Influence of Red Mud Catalyst and Reaction Atmosphere on Hydrothermal Liquefaction of Algae

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Feedstock Characterization

2.3. Catalyst Preparation

2.4. Catalyst Characterization

2.5. Experimental Setup and Procedure

2.6. Product Separation

2.7. Product Analysis

3. Results and Discussion

3.1. Feedstock Characterization

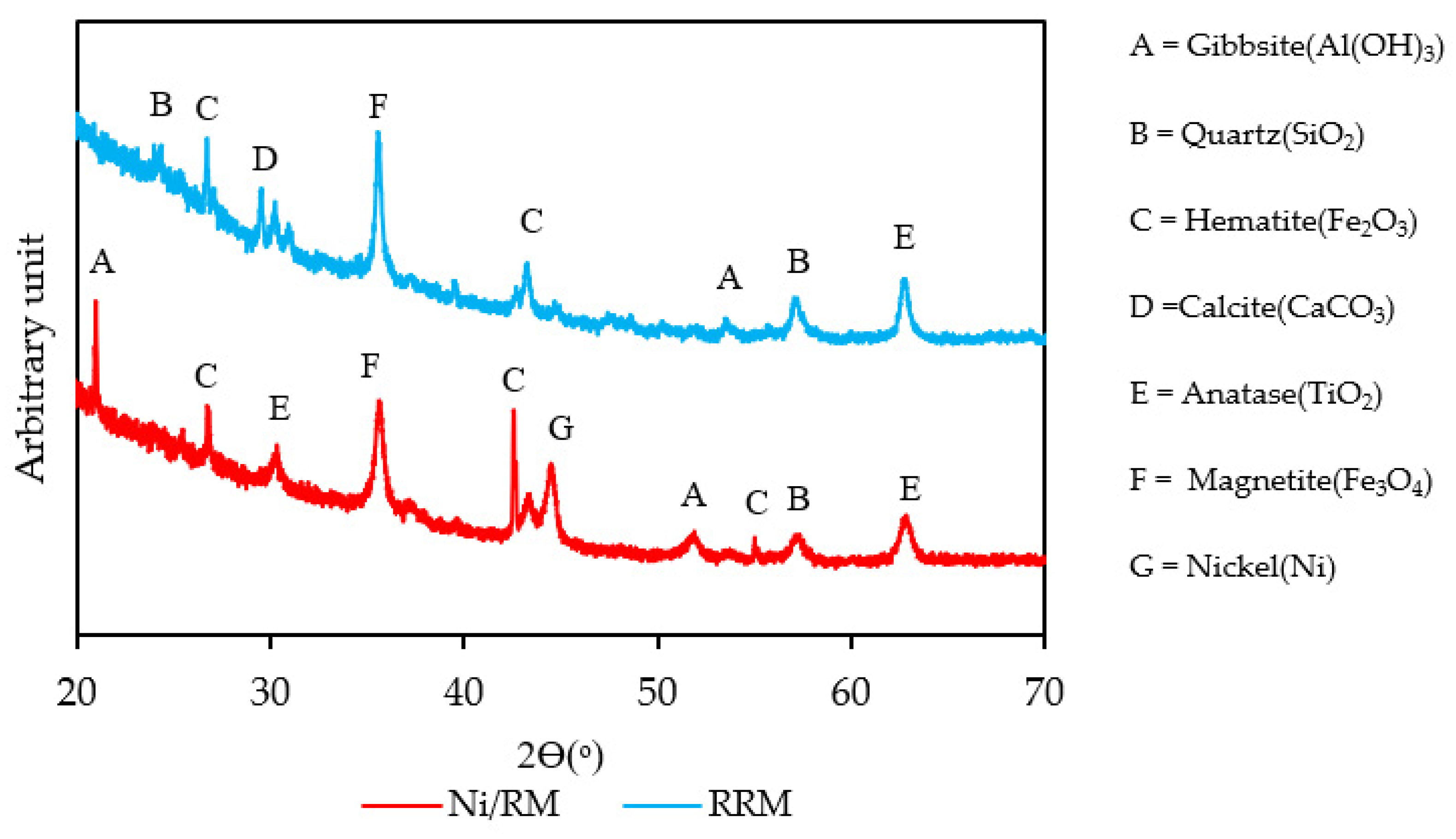

3.2. Catalyst Characterization

3.3. HTL Products Characterization

3.3.1. Products Yield Distribution

3.3.2. Biocrude Characterization

Physicochemical Properties

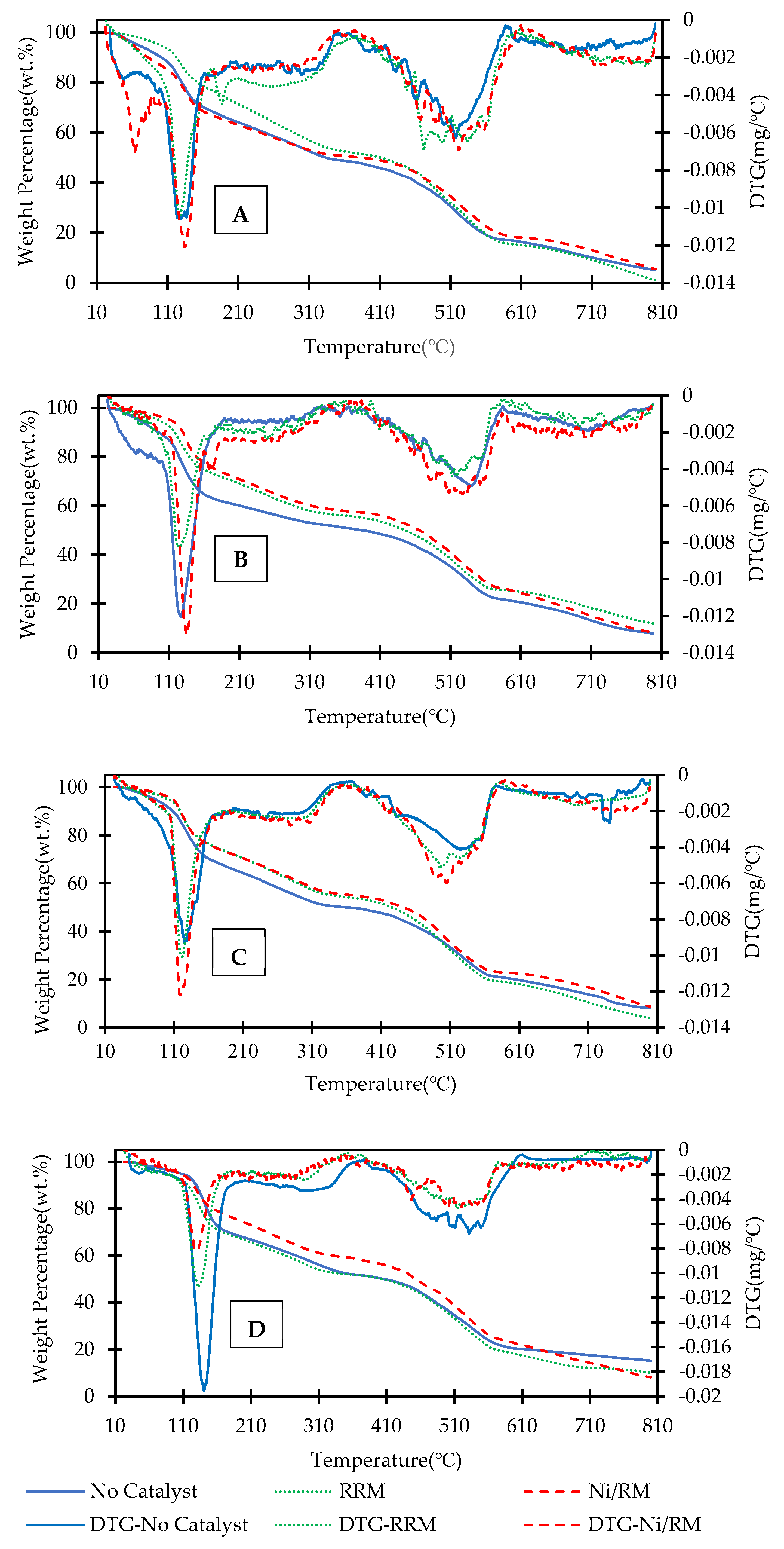

Thermogravimetric Analysis

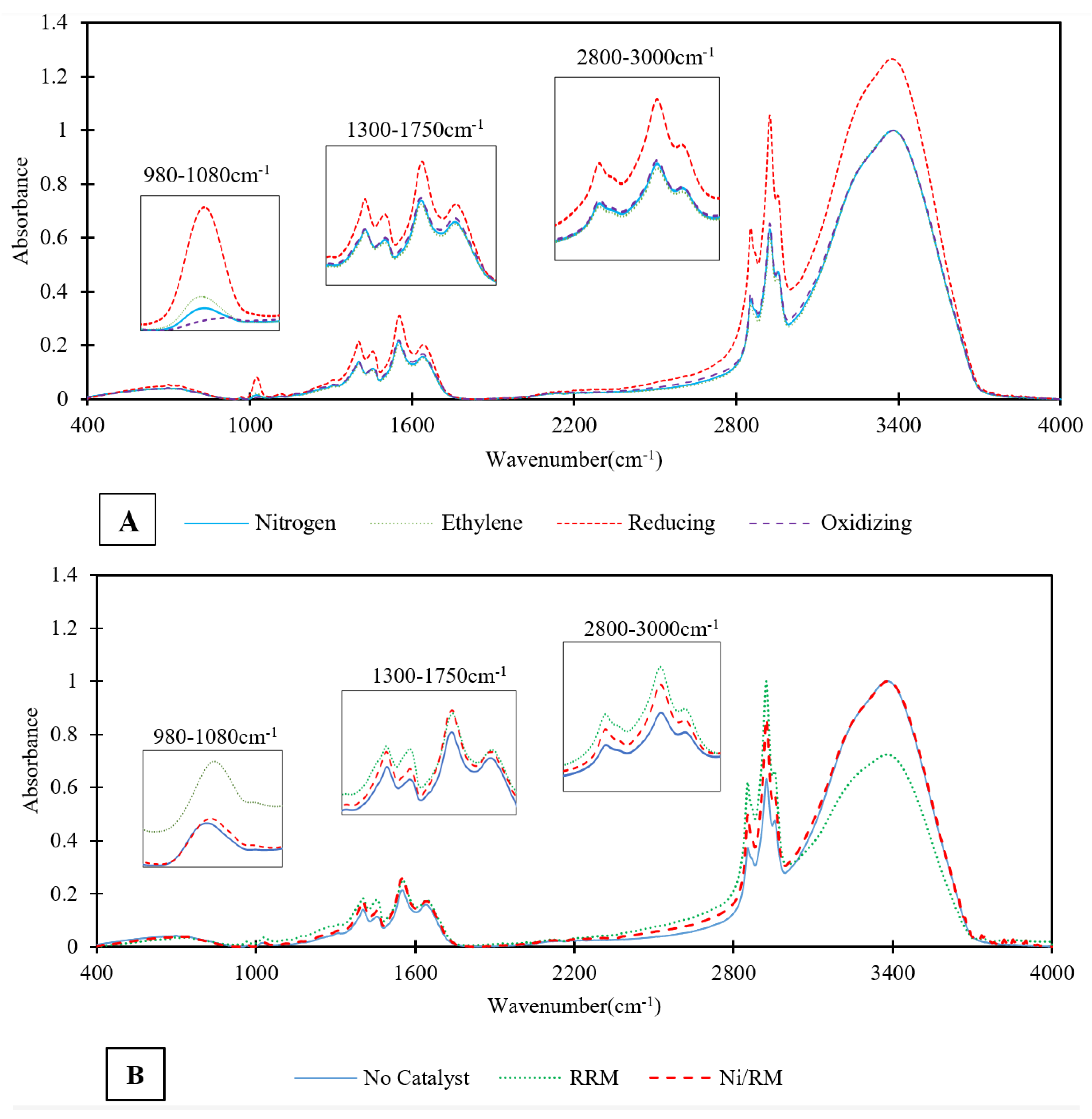

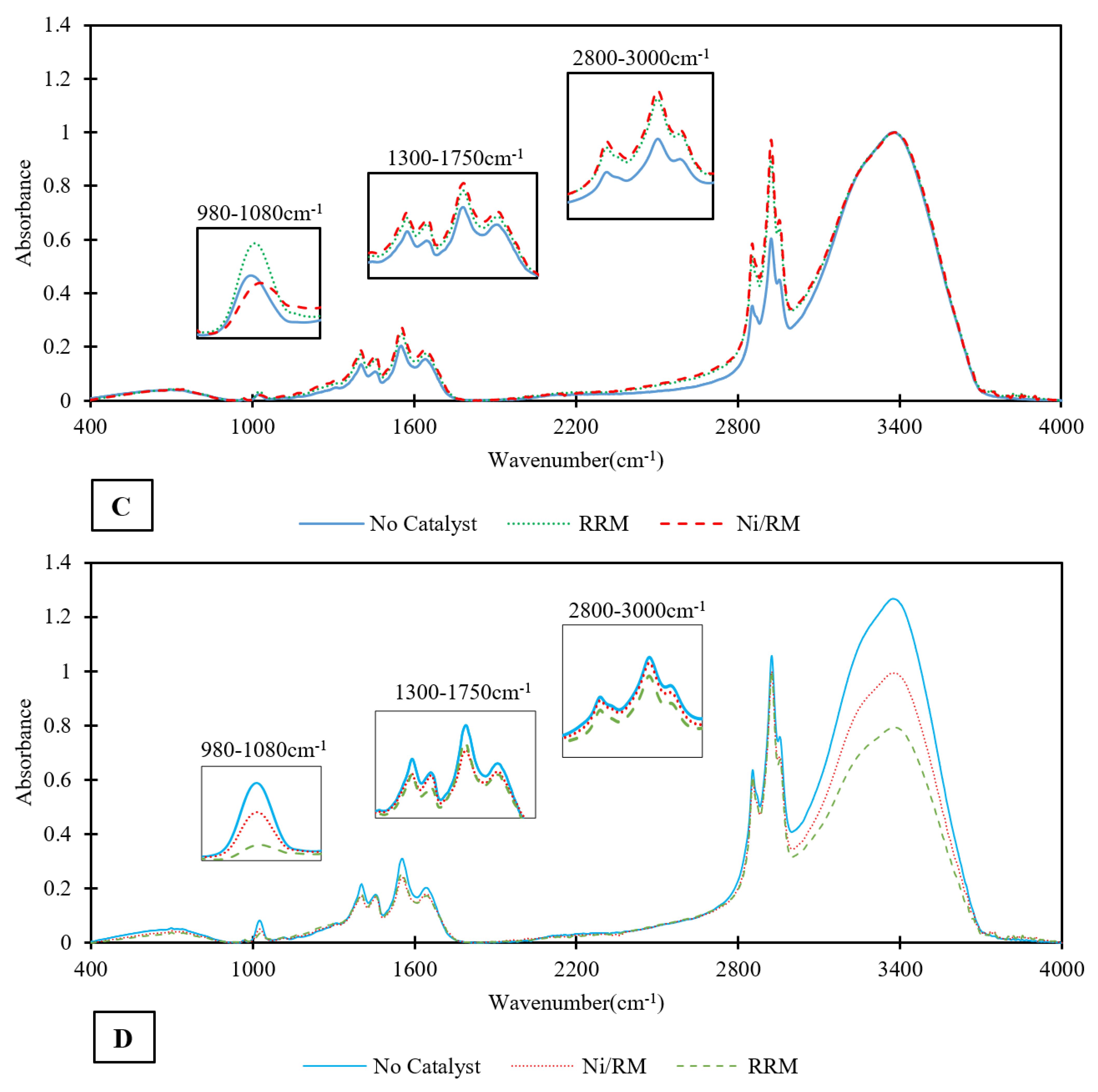

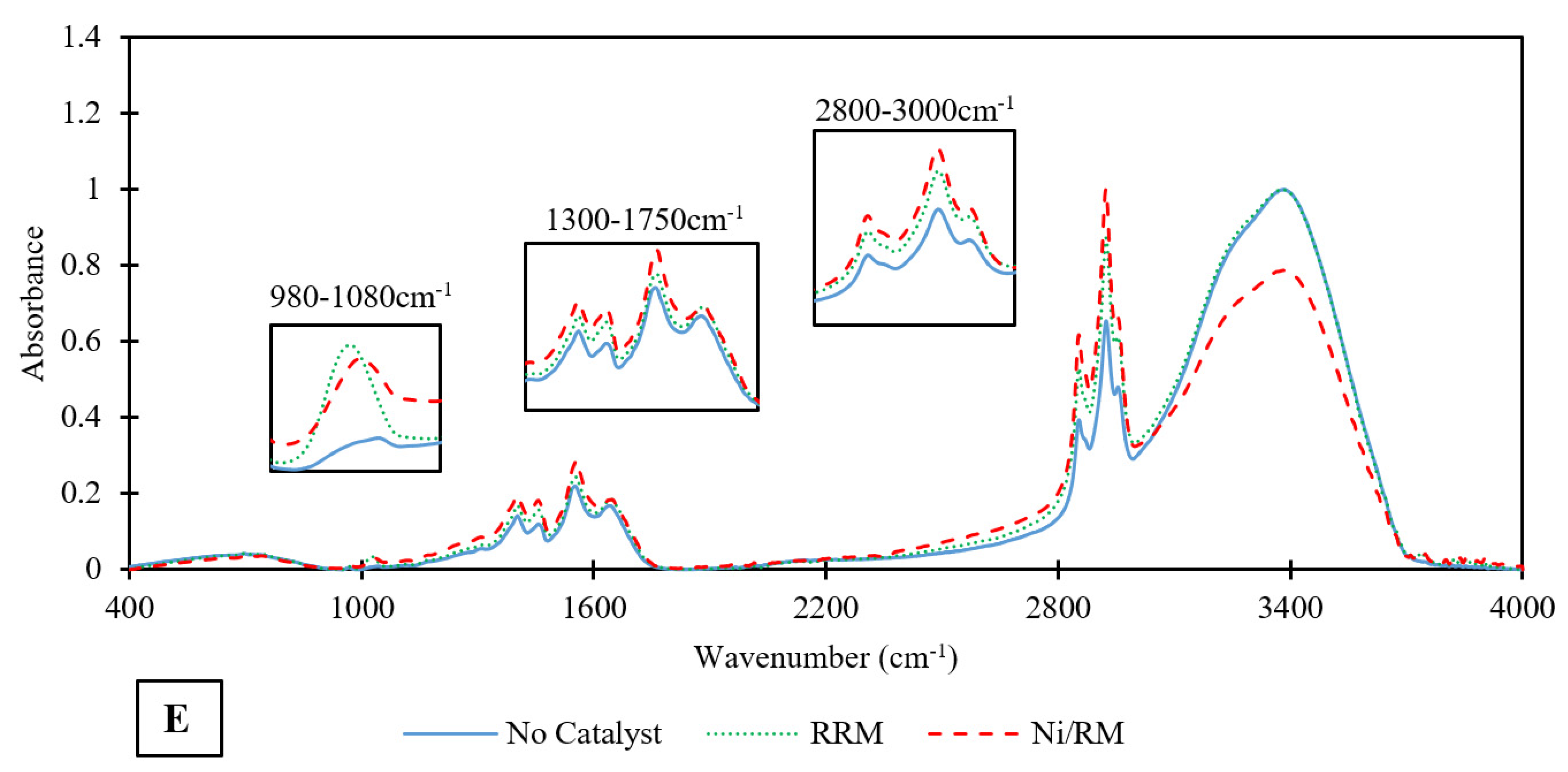

FTIR Analysis

NMR Analysis

GC-MS Analysis

3.3.3. Analysis of Byproducts

3.4. Carbon and Nitrogen Distribution

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Peterson, A.A.; Vogel, F.; Lachance, R.P.; Fröling, M.; Michael, J.; Antal, J.; Tester, J.W. Thermochemical Biofuel Production in Hydrothermal Media: A Review of Sub- and Supercritical Water Technologies. Energy Environ. Sci. 2008, 1, 32–65. [Google Scholar] [CrossRef]

- Elgarahy, A.M.; Hammad, A.; El-Sherif, D.M.; Abouzid, M.; Gaballah, M.S.; Elwakeel, K.Z. Thermochemical Conversion Strategies of Biomass to Biofuels, Techno-Economic and Bibliometric Analysis: A Conceptual Review. J. Environ. Chem. Eng. 2021, 9, 106503. [Google Scholar] [CrossRef]

- Baloch, H.A.; Nizamuddin, S.; Siddiqui, M.T.H.; Riaz, S.; Jatoi, A.S.; Dumbre, D.K.; Mubarak, N.M.; Srinivasan, M.P.; Griffin, G.J. Recent Advances in Production and Upgrading of Bio-Oil from Biomass: A Critical Overview. J. Environ. Chem. Eng. 2018, 6, 5101–5118. [Google Scholar] [CrossRef]

- Bi, Z.; Zhang, J.; Peterson, E.; Zhu, Z.; Xia, C.; Liang, Y.; Wiltowski, T. Biocrude from Pretreated Sorghum Bagasse through Catalytic Hydrothermal Liquefaction. Fuel 2017, 188, 112–120. [Google Scholar] [CrossRef]

- Watson, J.; Wang, T.; Si, B.; Chen, W.-T.; Aierzhati, A.; Zhang, Y. Valorization of Hydrothermal Liquefaction Aqueous Phase: Pathways towards Commercial Viability. Prog. Energy Combust. Sci. 2020, 77, 100819. [Google Scholar] [CrossRef]

- Shurin, J.B.; Abbott, R.L.; Deal, M.S.; Kwan, G.T.; Litchman, E.; McBride, R.C.; Mandal, S.; Smith, V.H. Industrial-Strength Ecology: Trade-Offs and Opportunities in Algal Biofuel Production. Ecol. Lett. 2013, 16, 1393–1404. [Google Scholar] [CrossRef] [Green Version]

- Wang, S.; Zhao, S.; Uzoejinwa, B.B.; Zheng, A.; Wang, Q.; Huang, J.; Abomohra, A.E.-F. A State-of-the-Art Review on Dual Purpose Seaweeds Utilization for Wastewater Treatment and Crude Bio-Oil Production. Energy Convers. Manag. 2020, 222, 113253. [Google Scholar] [CrossRef]

- Bhushan, S.; Kalra, A.; Simsek, H.; Kumar, G.; Prajapati, S.K. Current Trends and Prospects in Microalgae-Based Bioenergy Production. J. Environ. Chem. Eng. 2020, 8, 104025. [Google Scholar] [CrossRef]

- Jazie, A.A.; Haydary, J.; Abed, S.A.; Al-Dawody, M.F. Hydrothermal Liquefaction of Fucus Vesiculosus Algae Catalyzed by Hβ Zeolite Catalyst for Biocrude Oil Production. Algal Res. 2022, 61, 102596. [Google Scholar] [CrossRef]

- Kandasamy, S.; Devarayan, K.; Bhuvanendran, N.; Zhang, B.; He, Z.; Narayanan, M.; Mathimani, T.; Ravichandran, S.; Pugazhendhi, A. Accelerating the Production of Bio-Oil from Hydrothermal Liquefaction of Microalgae via Recycled Biochar-Supported Catalysts. J. Environ. Chem. Eng. 2021, 9, 105321. [Google Scholar] [CrossRef]

- Xia, J.; Han, L.; Zhang, C.; Guo, H.; Rong, N.; Baloch, H.A.; Wu, P.; Xu, G.; Ma, K. Hydrothermal Co-Liquefaction of Rice Straw and Nannochloropsis: The Interaction Effect on Mechanism, Product Distribution and Composition. J. Anal. Appl. Pyrolysis 2022, 161, 105368. [Google Scholar] [CrossRef]

- Norouzi, O.; Mazhkoo, S.; Haddadi, S.A.; Arjmand, M.; Dutta, A. Hydrothermal Liquefaction of Green Macroalgae Cladophora Glomerata: Effect of Functional Groups on the Catalytic Performance of Graphene Oxide/Polyurethane Composite. Catal. Today 2022, 404, 93–104. [Google Scholar] [CrossRef]

- Yu, J.; Audu, M.; Myint, M.T.; Cheng, F.; Jarvis, J.M.; Jena, U.; Nirmalakhandan, N.; Brewer, C.E.; Luo, H. Bio-Crude Oil Production and Valorization of Hydrochar as Anode Material from Hydrothermal Liquefaction of Algae Grown on Brackish Dairy Wastewater. Fuel Process. Technol. 2022, 227, 107119. [Google Scholar] [CrossRef]

- Guo, B.; Yang, B.; Weil, P.; Zhang, S.; Hornung, U.; Dahmen, N. The Effect of Dichloromethane on Product Separation during Continuous Hydrothermal Liquefaction of Chlorella Vulgaris and Aqueous Product Recycling for Algae Cultivation. Energy Fuels 2022, 36, 922–931. [Google Scholar] [CrossRef]

- Biswas, B.; Kumar, A.; Kaur, R.; Krishna, B.B.; Bhaskar, T. Co-Hydrothermal Liquefaction of Lignin and Macroalgae: Effect of Process Parameters on Product Distribution. BioEnergy Res. 2022. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, J.; Pan, W.; An, G.; Deng, Y.; Li, Y.; Hu, Y.; Xiao, Y.; Liu, T.; Leng, S.; et al. A Novel Strategy to Simultaneously Enhance Bio-Oil Yield and Nutrient Recovery in Sequential Hydrothermal Liquefaction of High Protein Microalgae. Energy Convers. Manag. 2022, 255, 115330. [Google Scholar] [CrossRef]

- Mishra, S.; Mohanty, K. Co-HTL of Domestic Sewage Sludge and Wastewater Treatment Derived Microalgal Biomass—An Integrated Biorefinery Approach for Sustainable Biocrude Production. Energy Convers. Manag. 2020, 204, 112312. [Google Scholar] [CrossRef]

- Islam, M.B.; Khalekuzzaman, M.; Kabir, S.B.; Hossain, M.R.; Alam, M.A. Substituting Microalgal Biomass with Faecal Sludge for High-Quality Biocrude Production through Co-Liquefaction: A Sustainable Biorefinery Approach. Fuel Process. Technol. 2022, 225, 107063. [Google Scholar] [CrossRef]

- Kim, Z.-H.; Park, H.; Lee, C.-G. Seasonal Assessment of Biomass and Fatty Acid Productivity by Tetraselmis sp. in the Ocean Using Semi-Permeable Membrane Photobioreactors. J. Microbiol. Biotechnol. 2016, 26, 1098–1102. [Google Scholar] [CrossRef] [Green Version]

- Fon Sing, S.; Isdepsky, A.; Borowitzka, M.A.; Lewis, D.M. Pilot-Scale Continuous Recycling of Growth Medium for the Mass Culture of a Halotolerant Tetraselmis sp. in Raceway Ponds under Increasing Salinity: A Novel Protocol for Commercial Microalgal Biomass Production. Bioresour. Technol. 2014, 161, 47–54. [Google Scholar] [CrossRef]

- Miyata, Y.; Sagata, K.; Hirose, M.; Yamazaki, Y.; Nishimura, A.; Okuda, N.; Arita, Y.; Hirano, Y.; Kita, Y. Fe-Assisted Hydrothermal Liquefaction of Lignocellulosic Biomass for Producing High-Grade Bio-Oil. ACS Sustain. Chem. Eng. 2017, 5, 3562–3569. [Google Scholar] [CrossRef] [Green Version]

- Cao, J.-L.; Yan, Z.-L.; Deng, Q.-F.; Wang, Y.; Yuan, Z.-Y.; Sun, G.; Jia, T.-K.; Wang, X.-D.; Bala, H.; Zhang, Z.-Y. Mesoporous Modified-Red-Mud Supported Ni Catalysts for Ammonia Decomposition to Hydrogen. Int. J. Hydrogen Energy 2014, 39, 5747–5755. [Google Scholar] [CrossRef]

- Saral, J.S.; Ranganathan, P. Catalytic Hydrothermal Liquefaction of Spirulina Platensis for Biocrude Production Using Red Mud. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Caprariis, B.D.; Damizia, M.; Tai, L.; Filippis, P.D. Hydrothermal Liquefaction of Biomass Using Waste Material as Catalyst: Effect on the Bio-Crude Yield and Quality. Chem. Eng. Trans. 2022, 92, 607–612. [Google Scholar] [CrossRef]

- Zhang, W.; Liang, Y. Hydrothermal Liquefaction of Sewage Sludge—Effect of Four Reagents on Relevant Parameters Related to Biocrude and PFAS. J. Environ. Chem. Eng. 2022, 10, 107092. [Google Scholar] [CrossRef]

- Pongsiriyakul, K.; Kiatkittipong, W.; Adhikari, S.; Lim, J.W.; Lam, S.S.; Kiatkittipong, K.; Dankeaw, A.; Reubroycharoen, P.; Laosiripojana, N.; Faungnawakij, K.; et al. Effective Cu/Re Promoted Ni-Supported γ-Al2O3 Catalyst for Upgrading Algae Bio-Crude Oil Produced by Hydrothermal Liquefaction. Fuel Process. Technol. 2021, 216, 106670. [Google Scholar] [CrossRef]

- Guo, B.; Walter, V.; Hornung, U.; Dahmen, N. Hydrothermal Liquefaction of Chlorella Vulgaris and Nannochloropsis Gaditana in a Continuous Stirred Tank Reactor and Hydrotreating of Biocrude by Nickel Catalysts. Fuel Process. Technol. 2019, 191, 168–180. [Google Scholar] [CrossRef]

- Jahromi, H.; Agblevor, F.A. Hydrotreating of Guaiacol: A Comparative Study of Red Mud-Supported Nickel and Commercial Ni/SiO2-Al2O3 Catalysts. Appl. Catal. A Gen. 2018, 558, 109–121. [Google Scholar] [CrossRef]

- Peng, W.; Wu, C.; Wu, S.; Wu, Y.; Gao, J. The Effects of Reaction Atmosphere on Composition, Oxygen Distribution, and Heating Value of Products from the Hydrothermal Liquefaction of Corn Stalk. Energy Sources Part A Recovery Util. Environ. Eff. 2014, 36, 347–356. [Google Scholar] [CrossRef]

- Wang, G.; Li, W.; Li, B.; Chen, H. Direct Liquefaction of Sawdust under Syngas. Fuel 2007, 86, 1587–1593. [Google Scholar] [CrossRef]

- Yang, C.; Jia, L.; Chen, C.; Liu, G.; Fang, W. Bio-Oil from Hydro-Liquefaction of Dunaliella Salina over Ni/REHY Catalyst. Bioresour. Technol. 2011, 102, 4580–4584. [Google Scholar] [CrossRef] [PubMed]

- Rahman, T.; Jahromi, H.; Roy, P.; Adhikari, S.; Hassani, E.; Oh, T.-S. Hydrothermal Liquefaction of Municipal Sewage Sludge: Effect of Red Mud Catalyst in Ethylene and Inert Ambiences. Energy Convers. Manag. 2021, 245, 114615. [Google Scholar] [CrossRef]

- Channiwala, S.A.; Parikh, P.P. A Unified Correlation for Estimating HHV of Solid, Liquid and Gaseous Fuels. Fuel 2002, 81, 1051–1063. [Google Scholar] [CrossRef]

- Roy, P.; Jahromi, H.; Adhikari, S.; Zou Finfrock, Y.; Rahman, T.; Ahmadi, Z.; Mahjouri-Samani, M.; Feyzbar-Khalkhali-Nejad, F.; Oh, T.-S. Performance of Biochar Assisted Catalysts during Hydroprocessing of Non-Edible Vegetable Oil: Effect of Transition Metal Source on Catalytic Activity. Energy Convers. Manag. 2022, 252, 115131. [Google Scholar] [CrossRef]

- Harun, K.; Adhikari, S.; Jahromi, H. Hydrogen Production via Thermocatalytic Decomposition of Methane Using Carbon-Based Catalysts. RSC Adv. 2020, 10, 40882–40893. [Google Scholar] [CrossRef]

- Jahromi, H.; Adhikari, S.; Roy, P.; Hassani, E.; Pope, C.; Oh, T.-S.; Karki, Y. Production of Green Transportation Fuels from Brassica Carinata Oil: A Comparative Study of Noble and Transition Metal Catalysts. Fuel Process. Technol. 2021, 215, 106737. [Google Scholar] [CrossRef]

- RStudio Team. RStudio: Integrated Development Environment for R; RStudio Team: Boston, MA, USA, 2019. [Google Scholar]

- Jahromi, H.; Adhikari, S.; Roy, P.; Shelley, M.; Hassani, E.; Oh, T.-S. Synthesis of Novel Biolubricants from Waste Cooking Oil and Cyclic Oxygenates through an Integrated Catalytic Process. ACS Sustain. Chem. Eng. 2021, 9, 13424–13437. [Google Scholar] [CrossRef]

- Wang, Q.; Prasad, R.; Higgins, B.T. Aerobic Bacterial Pretreatment to Overcome Algal Growth Inhibition on High-Strength Anaerobic Digestates. Water Res. 2019, 162, 420–426. [Google Scholar] [CrossRef]

- Wang, P.; Peng, H.; Adhikari, S.; Higgins, B.; Roy, P.; Dai, W.; Shi, X. Enhancement of Biogas Production from Wastewater Sludge via Anaerobic Digestion Assisted with Biochar Amendment. Bioresour. Technol. 2020, 309, 123368. [Google Scholar] [CrossRef]

- Vo, T.K.; Kim, S.-S.; Ly, H.V.; Lee, E.Y.; Lee, C.-G.; Kim, J. A General Reaction Network and Kinetic Model of the Hydrothermal Liquefaction of Microalgae Tetraselmis sp. Bioresour. Technol. 2017, 241, 610–619. [Google Scholar] [CrossRef]

- Eboibi, B.E.; Lewis, D.M.; Ashman, P.J.; Chinnasamy, S. Effect of Operating Conditions on Yield and Quality of Biocrude during Hydrothermal Liquefaction of Halophytic Microalga Tetraselmis sp. Bioresour. Technol. 2014, 170, 20–29. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shakya, R.; Whelen, J.; Adhikari, S.; Mahadevan, R.; Neupane, S. Effect of Temperature and Na2CO3 Catalyst on Hydrothermal Liquefaction of Algae. Algal Res. 2015, 12, 80–90. [Google Scholar] [CrossRef] [Green Version]

- Eboibi, B.E.-O.; Lewis, D.M.; Ashman, P.J.; Chinnasamy, S. Hydrothermal Liquefaction of Microalgae for Biocrude Production: Improving the Biocrude Properties with Vacuum Distillation. Bioresour. Technol. 2014, 174, 212–221. [Google Scholar] [CrossRef]

- Jahromi, H.; Rahman, T.; Roy, P.; Adhikari, S. Hydrotreatment of Solvent-Extracted Biocrude from Hydrothermal Liquefaction of Municipal Sewage Sludge. Energy Convers. Manag. 2022, 263, 115719. [Google Scholar] [CrossRef]

- Roy, P.; Jahromi, H.; Rahman, T.; Adhikari, S.; Feyzbar-Khalkhali-Nejad, F.; Barbary Hassan, E.; Oh, T.-S. Understanding the Effects of Feedstock Blending and Catalyst Support on Hydrotreatment of Algae HTL Biocrude with Non-Edible Vegetable Oil. Energy Convers. Manag. 2022, 268, 115998. [Google Scholar] [CrossRef]

- Jones, S.B.; Zhu, Y.; Anderson, D.B.; Hallen, R.T.; Elliott, D.C.; Schmidt, A.J.; Albrecht, K.O.; Hart, T.R.; Butcher, M.G.; Drennan, C.; et al. Process Design and Economics for the Conversion of Algal Biomass to Hydrocarbons: Whole Algae Hydrothermal Liquefaction and Upgrading; U.S. Department of Energy Bioenergy Technologies Office: Washington, DC, USA, 2014; Report No. 23227.

- Wang, W.; Xu, Y.; Wang, X.; Zhang, B.; Tian, W.; Zhang, J. Hydrothermal Liquefaction of Microalgae over Transition Metal Supported TiO2 Catalyst. Bioresour. Technol. 2018, 250, 474–480. [Google Scholar] [CrossRef]

- Li, H.; Hu, J.; Zhang, Z.; Wang, H.; Ping, F.; Zheng, C.; Zhang, H.; He, Q. Insight into the Effect of Hydrogenation on Efficiency of Hydrothermal Liquefaction and Physico-Chemical Properties of Biocrude Oil. Bioresour. Technol. 2014, 163, 143–151. [Google Scholar] [CrossRef]

- Jahromi, H.; Agblevor, F.A. Hydrodeoxygenation of Pinyon-Juniper Catalytic Pyrolysis Oil Using Red Mud-Supported Nickel Catalysts. Appl. Catal. B Environ. 2018, 236, 1–12. [Google Scholar] [CrossRef]

- Duan, P.; Savage, P.E. Hydrothermal Liquefaction of a Microalga with Heterogeneous Catalysts. Ind. Eng. Chem. Res. 2011, 50, 52–61. [Google Scholar] [CrossRef]

- Sushil, S.; Batra, V.S. Catalytic Applications of Red Mud, an Aluminium Industry Waste: A Review. Appl. Catal. B Environ. 2008, 81, 64–77. [Google Scholar] [CrossRef]

- Stigter, J.B.; de Haan, H.P.M.; Guicherit, R.; Dekkers, C.P.A.; Daane, M.L. Determination of Cadmium, Zinc, Copper, Chromium and Arsenic in Crude Oil Cargoes. Environ. Pollut. 2000, 107, 451–464. [Google Scholar] [CrossRef] [PubMed]

- Gazulla, M.F.; Rodrigo, M.; Orduña, M.; Ventura, M.J.; Andreu, C. Determination of Phosphorus in Crude Oil and Middle Distillate Petroleum Products by Inductively Coupled Plasma–Optical Emission Spectrometry. Anal. Lett. 2017, 50, 2465–2474. [Google Scholar] [CrossRef]

- Han, Y.; Hoekman, K.; Jena, U.; Das, P. Use of Co-Solvents in Hydrothermal Liquefaction (HTL) of Microalgae. Energies 2020, 13, 124. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Chen, L.; Kong, W.; Wang, T.; Zhang, Q.; Long, J.; Xu, Y.; Ma, L. Upgrading of Bio-Oil to Boiler Fuel by Catalytic Hydrotreatment and Esterification in an Efficient Process. Energy 2015, 84, 83–90. [Google Scholar] [CrossRef]

- Eboibi, B.E.; Lewis, D.M.; Ashman, P.J.; Chinnasamy, S. Influence of Process Conditions on Pretreatment of Microalgae for Protein Extraction and Production of Biocrude during Hydrothermal Liquefaction of Pretreated Tetraselmis sp. RSC Adv. 2015, 5, 20193–20207. [Google Scholar] [CrossRef]

- Gu, X.; Martinez-Fernandez, J.S.; Pang, N.; Fu, X.; Chen, S. Recent Development of Hydrothermal Liquefaction for Algal Biorefinery. Renew. Sustain. Energy Rev. 2020, 121, 109707. [Google Scholar] [CrossRef]

- Guo, Y.; Yeh, T.; Song, W.; Xu, D.; Wang, S. A Review of Bio-Oil Production from Hydrothermal Liquefaction of Algae. Renew. Sustain. Energy Rev. 2015, 48, 776–790. [Google Scholar] [CrossRef]

- Sipponen, M.H.; Özdenkci, K.; Muddassar, H.R.; Melin, K.; Golam, S.; Oinas, P. Hydrothermal Liquefaction of Softwood: Selective Chemical Production Under Oxidative Conditions. ACS Sustain. Chem. Eng. 2016, 4, 3978–3984. [Google Scholar] [CrossRef] [Green Version]

- Zhou, D.; Zhang, L.; Zhang, S.; Fu, H.; Chen, J. Hydrothermal Liquefaction of Macroalgae Enteromorpha Prolifera to Bio-Oil. Energy Fuels 2010, 24, 4054–4061. [Google Scholar] [CrossRef]

- Biller, P.; Ross, A.B. Potential Yields and Properties of Oil from the Hydrothermal Liquefaction of Microalgae with Different Biochemical Content. Bioresour. Technol. 2011, 102, 215–225. [Google Scholar] [CrossRef]

- Toor, S.S.; Rosendahl, L.; Rudolf, A. Hydrothermal Liquefaction of Biomass: A Review of Subcritical Water Technologies. Energy 2011, 36, 2328–2342. [Google Scholar] [CrossRef]

- Han, Y.; Hoekman, S.K.; Cui, Z.; Jena, U.; Das, P. Hydrothermal Liquefaction of Marine Microalgae Biomass Using Co-Solvents. Algal Res. 2019, 38, 101421. [Google Scholar] [CrossRef]

- Jazrawi, C.; Biller, P.; Ross, A.B.; Montoya, A.; Maschmeyer, T.; Haynes, B.S. Pilot Plant Testing of Continuous Hydrothermal Liquefaction of Microalgae. Algal Res. 2013, 2, 268–277. [Google Scholar] [CrossRef]

| Tetraselmis | Nannochloropsis | Pavlova | Isochrysis | |

|---|---|---|---|---|

| Proximate Analysis a | ||||

| (wt.%) | ||||

| Moisture | 82.00 ± 1.20 | 68.88 ± 1.24 | 75.80 ± 0.42 | 73.93 ± 1.44 |

| Ash | 2.60 ± 0.10 | 3.42 ± 0.38 | 3.47 ± 0.33 | 3.39 ± 0.29 |

| Volatile content | 13.20 ± 0.30 | 22.51 ± 1.28 | 17.74 ± 0.77 | 18.20 ± 1.01 |

| Elemental Composition b | ||||

| (wt.%) | ||||

| C | 32.20 ± 0.31 | 56.83 ± 0.33 | 54.34 ± 1.36 | 55.76 ± 1.14 |

| H | 5.13 ± 0.23 | 9.32 ± 0.06 | 8.69 ± 0.41 | 8.70 ± 0.34 |

| N | 4.42 ± 0.05 | 10.13 ± 0.06 | 8.67 ± 0.21 | 7.96 ± 0.06 |

| S | 0.79 ± 0.11 | 0.37 ± 0.19 | 0.82 ± 0.09 | 0.62 ± 0.10 |

| Ash | 15.00 ± 0.20 | 3.42 ± 0.38 | 3.47 ± 0.33 | 3.39 ± 0.29 |

| O c | 42.46 ± 0.90 | 19.93 ± 0.26 | 24.01 ± 2.07 | 23.57 ± 1.65 |

| H/C ratio | 1.90 | 1.96 | 1.91 | 1.87 |

| HHV b (MJ/kg) | 12.60 ± 0.20 | 24.02 ± 0.07 | 22.69 ± 0.07 | 22.97 ± 0.02 |

| Biochemical Composition b | ||||

| (wt.%) | ||||

| Protein | 63.00 | 62.79 | 46.94 | 44.36 |

| Lipid | 11.00 | 18.12 | 13.88 | 18.98 |

| Carbohydrate | 11.00 | 8.92 | 28.00 | 25.46 |

| Nitrogen | Ethylene | Reducing | Oxidizing | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM | ||

| Elemental Composition a (wt.%) | C | 47.9 ± 0.6 | 61.0 ± 0.1 | 53.9 ± 0.5 | 48.9 ± 0.2 | 57.0 ± 0.3 | 58.2 ± 0.3 | 54.3 ± 1.0 | 61.0 ± 0.1 | 59.3 ± 0.3 | 52.5 ± 0.3 | 54.6 ± 0.6 | 60.2 ± 0.3 |

| H | 10.3 ± 0.4 | 10.6 ± 0.2 | 10.2 ± 0.1 | 10.4 ± 0.2 | 10.6 ± 0.1 | 10.5 ± 0.3 | 10.2 ± 0.5 | 10.9 ± 0.1 | 11.2 ± 0.1 | 10.1 ± 0.6 | 10.4 ± 0.1 | 9.5 ± 0.8 | |

| N | 3.1 ± 0.1 | 4.4 ± 0.1 | 4.0 ± 0.1 | 3.1 ± 0.1 | 4.1 ± 0.1 | 4.2 ± 0.1 | 3.5 ± 0.1 | 4.5 ± 0.1 | 4.5 ± 0.1 | 3.5 ± 0.1 | 3.9 ± 0.1 | 4.4 ± 0.1 | |

| S | 0.4 ± 0.1 | 0.5 ± 0.1 | 0.2 ± 0.1 | 0.5 ± 0.1 | 0.6 ± 0.1 | 0.2 ± 0.1 | 0.3 ± 0.2 | 0.4 ± 0.1 | 0.2 ± 0.1 | 0.5 ± 0.3 | 0.6 ± 0.1 | 0.3 ± 0.1 | |

| Ash | 6.0 ± 0.1 | 4.9 ± 0.1 | 4.5 ± 0.0 | 5.3 ± 0.1 | 3.8 ± 0.0 | 4.4 ± 0.2 | 4.4 ± 0.1 | 3.9 ± 0.1 | 2.9 ± 0.1 | 5.6 ± 0.0 | 3.4 ± 0.1 | 4.5 ± 0.0 | |

| O b | 32.3 ± 1.3 | 18.8 ± 0.4 | 27.2 ± 0.7 | 31.8 ± 0.6 | 23.9 ± 0.3 | 22.5 ± 0.8 | 27.2 ± 1.9 | 19.4 ± 0.3 | 21.9 ± 0.7 | 27.7 ± 1.2 | 27.1 ± 0.9 | 21.2 ± 1.1 | |

| Water Content (wt.%) | 16.0 ± 2.3 | 10.3 ± 1.7 | 19.3 ± 2.2 | 16.6 ± 2.1 | 12.6 ± 1.8 | 10.0 ± 0.9 | 14.7 ± 1.2 | 11.7 ± 1.6 | 12.3 ± 1.0 | 13.9 ± 2.3 | 14.4 ± 1.2 | 12.1 ± 0.7 | |

| HHV (MJ/kg) | 25.4 ± 0.8 | 31.7 ± 0.3 | 27.9 ± 0.3 | 26.0 ± 0.3 | 29.8 ± 0.2 | 30.3 ± 0.6 | 28.0 ± 1.1 | 32.1 ± 0.2 | 31.5 ± 0.4 | 27.3 ± 0.9 | 28.4 ± 0.4 | 29.9 ± 1.1 | |

| TAN (mgKOH/g) | 21.9 ± 0.1 | 27.3 ± 1.0 | 14.0 ± 01 | 18.9 ± 0.4 | 24.6 ± 0.3 | 27.5 ± 0.3 | 26.3 ± 0.1 | 28.5 ± 0.1 | 28.3 ± 0.4 | 24.4 ± 1.8 | 27.1 ± 0.2 | 30.0 ± 0.8 | |

| Heavy Metal and Phosphorus (ppm) | Co | 37.9 ± 0.1 | 44.3 ± 0.5 | 16.7 ± 0.3 | 40.3 ± 0.7 | 65.0 ± 0.2 | 57.1 ± 0.3 | 22.4 ± 0.8 | 22.1 ± 0.4 | 71.2 ± 0.5 | 20.6 ± 0.2 | 50.1 ± 0.6 | 52.6 ± 0.1 |

| Cr | 1.3 ± 0.2 | 1.5 ± 0.4 | 1.0 ± 0.6 | 1.5 ± 0.8 | 0.4 ± 0.0 | 0.6 ± 0.0 | 0.9 ± 0.0 | 3.7 ± 0.6 | 2.7 ± 0.7 | 0.2 ± 0.0 | 1.9 ± 0.3 | 1.4 ± 0.4 | |

| Cu | 13.1 ± 1.0 | 4.0 ± 0.5 | 8.7 ± 1.2 | <0.5 ± 0.0 | <0.5 ± 0.0 | 13.4 ± 1.1 | 4.0 ± 0.8 | <0.5 ± 0.0 | 4.7 ± 0.3 | <0.5 ± 0.0 | <0.5 ± 0.0 | 14.6 ± 1.4 | |

| Fe | 1075.0 ± 2.3 | 2788.1 ± 1.4 | 3173.1 ± 0.5 | 1145.2 ± 0.7 | 3408.6 ± 1.3 | 3253.5 ± 1.6 | 854.1 ± 0.8 | 2405.3 ± 0.7 | 1518.9 ± 1.4 | 588.4 ± 0.7 | 1050.5 ± 0.5 | 2233.7 ± 0.3 | |

| Mn | <2.5 ± 0.0 | <2.5 ± 0.0 | <2.5 ± 0.0 | 5.0 ± 1.0 | 5.0 ± 1.1 | <2.5 ± 0.0 | 5.0 ± 1.0 | 5.0 ± 1.1 | 5.6 ± 1.7 | 9.6 ± 1.4 | 5.0 ± 1.0 | <2.5 ± 0.0 | |

| Ni | 280.5 ± 1.2 | 15.5 ± 0.7 | 1448.7 ± 1.6 | 12.7 ± 1.0 | 87.4 ± 1.6 | 1113.2 ± 1.4 | 8.1 ± 1.1 | 6.8 ± 1.2 | 1938.2 ± 2.3 | 16.5 ± 1.1 | 16.1 ± 0.6 | 1540.1 ± 1.6 | |

| P | 37.5 ± 0.6 | 9.6 ± 1.0 | 32.0 ± 1.6 | 43.0 ± 0.9 | 6.1 ± 1.4 | 9.3 ± 0.6 | 160.4 ± 0.3 | 34.9 ± 1.0 | 535.4 ± 0.5 | 25.5 ± 0.4 | 2.5 ± 0.7 | 8.7 ± 0.4 | |

| Zn | 13.5 ± 1.1 | 5.9 ± 0.6 | 12.2 ± 0.8 | <2.5 ± 0.0 | <2.5 ± 0.0 | 8.9 ± 1.4 | 14.0 ± 0.6 | <2.5 ± 0.0 | 9.0 ± 1.1 | 9.9 ± 0.6 | <2.5 ± 0.0 | 9.8 ± 1.0 | |

| Area (%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nitrogen | Ethylene | Reducing | Oxidizing | ||||||||||

| Compounds | Chemical Formula | No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM |

| n-Hexadecanoic acid | C16H32O2 | 9.9 | 10.3 | 7.9 | 14.2 | 21.4 | 15.6 | 14.7 | 26.1 | 25.3 | 20.7 | 22.6 | 12.5 |

| Oleic Acid | C18H34O2 | 6.0 | 10.9 | 6.0 | 10.3 | 12.9 | 20.7 | 8.7 | 17.6 | 10.9 | 10.0 | 16.6 | 14.6 |

| Phenol, 2,2’-methylenebis[6-(1,1-dimethylethyl)-4-ethyl]- | C25H36O2 | 10.2 | 3.2 | 8.1 | 1.5 | 1.4 | 2.4 | 6.2 | 0.6 | 1.0 | 2.5 | 1.1 | 1.0 |

| Phenol | C6H6O | 2.3 | 0.7 | 2.6 | 2.0 | 1.3 | 0.6 | <LOD | 1.6 | 1.9 | <LOD | 1.4 | 1.2 |

| 2-Pentadecanone, 6,10,14-trimethyl- | C18H36O | 4.3 | 2.0 | 2.5 | 3.6 | 2.1 | 0.8 | 3.3 | 1.6 | 1.9 | 4.8 | 1.4 | 1.6 |

| Phenylethyl Alcohol | C8H10O | <LOD | <LOD | 0.5 | 1.2 | 2.8 | 1.1 | <LOD | 2.3 | 1.6 | <LOD | 1.9 | 0.9 |

| Isophytol | C20H40O | 3.2 | <LOD | <LOD | 5.5 | <LOD | 0.5 | 6.7 | <LOD | <LOD | 3.6 | <LOD | 1.0 |

| Dianhydromannitol | C6H10O4 | <LOD | <LOD | 1.0 | 1.5 | <LOD | <LOD | 1.1 | <LOD | <LOD | <LOD | 2.3 | 0.9 |

| 9H-Pyrido[3,4-b]indole, 1-methyl- | C12H10N | 3.1 | 1.5 | 2.5 | 2.5 | 1.1 | 2.9 | 4.7 | 2.2 | 1.2 | 2.5 | 2.1 | 2.0 |

| Pyridine, 3-phenyl- | C11H9N | <LOD | 0.9 | 0.6 | <LOD | 0.2 | 0.2 | <LOD | 0.4 | 0.5 | 1.6 | 0.8 | 1.2 |

| Indole | C8H7N | <LOD | 0.8 | 1.9 | 1.2 | 0.6 | 0.5 | <LOD | 0.7 | 1.7 | 1.9 | 1.1 | 2.0 |

| 1H-Indole, 3-methyl- | C9H9N | <LOD | <LOD | 1.0 | 0.8 | 0.4 | <LOD | <LOD | 0.7 | 1.0 | <LOD | 1.2 | 1.9 |

| Quinoline, 1,2,3,4-tetrahydro- | C9H11N | <LOD | <LOD | 0.6 | 1.0 | 0.6 | 0.5 | <LOD | 0.4 | 0.7 | <LOD | 0.4 | 1.0 |

| 2-Hexadecene, 3,7,11,15-tetramethyl-, [R-[R*,R*-(E)]]- | C20H40 | 21.0 | 28.6 | 24.7 | 13.9 | 15.6 | 13.6 | 14.7 | 5.8 | 10.2 | 14.0 | 6.1 | 16.4 |

| Nitrogen | Ethylene | Reducing | Oxidizing | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM | No Catalyst | RRM | Ni/RM | ||

| Aqueous Phase (g/L) | TOC | 11.42 ± 1.00 | 13.19 ± 0.53 | 13.65 ± 0.20 | 12.53 ± 0.82 | 13.98 ± 1.50 | 13.79 ± 0.14 | 12.65 ± 1.31 | 13.26 ± 0.45 | 15.80 ± 0.38 | 12.06 ± 0.77 | 13.95 ± 0.89 | 16.41 ± 0.93 |

| NH4+-N | 2.87 ± 0.34 | 4.00 ± 0.43 | 3.92 ± 0.22 | 2.71 ± 0.19 | 3.74 ± 0.36 | 2.83 ± 0.54 | 3.13 ± 0.46 | 3.15 ± 0.27 | 4.02 ± 0.43 | 3.00 ± 0.76 | 4.20 ± 0.45 | 3.64 ± 0.44 | |

| NO3−-N | 0.02 ± 0.00 | 0.06 ± 0.01 | 0.02 ± 0.00 | 0.01 ± 0.00 | 0.02 ± 0.00 | 0.05 ± 0.01 | 0.03 ± 0.00 | 0.02 ± 0.00 | 0.06 ± 0.02 | 0.02 ± 0.00 | 0.05 ± 0.01 | 0.06 ± 0.01 | |

| Org-N a | 7.41 ± 0.16 | 7.24 ± 0.04 | 7.12 ± 0.54 | 7.54 ± 0.35 | 7.62 ± 0.40 | 7.83 ± 0.30 | 7.52 ± 0.17 | 7.37 ± 0.05 | 6.68 ± 0.40 | 6.98 ± 0.01 | 7.19 ± 0.28 | 7.86 ± 0.01 | |

| TN | 10.30 ± 0.50 | 11.30 ± 0.48 | 11.06 ± 0.76 | 10.26 ± 0.54 | 11.38 ± 0.76 | 10.71 ± 0.85 | 10.68 ± 0.63 | 10.54 ± 0.32 | 10.76 ± 0.85 | 10.00 ± 0.75 | 11.44 ± 0.18 | 11.56 ± 0.46 | |

| COD | 86.00 ± 0.30 | 99.60 ± 0.01 | 89.20 ± 0.10 | 87.60 ± 0.10 | 110.0 ± 0.11 | 96.40 ± 3.61 | 89.90 ± 0.23 | 101.10 ± 0.82 | 119.10 ± 0.22 | 91.20 ± 0.31 | 103.00 ± 0.21 | 107.60 ± 0.12 | |

| pH | 8.30 ± 0.60 | 8.60 ± 0.10 | 8.40 ± 0.31 | 8.70 ± 0.12 | 8.30 ± 0.52 | 8.70 ± 0.22 | 8.30 ± 0.20 | 8.50 ± 0.10 | 7.90 ± 0.10 | 8.20 ± 0.20 | 8.10 ± 0.10 | 8.20 ± 0.30 | |

| Solid Residue (wt.%) | C | 34.2 ± 2.3 | 25.1 ± 0.1 | 21.1 ± 1.4 | 36.9 ± 0.1 | 18.3 ± 1.0 | 22.5 ± 0.1 | 28.9 ± 0.9 | 20.7 ± 0.3 | 18.0 ± 0.2 | 37.4 ± 1.6 | 24.9 ± 1.4 | 24.7 ± 0.1 |

| H | 4.8 ± 0.1 | 2.7 ± 0.1 | 2.5 ± 0.2 | 4.4 ± 0.1 | 2.1 ± 0.2 | 2.4 ± 0.1 | 3.4 ± 0.2 | 1.9 ± 1.4 | 2.7 ± 0.1 | 3.5 ± 0.6 | 3.4 ± 0.3 | 3.2 ± 0.1 | |

| N | 2.3 ± 0.2 | 1.6 ± 0.1 | 1.4 ± 0.1 | 2.2 ± 0.1 | 1.3 ± 0.1 | 1.5 ± 0.4 | 1.9 ± 0.1 | 1.4 ± 0.1 | 1.2 ± 0.1 | 2.8 ± 0.1 | 1.8 ± 0.2 | 1.8 ± 0.1 | |

| S | 0.3 ± 0.1 | 0.5 ± 0.1 | 1.2 ± 0.1 | 0.4 ± 0.2 | 0.4 ± 0.1 | 1.2 ± 0.1 | 0.3 ± 0.1 | 0.4 ± 0.1 | 1.4 ± 0.1 | 0.3 ± 0.1 | 0.4 ± 0.1 | 0.8 ± 0.2 | |

| Ash | 55.4 ± 0.1 | 58.1 ± 0.2 | 64.3 ± 0.1 | 55.3 ± 0.3 | 68.5 ± 0.2 | 62.9 ± 0.4 | 59.6 ± 0.2 | 57.2 ± 0.1 | 70.5 ± 0.1 | 46.7 ± 0.1 | 47.8 ± 0.2 | 56.9 ± 0.3 | |

| Oa | 3.1 ± 2.8 | 12.0 ± 0.4 | 9.5 ± 1.8 | 0.9 ± 0.7 | 9.4 ± 1.5 | 9.6 ± 0.9 | 5.9 ± 1.3 | 18.4 ± 1.8 | 6.1 ± 0.4 | 9.4 ± 2.4 | 21.8 ± 2.1 | 12.6 ± 0.8 | |

| Gas Composition (mol%) | H2 | 1.5 ± 0.0 | 6.1 ± 0.2 | 4.8 ± 0.1 | 1.1 ± 0.0 | 8.0 ± 0.1 | 6.7 ± 0.1 | Consumed | 1.0 ± 0.1 | 3.9 ± 0.2 | 2.5 ± 0.1 | ||

| CH4 | 0.1 ± 0.0 | 1.5 ± 0.1 | 0.1 ± 0.0 | 0.1 ± 0.0 | 1.4 ± 0.1 | 3.0 ± 0.1 | 0.1 ± 0.0 | 1.1 ± 0.1 | 0.1 ± 0.0 | 0.1 ± 0.0 | 0.7 ± 0.1 | 0.1 ± 0.0 | |

| CO | 3.2 ± 0.1 | 0.8 ± 0.1 | 4.8 ± 0.1 | 2.2 ± 0.0 | 2.5 ± 0.1 | 0.1 ± 0.0 | 3.1 ± 0.1 | 2.4 ± 0.1 | 8.4 ± 0.1 | 1.7 ± 0.0 | 3.8 ± 0.2 | 2.9 ± 0.0 | |

| CO2 | 80.8 ± 0.9 | 62.1 ± 0.1 | 65.8 ± 0.3 | 72.7 ± 1.2 | 41.0 ± 1.6 | 58.7 ± 0.1 | 82.8 ± 0.8 | 67.5 ± 0.6 | 69.8 ± 0.2 | 85.1 ± 1.5 | 52.9 ± 0.5 | 72.7 ± 0.1 | |

| Balance a | 14.4 ± 0.9 | 29.4 ± 0.3 | 24.6 ± 0.3 | 23.9 ± 1.3 | 47.1 ± 1.5 | 31.5 ± 0.1 | 14.0 ± 0.7 | 29.1 ± 0.8 | 21.8 ± 0.1 | 12.2 ± 1.5 | 38.1 ± 1.0 | 21.7 ± 0.1 | |

| Gas Consumption (mol/kg feedstock) | 0 | 0 | 0 | 0.11 ± 0.02 | 0.72 ± 0.2 | 1.48 ± 0.4 | 0.01 ± 0.0 | 0.04 ± 0.01 | 1.52 ± 0.3 | 1.22 ± 0.1 | 1.07 ± 0.2 | 1.23 ± 0.4 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rahman, T.; Jahromi, H.; Roy, P.; Adhikari, S.; Feyzbar-Khalkhali-Nejad, F.; Oh, T.-S.; Wang, Q.; Higgins, B.T. Influence of Red Mud Catalyst and Reaction Atmosphere on Hydrothermal Liquefaction of Algae. Energies 2023, 16, 491. https://doi.org/10.3390/en16010491

Rahman T, Jahromi H, Roy P, Adhikari S, Feyzbar-Khalkhali-Nejad F, Oh T-S, Wang Q, Higgins BT. Influence of Red Mud Catalyst and Reaction Atmosphere on Hydrothermal Liquefaction of Algae. Energies. 2023; 16(1):491. https://doi.org/10.3390/en16010491

Chicago/Turabian StyleRahman, Tawsif, Hossein Jahromi, Poulami Roy, Sushil Adhikari, Farshad Feyzbar-Khalkhali-Nejad, Tae-Sik Oh, Qichen Wang, and Brendan T. Higgins. 2023. "Influence of Red Mud Catalyst and Reaction Atmosphere on Hydrothermal Liquefaction of Algae" Energies 16, no. 1: 491. https://doi.org/10.3390/en16010491

APA StyleRahman, T., Jahromi, H., Roy, P., Adhikari, S., Feyzbar-Khalkhali-Nejad, F., Oh, T.-S., Wang, Q., & Higgins, B. T. (2023). Influence of Red Mud Catalyst and Reaction Atmosphere on Hydrothermal Liquefaction of Algae. Energies, 16(1), 491. https://doi.org/10.3390/en16010491