Cycle Characteristics of a New High-Temperature Heat Pump Based on Absorption–Compression Revolution

Abstract

:1. Background

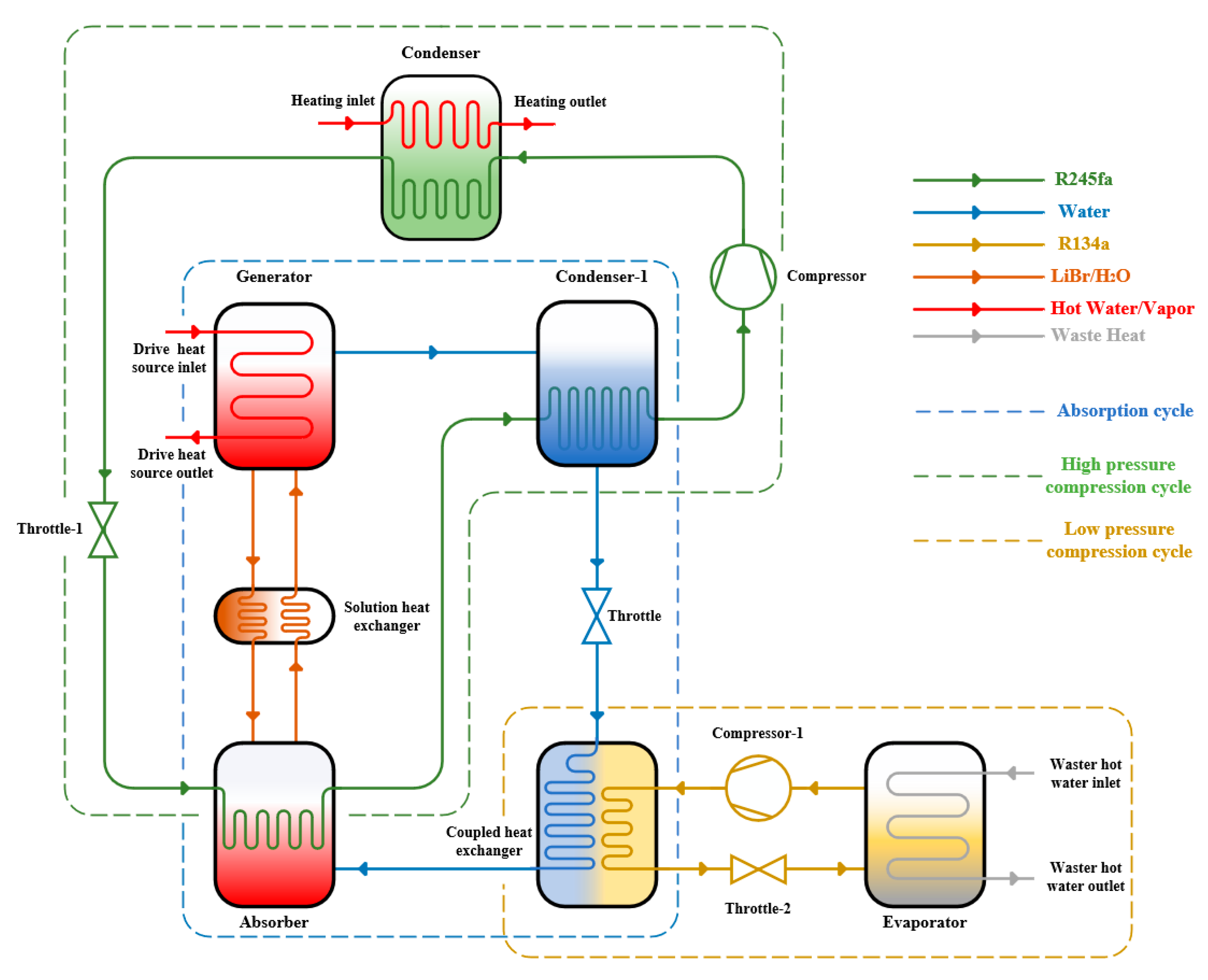

1.1. Introduction to the Theoretical Cycle

1.2. Modeling Analysis of the Thermodynamic Cycle

- (1)

- The phase transition of the refrigerant in the heat exchanger is an isobaric process;

- (2)

- The enthalpy of the refrigerant remains unchanged before and after throttling and lowering the pressure;

- (3)

- The heat loss of the refrigerant and the carrier refrigerant is ignored during the processes of phase transition and pipeline flow;

- (4)

- The actual cycle coefficient of the unit is set as the product of the motor efficiency, mechanical efficiency, and isentropic efficiency. The motor efficiency was set to 0.85, the mechanical efficiency was set to 0.85, and the isentropic efficiency was set to 0.90 [15].

- (5)

- The difference between the heat exchange end of the evaporator and the condenser should be set to 10 °C, and the degree of superheat and subcooling should be set to 5 °C [16].

2. Results

2.1. Influence of the Absorption Cycle Evaporation Temperature on Cycle Performance

2.1.1. Influence of the Absorption Cycle Evaporation Temperature on the Concentration of Lithium Bromide Solution

2.1.2. Effect of the Absorption Cycle Evaporation Temperature on the Absorption Cycle’s COP

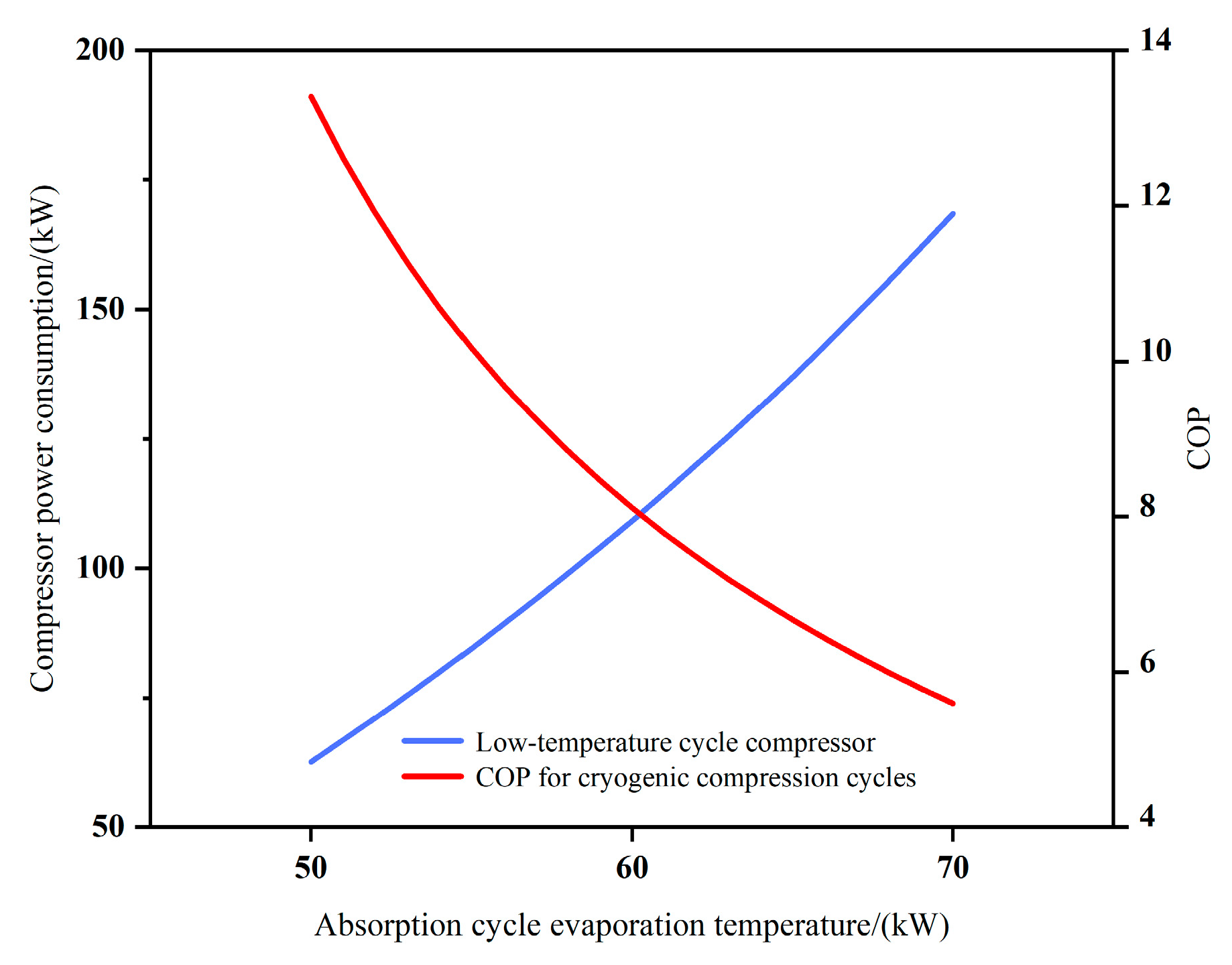

2.1.3. Effect of the Absorption Cycle Evaporation Temperature on the Power Consumption and COP of a Low-Temperature Compressor

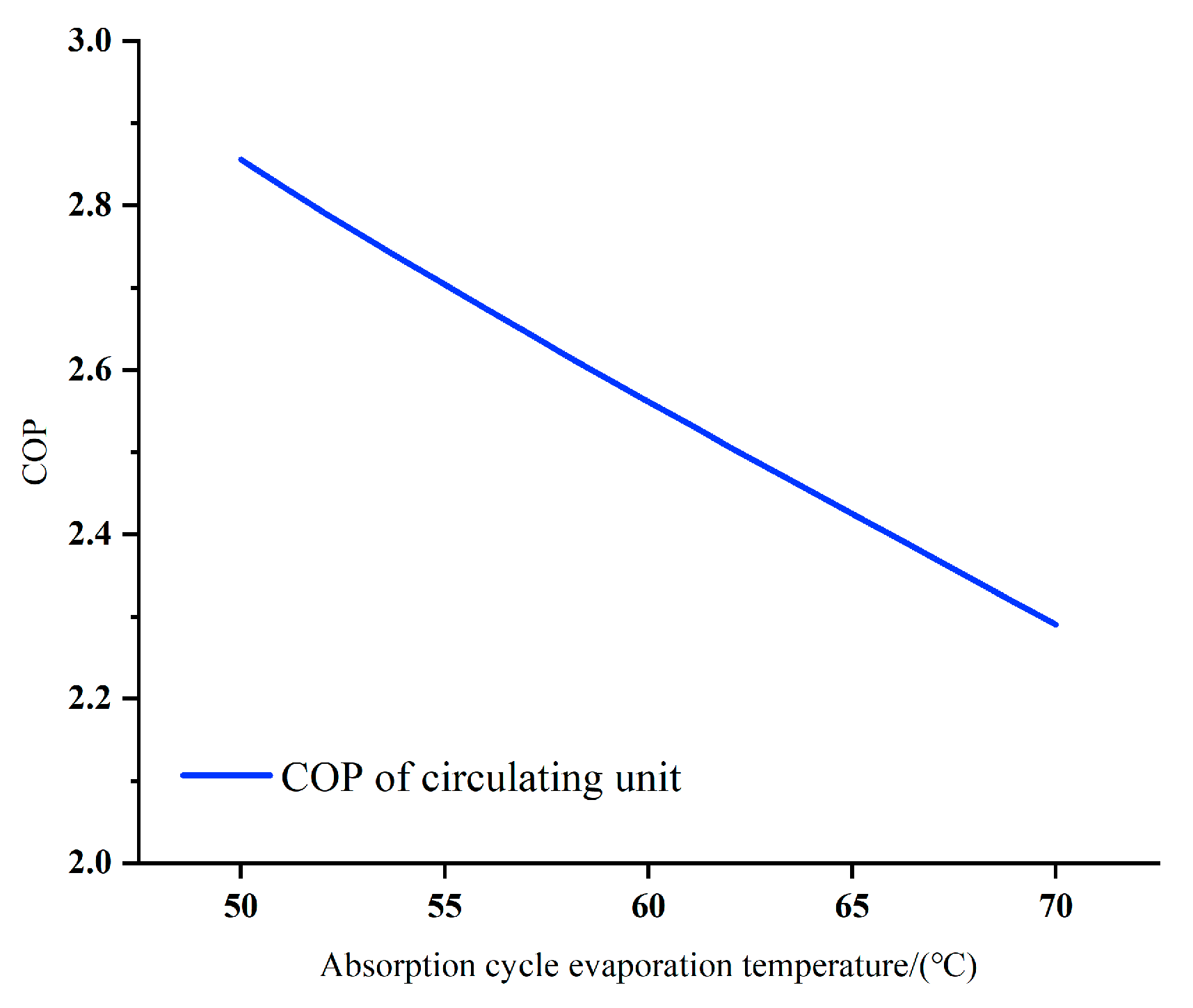

2.1.4. Effect of the Absorption Cycle Condensation Temperature on the COP of the Cycle Unit

2.2. Effect of Absorption Cycle Condensation Temperature on Cycle Performance

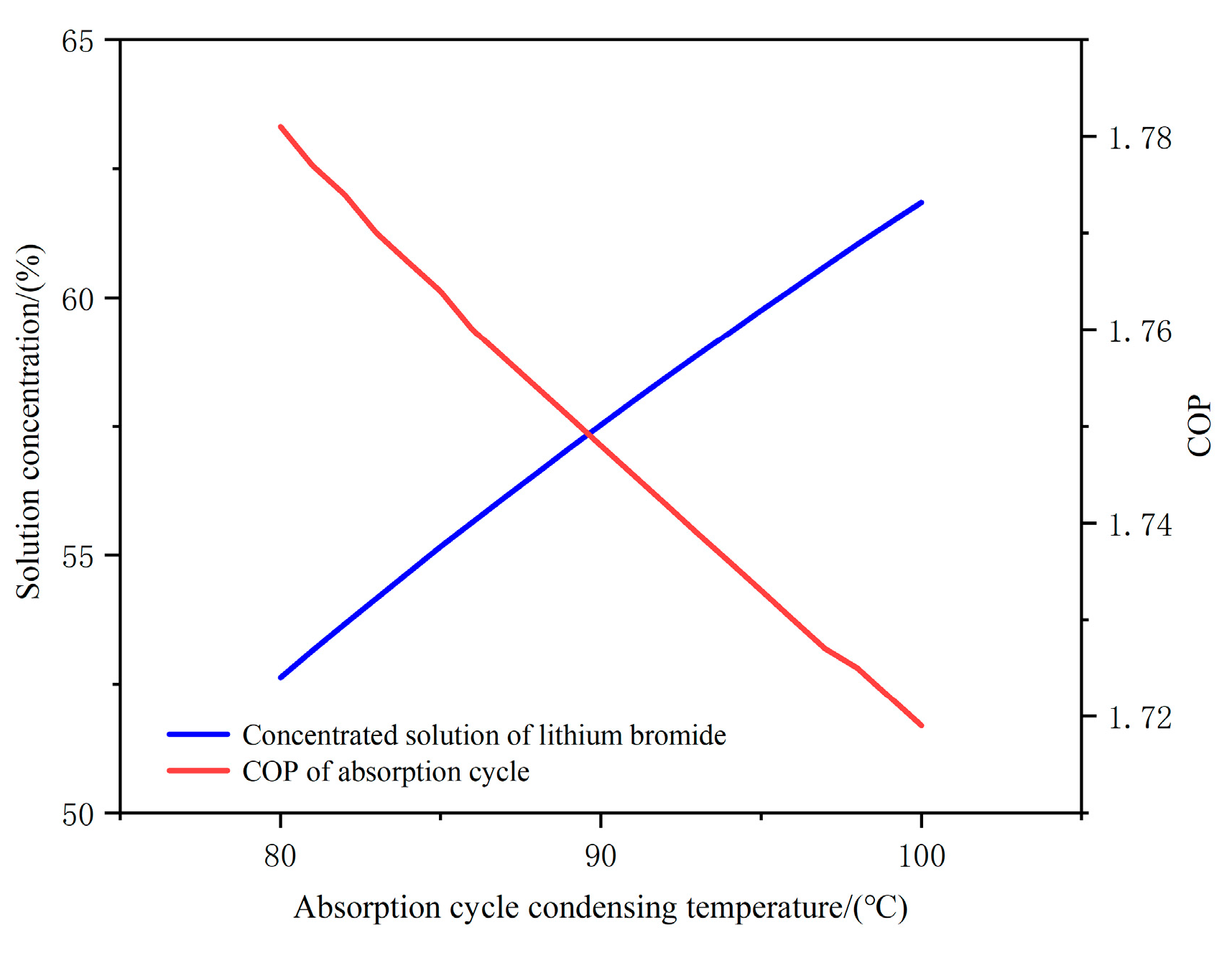

2.2.1. Effect of the Absorption Cycle Condensation Temperature on the Concentration of the Lithium Bromide Solution and the COP of Absorption

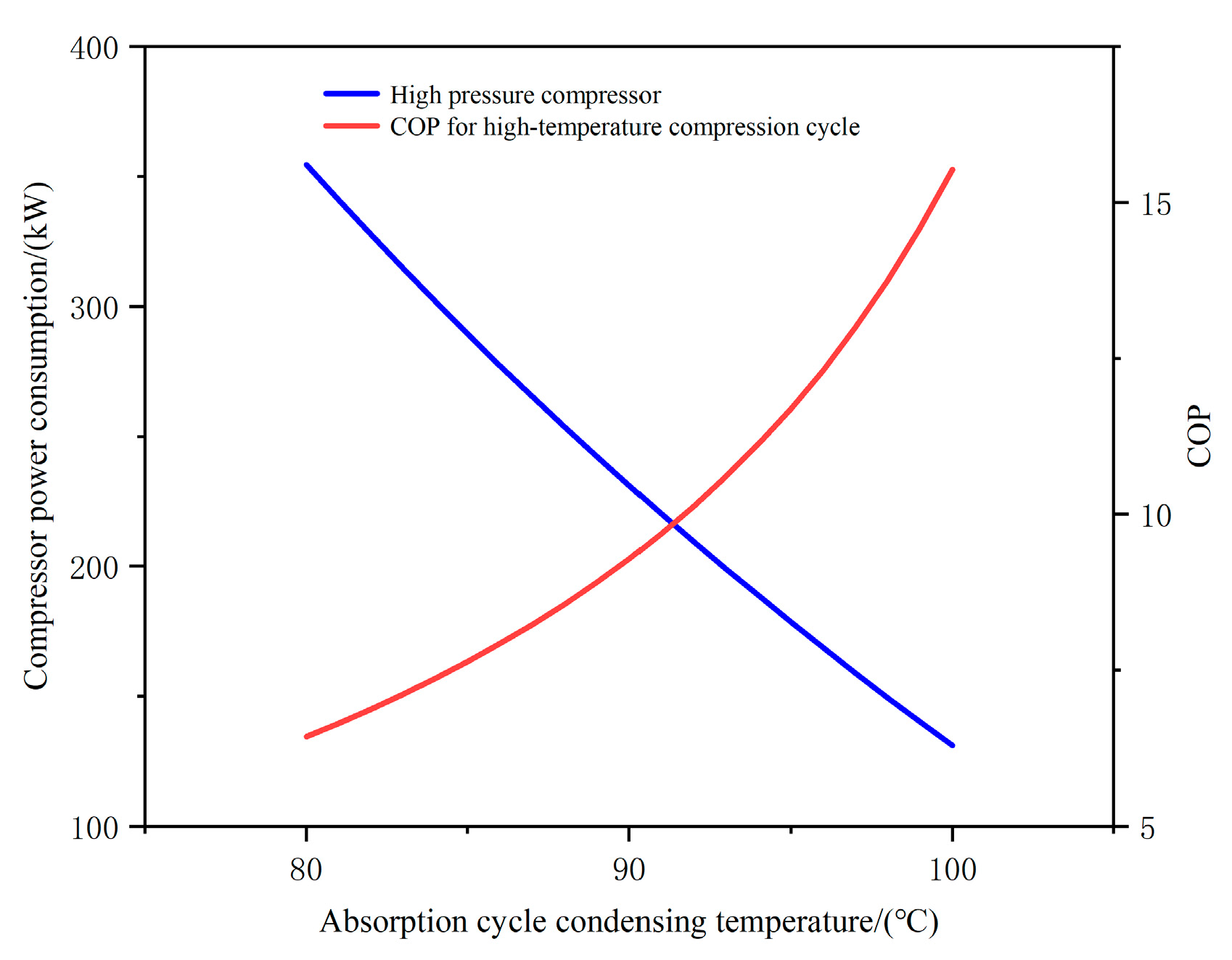

2.2.2. Effect of the Absorption Cycle Condensation Temperature on the Power Consumption and COP of the High-Temperature Compressor

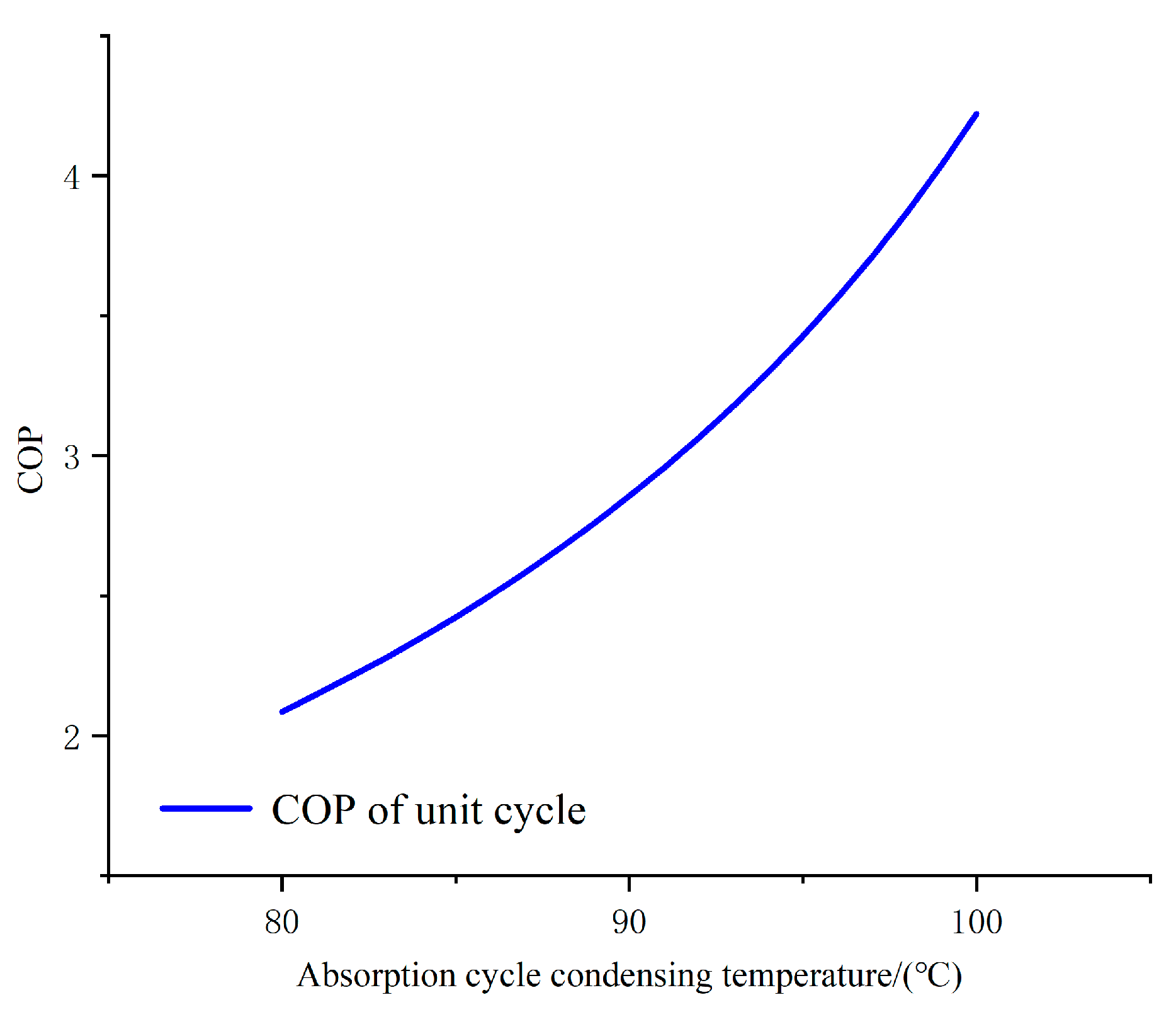

2.2.3. Effect of the Absorption Cycle Condensation Temperature on the COP of the Cycle Unit

2.3. Effect of the Heating Temperature on the Cycle Performance

2.3.1. Effect of the Heating Temperature on the Power Consumption and COP of the High-Temperature Compressor

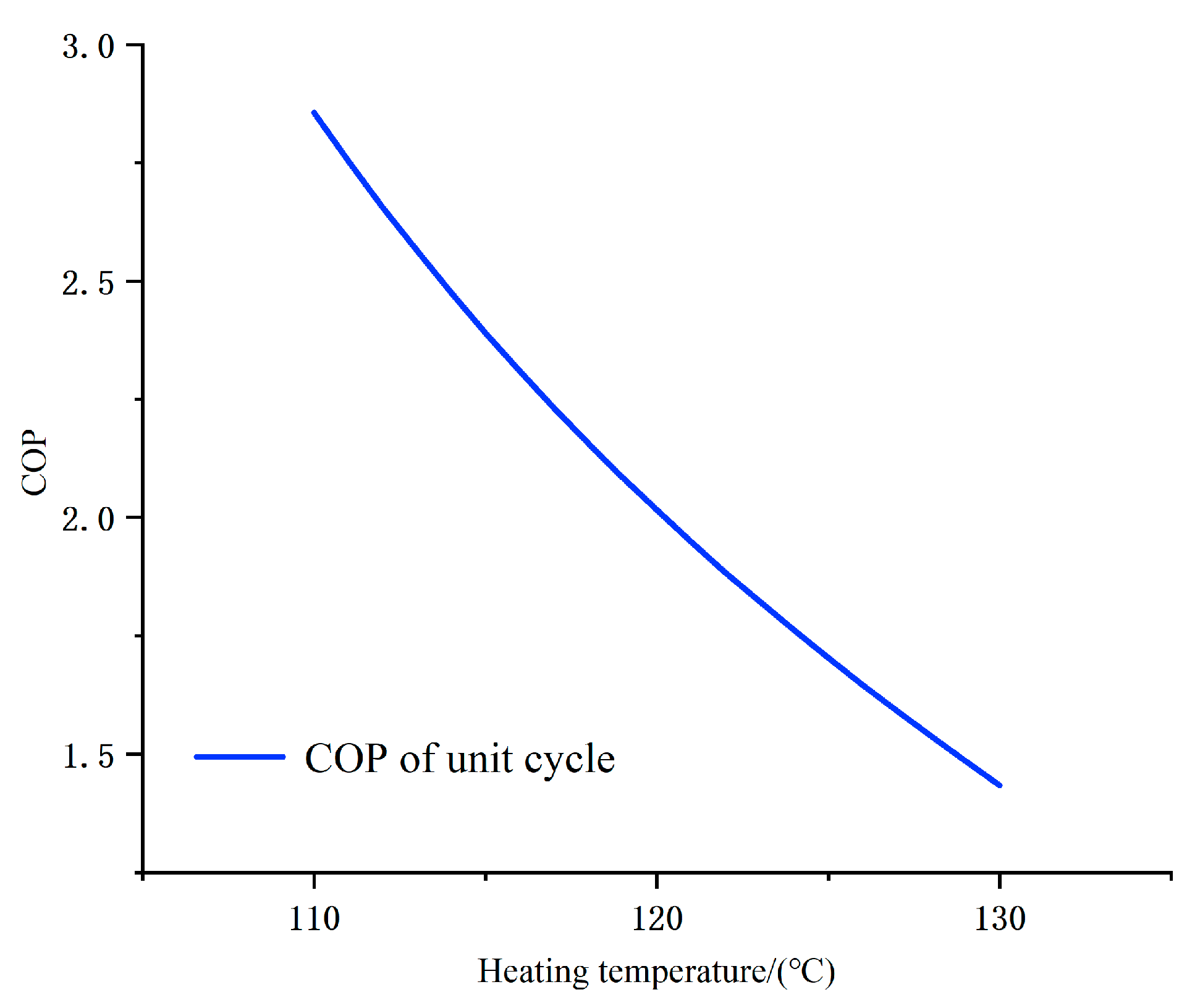

2.3.2. Effect of the Heating Temperature on the Cyclic COP of the Unit

2.4. Influence of the Waste Heat Outlet Temperature on the Cycle Performance

2.4.1. Influence of the Residual Hot Water Outlet Temperature on the Power Consumption and COP of the Low-Pressure Compressor

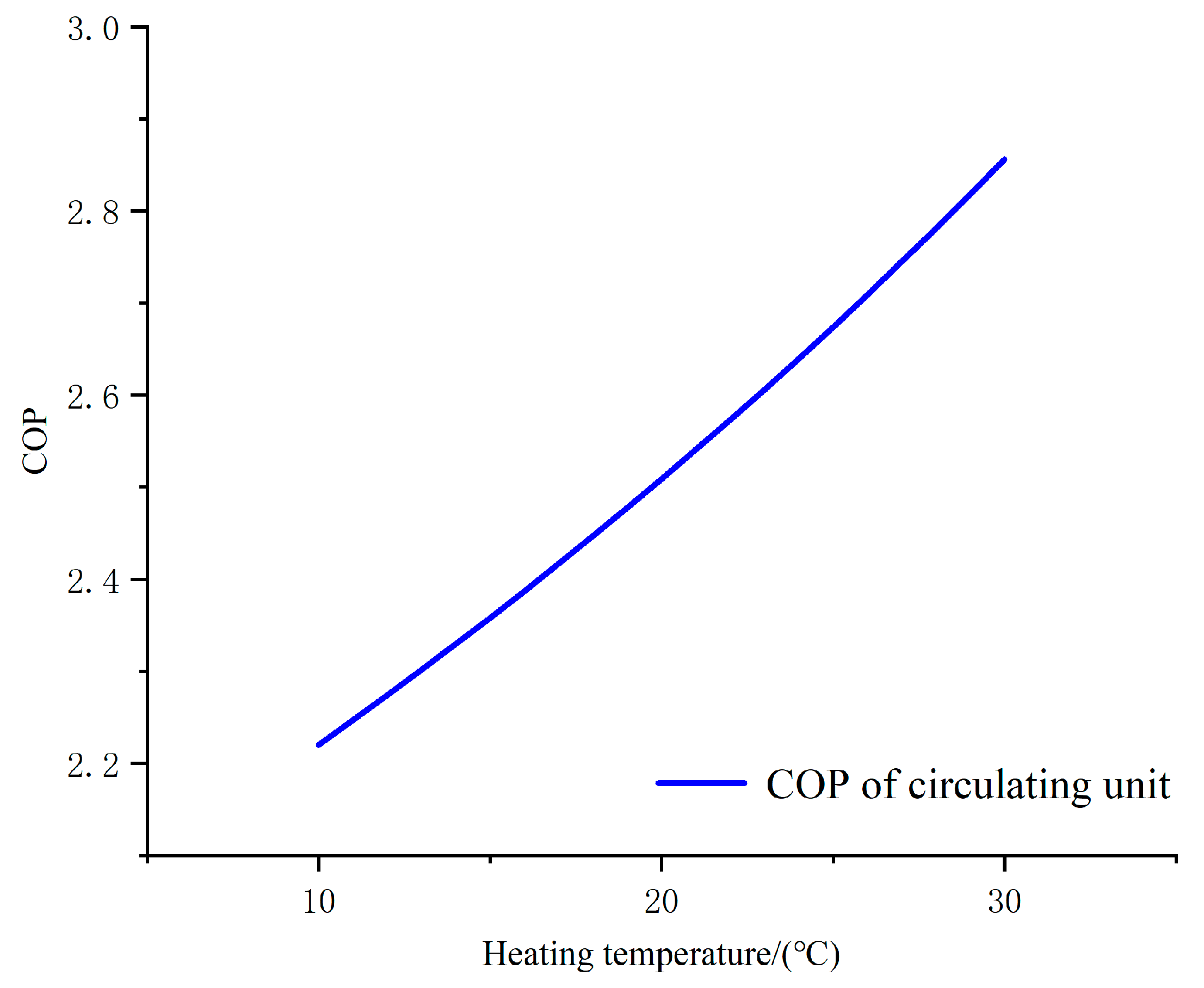

2.4.2. Influence of the Residual Hot Water Outlet Temperature on the Power Consumption and COP of the Low-Pressure Compressor

3. Summary and Prospects

- (1)

- High efficiency and energy savings: compared with traditional absorption heat pumps, the absorption–compression heat pump has a higher energy efficiency ratio, making significant savings in energy consumption and improving energy efficiency [18].

- (2)

- Recycling waste heat: the absorption–compression heat pump uses waste heat to drive the absorption cycle to recover and utilize the waste heat generated in industrial processes, reducing energy waste [19].

- (3)

- Wide application range: absorption–compression heat pumps can work in a wide range of pressure and temperature HVACs, heating, cooling, and other fields, and have a wide range of application prospects [20].

- (4)

- Multi-energy utilization: the absorption–compression heat pump can use different energy sources, such as electric and waste heat, as its driving energy. This diversified energy utilization capacity increases its utilization rate in various fields.

- (1)

- High cost: compared with traditional heat pumps, the process of using an absorption–compression coupled-cycle heat pump requires a lot of heat-exchange equipment, significantly increasing its manufacturing costs; this means that the unit requires a high initial investment, and this investment has a long payback period [21].

- (2)

- The process requirements are strict: the manufacturing of the absorption–compression coupling circulation heat pump requires a more advanced technical level and a more complex production process, and the heat exchanger needs to be specially designed for different scenarios.

- (1)

- New circulating medium: the development and application of a new circulating medium would improve the performance and efficiency of the absorption–compression coupled circulating heat pump. For example, a freon mixed working medium could significantly improve its energy efficiency ratio [22].

- (2)

- Optimizing cycle processes: optimizing cycle processes can improve the system’s energy efficiency and reduce costs [23].

- (3)

- Expansion of applications: the absorption–compression coupled-cycle heat pump can be used in multi-energy combined drives, including waste heat and electricity. It can be used to build air conditioning, in industrial production, and in other fields involving heating.

4. Conclusions

- (1)

- When the evaporation temperature of the absorption cycle increased from 50 °C to 70 °C, the heat load of the absorber and condenser increased and the COP of the absorption cycle rose from 1.75 to 1.84. The COP of the low-temperature compression cycle was reduced from 13.4 to 5.6. The COP of the circulating unit decreased from 2.55 to 2.05.

- (2)

- The COP decreased from 1.78 to 1.72 when the condensation temperature of the absorption cycle increased from 80 °C to 100 °C. The COP of the high-temperature compression cycle rose from 6.4 to 15.5. The unit cycle’s COP increased from 2.09 to 4.22.

- (3)

- When the heating temperature increased from 100 °C to 120 °C, the power consumption of the high-temperature compressor increased from 133.7 kW to 353.5 kW. The COP of the high-temperature compression cycle decreased from 15.47 to 6.35. The coupling cycle’s COP decreased from 3.54 to 1.84.

- (4)

- When the temperature of the waste heat outlet was reduced from 30 °C to 10 °C, the power consumption of the low-temperature compressor increased from 62.59 kW to 146.6kW. The COP of the low-temperature compression cycle decreased from 13.4 to 5.72. The COP of the coupling cycle was reduced from 2.86 to 2.22.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- The IEA. The Global Energy Review, 2021; The IEA: Paris, French, 2021; Available online: https://www.iea.org/reports/global-energy-review-2021?language=zh (accessed on 12 March 2023).

- Yan, C. Development of Water Source Heat Pump with 120 °C Quasi-Two-Stage Compression High Temperature Process. Ph.D. Thesis, Qingdao Technological University, Qingdao, China, 2022. [Google Scholar]

- Li, G. Experimental Research and Optimization Theory Based on Exergy Analysis of High Temperature Rise Overlapping Industrial Heat Pumps. Ph.D. Thesis, Tianjin University of Commerce, Tianjin, China, 2021. [Google Scholar]

- Hassan, A.H.; Corberan, J.M.; Ramirez, M.; Trebilcock-Kelly, F.; Payá, J. A high-temperature heat pump for compressed heat energy storage applications: Design, modeling, and performance. Energy Rep. 2022, 8, 10833–10848. [Google Scholar] [CrossRef]

- Fan, C.; Yan, G.; Yu, J. Thermodynamic analysis of a New Air Source High-Temperature Heat pump. J. Eng. Thermophys. 2020, 41, 83–88. [Google Scholar]

- Song, J. Research on Key Technologies of High Temperature Heat Pump. Ph.D. Thesis, Guizhou University, Guiyang, China, 2021. [Google Scholar]

- An, M.; Zhao, X.; Xu, Z.; Wang, R. Coupling Compression-absorption Heat pump Cycle for Industrial waste Heat Recovery. J. Shanghai Jiaotong Univ. 2020, 55, 434–443. [Google Scholar]

- Verdnik, M.; Rieberer, R. Influence of operating parameters on the COP of an R600 high-temperature heat pump. Int. J. Refrig. 2022, 140, 103–111. [Google Scholar] [CrossRef]

- Yang, Z. Simulation Research of High Temperature Heat Pump System Based on Waste Heat Utilization. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2020. [Google Scholar]

- Feng, H.; Bao, R.; Liu, F.; Shen, J.; Yu, Y. Research on a new type of Lithium bromide absorption compression compound heat pump System. Energy Conserv. 2019, 9, 45–47. (In Chinese) [Google Scholar]

- Liu, C.; Jiang, Y.; Han, W.; Kang, Q. A high-temperature hybrid absorption-compression heat pump for waste heat recovery. Energy Convers. Manag. 2018, 172, 391–401. [Google Scholar] [CrossRef]

- Jian, S.; Yinwu, W.; Kexin, W.; Ge, Z.; Yang, Y. Analysis of a New Super High Temperature Hybrid Absorption-Compression Heat Pump Cycle. Energies 2022, 15, 7515. [Google Scholar] [CrossRef]

- Zhang, X. Simulation and Experimental Study on Trans-Critical CO2 Water-Water Heat Pump System. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2020. [Google Scholar]

- Wang, B. Numerical Simulation and Performance Research of Absorption Heat Pump Based on R134a-DMF Working Medium. Ph.D. Thesis, Shandong Construction University, Jinan, China, 2022. [Google Scholar]

- Ma, S. New Coupling Heat Pump Thermodynamic Cycle Characteristics Research. Ph.D. Thesis, North China Electric Power University, Beijing, China, 2022. [Google Scholar]

- Sun, J.; Ma, S.; Huo, C. Cycle Performance Analysis of a Novel Compression-Absorption Heat Pump Based on Steam Working Medium. Acta Energ. Sol. Sin. 2022, 43, 15–206. [Google Scholar]

- Zhimin, T.; Xiao, F.; Minbo, Y.; Wang, Y. Energy and economic performance comparison of heat pump and power cycle in low grade waste heat recovery. Energy 2022, 260, 125149. [Google Scholar]

- Ma, S.; Zhou, S.; Wang, Y. Performance Analysis of a New Heat Pump Based on Absorption and Compression. J. North China Electr. Power Univ. 2022, 49, 105–112. [Google Scholar]

- Wang, H.; Hua, P.; Wu, X.; Zhang, R.; Granlund, K.; Li, J.; Zhu, Y.; Lahdelma, R.; Teppo, E.; Yu, L. Heat-power decoupling and energy saving of the CHP unit with heat pump based waste heat recovery system. Energy 2022, 250, 123846. [Google Scholar] [CrossRef]

- Yoann, J.; Frédéric, L.; Alexis, L.; Clausse, M. Combined energetic, economic and climate change assessment of heat pumps for industrial waste heat recovery. Appl. Energy 2022, 313, 118854. [Google Scholar]

- Umara, K.; Ron, Z.; Lydia, S.; Tveit, T.-M. Life cycle cost analysis (LCCA) of Stirling-cycle-based heat pumps vs. conventional boilers. Clean. Environ. Syst. 2023, 8, 100105. [Google Scholar]

- Hamed, A.; Elias, V.; Toon, D.; Beyne, W.; Lecompte, S.; Quoilin, S.; Arteconi, A. A comprehensive analysis of binary mixtures as working fluid in high temperature heat pumps. Energy Convers. Manag. 2023, 277, 116652. [Google Scholar]

- Zhang, H.; Liu, X.; Liu, Y.; Duan, C.; Dou, Z.; Qin, J. Energy and exergy analyses of a novel cogeneration system coupled with absorption heat pump and organic Rankine cycle based on a direct air cooling coal-fired power plant. Energy 2021, 229, 120641. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Qin, Y.; Liu, R.; Wang, G.; Liu, D.; Yang, Y. Cycle Characteristics of a New High-Temperature Heat Pump Based on Absorption–Compression Revolution. Energies 2023, 16, 4267. https://doi.org/10.3390/en16114267

Sun J, Qin Y, Liu R, Wang G, Liu D, Yang Y. Cycle Characteristics of a New High-Temperature Heat Pump Based on Absorption–Compression Revolution. Energies. 2023; 16(11):4267. https://doi.org/10.3390/en16114267

Chicago/Turabian StyleSun, Jian, Yu Qin, Ran Liu, Guoshun Wang, Dingqun Liu, and Yongping Yang. 2023. "Cycle Characteristics of a New High-Temperature Heat Pump Based on Absorption–Compression Revolution" Energies 16, no. 11: 4267. https://doi.org/10.3390/en16114267

APA StyleSun, J., Qin, Y., Liu, R., Wang, G., Liu, D., & Yang, Y. (2023). Cycle Characteristics of a New High-Temperature Heat Pump Based on Absorption–Compression Revolution. Energies, 16(11), 4267. https://doi.org/10.3390/en16114267