Economic Load-Reduction Strategy of Central Air Conditioning Based on Convolutional Neural Network and Pre-Cooling

Abstract

:1. Introduction

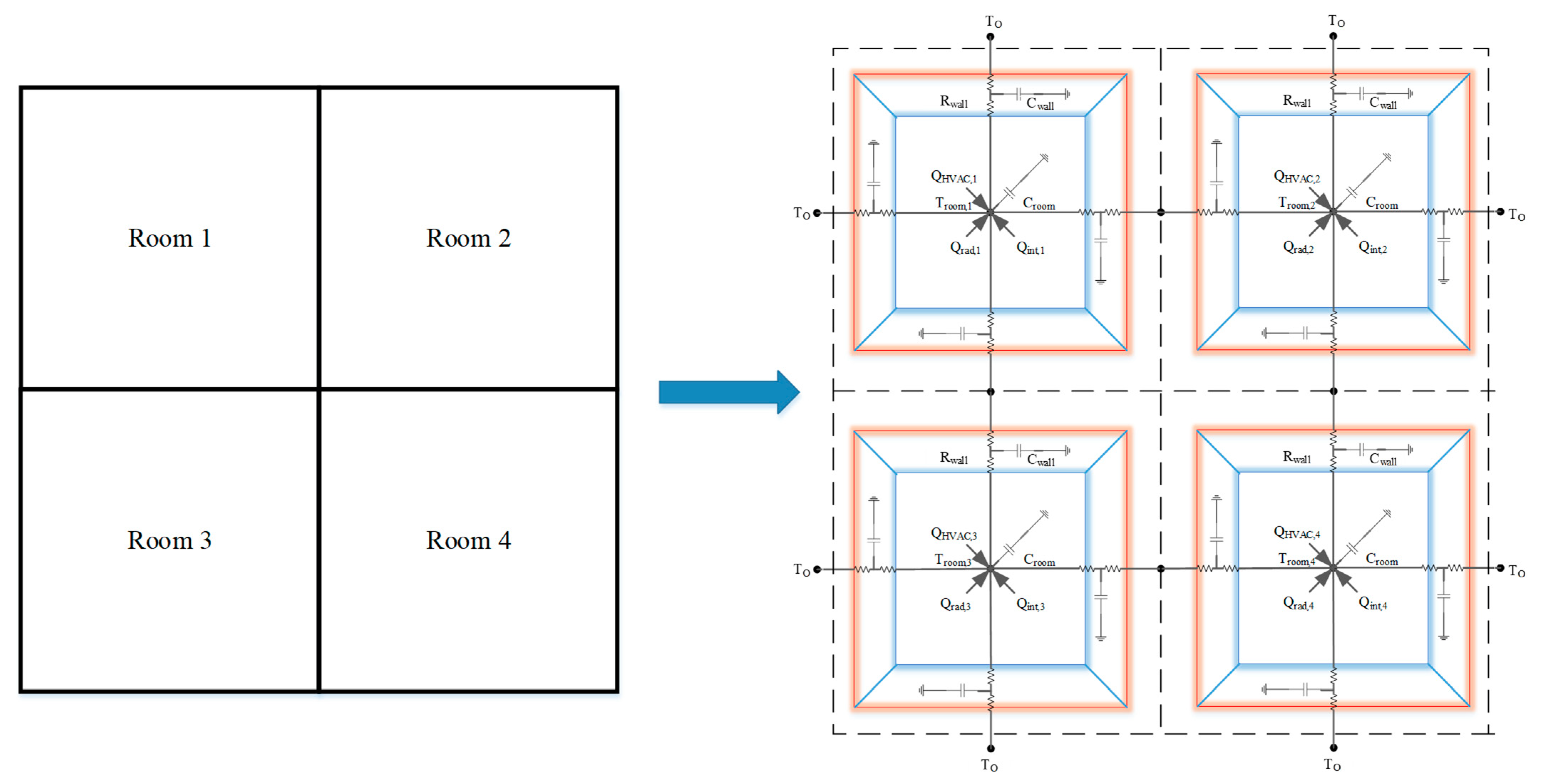

2. Building Model Based on CNN

2.1. Analysis of Influencing Factors

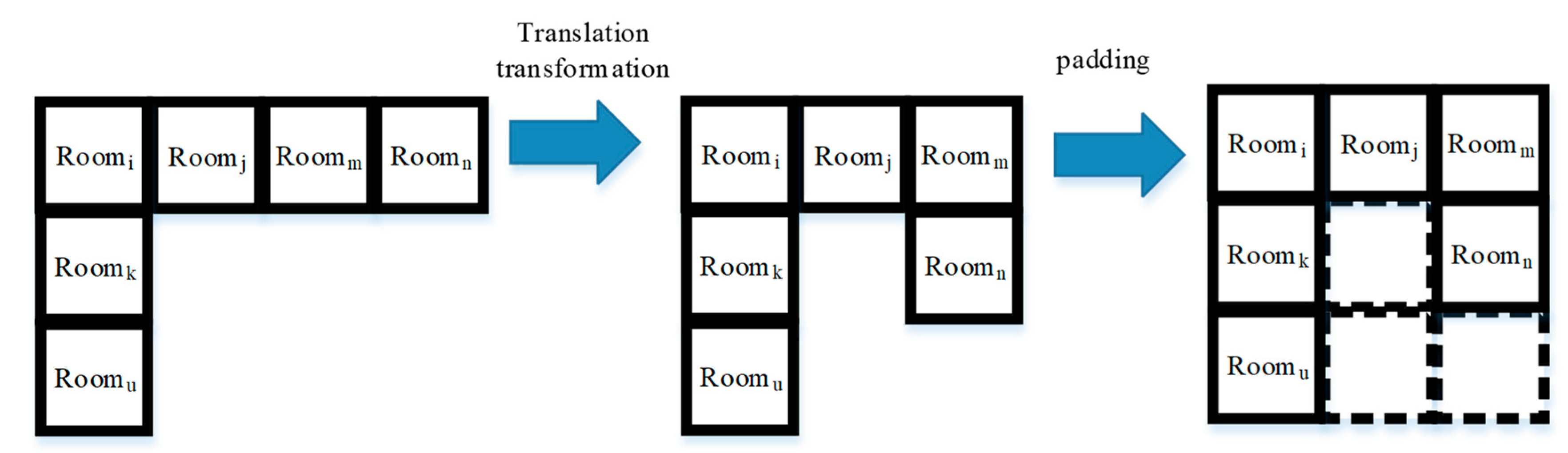

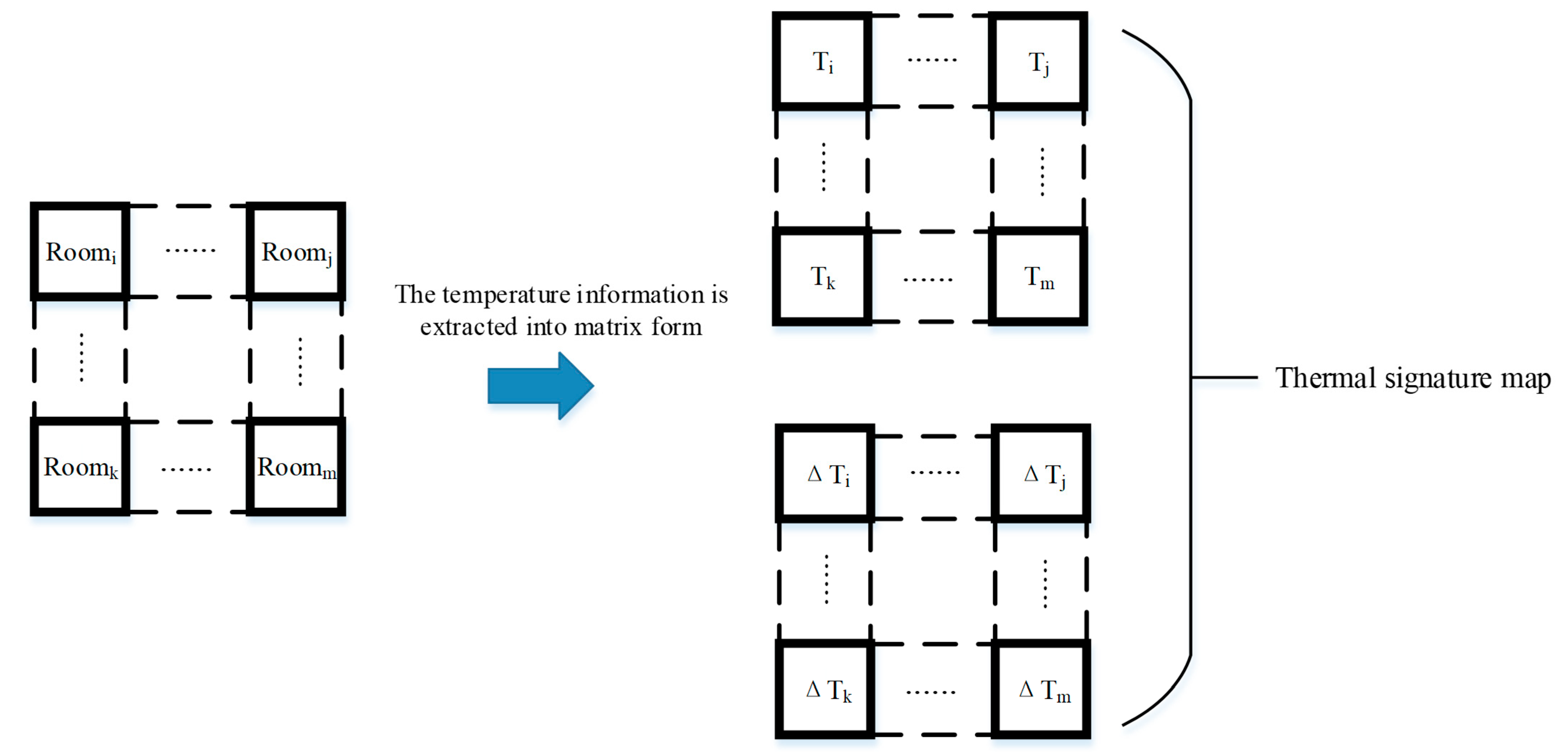

2.2. Network Structure Design

3. Central Air Conditioning Energy Consumption Model and Its Optimal Working Condition

3.1. Energy Consumption Model

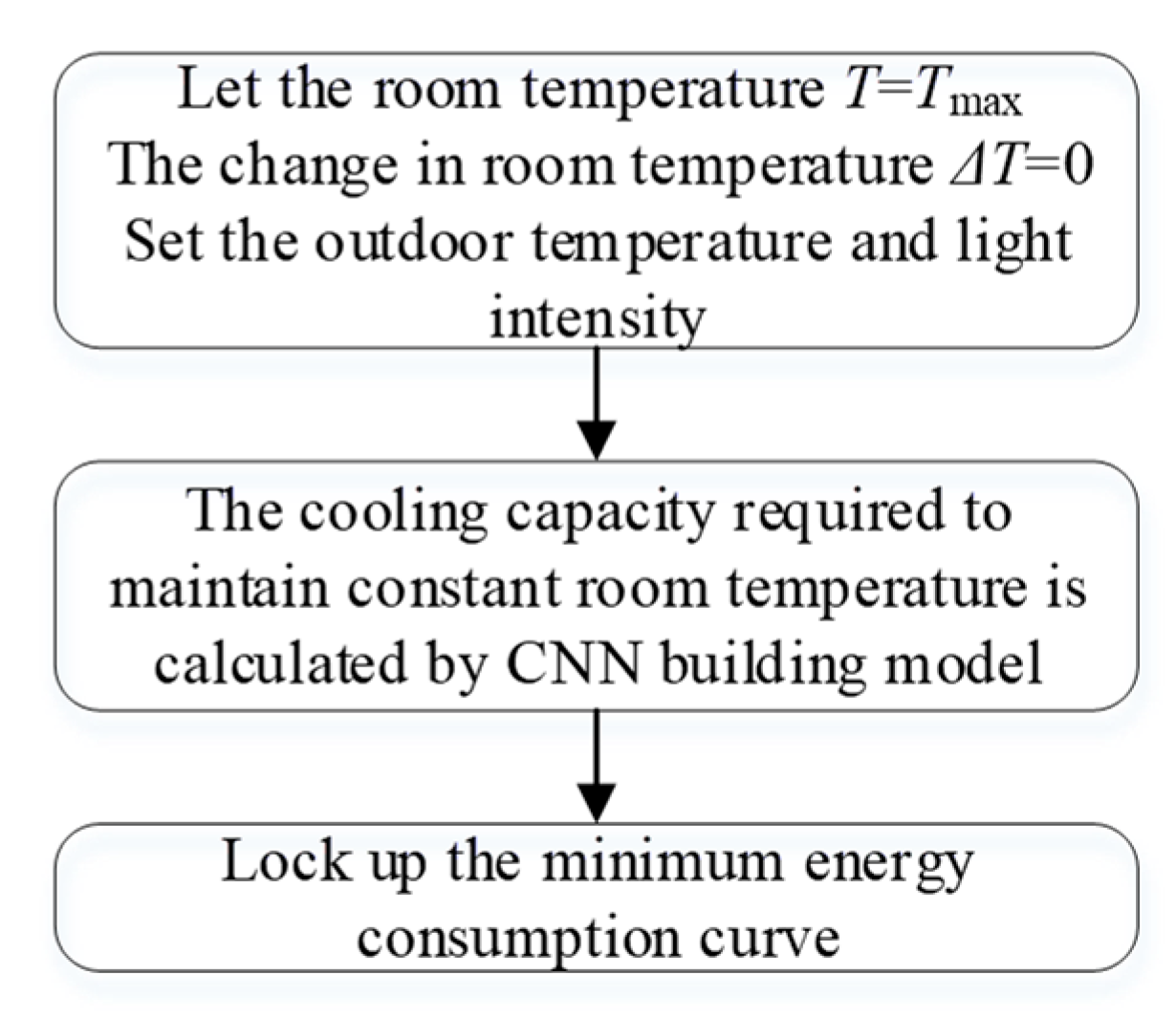

3.2. Optimal Working Condition Solving Model

4. Load-Shedding Potential and Economic Load-Shedding Strategy of Central Air Conditioning Cluster

4.1. Load Baseline Calculation Method

4.2. Load Reduction Potential Evaluation Model

4.3. Economic Load Reduction Strategy

5. Example Analysis

5.1. CNN Building Model

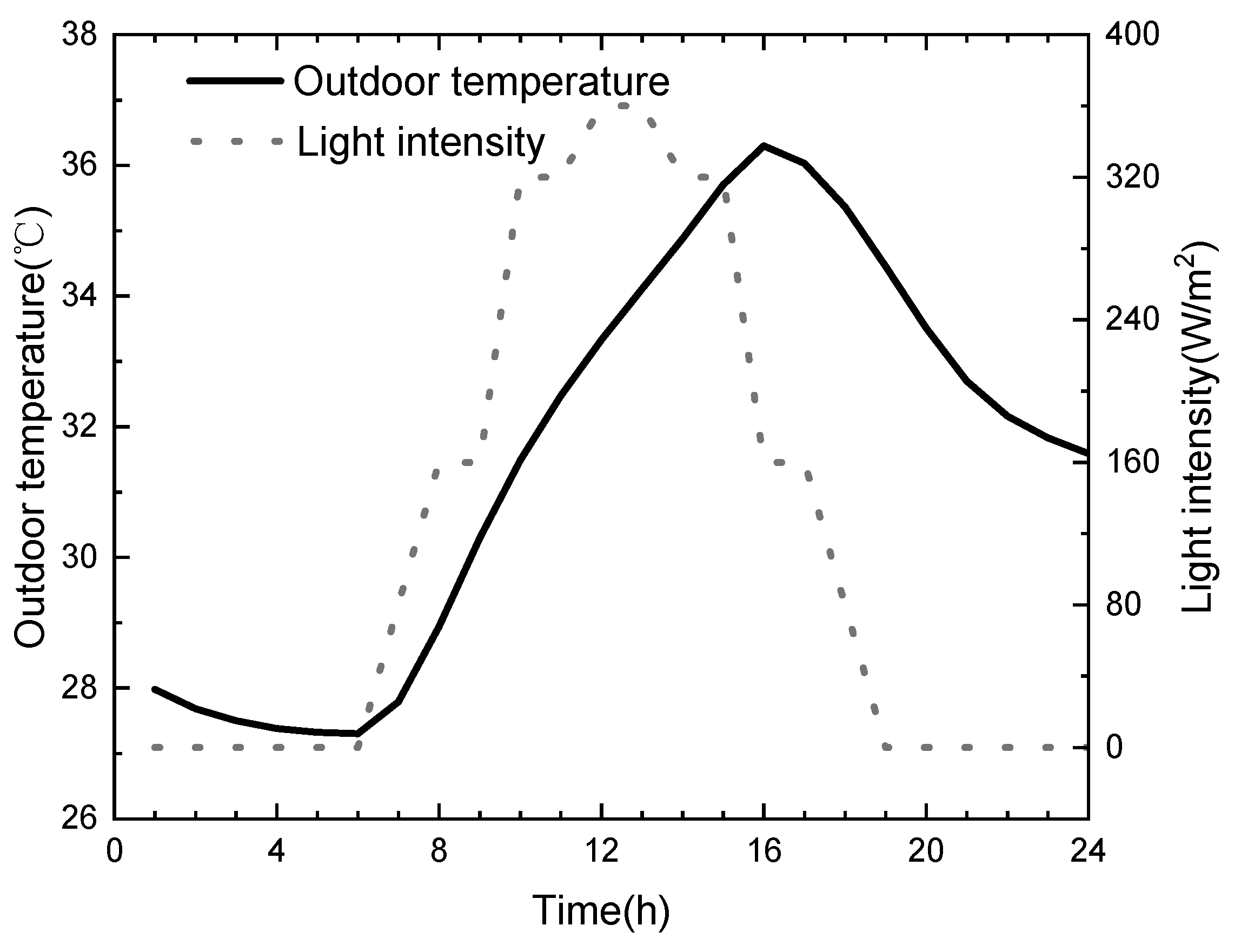

5.1.1. Data Set Design

5.1.2. Training Effect

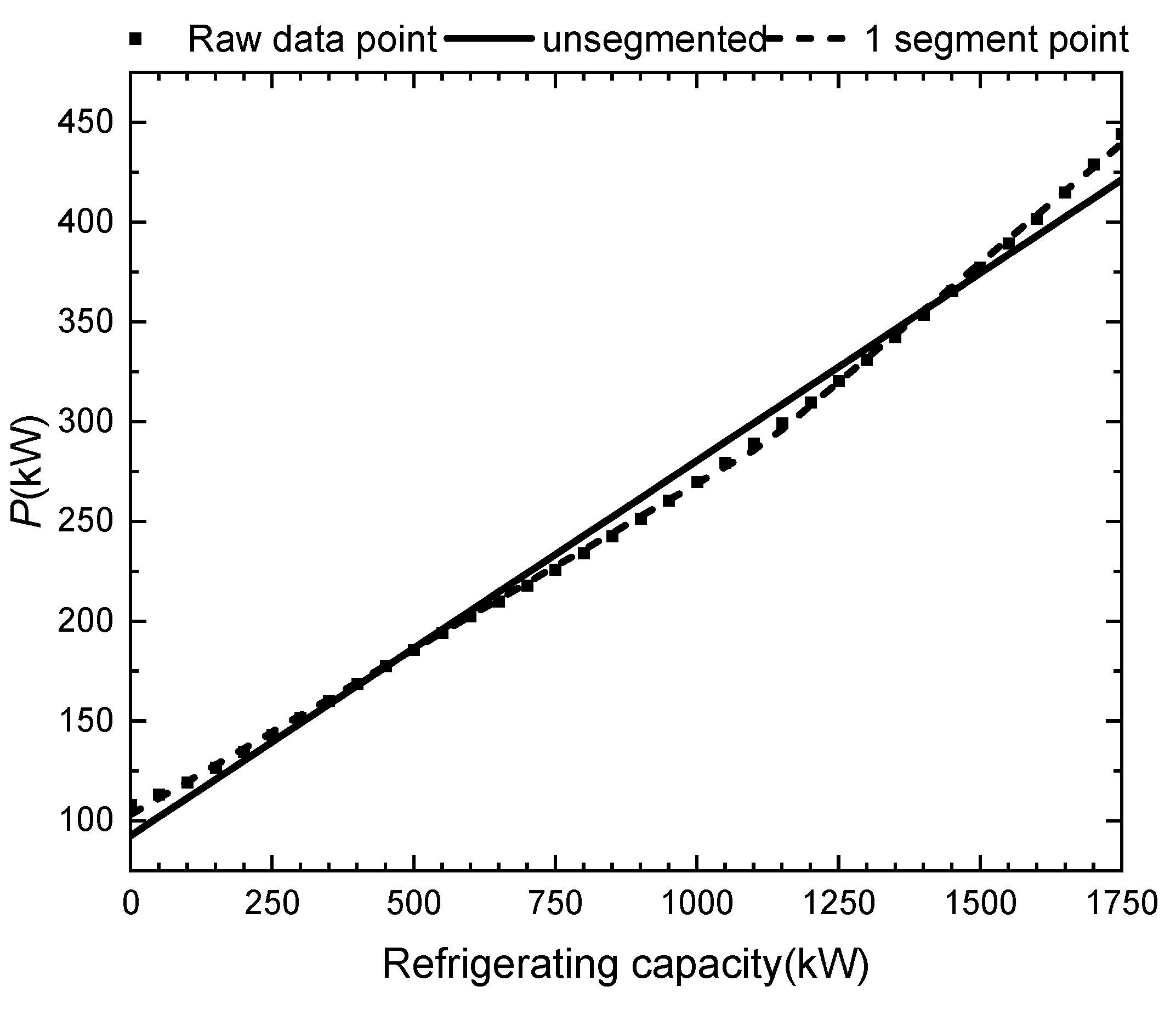

5.2. Optimal Condition of Central Air Conditioning

5.3. Load-Reduction Potential Evaluation and Economic Load-Reduction Strategy

5.3.1. Load Base Line

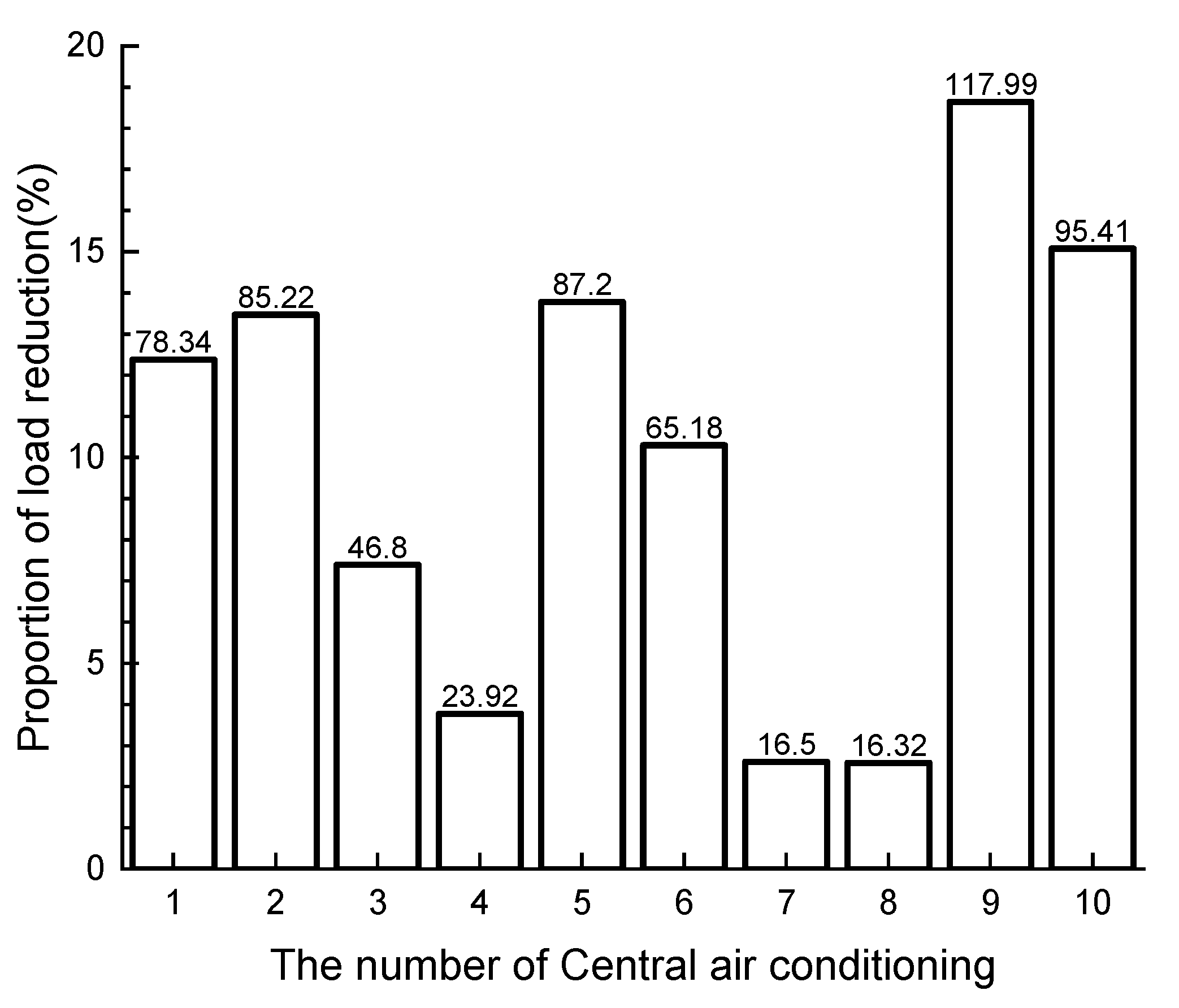

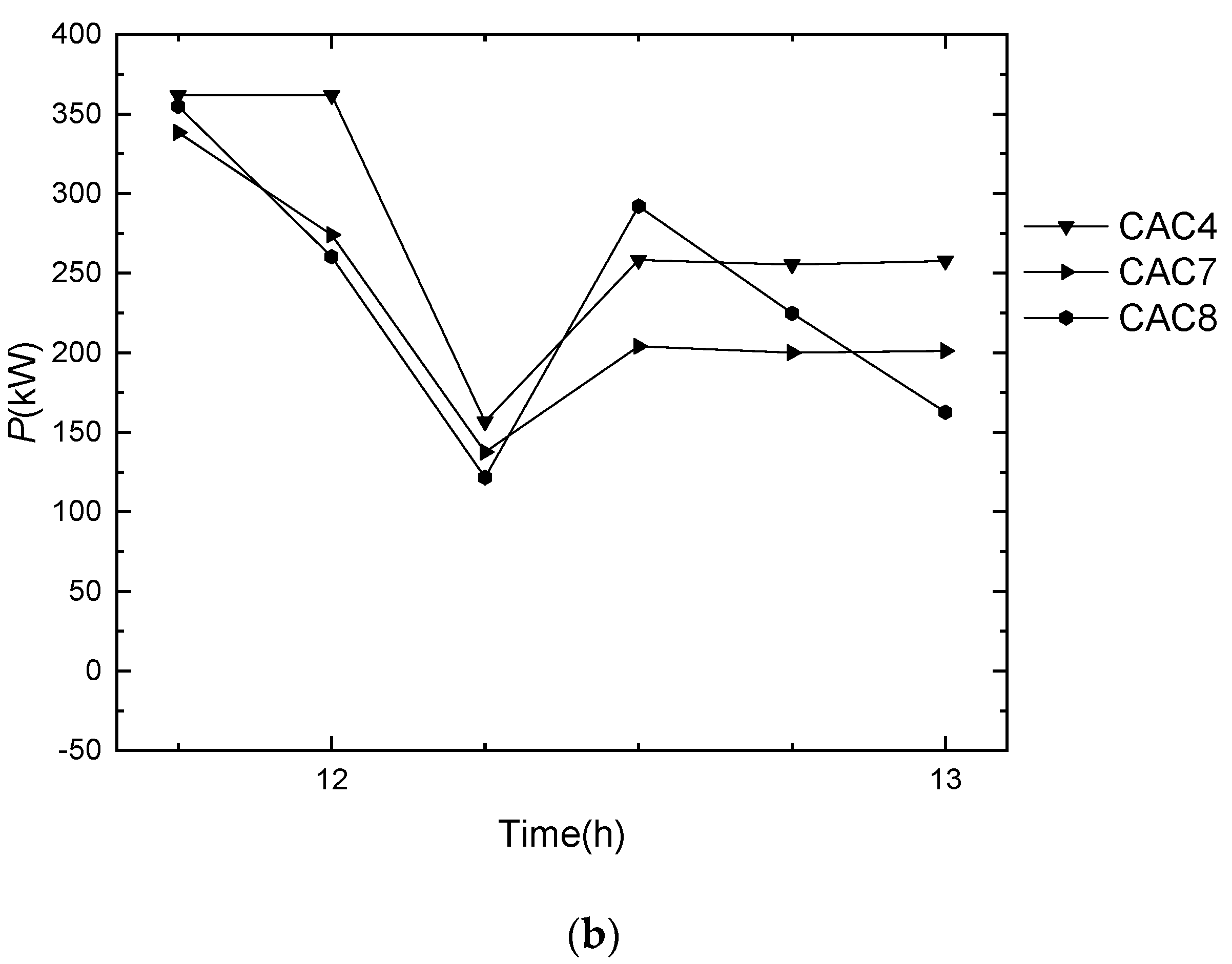

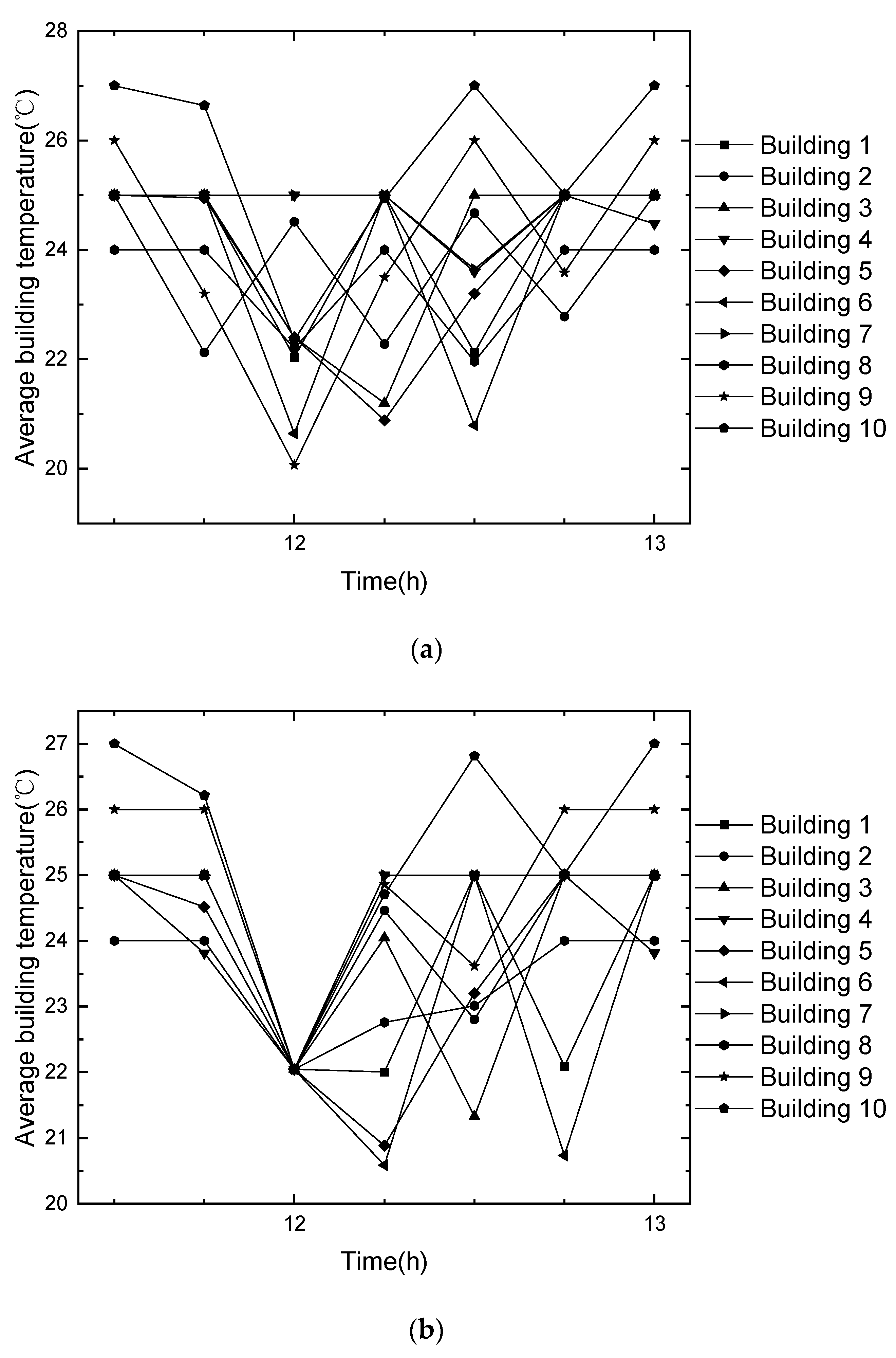

5.3.2. Load-Reduction Potential Assessment

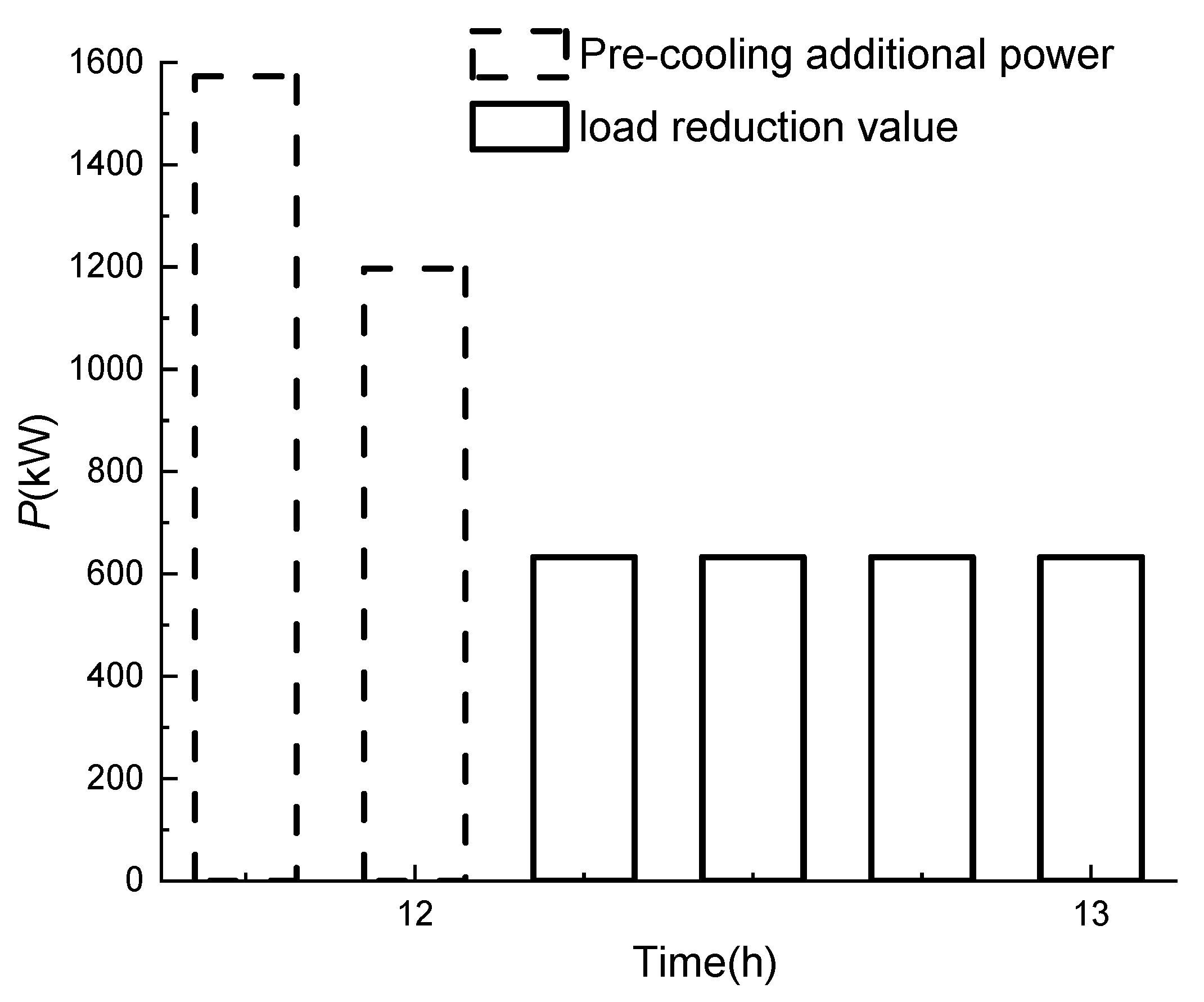

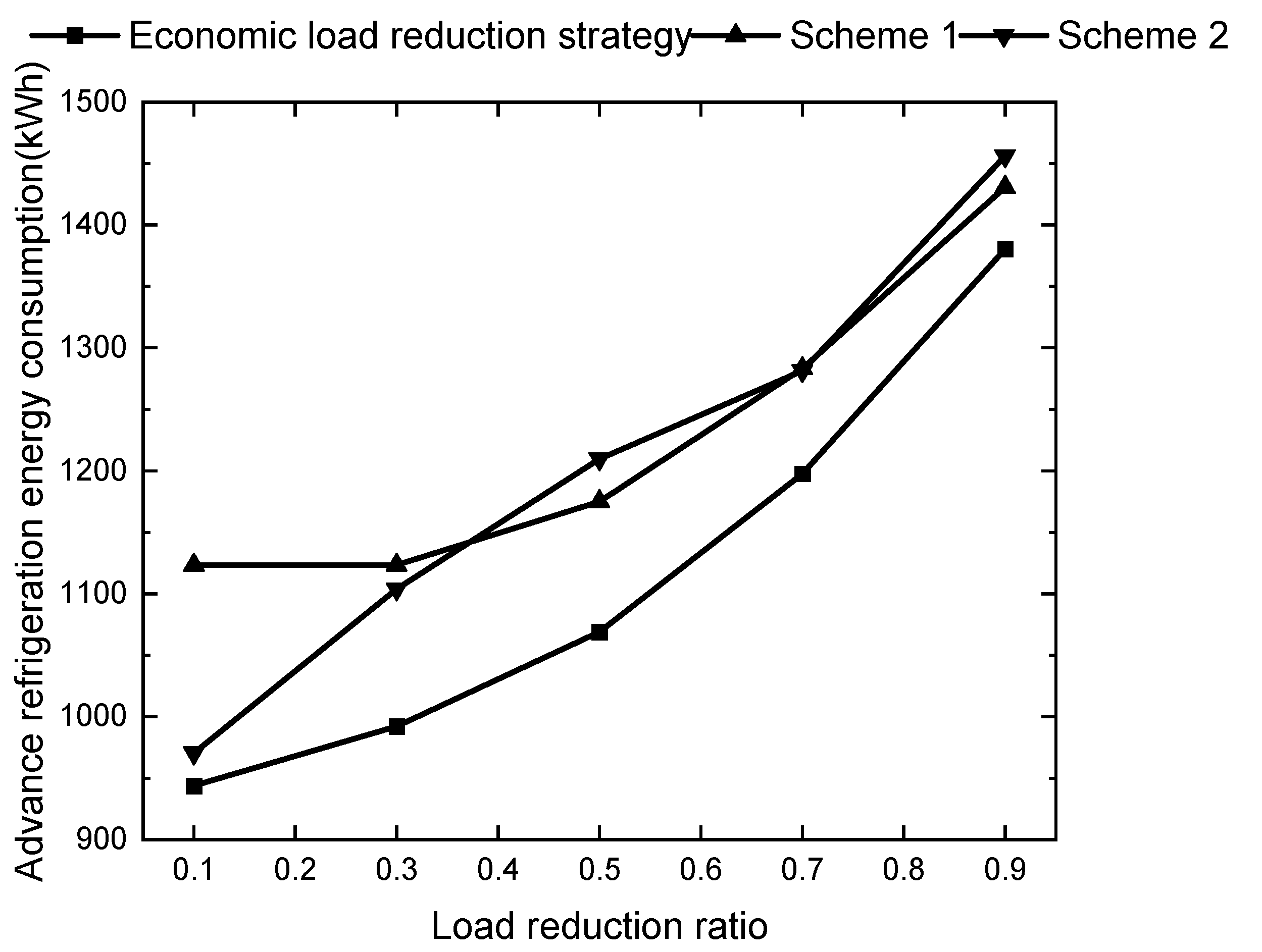

5.3.3. Economic Load-Reduction Strategy

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, M.; Gao, C.; Su, W. Modeling and controlling of air-conditioning load for demand response applications. Dianli Xitong Zidonghua/Autom. Electr. Power Syst. 2016, 40, 158–167. [Google Scholar] [CrossRef]

- Bao, Y.; Cheng, L. Parameter identification method of second-order equivalent thermal parameter model for air conditioning loads. Autom. Electr. Power Syst. 2021, 45, 37–43. [Google Scholar]

- Wu, C.; Shen, H.; Wang, Z. Data-driven online identification method for parameters of inverter air-conditioning load model. Autom. Electr. Power Syst. 2022, 46, 120–129. [Google Scholar]

- Liao, S.; Xu, J.; Jin, C. Modeling and optimization for home appliances based on air-conditioning parameters identification. Electr. Meas. Instrum. 2019, 56, 43–47+68. [Google Scholar]

- Lu, T. Research on Energy Storage Modeling and Control Strategy of the Air Conditioning Load; Southeast University: New Albany, Indiana, 2015. [Google Scholar]

- Wang, C.; Fu, S.; Zhang, L.; Jiang, Y.; Shu, Y. Optimal control of source–load–storage energy in DC microgrid based on the virtual energy storage system. Energy Rep. 2023, 9, 621–630. [Google Scholar] [CrossRef]

- Tu, C.; Cao, J.; Yu, D. Control strategy of virtual energy storage system participating in frequency modulation based on air conditioning loads. Power Demand Side Manag. 2019, 21, 16–21. [Google Scholar]

- Chen, H.; Li, Z.; Jin, X.; Jiang, T.; Li, X.; Mu, Y. Modeling and Optimization of Active Distribution Network With Integrated Smart Buildings. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2018, 38, 6550–6562. [Google Scholar] [CrossRef]

- Chen, H.; Li, Z.; Jang, T. Flexible energy scheduling strategy in smart buildings based on model predictive control. Autom. Electr. Power Syst. 2019, 43, 116–124. [Google Scholar]

- Fan, D.; Zhang, Z.; Wang, Y. Day ahead scheduling strategy for air conditioning load aggregators considering user regulation behavior diversity. Power Syst. Prot. Control 2022, 50, 133–142. [Google Scholar]

- Yang, X.; Fu, G.; Liu, F. Potential evaluation and control strategy of air conditioning load aggregation response considering multiple factors. Power Syst. Technol. 2022, 46, 699–714. [Google Scholar]

- Yang, X.; Ding, X.; Lu, X. Inverter air conditioner load modeling and operational control for demand response. Power Syst. Prot. Control 2021, 49, 132–140. [Google Scholar]

- Yang, J.; Shi, K.; Cui, X. Peak load reduction method of inverter air-conditioning group under demand response. Autom. Electr. Power Syst. 2018, 42, 44–52. [Google Scholar]

- Pan, L.; Wang, S.; Wang, J.; Xiao, M.; Tan, Z. Research on Central Air Conditioning Systems and an Intelligent Prediction Model of Building Energy Load. Energies 2022, 15, 9295. [Google Scholar] [CrossRef]

- Zhang, Q. Study on Energy Saving Control Strategies of Central Air Conditioning System; Southeast University: New Albany, Indiana, 2016. [Google Scholar]

- Li, H. Optimization Control and Energy Saving Technology for Cooling System of HVAC System; Xi’an University of Architecture and Technology: Xi’an, China, 2011. [Google Scholar]

- Jiang, i.; Ju, P.; Wang, C.; Li, H.; Liu, J. Coordinated Control of Air-Conditioning Loads for System Frequency Regulation. IEEE Trans. Smart Grid 2021, 12, 548–560. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, Z.; Sun, Y. An optimal control strategy of cluster air-conditioning loads considering differentiated energy consumption demand. Electr. Meas. Instrum. 2021, 58, 22–27. [Google Scholar]

- Yang, C.; Xu, Q.; Wang, X. Strategy of constructing virtual peaking unit by public buildings’ central air conditioning loads for day-ahead power dispatching. J. Mod. Power Syst. Clean Energy 2017, 5, 187–201. [Google Scholar] [CrossRef] [Green Version]

- Bashash, S.; Lee, K.L. Automatic Coordination of Internet-Connected Thermostats for Power Balancing and Frequency Control in Smart Microgrids. Energies 2019, 12, 1936. [Google Scholar] [CrossRef] [Green Version]

- Lu, S.; Li, T.; Yan, X.; Yang, S. Evaluation of Photovoltaic Consumption Potential of Residential Temperature-Control Load Based on ANP-Fuzzy and Research on Optimal Incentive Strategy. Energies 2022, 15, 8640. [Google Scholar] [CrossRef]

- He, H.; Guo, J.; Wang, Y. Research on multi-objective optimization strategy for ice storage air conditioning system for distribution network wind power consumption. Power Syst. Prot. Control 2019, 47, 180–187. [Google Scholar]

- Gao, C.; Zhang, L.; Yang, X. Research on Load Aggregation of Central Air Conditioning and Its Participation in the Operation of Power System. Zhongguo Dianji Gongcheng Xuebao/Proc. Chin. Soc. Electr. Eng. 2017, 37, 3184–3191. [Google Scholar] [CrossRef]

- Chen, Z.; Shi, J.; Song, Z.; Yang, W.; Zhang, Z. Genetic Algorithm Based Temperature-Queuing Method for Aggregated IAC Load Control. Energies 2022, 15, 535. [Google Scholar] [CrossRef]

- Wang, B.; Zhu, F.; Ji, W.; Cao, Y. Load cutting potential modeling of central air-conditioning and analysis on influencing factors. Autom. Electr. Power Syst. 2016, 40, 44–52. [Google Scholar] [CrossRef]

| Model | Calculation Time | Parameter Number | Calculation Accuracy |

|---|---|---|---|

| Second-order ETP model | Short | 4, Irrelated to the scale of the building. | Inaccurate: The temperature of each room may exceed the comfort range. |

| RC network model | Long | Uncertainty, Related to the building scale; increases significantly with the scale. | Accurate: The comfort of each room is ensured. |

| Building Number | Wall Thermal Resistance Rwall (K/W) | Thermal Resistance of Windows Rwin (K/W) | Wall Heat Capacity Cwall (J/K) | Room Heat Capacity Croom (J/K) | Comfort Range (°C) |

|---|---|---|---|---|---|

| 1 | 0.08 | 0.02 | 2.6 × 107 | 2.5 × 105 | 20~25 |

| 2 | 0.12 | 0.03 | 2.6 × 107 | 2.5 × 105 | 20~25 |

| 3 | 0.06 | 0.015 | 2.6 × 107 | 2.5 × 105 | 20~25 |

| 4 | 0.04 | 0.1 | 2.6 × 107 | 2.5 × 105 | 20~25 |

| 5 | 0.08 | 0.02 | 3.9 × 107 | 3.75 × 105 | 20~25 |

| 6 | 0.08 | 0.02 | 1.95 × 107 | 1.875 × 105 | 20~25 |

| 7 | 0.08 | 0.02 | 1.3 × 107 | 1.25 × 105 | 20~25 |

| 8 | 0.08 | 0.02 | 2.6 × 107 | 2.5 × 105 | 21~24 |

| 9 | 0.08 | 0.02 | 2.6 × 107 | 2.5 × 105 | 19~26 |

| 10 | 0.08 | 0.02 | 2.6 × 107 | 2.5 × 105 | 18~27 |

| Argument | Range |

|---|---|

| Room temperature initial value Troom,i (°C) | Tmin~Tmax |

| Light intensity Qrad (W) | 0~360 |

| Outdoor temperature To (°C) | 26~38 |

| Cooling capacity per cooling area QHVAC,t (W) | 0~1500 |

| Training Times | Loss | RMSE | Acc |

|---|---|---|---|

| 1 | 355,408,544 | 18,852.28 | 0.1345% |

| 2 | 352,316,576 | 18,770.09 | 0.5724% |

| 3 | 345,913,856 | 18,598.75 | 1.484% |

| …… | …… | …… | …… |

| 99,998 | 1432.64 | 37.85 | 99.83% |

| 99,999 | 1432.13 | 37.84 | 99.84% |

| 100,000 | 1432.07 | 37.84 | 99.84% |

| Model | Calculation Time | Parameter Number | The Number of Measurement Points Required to Identify the Model | Whether Interaction Can Be Considered |

|---|---|---|---|---|

| ETP model | Negligible | 4 | 1 | × |

| RC model | 1.053 s | 145 | 85 | √ |

| CNN model | 0.189 s | 81 | 25 | √ |

| Scheme | Pre-Cooling Energy Consumption (kWh) | Cost (RMB) |

|---|---|---|

| Economic load-reduction strategy | 959.29 | 1151.15 |

| Conventional scheme 1 | 1123.54 | 1348.25 |

| Conventional scheme 2 | 1043.89 | 1252.67 |

| Scheme | Pre-Cooling Energy Consumption (kWh) | Cost (RMB) |

|---|---|---|

| Economic load-reduction strategy | 1287.08 | 1544.49 |

| Conventional scheme 1 | 1365.27 | 1638.32 |

| Conventional scheme 2 | 1365.62 | 1638.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, S.; Zhang, B.; Ma, L.; Xu, H.; Li, Y.; Yang, S. Economic Load-Reduction Strategy of Central Air Conditioning Based on Convolutional Neural Network and Pre-Cooling. Energies 2023, 16, 5035. https://doi.org/10.3390/en16135035

Lu S, Zhang B, Ma L, Xu H, Li Y, Yang S. Economic Load-Reduction Strategy of Central Air Conditioning Based on Convolutional Neural Network and Pre-Cooling. Energies. 2023; 16(13):5035. https://doi.org/10.3390/en16135035

Chicago/Turabian StyleLu, Siyue, Baoqun Zhang, Longfei Ma, Hui Xu, Yuantong Li, and Shaobing Yang. 2023. "Economic Load-Reduction Strategy of Central Air Conditioning Based on Convolutional Neural Network and Pre-Cooling" Energies 16, no. 13: 5035. https://doi.org/10.3390/en16135035