1. Introduction

Autonomous vehicles (AVs) have been a popular topic in recent years, as they can potentially reduce fatalities and improve efficiency in road transport. At the same time, the driving environment is becoming increasingly complicated, as there exists various road traffic participants, e.g., road vehicles, e-scooter riders, cyclists and pedestrians. Therefore, to ensure the safe driving of vehicles, it is especially important to develop advanced active safety systems, e.g., those for path following and yaw stability control. Although extensive studies, e.g., [

1], have been carried out with the aim of achieving yaw stability, purely utilising active steering and/or braking control may not always yield the desired performance. For instance, for the studies conducted in [

2,

3,

4], the vehicle did not complete the obstacle avoidance manoeuvres with accurate trajectory tracking or without decelerating significantly, leading to compromised safety or comfort for AVs operating in such conditions.

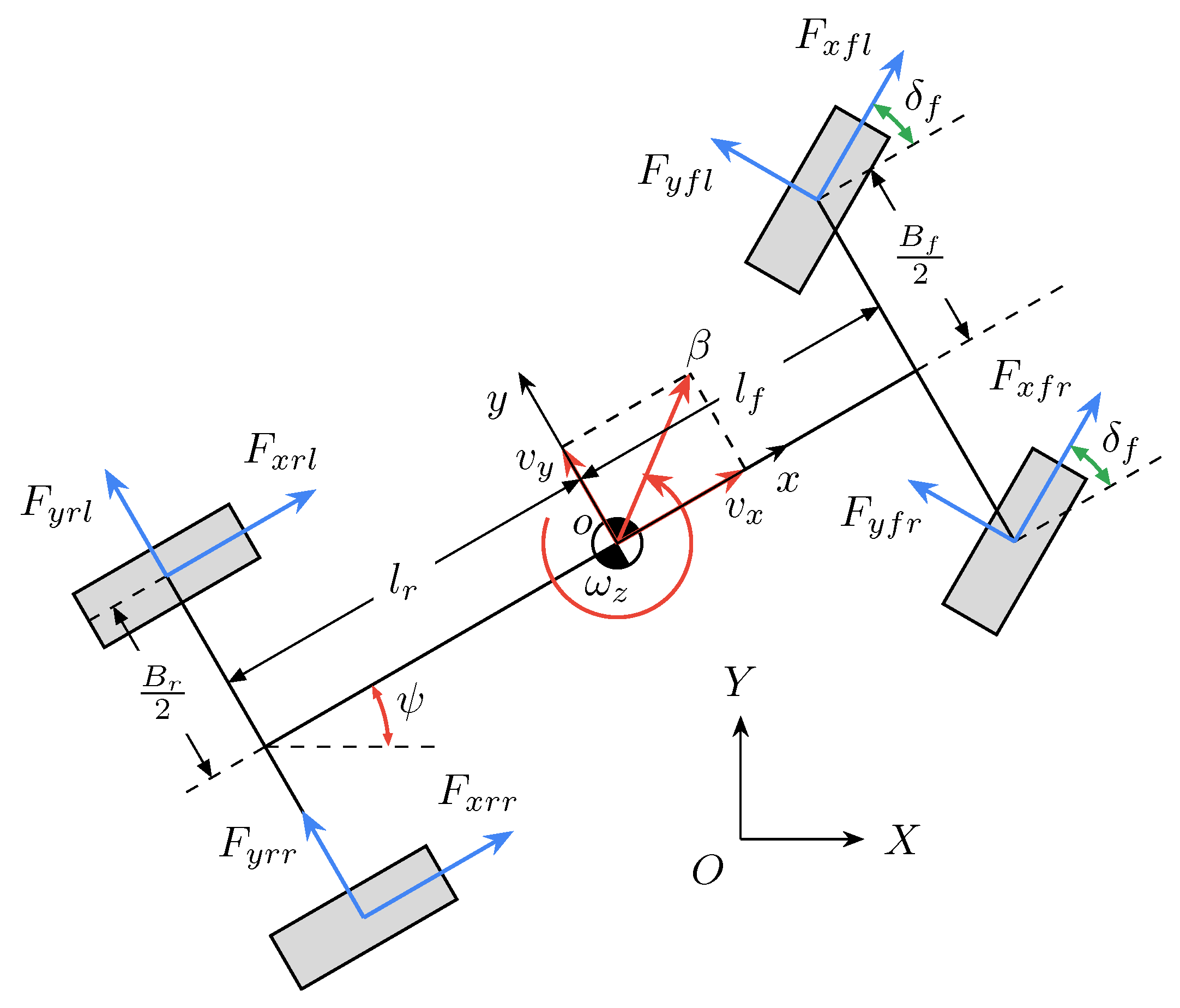

With the introduction of AVs there is a need for by-wire actuation, which has increased the interest in over-actuated vehicle platforms. Here, over-actuation refers to vehicles with more actuators than the degrees of freedom (DoF) to be controlled. For instance, the actuators in a vehicle with individual steering, traction and camber actuation outnumber the DoF to be controlled, i.e., the longitudinal, lateral and yaw directions of the vehicle. This, compared to conventional vehicles, provides additional DoF for controlling the vehicle, and thus can potentially improve driving safety in addition to other objectives.

Torque vectoring has been studied extensively in order to stabilise the vehicle and/or follow the desired path [

5,

6,

7,

8,

9,

10,

11,

12,

13,

14,

15]. This is usually achieved by generating a differential yaw moment by individually regulating wheel torques. Specifically, Jonasson et al. [

5] explored the capability of torque vectoring for enhancing stability through a safety-critical double-lane change manoeuvre, and showed its potential in improving entry velocity. Nam et al. [

6] utilised active front steering and rear-wheel torque vectoring for tracking yaw rate and sideslip angle trajectories, and the lateral stability was improved. Zhai et al. [

8] designed torque vectoring algorithms through multi-layer controllers and showed improved lateral stability and manoeuvrability. An adaptive backstepping sliding mode controller was implemented by Zhang et al. [

11], which enhanced the vehicle manoeuvrability and stability while being robust to varying vehicle masses and tyre types. Liang et al. [

12] controlled an off-road vehicle by exploring torque vectoring and rear-wheel steering, and improved the tracking performance for the yaw rate and sideslip angle. To follow the desired path, an adaptive control scheme was proposed in [

13], where the variation in tyre cornering stiffness was considered, with the results showing improved lateral path tracking. Backstepping and model predictive control (MPC) were combined in [

14] to follow the given path, and they were found to improve the path tracking and yaw stability. Furthermore, an earlier study by the authors [

15] improved path following and yaw stability performances concurrently by exploiting torque vectoring. Although previous studies showed promising findings in applying torque vectoring for improving vehicle stability, the available longitudinal tyre forces and thus the desired yaw moment are limited by the combined slip coupling between longitudinal and lateral tyre forces in such critical driving conditions.

Camber control has also been studied to improve vehicle safety due to its potential to improve lateral tyre forces [

16]. For instance, camber control has been utilised to enhance the trajectory tracking performance [

17] and to increase the cornering margins [

18]. The authors of [

19] examined active camber for enhancing the path following and yaw stability performances and found a considerable improvement in the passing velocity and tracking accuracy.

Although existing studies on exploiting over-actuation for achieving active safety have shown promising results, the following points can be further explored. Firstly, there is a lack in comparisons of different over-actuation configurations for AV applications in safety-critical conditions, especially in the context of concurrent path following and yaw stability control. In particular, it is important to evaluate how torque vectoring and active camber can be integrated together to potentially further improve the safety performance. Secondly, previous studies have mainly determined the reference yaw rate and sideslip angle by using single-track models, which is a separate process to path planning. However, this may compromise the overall path following and yaw stability performance. Finally, the robustness of the configuration performance to trajectory variations needs to be explored further.

This study aims to address the issues identified above by evaluating the effect of various over-actuation configurations on the path following and yaw stability performance of AVs in critical driving scenarios. This study mainly contributes to safe autonomous driving in the following three aspects. Firstly, four motion actuator configurations are analysed and compared, i.e., active front steering (S), active front steering + torque vectoring (ST), active front steering + active camber (SC), as well as the integrated control of active front steering + torque vectoring + active camber (STC). The evaluation is achieved through the framework of nonlinear MPC, where constraints on yaw stability and actuator limits are explicitly considered. Secondly, the assessment is carried out based on reference signals obtained through the concurrent yaw rate, sideslip angle and path planning. Finally, an investigation is carried out on the robustness of the over-actuation configurations to reference trajectory variations.

It is important to note that this study does not address the issues of cost and the mechanical system complexity associated with torque vectoring and active camber systems. In fact, there are efforts from the industry devoted to developing these vehicle technologies for electric and autonomous driving applications, e.g., [

20,

21]. Besides the safety improving advantages as mentioned above, existing studies have already shown the energy saving potential of such vehicle platforms [

22,

23]. Moreover, these types of vehicle configurations enable various other benefits such as more DoF for vehicle dynamics control [

24], fault-tolerance [

25] and motion comfort enhancement [

26].

4. Results and Discussion

This section presents an evaluation of four motion actuator combinations through the controllers designed in

Section 3, i.e., S, ST, SC and STC. For a fair comparison, the four controllers share the same form of nonlinear MPC formulation as given in Equation (27), are implemented in the same manner and are evaluated in the same framework shown in

Figure 3. The main differences between the four controllers are that they have different state equations, control vectors and tuning parameters, as detailed in Equation (34).

During the evaluation, a vehicle plant model that features the KTH Research Concept Vehicle (RCV) [

44] was used to simulate the vehicle behaviour. Specifically, the vehicle plant has the capability to individually steer, drive/brake and camber each wheel. The plant model was developed in Dymola [

45] with the physical modelling language

Modelica and the Vehicle Dynamics Library. As a result of this, the vehicle plant can be modelled by considering the detailed components of a vehicle, e.g., springs and dampers. As a result, the main components of the plant model include front and rear suspensions, Pacejka tyre models [

46], steer, drive and camber actuators and an aerodynamics unit. Additional modelling details, model parameters and an illustration of this Dymola vehicle plant can be found in [

15] (Section II-E) and [

40] (Figure 2.7). Finally, the Dymola plant model was exported as a functional mock-up unit (FMU) [

47] for co-simulation with the nonlinear MPC controllers implemented with

MPCTools. The FMU vehicle plant contains 44 continuous states and 57,330 variables, making it much more advanced than the controller model denoted by Equation (25). Therefore, this FMU plant model is a suitable choice for comparing the four motion actuation configurations and assessing their robustness.

The results from the four motion actuator configurations are generated with the following two steps:

Reference trajectories are generated with various initial velocities in a single-lane change (SLC) manoeuvre [

33] by using two trajectory planners to test the robustness of the configurations. The advanced trajectory planner is modelled by using a double-track vehicle model that considers load transfer (Planner DTMlt in [

33]) and the Pacejka tyre model [

46]. The simplified planner adopts a single-track vehicle model and a linear tyre model, and it does not include the sideslip angle variation term in the yaw rate constraint as does the advanced planner.

The four controllers are used to control the vehicle by following the reference trajectories, i.e., the reference yaw rate, sideslip angle, yaw angle, lateral position and longitudinal velocity, while complying with the yaw stability constraints, i.e., the constraints on the yaw rate and sideslip angle, at various initial velocities in the SLC manoeuvre. Both the reference trajectories and the yaw stability constraints directly come from the trajectory planners.

Passing velocity and tracking accuracy. In particular, the highest passing velocity refers to the maximum initial velocity that the vehicle is able to complete the manoeuvre at while not colliding with the lane boundary, and tracking accuracy is quantified by using the performance indicators RMS and maximum tracking error, as detailed in [

15] (Section IV).

Safety distance, i.e., the distance between vehicle corners and the lane boundary at four critical locations.

Robustness test, i.e., the performance consistency against reference trajectory variations.

As an example,

Figure 4 shows the generated reference trajectories from the advanced planner in the SLC manoeuvre with an initial of being 73 km/h. Similarly, reference trajectories are generated at various other initial velocities from both the advanced and simplified planners (results not shown to save space). Subsequently, these reference trajectories are used by the four controllers for trajectory tracking in the following discussions.

Considering their physical limits, the capability of the steering, torque and camber actuators of the vehicle are constrained to be within ±25°, ±1490.2 Nm and ±15°, respectively. Accordingly, the rates of change of these actuators are defined as ±37 °/s, ±2980.5 Nm/s and ±45 °/, respectively.

As different combinations of actuators are considered in the four controllers, the weight matrices are set accordingly for each controller. Specifically, the same components in the weight matrices are used for all the controllers where applicable, for a fair comparison. To this end, the tuning parameters for the four controllers are set as follows:

When tuning the weight matrices, the unit and relative importance of the corresponding variables are considered. For instance, the steering angle (rad) has a considerably larger component than the wheel torque (Nm) in the

matrix, considering that SI (International System of Units) units are adopted. Additionally,

generally has larger components than

as trajectory tracking is more important than actuator usage in the present study. Moreover, the purpose of using a significantly large

matrix is to penalise the potential violation of the state constraint, as defined in Equation (33). Finally, a preview time of around 1 s is selected. This then is used to determine the horizon length 33, in the case that the sampling interval from the planner trajectories is around 30 ms. A more detailed description of the tuning process can be found in [

15] (Section IV).

4.1. Velocity and Accuracy

Table 1 shows the highest passing velocity of the four configurations with the reference trajectories from the advanced planner. As can be seen, the configuration S yields the lowest passing velocity among all the configurations, which is 3 km/h lower than that from ST and SC; on the other hand, STC has a 6 km/h higher passing velocity than the configuration S.

The configuration S produces in general the largest tracking errors for the yaw rate, sideslip angle and yaw angle at the initial velocity of 73 km/h with the advanced planner, as shown in

Table 2 and

Figure 5. It can also be seen that ST results in a lower tracking accuracy than SC at the same initial velocity with the advanced planner. On the other hand, at the same initial velocity, STC in general results in smaller tracking errors for the yaw rate, sideslip angle and yaw angle than the other configurations, as can be seen in

Table 2 and

Figure 5. Moreover, when the initial velocity increases to 76 km/h, STC produces a smaller peak sideslip angle than the other configurations at the position around 20 m, as can be seen in

Figure 6b.

The improved performance of the configuration SC over ST is mainly due to the fact that active camber is more effective than torque vectoring in the present study. Firstly, ST needs to produce an appropriate amount of total longitudinal forces such that it satisfies the longitudinal movement requirement indicated by Equation (1). However, this may limit ST in generating the required yaw moment. Secondly, the capability of torque vectoring is limited by the coupled longitudinal and lateral tyre forces through friction circle/ellipse constraints [

46]. Specifically, the vehicle brakes and steers simultaneously at a position of around 10 m (see

Figure 6g,k). In such combined slip conditions, relatively large lateral tyre forces are required because the vehicle needs to maintain yaw stability (see

Figure 7b,f). This then indicates that it cannot be realistic to generate larger longitudinal tyre forces from certain wheels for a larger torque vectoring (see

Figure 6k). As a result, the build-up of critical vehicle states, e.g., the sideslip angle, from ST is quicker than that from SC, as shown in

Figure 6b. In contrast, the improved performance of SC over ST can be attributed to the following two points. Firstly, the lateral tyre forces are much larger than the corresponding longitudinal tyre forces for most of the time in the test scenarios (see

Figure 7c,g), meaning that it can be more effective to control the lateral tyre forces than the longitudinal forces. Secondly, with different values of camber angle produced in the front and rear wheels, an additional yaw moment can be generated by controlling the lateral tyre forces, as can be seen from

Figure 6h and

Figure 7g.

The working principles of SC can be further explained by examining

Figure 6,

Figure 7 and

Figure 8. At a position of around

, the steering angle of the front wheels reaches

, as shown in

Figure 6g, and the tyre slip angles of the four wheels are

,

,

and

, respectively, as shown in

Figure 8g. This means that, at this position, controlling the inclination angle of the two front wheels may not be as effective as controlling the two rear wheels, considering the relationship between camber stiffness and slip angle, as illustrated in

Figure 2. This is why SC produces a camber angle for the rear wheels (

) twice the value of the front wheels (

) at this position, as can be seen in

Figure 6h. Moreover, the fact that the vehicle is decelerating while steering to the left at this position means the rear right wheel has a larger vertical load than the rear left wheel, as shown in

Figure 6c,g and

Figure 8j,k. This explains the higher tyre utilisation in the rear right wheel of SC than that of ST at the position around

, as can be observed in

Figure 8b,c.

As for the STC configuration, it combines the features of both ST and SC. Therefore, STC does not need to exploit as much torque vectoring as ST to rotate the vehicle at the position around

, as shown in

Figure 6k,m. Moreover, compared with SC, STC results in lower build-up and rate of change in sideslip angle, as well as smaller peak camber demand in the entire manoeuvre, as evident in

Figure 6b,h,i. In short, by exploiting the steering, torque and camber actuators in an integrated manner, STC can regulate both the longitudinal and lateral forces of individual wheels when needed, thus resulting in a larger safety margin and an improved performance.

4.2. Safety Distance

Although from

Figure 6e it can be seen that the configuration S yields a rather smooth path through the SLC manoeuvre at the initial velocity of 76 km/h, the front left corner of the vehicle in fact collides with the lane boundary at the position around

. Therefore, this section discusses the safety distance between the four vehicle corners and the lane boundary at four critical locations with the advanced planner. Moreover, safety distance can be viewed as a performance indicator for position tracking, which complements the trajectory tracking results given in

Table 2.

To identify the critical locations where the vehicle is likely to collide with the lane boundary, tests were carried out for the four controllers at various velocities until the highest passing velocity. The resulted position envelope at the three highest passing velocities (see

Table 1) is shown in

Figure 9a–c, to make the plots easier to interpret. As can be seen, the vehicle tends to collide with the lane boundary at four positions, which are indicated by “PA”, “PB”, “PC” and “PD”, respectively.

As shown in

Table 3, at locations “PA”, “PB”, “PC” and “PD”, the vehicle tends to collide with the lane boundary with the front right, front left, front right and rear left corners, respectively. In general, the vehicle is most likely to collide with the lane boundary at location “PB” for all the configurations. Moreover, at this location, the safety distance from STC increases by 33% (3 cm), compared with that from S and ST, when tested at an initial velocity of 73 km/h. Furthermore, when the velocity increases to 76 km/h, the safety distance (at “PB”) from STC is 166% (5 cm) larger than that from ST. It should be noted that this 5 cm increase in safety distance can be of significant importance in a near crash scenario.

The increased safety distance of STC over ST at “PB” can be explained after examining their location envelopes formed from the four critical locations, e.g., with the initial velocity of 73 km/h. As indicated by

Table 3, the resulting overall position envelope (especially the first half of the manoeuvre) from STC shifts closer to the lane boundary on the right side of the vehicle, compared with that from ST. By using this strategy, STC succeeds in manoeuvring the vehicle further away from the lane boundary at the most critical location “PB” and at a higher velocity.

When the initial velocity increases from 73 to 79 km/h, the safety distances of STC at locations “PA”, “PB”, “PC” and “PD” change by 6, −8, −5 and −8 cm, respectively, as shown in

Table 3. Taking the right-side corners of the vehicle as an example, this means that the position envelope at “PA” moves to the left while at “PC” it moves to the right. Similarly, it can be seen that the position envelope at “PA” moves backwards along the

X axis while at “PD”, it shifts forwards. This means that the envelope tube formed from the trajectories of the vehicle corners is somewhat stretched along the

X direction. In other words, when the initial velocity increases, STC tends to produce a smoother position envelope.

4.3. Robustness Test

To assess the robustness of the over-actuation configurations, tests were carried out by using reference trajectories from the simplified planner. As can be seen from

Table 4, compared with the configuration S, ST does not gain in passing velocity with the simplified planner, which is worse than the case with the advanced planner, where there was a 3 km/h gain. On the other hand, the passing velocity difference between SC and ST increases from 0 in the case with the advanced planner to 10 km/h with the simplified planner. Moreover, the passing velocity difference between STC and SC with the simplified planner is 2 km/h, which is similar to the case with the advanced planner. Furthermore, the passing velocity gap between STC and S increases to 12 km/h when using the reference trajectories from the simplified planner; in contrast, the passing velocity difference between these two configurations is merely 6 km/h with the advanced planner.

Table 5 and

Figure 10 and

Figure 11 show the tracking performance of the four configurations with the simplified planner. As can be seen, the configuration S performs the worst among all the four configurations in terms of the tracking accuracy and the magnitude of the resulting critical vehicle states, e.g., sideslip angle, which is similar to the case with the advanced planner. Moreover, ST again is inferior to SC with the simplified planner with respect to the tracking accuracy and the resulting peak sideslip angle.

STC yields a similar tracking accuracy to SC with the simplified planner at the initial velocity of 67 km/h, as can be seen from

Table 5 and

Figure 10 and

Figure 11. This could be due to the fact that, at this relatively low velocity, STC does not need to utilise the full potential of the available actuators. When the initial velocity increases to 77 km/h, STC yields a higher accuracy than SC, as shown in

Table 5. Moreover, at this higher velocity, both SC and STC request more actuator usage than the case at 67 km/h, which can be observed in

Figure 12a,b, as a result of the more severe driving conditions. Still, at 77 km/h, the peak camber angle in both the front and rear wheels from STC is lower than that from SC due to its integrated usage of camber and torque actuators.

The safety distance of the four configurations at the four critical positions with the simplified planner can be seen in

Table 6. “PB” is again the most critical position where the vehicle is likely to collide with the lane boundary for all the configurations. Moreover, the safety distance from STC is 75% larger (3 cm) than that from SC at this location with the initial velocity of 77 km/h. Furthermore, when the initial velocity increases from 67 to 79 km/h, STC also generates a smoother position envelope (the figure for 79 km/h is not shown to save space), which is similar to the observation with the advanced planner.