Segmentary Damage Constitutive Model and Evolution Law of Rock under Water-Force Coupling Action of Pumped Storage in Deep Mine

Abstract

:1. Introduction

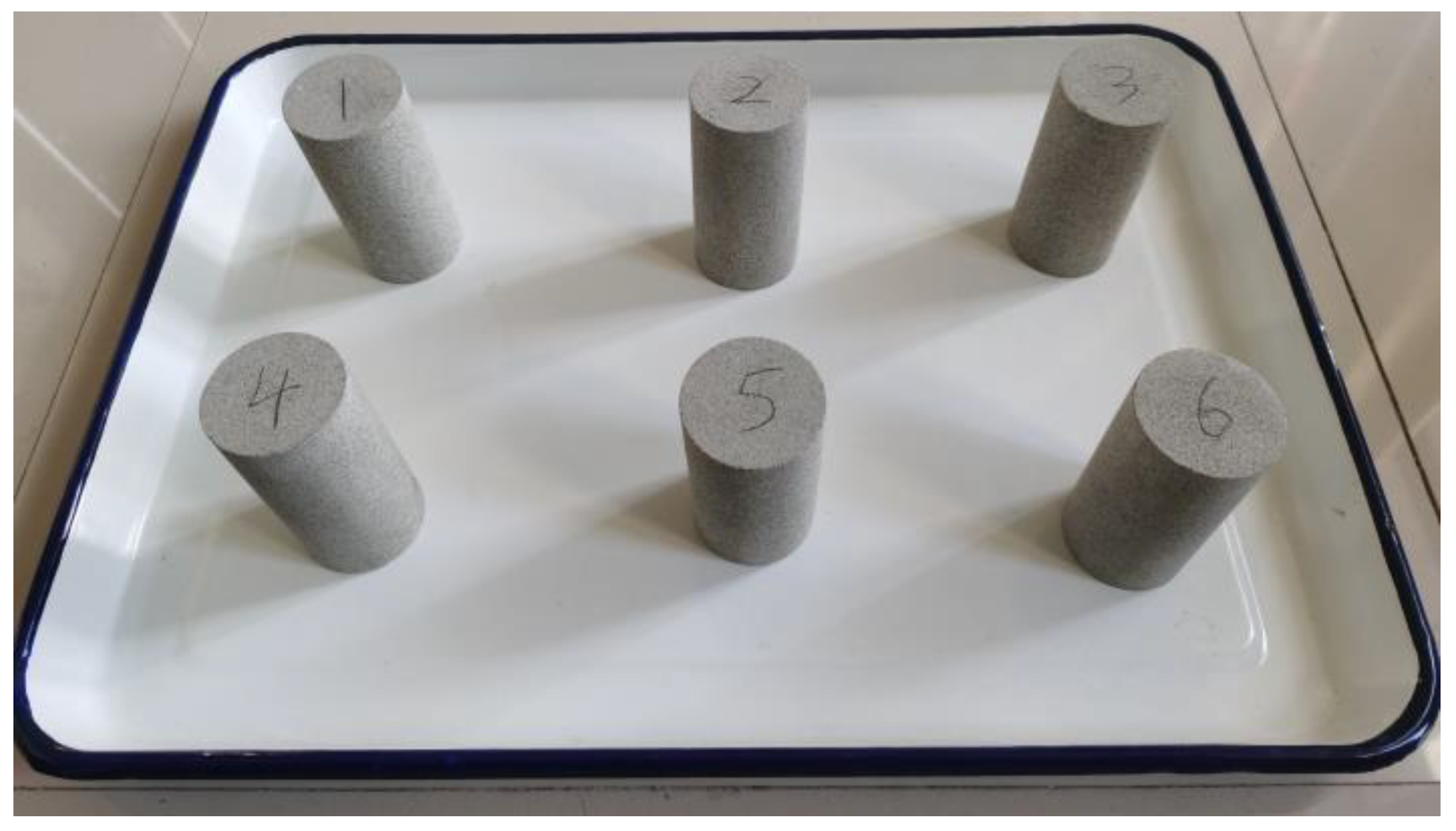

2. Materials and Methods

2.1. Laboratory Test Program

2.2. Constitutive Description Method

3. Construction of Constitutive Model

3.1. Damage Variable Determination

3.2. Damage Constitutive Model after Water–Rock Interaction

3.3. Parameter m and Identification

4. Model Validation and Parameter Study

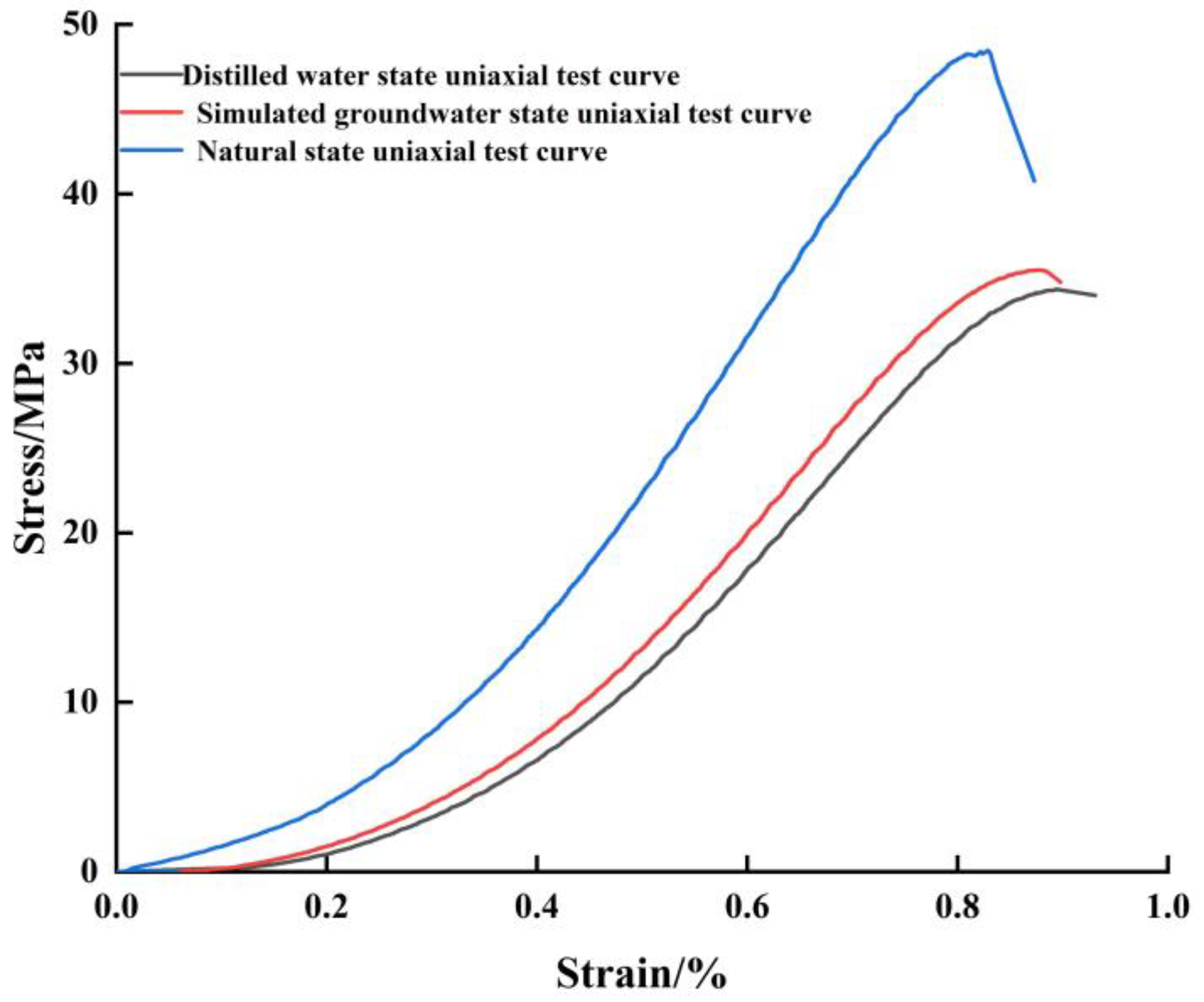

4.1. Test Verification

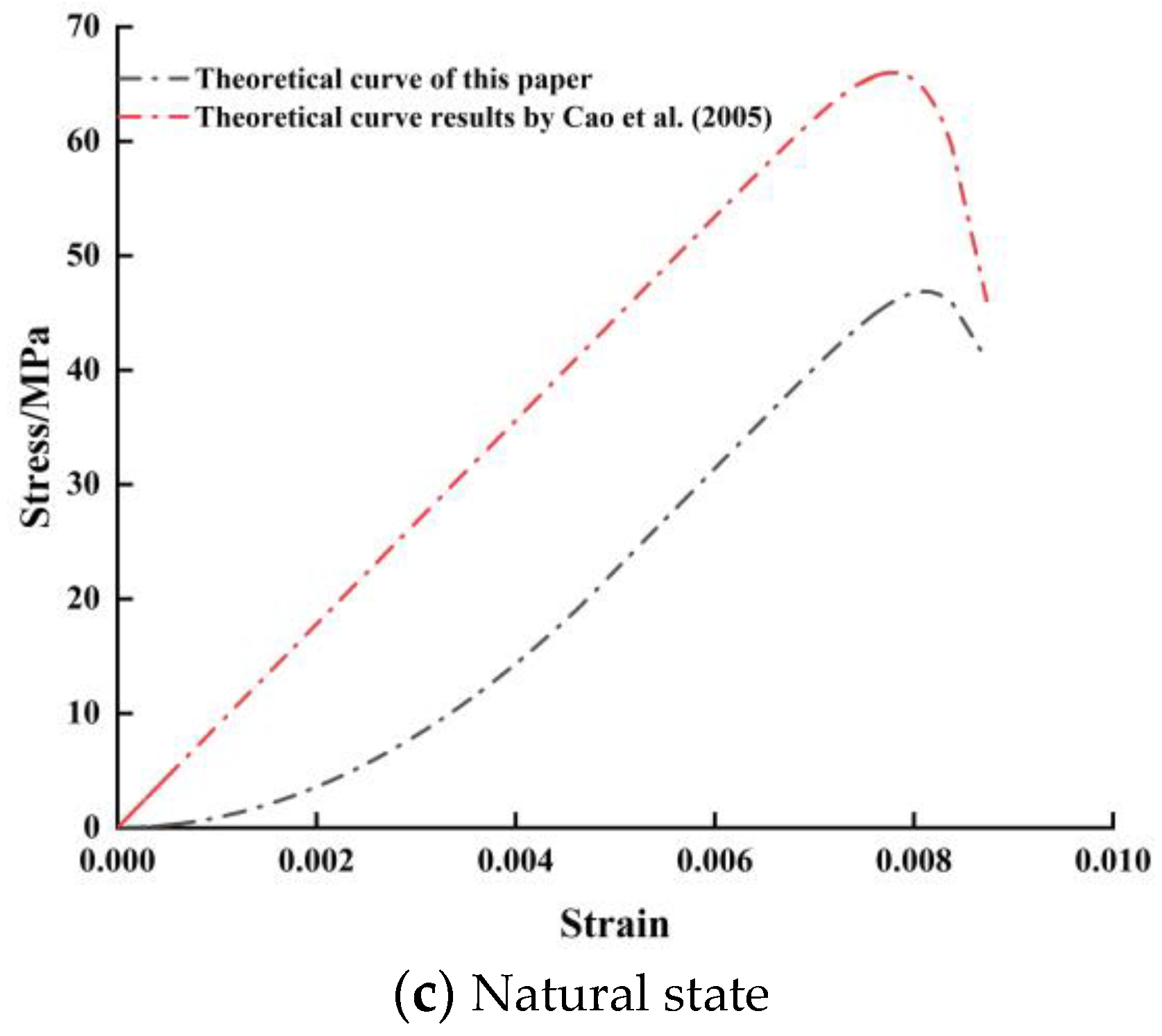

4.2. Comparison of Theoretical Curves in Literature

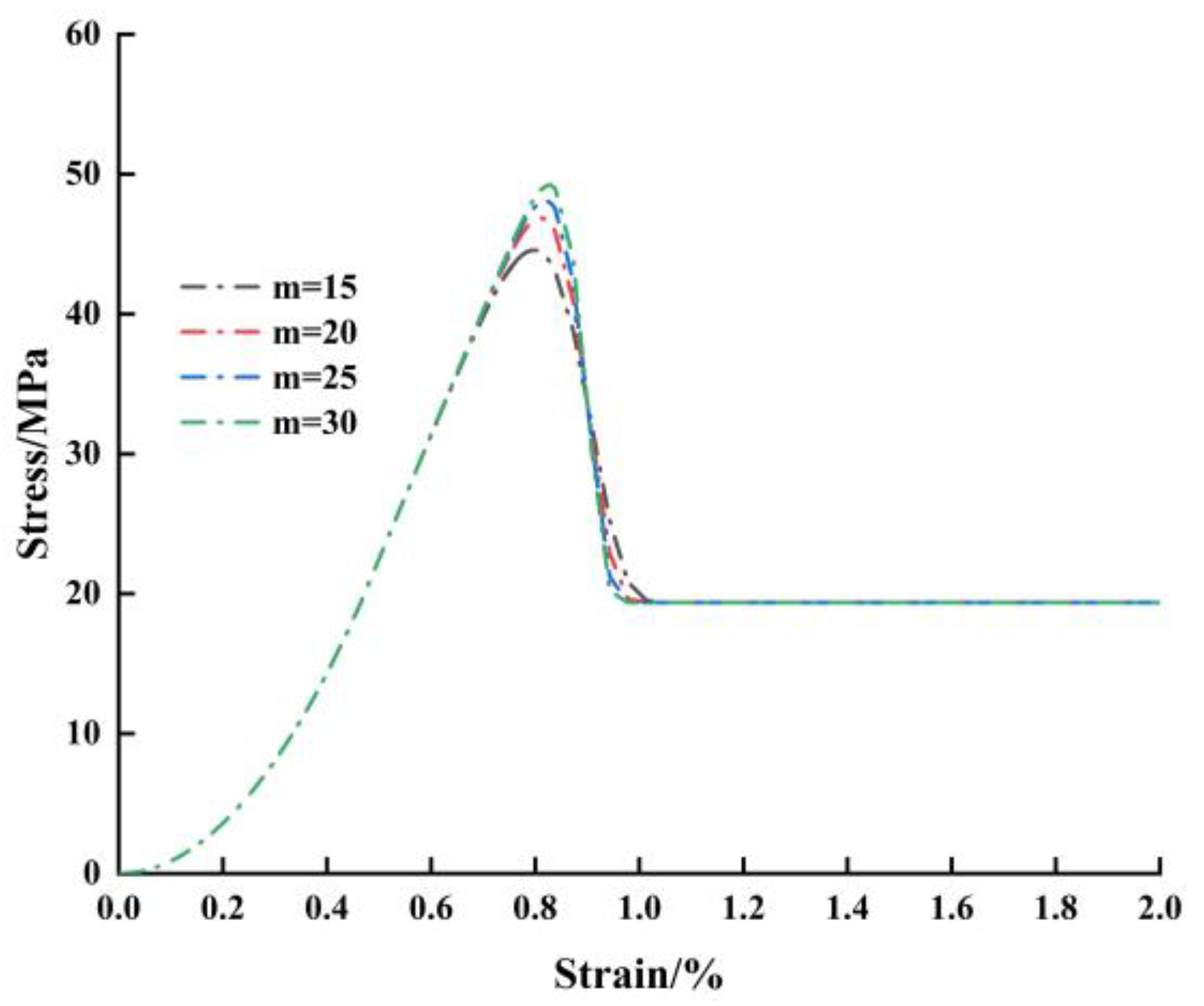

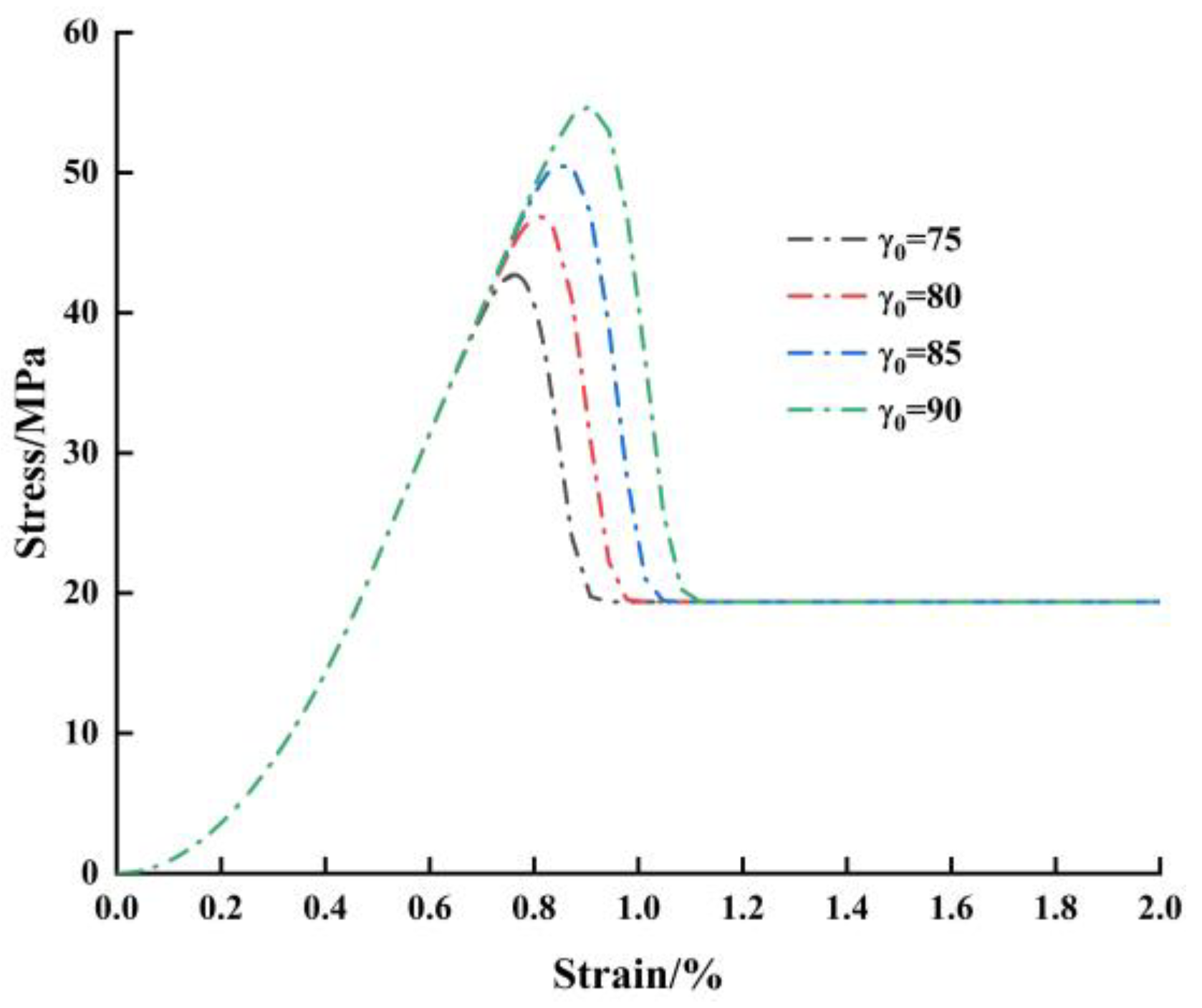

4.3. Parameter Study

5. Damage Evolution Analysis

5.1. Damage Evolution Analysis of Mechanical Parameters

5.2. Constitutive Damage Evolution Analysis

- (1)

- Physical effectWith the long-term immersion, the aqueous solution continues to enter the gap between the rock particles, which has a good lubrication and migration effect on the particles.

- (2)

- Chemical effectThe chemical reaction and ion exchange of the aqueous solution to the rock cement and some minerals lead to dissolution; the connection between the rock particles weakens, and holes appear.

- (3)

- Mechanical effectThe seepage of aqueous solution leads to the pressure on the pores inside the rock.

6. Conclusions

- (1)

- Compared with sandstone in natural state, the mechanical parameters such as compressive strength and elastic modulus of rock are obviously weakened after soaking in aqueous solution, and the weakening effect in distilled water is greater than that in simulated groundwater.

- (2)

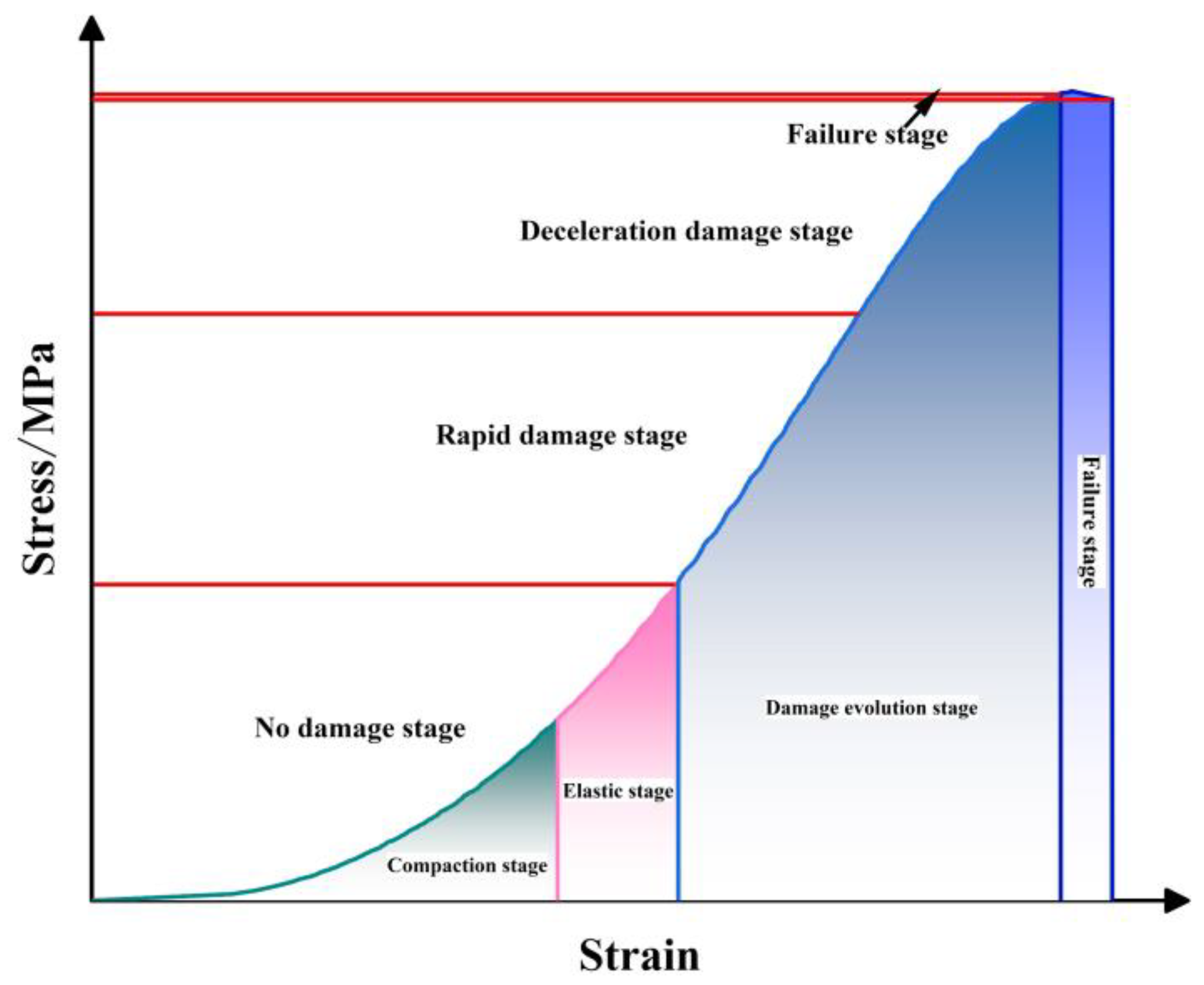

- The failure process of sandstone is a continuous damage accumulation process. Similar to the uniaxial loading process, the damage evolution process of sandstone can be roughly divided into four stages: no damage, rapid damage, deceleration damage and failure. Simulated groundwater can effectively enhance the ductility of rock.

- (3)

- According to the curve of long strain compaction section, a piecewise damage statistical constitutive model based on Mohr–Coulomb criterion is constructed, which can describe the stress–strain relationship of rock loading failure under three water environments.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.H.; Zhou, J.X.; Zhu, X.X.; Li, C.P.; Yan, G.G.; Liu, R.T.; Duan, F.W. Day-ahead Optimal Dispatch of Thermal/Storage/Load Considering Variable Time Period Control in Power System with High Penetration New Energy. Power Syst. Technol. 2022, 47, 51–63. [Google Scholar]

- Yang, C.; Shen, Z.Z.; Tan, J.C.; Li, G.H. Analytical Method for Estimating Leakage of Reservoir Basins for Pumped Storage Power Stations. Bull. Eng. Geol. Environ. 2021, 80, 5145–5158. [Google Scholar] [CrossRef]

- Liu, K.Z.; He, J.; Luo, Z.; Shan, H.; Li, C.L.; Mei, R.; Yan, Q.C.; Wang, X.J.; Wei, L. Load Frequency Control of Pumped Storage Power Station Based On LADRC. Processes 2020, 8, 380. [Google Scholar] [CrossRef]

- Yuan, L. Comprehensive Development and Utilization of Abandoned Mine Resources Helping to achieve the “carbon peak, carbon neutral” target. Sci. Technol. Rev. 2021, 39, 1. [Google Scholar]

- Pu, H.; Xu, J.C.; Bian, Z.F.; Holger, S. Research status and progress of geothermal energy development and utilization from closed/abandoned coal mines. J. China Coal Soc. 2022, 47, 2243–2269. [Google Scholar]

- Abdiev, A.; Mambetova, R.; Abdiev, A.; Abdiev, S. Studying a correlation between characteristics of rock and their conditions. Min. Miner. Depos. 2020, 14, 87–100. [Google Scholar] [CrossRef]

- Vasyliev, L.; Malich, M.; Vasyliev, D.; Katan, V.; Rizo, Z. Improving a technique to calculate strength of cylindrical rock samples in terms of uniaxial compression. Min. Miner. Depos. 2023, 17, 43–50. [Google Scholar] [CrossRef]

- Luo, T.; Guo, B.H.; Jiao, F.; Guo, F. The Influence of Hydrochemical Erosion on the Mechanical Characteristics of Sandstone. Chin. J. Undergr. Space Eng. 2019, 15, 1316–1322. [Google Scholar]

- Li, H.G.; Li, H.M.; Xu, G.S. Influence of water content on mechanical characteristics of weakly cemented sandstone. J. Min. Strat. Control Eng. 2021, 3, 60–66. [Google Scholar]

- Zhang, X.W.; Xu, J.H.; Huang, N.; Sun, L.; Cao, Y. Mechanical properties and energy damage charateristics of sanstone subjected to hydrochemical erosion. J. Min. Strat. Control Eng. 2022, 4, 79–89. [Google Scholar]

- Li, J.; Wang, L.H.; Chen, Z.J.; Xiang, L. Study on Deterioration Characteristics of Sandstone under Long-term Immersion and Dry-Wet Cycle. Water Res. Power 2017, 35, 123–126. [Google Scholar]

- Wang, W.; Gu, F.; He, L.; Liu, Z.; Cao, T.; Li, G.Q. Experimental study on deteriorating characteristics of metamorphic sandstone mechanical parameters under the effect of wetting-drying cycles. J. Water Res. Water Eng. 2022, 33, 179–185+193. [Google Scholar]

- Qiao, L.P.; Liu, J.; Feng, X.T. Study on damage mechanism of sandstone under hydro-phyciso-chemical effects. Chin. J. Rock Mech. Eng. 2007, 26, 2117–2124. [Google Scholar]

- Deng, H.F.; Hu, A.L.; Li, J.L.; Zhang, X.J.; Hu, Y.; Chang, D.L.; Zhu, M. Statistical damage constitutive model of sandstone under water-rock interaction. Rock Soil Mech. 2017, 38, 631–639. [Google Scholar]

- He, Z.L.; Zhu, Z.D.; Ruan, H.N.; Dai, B.B. A Statistical Constitutive Damage Model for Rock under Water Pressure. J. Yangtze River Sci. Res. Inst. 2019, 36, 54–59. [Google Scholar]

- Zhao, Z.H.; Jin, H.Z.; Guo, J.C.; Chen, M.T.; Lu, C. Study on softening constitutive model of deep shale under hydration. Chin. J. Rock Mech. Eng. 2022, 41 (Suppl. S2), 3189–3197. [Google Scholar]

- Li, B.B.; Wang, Z.H.; Ren, C.B.; Zhang, Y.; Xu, J.; Li, J.H. Mechanical properties and damage constitutive model of coal under the coupled hydro-mechanical effect. Rock Soil Mech. 2021, 42, 315–323+332. [Google Scholar]

- Tang, L.S.; Zhang, P.C. Influence of Chemical Damage of Water on Elastic Modulus of Rocks. Acta Sci. Nat. Univ. Sunyatseni 2000, 39, 126–128. [Google Scholar]

- Cao, R.L.; He, S.H.; Wei, J.; Wang, F. Study of modified statistical damage softening constitutive model for rock considering residual strength. Rock Soil Mech. 2013, 34, 1652–1660+1667. [Google Scholar]

- Luo, J.A.; Liu, F.M.; Liu, Z.X.; Ma, L.M.; Chen, Y.K.; Li, X.W. Study and Correction of Cyclic Loading-Unloading Constitutive Model of Rock Based on Octahedral Theory. Chin. J. High Press. Phys. 2020, 34, 82–90. [Google Scholar]

- Li, H.C.; Zhang, S. A constitutive damage model of rock based on the assumption of modified Lemaitre strain equivalence hypothesis. Rock Soil Mech. 2017, 38, 1321–1326+1334. [Google Scholar]

- Cao, W.G.; Zhang, S. Study on the Statistical Analysis of Rock Damage Based on Mohr-Coulomb Criterion. J. Hunan Univ. (Nat. Sci.) 2005, 32, 43–47. [Google Scholar]

- Xu, Q.; Tian, A.; Luo, X.; Liao, X.; Tang, Q. Chemical Damage Constitutive Model Establishment and the Energy Analysis of Rocks Under Water–Rock Interaction. Energies. 2022, 15, 9386. [Google Scholar] [CrossRef]

- Yan, J.; Zou, Z.; Guo, S.; Zhang, Q.; Hu, X.; Luo, T. Mechanical Behavior and Damage Constitutive Model of Granodiorite in a Deep Buried Tunnel. Bull. Eng. Geol. Environ. 2022, 81, 118. [Google Scholar] [CrossRef]

| Rock State | Elastic Modulus E/GPa | Threshold Strain in Compaction Stage | Threshold Stress in Compaction Stage | ||||

|---|---|---|---|---|---|---|---|

| Distilled water immersion | 6.5 | 0.538 | 13.75 | 0.894 | 34.37 | 22.83 | 65.22 |

| Simulated groundwater immersion | 6.7 | 0.516 | 14.21 | 0.875 | 35.50 | 20.31 | 63.78 |

| Natural state | 8.9 | 0.465 | 19.38 | 0.829 | 48.46 | 20.70 | 80.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, J.; Wang, L. Segmentary Damage Constitutive Model and Evolution Law of Rock under Water-Force Coupling Action of Pumped Storage in Deep Mine. Energies 2023, 16, 4322. https://doi.org/10.3390/en16114322

Luo J, Wang L. Segmentary Damage Constitutive Model and Evolution Law of Rock under Water-Force Coupling Action of Pumped Storage in Deep Mine. Energies. 2023; 16(11):4322. https://doi.org/10.3390/en16114322

Chicago/Turabian StyleLuo, Ji’an, and Liangliang Wang. 2023. "Segmentary Damage Constitutive Model and Evolution Law of Rock under Water-Force Coupling Action of Pumped Storage in Deep Mine" Energies 16, no. 11: 4322. https://doi.org/10.3390/en16114322