. 2020. Available online: https://unfccc.int/sites/default/files/resource/cze-2020-nir-7may20.pdf (accessed on 10 September 2022).

- International Energy Agency. Czech Republic 2021. Energy Policy Review; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Předpis, č. 78/2013 Sb.Vyhláška o energetické náročnosti budov, 22.03.2013, Czech Republic. Available online: https://www.zakonyprolidi.cz/cs/2013-78 (accessed on 10 September 2022).

- Österreichisches Institut für Bautechnik: Richtlinie 6 Energieeinsparung und Wärmeschutz. 2015. Available online: https://www.oib.or.at/sites/default/files/richtlinie_6_26.03.15.pdf (accessed on 10 September 2022).

- National Building Code of Finland. Part D3 Energy-Efficiency; Ministry of the Environment: Helsinki, Finland, 2018. [Google Scholar]

- Haakana, M.; Laitila, P.; Forssell, K.M.; Motiva, O.Y. Implementation of the EPBD in Finland, 2016, The Concerted Action EPBD (CA EPBD). 2016. Available online: https://epbd-ca.eu/ca-outcomes/outcomes-2015-2018/book-2018/countries/finland (accessed on 14 September 2022).

- National Center for Emissions Management and Balancing. Available online: https://www.kobize.pl/pl/fileCategory/id/28/wskazniki-emisyjnosci, (accessed on 12 September 2022).

- IPCC. Annex I: Properties of CO2 and Carbon-Based Fuels. In Special Report on Carbon dioxide Capture and Storage; IPCC: Geneva, Switzerland; Available online: https://www.ipcc.ch/site/assets/uploads/2018/03/srccs_annex1-1.pdf (accessed on 12 September 2022).

- Calculation Criteria Used In The Sitra Lifestyle Test, SISTRA. 2021. Available online: https://lifestyletest.sitra.fi/ (accessed on 14 September 2022).

- Blagoeva, D.; Pavel, C.C. Competitive Landscape of the EU’s Insulation Materials Industry for Energy-Efficient Buildings; EUR 28816 EN; Publications Office of the European Union: Luxembourg, 2018; ISBN 978-92-79-96383-4. [Google Scholar] [CrossRef]

- IAL Consultants. Press release: The European Market for Thermal Insulation Products. 2022. Available online: www.ialconsultants.com/media/1090/thermal-insulation-press-release-2021.pdf (accessed on 14 September 2022).

- Shrestha, S.S.; Biswas, K.; Desjarlais, A.O. A protocol for lifetime energy and environmental impact assessment of building insulation materials. Environ. Impact Assess. Rev. 2014, 46, 25–31. [Google Scholar] [CrossRef]

- Central Statistical Office. Inhabited buildings. National Census of Population and Housing, Warsaw. 2013. Available online: https://warszawa.stat.gov.pl/publikacje-i-foldery/spisy-powszechne/narodowy-spis-powszechny-ludnosci-i-mieszkan-2011-zamieszkane-budynki,8,1.html (accessed on 16 October 2022).

- Wójcik, R. Docieplanie Budynków od Wewnątrz; Grupa Medium: Warszawa, Poland, 2018. [Google Scholar]

- Onyszkiewicz, J.; Sadowski, K. Proposals for the revitalization of prefabricated building facades in terms of the principles of sustainable development and social participation. J. Build. Eng. 2022, 46, 103713. [Google Scholar] [CrossRef]

- Available online: https://www.degreedays.net/# (accessed on 1 September 2022).

- Sunikka-Blank, M.; Galvin, R. Introducing the prebound effect: The gap between performance and actual energy consumption. Build. Res. Inf. 2012, 40, 260–273. [Google Scholar] [CrossRef]

| Energy Carrier | Europe [55] | Poland [56] | Germany [57] | Czech Republic [58] | Austria [59] | Finland [60,61] |

|---|---|---|---|---|---|---|

| Electricity | 2.3 | 3.0 | 2.6 | 3.0 | 1.32 | 1.2 |

| Natural gas | 1.1 | 1.1 | 1.1 | 1.2 | 1.16 | 1.0 |

| Oil | 1.1 | 1.1 | 1.1 | 1.2 | 1.23 | 1.0 |

| Wood, pieces | 0.2 | 0.2 | 0.2 | 0.2 | 0.06 | 1.0 |

| District heating | 1.3 | 1.3 | 0.7 (FF > 70%) | 1.0 | 1.38 | 0.5 |

| Energy Carrier | Europe | Poland | Germany | Czech Republic | Austria | Finland |

|---|---|---|---|---|---|---|

| Electricity | 420 [55] | 698 [62] | 331 [59] | 406 [58,63,64] | 389 [59] | 329.62 [65] |

| Natural gas | 180 [66] | 180 [66] | 180 [66] | 180 [66] | 180 [66] | 180 [66] |

| Oil | 213 [66] | 213 [66] | 213 [66] | 213 [66] | 213 [66]] | 213 [66] |

| Wood, pieces | 282 [66] | 282 [66] | 282 [66] | 282 [66] | 282 [66] | 282 [66] |

| District heating | 260 [55] | 340 [62] | 230 [59] | 298 * [63,64] | 219 [59] | 158 [65] |

| Material | Density (kg∙m−3) | Thermal Conductivity (W∙m−1∙K−1) | |

|---|---|---|---|

| Iins,1 | Stone wool | 35–130 | 0.033–0.040 |

| Iins,2 | Glass wool | 12–64 | 0.031–0.045 |

| Iins,3 | EPS (expanded polystyrene) | 15–30 | 0.031–0.044 |

| Iins,4 | XPS (extruded polystyrene) | 24–38 | 0.030–0.040 |

| Iins,5 | PUR (polyurethane foam) | 31.5–35 | 0.022–0.040 |

| Iins,6 | Cellulose | 30–80 | 0.037–0.042 |

| Member State | Europe (Aver.) | Europe | Poland | Germany | Czech Republic | Austria | Finland | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ind. | Gen. | Ind. | Gen. | Ind. | Gen. | Ind. | Gen. | Ind. | Gen. | Ind. | Gen. | Ind. | Gen. | ||

| Stone wool | numb. | 47 | 4 | 0 | 0 | 3 | 3 | 9 | 0 | 12 | 0 | 13 | 0 | 10 | 1 |

| GWP | 4.03 | 6.09 | - | - | 1.44 | 6.62 | 3.90 | - | 2.95 | - | 4.82 | - | 5.22 | 4.47 | |

| Glass wool | numb. | 63 | 4 | 0 | 0 | 15 | 4 | 4 | 0 | 17 | 0 | 17 | 0 | 42 | 0 |

| GWP | 1.54 | 2.88 | - | - | 1.49 | 2.88 | 1.78 | - | 0.89 | - | 2.65 | - | 1.40 | - | |

| EPS | numb. | 49 | 5 | 0 | 0 | 1 | 0 | 4 | 3 | 2 | 0 | 40 | 0 | 2 | 2 |

| GWP | 2.68 | 1.89 | - | - | 1.87 | - | 1.57 | 1.90 | 1.78 | - | 2.93 | - | 1.20 | 1.88 | |

| XPS | numb. | 34 | 8 | 0 | 3 | 1 | 0 | 8 | 4 | 1 | 0 | 23 | 0 | 1 | 0 |

| GWP | 4.56 | 3.58 | - | 3.21 | 7.39 | - | 2.88 | 3.51 | 2.44 | - | 5.19 | - | 2.84 | - | |

| PUR | numb. | 10 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 10 | 0 | 0 | 0 |

| GWP | 3.36 | 3.10 | - | - | - | 3.10 | - | - | - | - | 3.36 | - | - | - | |

| Cellulose | numb. | 12 | 2 | 2 | 0 | 1 | 1 | 0 | 0 | 0 | 1 | 8 | 0 | 1 | 0 |

| GWP | 0.47 | 0.37 | 0.29 | - | 0.30 | 0.44 | - | - | - | 0.31 | 0.60 | - | 0.14 | - | |

| No | Type of Wall | Characteristic | Section |

|---|---|---|---|

| 1. Wwall.1 | Massive wall made of solid brick | Thickness: 44 cm Composition: 1.5 bricks, joint and internal cement-lime plaster Thermal resistance (R): 0.735 m2∙K∙W−1 |  |

| 2. Wwall.2 | Massive wall made of perforated brick | Thickness: 41 cm Composition: 1.5 bricks, joint and internal cement-lime plaster Thermal resistance (R): 0.820 m2∙K∙W−1 |  |

| 3. Wwall.3 | Cavity wall | Thickness: 45 cm Composition: 1.5 solid bricks, joint and internal cement-lime plaster Thermal resistance (R): 1.515 m2∙K∙W−1 |  |

| 4. Wwall.4 | Slag concrete wall | Thickness: 40 cm Composition: slag concrete (ρ = 1200 kg/m3) with internal cement-lime plaster. Thermal resistance (R): 0.993 m2K/W |  |

| 5. Wwall.5 | Wall of autoclaved aerated concrete | Thickness: 25.5 cm Composition: aerated concrete blocks (ρ = 600 kg/m3) with internal cement-lime plaster. Thermal resistance (R): 1.007 m2∙K∙W−1 |  |

| 6. Wwall.6 | Large panel system (LPS) WWP curtain wall | Thickness: 28.5 cm Composition: reinforced concrete structural part 14 cm, insulation made of polystyrene or mineral wool 6 cm, the textural reinforced concrete part 6 cm, with internal cement-lime plaster. Thermal resistance (R): 1.950 m2∙K∙W−1 |  |

| 7. Wwall.7 | Half-timbered work wall | Thickness: 14.5 cm Composition: timber frame wall with the filling of clay mixed and made with chaff, sawdust or shavings, or a 0.5 brick, internal cement-lime plaster. Thermal resistance (R): 0.406 m2∙K∙W−1 |  |

| (a) | |

| Source of Energy | CPP |

| Electricity | 0.3 |

| Natural gas | 1.3 |

| Oil | 1.1 |

| Wood, pieces | 2.9 |

| District Heat | 1.0 |

| (b) | |

| Insulation Material | CPP |

| Stone/Rockwool | 2.3 |

| Glass wool | 1.0 |

| EPS | 1.0 |

| XPS | 1.8 |

| PUR | 1.5 |

| Cellulose | 0.2 |

| (a) | |

| Source of Energy | CPP |

| Electricity | 0.3 |

| Natural gas | 1.5 |

| Oil | 1.2 |

| Wood, pieces | 5.1 |

| District Heat | 0.9 |

| (b) | |

| Insulation Material | CPP |

| Stone/Rockwool | 3.4 |

| Glass wool | 1.5 |

| EPS | 1.5 |

| XPS | 2.1 |

| PUR | 2.1 |

| Cellulose | 0.2 |

| (a) | |

| Source of Energy | CPP |

| Electricity | 0.1 |

| Natural gas | 1.4 |

| Oil | 1.2 |

| Wood, pieces | 4.9 |

| District Heat | 0.6 |

| (b) | |

| Insulation Material | CPP |

| Stone/Rockwool | 2.1 |

| Glass wool | 0.9 |

| EPS | 1.0 |

| XPS | 3.9 |

| PUR | 1.6 |

| Cellulose | 0.2 |

| (a) | |

| Source of Energy | CPP |

| Electricity | 0.3 |

| Natural gas | 1.1 |

| Oil | 1.0 |

| Wood, pieces | 4.0 |

| District Heat | 1.4 |

| (b) | |

| Insulation Material | CPP |

| Stone/Rockwool | 2.6 |

| Glass wool | 1.2 |

| EPS | 1.1 |

| XPS | 2.0 |

| PUR | 2.1 |

| Cellulose | 0.3 |

| (a) | |

| Source of Energy | CPP |

| Electricity | 0.1 |

| Natural gas | 0.8 |

| Oil | 0.6 |

| Wood, pieces | 2.9 |

| District Heat | 0.6 |

| (b) | |

| Insulation Material | CPP |

| Stone/Rockwool | 1.5 |

| Glass wool | 0.5 |

| EPS | 0.9 |

| XPS | 1.3 |

| PUR | 1.7 |

| Cellulose | 0.2 |

| (a) | |

| Source of Energy | CPP |

| Electricity | 0.7 |

| Natural gas | 1.7 |

| Oil | 1.3 |

| Wood, pieces | 20.4 |

| District Heat | 1.1 |

| (b) | |

| Insulation Material | CPP |

| Stone/Rockwool | 7.5 |

| Glass wool | 34.1 |

| EPS | 3.4.5 |

| XPS | 6.8.0 |

| PUR | 5.2 |

| Cellulose | 0.9 |

| (a) | |

| Source of Energy | CPP |

| Electricity | 0.4 |

| Natural gas | 0.9 |

| Oil | 0.7 |

| Wood, pieces | 0.6 |

| District Heat | 2.0 |

| (b) | |

| Insulation Material | CPP |

| Stone/Rockwool | 2.0 |

| Glass wool | 0.5 |

| EPS | 0.6 |

| XPS | 1.1 |

| PUR | 1.2 |

| Cellulose | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadowski, K. Comparison of the Carbon Payback Period (CPP) of Different Variants of Insulation Materials and Existing External Walls in Selected European Countries. Energies 2023, 16, 113. https://doi.org/10.3390/en16010113

Sadowski K. Comparison of the Carbon Payback Period (CPP) of Different Variants of Insulation Materials and Existing External Walls in Selected European Countries. Energies. 2023; 16(1):113. https://doi.org/10.3390/en16010113

Chicago/Turabian StyleSadowski, Kajetan. 2023. "Comparison of the Carbon Payback Period (CPP) of Different Variants of Insulation Materials and Existing External Walls in Selected European Countries" Energies 16, no. 1: 113. https://doi.org/10.3390/en16010113

APA StyleSadowski, K. (2023). Comparison of the Carbon Payback Period (CPP) of Different Variants of Insulation Materials and Existing External Walls in Selected European Countries. Energies, 16(1), 113. https://doi.org/10.3390/en16010113