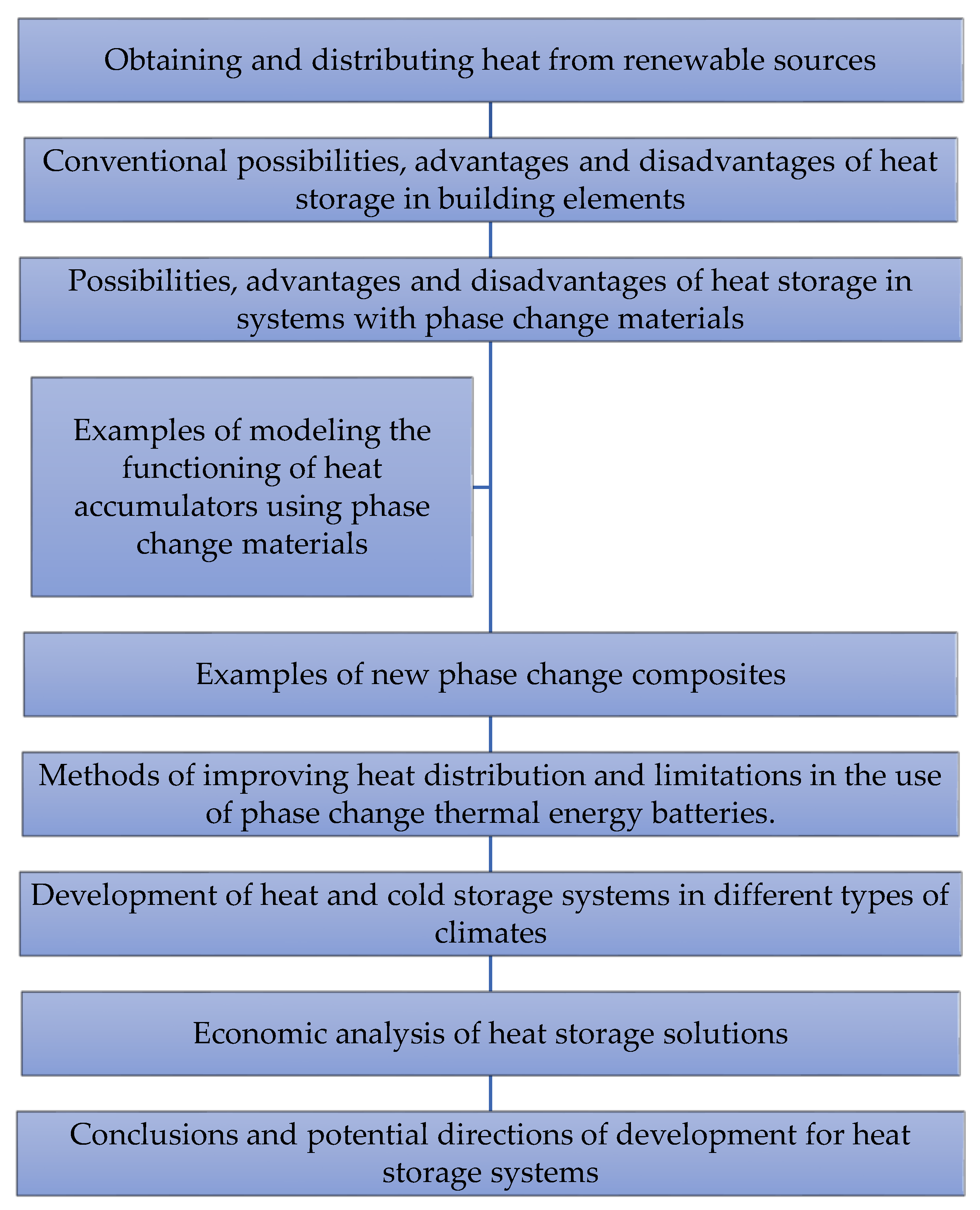

Modern Thermal Energy Storage Systems Dedicated to Autonomous Buildings

Abstract

:1. Introduction

1.1. Thermal Energy Acquisition and Distribution Methods from Renewable Sources

- Solar energy. Most renewable sources are directly or indirectly dependent on the sun. Most of the direct gains are absorbed at latitudes around the equator, but this energy is then dispersed across the planet in the form of winds and ocean currents.

- Wind energy. Air currents can be captured and used to drive wind turbines. Wind energy shows the fastest growth among all renewable sources.

- Hydropower. We can also obtain energy from water, based on either its movement or its temperature differences.

- Geothermal energy. This is obtained by capturing the heat of the earth itself, usually from depths of up to several kilometres below its surface. It is an expensive source of renewable energy.

- Biomass. We know different forms of solid biomass: wood fuel, organic components of municipal waste, or unused parts of agricultural crops. Most types of biomass contain usable energy.

- Biofuels. Liquid biofuels are generally bioalcohols (e.g., bioethanol) or biooils (biodiesel or pure vegetable oils). Their biggest advantage is the lower emissions.

- Biogas. This can easily be produced from biologically active waste substances that arise, for example, from the production of paper or sugar and from sewage, animal waste, and other substances. These various wastes must be allowed to settle together and to undergo natural fermentation to produce methane.

1.2. ZeroEnergy and Autonomous Buildings

2. Conventional Possibilities, Advantages, and Disadvantages of Heat Storage in Building Elements

3. Possibilities, Advantages, and Disadvantages of Heat Storage in Systems with Phase Change Materials

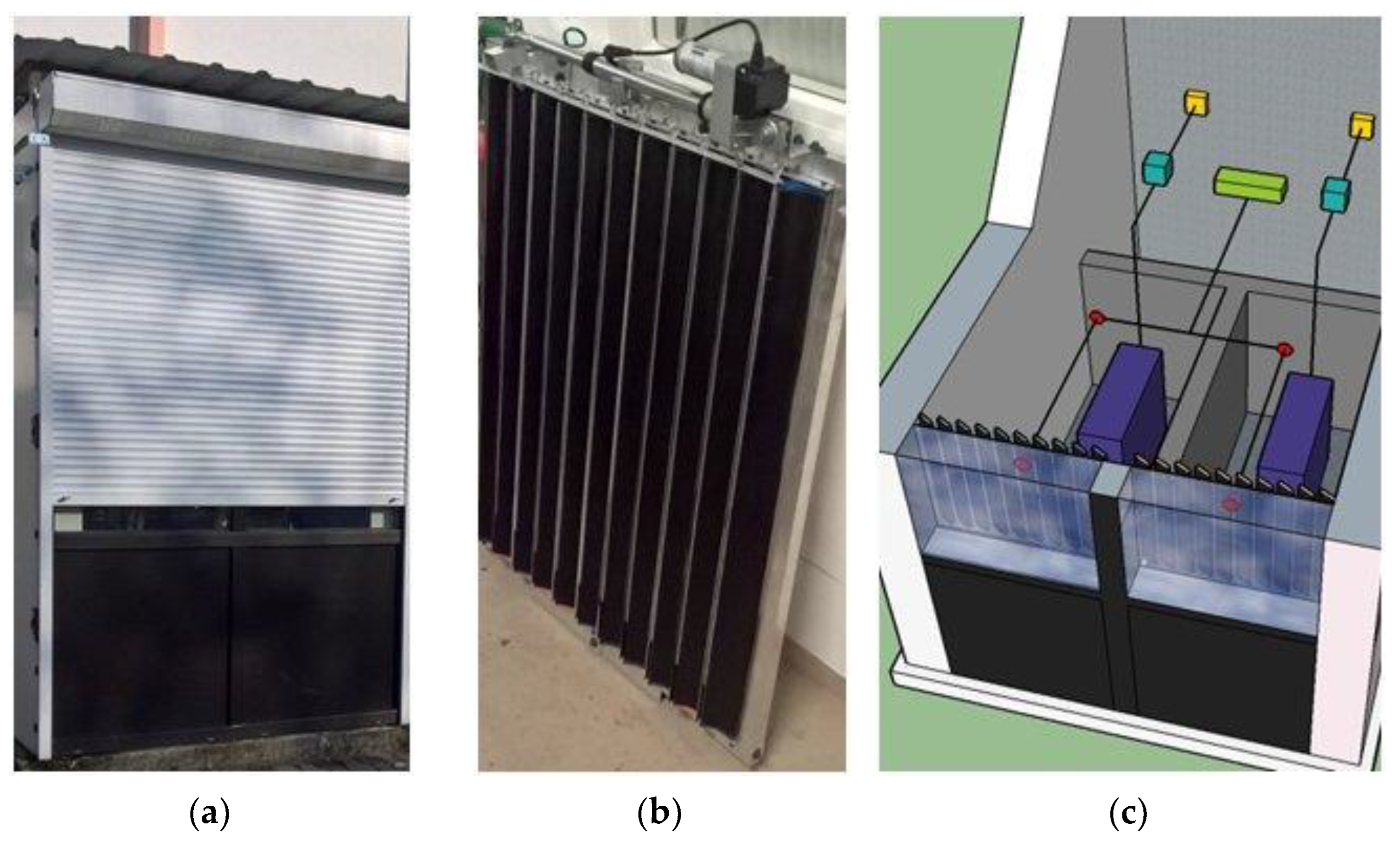

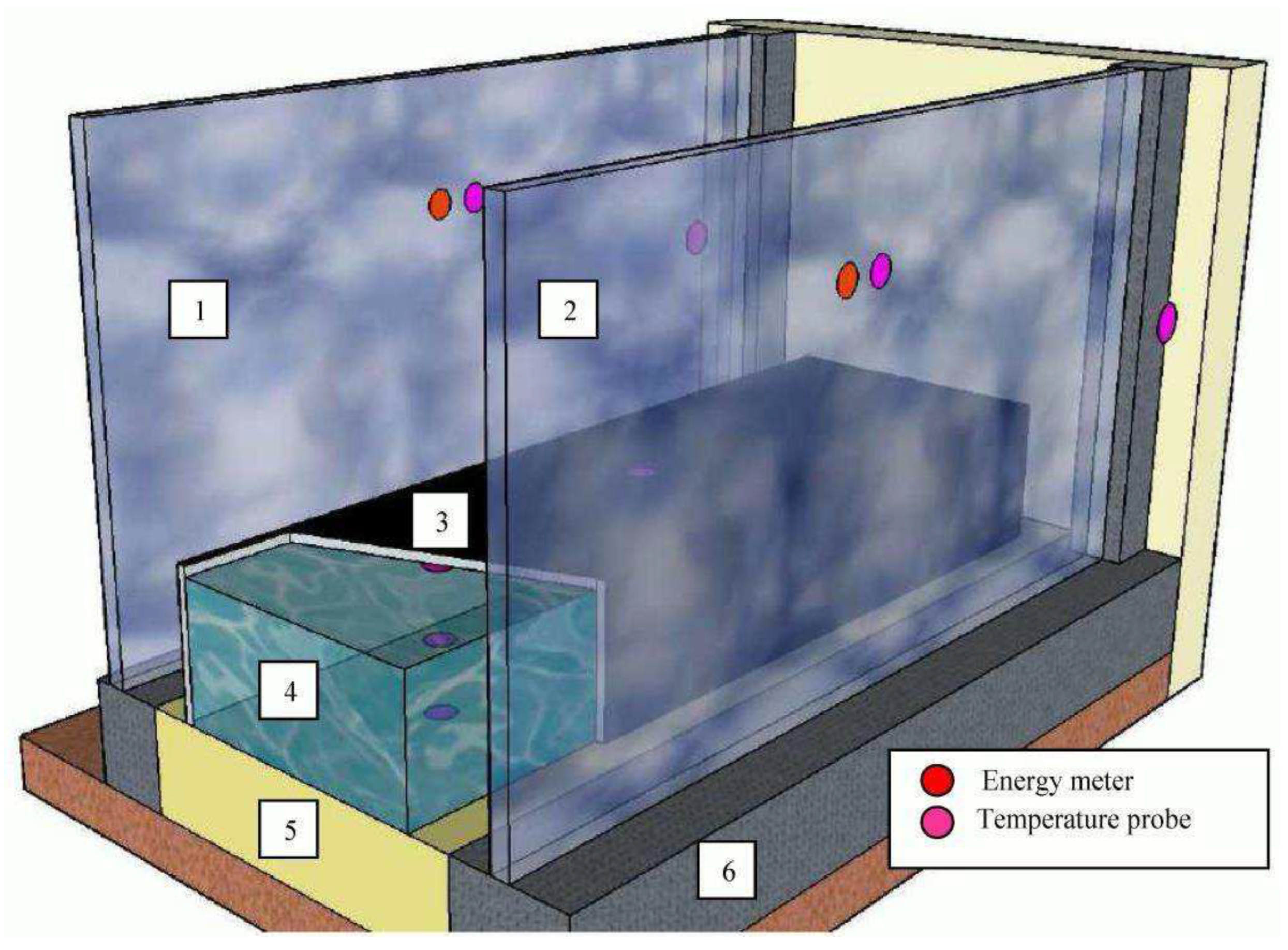

3.1. Phase Change Materials in Transparent Partitions

3.2. Phase Change Materials in Opaque Partitions

3.3. Phase Change Materials in the Form of Thermal Energy Batteries/Storage Systems

4. Examples of Modelling the Functioning of Heat Accumulators Using Phase Change Materials

- Finite elements method, using splines and specific boundary conditions.

- Finite differences method, using splines and specific boundary conditions and meeting the thermal diffusivity condition.

- Finite volumes method, using splines and specific boundary conditions.

- Statistical methods linked to the experiment plan and multi-variable function response planes.

- Methods using fuzzy sets, e.g., Mamdani–Assilian models, used when a large pool of empirical results for verifying the model is not available.

- Methods using artificial neural networks.

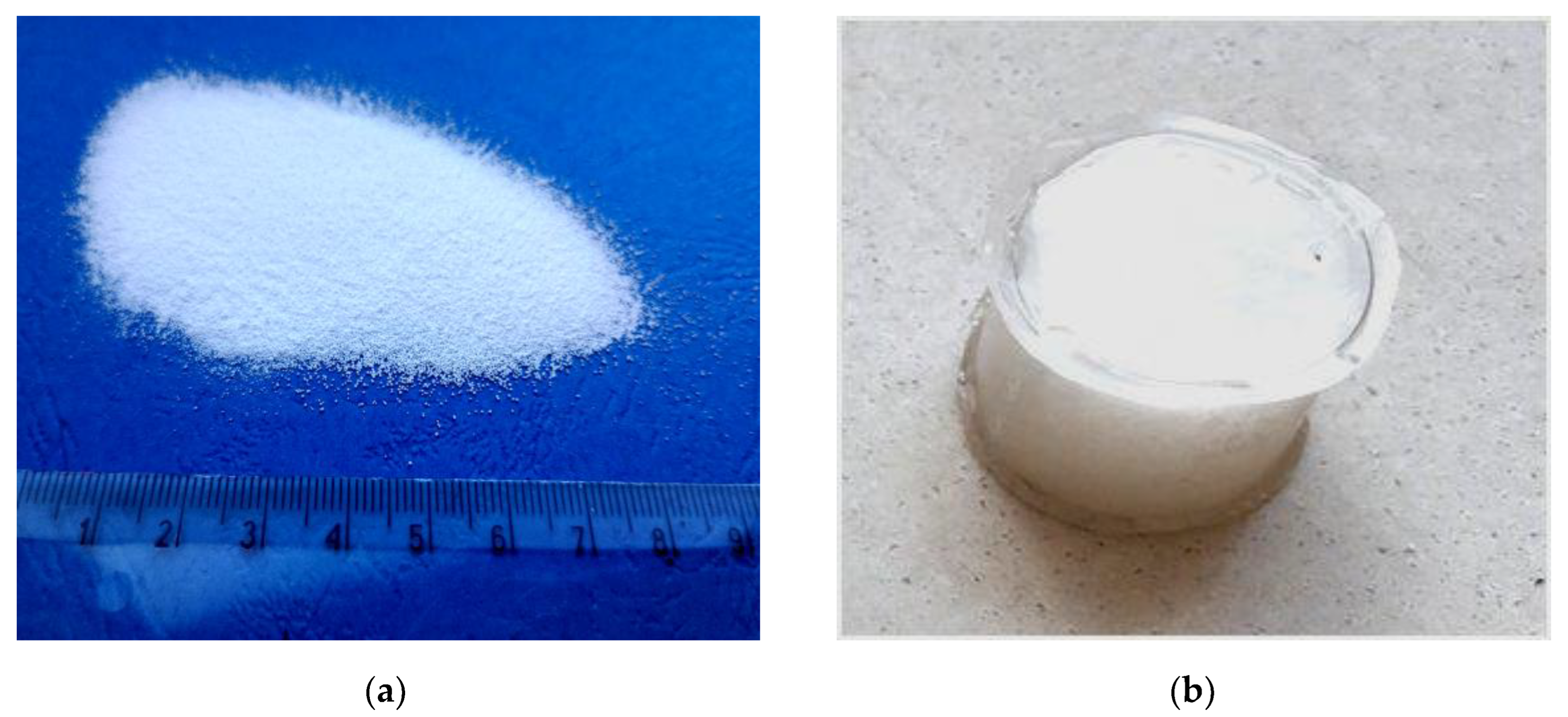

5. Examples of New Phase Change Composites

6. Methods of Improving Heat Distribution and the Limitations in the Use of Phase Change Thermal Energy Batteries

7. Development of Heat and Cold Storage Systems in Different Types of Climates

8. Economic Assessment of the Use of Heat Storage in the Building

9. Discussion

Author Contributions

Funding

Conflicts of Interest

Abbreviation

| Symbol | Name |

| ADBEIPCM | Adaptive Dynamic Building Envelope Integrated with PCM |

| AHGR | Average Heat Gain Reduction |

| AITR | Average Indoor Temperature Reduction |

| AB | Autonomous Buildings |

| CLHS | Cascade Latent Heat Storage |

| COP | Coefficient Of Performers |

| CO2 ES | Associated CO2 Emissions Saving |

| ECS | Energy Cost Saving |

| EPBD | Energy Performance Building Design |

| FC | Foamed Concrete |

| HDPE | Shape-stabilized PCM |

| HP | Heat pump |

| H-PCM | High-temperature Phase Change Material |

| LCA | Live Cycle Assessment |

| LCC | Live Cycle Cost |

| LSCA | Live Sustainability Cost Analysis |

| LSF | Lightweight Steel-Framed |

| NZEB | Net Zero Energy Buildings |

| PCM | Phase Change Materials |

| PCM-FC | Phase Change Material—Foamed Concrete |

| PGE | Polyethylene Glycol |

| PV | Photovoltaic panel |

| SGSP | Salt Gradient Solar Pond |

| SSPCM | Shape-Stable Phase Change Materials |

| STB | Sorption Thermal Battery |

| TEG | Thermoelectric Power Generator |

| TES | Thermal Energy Storage |

| TLLR | Thermal Load Levelling Reduction |

| ZB | Zero Energy Buildings |

| ZZZZ | Zero Carbon, Zero Energy, Zero Grid Connection, and Zero Energy Bills |

References

- Sun, S.; Liu, Z.; Hou, Y.; Li, X.; Xie, Y.; Zhai, H.; Wei, X. Analysis of harmonic characteristics based on improved double-LCC compensation network structure. Energy Rep. 2022, 8, 891. [Google Scholar] [CrossRef]

- Larsen, V.G.; Tollin, N.; Sattrup, P.A.; Birkved, M.; Holmboe, T. What are the challenges in assessing circular economy for the built environment? A literature review on integrating LCA, LCC and S-LCA in life cycle sustainability assessment, LCSA. J. Build. Eng. 2022, 50, 104203. [Google Scholar] [CrossRef]

- Cardoso, V.E.M.; Simões, L.M.; Ramos, N.M.M.; Almeida, R.M.S.F.; Almeida, M.; Mateus, R. Impact of air barriers application in LCA and LCC of naturally ventilated dwellings in mild climate regions. Energy Build. 2023, 279, 112667. [Google Scholar] [CrossRef]

- Ropo, M.; Mustonen, H.; Knuutila, M.; Luoranen, M.; Kosonen, A. Considering embodied CO2 emissions and carbon compensation cost in life cycle cost optimization of carbon-neutral building energy systems. Environ. Impact Assess. Rev. 2023, 101, 107100. [Google Scholar] [CrossRef]

- Vasishta, T.; Mehany, M.H.; Killingsworth, J. Comparative life cycle assesment (LCA) and life cycle cost analysis (LCCA) of precast and cast–in–place buildings in United States. J. Build. Eng. 2023, 67, 105921. [Google Scholar] [CrossRef]

- Harter, H.; Willenborg, B.; Lang, W.; Kolbe, T.H. Life Cycle Assessment of building energy systems on neighbourhood level based on semantic 3D city models. J. Cleaner Prod. 2023, 407, 137164. [Google Scholar] [CrossRef]

- Byrne, E.P. The evolving engineer; professional accreditation sustainability criteria and societal imperatives and norms. Educ. Chem. Eng. 2023, 43, 23. [Google Scholar] [CrossRef]

- Wijesooriya, N.; Brambilla, A.; Markauskaite, L. Biophilic design frameworks: A review of structure, development techniques and their compatibility with LEED sustainable design criteria. Clean. Prod. Lett. 2023, 4, 100033. [Google Scholar] [CrossRef]

- Bhyan, P.; Shrivastava, B.; Kumar, N. Allocating weightage to sustainability criteria’s for performance assessment of group housing developments: Using fuzzy analytic hierarchy process. J. Build. Eng. 2023, 65, 105684. [Google Scholar] [CrossRef]

- Ranjbar, N.; Balali, A.; Valipour, A.; Yunusa-Kaltungo, A.; Edwards, R.; Pignatta, G.; Moehler, R.; Shen, W. Investigating the environmental impact of reinforced-concrete and structural-steel frames on sustainability criteria in green buildings. J. Build. Eng. 2021, 43, 103184. [Google Scholar] [CrossRef]

- Gilani, G.; Hosseini, S.M.A.; Pons-Valladares, O.; de la Fuente, A. An enhanced multi-criteria decision-making approach oriented to sustainability analysis of building facades: A case study of Barcelona. J. Build. Eng. 2022, 54, 104630. [Google Scholar] [CrossRef]

- Fan, Y.B.; Jiang, L.; Zhang, X.J.; Xu, X.G.; Frazzica, A. Heat pump assisted open three-phase sorption thermal battery for efficient heat storage. Energy Convers. Manag. 2022, 277, 116630. [Google Scholar] [CrossRef]

- Tzinnis, E.; Baldini, L. Combining sorption storage and electric heat pumps to foster integration of solar in buildings. Appl. Energy 2021, 301, 117455. [Google Scholar] [CrossRef]

- Aydin, D.; Casey, S.P.; Chen, X.; Riffat, S. Numerical and experimental analysis of a novel heat pump driven sorption storage heater. Appl. Energy 2018, 211, 954. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, L. Solid sorption heat pipe coupled with direct air cooling technology for thermal control of rack level in internet data centers: Design and numerical simulation. Int. J. Heat Mass Transf. 2019, 145, 118714. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, L.W.; An, G.L. Experimental study on sorption and heat transfer performance of NaBr-NH3 for solid sorption heat pipe. Int. J. Heat Mass Transf. 2018, 117, 125. [Google Scholar] [CrossRef]

- Zhang, X.; Tian, Y.; Wang, L.; Zhang, B. Performance regulation characteristics of bi-halide sorbents in the thermochemical sorption system for cold/heat storage. Appl. Therm. Eng. 2023, 219 Pt A, 119453. [Google Scholar] [CrossRef]

- Li, W.; Klemeš, J.J.; Wang, Q.; Zeng, M. Efficient thermal management strategy of Li-ion battery pack based on sorption heat storage. Energy Convers. Manag. 2022, 256, 115383. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, T.; Yu, N.; Wang, C.Y. Experimental investigation on a strontium chloride/ammoniasorption heat storage system. Appl. Therm. Eng. 2023, 219 Pt B, 119478. [Google Scholar] [CrossRef]

- Yan, T.; Zhang, H. A critical review of salt hydrates as thermochemical sorption heat storage materials: Thermophysical properties and reaction kinetics. Sol. Energy 2022, 242, 157. [Google Scholar] [CrossRef]

- Fumey, B.; Weber, R.; Baldini, L. Heat transfer constraints and performance mapping of a closed liquid sorption heat storage process. Appl. Energy 2023, 335, 120755. [Google Scholar] [CrossRef]

- Lin, Y.C.; Liu, W.; Zhang, X.J.; Jiang, L. Performance analysis on open thermochemical sorption heat storage from a real mass transfer perspective. J. Energy Storage 2022, 54, 105267. [Google Scholar] [CrossRef]

- Chao, J.; Xu, J.; Bai, Z.; Wang, P.; Wang, R.; Li, T. Integrated heat and cold storage enabled by high-energy-density sorption thermal battery based on zeolite/MgCl2 composite sorbent. J. Energy Storage 2023, 64, 107155. [Google Scholar] [CrossRef]

- Nguyen, M.H.; Zbair, M.; Dutournié, P.; Bennici, S. Thermochemical sorption heat storage: Investigate the heat released from activated carbon beads used as porous host matrix for MgSO4 salt. J. Energy Storage 2023, 59, 106452. [Google Scholar] [CrossRef]

- Zhang, C.; Li, Y.; Yang, L.; Fan, X.; Chu, L. Analysis on H2 production process integrated CaO/Ca(OH)2 heat storage and sorption enhanced staged gasification using calcium looping. Energy Convers. Manag. 2022, 253, 115169. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Khan, H.A.; Al-Othman, A.; Almomani, F.; Ajith, S. A comprehensive review on the recent advances in materials for thermal energy storage applications. Int. J. Thermofluids 2023, 18, 100326. [Google Scholar] [CrossRef]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards building’s energy efficiency. Energy Build. 2013, 59, 82. [Google Scholar] [CrossRef]

- Weinläder, H.; Beck, A.; Fricke, J. PCM-facade-panel for daylighting and room heating. Sol. Energy 2005, 78, 177. [Google Scholar] [CrossRef]

- Li, S.; Zou, K.; Sun, G.; Zhang, X. Simulation research on the dynamic thermal performance of a novel tripleglazed window filled with PCM. Sustain. Cities Soc. 2018, 40, 266. [Google Scholar] [CrossRef]

- Li, D.; Wu, Y.; Liu, C.; Zhang, G.; Arıcı, M. Numerical investigation of thermal and optical performance of window units filled with nanoparticle enhanced PCM. Int. J. Heat Mass Transf. 2018, 125, 1321. [Google Scholar] [CrossRef]

- Musiał, M. Analysis of the impact of selected factors on the effectiveness of using PCM in mobile window insulation. E3S Web Conf. 2018, 49, 00073. [Google Scholar] [CrossRef]

- Musiał, M. Evaluation of the energy efficiency of an internal blind containing PCM. E3S Web Conf. 2018, 49, 00074. [Google Scholar] [CrossRef]

- Lichołai, L.; Musiał, M.; Szyszka, J. International Patent Application EP.15461528.0, 2015.

- Mehling, H. Strategic project ‘Innovative PCM-Technology’—Results and future perspectives. In Proceedings of the 8th Expert Meeting and Workshop, Kizkalesi, Turkey, 18–20 April 2005. [Google Scholar]

- Weinläder, H.; Koerner, W.; Heidenfelder, M. Monitoring results of an interior sun protection system with integrated latent heat storage. Energy Build. 2011, 43, 2468. [Google Scholar] [CrossRef]

- Li, Y.; Darkwa, J.; Kokogiannakis, G.; Su, W. Phase change material blind system for double skin façade integration: System development and thermal performance evaluation. Appl. Energy 2019, 252, 113376. [Google Scholar] [CrossRef]

- Bontemps, A.; Ahmad, M.; Johannčs, K.; Sallée, H. Experimental and modelling study of twin cells with latent heat storage walls. Energy Build. 2011, 43, 2456. [Google Scholar] [CrossRef]

- Jaworski, M.; Abeid, S. Thermal conductivity of gypsum with incorporated phase change material (PCM) for building applications. J. Power Technol. 2011, 91, 49. [Google Scholar]

- Wnuk, R.; Jaworski, M. Investigation of thermal characteristics of heat accumulating building elements containing PCM (phase change materials). Pol. Sol. Energy 2010, 2, 5. (In Polish) [Google Scholar]

- Cabeza, L.F.; Castellón, C.; Nogués, M.; Medrano, M.; Leppers, R.; Zubillaga, O. Use of microencapsulated PCM in concrete walls for energy savings. Energy Build. 2007, 39, 113. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Medrano, M.; Castellón, C.; Castell, A.; Solé, C.; Roca, J.; Nogués, M. Thermal energy storage with phase change materials in building envelopes. Contrib. Sci. 2007, 3, 501. [Google Scholar] [CrossRef]

- Zhu, N.; Wang, S.; Xu, X.; Ma, Z. A simplified dynamic model of building structures integrated with shaped-stabilized phase change materials. Int. J. Therm. Sci. 2010, 49, 1722. [Google Scholar] [CrossRef]

- Xiao, M.; Feng, B.; Gong, K. Preparation and performance of shape stabilized phase change thermal storage materials with high thermal conductivity 2002. Energy Convers. Manag. 2002, 43, 103. [Google Scholar] [CrossRef]

- Sar, A. Form-stable paraffin/high density polyethylene composites as solid-liquid phase change material for thermal energy storage: Preparation and thermal properties. Energy Convers. Manag. 2004, 45, 2033. [Google Scholar] [CrossRef]

- Xiao, M.; Feng, B.; Gong, K. Thermal performance of a high conductive shape stabilized thermal storage material. Sol. Energy Mater. Sol. Cells 2001, 69, 293. [Google Scholar] [CrossRef]

- Zhou, G.; Yang, Y.; Xu, H. Energy performance of a hybrid space-cooling system in an office building using SSPCM thermal storage and night ventilation. Sol. Energy 2011, 85, 477. [Google Scholar] [CrossRef]

- Musiał, M. Analysis of the impact of PCM elements’ geometry on their heat storage efficiency. Bauphysik 2019, 41, 324–330. [Google Scholar] [CrossRef]

- Soares, N.; Gaspar, A.R.; Santos, P.; Costa, J.J. Multi-dimensional optimization of the incorporation of PCM-drywalls in lightweight steel-framed residential buildings in different climates. Energy Build. 2014, 70, 411. [Google Scholar] [CrossRef]

- Saffari, M.; Roe, C.; Finn, D.P. Improving the building energy flexibility using PCM-enhanced envelopes. Appl. Therm. Eng. 2022, 217, 119092. [Google Scholar] [CrossRef]

- Zahir, M.H.; Irshad, K.; Shafiullah, M.; Ibrahim, N.I.; Islam, A.K.M.K.; Mohaisen, K.O.; Sulaiman, F.A.A. Challenges of the application of PCMs to achieve zero energy buildings under hot weather conditions: A review. J. Energy Storage 2023, 64, 107156. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Experimental study of PCM-enhanced building envelope towards energy-saving and decarbonisation in a severe hot climate. Energy Build. 2023, 279, 112680. [Google Scholar] [CrossRef]

- Al-Absi, Z.A.; Hafizal, M.I.M.; Ismail, M. Innovative PCM-incorporated foamed concrete panels for walls’ exterior cladding: An experimental assessment in real-weather conditions. Energy Build. 2023, 288, 113003. [Google Scholar] [CrossRef]

- Li, Q.; Ju, Z.; Wang, Z.; Ma, L.; Jiang, W.; Li, D.; Jia, J. Thermal performance and economy of PCM foamed cement walls for buildings in different climate zones. Energy Build. 2022, 277, 112470. [Google Scholar] [CrossRef]

- Agarwal, P.; Prabhakar, A. Energy and thermo-economic analysis of PCM integrated brick in composite climatic condition of Jaipur—A numerical study. Sustain. Cities Soc. 2023, 88, 104294. [Google Scholar] [CrossRef]

- Krasoń, J.; Miąsik, P.; Lichołai, L.; Dębska, B.; Starakiewicz, A. Analysis of the Thermal Characteristics of a Composite Ceramic Product Filled with Phase Change Material. Buildings 2019, 9, 217. [Google Scholar] [CrossRef]

- Leitzke, R.K.; Grala da Cunha, E.; Ferrugem, A.P.; Leal da Silva, T. The use of multi-objective evolutionary algorithms to assess phase change materials in a residence with light framings in bioclimatic zones 1, 2 and 3. Energy Build. 2023, 284, 112847. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Zhang, X.; Hu, M.; Zhang, L.; Fan, J. Adaptive dynamic building envelope integrated with phase change material to enhance the heat storage and release efficiency: A state-of-the-art review. Energy Build. 2023, 286, 112928. [Google Scholar] [CrossRef]

- Imafidon, O.J.; Ting, D.S.-K. Retrofitting buildings with phase change materials (PCM)—The effects of PCM location and climatic condition. Build. Environ. 2023, 236, 110224. [Google Scholar] [CrossRef]

- Lichołai, L.; Starakiewicz, A.; Krasoń, J.; Miąsik, P. The Influence of Glazing on the Functioning of a Trombe Wall Containing a Phase Change Material. Energies 2021, 14, 5243. [Google Scholar] [CrossRef]

- Zhu, M.; Nan, W.; Wang, Y. Analysis on the thermal behaviour of the latent heat storage system using S-CO2 and H-PCM. Renew. Energy 2023, 208, 240. [Google Scholar] [CrossRef]

- Momeni, M.; Fartaj, A. Numerical thermal performance analysis of a PCM-to-air and liquid heat exchanger implementing latent heat thermal energy storage. J. Energy Storage 2023, 58, 106363. [Google Scholar] [CrossRef]

- Musiał, M.; Lichołai, L. The Impact of a Mobile Shading System and a Phase-Change Heat Store on the Thermal Functioning of a Transparent Building Partition. Materials 2021, 14, 2512. [Google Scholar] [CrossRef]

- Lichołai, L.; Musiał, M. Experimental analysis of the functioning of a window with a phase change heat accumulator. Materials 2020, 13, 3647. [Google Scholar] [CrossRef]

- Musiał, M. Use of organic aliphatic esters to obtain an energy-efficient eutectic mixture. Przem. Chem. 2018, 97, 1855. [Google Scholar] [CrossRef]

- Lichołai, L.; Musiał, M. Use of copolymers of vinyl acetate and alkyl acrylates for coating organic phase change materials. Przem. Chem. 2018, 97, 1852. [Google Scholar] [CrossRef]

- Musiał, M. Experimental and Numerical Analysis of the Energy Efficiency of Transparent Partitions with a Thermal Storage Unit. J. Ecol. Eng. 2020, 21, 201. [Google Scholar] [CrossRef]

- Li, W.Q.; Li, Y.X.; Yang, T.H.; Zhang, T.Y.; Qin, F. Experimental investigation on passive cooling, thermal storage and thermoelectric harvest with heat pipe-assisted PCM-embedded metal foam. Int. J. Heat Mass Transf. 2023, 201, 123651. [Google Scholar] [CrossRef]

- Rghif, Y.; Colarossi, D.; Principi, P. Salt gradient solar pond as a thermal energy storage system: A review from current gaps to future prospects. J. Energy Storage 2023, 61, 106776. [Google Scholar] [CrossRef]

- Gu, H.; Chen, Y.; Yao, X.; Huang, L.; Zou, D. Review on heat pump (HP) coupled with phase change material (PCM) for thermal energy storage. Chem. Eng. J. 2023, 455, 140701. [Google Scholar] [CrossRef]

- Pogorzelski, J.A. Building Thermal Physics; Polish Scientific Publisher: Warsaw, Poland, 1976. (In Polish) [Google Scholar]

- Vogel, A.I. Organic Preparation; Polish Scientific Publisher: Warsaw, Poland, 2006. (In Polish) [Google Scholar]

- Smolec, W. Photothermal Solar Energy Conversion; Polish Scientific Publisher: Warsaw, Poland, 2000. (In Polish) [Google Scholar]

- Tak, N. Type-1 possibilistic fuzzy forecasting functions. J. Comput. Appl. Math. 2020, 370, 112653. [Google Scholar] [CrossRef]

- Askari, S. A novel and fast MIMO fuzzy inference system based on a class of fuzzy clustering algorithms with interpretability and complexity analysis. Expert Syst. Appl. 2017, 84, 301. [Google Scholar] [CrossRef]

- Liu, J.; Tavakoli, F.; Sajadi, S.M.; Mahmoud, M.Z.; Heidarshenas, B.; Aybar, H.S. Numerical evaluation and artificial neural network modeling of the effect of oval PCM compartment dimensions around a triple lithium-ion battery pack despite forced airflow. Eng. Anal. Bound. Elem. 2022, 142, 71. [Google Scholar] [CrossRef]

- Alnaqi, A.A.; Alsarraf, J.; Al-Rashed, A.A.A.A. Transient numerical study on injecting PCM in buildings along with extra comfort ventilation: Use of artificial neural network to decline energy utilization. Eng. Anal. Bound. Elem. 2022, 143, 559. [Google Scholar] [CrossRef]

- Eldokaishi, A.O.; Abdelsalam, M.Y.; Kamal, M.M.; Abotaleb, H.A. Modeling of water-PCM solar thermal storage system for domestic hot water application using Artificial neural networks. Appl. Therm. Eng. 2022, 204, 118009. [Google Scholar] [CrossRef]

- Stefan, J. On the theory of ice formation, in particular on ice formation in the polar sea. Wiedemann Ann. Phys. Chem. 1891, 42, 269–286. (In Germany) [Google Scholar] [CrossRef]

- Baskar, I.; Chellapandian, M. Experimental and finite element analysis on the developed real-time form stable PCM based roof system for thermal energy storage applications. Energy Build. 2022, 276, 112514. [Google Scholar] [CrossRef]

- Cueto, O.; Trabelsi, A.; Cagli, C.; Cyrille, M.C. Coupling a phase field model with an electro-thermal solver to simulate PCM intermediate resistance states for neuromorphic computing. Solid-State Electron. 2023, 200, 108542. [Google Scholar] [CrossRef]

- Feng, Y.; Qin, Y. Nanoparticles effect on freezing of PCM utilizing finite element approach. J. Mol. Liq. 2022, 366, 120168. [Google Scholar] [CrossRef]

- Benhamou, J.; Lahmer, E.B.; Jami, M. Three-dimensional simulation of conjugate heat transfer using the hybrid lattice Boltzmann-finite difference method. Int. Commun. Heat Mass Transf. 2022, 139, 106486. [Google Scholar] [CrossRef]

- Ullah, H.; Hayat, T.; Ahmad, S.; Alhodaly, M.S. Entropy generation and heat transfer analysis in power-law fluid flow: Finite difference method. Int. Commun. Heat Mass Transf. 2021, 122, 105111. [Google Scholar] [CrossRef]

- Patil, H.M.; Maniyeri, R. Finite difference method based analysis of bio-heat transfer in human breast cyst. Therm. Sci. Eng.Prog. 2019, 10, 42. [Google Scholar] [CrossRef]

- Deng, D.; Jiang, Y.; Liang, D. High-order finite difference methods for a second order dual-phase-lagging models of microscale heat transfer. Appl. Math. Comput. 2017, 309, 31–48. [Google Scholar] [CrossRef]

- Li, M.-J.; Chen, J.; Lian, Y.; Xiong, F.; Fang, D. An efficient and high-fidelity local multi-mesh finite volume method for heat transfer and fluid flow problems in metal additive manufacturing. Comput. Methods Appl. Mech. Eng. 2023, 404, 115828. [Google Scholar] [CrossRef]

- Musiał, M.; Licholai, L.; Pękala, A. Analysis of the thermal performance of isothermal composite heat accumulators containing organic phase change material. Energies 2023, 16, 1409. [Google Scholar] [CrossRef]

- Hedayat, A.; Davari, A. Feasibility study to increase the reactor power at natural convection mode in Tehran Research Reactor (TRR) through a hybrid thermal-hydraulic simulation and analysis using the RELAP5 code and Computational Fluid Dynamic (CFD) modeling by ANSYS-FLUENT. Prog. Nucl. Energy 2022, 150, 104285. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, H.; Fang, G. Review on thermal conductivity improvement of phase change materials with enhanced additives for thermal energy storage. J. Energy Storage 2022, 51, 104568. [Google Scholar] [CrossRef]

- Cui, H.; Zou, J.; Gong, Z.; Zheng, D.; Bao, X.; Chen, X. Study on the thermal and mechanical properties of steel fibre reinforced PCM-HSB concrete for high performance in energy piles. Constr. Build. Mater. 2022, 350, 128822. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, R.; Li, J. High latent heat phase change materials (PCMs) with low melting temperature for thermal management and storage of electronic devices and power batteries: Critical review. Renew. Sustain. Energy Rev. 2022, 168, 112783. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, Z.; Zhang, H.; Sun, X.; Dou, B.; Wu, W.; Zhang, G.; Jiang, L. Experimental investigation of the comprehensive heat transfer performance of PCMs filled with CMF in a heat storage device. Int. J. Heat Mass Transf. 2022, 188, 122582. [Google Scholar] [CrossRef]

- Wang, L.; Kan, A.; Yu, W. Melting behavior and heat transfer performance in a modified PCM-filled enclosure with fins under hypergravity conditions. Int. Commun. Heat Mass Transf. 2022, 138, 106415. [Google Scholar] [CrossRef]

- Zhao, J.; Li, Y.; Fang, X.; Sun, J.; Zhang, W.; Wang, B.; Xu, J.; Liu, Y.; Guo, H. High interface compatibility and phase change enthalpy of heat storage wood plastic composites as bio-based building materials for energy saving. J. Energy Storage 2022, 51, 104293. [Google Scholar] [CrossRef]

- Zhang, S.; Pu, L.; Mancin, S.; Ma, Z.; Xu, L. Experimental study on heat transfer characteristics of metal foam/paraffin composite PCMs in large cavities: Effects of material types and heating configurations. Appl. Energy 2022, 325, 119790. [Google Scholar] [CrossRef]

- Liu, D.; Xie, K.; Zhang, H.; Qiang, Y.; Yang, D.; Wang, Z.; Zhu, L.; Akkurt, N.; Du, Y.; Shen, M.; et al. Numerical evaluation of convective heat transfer properties of two-dimensional rotating PCM melt in the unilaterally heated rectangular container. Renew. Energy 2022, 193, 920. [Google Scholar] [CrossRef]

- Ho, C.J.; Huang, S.H.; Lai, C.M. Enhancing laminar forced convection heat transfer by using Al2O3/PCM nanofluids in a concentric double-tube duct. Case Stud. Therm. Eng. 2022, 35, 102147. [Google Scholar] [CrossRef]

- Mozafari, M.; Lee, A.; Cheng, S. A novel dual-PCM configuration to improve simultaneous energy storage and recovery in triplex-tube heat exchanger. Int. J. Heat Mass Transf. 2022, 186, 122420. [Google Scholar] [CrossRef]

- Ho, C.J.; Jang, C.; Lai, C.M. Natural convection heat transfer in PCM suspensions in a square enclosure with bottom heating and top cooling. Therm. Sci. Eng. Prog. 2021, 255, 101037. [Google Scholar] [CrossRef]

- Kouravand, A.; Kasaeian, A.; Pourfayaz, F.; Amin, M.; Rad, V. Evaluation of a nanofluid-based concentrating photovoltaic thermal system integrated with finned PCM heatsink: An experimental study. Renew. Energy 2022, 11, 1010–1025. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Saidur, R.; Al-Sulaiman, F.A.; Al-Ahmed, A.; Ben-Mansour, R. Multiwalled CNT and graphene nanoplatelets based nano-enhanced PCMs: Evaluation for the thermal performance and its implications on the performance of hybrid PV/thermal systems. Mater. Do Day Commun. 2022, 31, 103618. [Google Scholar] [CrossRef]

- Lin, X.; Chen, X.Y.; Weng, L.; Hu, D.; Qiu, C.; Liu, P.; Zhang, Y.; Fan, M.; Sun, W.; Guo, X. In-situ copper ion reduction and micro encapsulation of wood-based composite PCM with effective anisotropic thermal conductivity and energy storage. Sol. Energy Mater. Sol. Cells 2022, 242, 111762. [Google Scholar] [CrossRef]

- Ryms, M.; Januszewicz, K.; Haustein, E.; Kazimierski, P.; Lewandowski, W.M. Thermal properties of a cement composite containing phase change materials (PCMs) with post-pyrolytic char obtained from spent tyres as a carrier. Energy 2022, 239, 121936. [Google Scholar] [CrossRef]

- Yousefi, A.; Tang, W.; Khavarian, M.; Fang, C. Development of novel form-stable phase change material (PCM) composite using recycled expanded glass for thermal energy storage in cementitious composite. Renew. Energy 2021, 175, 14. [Google Scholar] [CrossRef]

- Das, D.; Bordoloi, U.; Muigaia, H.H.; Kalita, P. A novel form stable PCM based bio composite material for solar thermal energy storage applications. J. Energy Storage 2020, 30, 101403. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y.; Luo, C.; Pana, C. Fabrication and properties of novel tubular carbon fiber-ionic liquids/stearic acid composite PCMs. Renew. Energy 2021, 177, 411. [Google Scholar] [CrossRef]

- Vennapusa, J.R.; Konala, A.; Dixit, P.; Chattopadhyay, S. Caprylic acid based PCM composite with potential for thermal buffering and packaging applications. Mater. Chem. Phys. 2020, 253, 123453. [Google Scholar] [CrossRef]

- Kim, H.G.; Qudoos, A.; Jeon, I.K.; Ryou, J.S. Assessment of PCM/SiC-based composite aggregate in concrete: Mechanical, physical and microstructural properties. Constr. Build. Mater. 2020, 262, 120088. [Google Scholar] [CrossRef]

- Kim, H.G.; Qudoosb, A.; Jeon, I.K.; Woo, B.H.; Ryou, J.S. Assessment of PCM/SiC-based composite aggregate in concrete: Energy storage performance. Constr. Build. Mater. 2020, 258, 119637. [Google Scholar] [CrossRef]

- Ali, M.A.; Fayaza; Viegas, R.F.; Kumar, M.B.S.; Kannapiran, R.K.; Feroskhana, M. Enhancement of heat transfer in paraffin wax PCM using nano graphene composite for industrial helmets. J. Energy Storage 2019, 26, 100982. [Google Scholar] [CrossRef]

- Wang, G.; Bai, L.; Lin, J. Liquid-structure coupled simulation study on impacts of HTF temperature on discharge and mechanics performances of PCM heat storage system. Case Stud. Therm. Eng. 2023, 44, 102885. [Google Scholar] [CrossRef]

- Abhinand, S.; Sharma, A.; Kothadia, H.B. Performance analysis of PCM melting in a fin-assisted thermal energy storage system—A numerical study. Int. Commun. Heat Mass Transf. 2023, 144, 106747. [Google Scholar] [CrossRef]

- Afaynou, I.; Faraji, H.; Choukairy, K.; Arshad, A.; Arıcı, M. Heat transfer enhancement of phase-change materials (PCMs) based thermal management systems for electronic components: A review of recent advances. Int. Commun. Heat Mass Transf. 2023, 143, 106690. [Google Scholar] [CrossRef]

- Bentivoglio, F.; Rouge, S.; Soriano, O.; de Sousa, A.T. Design and operation of a 180 kWh PCM heat storage at the Flaubert substation of the Grenoble urban heating network. Appl. Therm. Eng. 2021, 185, 116402. [Google Scholar] [CrossRef]

- Guan, Y.; Meng, Q.; Ji, T.; Hu, W.; Li, W.; Liu, T. Experimental study of the thermal characteristics of a heat storage wall with micro-heat pipe array (MHPA) and PCM in solar greenhouse. Energy 2023, 264, 126183. [Google Scholar] [CrossRef]

- Musiał, M.; Pękala, A. Functioning of Heat Accumulating Composites of Carbon Recyclate and Phase Change Material. Materials 2022, 15, 2331. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Wang, Y.; Qi, C.; Zhang, W. Reverse latent heat power generation properties of PCM/nanoparticles/metal foam at night. Colloids Surf. A 2023, 665, 131240. [Google Scholar] [CrossRef]

- Rathod, M.K.; Joshi, V.; Rakshit, D. Chapter 4-Heat transfer in metal foam infused PCM: A case study. In Phase Change Materials for Heat Transfer; Elsevier: Amsterdam, The Netherlands, 2023; Volume 103. [Google Scholar] [CrossRef]

- Baruah, J.S.; Athawale, V.; Rath, P.; Bhattacharya, A. Melting and energy storage characteristics of macro-encapsulated PCM-metal foam system. Int. J. Heat Mass Transf. 2022, 182, 121993. [Google Scholar] [CrossRef]

- Kong, X.; Li, J.; Fan, M.; Li, W.; Li, H. Study on the thermal performance of a new double layer PCM trombe wall with multiple phase change points. Sol. Energy Mater. Sol. Cells 2022, 240, 111685. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, J.; Xie, H.; Guo, Z. Microencapsulated phase change n-Octadecane with high heat storage for application in building energy conservation. Appl. Energy 2023, 329, 120284. [Google Scholar] [CrossRef]

- Kant, K.; Pitchumani, R. Advances and opportunities in thermochemical heat storage systems for buildings applications. Appl. Energy 2022, 321, 119299. [Google Scholar] [CrossRef]

- Chao, L.; Sun, C.; Peng, L.; Li, J.; Sun, M.; Bao, L.; Liu, J.; Ma, Y. Passive energy-saving buildings realized by the combination of transparent heat-shielding glass and energy storage cement. Constr. Build. Mater. 2023, 365, 130023. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, M.; Qin, H. The energy storage characteristic analysis and optimization of latent heat energy storage component with finned tubes in building envelope. Case Stud. Therm. Eng. 2022, 33, 101946. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, S.; Mazhar, A.R.; Wang, J.; Li, Y. Phase change materials embedded with tuned porous media to alleviate overcharging problem of cascaded latent heat storage system for building heating. Energy Build. 2023, 281, 112746. [Google Scholar] [CrossRef]

- Lu, S.; Lin, Q.; Liu, Y.; Yue, L.; Wang, R. Study on thermal performance improvement technology of latent heat thermal energy storage for building heating. Appl. Energy 2022, 323, 119594. [Google Scholar] [CrossRef]

- Lai, K.; Wang, W.; Giles, H. Solar shading performance of window with constant and dynamic shading function in different climate zones. Sol. Energy 2017, 147, 113. [Google Scholar] [CrossRef]

- Samadi, S.; Noorzai, E.; OBeltrán, L.; Abbasi, S. A computational approach for achieving optimum daylight inside buildings through automated kinetic shading systems. Front. Archit. Res. 2020, 9, 335. [Google Scholar] [CrossRef]

- Ghosh, A.; Neogi, S. Effect of fenestration geometrical factors on building energy consumption and performance evaluation of a new external solar shading device in warm and humid climatic condition. Sol. Energy 2018, 169, 94. [Google Scholar] [CrossRef]

- Huo, H.; Xua, W.; Li, A.; Cui, G.; Wu, Y.; Liu, C. Field comparison test study of external shading effect on thermal-optical performance of ultralow-energy buildings in cold regions of China. Build. Environ. 2020, 180, 106926. [Google Scholar] [CrossRef]

- Chi, F.; Zhu, Z.; Jin, L.; Bart, D. Calculation method of shading area covering southerly orientated windows for the Tangwu building in Sizhai village. Sol. Energy 2019, 180, 39–56. [Google Scholar] [CrossRef]

- Bhatia, A.; Sangireddy, S.A.R.; Garg, V. An approach to calculate the equivalent solar heat gain coefficient of glass windows with fixed and dynamic shading in tropical climates. J. Build. Eng. 2019, 22, 90. [Google Scholar] [CrossRef]

- Sherif, A.; Sabry, H.; Arafa, R.; Wagdy, A. The Impact of Alternative Window Glazing Types and a Shading System on the Daylighting of Hospital Patient Rooms: Simulation Analysis under a Desert Clear Sky. Energy Procedia 2015, 78, 1805. [Google Scholar] [CrossRef]

- Abazari, T.; Mahdavinejad, M. Integrated Model for Shading and Airflow Window in BSk. Energy Procedia 2017, 122, 571. [Google Scholar] [CrossRef]

- Zheng, X.; Dai, T.; Tang, M. An experimental study of vertical greenery systems for window shading for energy saving in summer. J. Clean. Prod. 2020, 259, 120708. [Google Scholar] [CrossRef]

- Invidiata, A.; Ghisi, E. Life-cycle energy and cost analyses of window shading used to improve the thermal performance of houses. J. Clean. Prod. 2016, 133, 1371. [Google Scholar] [CrossRef]

- Vigna, I.; Bianco, L.; Goia, F.; Serra, V. Phase Change Materials in Transparent Building Envelopes: A Strengths, Weakness, Opportunities and Threats (SWOT) Analysis. Energies 2018, 11, 111. [Google Scholar] [CrossRef]

- Nyoumbi, C.D.; Tambue, A. Convergence of a fitted finite volume method for pricing two dimensional assets with stochastic volatilities. Math. Comput. Simul. 2023, 207, 388. [Google Scholar] [CrossRef]

- Qiu, S.; Solomon, L.; Fang, M. Study of Material Compatibility for a Thermal Energy Storage System with Phase Change Material. Energies 2018, 11, 572. [Google Scholar] [CrossRef]

- Park, H.J.; Yun, Y.B.; Chang, J.S.; Wi, S.; Jeon, J.; Kim, S. Impact of a passive retrofit shading system on educational building to improve thermal comfort and energy consumption. Energy Build. 2020, 216, 109930. [Google Scholar] [CrossRef]

- Sá, A.V.; Azenha, M.; Guimarães, A.S.; Delgado, J.M.P.Q. FEM Applied to Building Physics: Modeling Solar Radiation and Heat Transfer of PCM Enhanced Test Cells. Energies 2020, 13, 2200. [Google Scholar] [CrossRef]

- Zhou, Q.; Liu, P.-F.; Tzeng, C.-T.; Lai, C.-M. Thermal Performance of Microencapsulated Phase Change Material (mPCM) in Roof Modules during Daily Operation. Energies 2018, 11, 679. [Google Scholar] [CrossRef]

- Hu, Y.; Heiselberg, P.K. A new ventilated window with PCM heat exchanger-Performance analysis and design optimization. Energy Build. 2018, 169, 185. [Google Scholar] [CrossRef]

- Lundström, L.; Akander, J.; Zambrano, J. Development of a Space Heating Model Suitable for the Automated Model Generation of Existing Multifamily Buildings—A Case Study in Nordic Climate. Energies 2019, 12, 485. [Google Scholar] [CrossRef]

- Li, C.; Lyu, Y.; Li, C.; Qiu, Z. Energy performance of water flow window as solar collector and cooling terminal under adaptive control. Sustain. Cities Soc. 2020, 59, 102152. [Google Scholar] [CrossRef]

- Lyu, Y.-L.; Liu, W.-J.; Sua, H.; Wuc, X. Numerical analysis on the advantages of evacuated gap insulation of vacuum-water flow window in building energy saving under various climates. Energy 2019, 175, 353. [Google Scholar] [CrossRef]

- Szyszka, J.; Starakiewicz, A. A quasi-box window concept to improve the thermal-insulation property of old windows—Case study. E3S Web Conf. SOLINA 2018, 49, 00115. [Google Scholar] [CrossRef]

- Li, D.; Zhang, C.; Li, Q.; Liu, C.; Arıcı, M.; Wu, Y. Thermal performance evaluation of glass window combining silica aerogels and phase change materials for cold climate of China. Appl. Therm. Eng. 2020, 165, 114547. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hachem, F.; Chahine, K.; Castelain, C. Energetic and economic analyses of integrating enhanced macro-encapsulated PCM’s with active underfloor hydronic heating system. Energy Rep. 2022, 8, 848. [Google Scholar] [CrossRef]

- Hou, J.; Liu, Z.-A.; Zhang, L.; Zhang, T.; Hou, C.; Fukuda, H. Parametric and economic analysis of incorporating phase change material (PCM) into exterior walls to reduce energy demand for traditional dwellings in northeast of Sichuan hills, China. Appl. Therm. Eng. 2023, 223, 119982. [Google Scholar] [CrossRef]

- Elfeky, K.E.; Mohammed, A.G.; Wang, Q. Thermo-economic evaluation of PCM layer thickness change on the performance of the hybrid heat storage tank for concentrating solar power plants. Energy 2022, 253, 124128. [Google Scholar] [CrossRef]

- Tafuni, A.; Giannotta, A.; Mersch, M.; Pantaleo, A.M.; Amirante, R.; Markides, C.N.; De Palma, P. Thermo-economic analysis of a low-cost greenhouse thermal solar plant with seasonal energy storage. Energy Convers. Manag. 2023, 288, 117123. [Google Scholar] [CrossRef]

- Li, H.; Hou, J.; Hong, T.; Ding, Y.; Nord, N. Energy, economic, and environmental analysis of integration of thermal energy storage into district heating systems using waste heat from data centres. Energy 2021, 219, 119582. [Google Scholar] [CrossRef]

- Pelella, F.; Zsembinszki, G.; Viscito, L.; Mauro, A.W.; Cabeza, L.F. Thermo-economic optimization of a multi-source (air/sun/ground) residential heat pump with a water/PCM thermal storage. Appl. Energy 2023, 331, 120398. [Google Scholar] [CrossRef]

- Taheri, B.; Jabari, F.; Foroud, A.A. A green cogeneration microgrid composed of water-source heat pumps, a gravity energy storage, and a bio-fueled gas turbine: Design and techno-economic optimization. Sustain. Cities Soc. 2023, 95, 104594. [Google Scholar] [CrossRef]

- Fu, H.; Fang, L.; Yu, M.; Cui, P.; Zhang, W.; Mao, Y.; Zhuang, Z.; Fang, Z. Influence and economic analysis of heat storage in the non-heating season on the heat extraction capacity of mid-deep borehole heat exchangers. Energy Build. 2023, 278, 112619. [Google Scholar] [CrossRef]

- Shayan, M.E.; Najafi, G.; Ghobadian, B.; Gorjian, S.; Mamat, R.; Ghazali, M.F. Multi-microgrid optimization and energy management under boost voltage converter with Markov prediction chain and dynamic decision algorithm. Renew. Energy 2022, 201, 179. [Google Scholar] [CrossRef]

- Shayan, M.E.; Najafi, G.; Ghobadian, B.; Gorjian, S.; Mazlan, M.; Samami, M.; Shabanzadeh, A. Flexible Photovoltaic System on Non-Conventional Surfaces: A Techno-Economic Analysis. Sustainability 2022, 14, 3566. [Google Scholar] [CrossRef]

| Place of Application of Phase Change Materials in Buildings (Bibliography Numbers) | ||||||

|---|---|---|---|---|---|---|

| Method of combining PCM with conventional building materials | Walls | Floors | Windows and blinds | Heat storage | Active solar system | |

| Combining capsules, microcapsules containing PCM with cement or gypsum | 53–55, 59 | 53 | 27–29, 38–41 | 67 | ||

| Impregnation of porous materials, e.g., aerated concrete, ceramic bricks | 55, 58–59 | 73 | 87 | |||

| Direct mixing of PCM with cement or gypsum | 38 | 38 | 86 | |||

| Production of stable composites containing up to 80% of pure PCM with a polymer matrix (HDPE—shape-stabilized PCM) | 64–66 | 42–66 | 20 | 94 | ||

| Boards laminated with an inner layer of PCM | 57 | 56 | 42–45 | 78, 94 | ||

| Heat accumulators in the form of cylinders or cuboids with dimensions of a few to several centimetres covered with a polymer coating, placed in the free spaces of hollow elements | 12 | 31–31, 47 | 60–61 | 67, 72 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Musiał, M.; Lichołai, L.; Katunský, D. Modern Thermal Energy Storage Systems Dedicated to Autonomous Buildings. Energies 2023, 16, 4442. https://doi.org/10.3390/en16114442

Musiał M, Lichołai L, Katunský D. Modern Thermal Energy Storage Systems Dedicated to Autonomous Buildings. Energies. 2023; 16(11):4442. https://doi.org/10.3390/en16114442

Chicago/Turabian StyleMusiał, Michał, Lech Lichołai, and Dušan Katunský. 2023. "Modern Thermal Energy Storage Systems Dedicated to Autonomous Buildings" Energies 16, no. 11: 4442. https://doi.org/10.3390/en16114442

APA StyleMusiał, M., Lichołai, L., & Katunský, D. (2023). Modern Thermal Energy Storage Systems Dedicated to Autonomous Buildings. Energies, 16(11), 4442. https://doi.org/10.3390/en16114442