Evaluation of Four Types of Kilns Used to Produce Charcoal from Several Tree Species in Mexico

Abstract

1. Introduction

2. Materials and Methods

2.1. Sites of Study

2.2. Description of Kilns

2.2.1. Brazilian Beehive Kiln

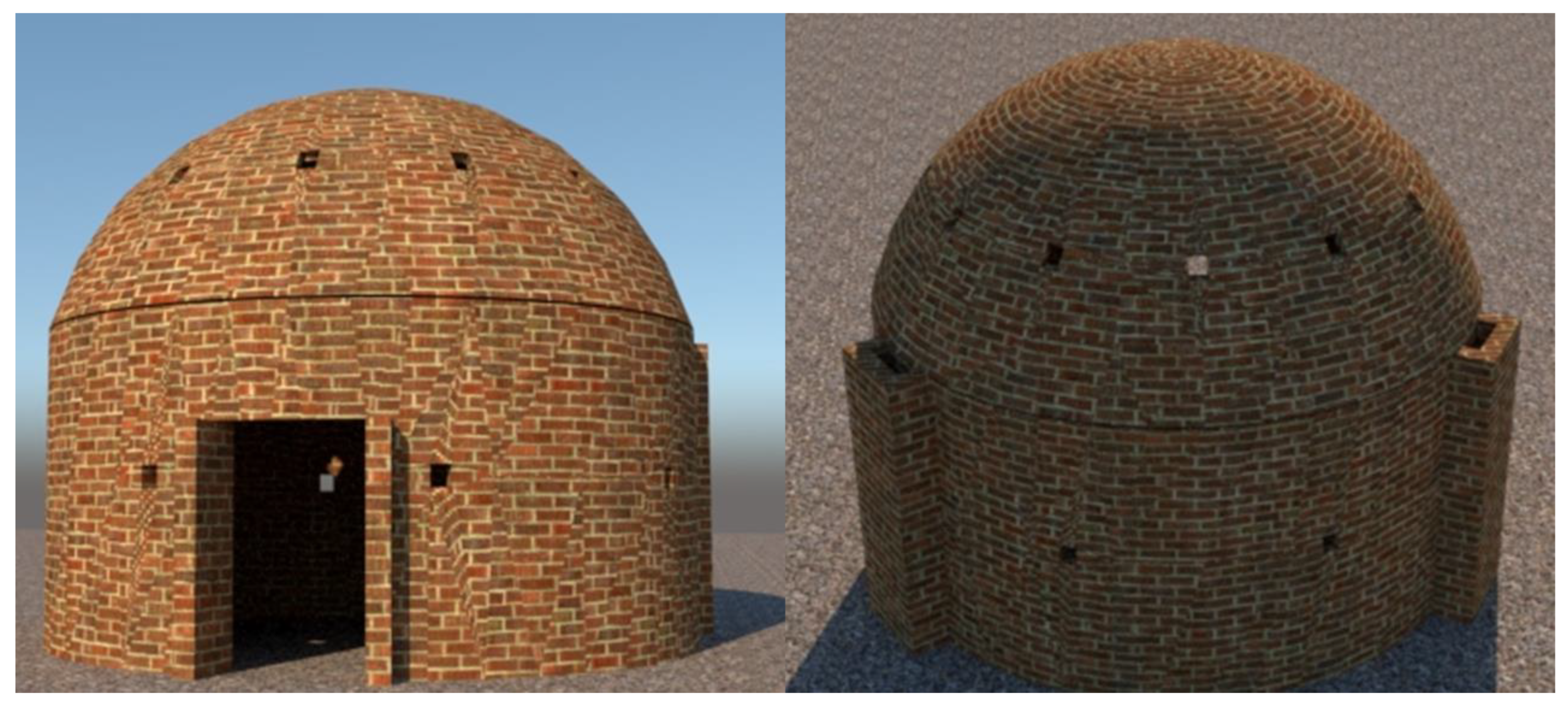

2.2.2. Modified Brazilian Beehive Kiln

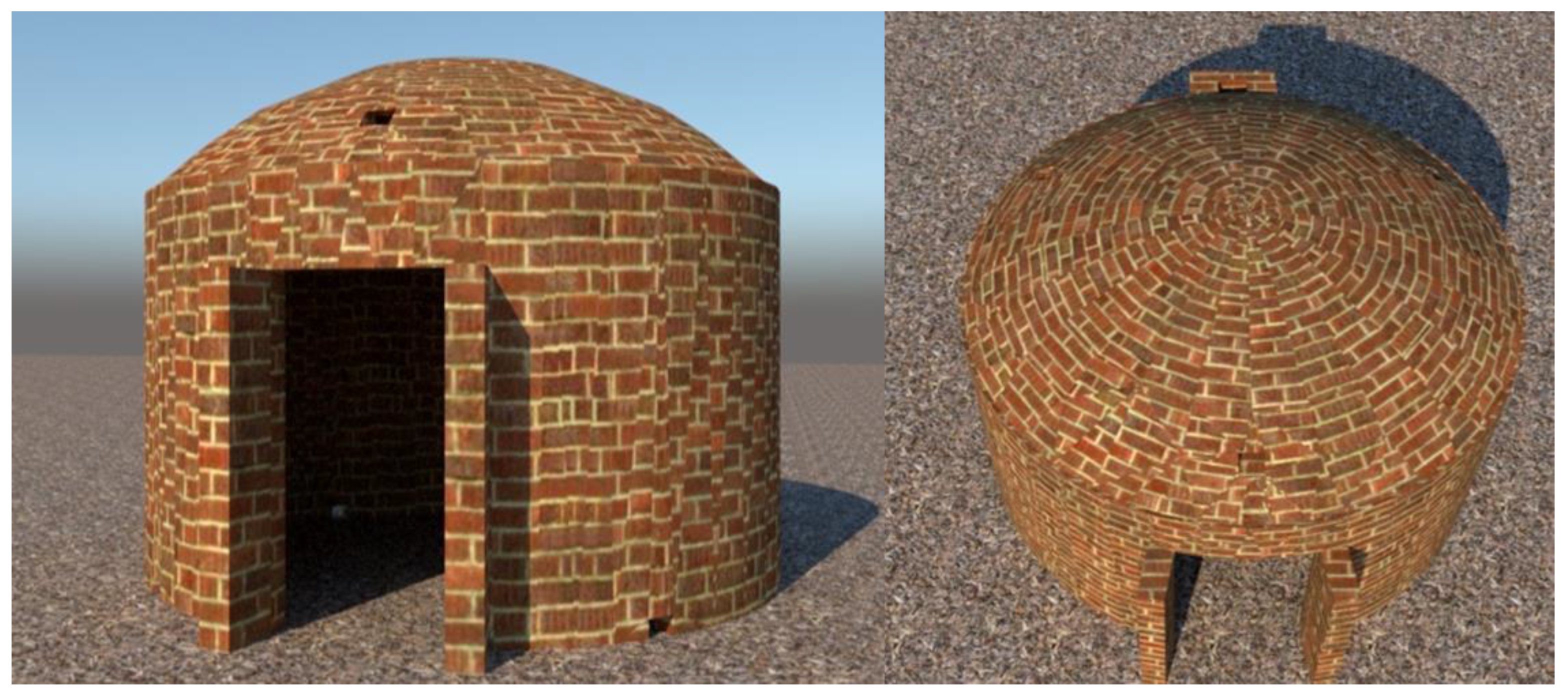

2.2.3. Argentinian Half-Orange Kiln

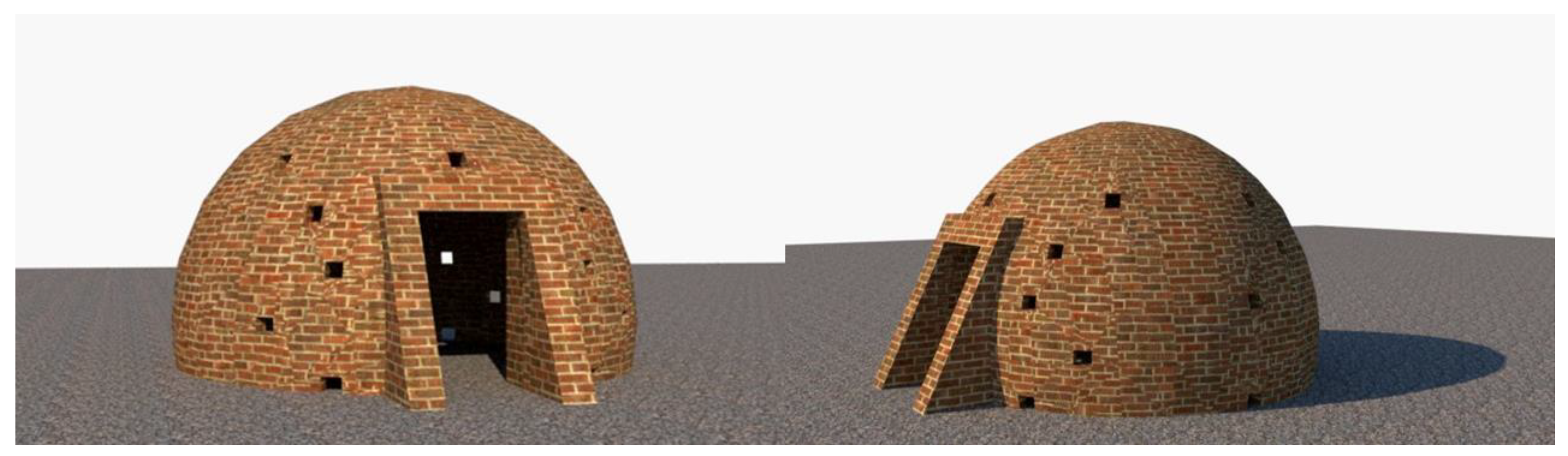

2.2.4. Metallic Industrial Type Kiln

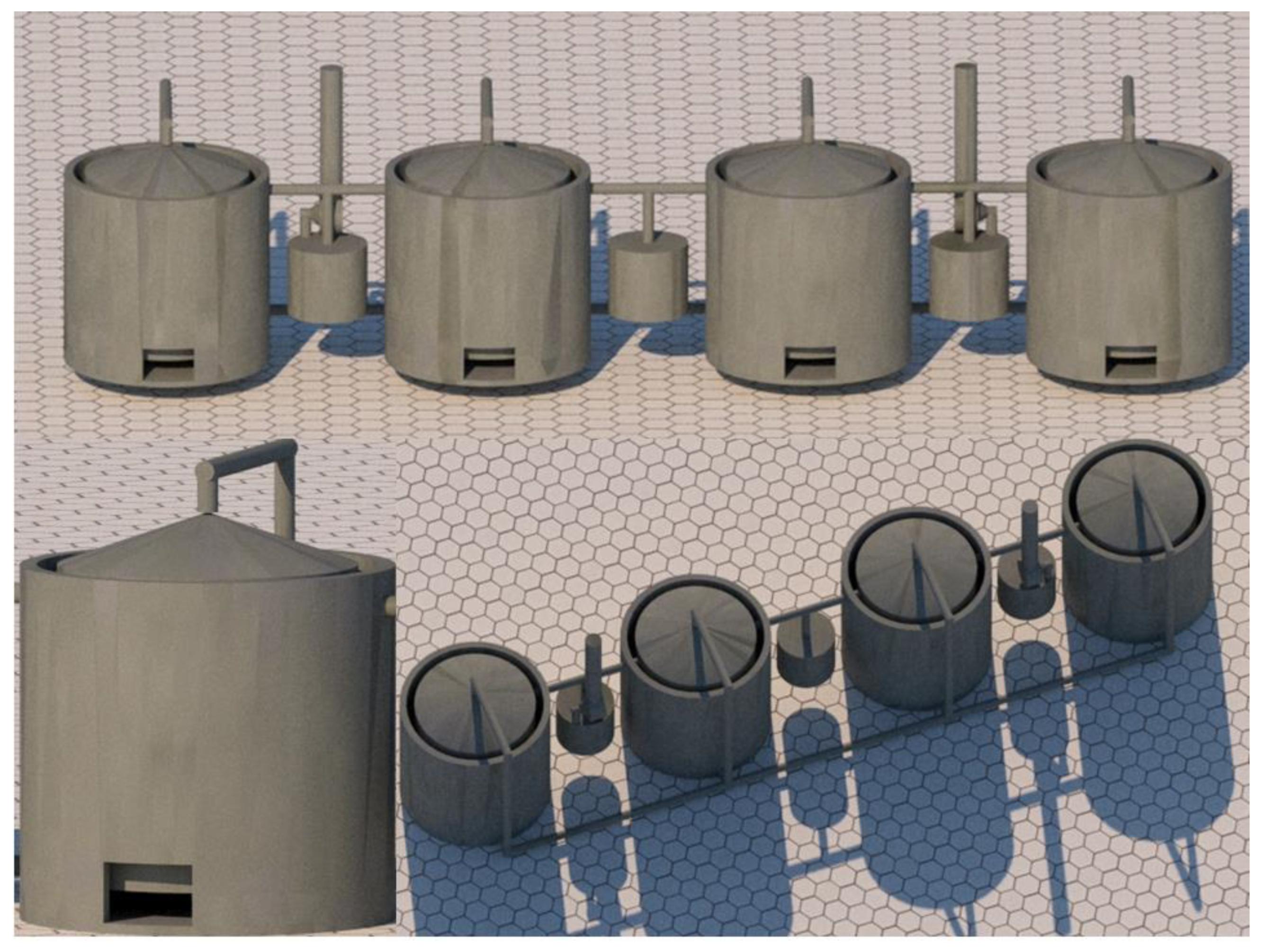

2.3. Samples Preparation

2.4. Carbonization Process Monitoring

2.5. Charcoal Characterization

2.5.1. Charcoal Yield

- Y = Yield

- V = Volume of sample

- m = Mass of pyrolyzed sample

2.5.2. Physicochemical Analysis

2.5.3. Mass Yield

- MY = Mass yield

- RM = Mass yield

- MGB = Mass of green biomass (kg)

- MC = Mass of charcoal (kg)

2.6. Higher Heating Value

2.7. Statistical Analysis

3. Results

3.1. Description of the Carbonization Process

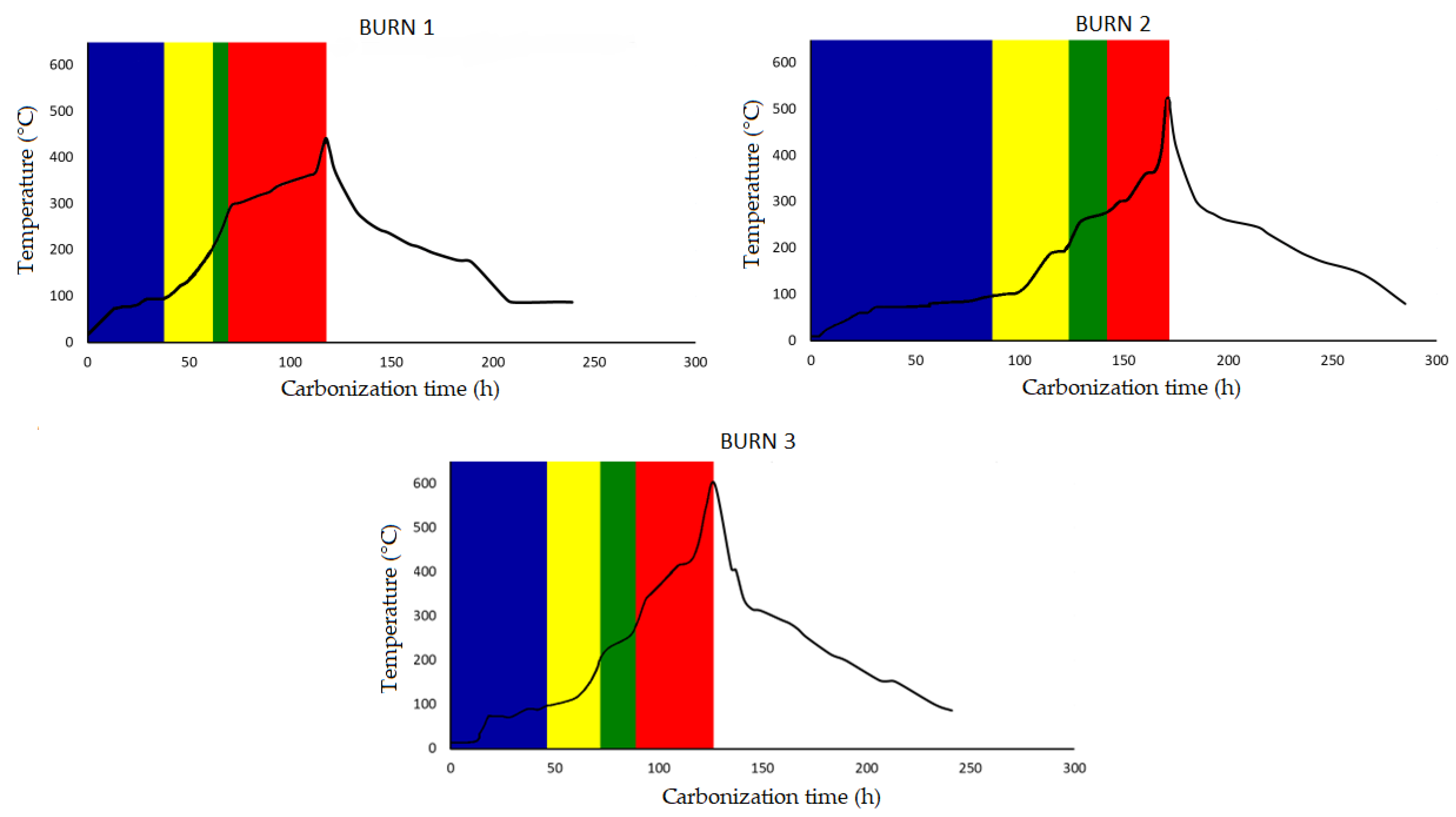

3.1.1. Brazilian Beehive Kiln

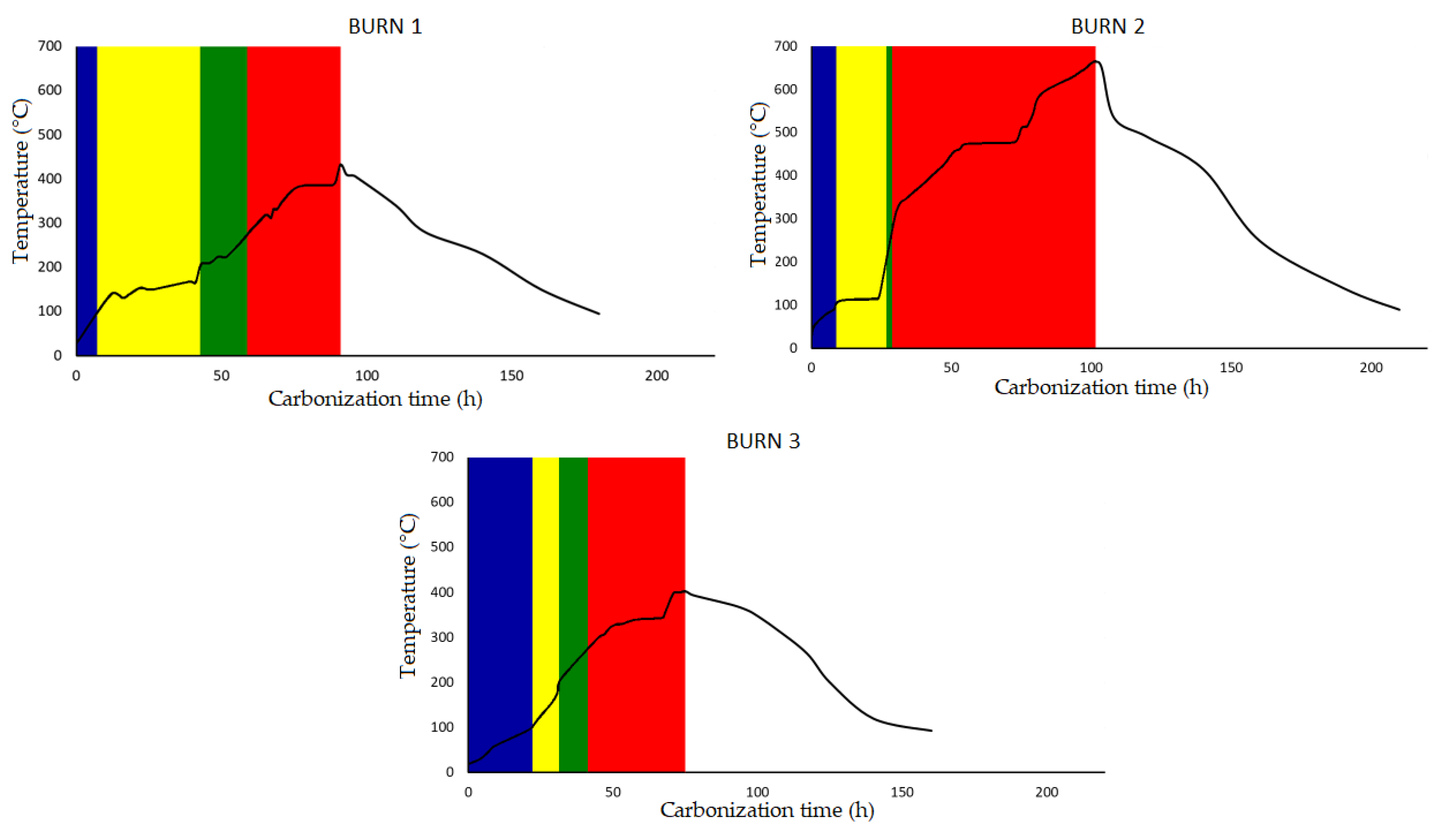

3.1.2. Modified Brazilian Beehive Kiln

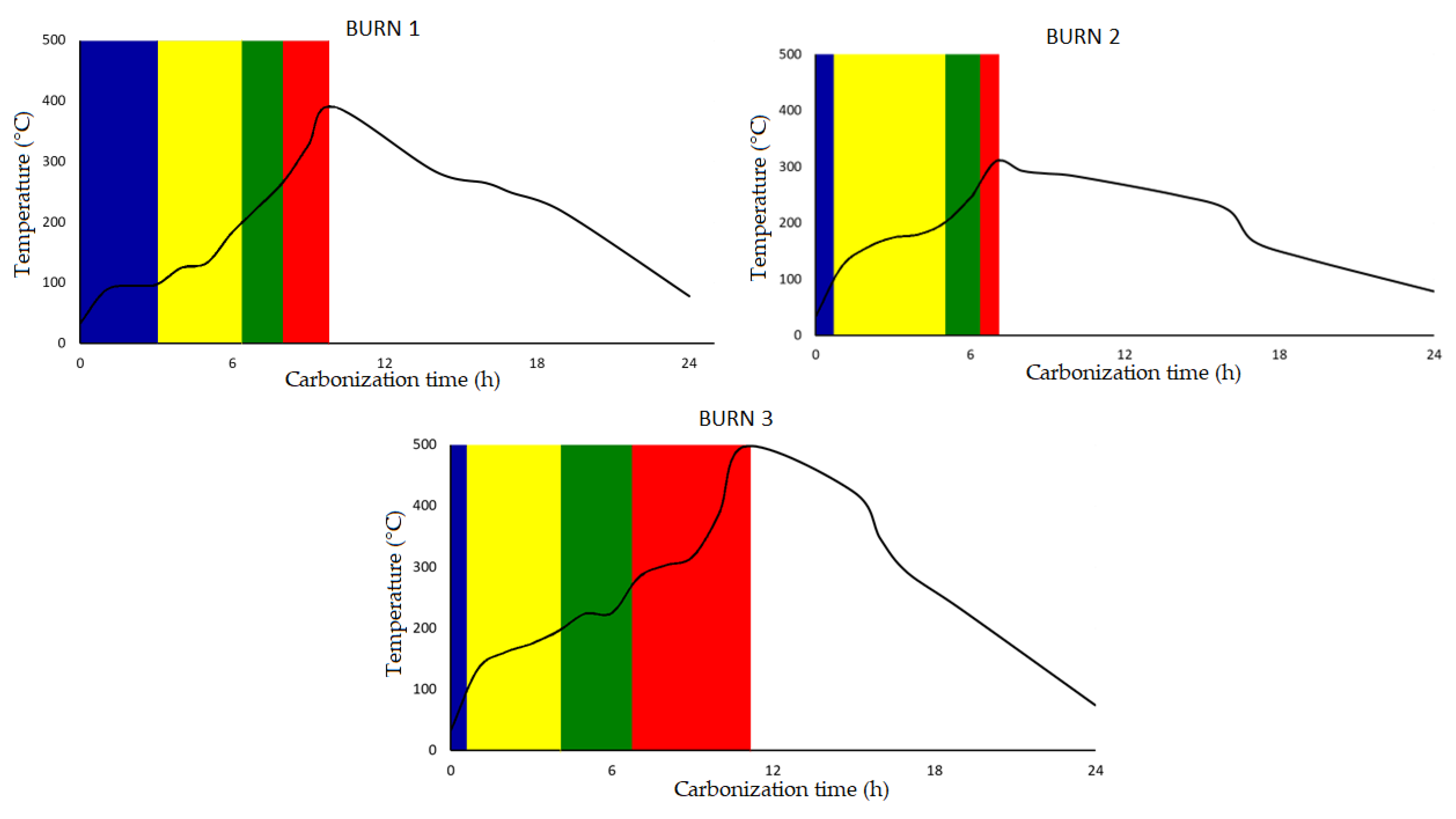

3.1.3. Argentine Half-Orange Kiln

3.1.4. Industrial Metal Kiln

3.2. Yield

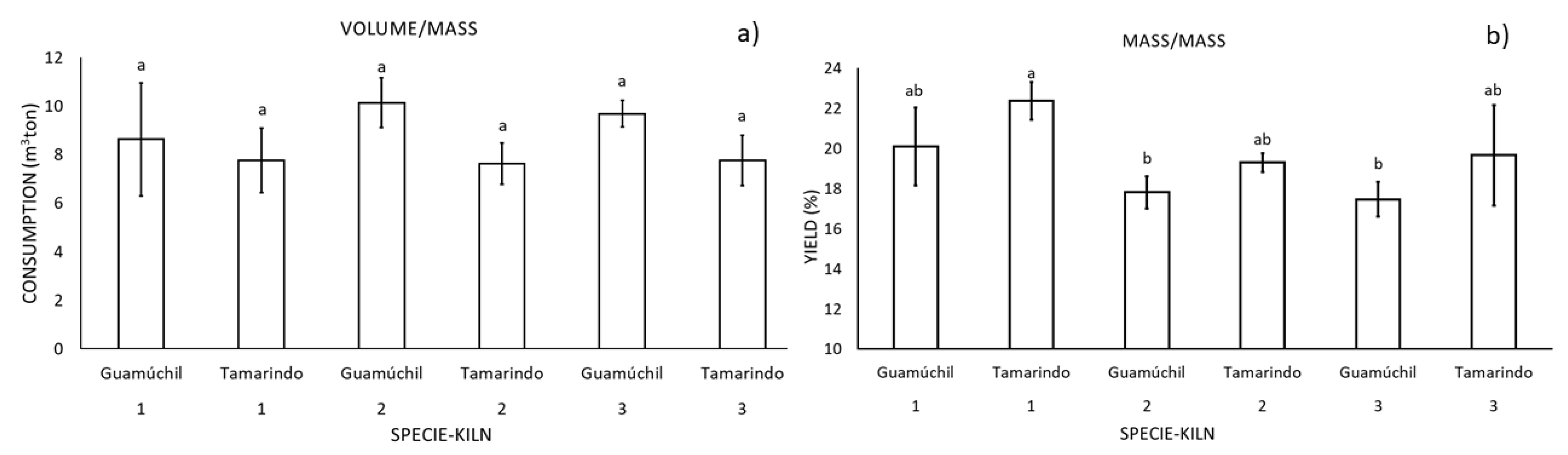

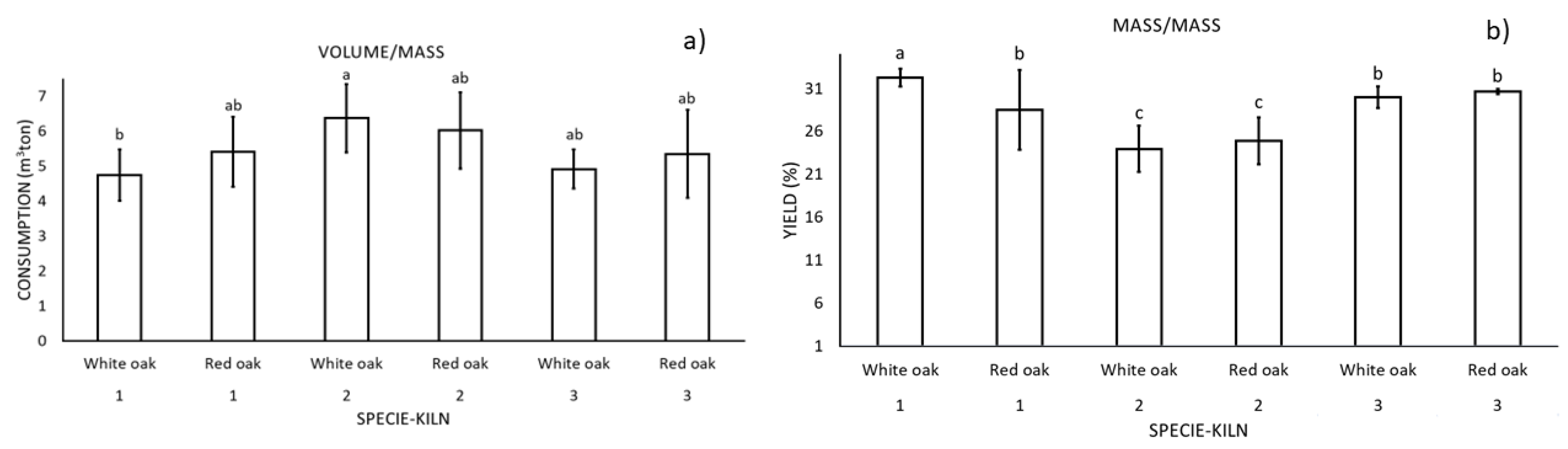

3.2.1. Brazilian Beehive-Type Kiln

3.2.2. Modified Brazilian Beehive kiln

3.2.3. Argentinian Half-Orange Kiln

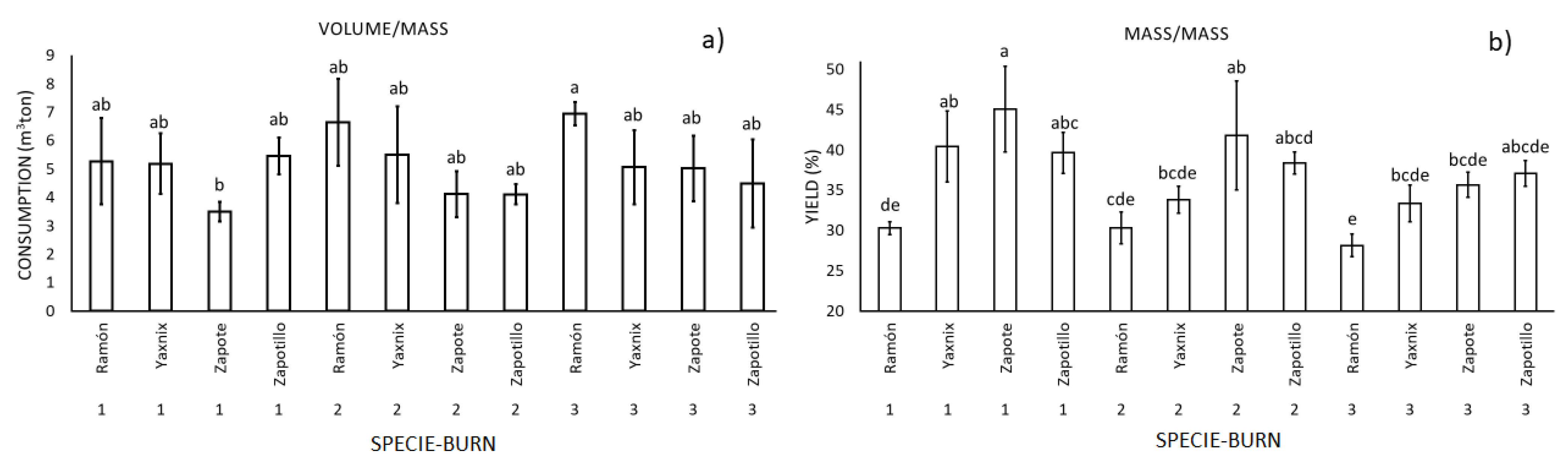

3.2.4. Metallic Industrial Kiln

3.3. Proximal Analysis of Charcoal

3.3.1. Brazilian Beehive-Type Kiln

3.3.2. Modified Brazilian Beehive Kiln

3.3.3. Argentinian Half-Orange Kiln

3.3.4. Metallic Industrial Kiln

3.4. Higher Heating Value

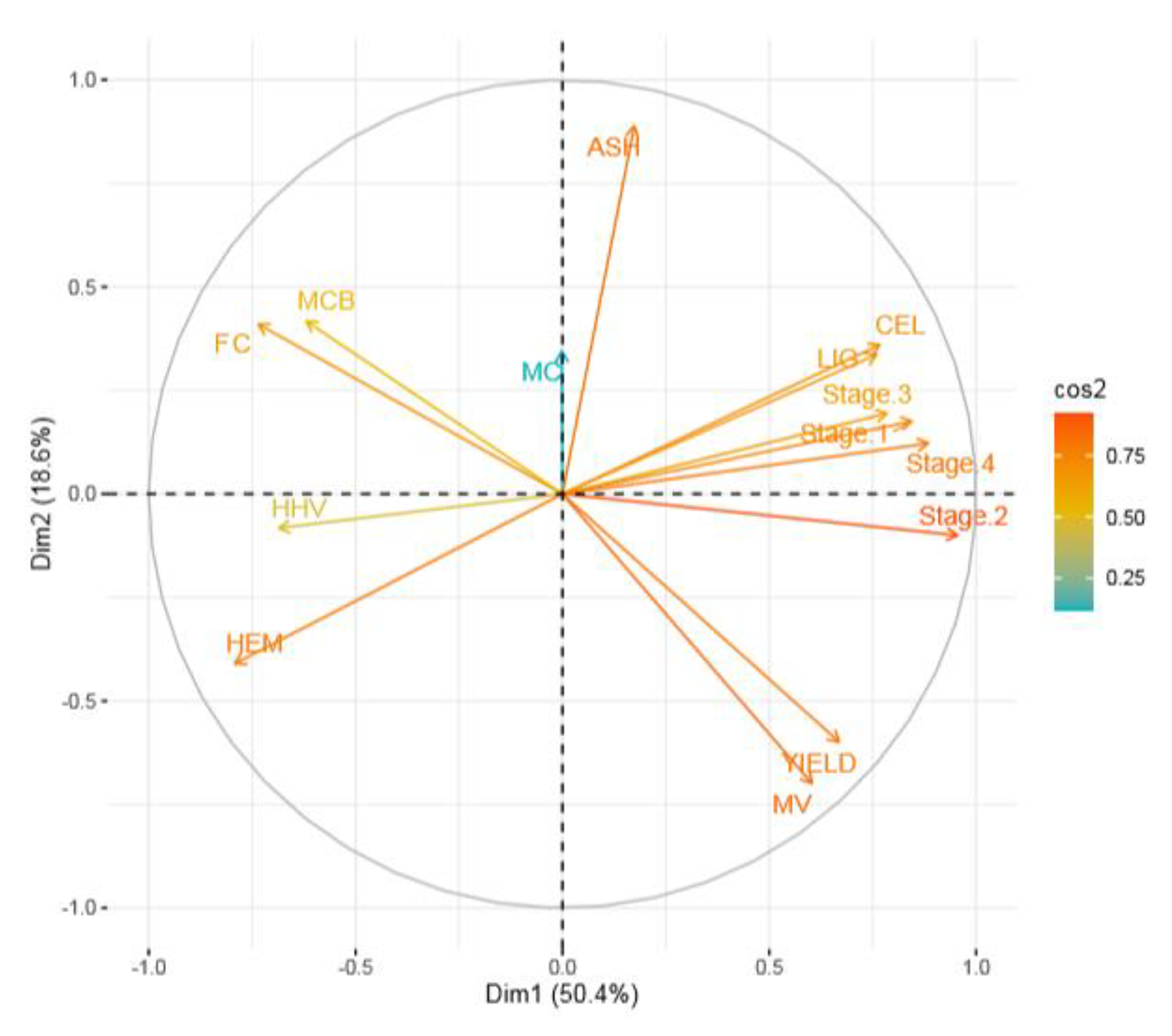

3.5. Principal Component Analysis

4. Discussion

4.1. Carbonization Conditions

4.2. Yield

4.3. Physicochemical Analysis

4.4. Principal Component Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- IEA. Data and Statistics. 2019. Available online: https://www.iea.org/data-and-statistics (accessed on 1 June 2020).

- UN. 7 Affordable and Clean Energy, Goal 7- Ensure Access To Affordable, Reliable, Sustainable and Modern Energy. 2019. Available online: https://www.un.org/en/chronicle/article/goal-7-ensure-access-affordable-reliable-sustainable-and-modern-energy-all (accessed on 6 December 2019).

- Demirbas, A. Sustainable charcoal production and charcoal briquetting. Energy Sources Part A 2009, 31, 1694–1699. [Google Scholar] [CrossRef]

- Oyebanji, J.A.; Oyedepo, S.O. Compositional and experimental investigation of the effect of reactor temperature on softwood and hardwood pyrolysis. World J. Eng. 2018, 15, 21–26. [Google Scholar] [CrossRef]

- Canal, W.D.; Carvalho, A.M.M.; Figueiró, C.G.; Carneiro, A.D.C.O.; Fialho, L.D.F.; Donato, D.B. Impact of wood moisture in charcoal production and quality. Floresta E Ambient. 2020, 27, 1–7. [Google Scholar] [CrossRef]

- Antal, M.J.; Grønli, M. The art, science, and technology of charcoal production. Ind. Eng. Chem. Res. 2003, 42, 1619–1640. [Google Scholar] [CrossRef]

- Oaks, R. Making Charcoal and Biochar A Comprehensive Guide. Ramsbury, Marlborough Wiltshire SN8 2HR. 2018. Available online: http://www.crowood.com (accessed on 12 October 2022).

- Jelonek, Z.; Drobniak, A.; Mastalerz, M.; Jelonek, I. Environmental implications of the quality of charcoal briquettes and lump charcoal used for grilling. Sci. Total Environ. 2020, 747, 25. [Google Scholar] [CrossRef] [PubMed]

- Nabukalu, C.; Gieré, R. Charcoal as an energy resource: Global trade, production and socioeconomic practices observed in Uganda. Resources 2019, 8, 183. [Google Scholar] [CrossRef]

- Sangsuk, S.; Buathong, C.; Suebsiri, S. High-energy conversion efficiency of drum kiln with heat distribution pipe for charcoal and biochar production. Energy Sustain. Dev. 2020, 59, 1–7. [Google Scholar] [CrossRef]

- Francisco, A.; Junior, D.; Pompeu, R.; Álison, E.; Aécio, S.; Sousa, D. Investigating the pyrolysis temperature to define the use of charcoal. Eur. J. Wood Wood Prod. 2020, 78, 193–204. [Google Scholar] [CrossRef]

- FAO. The Charcoal Transition: Greening The Charcoal Value Chain To Mitigate Climate Change And Improve Local Livelihoods; FAO: Rome, Italy, 2017. [Google Scholar]

- Arias-Chalico, T. Situación Actual Y Escenarios Para El Desarrollo De Biocombustibles Sólidos En México Hacia 2024 Y 2030. 2018. Available online: http://rembio.org.mx/newsite/wp-content/uploads/2020/11/Situacion-actual-y-escenarios-para-el-desarrollo-de-biocombustibles-solidos-en-Mexico.pdf (accessed on 22 January 2022).

- Surup, G.R.; Trubetskaya, A.; Tangstad, M. Charcoal as an alternative reductant in ferroalloy production: A review. Processes 2020, 8, 1432. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Rodrigues, T.; Junior, A.B. Charcoal: A discussion on carbonization kilns. J. Anal. Appl. Pyrolysis 2019, 143, 16. [Google Scholar] [CrossRef]

- Freddy, Z.J.; Joseph, Z.M.; Benoit, N.; Evariste, F.F.; Ruben, M.; Maximilien, N.; Bernard, B.A. Physicochemical and hygroscopic properties of charcoals produced from residues of two tropical woods from Cameroon. Int. J. Coal Prep. Util. 2022, 1–24. [Google Scholar] [CrossRef]

- Arias-Chalico, T. Carbón Vegetal en México Consumo, Mercados y Productores. Naturaleza y Desarrollo NYDE AC. Available online: https://kipdf.com/carbon-vegetal-en-mexico_5ae745e67f8b9a18528b45c6.html (accessed on 15 February 2022).

- Kajina, W.; Junpen, A.; Garivait, S.; Kamnoet, O.; Keeratiisariyakul, P.; Rousset, P. Charcoal production processes: An overview. J. Sustain. Energy Environ. 2019, 10, 19–25. [Google Scholar]

- FAO. Métodos Simples Para Fabricar Carbón Vegetal. 1983. Available online: http://www.fao.org/docrep/x5328s/x5328s00.htm (accessed on 1 March 2022).

- Bustamante-García, V.; Carrillo-Parra, A.; González-Rodríguez, H.; Ramírez-Lozano, R.; Corral-Rivas, J.; Garza-Ocañas, F. Evaluation of a charcoal production process from forest residues of Quercus sideroxyla Humb., & Bonpl. in a Brazilian beehive kiln. Ind. Crop. Prod. 2013, 42, 169–174. [Google Scholar] [CrossRef]

- Carrillo-Parra, A.; Foroughbakhch-Pournavab, R.; Bustamante-García, V. Calidad del carbón de Prosopis laevigata (Humb. & Bonpl. ex Willd.) M.C. Johnst. y Ebenopsis ebano (Berland.) Bar-neby & J.W. Grimes elaborado en horno tipo fosa. Rev. mex. de cienc. Forestales 2013, 62–71. Available online: https://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S2007-11322013000300007 (accessed on 5 February 2022).

- Ngangyo-Heya, M.; Foroughbahchk-Pournavab, R.; Carrillo-Parra, A.; Rutiaga-Quiñones, J.G.; Zelinski, V.; Pintor-Ibarra, L.F. Calorific value and chemical composition of five semi-arid mexican tree species. Forests 2016, 7, 58. [Google Scholar] [CrossRef]

- Petrović, S.; Glavonjic, B. Standards and Certificates for Charcoal and Charcoal Briquettes in the Function of Harmonization of their Quality and Market Development. In Proceedings of the Development Trends in Economic and Management in Wood Processing and Furniture Manufacturing, Kozina, Slovenia, 9 June 2011; Faculty of Forestry University of Belgrade: Beograd, Serbia, 2011. Available online: https://www.researchgate.net/publication/352120554_STANDARDS_AND_CERTIFICATES_FOR_CHARCOAL_AND_CHARCOAL_BRIQUETTES_IN_THE_FUNCTION_OF_HARMONIZATION_OF_THEIR_QUALITY_AND_MARKET_DEVELOPMENT (accessed on 1 December 2022).

- FAO. Industrial Charcoal Making-Quality Contrôle of Charcoal and by Products. 1985. Available online: http://www.fao.org/3/x5555e/x5555e.pdf (accessed on 3 March 2022).

- García-Quezada, J.; Musule-Lagunes, R.; Carrillo-Ávila, N.; Carrillo-Parra, A. Tipo de hornos para la producción de carbón vegetal en México. In Optimización De Los Procesos De Extracción De Biomasa Sólida Para Uso Energético, 1st ed.; Programa Iberoamericano De Ciencia Y Tecnología Para El Desarrollo (CYTED): Cambridge, UK, 2021; Volume 1, pp. 293–321. [Google Scholar]

- De la Cruz-Montelongo, C.; Gamboa, J.H.; Sánchez, I.A.O.; Saucedo, J.C.R.; Serna, R.R.; Carrillo-Parra, A. Caracterización energética del carbón vegetal producido en el Norte-Centro de México. Madera Y Bosques 2020, 26, 13. [Google Scholar] [CrossRef]

- Manals, E.; Penedo, M.; Giralt, G. Análisis termogravimetrico y térmico diferencial de diferentes biomasas vegetales. Tecnol. Química vol. 2011, 31, 180–190. [Google Scholar]

- Oliveira, A.C.; Carneiro, A.D.C.O.; Pereira, B.L.C.; Vital, B.R.; Carvalho, A.M.M.L.; Trugilho, P.F.; Damásio, R.A.P. Otimização da produção do carvão vegetal por meio do controle de temperaturas de carbonização. Rev. Árvore 2013, 3, 557–566. [Google Scholar] [CrossRef]

- Vilela, A.D.O.; Lora, E.S.; Quintero, Q.R.; Vicintin, R.A.; Souza, T.P.D.S.E. A new technology for the combined production of charcoal and electricity through cogeneration. Biomass Bioenergy 2014, 69, 222–240. [Google Scholar] [CrossRef]

- Montoya, J.I.; Colombiano, I. Pirólisis Rápida De Biomasa; Universidad Nacional de Colombia: Bogotá, Colombia, 2014. [Google Scholar]

- Wang, S.; Luo, Z. Biomass components and characteristics. In Pyrolysis of Biomass; Walter de Gruyter: Berlin, Germany, 2016; p. 32. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A comprehensive review on the pyrolysis of lignocellulosic biomass. Renew. Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Pereira, E.G.; Fauller, H.; Magalhães, M.; Guirardi, B.; Martins, M.A. Potential use of wood pyrolysis coproducts: A review. Environ. Prog. Sustain. Energy 2022, 41, e13705. [Google Scholar] [CrossRef]

- Elyounssia, K.; Blinb, J.; Halim, M. High-yield charcoal production by two-step pyrolysis. J. Anal. Appl. Pyrolysis 2010, 87, 138–143. [Google Scholar] [CrossRef]

- ASTM. Standard Test Method for Chemical Analysis of Wood Charcoal. 2021, pp. 1–2. Available online: https://www.astm.org/d1762-84r21.html (accessed on 1 September 2022).

- Basu, P.; Rao, S.; Dhungana, A. An investigation into the effect of biomass particle size on its torrefaction. Can. J. Chem. Eng. 2013, 91, 466–474. [Google Scholar] [CrossRef]

- UNE-EN 18125; Biocombustibles Sólidos Determinación Del Poder Calorífico. INTECO: Bruck, Austria, 2018.

- Lê, S.; Josse, J.; Rennes, A.; Husson, F. FactoMineR: An R Package for Multivariate Analysis. 2008. Available online: http://www.jstatsoft.org/ (accessed on 11 February 2022).

- Pyshyev, S.; Miroshnichenko, D.; Malik, I.; Contreras, A.B.; Hassan, N.; ElRasoul, A.A.; Carbosur, C.M.F. State of the art in the production of charcoal: A review. Chem. Chem. Technol. 2021, 15, 61–73. [Google Scholar] [CrossRef]

- Chen, W.; Chen, Y.; Yang, H.; Li, K.; Chen, X.; Chen, H. Investigation on biomass nitrogen-enriched pyrolysis: Influence of temperature. Bioresour. Technol. 2018, 249, 247–253. [Google Scholar] [CrossRef]

- Stefanidis, S.D.; Kalogiannis, K.G.; Iliopoulou, E.F.; Michailof, C.M.; Pilavachi, P.A.; Lappas, A.A. A study of lignocellulosic biomass pyrolysis via the pyrolysis of cellulose, hemicellulose and lignin. J. Anal. Appl. Pyrolysis 2014, 105, 143–150. [Google Scholar] [CrossRef]

- Basile, L.; Tugnoli, A.; Cozzani, V. Influence of macrocomponents on the pyrolysis heat demand of lignocellulosic biomass. Ind. Eng. Chem. Res. 2017, 56, 6432–6440. [Google Scholar] [CrossRef]

- Rodrigues, T.; Junior, A.B. Technological prospecting in the production of charcoal: A patent study. Renew. Sustain. Energy Rev. 2019, 111, 170–183. [Google Scholar] [CrossRef]

- Arias-Chalico, T. Manual De Operación Del Horno De Ladrillos Con 8 A 12 Chimeneas Metálicas Para Leña De Encino; Naturaleza y Desarrollo A.C. pp. 1–7. Available online: http://nyde.org.mx/wp-content/uploads/MANUAL-DE-OPERACION-DEL-HORNO-RABO-QUENTE-con-8-a-12-CHIMENEAS.pdf (accessed on 6 December 2022).

- Massuque, J.; De Assis, M.R.; Loureiro, B.A.; Matavel, C.E.; Trugilho, P.F. Influence of lignin on wood carbonization and charcoal properties of Miombo woodland native species. Eur. J. Wood Wood Prod. 2021, 79, 527–535. [Google Scholar] [CrossRef]

- De Abreu Neto, R.; De Assis, A.A.; Ballarin, A.W.; Hein, P.R.G. Effect of final temperature on charcoal stiffness and its correlation with wood density and hardness. SN Appl. Sci. 2020, 2, 1020. [Google Scholar] [CrossRef]

- Bailis, R.; Rujanavech, C.; Dwivedi, P.; Vilela, A.D.O.; Chang, H.; de Miranda, R.C. Innovation in charcoal production: A comparative life-cycle assessment of two kiln technologies in Brazil. Energy Sustain. Dev. 2013, 17, 189–200. [Google Scholar] [CrossRef]

- UNE-EN 1860-2; Aparatos, Combustibles Sólidos Y Sustancias De Encendido Para El Asado En Barbacoas. INTECO: Bruck, Austria, 2005.

- Costa, A.; Ramalho, F.; Costa, L.; Trugilho, P.; Hein, P. Classification of commercial charcoal for domestic use by near infrared spectroscopy. Biomass Bioenergy 2019, 127, 105280. [Google Scholar] [CrossRef]

- Missio, A.L.; Mattos, B.D.; Gatto, D.A.; De Lima, E.A. Thermal Analysis of Charcoal from Fast-Growing Eucalypt Wood: Influence of Raw Material Moisture Content. J. Wood Chem. Technol. 2014, 34, 191–201. [Google Scholar] [CrossRef]

- Lima, M.D.R.; Patrício, E.P.S.; Junior, U.D.O.B.; de Assis, M.R.; Xavier, C.N.; Bufalino, L.; Trugilho, P.F.; Hein, P.R.G.; Protásio, T.D.P. Logging wastes from sustainable forest management as alternative fuels for thermochemical conversion systems in Brazilian Amazon. Biomass Bioenergy 2020, 140, 105660. [Google Scholar] [CrossRef]

| Kiln Type | Total Capacity (m3) | Coordenates Latitude and Longitude (°) | State | Community | Firewood Species |

|---|---|---|---|---|---|

| Brazilian beehive | 40.00 | 23.7147–105.0670 | Durango | El Encinal | Arbutus xalapensis (Madrone), Quercus durifolia (white oak) y Quercus sideroxyla (red oak) |

| Modified Brazilian beehive | 12.00 | 18.9338–104.0082 | Colima | Ciudad de Armería | Pithecellobium dulce (Guamúchil) y Tamarindus indica (Tamarindo) |

| Argentine half-orange | 16.00 | 19.9288–103.4382 | Jalisco | Unión de Guadalupe | Quercus magnoliifolia (white oak) y Quercus sideroxyla (red oak) |

| Industrial metal | 5.20 | 19.0735–88.8074 | Quintana Roo | 18 de Marzo | Brosimum alicastrum (Ramón), Vitex gaumeri (Yaxnic), Manilkara zapota (Zapote), Pouteria unilocularis (Zapotillo) |

| Species | Biomass Origin | Cellulose (%) | Hemicellulose (%) | Lignin (%) | Moisture Content (%) |

|---|---|---|---|---|---|

| Madrone | Durango | 52.92 ± 1.45 | 14.11 ± 1.98 | 20.41 ± 0.94 | 34.05 ± 14.21 |

| White oak | 44.34 ± 1.91 | 16.16 ± 2.64 | 19.58 ± 1.08 | 50.40 ± 5.03 | |

| Red oak | 47.55 ± 1.86 | 16.29 ± 1.12 | 19.82 ± 1.30 | 43.86 ± 8.85 | |

| Guamúchil | Colima | 57.40 ± 4.05 | 10.69 ± 1.34 | 22.44 ± 0.68 | 91.97 ± 3.22 |

| Tamarindo | 60.78 ± 2.22 | 11.52 ± 1.47 | 19.58 ± 0.72 | 22.13 ± 6.56 | |

| White oak | Jalisco | 59.98 ± 0.45 | 13.30 ± 0.52 | 17.79 ± 1.08 | 34.60 ± 9.27 |

| Red oak | 54.75 ± 3.47 | 14.06 ± 1.33 | 20.79 ± 1.93 | 37.34 ± 6.13 | |

| Ramón | Chetumal | 64.55 ± 0.39 | 8.44 ± 0.34 | 22.62 ± 0.77 | 10.75 ± 1.23 |

| Yaxnic | 64.03 ± 0.88 | 5.55 ± 0.46 | 22.90 ± 1.01 | 11.55 ± 1.00 | |

| Zapote | 60.59 ± 0.93 | 12.16 ± 0.31 | 21.69 ± 1.23 | 12.46 ± 2.30 | |

| Zapotillo | 63.60 ± 1.39 | 8.23 ± 1.32 | 23.84 ± 0.91 | 11.16 ± 0.74 |

| Burn | Phase 1 | Phase 2 | Phase 3 | Phase 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Time | R | Time | R | Time | R | Time | R | |

| 1 | 38 | 0.04 | 22 | 0.08 | 10 | 0.13 | 48 | 0.06 |

| 2 | 93 | 0.02 | 28 | 0.06 | 23 | 0.06 | 27 | 0.15 |

| 3 | 48 | 0.03 | 23 | 0.07 | 17 | 0.08 | 40 | 0.13 |

| Burn | Phase 1 | Phase 2 | Phase 3 | Phase 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Time | R | Time | R | Time | R | Time | R | |

| 1 | 66 | 0.02 | 54 | 0.03 | 10 | 0.13 | 39 | 0.07 |

| 2 | 4 | 0.32 | 22 | 0.08 | 13 | 0.10 | 28 | 0.20 |

| 3 | 4 | 0.32 | 61 | 0.03 | 2 | 0.67 | 27 | 0.20 |

| Burn | Phase 1 | Phase 2 | Phase 3 | Phase 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Time | R | Time | R | Time | R | Time | R | |

| 1 | 10 | 0.13 | 43 | 0.04 | 3 | 0.44 | 13 | 0.22 |

| 2 | 9 | 0.14 | 19 | 0.09 | 2 | 0.67 | 73 | 0.08 |

| 3 | 22 | 0.06 | 10 | 0.17 | 11 | 0.12 | 34 | 0.03 |

| Burn | Phase 1 | Phase 2 | Phase 3 | Phase 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Time | R | Time | R | Time | R | Time | R | |

| 1 | 3 | 0.56 | 3 | 0.56 | 2 | 0.67 | 3 | 0.62 |

| 2 | 1 | 1.67 | 4 | 0.42 | 2 | 0.67 | 1 | 0.50 |

| 3 | 1 | 1.67 | 4 | 0.42 | 2 | 0.67 | 5 | 0.93 |

| BURN | SPECIE | MC | VM | FC | ASH |

|---|---|---|---|---|---|

| 1 | Madrone | 1.98 ± 0.26 ab | 20.68 ± 2.15 a | 75.47 ± 2.20 b | 1.57 ± 0.45 e |

| White oak | 2.08 ± 0.12 c | 20.62 ± 1.86 a | 74.82 ± 2.00 b | 2.49 ± 0.16 bc | |

| Red oak | 1.95 ± 0.09 cd | 17.58 ± 0.56 b | 78.15 ± 0.43 a | 2.33 ± 0.09 cd | |

| 2 | Madrone | 1.69 ± 0.29 d | 21.67 ± 6.69 a | 74.76 ± 7.00 b | 1.88 ± 0.57 de |

| White oak | 2.68 ± 0.17 a | 18.76 ± 5.65 a | 75.76 ± 5.16 b | 2.80 ± 1.22 bc | |

| Red oak | 2.03 ± 0.38 c | 16.44 ± 8.45 ab | 77.26 ± 8.25 b | 4.27 ± 0.72 a | |

| 3 | Madrone | 2.49 ± 0.34 ab | 20.95 ± 2.15 a | 74.48 ± 2.59 b | 2.08 ± 0.25 de |

| White oak | 2.67 ± 0.15 ab | 20.45 ± 0.72 a | 74.35 ± 0.77 b | 2.53 ± 0.10 b | |

| Red oak | 2.44 ± 0.19 b | 20.10 ± 0.24 a | 75.11 ± 0.61 b | 2.35 ± 0.47 cd |

| BURN | SPECIE | MC | VM | FC | ASH |

|---|---|---|---|---|---|

| 1 | Guamúchil | 2.01 ± 0.21 c | 16.62 ± 1.10 a | 74.47 ± 1.76 c | 6.89 ± 0.87 a |

| Tamarindo | 1.98 ± 0.08 c | 16.71 ± 0.71 a | 76.43 ± 1.18 c | 4.88 ± 0.95 b | |

| 2 | Guamúchil | 7.33 ± 1.10 a | 7.88 ± 0.67 d | 74.38 ± 5.38 c | 10.41 ± 3.83 a |

| Tamarindo | 3.46 ± 0.93 b | 9.48 ± 3.58 bc | 81.61 ± 3.58 b | 5.46 ± 1.14 b | |

| 3 | Guamúchil | 0.89 ± 0.07 d | 10.60 ± 0.50 b | 80.40 ± 1.26 b | 8.10 ± 1.16 a |

| Tamarindo | 0.69 ± 0.06 e | 9.70 ± 0.57 c | 84.21 ± 0.94 a | 5.40 ± 0.68 b |

| BURN | SPECIE | MC | VM | CF | ASH |

|---|---|---|---|---|---|

| 1 | White oak | 1.50 ± 0.59 b | 20.79 ± 10.00 ab | 73.66 ± 9.68 bc | 4.03 ± 0.95 bc |

| Red oak | 2.00 ± 0.28 a | 25.14 ± 0.39 a | 69.53 ± 0.44 c | 3.30 ± 0.76 c | |

| 2 | White oak | 1.53 ± 0.40 bc | 19.18 ± 5.90 b | 75.16 ± 6.44 b | 4.14 ± 1.12 b |

| Red oak | 1.04 ± 0.14 c | 10.20 ± 2.45 c | 82.12 ± 1.84 a | 6.62 ± 1.49 a | |

| 3 | White oak | 1.99 ± 0.99 a | 22.08 ± 0.43 b | 72.24 ± 0.67 bc | 3.74 ± 0.36 bc |

| Red oak | 1.94 ± 0.05 a | 22.02 ± 0.95 b | 71.99 ± 1.55 b | 4.03 ± 0.82 b |

| BURN | SPECIE | MC | VM | FC | ASH |

|---|---|---|---|---|---|

| 1 | Ramón | 2.17 ± 0.22 bcd | 32.71 ± 4.42 a | 61.39 ± 4.39 hi | 3.73 ± 0.55 ef |

| Yaxnic | 1.85 ± 0.34 d | 22.66 ± 2.68 efg | 70.56 ± 2.02 c | 4.93 ± 1.65 bc | |

| Zapote | 1.91 ± 0.08 d | 28.94 ± 2.80 bc | 64.39 ± 3.35 fgh | 4.76 ± 0.53 bcde | |

| Zapotillo | 2.12 ± 0.04 bcd | 31.43 ± 2.24 ab | 61.30 ± 1.66 i | 5.15 ± 0.83 bc | |

| 2 | Ramón | 2.04 ± 0.26 cd | 31.22 ± 2.59 ab | 63.55 ± 2.21 ghi | 3.18 ± 0.69 fg |

| Yaxnic | 2.40 ± 0.25 b | 26.57 ± 2.33 d | 66.39 ± 3.60 ef | 4.64 ± 1.69 bcd | |

| Zapote | 2.41 ± 0.13 b | 27.97 ± 2.04 cd | 65.23 ± 3.60 efg | 4.38 ± 1.70 cde | |

| Zapotillo | 2.12 ± 0.20 bcd | 23.40 ± 2.01 e | 67.75 ± 1.54 de | 6.73 ± 0.63 a | |

| 3 | Ramón | 1.52 ± 0.11 e | 11.13 ± 0.87 h | 79.20 ± 0.59 a | 8.15 ± 1.25 a |

| Yaxnic | 2.79 ± 0.09 a | 21.57 ± 1.44 fg | 72.83 ± 0.89 ab | 2.81 ± 0.80 g | |

| Zapote | 2.36 ± 0.18 bc | 23.45 ± 2.87 ef | 68.91 ± 2.95 cd | 5.28 ± 0.91 b | |

| Zapotillo | 2.88 ± 0.30 a | 20.57 ± 0.76 g | 72.52 ± 0.63 b | 4.03 ± 0.16 de |

| KILN TYPE | BURN | SPECIE | HHV | MINIMUM HHV | MAXIMUM HHV |

|---|---|---|---|---|---|

| Brazilian beehive | 1 | White oak | 30.64 ± 0.08 gh | 30.55 | 30.70 |

| 2 | 30.61 ± 0.23 gh | 30.44 | 30.88 | ||

| 3 | 31.33 ± 0.52 ef | 30.74 | 31.69 | ||

| 1 | Red oak | 31.81 ± 0.12 cd | 31.67 | 31.89 | |

| 2 | 33.09 ± 0.22 a | 32.85 | 33.26 | ||

| 3 | 31.92 ± 0.40 cd | 31.53 | 32.32 | ||

| 1 | Madrone | 30.80 ± 0.21 g | 31.67 | 31.03 | |

| 2 | 32.89 ± 0.22 ab | 32.85 | 33.12 | ||

| 3 | 32.05 ± 0.28 bc | 31.53 | 32.35 | ||

| Modified Brazilian beehive | 1 | Guamúchil | 29.08 ± 0.24 jk | 28.82 | 29.28 |

| 2 | 27.07 ± 0.25 mn | 26.79 | 27.27 | ||

| 3 | 30.07 ± 0.14 i | 29.95 | 30.23 | ||

| 1 | Tamarindo | 29.29 ± 0.14 j | 29.15 | 29.43 | |

| 2 | 31.41 ± 0.13 f | 31.32 | 31.55 | ||

| 3 | 31.68 ± 0.04 de | 31.65 | 31.72 | ||

| Metallic industrial | 1 | Ramón | 29.10 ± 0.21 jk | 28.86 | 29.26 |

| 2 | 27.87 ± 0.21 lm | 27.63 | 28.01 | ||

| 3 | 31.36 ± 0.20 f | 31.23 | 31.59 | ||

| 1 | Yaxnic | 30.48 ± 0.18 hi | 30.31 | 30.66 | |

| 2 | 30.40 ± 0.29 hi | 30.17 | 30.72 | ||

| 3 | 30.56 ± 0.50 gh | 30.00 | 30.97 | ||

| 1 | Zapote | 23.89 ± 0.16 opq | 23.75 | 24.06 | |

| 2 | 25.88 ± 0.61 mno | 25.30 | 26.51 | ||

| 3 | 22.41 ± 0.18 q | 22.20 | 22.55 | ||

| 1 | Zapotillo | 23.47 ± 0.33 pq | 23.12 | 23.78 | |

| 2 | 24.03 ± 0.19 op | 23.84 | 24.21 | ||

| 3 | 25.35 ± 0.18 no | 25.15 | 25.51 | ||

| Argentinian half-orange | 1 | White oak | 31.67 ± 0.16 def | 31.53 | 31.84 |

| 2 | 32.26 ± 0.27 abc | 31.96 | 32.47 | ||

| 3 | 29.11 ± 0.31 j | 28.76 | 29.30 | ||

| 1 | Red oak | 29.31 ± 0.24 j | 29.12 | 29.58 | |

| 2 | 29.21 ± 0.10 j | 29.13 | 29.32 | ||

| 3 | 28.77 ± 0.35 kl | 28.36 | 28.99 |

| Variable | MC | VM | ASH | FC | HHV | YIELD | MCB | Stage1 | Stage2 | Stage3 | Stage4 | HEM | CEL | LIG |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MC | 1 | 0.12 | −0.18 | −0.3 | −0.21 | 0.23 | −0.061 | 0.12 | 0.21 | −0.27 | 0.21 | −0.088 | −0.005 | 0.2 |

| VM | 0.12 | 1 | −0.31 | −0.9 | −0.47 | 0.76 | −0.51 | 0.4 | 0.63 | 0.35 | 0.38 | −0.26 | 0.35 | 0.4 |

| ASH | −0.18 | −0.31 | 1 | 0.073 | −0.42 | −0.37 | −0.11 | 0.42 | 0.11 | 0.45 | 0.33 | −0.57 | 0.47 | 0.35 |

| FC | −0.3 | −0.9 | 0.073 | 1 | 0.66 | −0.76 | 0.47 | −0.49 | −0.65 | −0.36 | −0.47 | 0.42 | −0.43 | −0.53 |

| HHV | −0.21 | −0.47 | −0.42 | 0.66 | 1 | −0.5 | 0.27 | −0.54 | −0.53 | −0.49 | −0.38 | 0.53 | −0.44 | −0.59 |

| YIELD | 0.23 | 0.76 | −0.37 | −0.76 | −0.5 | 1 | −0.64 | 0.55 | 0.8 | 0.47 | 0.61 | −0.26 | 0.37 | 0.46 |

| MCB | −0.061 | −0.51 | −0.11 | 0.47 | 0.27 | −0.64 | 1 | −0.63 | −0.65 | −0.55 | −0.61 | 0.51 | −0.71 | −0.47 |

| Stage1 | 0.12 | 0.4 | 0.42 | −0.49 | −0.54 | 0.55 | −0.63 | 1 | 0.74 | 0.83 | 0.79 | −0.76 | 0.8 | 0.68 |

| Stage2 | 0.21 | 0.63 | 0.11 | −0.65 | −0.53 | 0.8 | −0.65 | 0.74 | 1 | 0.58 | 0.57 | −0.52 | 0.61 | 0.61 |

| Stage3 | −0.27 | 0.35 | 0.45 | −0.36 | −0.49 | 0.47 | −0.55 | 0.83 | 0.58 | 1 | 0.62 | −0.71 | 0.75 | 0.58 |

| Stage4 | 0.21 | 0.38 | 0.33 | −0.47 | −0.38 | 0.61 | −0.61 | 0.79 | 0.57 | 0.62 | 1 | −0.68 | 0.71 | 0.68 |

| HEM | −0.088 | −0.26 | −0.57 | 0.42 | 0.53 | −0.26 | 0.51 | −0.76 | −0.52 | −0.71 | −0.68 | 1 | −0.91 | −0.74 |

| CEL | −0.005 | 0.35 | 0.47 | −0.43 | −0.44 | 0.37 | −0.71 | 0.8 | 0.61 | 0.75 | 0.71 | −0.91 | 1 | 0.61 |

| LIG | 0.2 | 0.4 | 0.35 | −0.53 | −0.59 | 0.46 | −0.47 | 0.68 | 0.61 | 0.58 | 0.68 | −0.74 | 0.61 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Quezada, J.; Musule-Lagunes, R.; Prieto-Ruíz, J.A.; Vega-Nieva, D.J.; Carrillo-Parra, A. Evaluation of Four Types of Kilns Used to Produce Charcoal from Several Tree Species in Mexico. Energies 2023, 16, 333. https://doi.org/10.3390/en16010333

García-Quezada J, Musule-Lagunes R, Prieto-Ruíz JA, Vega-Nieva DJ, Carrillo-Parra A. Evaluation of Four Types of Kilns Used to Produce Charcoal from Several Tree Species in Mexico. Energies. 2023; 16(1):333. https://doi.org/10.3390/en16010333

Chicago/Turabian StyleGarcía-Quezada, Juan, Ricardo Musule-Lagunes, José Angel Prieto-Ruíz, Daniel José Vega-Nieva, and Artemio Carrillo-Parra. 2023. "Evaluation of Four Types of Kilns Used to Produce Charcoal from Several Tree Species in Mexico" Energies 16, no. 1: 333. https://doi.org/10.3390/en16010333

APA StyleGarcía-Quezada, J., Musule-Lagunes, R., Prieto-Ruíz, J. A., Vega-Nieva, D. J., & Carrillo-Parra, A. (2023). Evaluation of Four Types of Kilns Used to Produce Charcoal from Several Tree Species in Mexico. Energies, 16(1), 333. https://doi.org/10.3390/en16010333