A Review of Super-High-Temperature Heat Pumps over 100 °C

Abstract

1. Introduction

2. Working Fluid of High-Temperature Heat Pump

2.1. HFCs

2.2. HFOs and HCFOs

2.3. Natural Refrigerants

2.4. Mixed Working Fluid

2.5. Absorption Circulating Working Fluid Pair

2.6. Summary of Working Fluid

3. Cycle Process of High-Temperature Heat Pump

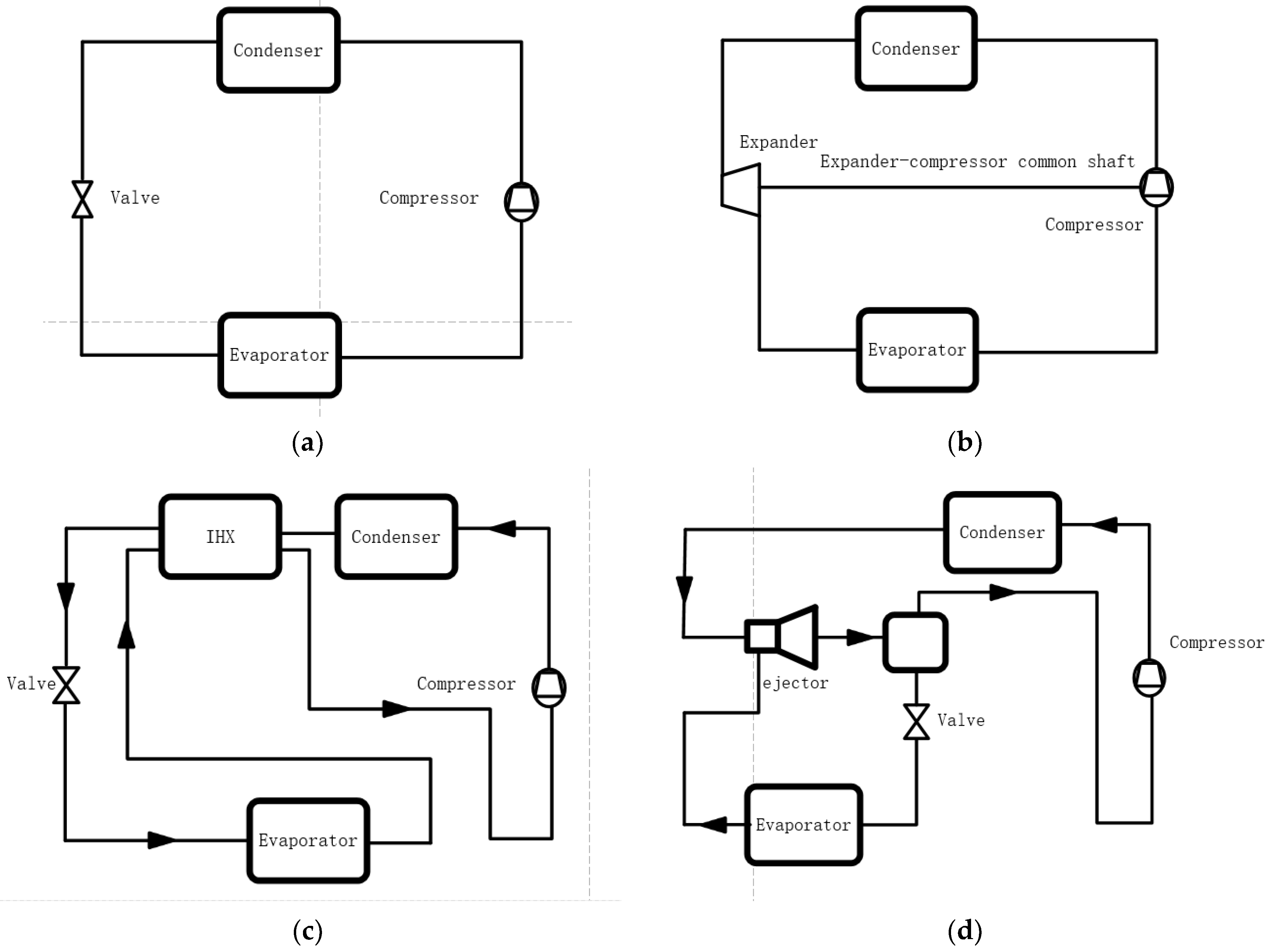

3.1. Compression Heat Pump

3.1.1. Single-Stage Compression Heat Pump

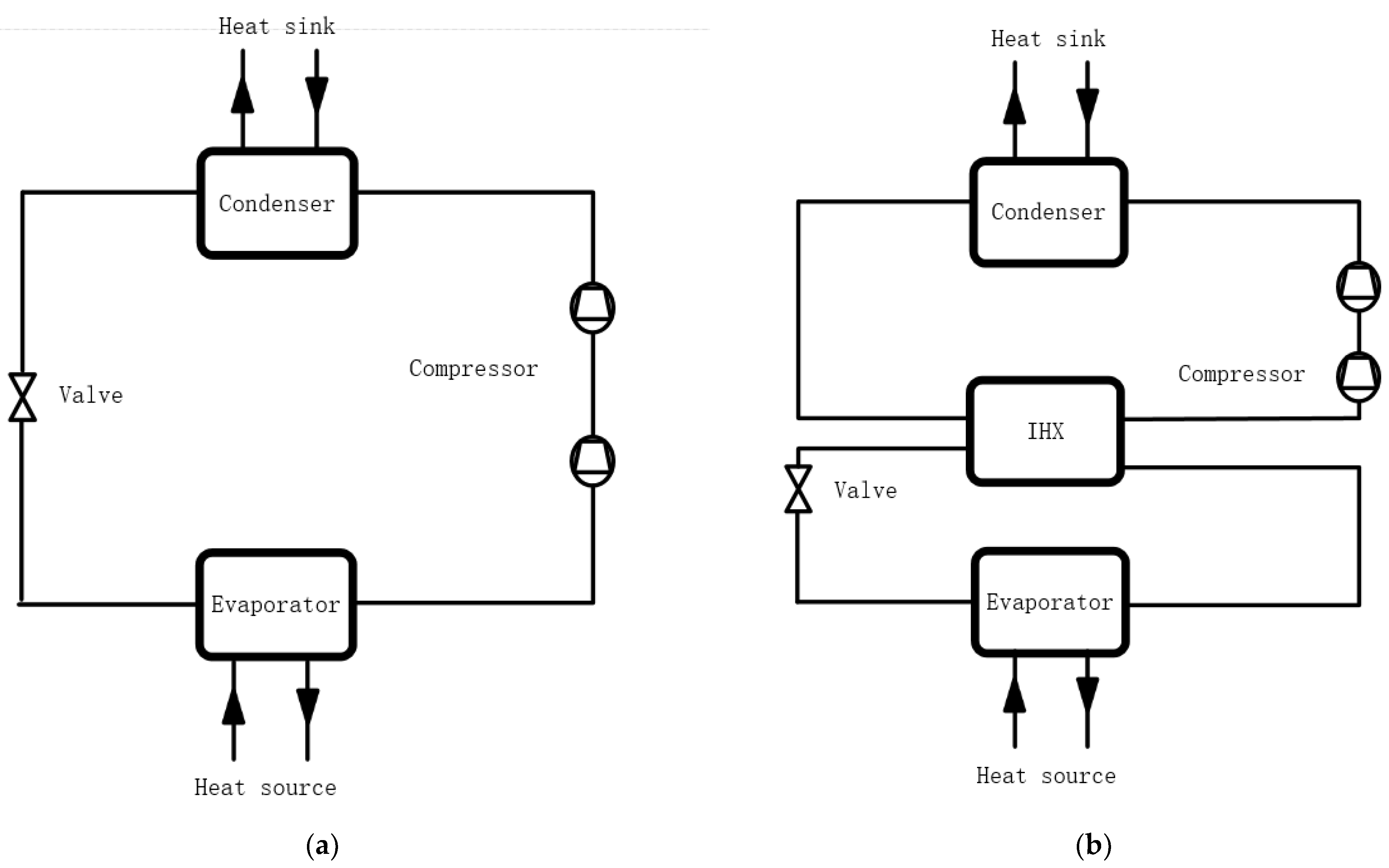

3.1.2. Two-Stage Compression Heat Pump

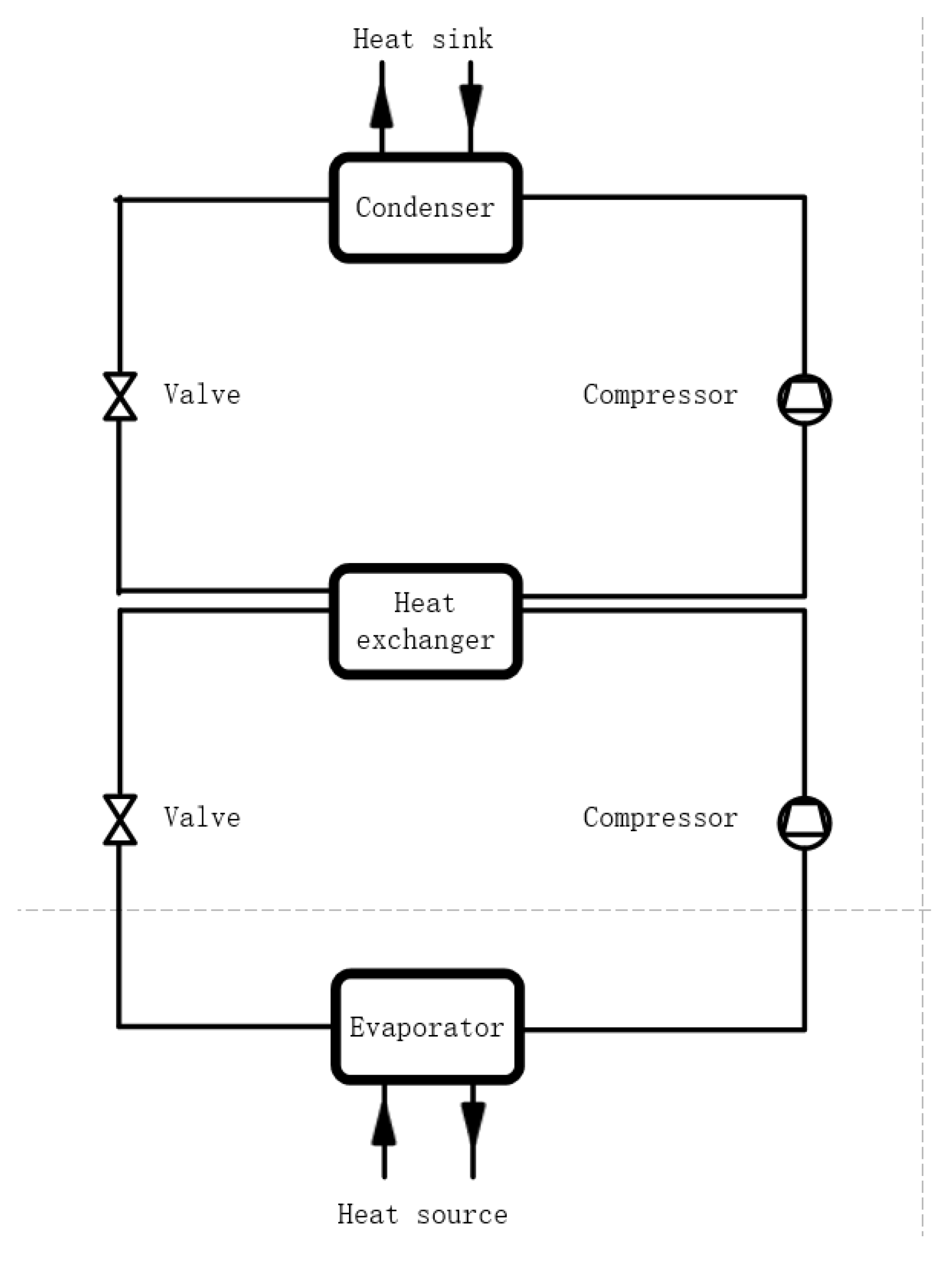

3.1.3. Cascade Heat Pump

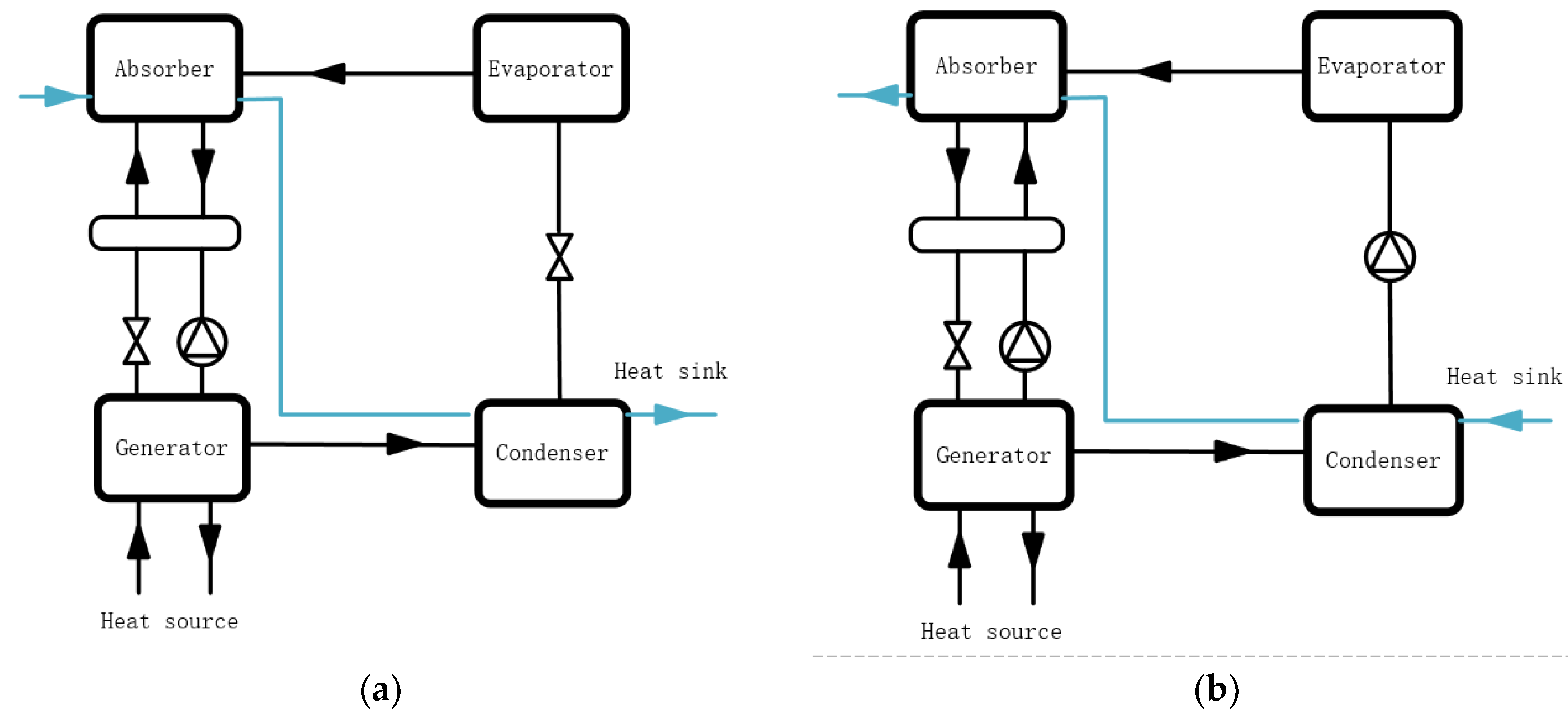

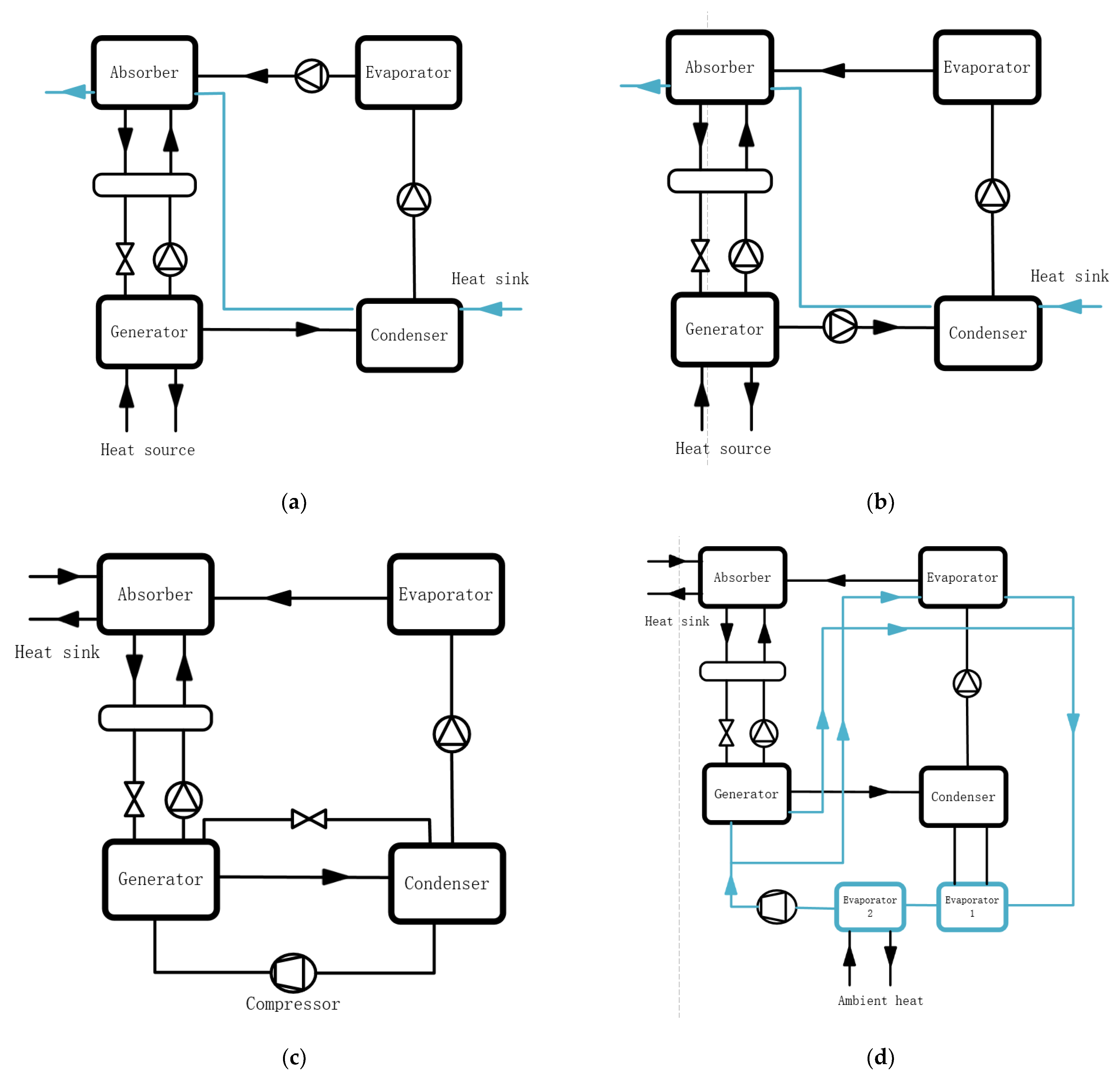

3.2. Absorption Heat Pump

3.3. Hybrid Heat Pump

4. Key Equipment of High-Temperature Heat Pump

| Researcher | Working Fluid | Maximum Heating Temperature (°C) | Compressor Type |

|---|---|---|---|

| Bamigbetan [18] | R290/R600 | 115 | piston compressor |

| Li [31] | BY6-BY3B | 168.4 | piston compressor |

| Yu [32] | BY-4 | 110 | scroll compressor |

| Pan [37] | R600/R245fa | 100 | piston compressor |

| Ma [50] | BY-3/R245fa | 142 | scroll compressor |

| Ahrens [70] | NH3-H2O | 120 | twin-screw compressor |

| Chamoun [72] | water | 120 | twin-screw compressor |

| Mateu-Royo [75] | R1224yd(z), R1233zd(E) | 140 | scroll compressor |

| Uusitalo [81] | R245fa | 90 | centrifugal compressor |

5. Application and Prospects of High-Temperature Heat Pump

6. Summary and Prospects

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- National Bureau of Statistics. China Energy Statistical Yearbook 2022; China Statistics Press: Beijing, China, 2022.

- Liu, S.Y.; Lin, Z.Z.; Jiang, Y.C.; Zhang, T.H.; Yang, L.; Tan, W.T.; Lu, F. Modelling and discussion on emission reduction transformation path of China’s electric power industry under “double carbon” goal. Heliyon 2022, 8, e10497. [Google Scholar] [CrossRef] [PubMed]

- Bergamini, R.; Jensen, J.K.; Elmegaard, B. Thermodynamic competitiveness of high temperature vapor compression heat pumps for boiler substitution. Energy 2019, 182, 110–121. [Google Scholar] [CrossRef]

- Lu, Z.N.; Gong, Y.L.; Yao, Y.; Luo, C.; Ma, W.B. Development of a high temperature heat pump system forsteam generation using medium-low temperature geothermal water. Energy Procedia 2019, 158, 6046–6054. [Google Scholar] [CrossRef]

- Liu, B.S.; Gong, Y.L.; Lu, Z.N.; Yao, Y. Several working fluids for high temperature heat pump steam system. Renew. Energy Resour. 2015, 33, 1755–1761. [Google Scholar]

- Ma, F.; Zhang, P. Investigation on the performance of a high-temperature packed bed latent heat thermal energy storage system using Al-Si alloy. Energy Convers. Manag. 2017, 150, 500–514. [Google Scholar] [CrossRef]

- Arpagaus, C.; Bless, F.; Uhlmann, M.; Svhiffmann, J.; Bertsch, S.S. High temperature heat pumps: Market overview, state of the art, research status, refrigerants, and application potentials. Energy 2018, 152, 985–1010. [Google Scholar] [CrossRef]

- Yan, H.; Ding, L.; Sheng, B.W.; Dong, X.Q.; Zhao, Y.X.; Zhong, Q.; Gong, W.C.; Gong, M.Q.; Guo, H.; Shen, J. Performance prediction of HFC, HC, HFO and HCFO working fluids for high temperature water source heat pumps. Appl. Therm. Eng. 2020, 185, 116324. [Google Scholar] [CrossRef]

- He, Y.N.; Xia, Y.; Jin, L.; Yang, D.F.; Cao, F. Investigation on application of refrigerant R1234ze in high-temperature heat pump. Fluid Mach. 2014, 42, 62–66. [Google Scholar]

- Frate, G.F.; Ferrari, L.; Desideri, U. Analysis of suitability ranges of high temperature heat pump working fluids. Appl. Therm. Eng. 2019, 150, 628–640. [Google Scholar] [CrossRef]

- Kondou, C.; Koyama, S. Thermodynamic assessment of high-temperature heat pumps using Low-GWP HFO refrigerants for heat recovery. Int. J. Refrig. 2015, 53, 126–141. [Google Scholar] [CrossRef]

- Longo, G.A.; Mancin, S.; Righetti, G.; Zilio, C.; Brown, J.S. Assessment of the low-GWP refrigerants R600a, R1234ze (Z) and R1233zd (E) for heat pump and organic Rankine cycle applications. Appl. Therm. Eng. 2020, 167, 114804. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Mota-Babiloni, A.; Navarro-Esbrí, J. Semi-empirical and environmental assessment of the low GWP refrigerant HCFO-1224yd (Z) to replace HFC-245fa in high temperature heat pumps. Int. J. Refrig. 2021, 127, 120–127. [Google Scholar] [CrossRef]

- Jiang, J.T.; Hu, B.; Wang, R.Z.; Liu, H.; Zhang, Z.P.; Li, H.B. Theoretical performance assessment of low-GWP refrigerant R1233zd(E) applied in high temperature heat pump system. Int. J. Refrig. 2021, 131, 897–908. [Google Scholar] [CrossRef]

- Wu, D.; Hu, B.; Wang, R.Z. Performance simulation and exergy analysis of a hybrid source heat pump system with low GWP refrigerants. Renew. Energy 2018, 116, 775–785. [Google Scholar] [CrossRef]

- Bamigbetan, O.; Eikevik, T.; Nekså, P.; Bantle, M. Extending ammonia high temperature heat pump using butane in a cascade system. In Proceedings of the 7th Conference on Ammonia and CO2 Refrigeration Technology, Ohrid, North Macedonia, 11–13 May 2017. [Google Scholar]

- Bamigbetan, O.; Eikevik, T.M.; Nekså, P.; Bantle, M.; Schlemminger, C. The development of a hydrocarbon high temperature heat pump for waste heat recovery. Energy 2019, 173, 1141–1153. [Google Scholar] [CrossRef]

- Bamigbetan, O.; Eikevik, T.M.; Neksi, P. Extending hydrocarbon heat pumps to higher temperatures: Predictions from simulation. In Proceedings of the International Workshop on High Temperature Heat Pumps, Copenhagen, Denmark, 11 September 2017; pp. 197–211. [Google Scholar]

- Yang, W.W.; Cao, X.Q.; He, Y.L.; Yan, F.Y. Theoretical study of a high-temperature heat pump system composed of a CO2 transcritical heat pump cycle and a R152a subcritical heat pump cycle. Appl. Therm. Eng. 2017, 120, 228–238. [Google Scholar] [CrossRef]

- Dai, B.M.; Liu, C.; Liu, S.C.; Wang, D.B.; Wang, Q.L.; Zou, T.H.; Zhou, X. Life cycle techno-enviro-economic assessment of dual-temperature evaporation transcritical CO2 high-temperature heat pump systems for industrial waste heat recovery. Appl. Therm. Eng. 2023, 219, 119570. [Google Scholar] [CrossRef]

- Wu, D.; Hu, B.; Wang, R.Z.; Fan, H.B.; Wang, R.J. The performance comparison of high temperature heat pump among R718 and other refrigerants. Renew. Energy 2020, 154, 715–722. [Google Scholar] [CrossRef]

- Yan, H.Z.; Wu, D.; Liang, J.Y.; Hu, B.; Wang, R.Z. Selection and validation on low-GWP refrigerants for a water-source heat pump. Appl. Therm. Eng. 2021, 193, 116938. [Google Scholar] [CrossRef]

- Wu, D.; Yan, H.Z.; Hu, B.; Wang, R.Z. Modeling and simulation on a Water Vapor High Temperature Heat Pump system. Energy 2019, 168, 1063–1072. [Google Scholar] [CrossRef]

- Wu, D.; Hu, B.; Wang, R.Z.; Jiang, N.S.; Li, Z.L. A review on development and prospect of water refrigerant and water vapor compressor. CIESC J. 2017, 68, 2959–2968. [Google Scholar]

- Wu, D.; Hu, B.; Wang, R.Z.; Jiang, N.S.; Li, Z.L.; Yu, J.J. Preliminary study on high temperature heat pump system with water refrigerant. CIESC J. 2018, 69, 95–100. [Google Scholar]

- Wu, D.; Jiang, J.T.; Hu, B.; Wang, R.Z. Experimental investigation on the performance of a very high temperature heat pump with water refrigerant. Energy 2020, 190, 116427. [Google Scholar] [CrossRef]

- Chamoun, M.; Rulliere, R.; Haberschill, P.; Berail, J.F. Dynamic model of an industrial heat pump using water as refrigerant. Int. J. Refrig. 2012, 35, 1080–1091. [Google Scholar] [CrossRef]

- Chamoun, M.; Rulliere, R.; Haberschill, P.; Peureux, J.L. Experimental and numerical investigations of a new high temperature heat pump for industrial heat recovery using water as refrigerant. Int. J. Refrig. 2014, 44, 177–188. [Google Scholar] [CrossRef]

- Chamoun, M.; Rulliere, R.; Haberschill, P. Experimental investigation of a new high temperature heat pump using water as refrigerant for industrial heat recovery. In Proceedings of the International Refrigeration and Air Conditioning Conference at Purdue, West Lafayette, IN, USA, 16–19 July 2012; pp. 479–489. [Google Scholar]

- Wu, X.; Xu, S.M.; Liu, J.W.; Dai, X.J.; Zhao, W.Z. Analysis of available blend refrigerants for medium-high temperature cascade heat pump. J. Refrig. 2018, 39, 53–58. [Google Scholar]

- Li, X.Q.; Zhang, Y.F.; Ma, X.L.; Deng, N.; Jin, Z.D.; Yu, X.H.; Li, W. Performance analysis of high-temperature water source cascade heat pump using BY3B/BY6 as refrigerants. Appl. Therm. Eng. 2019, 159, 113895. [Google Scholar] [CrossRef]

- Yu, X.H.; Zhang, Y.F.; Deng, N.; Chen, C.M.; Ma, L.J.; Dong, L.P.; Zhang, Y. Experimental performance of high temperature heat pump with near-azeotropic refrigerant mixture. Energy Build. 2014, 78, 43–49. [Google Scholar]

- Zhang, Y.; Zhang, Y.F.; Yu, X.H.; Guo, J.; Deng, N.; Dong, S.M.; He, Z.L.; Ma, X.L. Analysis of a high temperature heat pump using BY-5 as refrigerant. Appl. Therm. Eng. 2017, 127, 1461–1468. [Google Scholar]

- Yu, X.H.; Zhang, Y.F.; Zhang, Y.; He, Z.L.; Dong, S.M.; Ma, X.L.; Yao, S. Intelligent prediction on performance of high temperature heat pump systems using different refrigerants. J. Cent. South Univ. 2018, 25, 2754–2765. [Google Scholar] [CrossRef]

- Ma, L.M.; Wang, H.X.; Wang, J.X. Theoretical and experimental cycle performances of working fluid for high temperature heat pumps. J. Mech. Eng. 2010, 46, 142–147. [Google Scholar] [CrossRef]

- Wang, H.X. Performance of binary mixture working fluid of MB85 for moderate and high temperature heat pump. J. Tianjin Univ. (Sci. Technol.) 2011, 44, 1106–1110. [Google Scholar]

- Pan, L.S.; Wang, H.X.; Chen, Q.Y.; Chen, C. Theoretical and experimental study on several refrigerants of moderately high temperature heat pump. Appl. Therm. Eng. 2011, 31, 1886–1893. [Google Scholar] [CrossRef]

- Ji, L.A.; Shukla, S.K.; Zuo, Z.D.; Lu, X.H.; Ji, X.Y.; Wang, C.S. An overview of the progress of new working pairs in absorption heat pumps. Energy Rep. 2023, 9, 703–729. [Google Scholar] [CrossRef]

- Kim, Y.J.; Kim, S.; Joshi, Y.K.; Fedorov, A.G.; Kohl, P.A. Thermodynamic analysis of an absorption refrigeration system with ionic-liquid/refrigerant mixture as a working fluid. Energy 2012, 44, 1005–1016. [Google Scholar] [CrossRef]

- Sun, J.; Fu, L.; Zhang, S.G. Performance calculation of single effect absorption heat pump using LiBr+LiNO3+H2O as working fluid. Appl. Therm. Eng. 2010, 30, 2680–2684. [Google Scholar] [CrossRef]

- Wang, M.; Ferreira, C.A.I. Absorption heat pump cycles with NH3-ionic liquid working pairs. Appl. Energy 2017, 204, 819–830. [Google Scholar] [CrossRef]

- Yan, H.; Hu, B.; Wang, R.Z. Air-source heat pump heating based water vapor compression for localized steam sterilization applications during the COVID-19 pandemic. Renew. Sustain. Energy Rev. 2021, 145, 111026. [Google Scholar] [CrossRef]

- Luo, B.; Zou, P. Performance analysis of different single stage advanced vapor compression cycles and refrigerants for high temperature heat pumps. Int. J. Refrig. 2019, 104, 246–258. [Google Scholar] [CrossRef]

- Malyshev, A.A.; Malinina, O.S.; Tatarenko, Y.V.; Kireev, V.S. Exergy characteristics of a steam compressor heat pump. AIP Conf. Proc. 2019, 2141, 030005. [Google Scholar]

- Luo, B.J. Oil flooded compression cycle enhancement for two-stage heat pump in cold climate region: System design and theoretical analysis. Energy Convers. Manag. 2016, 115, 52–59. [Google Scholar] [CrossRef]

- Wang, H.L.; Jia, N.; Tian, J.R. Performance analysis of two stage compression cycle with an internal heat exchanger. Appl. Mech. Mater. 2014, 540, 110–113. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, Y.T.; Xu, J.Y.; Wang, L.; Huang, Z. Performance Analysis of Internal Heat Exchanger-Based Quasi-Two-Stage Vapor Compression Heat Pump System for High-Temperature Steam Production. Energy Technol. 2020, 8, 2000623. [Google Scholar]

- Jiang, S.; Wang, S.G.; Yu, Y.; Ma, Z.J.; Wang, J.H. Further analysis of the influence of interstage configurations on two-stage vapor compression heat pump systems. Appl. Therm. Eng. 2021, 184, 116050. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, S.G.; Jin, X.; Zhang, T.F. A general model for two-stage vapor compression heat pump systems. Int. J. Refrig. 2015, 51, 88–102. [Google Scholar] [CrossRef]

- Ma, X.L.; Zhang, Y.F.; Fang, L.; Yu, X.H.; Li, X.Q.; Sheng, Y.; Zhang, Y. Performance analysis of a cascade high temperature heat pump using R245fa and BY-3 as working fluid. Appl. Therm. Eng. 2018, 140, 466–475. [Google Scholar] [CrossRef]

- Kim, D.H.; Park, H.S.; Kim, M.S. Optimal temperature between high and low stage cycles for R134a/R410A cascade heat pump based water heater system. Exp. Therm. Fluid Sci. 2013, 47, 172–179. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, M.S. The effect of water temperature lift on the performance of cascade heat pump system. Appl. Therm. Eng. 2014, 67, 273–282. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, X.L.; Li, X.T.; Shi, W.X.; Wang, B.L. Comparisons of different working pairs and cycles on the performance of absorption heat pump for heating and domestic hot water in cold regions. Appl. Therm. Eng. 2012, 48, 349–358. [Google Scholar] [CrossRef]

- Xu, Z.Y.; Mao, H.C.; Liu, D.S.; Wang, R.Z. Waste heat recovery of power plant with large scale serial absorption heat pumps. Energy 2018, 165, 1097–1105. [Google Scholar] [CrossRef]

- Yang, X.J.; You, S.J.; Zhang, H. Economical optimization for double-stage LiBr absorption heat pumps. Phys. Procedia 2012, 24, 114–121. [Google Scholar]

- Balderas-Sánchez, I.N.; Rivera, W.; Jiménez-García, J.C. Thermodynamic analysis of a novel absorption heat transformer. Appl. Therm. Eng. 2019, 162, 114268. [Google Scholar] [CrossRef]

- Zhang, H.S.; Zhao, H.B.; Li, Z.L. Thermodynamic performance study on solar-assisted absorption heat pump cogeneration system in the coal-fired power plant. Energy 2016, 116, 942–955. [Google Scholar] [CrossRef]

- Feng, H.M.; Bao, R.Q.; Liu, F.C.; Shen, J.B.; Yu, Y. Study on new type II lithium bromide absorption compression composite heat pump system. Energy Energy Conserv. 2019, 9, 45–47. [Google Scholar]

- Schweigler, C.; Helm, M.; Eckert, T. Flexible heat pump or chiller with hybrid water/LiBr absorption/compression cycle. Int. J. Refrig. 2019, 105, 178–187. [Google Scholar] [CrossRef]

- Sun, J.; Ma, S.C.; Huo, C.; Ge, Z.H.; Zhou, S.X. Performance analysis of new compression absorption heat pump cycle based on steam working fluid. Acta Energ. Sol. Sin. 2022, 43, 15–20. [Google Scholar]

- Sun, J.; Ma, S.C.; Huo, C.; Liu, J.Y.; Ge, Z.H.; Yang, Y.P. Study on a hybrid heat exchanger based on absorption and compression cycles. J. Eng. Thermophys. 2021, 40, 9–15. [Google Scholar]

- Gao, J.T.; Xu, Z.Y.; Wang, R.Z. Enlarged temperature lift of hybrid compression-absorption heat transformer via deep thermal coupling. Energy Convers. Manag. 2021, 234, 113954. [Google Scholar] [CrossRef]

- Gao, J.T.; Xu, Z.Y.; Wang, R.Z. An air-source hybrid absorption-compression heat pump with large temperature lift. Appl. Energy 2021, 291, 116810. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, R.Z.; Xu, Z.Y. Air-source hybrid absorption-compression heat pumps with three-stage thermal coupling configuration for temperature lift over 150 °C. Energy Convers. Manag. 2022, 271, 116304. [Google Scholar] [CrossRef]

- Mamaev, V.K.; Shatalov, I.K.; Antipov, Y.A.; Vallejo-Maldonado, P.R. Correlation Between Volumetric Efficiency and Isentropic Efficiency of Piston Compressor of Thermal Pump. Chem. Pet. Eng. 2018, 53, 793–796. [Google Scholar] [CrossRef]

- Cai, D.H.; Qiu, C.B.; Pan, J.; Yang, X.H.; He, G.G.; Tetsuhide, Y.; Chen, X.X.; Li, H.J. Leakage characteristics and an updated volumetric efficiency prediction model of rolling piston type rotary compressor for small capacity air-conditioner and heat pump applications. Appl. Therm. Eng. 2017, 121, 1080–1094. [Google Scholar] [CrossRef]

- Engel, R.C.; Deschamps, C.J. Comparative analysis between the performances of reciprocating and rolling piston compressors applied to a domestic heat pump water heater. Int. J. Refrig. 2019, 102, 130–141. [Google Scholar] [CrossRef]

- Wen, Q.Y.; Zhi, R.P.; Wu, Y.T.; Lei, B.; Liu, S.W.; Shen, L.L. Performance optimization of a heat pump integrated with a single-screw refrigeration compressor with liquid refrigerant injection. Energy 2020, 207, 118197. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, Z.W.; Li, M.Z.; Chen, T.T.; Wang, Z.W. An optimal matching strategy for screw compressor for heat pump applications. Appl. Therm. Eng. 2018, 132, 333–340. [Google Scholar] [CrossRef]

- Ahrens, M.U.; Tolstorebrov, I.; Tønsberg, E.K.; Hafner, A.; Wang, R.Z.; Eikevik, T.M. Numerical investigation of an oil-free liquid-injected screw compressor with ammonia-water as refrigerant for high temperature heat pump applications. Appl. Therm. Eng. 2023, 219, 119425. [Google Scholar] [CrossRef]

- Park, J.T.; Lee, Y.S.; Kim, J.; Chae, K.J.; Yang, H.J. A study on the operating control of a heat pump system with screw compressors. Korean J. Air-Cond. Refrig. Eng. 2013, 25, 168–172. [Google Scholar]

- Chamoun, M.; Rulliere, R.; Haberschill, P.; Peureux, J.L. Modelica-based modeling and simulation of a twin screw compressor for heat pump applications. Appl. Therm. Eng. 2013, 58, 479–489. [Google Scholar] [CrossRef]

- Byrne, P.; Ghoubali, R.; Miriel, J. Scroll compressor modelling for heat pumps using hydrocarbons as refrigerants. Int. J. Refrig. 2014, 41, 1–13. [Google Scholar] [CrossRef]

- Kim, D.; Jeon, Y.; Jang, D.S.; Kim, Y. Performance comparison among two-phase, liquid, and vapor injection heat pumps with a scroll compressor using R410A. Appl. Therm. Eng. 2018, 137, 193–202. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Navarro-Esbrí, J.; Mota-Babiloni, A.; Moles, F.; Amat-Albuixech, M. Experimental exergy and energy analysis of a novel high-temperature heat pump with scroll compressor for waste heat recovery. Appl. Energy 2019, 253, 113504. [Google Scholar]

- Wang, J.J.; Qv, D.H.; Ni, L.; Yao, Y. Experimental study on an injection-assisted air source heat pump with a novel two-stage variable-speed scroll compressor. Appl. Therm. Eng. 2020, 176, 115415. [Google Scholar] [CrossRef]

- Peng, M.B.; Peng, X.; Wang, D.B.; Liu, X.X.; Yang, Y.S.; Wang, G.H.; Chen, B.Y. Investigation of the unsteady characteristic in a scroll compressor of a heat pump system for electric vehicles. J. Therm. Anal. Calorim. 2023, 148, 965–976. [Google Scholar] [CrossRef]

- Ko, H.; Jeong, D.; Lim, S.; Yup, K. Performance test of an oil-free centrifugal compressor equipped with magnetic bearing for a high temperature heat pump. Korean J. Air-Cond. Refrig. Eng. 2019, 31, 72–80. [Google Scholar]

- Liu, H.; Zhao, B.Y.; Zhang, Z.P.; Li, H.B.; Hu, B.; Wang, R.Z. Experimental validation of an advanced heat pump system with high-efficiency centrifugal compressor. Energy 2020, 213, 118968. [Google Scholar] [CrossRef]

- Meroni, A.; Zühlsdorf, B.; Elmegaard, B.; Haglind, F. Design of centrifugal compressors for heat pump systems. Appl. Energy 2018, 232, 139–156. [Google Scholar] [CrossRef]

- Uusitalo, A.; Turunen-Saaresti, T.; Honkatukia, J.; Tiainen, J.; Jaatinen-Varri, A. Numerical analysis of working fluids for large scale centrifugal compressor driven cascade heat pumps upgrading waste heat. Appl. Energy 2020, 269, 115056. [Google Scholar] [CrossRef]

- Kosmadakis, G. Estimating the potential of industrial (high-temperature) heat pumps for exploiting waste heat in EU industries. Appl. Therm. Eng. 2019, 156, 287–298. [Google Scholar] [CrossRef]

- Mateu-Royo, C.; Sawalha, S.; Mota-Babiloni, A.; Navarro-Esbri, J. High temperature heat pump integration into district heating network. Energy Convers. Manag. 2020, 210, 112719. [Google Scholar] [CrossRef]

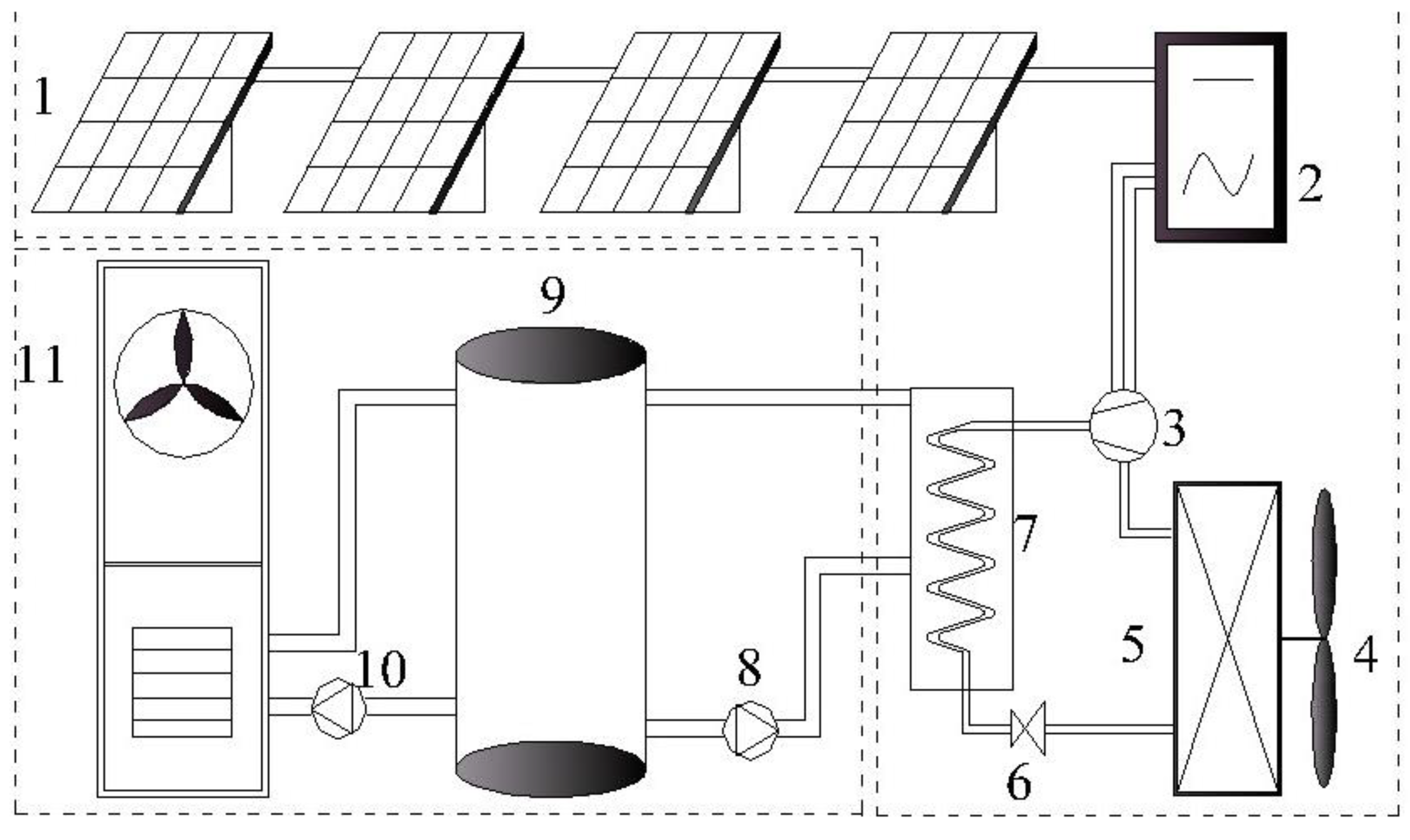

- Wang, L.; Li, M.; Han, Y.H. Analysis of energy storage and heating performance of photovolatic direct-driven air heat pump. Acta Energ. Sol. Sin. 2020, 41, 159–166. [Google Scholar]

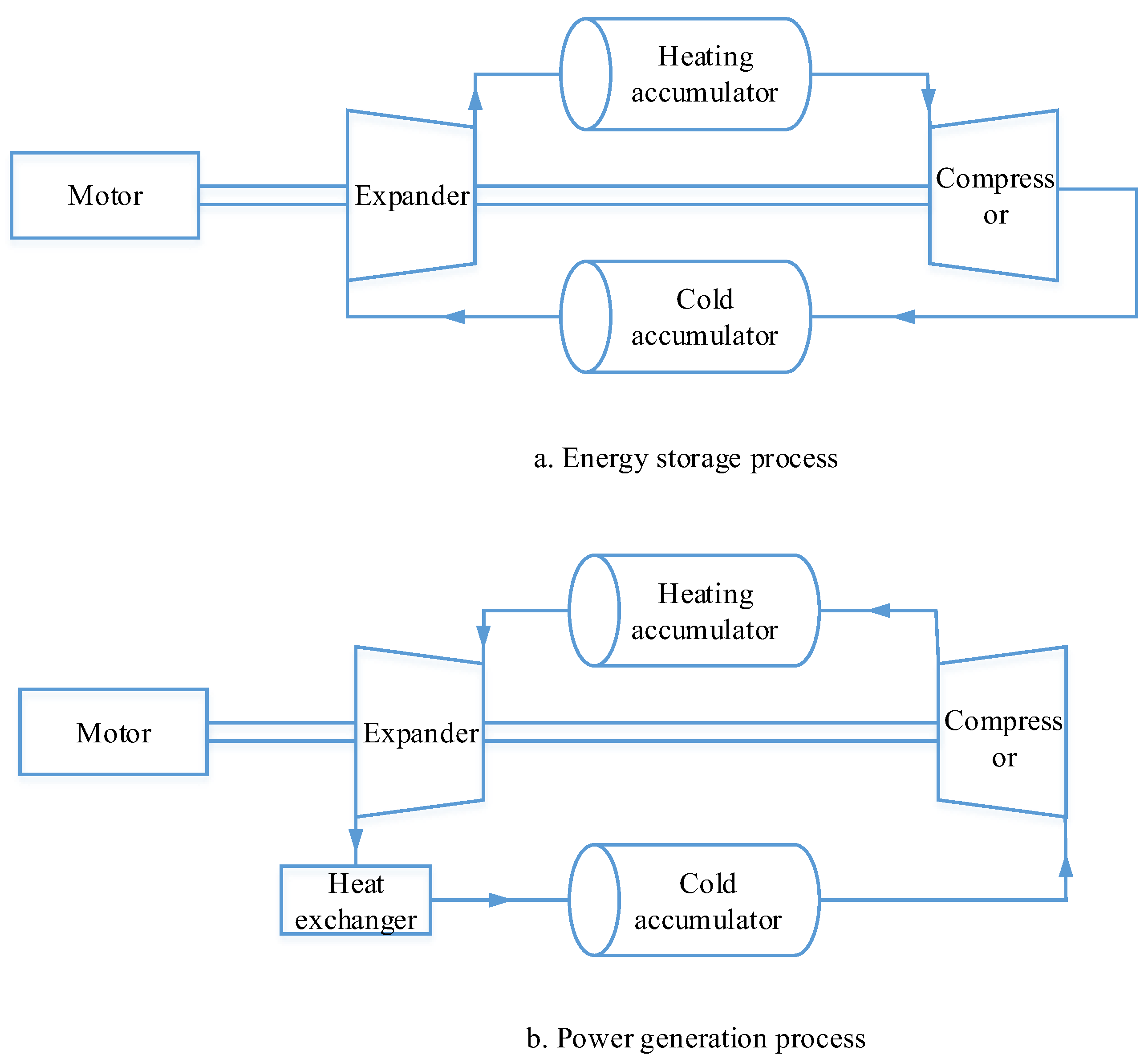

- Hassan, A.H.; Corberán, J.M.; Ramirez, M.; Trebilcock-Kelly, F.; Paya, J. A high-temperature heat pump for compressed heat energy storage applications: Design, modeling, and performance. Energy Rep. 2022, 8, 10833–10848. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, L.; Xu, Y.J.; Chen, H.S. Research progress in pumped heat electricity storage system: A Review. Proc. CSEE 2018, 38, 178–185. [Google Scholar]

- Wu, Z.Q.; Wang, J.H.; Bai, N. Exergy analysis for pumped thermal electricity storage system based on closed brayton cycle. Acta Energ. Sol. Sin. 2023, 44, 336–343. [Google Scholar]

- Lu, C.; Shi, X.P.; Jia, M.X.; Du, D.M.; He, Q. Dynamic model and start-up characteristics of pumped thermal electricity storage system. Proc. CSEE 2022, 42, 167–176. [Google Scholar]

| Researcher | Working Fluid | Heating Temperature (°C) |

|---|---|---|

| Liu [5] | R245fa | 120–140 |

| Arpagaus [7] | R1336mzz(Z) | 70–160 |

| Yan [8] | R1336mzz(Z), R1224yd(Z) | 70–110 |

| Frate [10] | R1233zd(E) | 110–150 |

| Kondou [11] | R1234ze(Z) | 160 |

| Longo [12] | R600a, R1233zd(E), R1234ze(Z) | 120, 150, 140 |

| Mateu-Royo [13] | R1224yd(Z) | 110–140 |

| Jiang [14] | R1233zd(E) | 60–160 |

| Wu [15] | R1234ze(Z) | 90–100 |

| Dai [20] | R744 | 120 |

| Wu [21] | R718 | 140 |

| Chamoun [27,28,29] | R718 | 130–140 |

| Li [30,31] | BY6-BY3B | 168.4 |

| Yu [32] | BY-4 | 90–110 |

| Wang [36] | MB85 | 97.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Wang, Y.; Qin, Y.; Wang, G.; Liu, R.; Yang, Y. A Review of Super-High-Temperature Heat Pumps over 100 °C. Energies 2023, 16, 4591. https://doi.org/10.3390/en16124591

Sun J, Wang Y, Qin Y, Wang G, Liu R, Yang Y. A Review of Super-High-Temperature Heat Pumps over 100 °C. Energies. 2023; 16(12):4591. https://doi.org/10.3390/en16124591

Chicago/Turabian StyleSun, Jian, Yinwu Wang, Yu Qin, Guoshun Wang, Ran Liu, and Yongping Yang. 2023. "A Review of Super-High-Temperature Heat Pumps over 100 °C" Energies 16, no. 12: 4591. https://doi.org/10.3390/en16124591

APA StyleSun, J., Wang, Y., Qin, Y., Wang, G., Liu, R., & Yang, Y. (2023). A Review of Super-High-Temperature Heat Pumps over 100 °C. Energies, 16(12), 4591. https://doi.org/10.3390/en16124591