Impact of Stearic Acid as Heat Storage Material on Energy Efficiency and Economic Feasibility of a Vacuum Tube Solar Water Heater

Abstract

1. Introduction

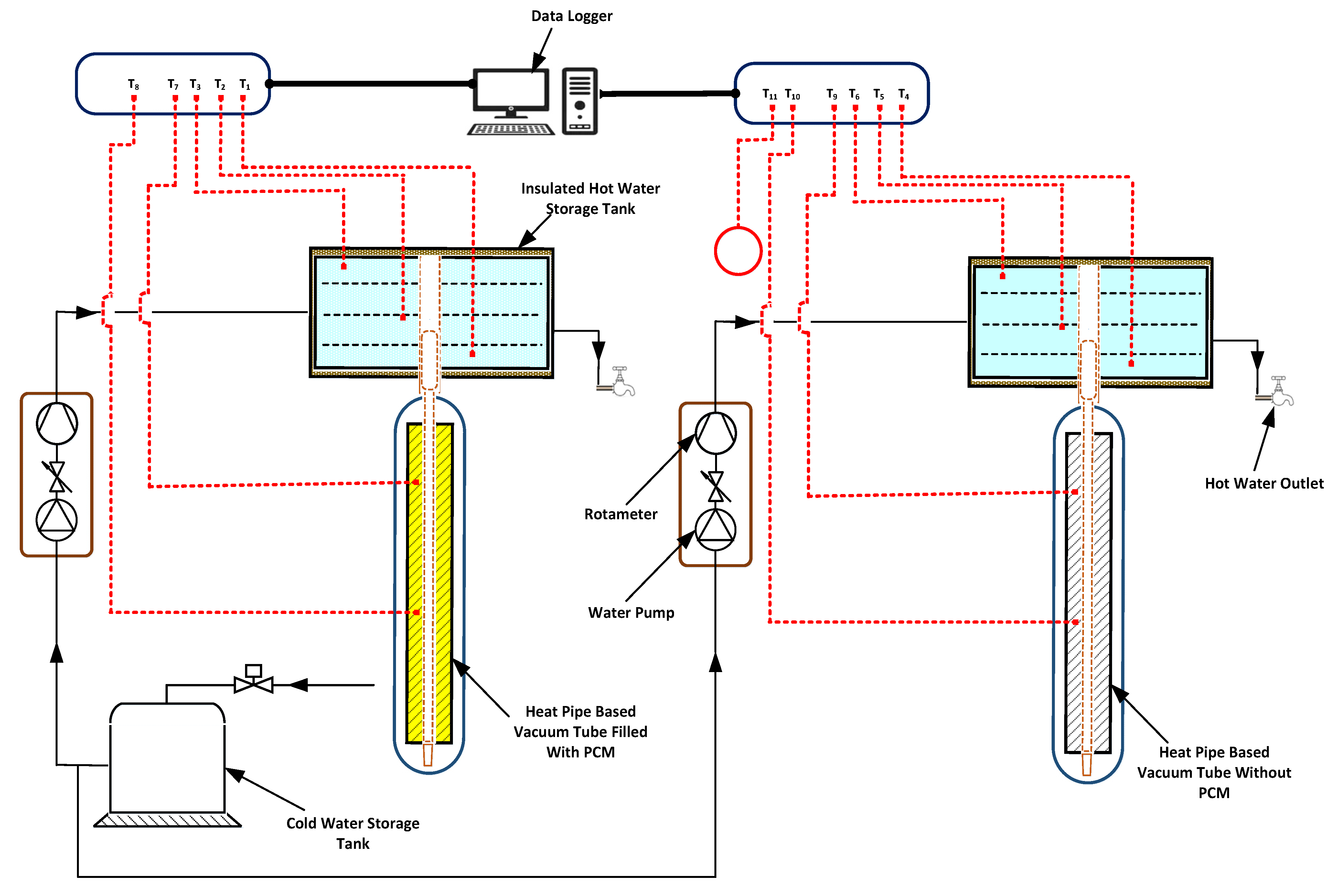

2. Description of Experimental Setup and Methodology

3. Heat Transfer and Economic Analysis

3.1. Heat Transfer Analysis

3.2. Economic Viability Analysis

4. Results and Discussion

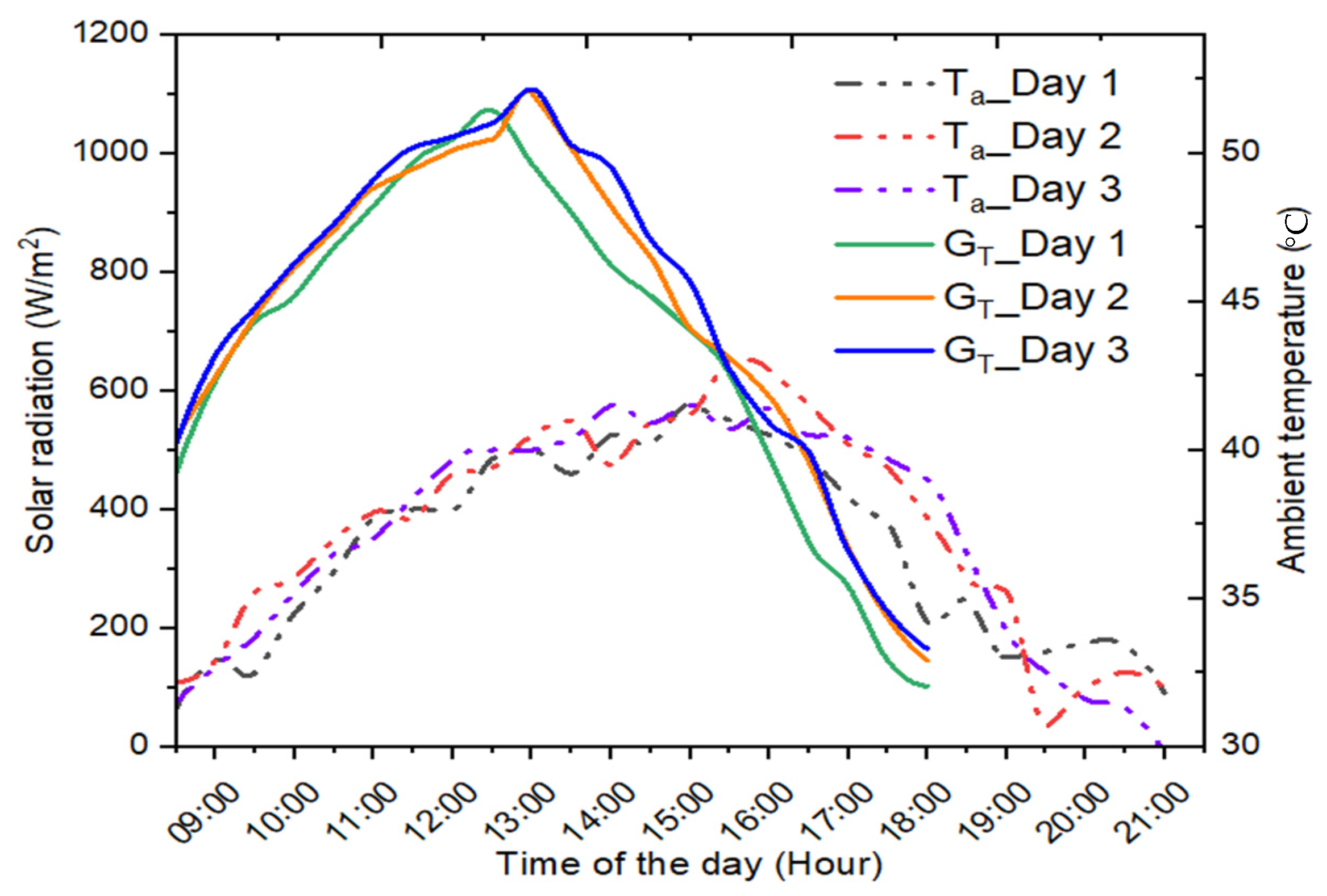

4.1. Disparity in Outside Air Temperature and Solar Energy for Different Test Days

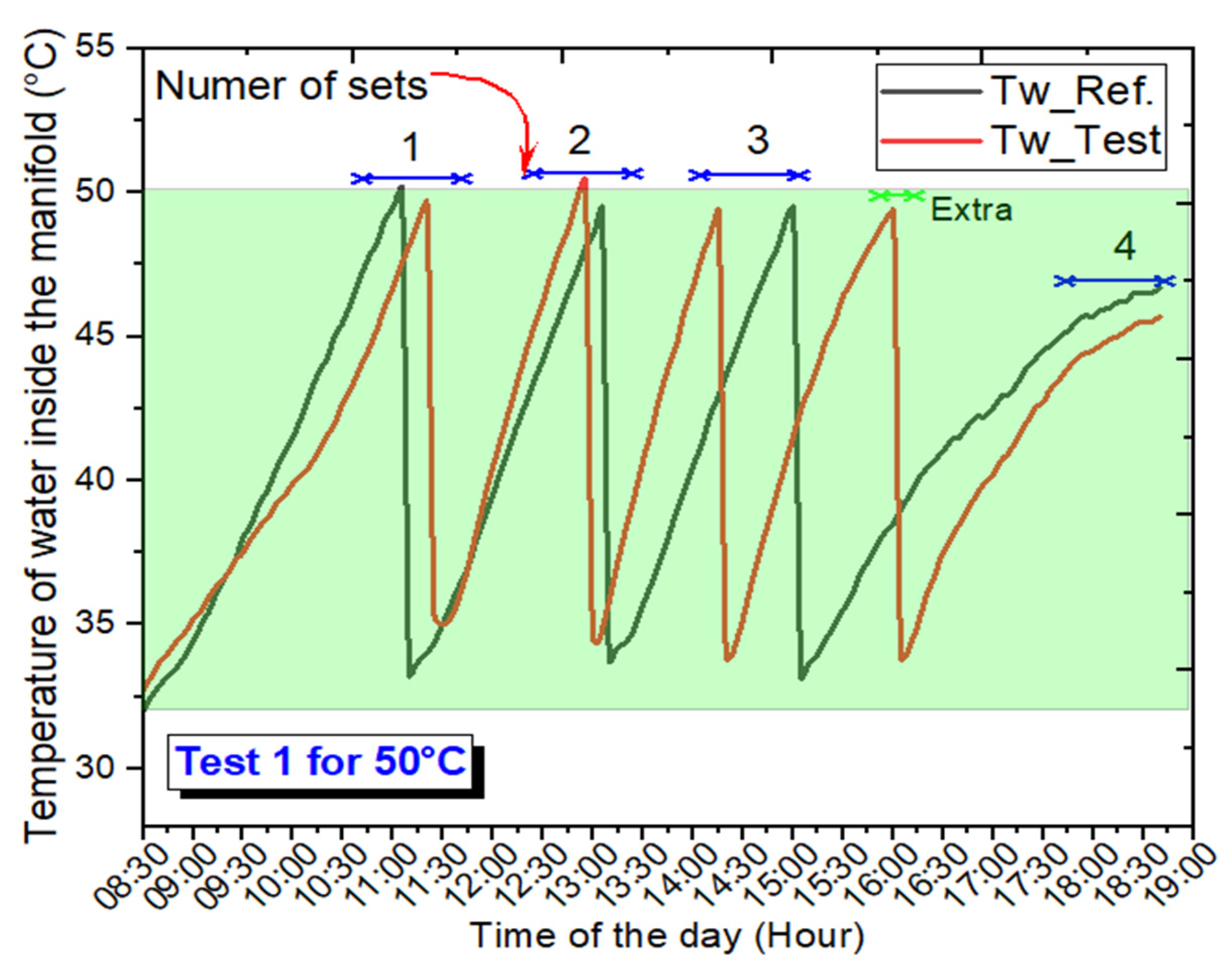

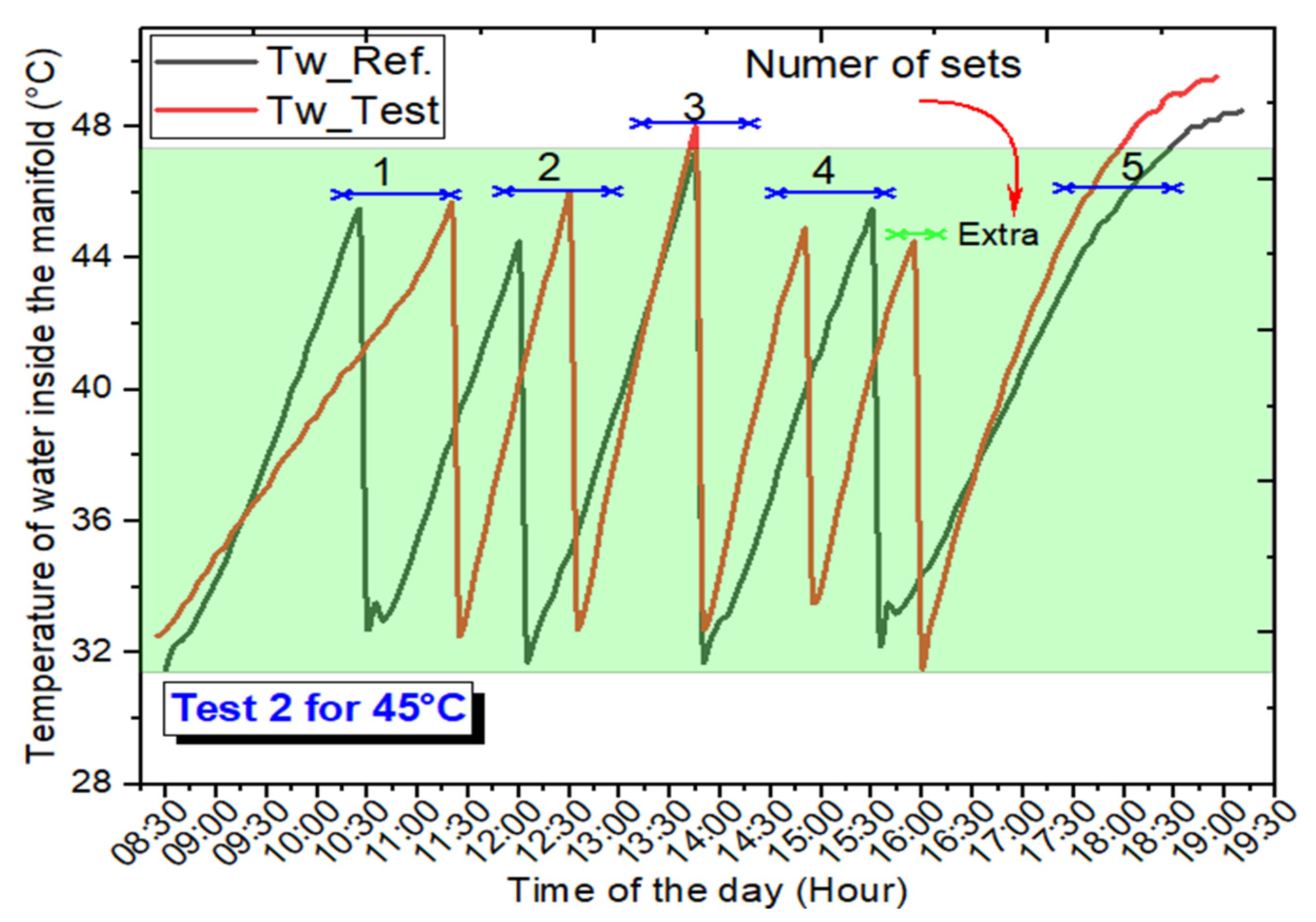

4.2. Disparity in Hot Water Temperature of Control and Testing Systems

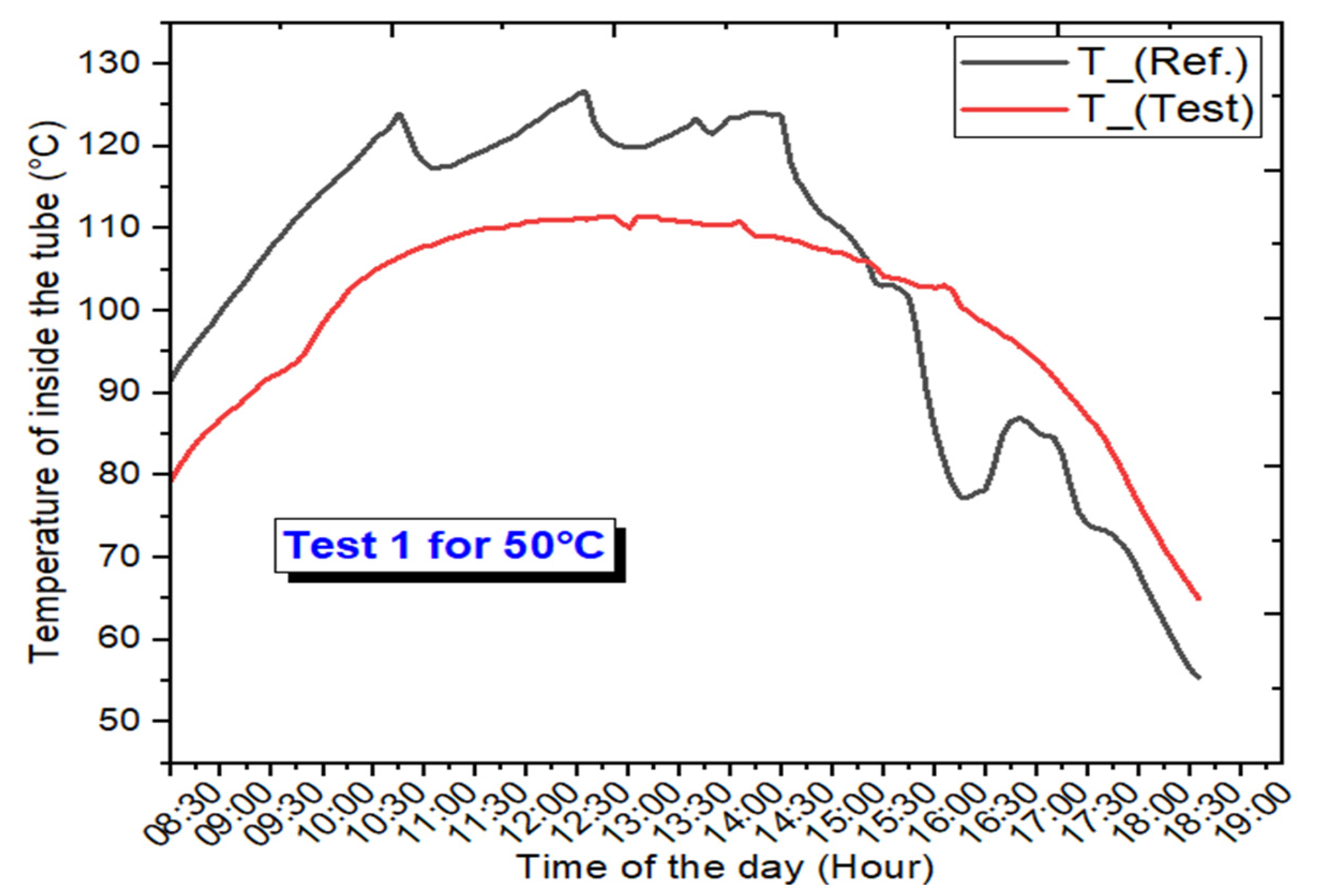

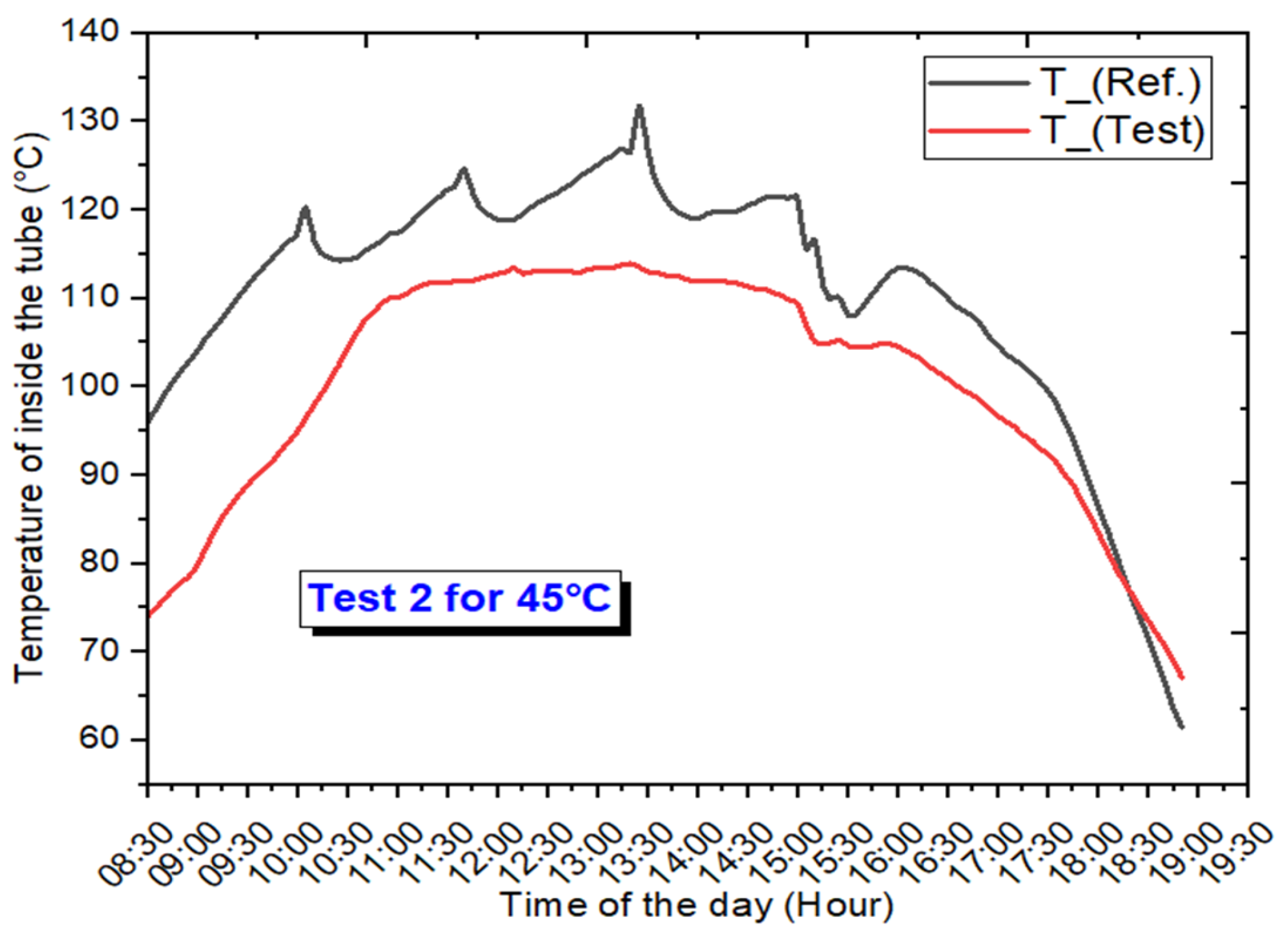

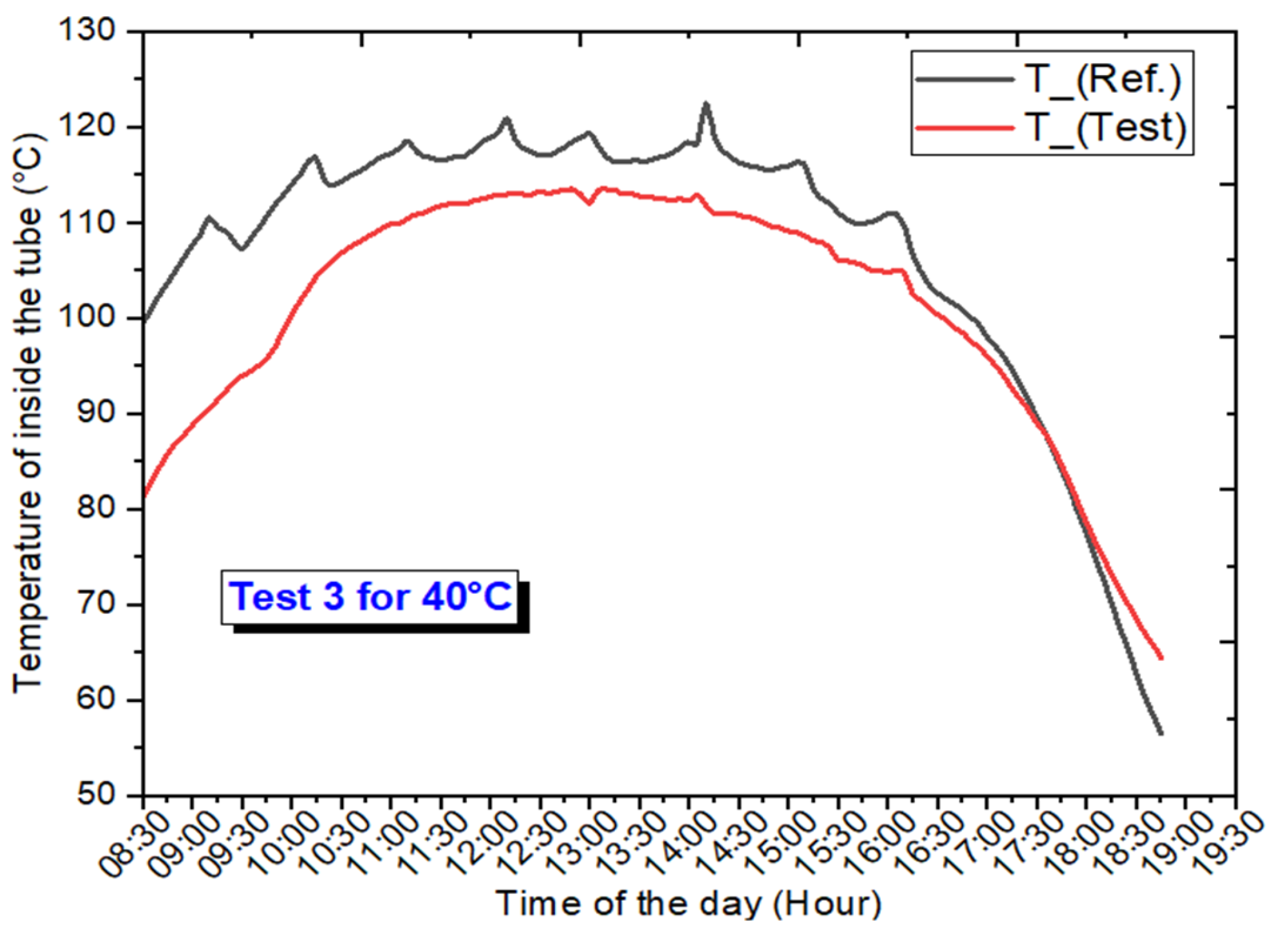

4.3. Temperature Variation in Internal Air and Heat Storage Material for Different Tests

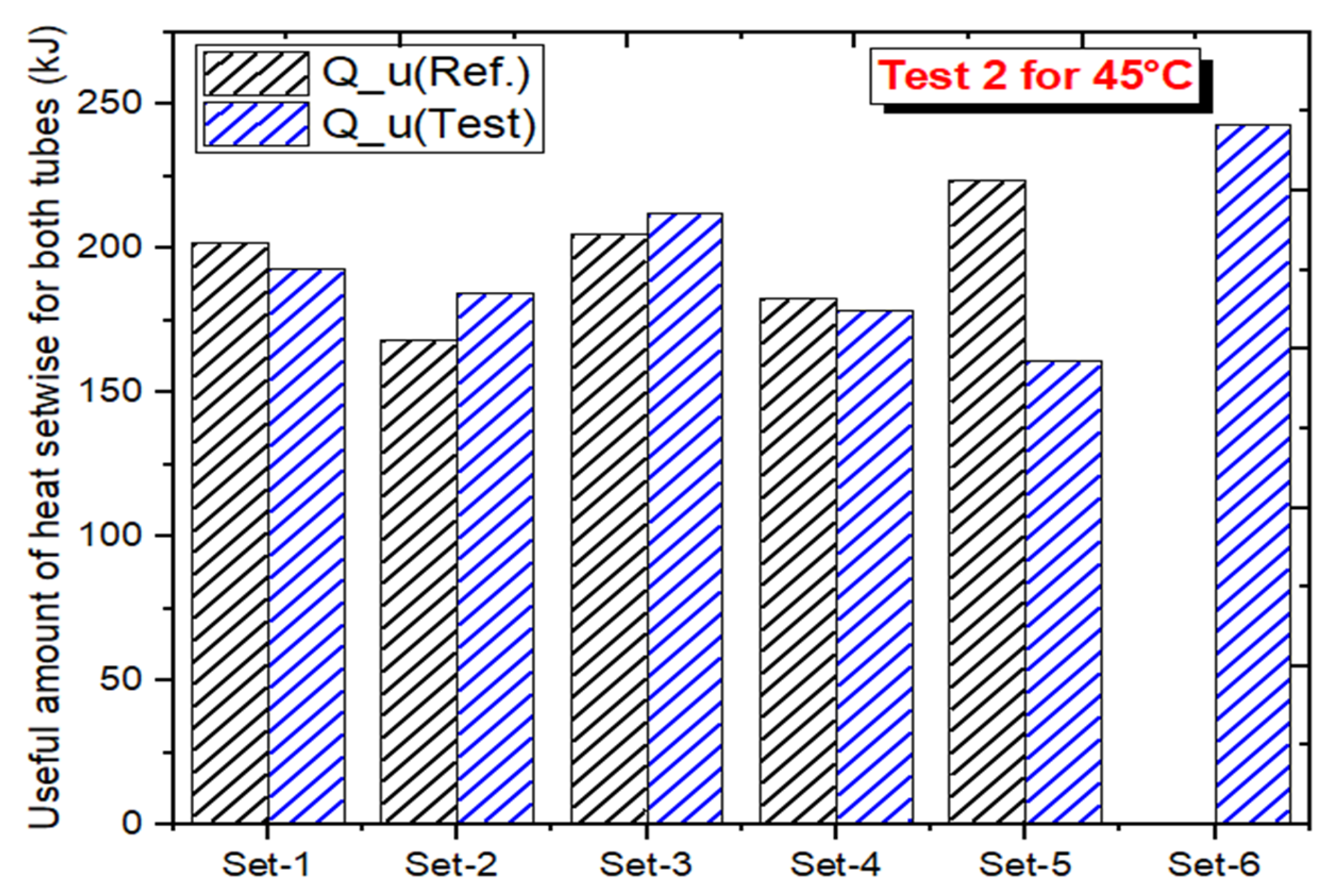

4.4. Variation of Set-Wise Useful Heat for Different Tests at 50, 45, and 40 °C

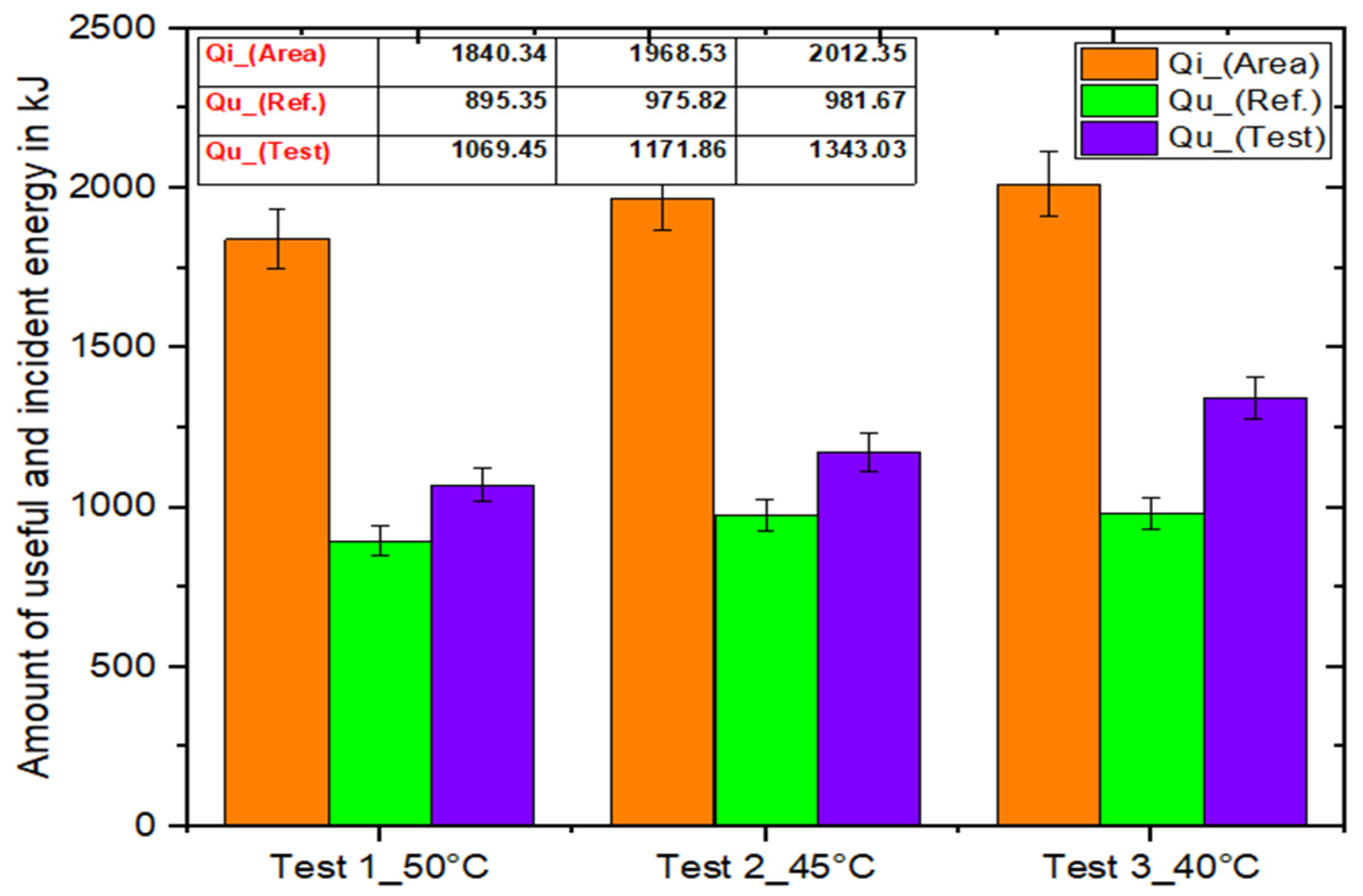

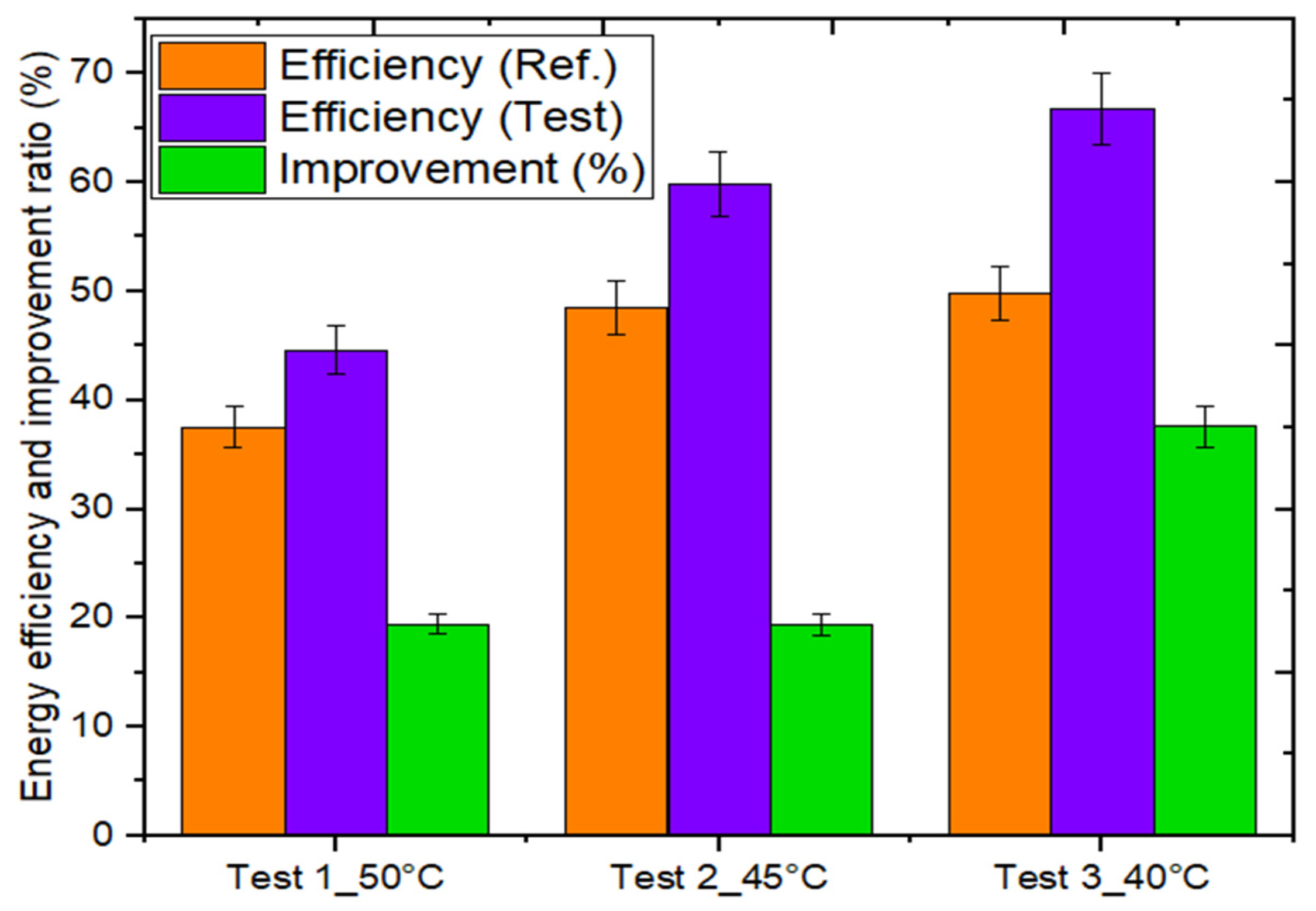

4.5. Disparity in Daily Thermal Energy Input/Output and Energy Efficiency of the Proposed Systems for Different Tests

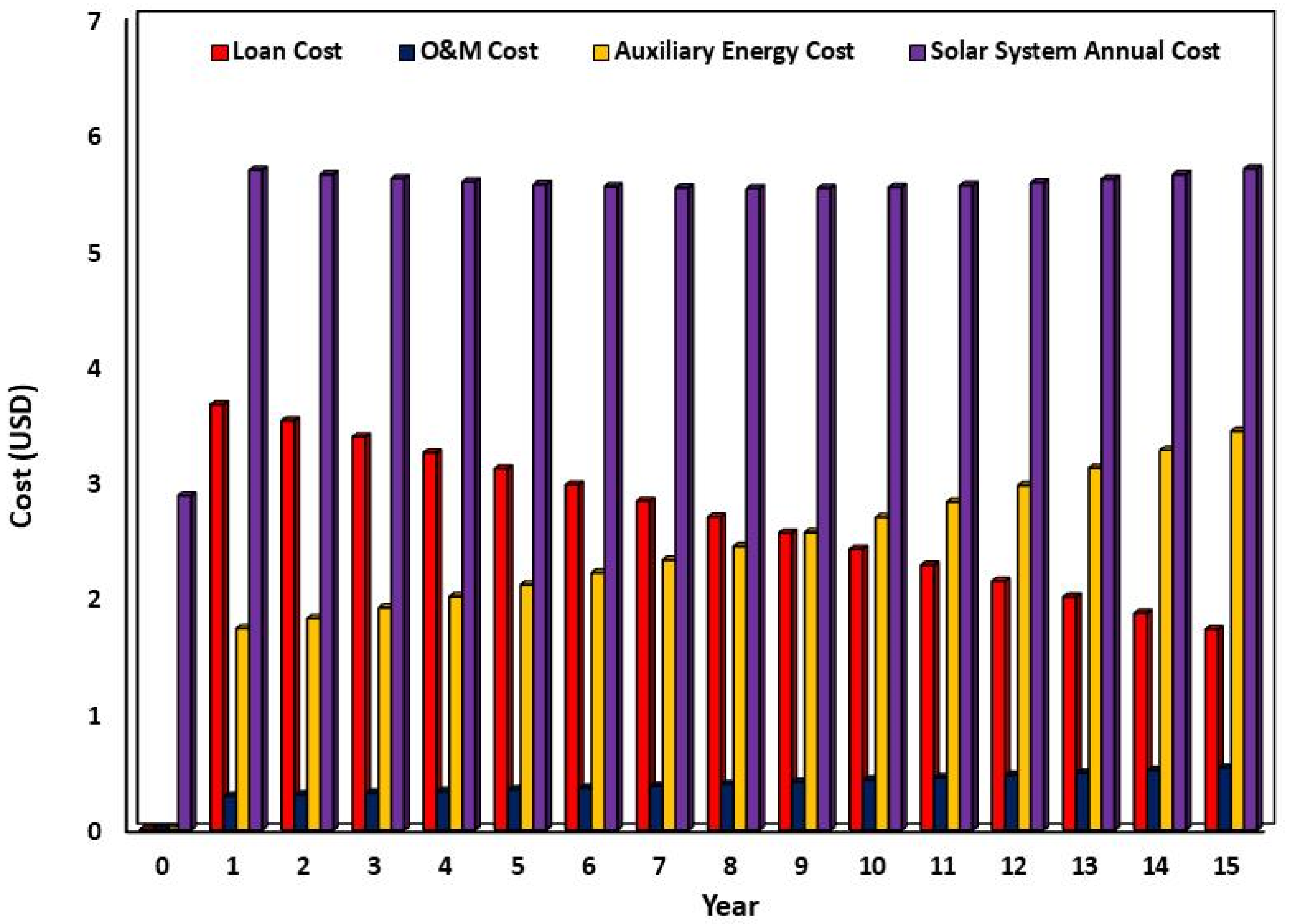

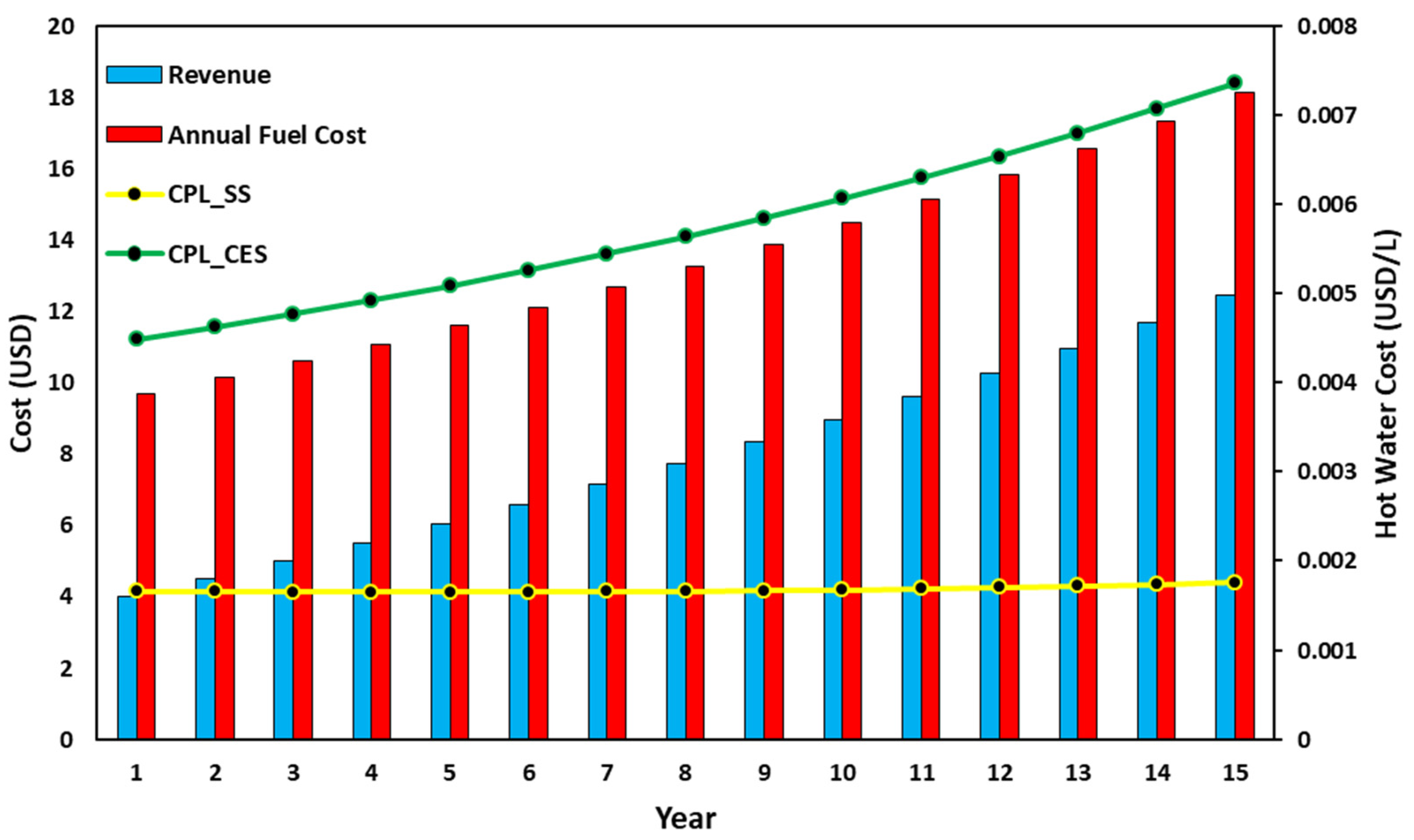

4.6. Outcomes of Technoeconomic Analysis

5. Conclusions

- ❖

- The testing system with PCM could produce hot water during late evening hours (non-sunny/night hours) and improve the collector’s thermal output.

- ❖

- The amount of total usable heat output produced by the testing system with PCM was 179.10, 196.04, and 361.36 kJ more than the system without storage for Test 1_50 °C, Test 2_45 °C, and 19.44% Test 3_40 °C, respectively.

- ❖

- The maximum energy efficiency of the two systems was 66.78 and 50.86% for Test 3_40 °C.

- ❖

- The improvement in the energy efficiency of the testing system was 37.67% for Test 1_50 °C, 19.37% for Test 2_45 °C, and 19.44% for Test 3_40 °C compared to the reference system.

- ❖

- The amount of additional hot water received from the testing system was 3.5 L for Test 1_50 °C and Test 2_45 °C and 10.5 L for Test 3_40 °C.

- ❖

- It was noted that at the end of 15 years, almost 118.8 USD in revenue could be earned by the proposed solar system. The total running cost of ELG and the proposed solar system was observed to be 202.62 and 86.70 USD, respectively.

- ❖

- On average, the cost of hot water production with the solar system and ELG was found to be 0.0016 and 0.004 USD/L, respectively. Therefore, the proposed solar system is highly recommended over conventional water heating systems in urban and rural areas.

- ❖

- The value of LEC was found to be 0.062 USD/electricity unit, which was much lower than the LEC value of ELG (0.116 USD/electricity unit). The value of NPW (73.73 USD) indicated high acceptability of the proposed system. Furthermore, the payback time was lower than the life of the system, making it suitable for use in the commercial sector.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, T.-T.; Zhao, Y.-H.; Diao, Y.-H.; Li, F.-F.; Quan, Z.-H. Experimental investigation and performance evaluation of a vacuum tube solar air collector based on micro heat pipe arrays. J. Clean. Prod. 2017, 142, 3517–3526. [Google Scholar] [CrossRef]

- Fuentes, E.; Arce, L.; Salom, J. A review of domestic hot water consumption profiles for application in systems and buildings energy performance analysis. Renew. Sustain. Energy Rev. 2018, 81, 1530–1547. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pandey, A.; Sari, A. Global advancement on experimental and thermal analysis of evacuated tube collector with and without heat pipe systems and possible applications. Appl. Energy 2018, 228, 351–389. [Google Scholar] [CrossRef]

- Pawar, V.R.; Sobhansarbandi, S. Heat transfer enhancement of a PCM-porous metal based heat pipe evacuated tube solar collector: An experimental study. Sol. Energy 2023, 251, 106–118. [Google Scholar] [CrossRef]

- Algarni, S.; Mellouli, S.; Alqahtani, T.; Almutairi, K.; Khan, A.; Anqi, A. Experimental investigation of an evacuated tube solar collector incorporating nano-enhanced PCM as a thermal booster. Appl. Therm. Eng. 2020, 180, 115831. [Google Scholar] [CrossRef]

- Essa, M.A.; Rofaiel, I.Y.; Ahmed, M.A. Experimental and Theoretical Analysis for the Performance of Evacuated Tube Collector Integrated with Helical Finned Heat Pipes using PCM Energy Storage. Energy 2020, 206, 118166. [Google Scholar] [CrossRef]

- Olfian, H.; Ajarostaghi, S.S.M.; Ebrahimnataj, M.; Farhadi, M.; Arıcı, M. On the thermal performance of evacuated tube solar collector integrated with phase change material. Sustain. Energy Technol. Assess. 2022, 53, 102437. [Google Scholar] [CrossRef]

- Li, Y.; Liang, X.; Song, W.; Li, T.; Wang, D.; Liu, Y. Optimization and thermal performance of U-type evacuated tube solar collector filled with phase change material. Energy Rep. 2022, 8, 6126–6138. [Google Scholar] [CrossRef]

- Wu, Y.; Tong, X.; Li, D.; Arıcı, M.; Liu, C.; Liu, Y.; Yang, R.; Yu, Y. Energy analysis of evacuated tube solar collector integrating phase change material in northeast China. J. Energy Storage 2022, 55, 105772. [Google Scholar] [CrossRef]

- O’neil, T.J.; Sobhansarbandi, S. Thermal performance investigation of energy storage based U-pipe evacuated tube solar collector: An experimental study. Sustain. Energy Technol. Assess. 2022, 52, 102146. [Google Scholar] [CrossRef]

- Senobar, H.; Aramesh, M.; Shabani, B. Evacuated tube solar thermal collector with enhanced phase change material thermal storage: An experimental study. J. Energy Storage 2021, 46, 103838. [Google Scholar] [CrossRef]

- Bouadila, S.; Rehman, T.-U.; Baig, M.A.A.; Skouri, S.; Baddadi, S. Energy, Exergy and Economic (3E) analysis of evacuated tube heat pipe solar collector to promote storage energy under North African climate. Sustain. Energy Technol. Assess. 2023, 55, 102959. [Google Scholar] [CrossRef]

- Kumar, P.; Mylsamy, K. A comprehensive study on thermal storage characteristics of nano-CeO2 embedded phase change material and its influence on the performance of evacuated tube solar water heater. Renew. Energy 2020, 162, 662–676. [Google Scholar] [CrossRef]

- Uniyal, A.; Prajapati, Y.K.; Ranakoti, L.; Bhandari, P.; Singh, T.; Gangil, B.; Sharma, S.; Upadhyay, V.V.; Eldin, S.M. Recent Advancements in Evacuated Tube Solar Water Heaters: A Critical Review of the Integration of Phase Change Materials and Nanofluids with ETCs. Energies 2022, 15, 8999. [Google Scholar] [CrossRef]

- Raza, S.A.; Ahmad, S.S.; Ratlamwala, T.A.H.; Hussain, G.; Alkahtani, M. Techno-Economic Analysis of Glazed, Unglazed and Evacuated Tube Solar Water Heaters. Energies 2020, 13, 6261. [Google Scholar] [CrossRef]

- Olczak, P.; Matuszewska, D.; Zabagło, J. The Comparison of Solar Energy Gaining Effectiveness between Flat Plate Collectors and Evacuated Tube Collectors with Heat Pipe: Case Study. Energies 2020, 13, 1829. [Google Scholar] [CrossRef]

- Jachura, A.; Sekret, R. Life Cycle Assessment of the Use of Phase Change Material in an Evacuated Solar Tube Collector. Energies 2021, 14, 4146. [Google Scholar] [CrossRef]

- Essa, M.A.; Mostafa, N.H.; Ibrahim, M.M. An experimental investigation of the phase change process effects on the system performance for the evacuated tube solar collectors integrated with PCMs. Energy Convers. Manag. 2018, 177, 1–10. [Google Scholar] [CrossRef]

- Olfian, H.; Ajarostaghi, S.S.M.; Farhadi, M.; Ramiar, A. Melting and solidification processes of phase change material in evacuated tube solar collector with U-shaped spirally corrugated tube. Appl. Therm. Eng. 2021, 182, 116149. [Google Scholar] [CrossRef]

- Ali, S.H.; Eidan, A.A.; Al Sahlani, A. Study the Effect of Phase Change Material on the Performance of Evacuated Tube Heat Pipe Solar Collector under Iraqi Climatic Conditions. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012009. [Google Scholar] [CrossRef]

- Kumar, P.M.; Mylsamy, K.; Alagar, K.; Sudhakar, K. Investigations on an evacuated tube solar water heater using hybrid-nano based organic phase change material. Int. J. Green Energy 2020, 17, 872–883. [Google Scholar] [CrossRef]

- Bouadila, S.; Baddadi, S.; Rehman, T.-U.; Ayed, R. Experimental investigation on the thermal appraisal of heat pipe-evacuated tube collector-based water heating system integrated with PCM. Renew. Energy 2022, 199, 382–394. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pandey, A.; Sharma, R.; Sari, A. PCM integrated glass in glass tube solar collector for low and medium temperature applications: Thermodynamic & techno-economic approach. Energy 2020, 198, 117238. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pathak, S.K.; Tripathi, P.A.; Sharma, R.; Singh, G.; Pandey, A. Thermal and chemical reliability of paraffin wax and its impact on thermal performance and economic analysis of solar water heater. Energy Sustain. Dev. 2023, 73, 39–53. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pandey, A.; Popli, S.; Singh, G.; Sharma, R.; Sari, A. Effect of simultaneous & consecutive melting/solidification of phase change material on domestic solar water heating system. Renew. Energy 2022, 188, 329–348. [Google Scholar] [CrossRef]

- Zheng, Y.; Hatzell, K.B. Technoeconomic analysis of solar thermal desalination. Desalination 2020, 474, 114168. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Popli, S.; Pandey, A. Technical & financial feasibility assessment of heat pipe evacuated tube collector for water heating using Monte Carlo technique for buildings. Energy 2023, 267, 126338. [Google Scholar] [CrossRef]

- Pathak, S.K.; Tyagi, V.; Chopra, K.; Sari, A. Thermal performance and design analysis of U-tube based vacuum tube solar collectors with and without phase change material for constant hot water generation. J. Energy Storage 2023, 66, 107352. [Google Scholar] [CrossRef]

- Retail Domestic Term Deposits-Interest Rates, (n.d.). Available online: https://sbi.co.in/web/interest-rates/deposit-rates/retail-domestic-term-deposits (accessed on 28 April 2023).

- Inflation in India 2028|Statista, (n.d.). Available online: https://www.statista.com/statistics/271322/inflation-rate-in-india/ (accessed on 28 April 2023).

- Velayudhan, S. Dissemination of solar photovoltaics: A study on the government programme to promote solar lantern in India. Energy Policy 2003, 31, 1509–1518. [Google Scholar] [CrossRef]

| Author (s) | Year | Type of System | Parameters Calculated | Increment in Energy Gain |

|---|---|---|---|---|

| Essa et al. [18] | 2018 | Serpentine | Energy and thermal output investigation | 6.8–21.9% |

| Olfian et al. [19] | 2020 | Serpentine | Thermal and system efficiency measurement and impact of operation temperature | 13.6–15% |

| Kumar et al. [13] | 2021 | Heat Pipe | Effect of different percentages of nano-boosted PCM and first and second law analysis | 3–5% |

| Wong et al. [20] | 2022 | Heat Pipe | Heat transfer and thermal efficiency investigation | 3–5% |

| Wu et al. [9] | 2022 | Serpentine | Impact of PCM’s properties and thermal efficiency analysis | 4.31% |

| Kumar et al. [21] | 2022 | Water in Glass | Effect of different percentages of nano-boosted PCM and energy and exergy investigation | 7% |

| Proposed Study | Experimental | Energy, Exergy, and Economic Analysis | 18–31% | |

| Property | Value/Specification |

|---|---|

| Color | Caramel white |

| Melting temperature range | 60–62 °C |

| Latent heat range | 185–190 J/g |

| Specific heat at 75 °C | 2.45 |

| Density at 75 °C | 1.19 |

| Purity | 99.8% |

| Item | Specification/Value |

|---|---|

| Number of vacuum tubes | 1 |

| Aperture area of collector | 0.080 |

| Diameter/length of an evaporator of heat pipe | 9.5/1600 mm |

| Diameter/length of the condenser of heat pipe | 14/63 mm |

| Material of heat pipe fin | Aluminium |

| Diameter of water storage header | 130 mm |

| Length of water storage header | 270 mm |

| Insulation on water storage header | Rockwool |

| Factors | Value | Unit |

|---|---|---|

| Initial investment on proposed collector [27] | 375 | USD/m2 area |

| Maintenance and operational cost of system [27] | 1 | % |

| Loan interest rate [28] | 9 | % |

| Loan term | 15 | years |

| Debt ratio | 90 | % |

| Price of electricity [27] | 0.081 | USD/unit |

| Life of system [28] | 15 | years |

| Rise in electricity price [27] | 10 | %/year |

| Discount/reinvestment rate [29] | 5 | % |

| Inflation rate [30] | 4.5 | %/year [27] |

| Rate of degradation of thermal energy | 0.50 | %/year |

| Average daily solar insolation based on the selected days during experiments | 6.76–7.39 | kWh/m² |

| Average daily energy efficiency based on experiment | 44–67 | % |

| Number of sunny days [31] | 300 | days/year |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chopra, K.; Tyagi, V.V.; Pathak, S.K.; Khajuria, A.; Pandey, A.K.; Rahman, N.A.; Mansor, M.; Sari, A. Impact of Stearic Acid as Heat Storage Material on Energy Efficiency and Economic Feasibility of a Vacuum Tube Solar Water Heater. Energies 2023, 16, 4291. https://doi.org/10.3390/en16114291

Chopra K, Tyagi VV, Pathak SK, Khajuria A, Pandey AK, Rahman NA, Mansor M, Sari A. Impact of Stearic Acid as Heat Storage Material on Energy Efficiency and Economic Feasibility of a Vacuum Tube Solar Water Heater. Energies. 2023; 16(11):4291. https://doi.org/10.3390/en16114291

Chicago/Turabian StyleChopra, K., V. V. Tyagi, Sudhir Kumar Pathak, Apaar Khajuria, A. K. Pandey, Nazaruddin Abd Rahman, Muhamad Mansor, and Ahmet Sari. 2023. "Impact of Stearic Acid as Heat Storage Material on Energy Efficiency and Economic Feasibility of a Vacuum Tube Solar Water Heater" Energies 16, no. 11: 4291. https://doi.org/10.3390/en16114291

APA StyleChopra, K., Tyagi, V. V., Pathak, S. K., Khajuria, A., Pandey, A. K., Rahman, N. A., Mansor, M., & Sari, A. (2023). Impact of Stearic Acid as Heat Storage Material on Energy Efficiency and Economic Feasibility of a Vacuum Tube Solar Water Heater. Energies, 16(11), 4291. https://doi.org/10.3390/en16114291