Technical Analysis of a Large-Scale Solar Updraft Tower Power Plant

Abstract

:1. Introduction

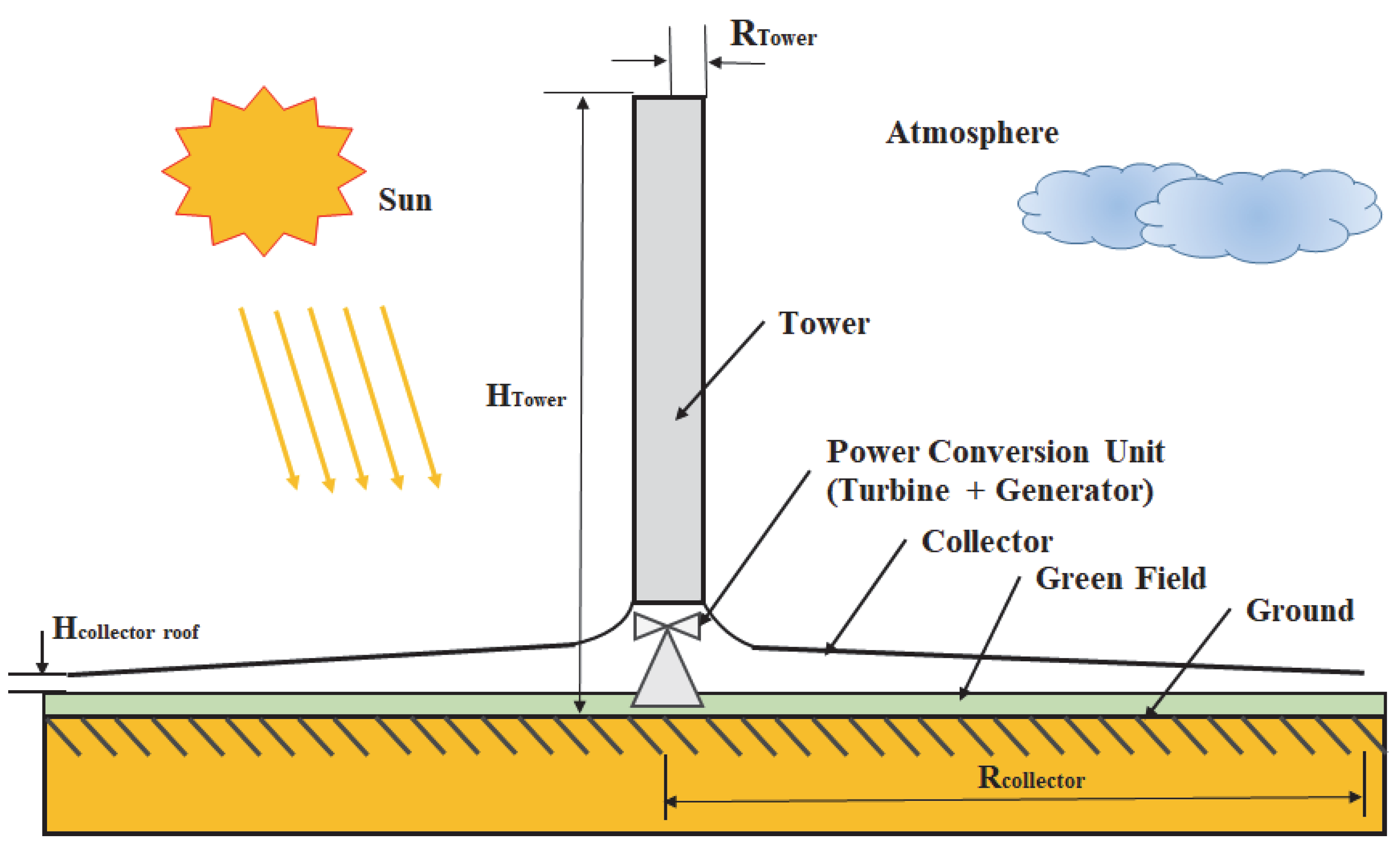

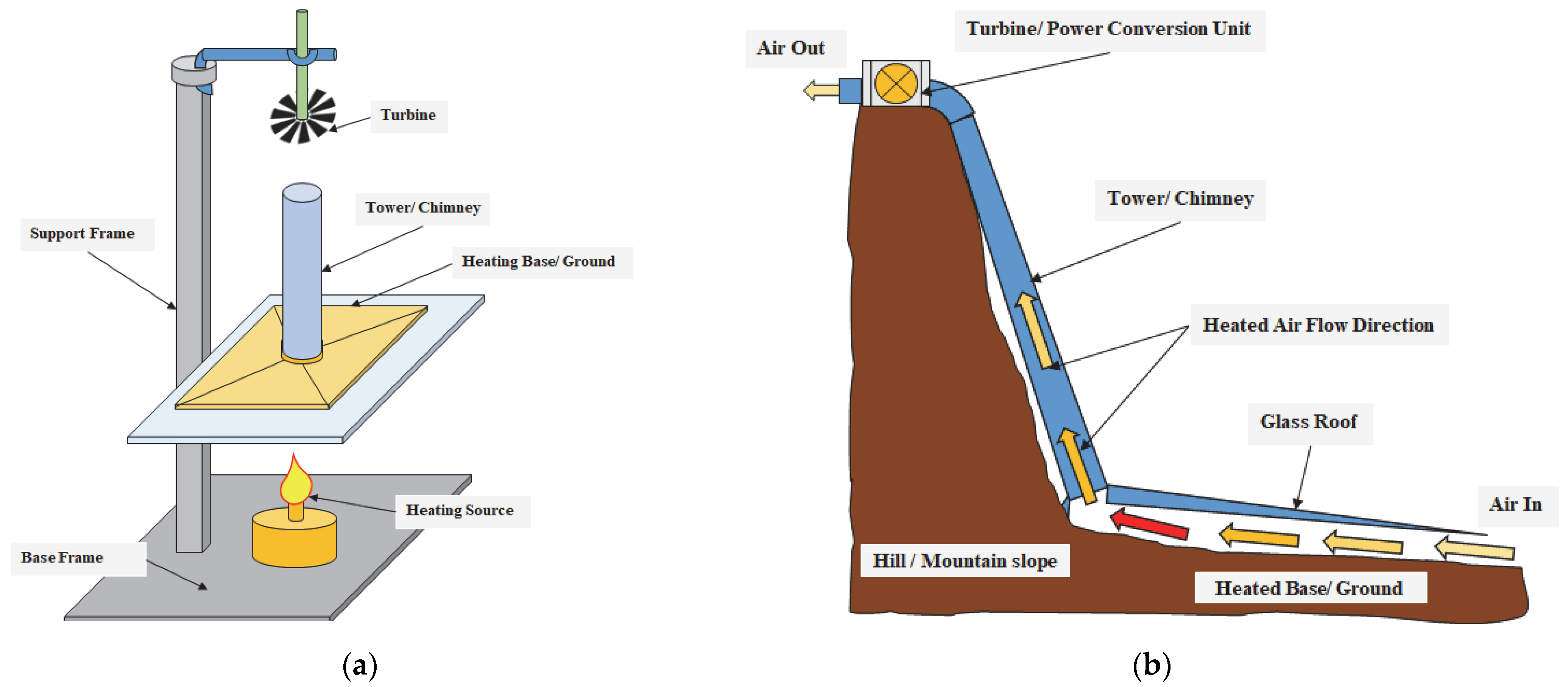

2. Analysis of SUTPP

2.1. Governing Conservation Equation

2.1.1. Collecting Unit Equations

2.1.2. Tower-Equations

2.2. Power Output

- ρavg = Average density of air through the turbine

- = Average mass flow rate through turbine

- pavg = Average pressure through the turbine

- = Average temperature through the turbine

- = Universal gas constant

- ΔpTPD = Total driving potential or total pressure difference in the plant

- = Collector inlet pressure-drop

- = Total pressure-drop throughout the collector

- = Pressure drop at the turbine inlet

- = Total pressure drop through the tower

- = Tower outlet pressure difference with ambient at tower outlet

- = Tower dynamic outlet loss at height H

- Increases in tower height directly regulate power output in a linear proportion, but, due to the effect of the friction factor, this relation is not truly linear. This relationship cannot determine the maximum tower height that can be achieved.

- Increases in SUTPP collector radius directly regulate power output in square proportions.

- The effect of collector efficiency also regulates power output, which can be increased by using good quality glass with glazing, a smooth ground surface, and low drag forces developed by the roof support structure.

- When the surrounding air temperature drops while the inside air temperature remains constant, the power output increases.

- Factors such as chimney shade, cloudy days, 24-h operation, and glazing affect the power output of the SUTPP, which is not considered in this study.

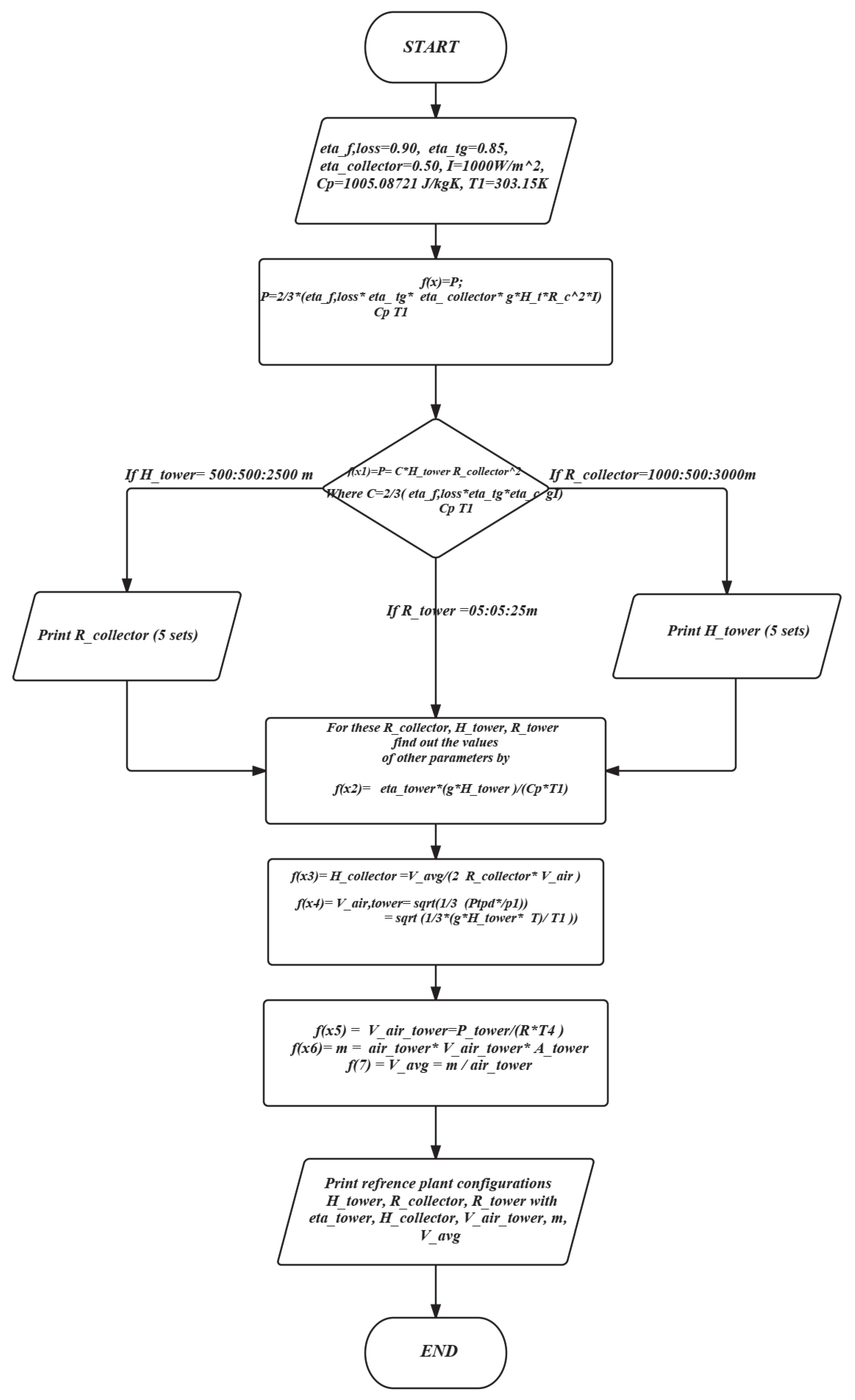

Calculation for Plant Output and Dimensions

3. Reference Purposed SUTP Plant Specification

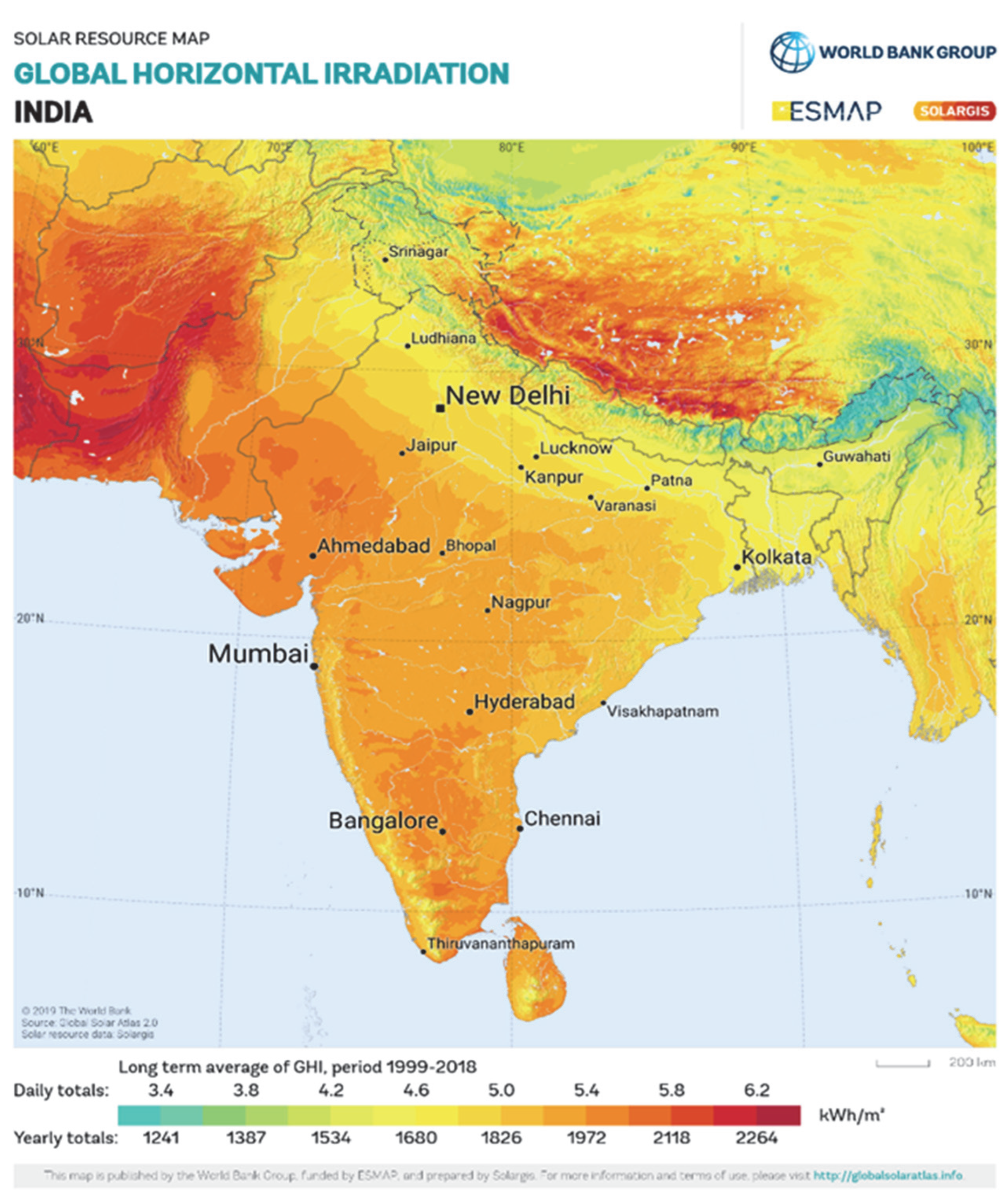

3.1. Meteorological Data of Reference Location

| Latitude | 27°35′ North |

| Longitude | 72°43′ East |

| Standard-time-zone (GMT) | +5:30 h |

Interpretation of Input Data

| Reference Site Data |

| SITE: Udat, Bikaner, Rajasthan, India |

| Site position (latitude/longitude): 27°35′, 72°43′ |

| Solar radiation (yearly average) |

| Monthly average Insolation interact on a horizontal-surface (kWh/m2/day): 05.081 |

| Monthly average Diffuse-Radiation incident on a horizontal surface (kWh/m2/day): 1.71 |

| Monthly average Direct-Normal Radiation (kWh/m2/day): 5.60 |

| Monthly average Daylight Hours (hours): 12.15 h |

| Length of day: 10 h (December) to 13 h (July) |

| Wind: |

| Monthly average wind-speed at 10 m above the earth surface for terrain cover with shrub (m/s): 03 |

| Wind Direction: In winter: North-Eastern |

| In summer: South-Western |

| Monthly averaged relative humidity (%): 42.1 |

| Monthly averaged atmospheric pressure (kPa): 98.3 |

| Atmospheric-pressure that has been adjusted for a site elevation of 209 m (kPa): 98.3 |

| Air temperature: |

| Monthly averaged earth skin temperature (°C): 27.8 |

| Monthly average air temperature at 10 m above the earth’s surface (°C): 24.9 |

| Air-temperature at 10 m above the surface, adjusted for a site-elevation of 209 m (°C): 24.6 |

| Average daily temperature range (°C): 10.15 |

| Terrain (SRTM3) |

| Elevation: 209 m |

| Slope inclination: 0.8° |

| Slope azimuth: 228° (SW) |

| Landscape (GLC/CLC) |

| Type: Deciduous shrub cover |

| GLC: Shrub cover, closed-open, deciduous |

| Elevation: 209 m |

| Population (GPW) |

| Density: 26 in h. /km2 |

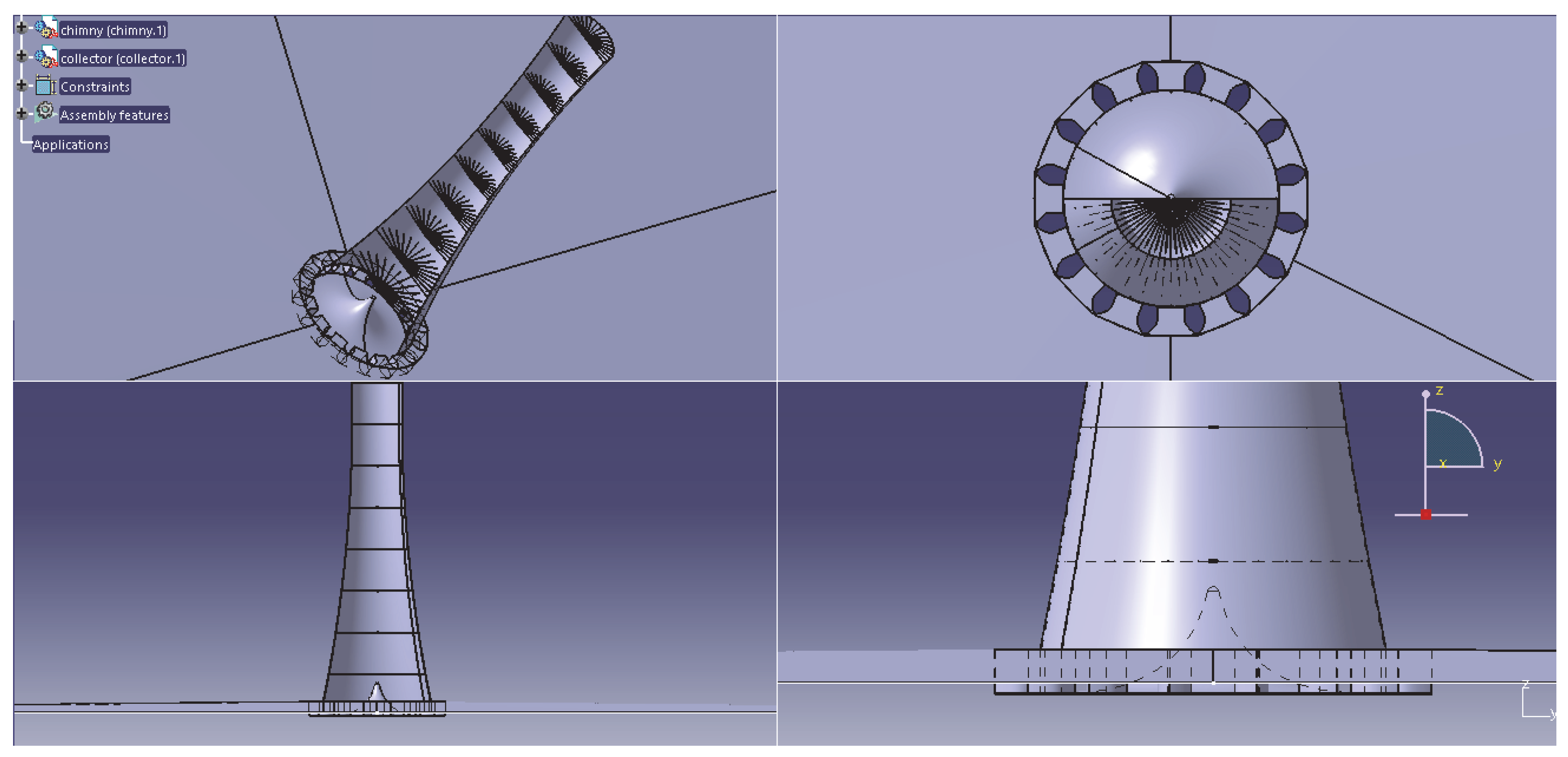

3.2. Analysis for SUTPP Model

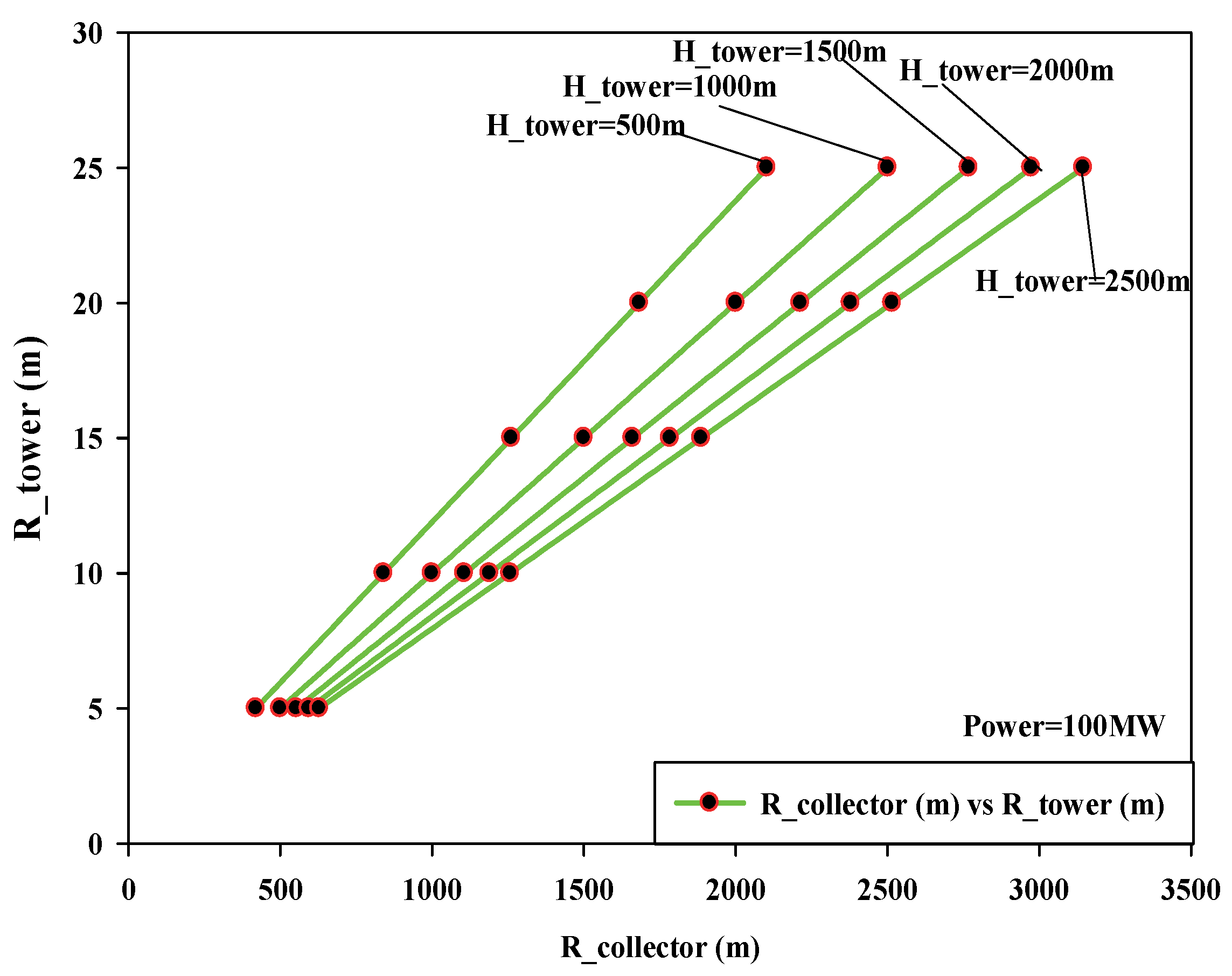

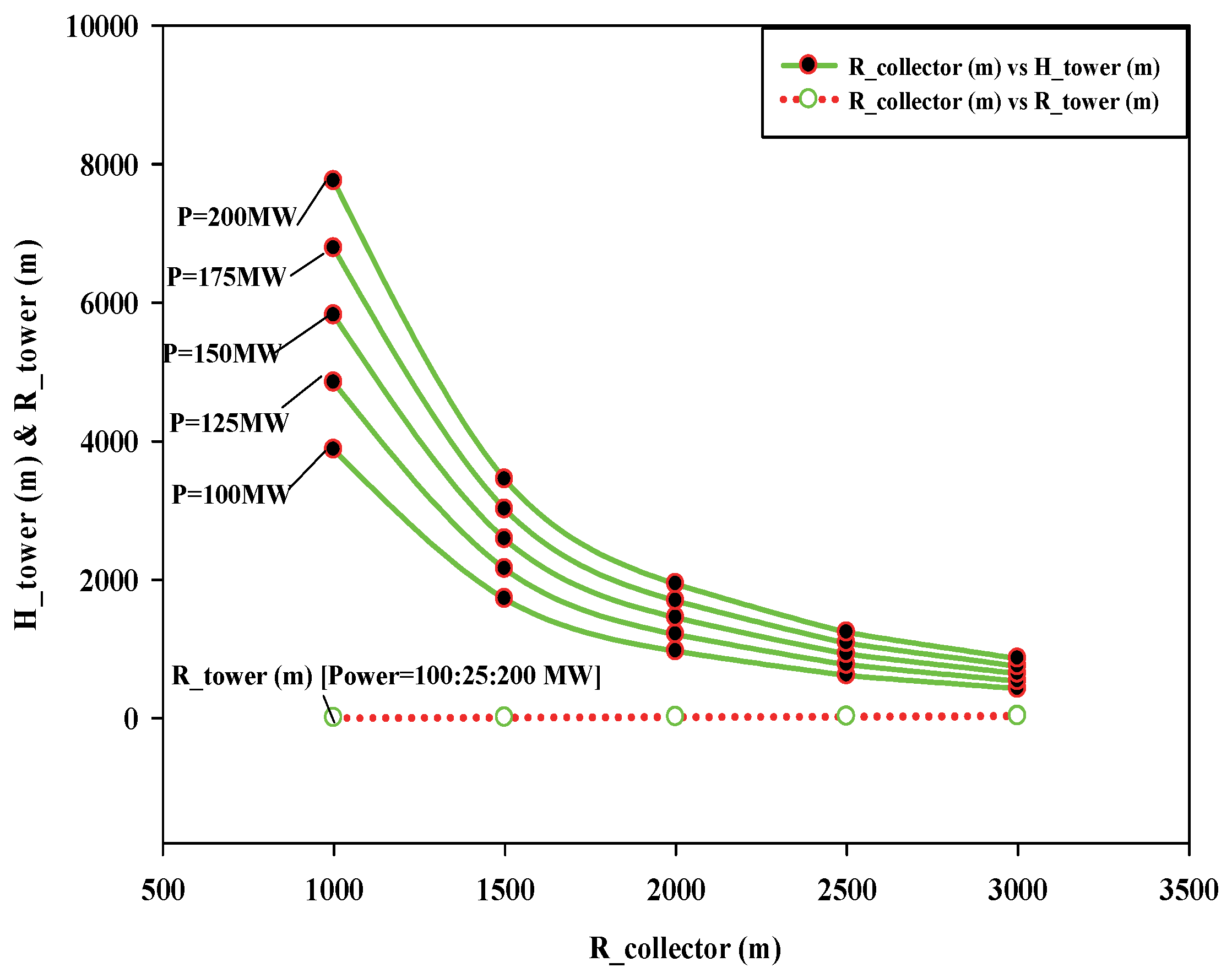

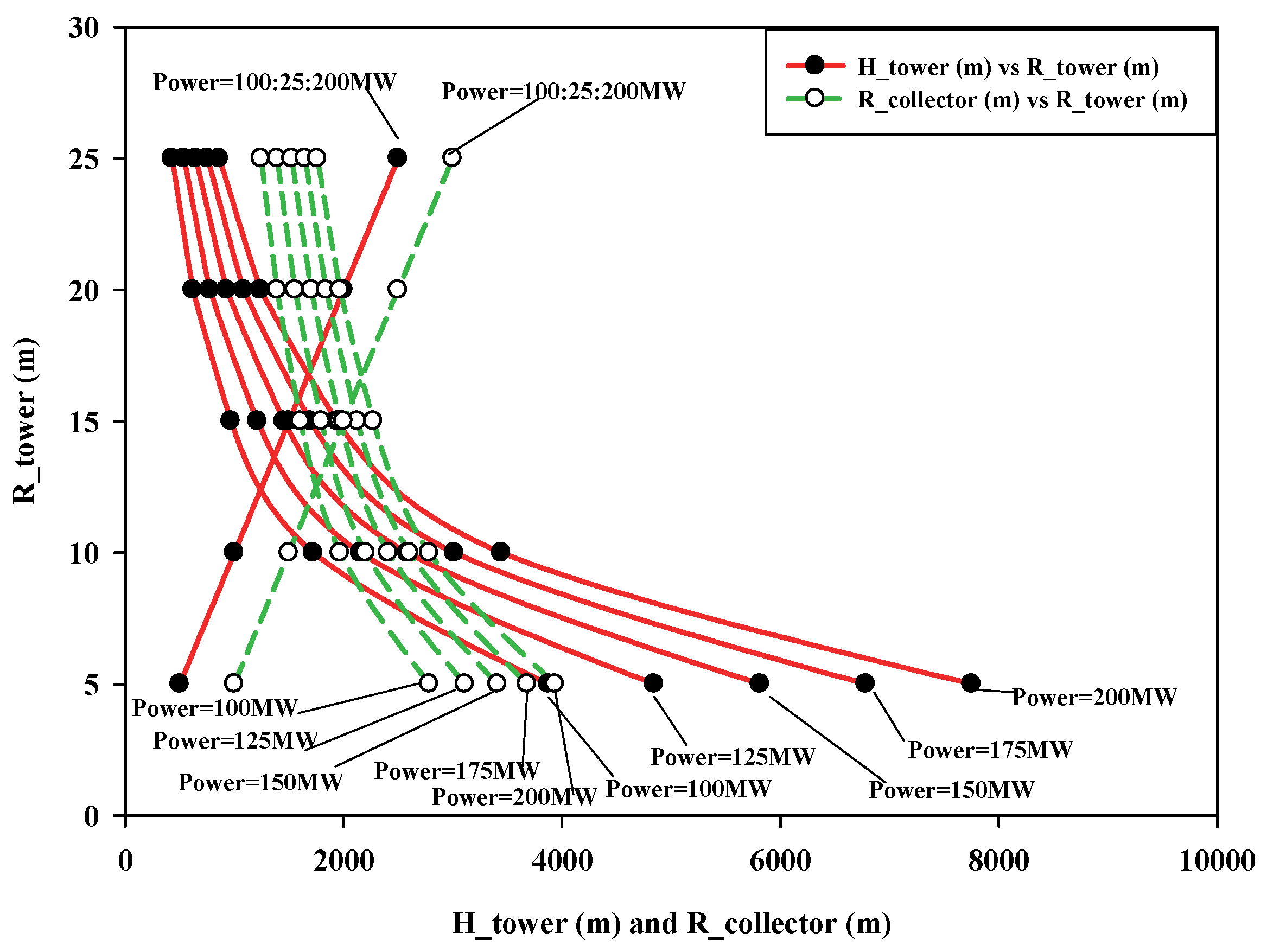

3.2.1. Selecting Dimensions, Limits, and Intervals for Optimization

| Dimension | Dimensional Limits (m) | Interval (m) |

|---|---|---|

| Tower-Height (HTower) | 500–2500 | 500 |

| Tower-Radius (RTower) | 05–25 | 05 |

| Collector -Radius (RCollector) | 1000–3000 | 500 |

| Power-Output | 100 MW–200 MW | 25 MW |

Collector

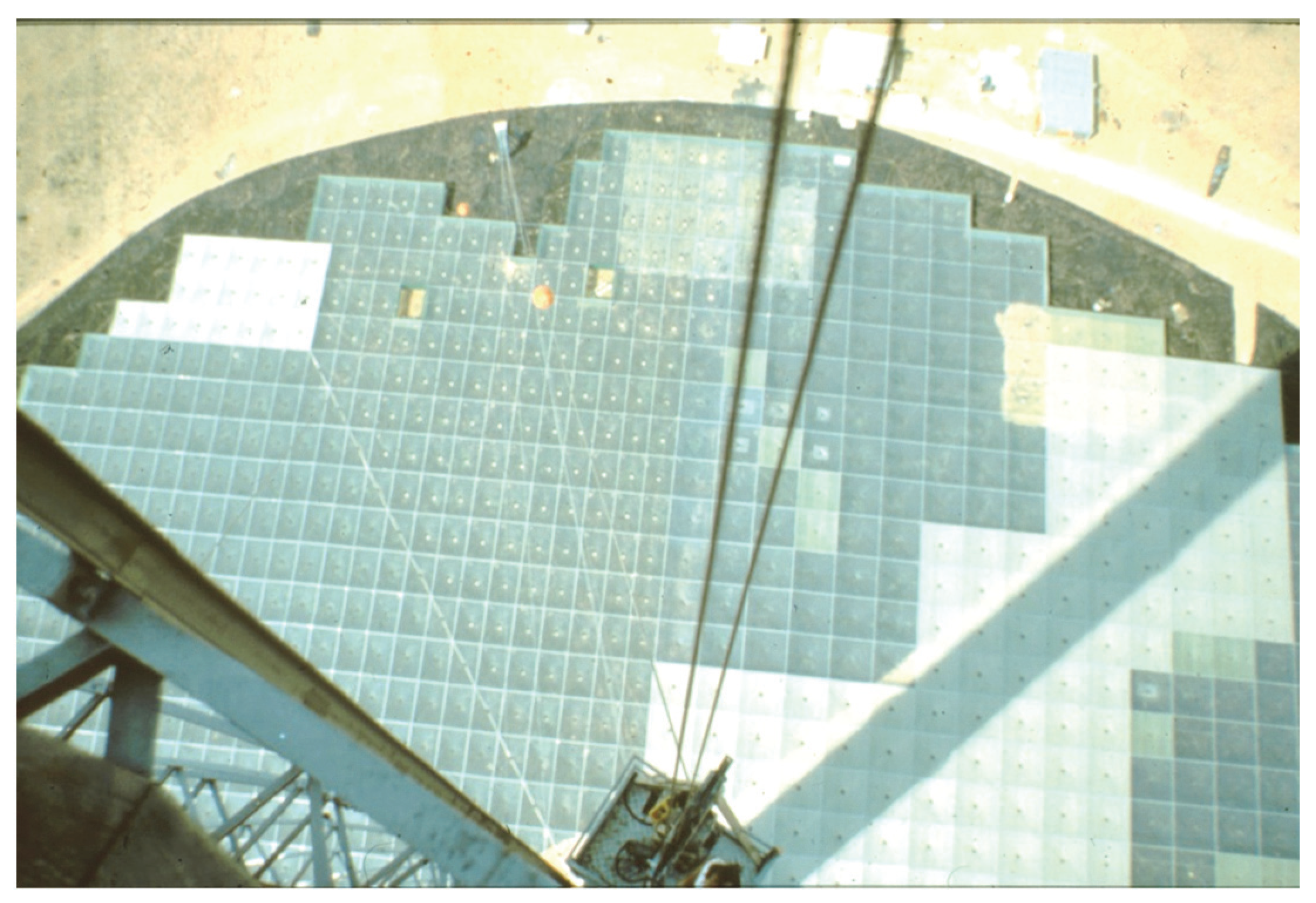

- The collector is made out of a support framework and a clear glass canopy (Figure 4).

- From the collector’s outside boundary to the tower’s exterior wall, the glass roof extends.

- The support structure for glass consists of a truss matrix supported by steel columns.

- For simulation purposes, the collector radius has an interval of 500 m, with a limiting range of 1000–3500 m.

- According to the connection, the real roof height rises toward the collector’s center. [41], where b is the roofing shape factor, H2 is the elevation of the collector roof, and rout is the outer radius of the collector. The collector elevation is considered in this model computation as being constant and equivalent to b = 1.

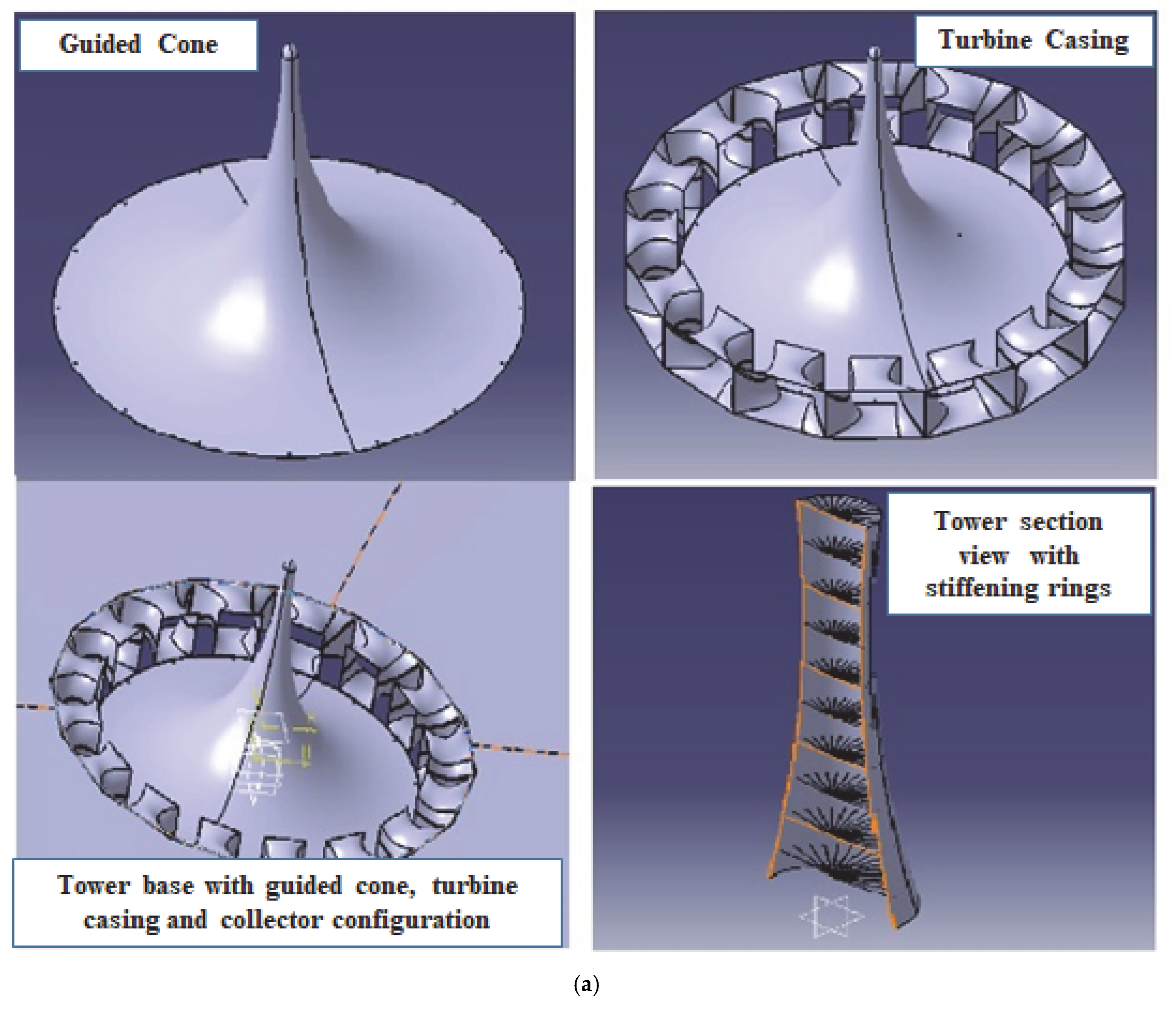

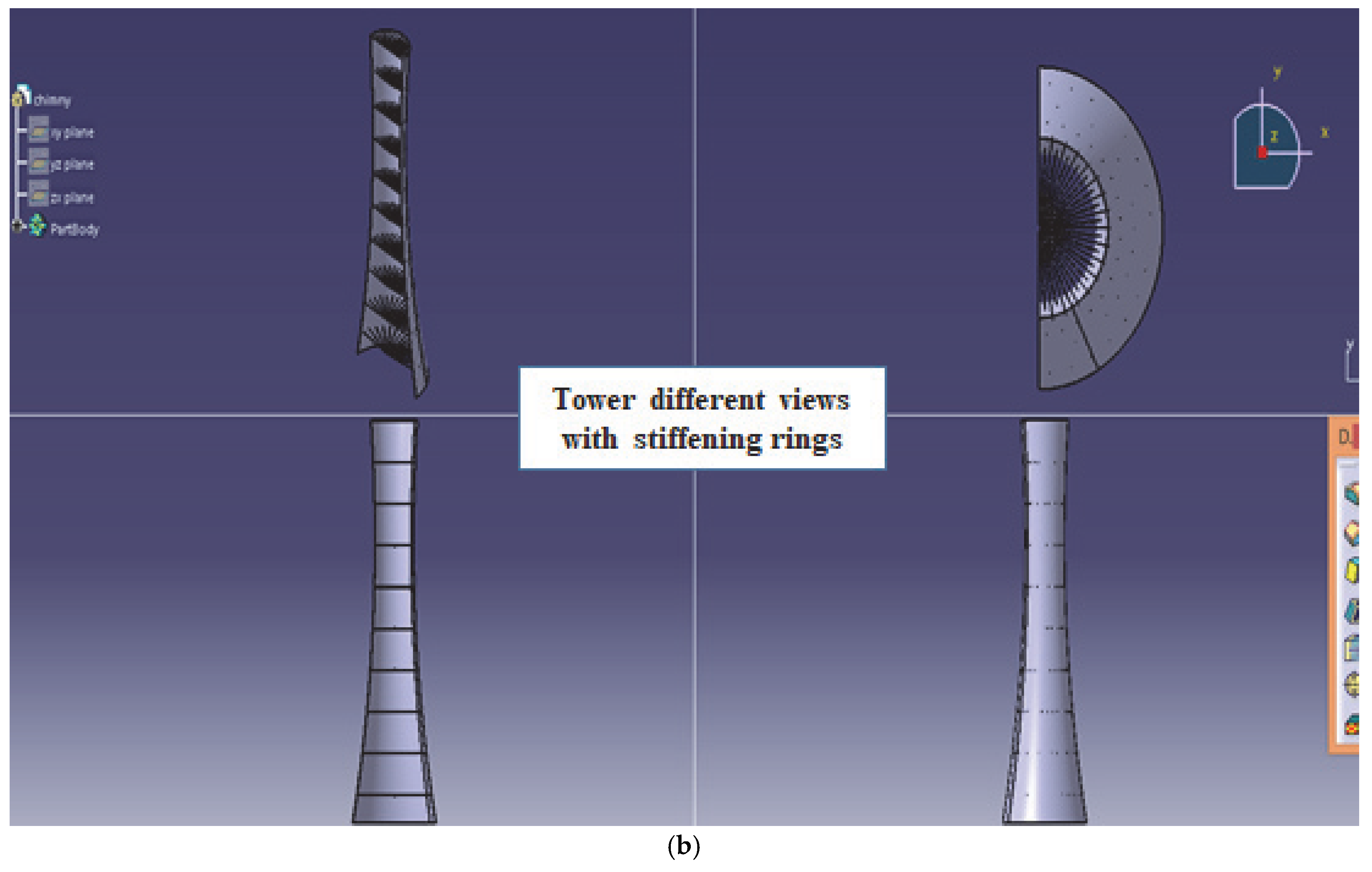

Solar Updraft Tower (Chimney)

Power Conversion Unit (PCU)

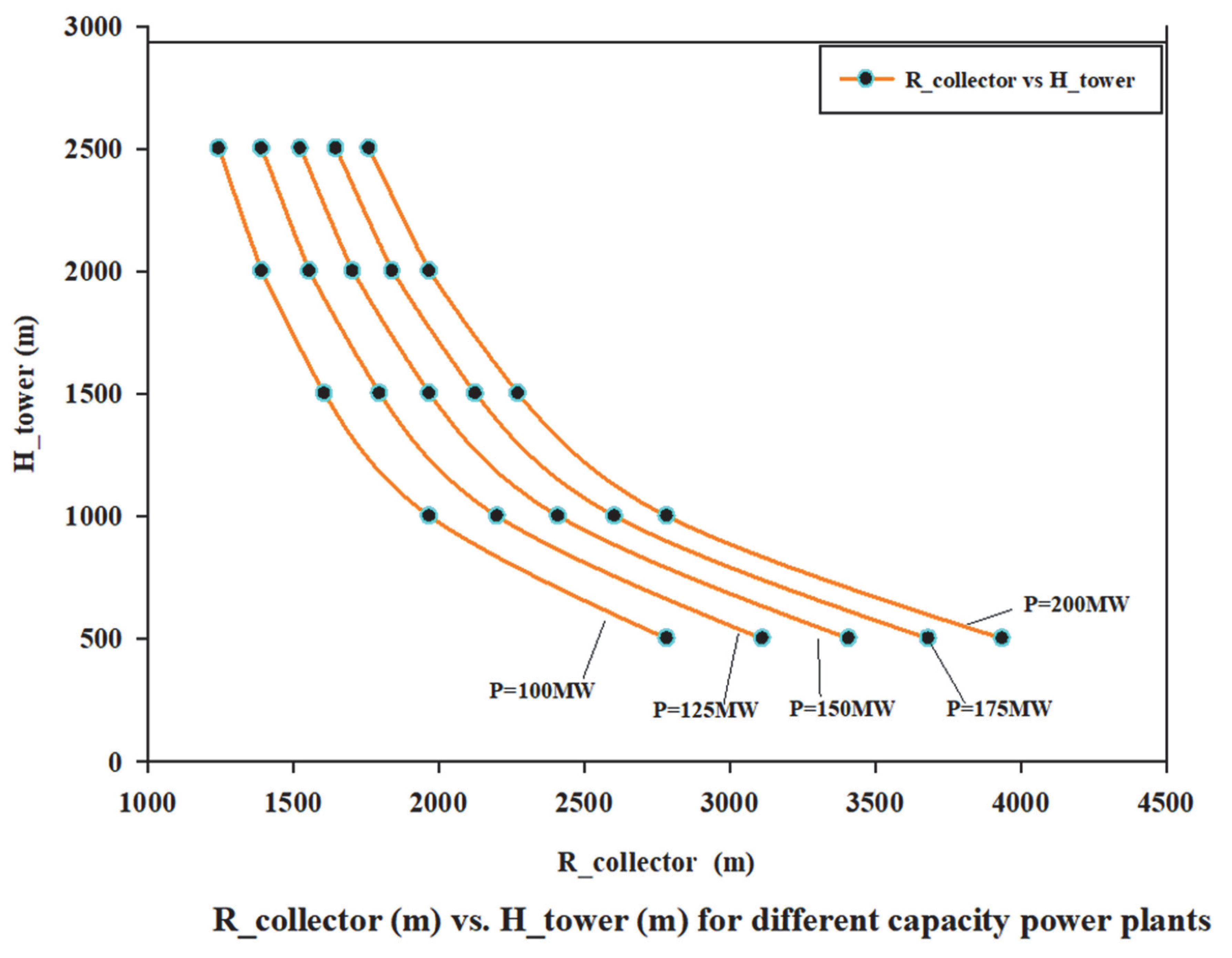

4. Thermo-Dimensional Optimization of a SUTPP

5. Experimental Methodology

6. Results and Discussion

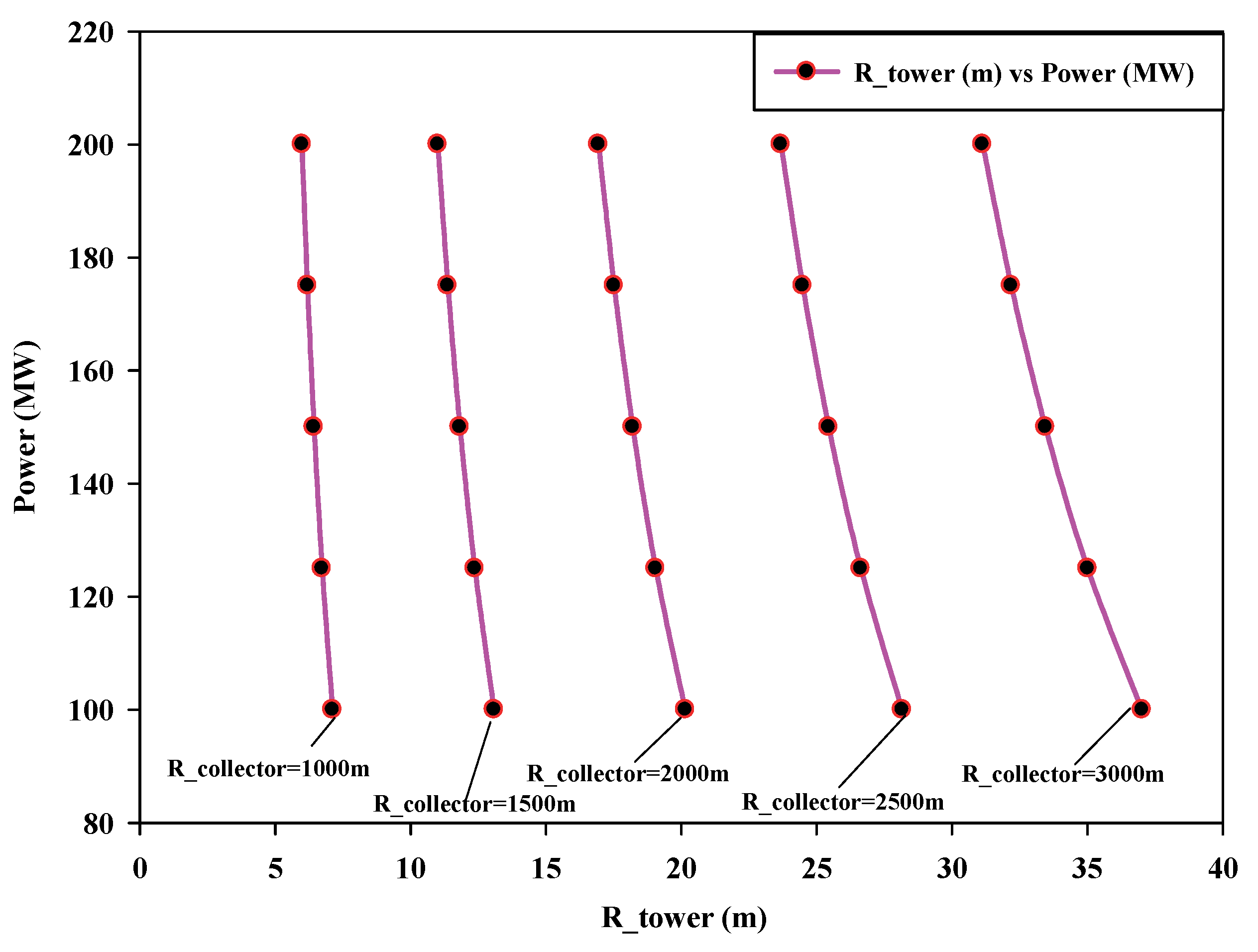

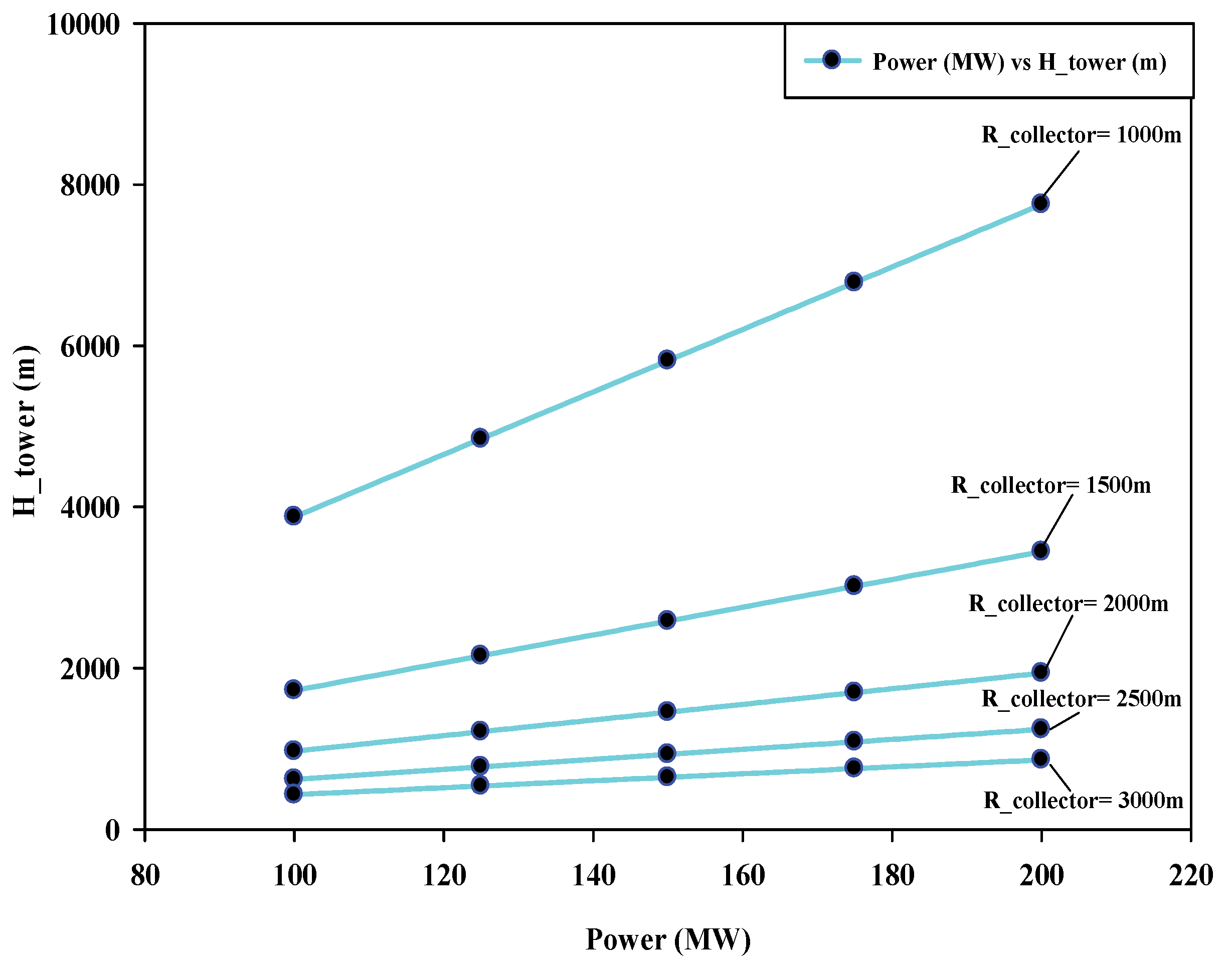

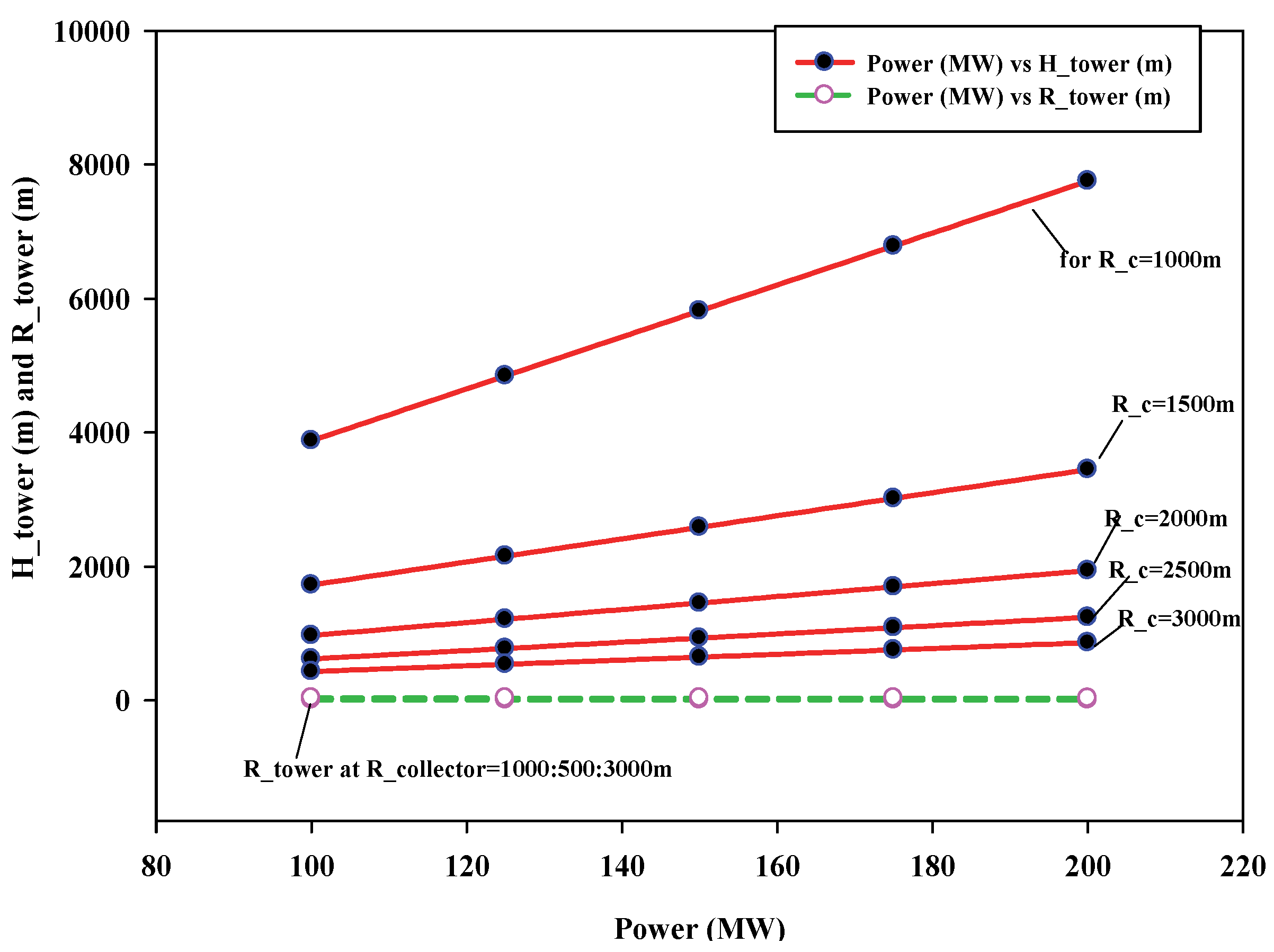

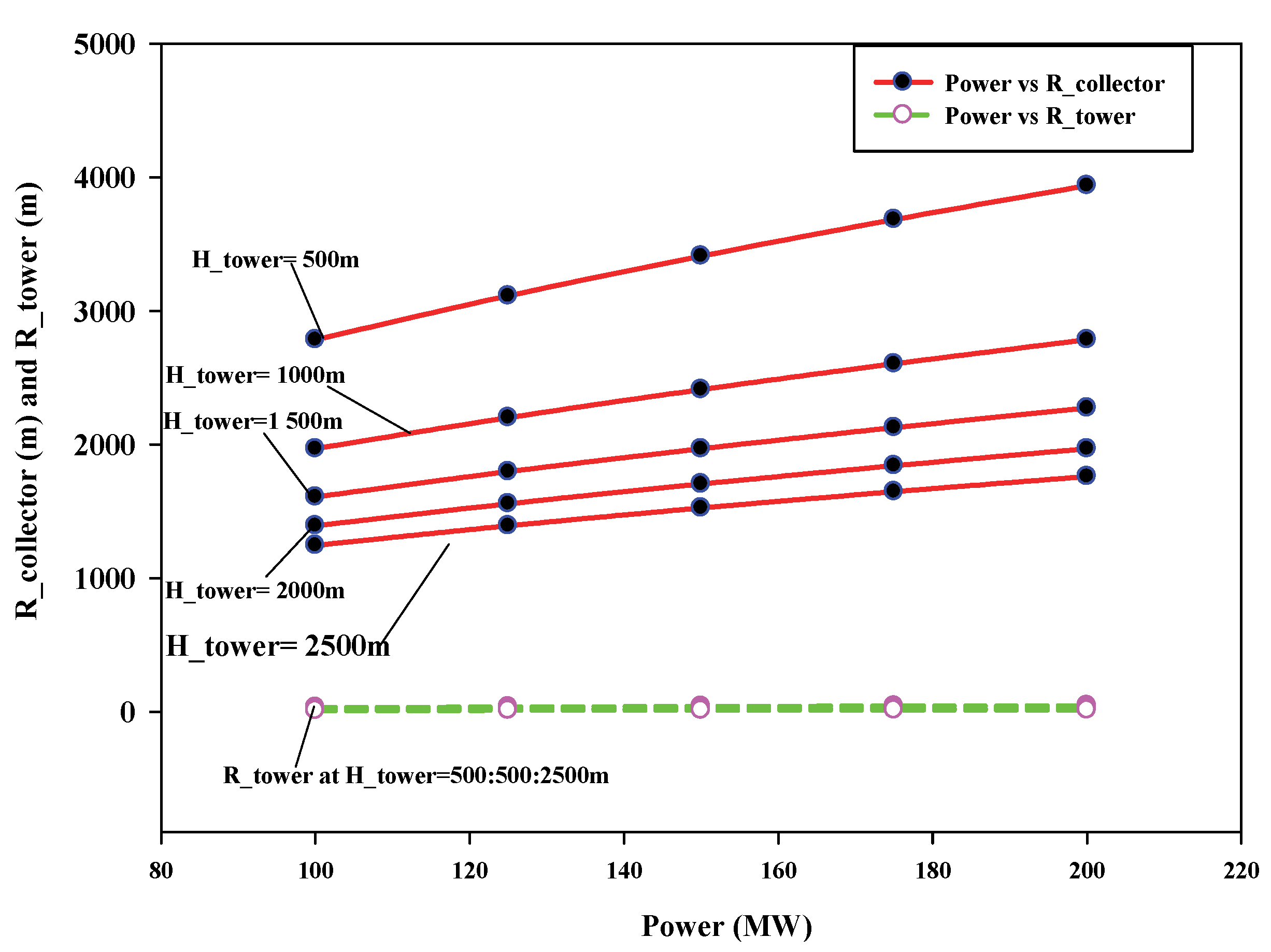

6.1. Effect of Variation in Dimensional Parameters on Power Output of SUTPP

6.2. Effect of Variation in Power Output on SUTPP Dimensional Parameters

7. Conclusions

- In a SUTPP for a fixed power output of 100 MW and with a variation in collector radius (RCollector) range from 1000 m to 3000 m, the tower height (HTower) varies from 3876.7 m to 430.7 m with a variation of 88.89%, while the change in the tower radius (RTower) takes place between 7.1 m and 37.0 m with a variation of 80.81%, respectively.

- Similarly, for a fixed power output of 100 MW and with a variation in tower height (HTower) ranging from 500 m to 2500 m, the collector radius (RCollector) varies from 2784.5 m to 1245.3 m with a variation of 55.27%, and the change in the tower radius (RTower) takes place between 33.1 m to 9.9 m with a variation of 70.09%, respectively.

- The results of the assessment show that the suggested geometrical parameters have a significant impact on the overall performance of the SUTPP. The amount of solar radiation and the suggested geometric parameters can also affect the SUTPP’s efficiency and power output.

- Large flat lands like Udat, Rajasthan, India, with position coordinates of 27°35′ and 72°43′, can be used for the installation of the SUTPP with a power output of 100 MW or an equal amount in a physically possible dimensional configuration and can be constructed through current available technologies.

8. Limitation and Future Scope

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols: | Subscripts: |

| A: Area, (m2) | a: Ambient |

| Cp: Specific heat capacity, J/(kg K) | avg: Mean/average |

| g: gravitational acceleration, (m/s2) | collector: Collector |

| h: Convective coefficient of heat transfer, (W/m2K) | g: Ground |

| H: Tower height, (m) | f: Friction factor |

| I: Average Insolation, (W/m2) | h: Hydraulic |

| L: Duct length, (m) | s: Smooth |

| : Mass flow rate, (kg/s) | Support: Fram support |

| P: Pressure, (Pa); Power, (W) | turbine: Turbine |

| q: Heat transfer, (m) | tg: Turbine-Generator |

| r: radious, (m) | th: Thermal |

| R: Universal gas constant, (J/mol-K); Radious, (m) | max.: Maximum |

| T: Temperature, (K) | t: Tower |

| V: Volume flow rate, (m3/sec) | v: Volume |

| W: Duct width, (m) | z: Elivation |

| Greek symbols: | Abbreviations: |

| Δ: Drop, gradient | SUTPP: Solar updraft tower power plant |

| η: Efficiency | HTVTS: Horizontal to vertical transition section |

| : air velocity (m/s) | DALR: Dry Adiabatic Lapse Rate |

| : Dynamic viscosity (Pa·s) | PCU: Power Conversion Unit |

| θ: collector slop (o) | TG: Turbine Generators |

| : density of air (kg/ m3) |

References

- Trieb, F.; Langniß, O.; Klaiß, H. Solar electricity generation—A comparative view of technologies, costs and environmental impact. Sol. Energy 1997, 59, 89–99. [Google Scholar] [CrossRef]

- Saini, M.; Sharma, A.; Singh, V.P.; Jain, S.; Dwivedi, G. Solar Thermal Receivers—A Review. Lect. Notes Mech. Eng. 2022, 2, 1_25. [Google Scholar] [CrossRef]

- Das, P.; Chandramohan, V.P. A review on solar updraft tower plant technology: Thermodynamic analysis, worldwide status, recent advances, major challenges and opportunities. Sustain. Energy Technol. Assessments 2022, 52, 102091. [Google Scholar] [CrossRef]

- Guo, P.; Li, T.; Xu, B.; Xu, X.; Li, J. Questions and current understanding about solar chimney power plant: A review. Energy Convers. Manag. 2019, 182, 21–33. [Google Scholar] [CrossRef]

- Balijepalli, R.; Chandramohan, V.P.; Kirankumar, K. Performance parameter evaluation, materials selection, solar radiation with energy losses, energy storage and turbine design procedure for a pilot scale solar updraft tower. Energy Convers. Manag. 2017, 150, 451–462. [Google Scholar] [CrossRef]

- Thirugnanasambandam, M.; Iniyan, S.; Goic, R. A review of solar thermal technologies. Renew. Sustain. Energy Rev. 2010, 14, 312–322. [Google Scholar] [CrossRef]

- Jain, S.; Sharma, M.P. Oxidation, Thermal, and Storage Stability Studies of Jatropha curcas Biodiesel. Int. Sch. Res. Netw. Renew. Energy 2012, 2012, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.; Bhattacharya, S.; Garg, A.; Jain, S. Process parameter optimization of low temperature transesterification of algae-jatropha oil blend. Energy 2018, 119, 983–988. [Google Scholar] [CrossRef]

- Goyal, P.; Sharma, M.P.; Jain, S. Optimization of transesterification of Jatropha curcas Oil to Biodiesel using Response Surface Methodology and its Adulteration with Kerosene. J. Mater. Environ. Sci. 2013, 4, 277–284. [Google Scholar]

- Jain, S.; Sharma, M.P. Oxidation and thermal behavior of Jatropha curcas biodiesel influenced by antioxidants and metal contaminants. Int. J. Eng. Sci. Technol. 2011, 3, 65–75. [Google Scholar] [CrossRef]

- Kumar, S.; Jain, S.; Kumar, H. Environmental Effects Prediction of jatropha-algae biodiesel blend oil yield with the application of artificial neural networks technique. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 41, 1285–1295. [Google Scholar] [CrossRef]

- Kumar, S.; Jain, S.; Kumar, H. Experimental Study on Biodiesel Production Parameter Optimization of Jatropha-Algae Oil Mixtures and Performance and Emission Analysis of a Diesel Engine Coupled with a Generator Fueled with Diesel/Biodiesel Blends. ACS Omega 2020, 5, 17033–17041. [Google Scholar] [CrossRef] [PubMed]

- Jain, S. 17-The production of biodiesel using Karanja (Pongamia pinnata) and Jatropha (Jatropha curcas) Oil. In Biomass, Biopolymer-Based Materials, and Bioenergy; Verma, D., Fortunati, E., Jain, S., Zhang, X., Eds.; Woodhead Publishing: Sawston, UK, 2019; pp. 397–408. ISBN 978-0-08-102426-3. [Google Scholar]

- Lord, J.; Thomas, A.; Treat, N.; Forkin, M.; Bain, R.; Dulac, P.; Behroozi, C.H.; Mamutov, T.; Fongheiser, J.; Kobilansky, N.; et al. Global potential for harvesting drinking water from air using solar energy. Nature 2021, 598, 611–617. [Google Scholar] [CrossRef]

- Singh, V.P.; Karn, A.; Dwivedi, G.; Alam, T.; Kumar, A. Experimental Assessment of Variation in Open Area Ratio on Thermohydraulic Performance of Parallel Flow Solar Air Heater. Arab. J. Sci. Eng. 2022, 12, 1–17. [Google Scholar] [CrossRef]

- Cyranoski, D. China tests giant air cleaner to combat smog. Nature 2018, 555, 152–153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lewis, N.S. Research opportunities to advance solar energy utilization. Science 2016, 351, 353–364. [Google Scholar] [CrossRef] [Green Version]

- Günther, H. Hundert Jahren: Die künftige Energieversorgung der Welt; KosmosFranckh’sche Verlagsbuchhandlung: Stuttgart, Germany, 1931; p. 125. [Google Scholar]

- Schlaich, J.; Bergermann, R.; Schiel, W.; Weinrebe, G. Sustainable electricity generation with solar updraft towers. Struct. Eng. Int. J. Int. Assoc. Bridg. Struct. Eng. 2004, 14, 225–229. [Google Scholar] [CrossRef]

- Ming, T.; Liu, W.; Pan, Y.; Xu, G. Numerical analysis of flow and heat transfer characteristics in solar chimney power plants with energy storage layer. Energy Convers. Manag. 2008, 49, 2872–2879. [Google Scholar] [CrossRef]

- Petela, R. Thermodynamic study of a simplified model of the solar chimney power plant. Sol. Energy 2009, 83, 94–107. [Google Scholar] [CrossRef]

- Muhammed, H.A.; Atrooshi, S.A. Modeling solar chimney for geometry optimization. Renew. Energy 2019, 138, 212–223. [Google Scholar] [CrossRef]

- Choi, Y.J.; Kam, D.H.; Park, Y.W.; Jeong, Y.H. Development of analytical model for solar chimney power plant with and without water storage system. Energy 2016, 112, 200–207. [Google Scholar] [CrossRef]

- Esmail, M.F.C.; Khodary, A.; Mekhail, T.; Hares, E. Effect of wind speed over the chimney on the updraft velocity of a solar chimney power plant: An experimental study. Case Stud. Therm. Eng. 2022, 37, 102265. [Google Scholar] [CrossRef]

- Huang, M.; Liu, G.; He, Y.; Li, A.; Tao, W. Structural Optimization of Solar Chimney Power Plant by a Genetic Algorithm. Hsi-An Chiao Tung Ta Hsueh/Journal Xi’an Jiaotong Univ. 2021, 55, 1–10. [Google Scholar] [CrossRef]

- Singh, V.P.; Jain, S.; Gupta, J.M.L. Performance assessment of double-pass parallel flow solar air heater with perforated multi-V ribs roughness—Part B. Exp. Heat Transf. 2022, 35, 1059–1076. [Google Scholar] [CrossRef]

- Kalash, S.; Naimeh, W.; Ajib, S. A review of sloped solar updraft power technology. Energy Procedia 2014, 50, 222–228. [Google Scholar] [CrossRef] [Green Version]

- Milani Shirvan, K.; Mirzakhanlari, S.; Mamourian, M.; Kalogirou, S.A. Optimization of effective parameters on solar updraft tower to achieve potential maximum power output: A sensitivity analysis and numerical simulation. Appl. Energy 2017, 195, 725–737. [Google Scholar] [CrossRef]

- Zhou, X.; Xu, Y. Solar updraft tower power generation. Sol. Energy 2016, 128, 95–125. [Google Scholar] [CrossRef]

- Singh, V.P.; Jain, S.; Karn, A.; Kumar, A.; Dwivedi, G.; Meena, C.S.; Dutt, N.; Ghosh, A. Recent Developments and Advancements in Solar Air Heaters: A Detailed Review. Sustainability 2022, 14, 12149. [Google Scholar] [CrossRef]

- Schlaich, J.; Bergermann, R.; Schiel, W.; Weinrebe, G. Design of commercial solar updraft tower systems—Utilization of solar induced convective flows for power generation. J. Sol. Energy Eng. Trans. ASME 2005, 127, 117–124. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Aja, O.C. Historic and recent progress in solar chimney power plant enhancing technologies. Renew. Sustain. Energy Rev. 2016, 58, 1269–1292. [Google Scholar] [CrossRef]

- Singh, V.P.; Jain, S.; Karn, A.; Dwivedi, G.; Kumar, A.; Mishra, S.; Sharma, N.K.; Bajaj, M.; Zawbaa, H.M.; Kamel, S. Heat transfer and friction factor correlations development for double pass solar air heater artificially roughened with perforated multi-V ribs. Case Stud. Therm. Eng. 2022, 39, 102461. [Google Scholar] [CrossRef]

- Amudam, Y.; Chandramohan, V.P. Influence of thermal energy storage system on flow and performance parameters of solar updraft tower power plant: A three dimensional numerical analysis. J. Clean. Prod. 2019, 207, 136–152. [Google Scholar] [CrossRef]

- Singh, V.P.; Jain, S.; Karn, A.; Kumar, A.; Dwivedi, G. Mathematical Modeling of Efficiency Evaluation of Double Pass Parallel Flow Solar Air Heater. Sustainability 2022, 14, 10535. [Google Scholar] [CrossRef]

- Schlaich, J.; Bergermann, R.; Schiel, W.; Weinrebe, G. Design of commercial solar tower systems—Utilization of solar induced convective flows for power generation. In Proceedings of the International Solar Energy Conference, Kohala Coast, HI, USA, 15–18 March 2003; pp. 573–581. [Google Scholar]

- Goldack, A. Natural frequencies and mode shapes of towers for solar updraft power plants. In Proceedings of the Proceedings of the 8th International Conference on Structural Dynamics, EURODYN 2011, Leuven, Belgium, 4–6 July 2011; pp. 3575–3581. [Google Scholar]

- Bernardes, M.D.S.; Voß, A.; Weinrebe, G. Thermal and technical analyses of solar chimneys. Sol. Energy 2003, 75, 511–524. [Google Scholar] [CrossRef]

- Hedderwick, R.A. Performance Evaluation of a Solar Chimney Power Plant. 2000. Available online: https://core.ac.uk/download/pdf/37320706.pdf (accessed on 27 December 2022).

- Pretorius, J.P.; Kroger, D.G. Solar chimney power plant performance. J. Sol. Energy Eng. Trans. ASME 2006, 128, 302–311. [Google Scholar] [CrossRef]

- Pretorius, J.P.; Kröger, D.G. Critical evaluation of solar chimney power plant performance. Sol. Energy 2006, 80, 535–544. [Google Scholar] [CrossRef]

- Zhou, X.; Yuan, S.; Bernardes, M.A.d.S. Sloped-collector solar updraft tower power plant performance. Int. J. Heat Mass Transf. 2013, 66, 798–807. [Google Scholar] [CrossRef]

- Das, P.; Chandramohan, V.P. CFD analysis on flow and performance parameters estimation of solar updraft tower (SUT) plant varying its geometrical configurations. Energy Sources Part A Recover. Util. Environ. Eff. 2018, 40, 1532–1546. [Google Scholar] [CrossRef]

- Singh, V.P.; Jain, S.; Gupta, J.M.L. Analysis of the effect of perforation in multi-v rib artificial roughened single pass solar air heater: Part A. Exp. Heat Transf. 2021, 36, 163–182. [Google Scholar] [CrossRef]

- Gannon, A.J.; Backstro, T.W. Von Solar Chimney Cycle Analysis With System Loss and Solar Collector Performance. J. Sol. Energy Eng. 2000, 122, 133–137. [Google Scholar] [CrossRef]

- Westdyk, D.; Kröger, D.G. Modeling evapotranspiration effects on air flowing in a small glass roofed Tunnel. J. Irrig. Drain. Eng. 2010, 136, 326–332. [Google Scholar] [CrossRef]

- Bernardes, M.D.S.; von Backström, T.W. Evaluation of operational control strategies applicable to solar chimney power plants. Sol. Energy 2010, 84, 277–288. [Google Scholar] [CrossRef]

- von Backström, T.W.; Gannon, A.J. Solar chimney turbine characteristics. Sol. Energy 2004, 76, 235–241. [Google Scholar] [CrossRef]

- Pasumarthi, N.; Sherif, S.A. Experimental and theoretical performance of a demonstration solar chimney model—Part I: Mathematical model development. Int. J. Energy Res. 1998, 22, 277–288. [Google Scholar] [CrossRef]

- Pasumarthi, N.; Sherif, S.A. Experimental and theoretical performance of a demonstration solar chimney model—Part II: Experimental and theoretical results and economic analysis. Int. J. Energy Res. 1998, 22, 443–461. [Google Scholar] [CrossRef]

- Bakshi, R. India’s emergence as a global leader in renewable energy technologies. Renew. energy 1998, 15, 107–113. [Google Scholar] [CrossRef]

- Sukhatme, S.P.; Nayak, J.K. Solar energy in western Rajasthan. Curr. Sci. 1997, 72, 62–68. [Google Scholar]

- Ramachandra, T.V.; Jain, R.; Krishnadas, G. Hotspots of solar potential in India. Renew. Sustain. Energy Rev. 2011, 15, 3178–3186. [Google Scholar] [CrossRef]

- Bakshi, P.R. An overview of renewable energy commercialization in India. Renew. Energy 1997, 10, 347–353. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, K.; Kaushik, N.; Sharma, S.; Mishra, S. Renewable energy in India: Current status and future potentials. Renew. Sustain. Energy Rev. 2010, 14, 2434–2442. [Google Scholar] [CrossRef]

- Singh, V.P.; Jain, S.; Kumar, A. Establishment of correlations for the Thermo-Hydraulic parameters due to perforation in a multi-V rib roughened single pass solar air heater. Exp. Heat Transf. 2022, 35, 1–20. [Google Scholar] [CrossRef]

- Meena, C.S.; Kumar, A.; Jain, S.; Rehman, A.U.; Mishra, S.; Sharma, N.K.; Bajaj, M.; Shafiq, M.; Eldin, E.T. Innovation in Green Building Sector for Sustainable Future. Energies 2022, 15, 6631. [Google Scholar] [CrossRef]

- Kurian, R.; Kulkarni, K.S.; Ramani, P.V.; Meena, C.S.; Kumar, A.; Cozzolino, R. Estimation of carbon footprint of residential building in warm humid climate of india through BIM. Energies 2021, 14, 4237. [Google Scholar] [CrossRef]

- Saini, L.; Meena, C.S.; Raj, B.P.; Agarwal, N.; Kumar, A. Net Zero Energy Consumption building in India: An overview and initiative toward sustainable future. Int. J. Green Energy 2022, 19, 544–561. [Google Scholar] [CrossRef]

- Hurtado, F.J.; Kaiser, A.S.; Zamora, B. Evaluation of the influence of soil thermal inertia on the performance of a solar chimney power plant. Energy 2012, 47, 213–224. [Google Scholar] [CrossRef]

- Guo, P.; Li, J.; Wang, Y.; Wang, Y. Evaluation of the optimal turbine pressure drop ratio for a solar chimney power plant. Energy Convers. Manag. 2016, 108, 14–22. [Google Scholar] [CrossRef]

- Bhattacharya, S.C.; Jana, C. Renewable energy in India: Historical developments and prospects. Energy 2009, 34, 981–991. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, P.; Kapoor, N.R.; Meena, C.S.; Jain, K.; Kulkarni, K.S.; Cozzolino, R. Ecological footprint of residential buildings in composite climate of India—A case study. Sustain. 2021, 13, 11949. [Google Scholar] [CrossRef]

- Haaf, W.; Friedrich, K.; Mayr, G.; Schlaich, J. Part I: Principle and Construction of the Pilot Plant in Manzanares. Int. J. Sol. Energy 1983, 2, 3–20. [Google Scholar] [CrossRef]

- Trieb, F.; Langniß, O.; Klaiß, H.; Zhou, X.; Yuan, S.; Bernardes, M.A.D.S.; Ming, T.; Wang, X.; de Richter, R.K.; Liu, W.W.; et al. A cost-benefit analysis of power generation from commercial reinforced concrete solar chimney power plant. Renew. Sustain. Energy Rev. 2013, 15, 104–113. [Google Scholar] [CrossRef]

- Krumar Mandal, D.; Pradhan, S.; Chakraborty, R.; Barman, A.; Biswas, N. Experimental investigation of a solar chimney power plant and its numerical verification of thermo-physical flow parameters for performance enhancement. Sustain. Energy Technol. Assessments 2022, 50, 101786. [Google Scholar] [CrossRef]

- Kumar, B.; Patil, A.K.; Jain, S.; Kumar, M. Effects of Double V Cuts in Perforated Twisted Tape Insert: An Experimental Study. Heat Transf. Eng. 2020, 41, 1473–1484. [Google Scholar] [CrossRef]

- Ming, T.; Liu, W.; Wu, Y.; Gui, J.; Peng, K.; Pan, T. Chapter 1—Introduction. In Solar Chimney Power Plant Generating Technology; Ming, T., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 1–46. ISBN 978-0-12-805370-6. [Google Scholar]

- Fluri, T.P.; Von Backström, T.W. Performance analysis of the power conversion unit of a solar chimney power plant. Sol. Energy 2008, 82, 999–1008. [Google Scholar] [CrossRef]

- Singh, V.P.; Jain, S.; Gupta, J.M.L. Analysis of the effect of variation in open area ratio in perforated multi-V rib roughened single pass solar air heater—Part A. Energy Sources Part A Recover. Util. Environ. Eff. 2022, 44, 1–21. [Google Scholar] [CrossRef]

- Zuo, L.; Yan, Z.; Qu, N.; Dai, P.; Zhou, T.; Zheng, Y.; Ge, Y. Solar chimney power plant combined with membrane distillation (SCPPMD), part I: Principle and operation characteristics. Energy Convers. Manag. 2022, 258, 115501. [Google Scholar] [CrossRef]

- Zuo, L.; Dai, P.; Yan, Z.; Li, C.; Zheng, Y.; Ge, Y. Design and optimization of turbine for solar chimney power plant based on lifting design method of axial-flow hydraulic turbine impeller. Renew. Energy 2021, 171, 799–811. [Google Scholar] [CrossRef]

- Kalash, S.; Naimeh, W.; Ajib, S. Experimental investigation of a pilot sloped solar updraft power plant prototype performance throughout a year. Energy Procedia 2014, 50, 627–633. [Google Scholar] [CrossRef] [Green Version]

- Pradhan, S.; Chakraborty, R.; Mandal, D.K.; Barman, A.; Bose, P. Design and performance analysis of solar chimney power plant (SCPP): A review. Sustain. Energy Technol. Assessments 2021, 47, 101411. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, V.P.; Dwivedi, G. Technical Analysis of a Large-Scale Solar Updraft Tower Power Plant. Energies 2023, 16, 494. https://doi.org/10.3390/en16010494

Singh VP, Dwivedi G. Technical Analysis of a Large-Scale Solar Updraft Tower Power Plant. Energies. 2023; 16(1):494. https://doi.org/10.3390/en16010494

Chicago/Turabian StyleSingh, Varun Pratap, and Gaurav Dwivedi. 2023. "Technical Analysis of a Large-Scale Solar Updraft Tower Power Plant" Energies 16, no. 1: 494. https://doi.org/10.3390/en16010494

APA StyleSingh, V. P., & Dwivedi, G. (2023). Technical Analysis of a Large-Scale Solar Updraft Tower Power Plant. Energies, 16(1), 494. https://doi.org/10.3390/en16010494