Abstract

In order to effectively combat the effects of global warming, all sectors must actively reduce greenhouse gas emissions in a sustainable and substantial manner. Sector coupling has emerged as a critical technology that can integrate energy systems and address the temporal imbalances created by intermittent renewable energy sources. Despite its potential, current sector coupling capabilities remain underutilized, and energy modeling approaches face challenges in understanding the intricacies of sector coupling and in selecting appropriate modeling tools. This paper presents a comprehensive review of sector coupling technologies and their role in the energy transition, with a specific focus on the integration of electricity, heat/cooling, and transportation, as well as the importance of hydrogen in sector coupling. Additionally, we conducted an analysis of 27 sector coupling models based on renewable energy sources, with the goal of aiding deciders in identifying the most appropriate model for their specific modeling needs. Finally, the paper highlights the importance of sector coupling in achieving climate protection goals, while emphasizing the need for technological openness and market-driven conditions to ensure economically efficient implementation.

1. Introduction

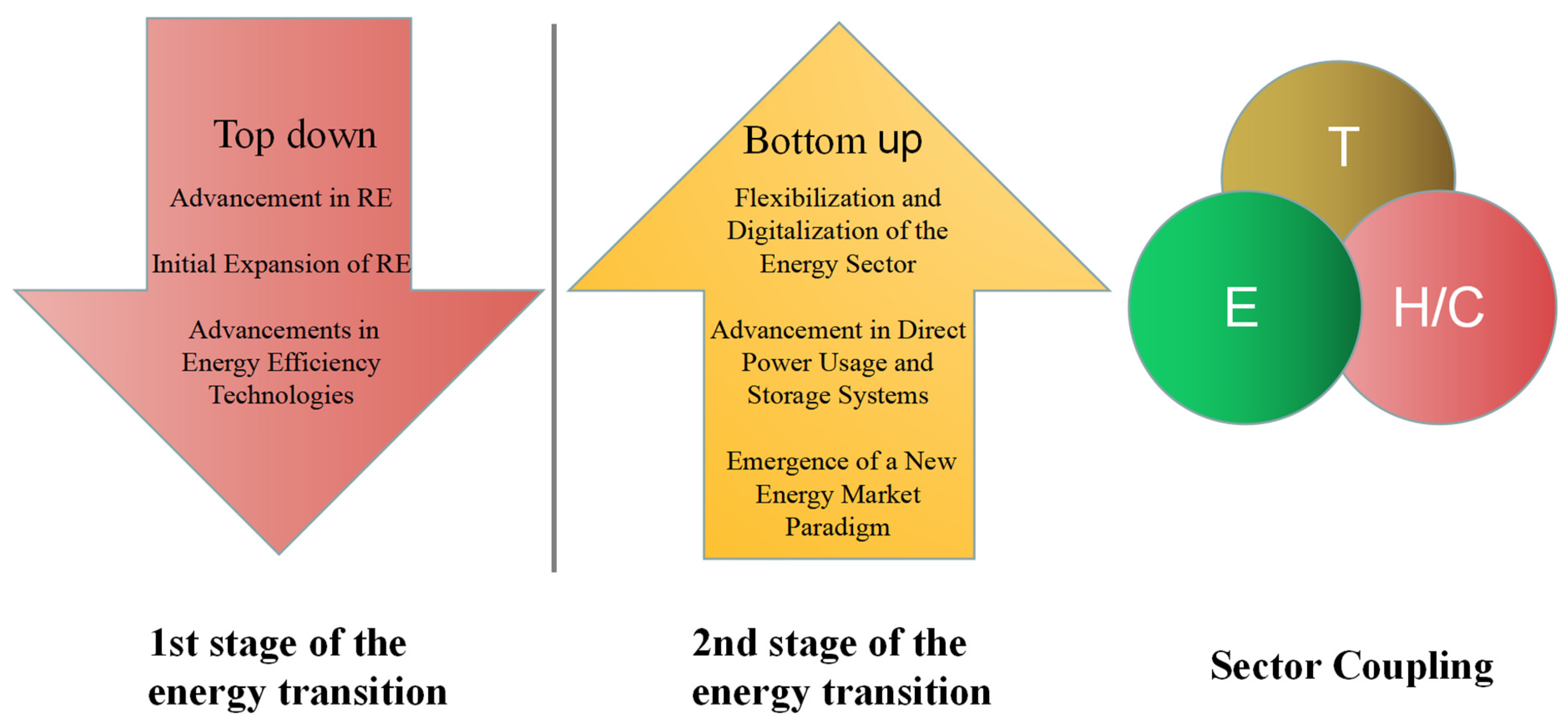

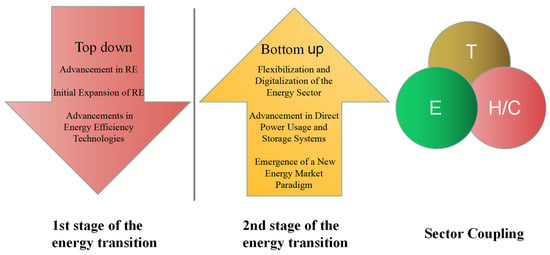

The German energy transition originated in the 1970s with the environmental and anti-nuclear movements, influenced by Lovins’ “Soft Energy Paths”, and gained momentum through the publication of the German translation of his book, leading to the adoption of the term “Energiewende” and subsequent political efforts to transition away from nuclear energy and fossil fuels [1]. In 2011, the German government embarked on a transformative journey towards sustainable energy by implementing a comprehensive legal framework and technological research, and unveiling the ambitious and pioneering energy transition strategy known as “Energiewende” [2]. As shown in Figure 1, the first stage focused on the establishment of a power supply system primarily driven by renewable energy sources, marking a significant shift away from conventional forms of electricity generation. This phase entailed substantial investments in renewable energy infrastructure, with particular emphasis on solar and wind power. Support policies and incentivized initiatives were introduced to encourage the adoption of renewable energy technologies by individuals and enterprises, leading to a substantial increase in renewable energy generation capacity, signifying notable progress in the first stage of renewable energy technologies within the power sector; however, challenges persist within the heat and transportation sectors. As such, the ensuing stage of energy transition endeavors to encompass the coupling of the three sectors. Owing to the transportation sector’s necessitation for high energy density and renewable energy provisions, meeting these demands may pose challenges for the electric power system. Consequently, a judicious approach incorporating a synergy of electricity and alternative energy sources, such as hydrogen, becomes imperative in adequately addressing the energy needs of the transportation sector.

Figure 1.

Two stages of German energy transition.

Building upon the foundation laid by its predecessor, the second stage of the energy transition represents a progressive stage characterized by the integration of energy systems, emphasizing sector coupling (SC). The importance of SC in the German energy transition cannot be overstated. Definitions of SC vary, ranging from considering the one-way path of electricity from the power sector to end-consumption sectors, to encompassing cross-energy-carrier integration, including excess heat utilization and biomass energy [3,4,5,6]. In this paper, SC is defined as the profound integration of significant energy consumption sectors, including electricity, heating/cooling, and transportation, fostering a synergistic relationship. This concept aligns with the United Nations Sustainable Development Goal (SDG) 7 (Affordable and Clean Energy), as it emphasizes the integration of different energy sectors to optimize energy consumption and promote the use of clean and affordable energy sources. SC also drives innovation in infrastructure and energy systems, fostering sustainable industrial development (SDG 9: Industry, Innovation, and Infrastructure). The integrated approach described aligns with SDG 11 (Sustainable Cities and Communities), enabling the development of smart, sustainable urban areas. Additionally, SC contributes to SDG 13 (Climate Action) by facilitating the integration of renewable energy sources and the electrification of various sectors [7]. It is important to acknowledge that in the SC’s definition, electricity is not solely generated from renewable resources. The authors argue that a complete elimination of nuclear and coal power may not be a desirable approach, primarily due to the need for flexibility in the energy system. By maintaining a diverse energy mix that includes a limited amount of nuclear and coal power, a stable electricity supply can be ensured during periods of low renewable energy generation or unexpected situations.

Power-to-X (P2X), such as power-to-gas (P2G), power-to-heat (P2H), and power-to-liquid (P2L), is a cross-vector integration that refers to the use of indirect electrification to produce a gas, heat or liquid energy medium from electricity for the end-use sector [8]. In detail, P2G is a technology for converting power into hydrogen and synthetic gas, which describes the chemical process of generating gas from water through water electrolysis and partly downstream methanation processes [9]. In this process, the resulting fuel gas can be stored and used for a variety of purposes. In particular, it can be used as a source of power conversion to fuel, such as for vehicles, aircraft, and ships. In recent years, the cost of P2G has fallen and it is projected that by 2050 the cost of the technology will be less than 500 euros per kilowatt of electricity input [9]. This technology makes economic and ecological sense, as P2G allows for sustainable energy use if electricity from renewable sources is used to produce natural gas. P2H is the conversion of electricity to heat at almost 100% efficiency through technologies such as heat pumps [10]. The advantage of P2H is that any surplus energy is not left unused and can be fed into the heating network. P2L typically involves a synthetic reaction of hydrogen produced by electricity to gas with CO2 to produce a liquid hydrocarbon fuel (dimethyl ester, kerosene, etc.) [11]. This technology is expected to become an important energy conversion technology in the future, which will be important for reducing carbon emissions and alleviating the energy crisis. P2X applications must grow significantly in end-use energy for the building, industry, and transportation sectors.

To better understand and optimize the complex interactions and synergies enabled by SC technology, the utilization of Energy System Modeling becomes crucial. Several studies have employed energy system modeling to investigate different aspects of renewable energy transition and its impact on various sectors. Bogdanov presented a tool to model complex energy system conversions in the power, heat, transport, and industrial sectors at full hourly resolution and tested for the case of Kazakhstan. The study revealed that SC and electrification could lower the levelized cost of electricity from 62 EUR/MWh in 2015 to 46 EUR/MWh in 2050, while maintaining heat costs at 30–35 EUR/MWh. This transition to 100% renewable energy could eliminate CO2 emissions by 2050, with 90% reduction by 2040 [12]. Nebel and Cantor simulated the predicted German energy system in 2030 with CO2 restrictions, analyzing the interconnections between electricity, heat, and hydrogen. With greater emission limits, renewable technology consumption fell and installed capacities grew. Sector coupling technologies reacted differently. As renewable energy penetration expanded, electrolyzers and heat pumps were used more [13]. In addition, energy system modeling can assess the impact of different policy measures and technology options on the energy system, thus providing a scientific basis for decision making. Carlos Osorio-Aravena studied Chile’s transition to 100% renewable energy [14]. The study compared energy transition policies in four sectors using the LUT Energy System Transition model and found that a sustainable energy system transition requires three vital elements (high level of renewable electrification across all sectors, flexibility, and renewable energy-based fuel production) and three key enablers (solar photovoltaic, interconnection, and full SC). The PyPSA-Eur-Sec-30 model considers cross-sector and cross-border integration and suggests that a cost-optimal system can reduce CO2 emissions by 95% compared to 1990 levels, with contributions from battery electric vehicles (BEV), P2G and long-term thermal energy storage (LTES). Cross-border transmission expansion lowers system costs, but the benefits weaken as SC becomes stronger [15]. By incorporating the findings of these studies, the paper aims to contribute to the understanding of energy system modeling, sector coupling technology, and their role in facilitating renewable energy transitions.

The rest of this paper is divided into five distinct sections. Section 2 offers a concise overview of the research methods employed in this review. Section 3 delineates the available technologies that facilitate SC, namely cross-vector integration or P2X. The central focus of Section 4 is the application of P2X and electrification in various sectors, including industries, transport, and buildings. In Section 5, special attention is given to the role of hydrogen in SC, namely its application in the chemical industry, steel production, vehicles, maritime transport, and air transport. Moreover, Section 6 provides a detailed review of 27 energy system models, aiming to analyze SC based on renewable energy. Finally, Section 7 discusses the key lessons learned from the review and provides insightful recommendations for future research in this area.

2. Research Methodology

The basis for this review is a bibliographic dataset from the most prominent academic database—ISI Web of Science (WoS) [16]. This paper used the keywords “sector coupling”, “energy transition”, “renewable energy”, and “energy system modeling” to filter the database. A total of 235 studies were selected for this review, including 204 journal articles, 28 review papers, 8 retrospective papers, and 3 editorial materials. The extracted bibliographic data include authors, titles, abstracts, sources, referenced citations, citation counts, document types, keywords, and conference information for each of the 235 articles.

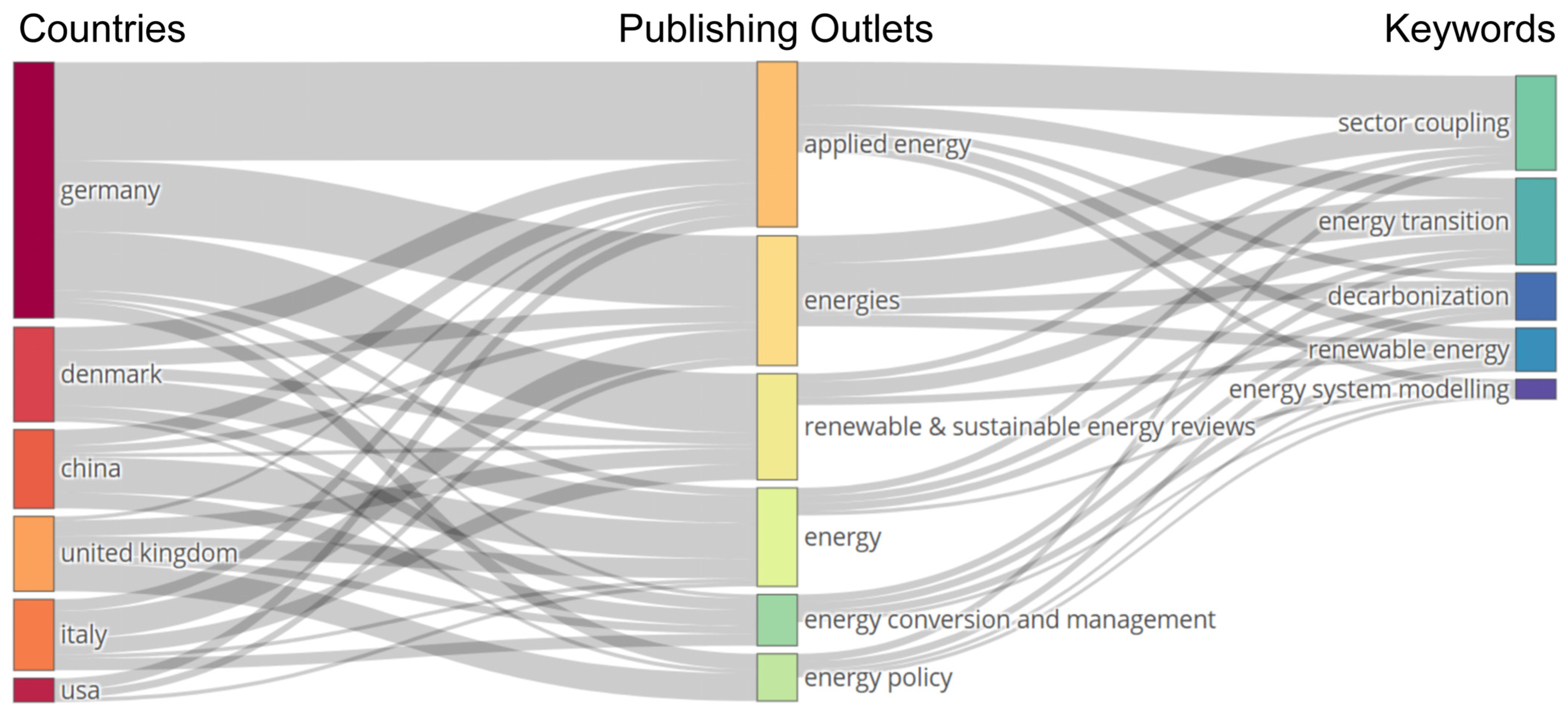

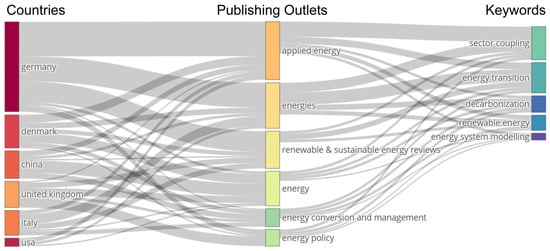

The interconnections between journals, countries, and research topics can provide useful insights. Therefore, this paper presents an innovative tripartite graph in Figure 2, which shows the interplay between countries (left), publishing outlets most relevant to SC and energy system modeling (middle), and keywords (right). We have observed that the majority of research on SC is predominantly published in two prominent energy journals, namely “Applied Energy” and “Energies”. Notably, these publications showcase a strong emphasis on European scholars, particularly those based in Germany. Overall, SC is a crucial step in the German energy transition.

Figure 2.

A three-fields-plot of countries, publishing outlets, and keywords most relevant to sector coupling technologies and models.

3. Technologies for Sector Coupling

3.1. Power-to-Heat (P2H)

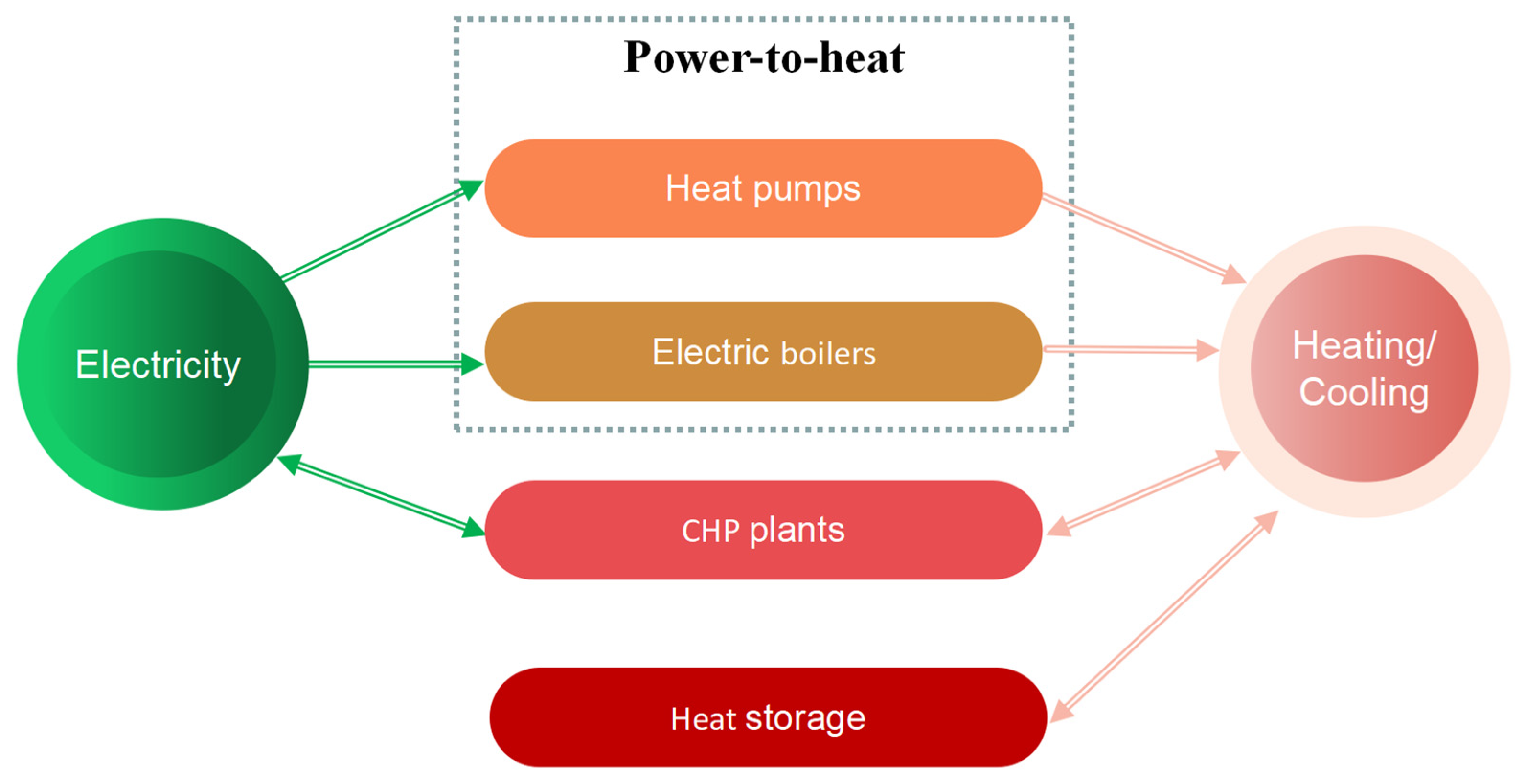

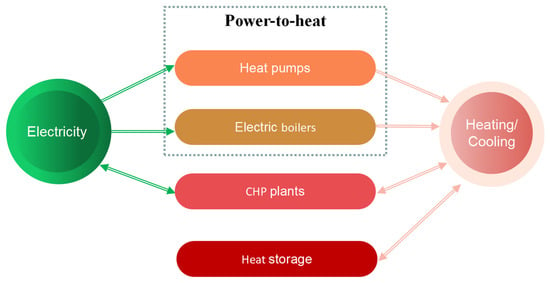

Power-to-heat involves the transformation of electricity to heat. This technology is utilized by both electric boilers (EBs) and heat pumps (HPs), as shown in Figure 3. Many household appliances, such as electric kettles and water heaters, also utilize the concept of P2H. Additionally, P2H is used for negative control energy supply, process heating, and district heating systems for water heating and space heating [17]. Conversely, the process of P2H conversion can also take the form of converting heat into electricity, such as by utilizing waste heat from gas-steam power plants [18]. In these cases, the waste heat generated during the gas power generation process is used to operate the steam power plant, which in turn converts the heat energy into electric energy.

Figure 3.

Schematic diagram of P2H.

A heat pump (HP) is a piece of equipment that utilizes the principles of the Carnot cycle and the reverse Carnot cycle to transfer heat and cold [18]. It consumes net reverse cycle work to generate heating energy, effectively utilizing low-grade thermal energy, which is otherwise difficult to utilize, thus achieving energy-saving purposes. The Coefficient of Performance (COP) is an important parameter for assessing the efficiency of a HP, as shown in Equation (1). For instance, the COP of a given air-cooling heat pump is 2. This equates to 2 kW of cooling power for every 1 kW of power utilized by the compressor of the pump.

A single heat pump system can replace two sets of devices, boilers and air conditioners, providing heating, cooling, and domestic hot water supply. The market currently offers two main types of heat pumps: geothermal (ground-source or water-source) heat pumps (GHPs) and air source heat pumps (ASHPs) [19]. Geothermal heat pumps (GHPs), also known as geo-exchange, earth-coupled, ground-source, and water-source heat pumps, have been utilized for decades. They have acquired significant acceptance in both residential and commercial structures. According to studies, roughly 70% of the energy consumed in a geothermal heat pump system is derived from renewable sources in the Earth, and the system is 45% more energy efficient than standard options, such as boilers and air source heat pumps (ASHPs), among others, although the exact efficiency improvement can vary depending on the specific type of standard equipment used [20]. ASHP operates on a well-established heat pump cycle, leveraging an electrically driven process to harness and upgrade low-temperature heat from the air to heat water. In this continual process, the key attribute of the ASHP is its efficient extraction of heat from the environment, accompanied by the generation of additional heat during refrigerant compression. This allows for a total heat gain in water that combines both the absorbed ambient heat and the heat created during compression [21,22]. ASHPs are particularly popular due to their environmentally friendly nature, flexibility, and energy-saving advantages. However, ASHPs are greatly affected by outdoor temperature in practical engineering applications, and heat pump systems do not operate efficiently, reliably, or stably when operating in low temperature environments.

An electric boiler (EB) is a boiler that uses electricity as its energy source and releases a heat-carrying medium, such as steam, hot water, or an organic heat carrier, via P2H. Electrode boilers, resistance boilers, and induction boilers are several varieties of EB that can be distinguished by their distinct operating principles.

The electrode boiler utilizes the high thermal resistance of water to convert electricity into heat energy. Therefore, the water used in the boiler needs to contain electrolytes to provide a certain level of resistance [23]. Additionally, it is necessary to control the conductivity within a reasonable range to prevent breakdown accidents. The heating element of the electrode boiler is typically an electrode rod or electrode plate made of stainless steel or graphite. Depending on the way the water flows and contacts the electrode, the electrode boiler can be divided into immersion type and spray type. In the immersion type, the electrode works by being fully submerged in water and directly in contact with the heating medium. In the spray type, the boiler water is directly sprayed onto the electrode for heating, and no insulation is required. The electrode boiler operates at a power supply voltage of 6–10 kV and requires high-voltage power distribution facilities. Maintenance conditions are relatively complex and require qualified personnel. The single unit power ranges from 0.3 MW to 50 MW, with commonly used power models above 10 MW. The boiler’s power can be adjusted infinitely between 1% and 100% based on the water flow or water level control. Due to the need for indirect heat exchange for external heating, the overall thermal efficiency is less than 90% [24].

The resistance boiler converts electrical energy into heat energy through resistance. The operation of the resistance boiler requires careful consideration of the relationship between voltage, current, and resistance. While greater resistance can generate more heat when the current is constant, for a fixed voltage, the power—defined by the formula P = V2/R—will decrease with increasing resistance. Therefore, the design and operational strategies of resistance boilers necessitate a careful calibration of these parameters to simultaneously accomplish the desired thermal output and sustain power efficiency at its zenith. The resistance component is made of stainless steel and is fully immersed in water during operation, isolated from the outside by insulating materials. The resistance boiler operates at a power supply voltage of 0.4 kV and requires high/low voltage transformation and distribution facilities, making it easy to maintain. The power output of a single unit typically ranges from 0.01 to 10 MW, with commonly used power ratings ranging from 2 to 10 MW, controlled by the number of resistance components [25]. Since there is no need for indirect heat exchange, the overall thermal efficiency can reach around 93% [22].

Induction boilers employ the electromagnetic induction principle, whereby metals within a magnetic field experience induced electromotive force, hence generating variable induced currents that ultimately raise the metal’s temperature. Fundamentally, the objective is to convert electrical energy into electromagnetic energy, which is then converted into thermal energy, representing a rapid heating technology that can reduce heating time by two-thirds compared to resistance boilers. With a heating efficiency of up to 95% and low maintenance costs, induction boilers are gaining popularity [26].

Installing a heat storage device transforms an electric boiler into a storage-type electric boiler, which is often classified into one of two groups. One group is water storage type, which is created by erecting a storage tank based on the three types of electric boilers discussed previously. When utilized on a broad scale, the power can reach several hundred megawatts. The second type of electric boiler is a solid or phase-change storage type that combines the heat storage device and the heating device. It has a high heat storage density, a small footprint, and can offer heating up to 400 °C [27].

3.2. Power-to-Gas (P2G)

Power-to-Gas (P2G) is a novel and environmentally friendly technology that converts electrical energy into natural gas through two steps. The first step is the electrolysis of water to obtain hydrogen, with oxygen as a byproduct, as shown in Equation (2). The produced hydrogen is mainly used for fuel cells and a small amount can be directly injected into the natural gas pipeline [28].

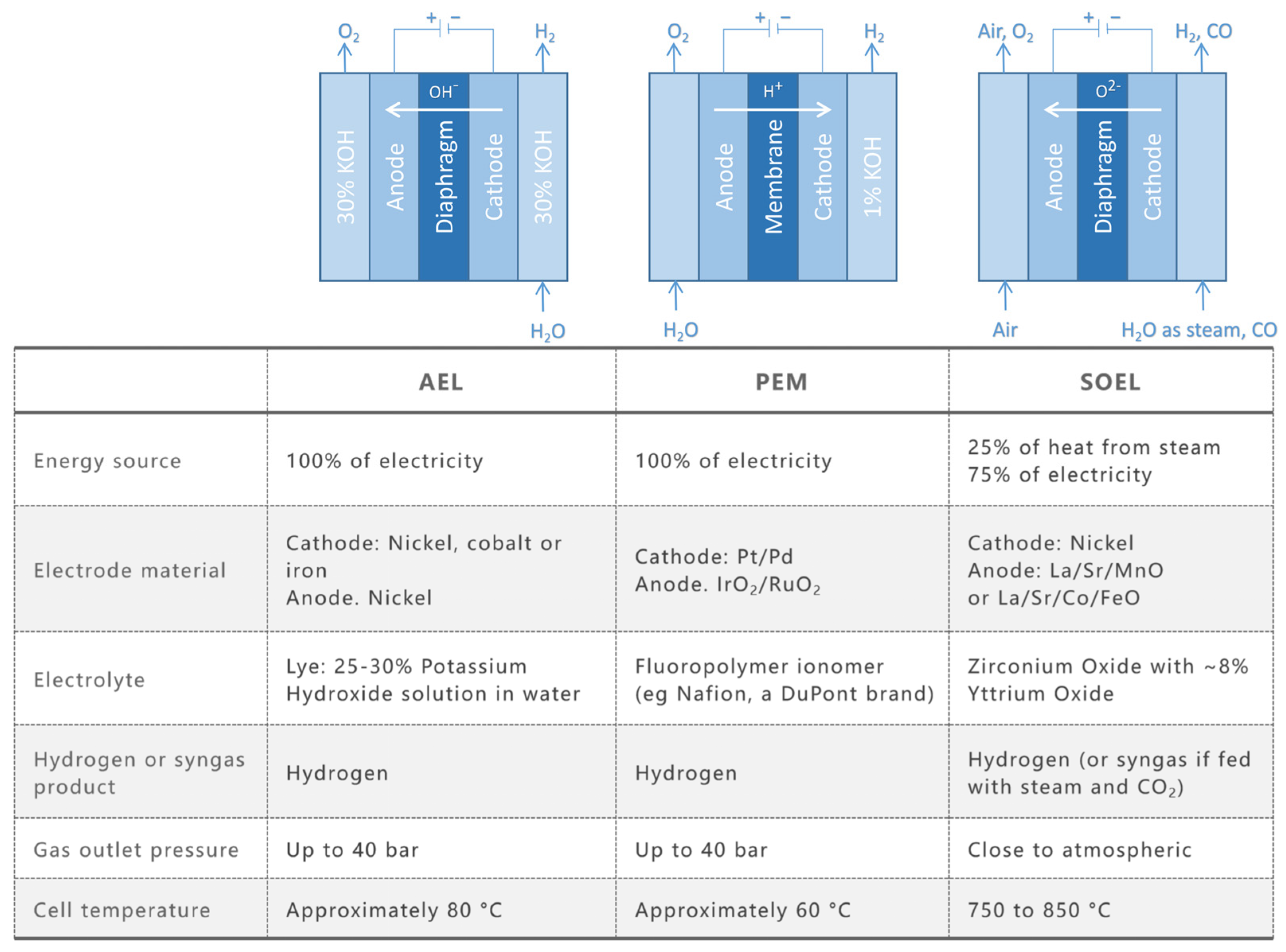

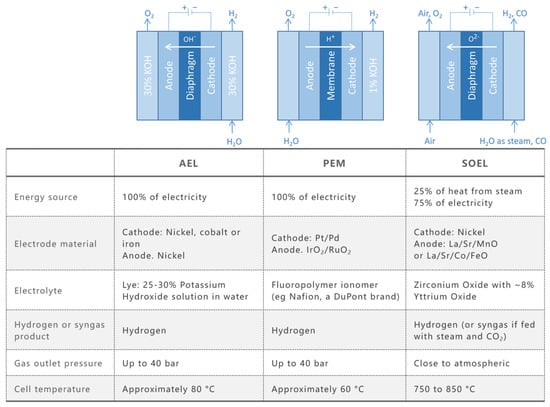

The first step in the electrolysis of water involves a reaction principle that is reasonably simple and requires fewer reaction conditions. There are now three primary types of electrolysis: alkaline electrolysis (AEL), polymer electrolyte membrane (PEM), and solid oxide electrolysis (SOEL). Their characteristics are shown in Figure 4.

Figure 4.

Characteristics of the three types of electrolytic water technology.

Alkaline electrolysis (AEL) is the most developed of the three electrolysis processes and has been commercially accessible for decades [29]. In an alkaline electrolyzer, the electrode is submerged in a liquid electrolyte. Typically, the electrolyte is a 25–30% KOH aqueous solution. Due to temperature differences and the buoyancy of product bubbles, product bubbles and heat are evacuated using a pump or natural circulation. The electrolyte is held in two distinct tanks, with each resultant gas (O2 and H2) serving as a gas-liquid separator, as well [30]. The typical current density for AEL is relatively low, generally in the range of 0.2–0.6 A cm−2 [31]. However, through catalytic gas purification, the quality of the dry product gas can be enhanced to greater than 99.999% for H2 and 99–99.8% for O2 [32,33,34,35,36].

General Electrics pioneered the introduction of Polymer Electrolyte Membrane or Proton Exchange Membrane (PEM) electrolysis in the 1960s, which is sometimes also referred to as Solid Polymer Electrolysis (SPE) [37]. PEM electrolyzers possess the remarkable ability to operate at significantly higher current densities, surpassing the 2 A cm−2 threshold. This characteristic reduces operational costs and has the potential to reduce overall electrolysis costs [38]. The maximum attainable current densities are limited by ohmic losses, but a thin membrane with superior proton conductivity (0.1 ± 0.02 S cm−1) enables the achievement of higher current densities [39]. The solid polymer membrane allows for a thinner electrolyte than that of alkaline electrolyzers, which is a crucial factor in achieving this notable characteristic.

In the 1980s, Dönitz and Erdle of the HotElly project at Dornier System GmbH were the pioneers in presenting their findings on the application of Solid Oxide Electrolysis (SOEL), utilizing a supported tubular electrolyte [40]. The remarkable ability of SOEL to convert electrical energy into chemical energy and achieve high efficiency in the production of hydrogen has generated significant interest in this technology since its inception. SOEL achieved 100% Faraday efficiency at a low voltage of 1.07 V, with current densities of 0.3 A cm−2 in single cells [41,42]. Westinghouse Electric Corporation Research and Development Centre has contributed significantly to the advancement of SOEL. Although SOEL is still in the developmental stage, research in this field has grown exponentially over the last decade. Interestingly, SOEL can be used for the electrolysis of CO2 to CO and the co-electrolysis of H2O/CO2 to H2/CO (syngas) due to the chemical flexibility and high operating temperature of these devices [43]. However, the long-term operation and high-temperature durability issues of ceramic materials need to be resolved to achieve the mass production of hydrogen using SOEL. The electrochemistry and structure of the materials must be thoroughly understood to overcome these limitations for future advancements in this field.

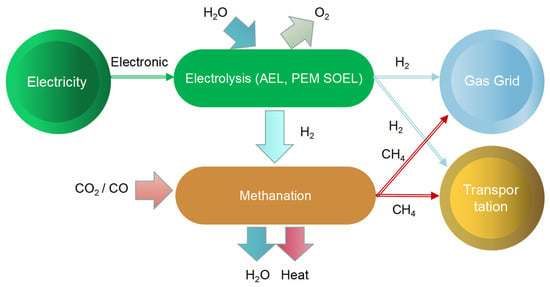

In the second step of the process, hydrogen undergoes methanation through a catalyst-mediated reaction with carbon dioxide, leading to the production of methane, as described by Equations (3)–(5). This synthesized methane can subsequently be incorporated as the principal constituent of natural gas through its mixing with other components of the natural gas pipeline.

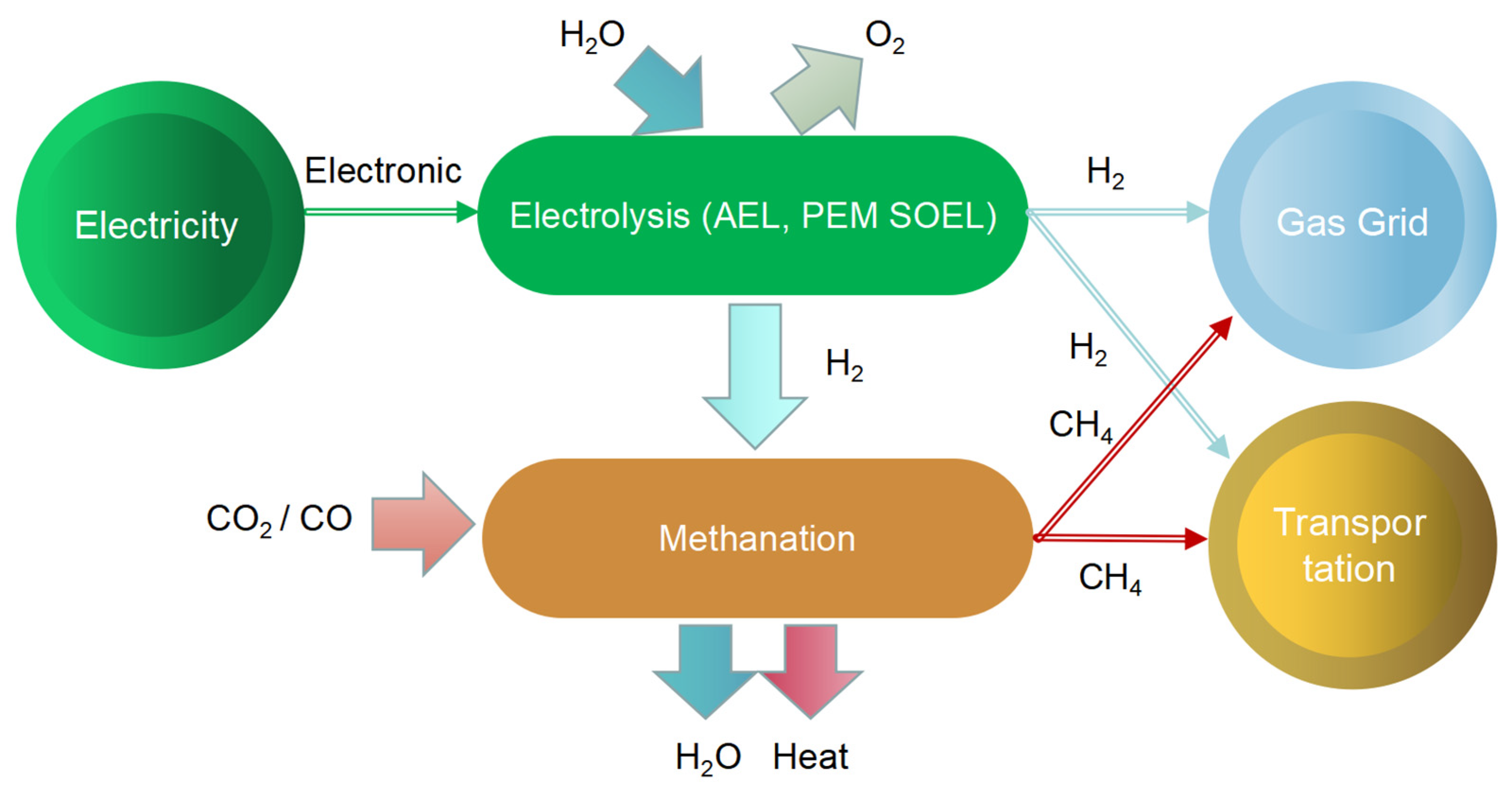

In the field of sustainable energy systems, P2G offers promising solutions for generating hydrogen or synthetic methane using excess electricity at low prices. As illustrated in Figure 5, the generated gas can be efficiently stored for subsequent conversion into electricity or utilized directly across various end-use sectors. Experimental P2G plants are predominantly located in Europe, with Germany and Denmark leading the field. Germany, in particular, is at the forefront of P2G research globally, with RWE, a major German power company, commissioning a P2G plant that utilized renewable energy to produce hydrogen, methane, and other gases in 2015 [44]. Another German company, E.ON, was the first to industrialize a P2G facility to inject hydrogen into natural gas pipelines [45].

Figure 5.

Schematic diagram of P2G.

3.3. Power-to-Liquids (e-Fuels)

The production of hydrogen and methane through the use of electricity is commonly known as P2G, while the production of liquid fuels through the same process is referred to as P2L.

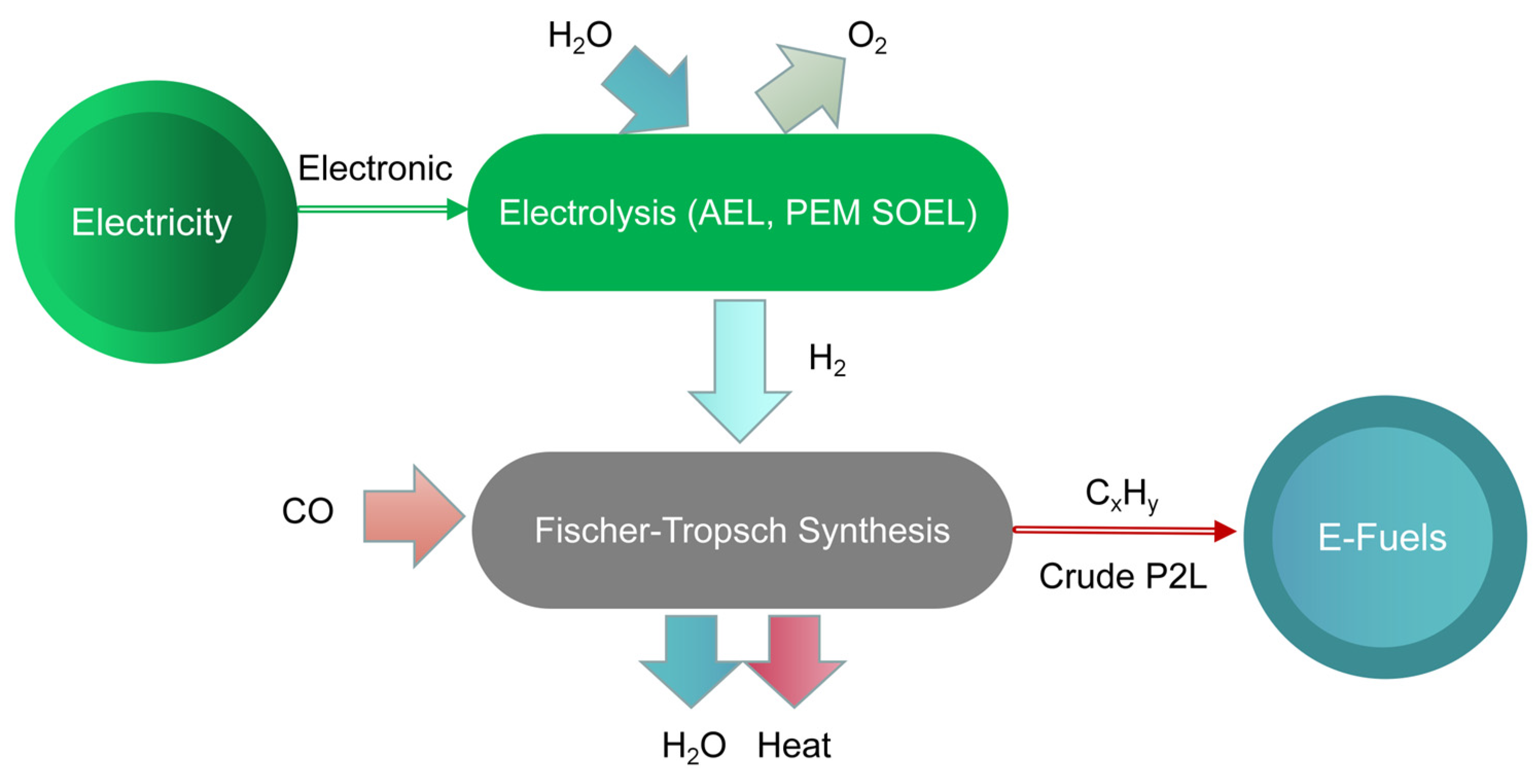

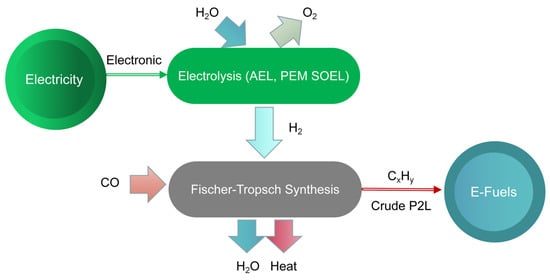

As shown in Figure 6, the production process of P2L consists of several key steps. Initially, an electrolyzer is employed to produce hydrogen, as specified in P2G Equation (2). Following this, the produced hydrogen is combined with CO2/CO. It is worth noting that CO2, which is typically a waste product of many industrial processes, plays a crucial role as a carbon source in P2L. Its integration with hydrogen facilitate the synthesis of hydrocarbons and their further conversion into specific end products. This approach effectively recycles CO2, turning it from waste into a valuable resource.

Figure 6.

Schematic diagram of P2L.

Synthesis methods include the Fischer–Tropsch process (Equation (6)) and methanol synthesis (Equation (7)), etc. As described by Equation (6), the process results in the production of branched hydrocarbons, olefins, and alcohols [46]. These synthetic hydrocarbons are subsequently refined and utilized as raw materials for a variety of chemicals such as motor fuels, plastics, and rubber [47]. These end products are known as electrofuels or e-fuels.

Methanol is a versatile chemical with widespread use in the synthesis of various compounds, including formaldehyde, methyl tert-butyl ether, gasoline, olefins, etc. Additionally, methanol can serve as a fuel source for methanol fuel cells.

The Fischer–Tropsch process results in a mixture of long-chain hydrocarbons that require further processing, whereas methanol synthesis produces high-purity products under mild conditions [48,49]. Energy efficiency decreases as the process moves from hydrogen to methane to liquid fuels. Other techniques for creating synthetic energy carriers, such as ammonia synthesis, are also conceivable. Additionally, hydrogen storage in Liquid Organic Hydrogen Carriers (LOHCs) is a possibility currently being demonstrated [50].

4. Applications of Sector Coupling Technologies

4.1. Direct Electrification Technologies for Industry

The present section provides a concise account of select electrification technologies that are pertinent to the industrial domain, such as heat pump technology and electric boiler technology in P2H, which offer diverse applications, as demonstrated in Table 1. Notably, the process of industrial electrification primarily concerns the substitution of electrically generated heat in lieu of combustion-generated heat. This distinguishes it from the electrification efforts undertaken in residential and commercial structures, given the necessity of accommodating a significantly broader temperature range and a wider range of potential technologies within the industrial sector.

Electric boilers have been recognized as an important opportunity for industrial electrification, with high thermal efficiency (above 99%), fast start-up times, and a low downtime [51]. They do not require on-site pollution control, combustion accessories such as water tanks and exhaust flues, or expensive combustion inspections [51]. Electric boilers can significantly increase the electrical load of industrial factories and can operate flexibly to take advantage of low-cost renewable energy sources [51,52]. However, their economic feasibility is affected by high electricity prices, compared to natural gas and other fuels [53]. Despite their lower capital cost than gas boilers, electric boilers may have fuel costs that are 2.5 to 3.7 times higher, which could offset some of the capital cost savings [53]. Additionally, the application, performance, and installation of boilers varies widely and energy efficiency reflects fuel type, combustion system limitations, equipment design, and steam system operational requirements [54]. The diversity of applications suggests the need for increased design requirements and greater expectations for service and customer support.

Table 1.

Electrification technologies for industry and their benefits and challenges [55,56,57,58].

Table 1.

Electrification technologies for industry and their benefits and challenges [55,56,57,58].

| Technology | Application | Benefits | Challenges | Status |

|---|---|---|---|---|

| Electric boiler | 100–150 °C Process heat, food, chemicals, plastics | Low CO2 when powered by renewable energy, less expensive/lower capital cost | Low efficiency with thermally produced electricity, higher energy costs on energy basis than natural gas | Commercial |

| Heat pump 90–160 °C | Sterilization, melting, reacting, processing | Efficient, convenient, avoid boiler house costs, fast response, safe, durable, low maintenance, cooling and heating options | Requires close proximity to heat source/load for highest efficiency, high electric supply needs, complexity | Experience limited, higher-temperature units emerging |

| Heat pump <90 °C | Drying/evaporation | Fast response, safety, durability, low maintenance, combined cooling/heating/dehumidification | Most efficient close to heat source, <7 °C heat quality varies, higher-capacity units need high power | Commercial |

| Direct arc melting | Steel and metal transformation of ores | High melt rates and pouring temperatures, excellent control of melt chemistry | - | - |

| Resistance heating | Primary metals, plastics, chemicals processing | Backup heat for heat pumps below 40 °C | - | - |

| Microwave, radiofrequency | Drying/evaporation, sterilization, melting, reacting, processing | Reduced drying times/ higher throughput, energy efficiency, uniform heating, targeted heating, compactness, increased reaction yields | Materials must be compatible, requires electrical capacity upgrades, payback can be longer | Commercial TRL 4–8 depending on application |

The industrial sector possesses considerable prospects for electrifying low-temperature operations through the utilization of heat pumps, which account for roughly 25% of the total industrial energy demand. Nevertheless, a portion of this low-temperature heat requirement is presently met by residual heat emanating from high-temperature heat procedures rather than dedicated heating technologies [59]. While heat pumps are currently being developed for high-temperature energy applications, they have yet to attain commercial viability. Nonetheless, high-temperature heat demand constitutes a significant 37% of the overall industrial energy demand, and can be met through the deployment of electric boilers to facilitate electrification [59]. Bamigbetan et al. have demonstrated both theoretically and experimentally that a cascade heat pump system using R290 and R600 as the low-temperature and high-temperature refrigerants, respectively, can produce heat of up to 120 °C with a boost of 90 °C [60]. Similarly, Bobelin et al. have shown that a high-temperature heat pump system utilizing ECO3TM as the refrigerant blend can provide hot water at 140 °C [61]. Chamoun et al. of the University of Lyon have designed a single-stage heat pump using water as the refrigerant, and experimentally verified its condensing temperature range of 130–145 °C [62]. Fleckl and Helminger et al. have demonstrated the feasibility of a high-temperature heat pump that can reach 150 °C using R1336mzz(Z) as the refrigerant, and further improved the system using an internal heat exchanger (IHX) [63]. The improved single-stage high-temperature heat pump system can achieve a heating temperature close to 160 °C, with a COP of 2.7 at a heating temperature of 156 °C. In Japan, the Super Heat Pump Energy Accumulation System (SHPES) project was launched in the 1980s, and the HEM-90A air-source heat pump system was developed by Kobe Steel Company, located at 2-4, Wakinohama-Kaigandori 2-chome, Chuo-ku, Kobe, Hyogo, Japan, in 2012 which can provide hot water at 90 °C with a COP of 2.8 [64]. Additionally, the company has also developed high-temperature heat pump systems with models SGH120 and SGH165, which can produce steam at 120 °C and 165 °C, respectively, with a COP of 2.5 when the heat source temperature is 70 °C. The system utilizes a semi-hermetic twin-screw compressor for stable operation [65]. The HeatUp project, located at the Norwegian University of Technology, endeavors to advance the development of high-temperature heat pumps that utilize natural working media such as R600, NH3, and water. The objective of the project was to achieve heat production temperatures exceeding 200 °C, which represents a significant technological breakthrough in this field [66]. To extend the utilization of high-temperature heat pumps in the industrial sector, researchers globally are striving to enhance the heat production temperature capabilities of these pumps. Despite ongoing theoretical and laboratory advancements, the industrialization of high-temperature heat pumps remains a distant objective, with substantial work remaining to be undertaken in this field.

Electric arc furnaces operate via the generation of an electric arc between the furnace chamber and the electrode, which generates sufficiently high temperatures to melt scrap metal [67]. This energy-efficient process facilitates the recycling of steel and other metal materials, including those that pose difficulties in other melting processes. Once melted, the metal is refined and cast into the required shape utilizing direct arc melting [68]. In the rubber industry, microwave technology has been utilized to enhance the vulcanization process, resulting in substantial improvements in vulcanization time and efficiency when combined with conventional heating and holding techniques. Microwave technology has also been applied in the semiconductor production process to etch, sputter, vaporize, and oxidize silicon wafers. Furthermore, the use of high-power microwave drying for drying 2–10 cm thick wooden panels has been shown to be effective in achieving fast drying speeds while preventing cracking and minimizing the deformation of the wood [69].

4.2. Coupling of Power to Transportation

The impending era of electrification and intelligence has instigated significant changes in the interpretation and expansion of vehicles. The conventional perception of vehicles as a mere mode of transportation has progressed towards the integration of intelligent terminals and vehicle-to-grid (V2G) energy storage systems, thereby facilitating a transformation in driving experience, maneuverability, and power level. Nonetheless, the current stage of electrification development poses a formidable challenge to the industry’s ultimate trend, given the integration of tens of thousands of components within vehicles.

The development of Battery Electric Vehicles (BEVs) is inseparable from the innovation of batteries, particularly traction battery technology, as the traction battery is the power source for the propulsion system of Electric Vehicles (EV) [70]. Upon the introduction of rechargeable lead-acid batteries, they were subsequently utilized in EVs. In the contemporary battery market, the emergence of various types of power batteries is attributed to the progression of battery technology. However, the specifications for traction batteries have remained relatively unaltered despite the adoption of novel technologies. Unlike starting, lighting, and ignition batteries, which are used intermittently, EV batteries require a steady and continuous supply of power to sustain the operation of the vehicle, making high energy capacity a critical requirement. Furthermore, high power density and high energy density are fundamental determinants of the quality of such batteries. At present, rechargeable batteries used in electric vehicles predominantly include lead-acid batteries, nickel-metal hydride (NiMH) batteries, and lithium-ion batteries. The usage of lead-acid and NiMH batteries has been prevalent in the electric vehicle industry over the past century. However, the current EV market is predominantly dominated by lithium-ion batteries [71]. Nevertheless, research and development activities are underway to explore promising alternative options such as aqueous or solid electrolyte batteries, Li-O2 batteries, Li-S batteries, and all-solid-state batteries, with the aim of potentially advancing them as the next generation of EV batteries. Table 2 presents a summary and comparison of EVs battery characteristics.

Table 2.

Summary and comparison of EVs battery characteristics [72,73,74,75,76].

A lead-acid battery consists of a negative plate made of metallic lead and a positive plate made of brown lead dioxide, both immersed in an electrolyte consisting of diluted sulfuric acid [77]. The lead-acid battery operates by storing electric energy, which can be converted from chemical energy to electrical energy. In the early 20th century, lead-acid batteries were extensively utilized for the purposes of starting, lighting, and ignition of internal combustion engine vehicles [78]. Although the initial investment cost of lead-acid batteries is comparatively low, their cycle life and specific energy are limited, leading to unsatisfactory cycling performance. Of particular concern is the issue of deep discharge, where lead-acid batteries risk irreversible capacity loss if discharged beyond a certain point. Furthermore, if lead-acid batteries are not handled appropriately, their toxic composition can potentially contaminate the soil [79]. As a result, lead-acid batteries are no longer a viable option for serving as the primary on-board energy storage device for contemporary EVs.

NiMH batteries have nickel hydroxide as the positive electrode, various materials as the negative electrode, and a solution of potassium hydroxide as the electrolyte [77]. Nickel batteries include nickel–iron (Ni-Fe), nickel–cadmium (Ni-Cd), nickel–zinc (Ni-Zn), nickel–hydrogen (Ni-H), and nickel–hydrogen (Ni-H2) batteries, among which nickel–hydrogen batteries have been the choice for electric vehicles since the 1990s [80,81,82]. NiMH batteries are a promising alternative to lead-acid batteries due to their higher energy density, which makes them well-suited for a variety of applications. However, they suffer from lower charging efficiency, higher self-discharge, and poor stability in high-temperature environments [83]. Additionally, patent issues have impeded the commercialization of NiMH batteries in heavy-duty vehicles, despite their continued success in specific applications such as start-stop mini-hybrid vehicles and temporary energy storage for train braking, ferries, and buses [82]. Although NiMH batteries have a lower gravitational energy density compared to Li-ion batteries, their high durability and long service life make them a viable option [84]. To address the energy density gap, researchers are exploring ways to improve NiMH battery technology, with over 10 million hybrid vehicles worldwide already using NiMH batteries for propulsion [85].

Since Sony commercialized the first lithium-ion batteries in 1991, these have become the dominant technology in energy storage and portable electronics markets, owing to their high-power storage capacity, compact form factor, and lightweight construction [86]. Lithium-ion batteries have distinguishing features that give them a competitive edge over other battery technologies. They deliver a high energy state of the battery during charge and discharge cycles, the process of which involves the movement of lithium ions between the cathode and anode through an electrolyte. The mass specific energy of lithium-ion batteries surpasses that of NiMH and lead-acid batteries by over two and four times, respectively [87]. Furthermore, their general operating voltage can exceed 4 V, significantly higher than NiMH and lead-acid batteries [88]. Another crucial advantage of lithium-ion batteries lies in their longevity and capacity for recharge cycles. They have the ability to undergo charging and discharging cycles more than 1200 times at an 80% Depth of Discharge (DOD), a feature which greatly outperforms other batteries [89]. Exhibiting a general average monthly self-discharge rate of 10% or less, lithium-ion batteries show significant superiority over nickel–cadmium and nickel–hydrogen batteries, with the latter discharging at a rate of over 20%. Despite these advantages, lithium-ion batteries present some challenges, such as their high internal resistance, large changes in operating voltage and recycling issues, and the risk of fire in case of battery malfunction or damage. In terms of fire risk, the development of precise detection algorithms for internal short circuits, state of charge, battery health, and capacity, as well as specialized automatic fire extinguishing systems tailored for LIBs, will be central to ensuring high safety levels for present and future LIB-based technologies [90,91,92,93,94]. Wolfgang strongly recommends a vertical integration of the battery value chain in Europe, starting with the extraction and refining of raw materials and introducing a circular battery economy through investments in recycling research and development and recovery capabilities [95].

4.3. Coupling of Power to Building

In 2021, building operations accounted for 30% of global final energy consumption and 27% of overall energy sector emissions (8% direct emissions in buildings and 19% indirect emissions from the production of electricity and heat for buildings) [96]. As previously discussed, the utilization of heat pump technology in P2H is expected to play a pivotal role in addressing the energy consumption challenges encountered by buildings.

The challenges associated with ASHP operation in low-temperature conditions have been subject to extensive investigation by numerous scholars. Such research endeavors have resulted in significant advancements towards enhancing the stability, heating efficiency, and COP of the heat pump units. The make-up cycle unit of the jet enthalpy technology exhibits remarkable performance, sustaining more than 78% of the nominal heating capacity at an ambient temperature of 25 °C. Notably, this heating capacity surpasses that of conventional inverter units by a notable margin, with an increment of 17% [97]. The transcritical CO2 cycle-based high-temperature heat pump technology has the potential to directly heat cold water with a temperature as low as 10 °C to over 90 °C, while effectively utilizing the temperature slip properties of CO2 in its supercritical state to ensure robust operation even in harsh environmental conditions, as low as −25 °C. The CO2 heat pump compressor exhibits up-frequency operation in low-temperature conditions, allowing for efficient heating output, meeting the heating requirements of colder regions, with an average COP of 2.236 [98,99]. A cascade cycle has been suggested to overcome the disadvantages of single-stage ASHP [100]. Bertsch and Groll conducted a comprehensive study involving the simulation, design, construction, and testing of a breadboard R410A air-source two-stage heat pump. The results demonstrated a COP of 2.1 at an ambient temperature of −30 °C [101]. Energy tower heat pump technology employs a subfreezing carrier medium during the heating season to extract heat from the air, effectively preventing frost formation. In the cooling season, it efficiently releases excess heat into the atmosphere. This technology is widely acknowledged as the optimal choice for energy-efficient, safe, and versatile heat pump systems operating in locations with external wet bulb temperatures below −9°C. Notably, it demonstrates a remarkable COP ranging from 3.0 to 3.5 in winter [102,103]. However, the operating characteristics of the heat source tower system and the mechanism of efficient heat absorption are still the core difficult problems of this technology.

According to the different heat exchange media, GHPs are generally divided into surface water source heat pumps, groundwater source heat pumps, and sewage source heat pumps. In recent years, surface water source heat pumps have experienced substantial growth, primarily attributed to their high efficiency, energy-saving capabilities, and eco-friendly attributes. Commonly used water sources are river water, lake water, and sea water near the city. Empirical tests have demonstrated a COP of approximately 3.28 for surface water source heat pumps in winter [104]. Surface water temperature is subject to significant fluctuations influenced by climate conditions, flow rates, and other factors, and these fluctuations directly impact the performance of surface water source heat pumps. Due to incomplete data on water temperature, these systems often rely on algorithms based on empirical values under design conditions. As a result, the study of surface water source heat pumps often involves predicting water temperature through either actual measurements or models. Wang and Wong proposed a numerical model for surface water source heat pump systems, which enabled the analysis of parameters such as intake temperature and energy-saving rates of the heat pump system and a comparison with experimental measurements [105]. The results of their study indicated that there was no significant reduction in energy-saving rate associated with a decrease in water delivery rate, while feeding water through multiple ports led to higher efficiency. To ensure stable water quality and flow rate, water extraction and water treatment should be tailored to the specific surface water source heat pump project [106].

The groundwater source heat pump is regarded as one of the most efficient and reliable heat pumps for heat production due to its relatively stable groundwater temperature. When properly maintained, ground source heat pumps are capable of achieving a COP of 5 at the start of the heating season, representing a 108% improvement over AHSPs [107]. Additionally, ground source heat pumps can yield significant cost savings of 70% to 80% compared to direct electric heating. Extraction wells, re-injection wells or surface water systems are the main components of groundwater source heat pumps. The modified version of the extraction well system, known as the standpipe well system, minimizes the need for re-injection wells and surface water discharge by re-injecting most of the return water into the source well [108]. Groundwater source heat pump systems present unique challenges that must be considered in their design and operation. One major challenge is the potential for fouling, corrosion, and blockage in the primary heat exchanger that transfers heat between the refrigerant and the groundwater. The second major challenge is the limitation on groundwater extraction due to the required flow rate through the primary heat exchanger, typically ranging from 0.027 to 0.054 L/s-kW, which may be further constrained by local water regulations [109]. The third major challenge is the absence of a complete rational evaluation system for assessing the suitability of groundwater source heat pumps in terms of zoning, the placement of heat source wells, and the negative environmental effects of pumping and irrigation. Additionally, the selection of evaluation indicators is not relevant.

The sewage source heat pump Is characterized by a more stable heat source temperature throughout the year and offers several advantages over the traditional air source heat pump. Specifically, the sewage source heat pump outperforms traditional ASHP with a 40% higher COP, while boasting an operating cost that is only 50% to 60% of that associated with central air conditioning [110]. In addition, the sewage source heat pump eliminates the need to consider drilling wells, recharging, or evaporator frost problems, making it a highly attractive option for economic, energy-saving, and environmentally friendly heating and cooling. However, the most critical challenges facing sewage source heat pump systems include clogging, scaling, and corrosion, with the quality of sewage being a key factor affecting system performance. Two types of systems are commonly used in engineering, namely, heat pump systems with pre-filtering devices and heat pump systems based on evacuated heat transfer, both of which have technical difficulties that need to be addressed. The fluidized bed process, which involves removing soft scale from the wastewater source heat pump system, may be an effective solution to this problem [111].

5. Roles of Hydrogen in Sector Coupling

The June 2020 national strategic plan for hydrogen energy in Germany set a target of reaching a domestic electrolyzer capacity of 5 million kW by 2030 and 10 million kW by 2040 [112]. However, the coalition agreement signed by the German government in December 2021 revised the 2030 target to 10 million kW of electrolyzer capacity, which doubled the original goal [113]. Hydrogen demand in Germany is expected to be 64 to 110 billion kWh in 2030 and 392 to 657 billion kWh in 2045 [114]. It is estimated that German domestic capacity will only be able to meet approximately 15% of the demand by 2030. By 2050, the production of hydrogen is predicted to consume about a quarter of the EU’s renewable electricity. As an essential component of an integrated energy system, hydrogen and P2X will continue to gain importance.

To efficiently develop the hydrogen economy globally, renewable hydrogen, which is more expensive, should mainly be utilized in industries that cannot be directly electrified. Beyond electrolysis, alternative methods of producing green hydrogen are also being extensively explored [115]. For instance, recent research has discussed the potential of the aqueous phase reforming process in treating and valorizing carbon-laden industrial wastewater. This process, capable of converting oxygenated molecules into hydrogen under relatively mild conditions, is seen as a promising avenue for the development of a circular, low-waste economy, although challenges remain in fully realizing this process at an industrial scale [116]. Xie presented a novel method for direct seawater electrolysis for hydrogen production, effectively addressing the issues of electrode side reactions and corrosion triggered by seawater’s complex components. The authors successfully operated this system, demonstrating its high potential for practical applications, and enabling efficient and flexible seawater electrolysis with prospective applications in one-step water-based effluent treatment, resource recovery, and hydrogen production [117]. Despite years of research by public stakeholders in industry, science, and other relevant sectors, there are only five application areas currently considered safe for the use of hydrogen energy and P2X: the chemical industry, steel production, vehicles, maritime transport, and air transport.

5.1. Hydrogen in the Chemical Industry

Hydrogen serves as a crucial feedstock rather than a source of energy in the chemical industry, where it is utilized for the production of basic materials like industrial gases, fertilizers, and petrochemicals, and their derivatives [118]. In addition, as described in the previous sections, renewable hydrogen can be converted into various products via diverse processes, such as methanol and Fischer–Tropsch production followed by refining, yielding conventional transportation fuels. It is noteworthy that methanol is an essential precursor for the production of synthetic resins, with a worldwide production that represents 25% of total methanol production [119]. Although most basic chemicals and petrochemicals rely on carbon, ammonia production relies on nitrogen, where hydrogen energy serves as the input. Recent research explores its potential as a zero-carbon fuel, particularly in the shipping industry and stationary power generation [120,121,122,123]. In addition, the advantage that ammonia does not require carbon dioxide in the production process offsets its high toxicity and the danger it poses to the aquatic environment [124]. Germany is set to construct its first ammonia import terminal at Brunsbüttel, with RWE planning to import 300,000 tons of green ammonia annually to produce nitrogen fertilizers and mineral oil products at the River Elbe port [125].

5.2. Hydrogen in the Steel Industry

In 2022, German produced 32.1 million tons of crude steel, of which 70% were produced using blast furnaces and converters and the remaining 30% using electric arc furnaces [126]. As a result, direct CO2 emissions from the steel industry were approximately 43.7 million tons in the same year. The steel industry’s potential for reducing carbon emissions can be realized through three different approaches [127,128,129,130]:

- Substituting fossil fuels like coal and natural gas with hydrogen in the deep processing of crude steel.

- Increasing the share of electric arc furnaces that use renewable energy for steel production, which requires the use of climate-neutral hydrogen in the natural gas burners of electric arc furnaces in the long term.

- Direct reduction utilizing green hydrogen and transitional hydrogen-rich fuels (such as natural gas), coupled with a move to primary steel production with carbon capture, utilization, and storage (CCUS) technology. Compared to the blast furnace pathway, the all-green hydrogen model has a 95% greater potential for CO2 reduction.

As per recent estimations, the European steel industry may experience a significant upsurge in hydrogen demand, with projections indicating an increase to 45 billion kWh by 2030 and to 123 billion kWh by 2050 [131]. However, in order to encourage the steel industry to invest in low carbon steel production, there is a need for targeted market projections, which can help to develop sales markets for green steel. The establishment of standards and product labeling are also critical prerequisites in the development of a sales market for green steel [132].

5.3. Hydrogen in Vehicles

A conventional internal combustion engine can lead to bulky and inefficient vehicles. In contrast, fuel cell electric vehicles (FCEVs) are powered by hydrogen, which convert energy into electricity more efficiently, and have only water as a byproduct. Hydrogen fuel cells are two to three times more efficient than internal combustion engines, making them a promising technology for the future of the transportation sector. FCEVs have the potential to reduce greenhouse gas emissions by 46.6% compared to conventional vehicles (CVs) [133]. However, a major obstacle to the large-scale use of hydrogen in the transportation sector is how to store it more efficiently. Due to its low density, hydrogen needs to be compressed and cooled for storage and cannot be stored as easily as conventional fossil fuels. Physically sealed storage methods, such as compression tanks, are the most favorable for storing hydrogen, primarily using all composite materials (Type IV) and sometimes metal-lined composites (Type III) [134]. The Toyota Mirai, as one of the first commercially sold FCEVs, distinguished itself in August 2021 when its second-generation model achieved a world record by travelling 1,360 km on a single fill of 5.65 kg of hydrogen [135]. FCEVs augmented by hydrogen refueling stations are expected to break the mileage limits of conventional battery-driven vehicles due to their high thermal efficiency in practical applications [136].

5.4. Hydrogen in Maritime Transportation

Maritime transportation is the linchpin of global trade, facilitating more than 80% of global freight transportation [137]. To reduce shipping emissions by 50% by 2050 compared to 2008, the International Maritime Organization (IMO) has set a target under its 2019 greenhouse gas strategy [138]. The majority of maritime vessels currently rely on single-fuel diesel engines, burning low-sulfur fuel oil and gas oil, and this technology is also employed in most new ship orders. Although liquefied natural gas (LNG) is the only commercially available alternative fuel and can potentially reduce CO2 emissions by up to 25%, it is viewed as a transition fuel due to its limited potential to lower greenhouse gas emissions and the high risk of incomplete methane combustion emissions [139]. High energy fuels (HEFs) are being considered as the most viable option for decarbonizing shipping in this century. Presently, synthetic methane or liquid Fischer–Tropsch fuels can be used as alternative fuels in dual-fuel marine engines, and methanol-fueled engines are already available on the market, with new ammonia-fueled engines under development, and fuel cells offer the possibility of using hydrogen energy directly. However, HEFs are not yet commercially available and cannot compete with fossil fuels. The selection of a suitable winner from among the various alternative fuels remains challenging, given the factors to consider, including fuel availability, infrastructure and storage, technology maturity, energy density, price, and environmental friendliness. The future of marine fuel is highly uncertain due to the typical service life of vessels of twenty to thirty years and the high cost of retrofitting ship fuel systems. This uncertainty inhibits investment because of the risk of stranded assets [140].

5.5. Hydrogen in Air Transportation

Civil aviation is actively exploring alternative fuels, with hydrogen and e-Kerosene emerging as two promising options [141]. E-Kerosene, a ready-to-use fuel produced by reacting green hydrogen with CO2 from Direct Air Capture (DAC) technologies, produces 90% fewer greenhouse gas emissions over its life cycle than fossil jet fuel A/A-1. Additionally, e-Kerosene’s lack of sulfur and lower NOx emissions from combustion compared to fossil jet fuels help to mitigate the non-CO2 effect [142]. Nevertheless, when accounting for non-CO2 effects, e-Kerosene’s greenhouse effect reduction compared to fossil jet fuel A/A-1 is approximately 50% [142]. The utilization of green hydrogen as a direct final energy carrier could potentially achieve 100% reduction in CO2 emissions from fuel combustion. Despite uncertainties about the feasibility of direct hydrogen use as an end-use energy carrier in commercial aviation, Airbus has announced plans to launch a long-range hydrogen-powered aircraft in 2035 [143]. However, differing opinions on the role of hydrogen in aviation have been voiced, with the CEO of Boeing stating that it will not play a major role until 2050 [144]. The commercial viability of these alternative fuels depends on factors such as infrastructure, technology maturity, cost, and environmental impact, and further research and development efforts are required to address these challenges.

6. Sector Coupling Models

This section presents a review of 27 energy models that are designed to analyze renewable energy-based sector coupling. These models are freely available under open-source licenses and cover a range of sectors, including electricity, thermal, natural gas, hydrogen, end-use, and transportation. The main objective of these models is to facilitate future research on modeling approaches that can integrate complex energy supply scenarios and enable the modeling of all forms of energy in an integrated manner. Additionally, these models can generate, store, and convert energy as needed, allowing for the evaluation of potential transition pathways towards climate neutrality. A detailed breakdown of each energy model, including commodity, demand sector, purpose, methodology, temporal resolution, geographic resolution, and processing software, can be found in Table 3. These data can assist the modeler in the process of identifying and selecting an appropriate model.

AnyMOD is a Julia package for creating energy system models that can be used to investigate the long-term developments of macro-energy systems [145]. It implements a novel graph-based method that varies the level of temporal and spatial detail by energy carrier to keep models with high resolution computationally tractable. The framework supports version-controlled model development to promote collaboration and transparency, and it is easy to use but difficult to master.

Balmorel is a local equilibrium energy system optimization model that utilizes a bottom-up approach and primarily focuses on the electricity and district heating sectors [146]. Its adaptability allows for its application in both long-term planning and shorter-term operational analysis. The Balmorel model is written in GAMS, which provides complete visibility of the modeling intricacies and supports any necessary user modifications to the model code. The model’s principal benefit is its flexibility in terms of temporal and spatial convergence, as well as in terms of the depiction of technical and policy measures, rendering it advantageous when contributing to the analysis of upcoming energy challenges.

Calliope is a framework that allows for the building of energy system models with high spatial and temporal resolution, which can analyze systems ranging from urban districts to entire continents [147]. It employs YAML and CSV files to specify technologies, locations, links, and other constraints, and formulates an optimization problem to solve, generating results in the form of xarray datasets that can be stored as NetCDF files. Calliope’s design separates the general framework from the problem-specific model, and it offers both a command-line interface and an API for programmatic usage. Calliope has been utilized in multiple studies and ongoing research projects, including examining the effects of increased resilience to uncertain future demand and the interaction between local and national stakeholders in the energy transition. The framework has been openly developed on GitHub and archived on Zenodo. Overall, Calliope provides a potent tool for the analysis and optimization of energy systems.

CapacityExpansion is a Julia-based modeling framework designed to be both flexible and extensible, enabling the development of a capacity expansion model that can address a wide range of research questions [148]. The framework allows for the integration of various input data, such as geographical, cost, technology, and time-series data, and its modular setup and optimization facilitate its use in various applications. Additionally, an interface is provided for the further analysis of the optimization results. Examples of models that use this framework include the National Energy Modeling System (NEMS), Integrated Planning Model (IPM), Aurora, etc. These models are capable of examining the effects of electricity sector policies or alternative technology on the generation and capacity mix over the mid to long term. However, these models have limitations such as the lack of chronological unit commitment, the use of plant models for dispatch, and a stylized representation of transmission and power flow.

The DESSTINEE model is a simulation model developed to study the European energy system in 2050, with a focus on the electricity sector [149]. Its primary objective is to evaluate the technical requirements for energy services, supply, and transmission, as well as the economic feasibility of developing the necessary infrastructure. With coverage of 40 European countries and 10 different forms of primary and secondary energy sources, the model offers a wide scope for analysis. The predictive simulation technique used in the model allows users to input relevant data and assumptions, from which the model calculates a set of solutions. The DESSTINEE model was developed as part of the Grand Challenge project and is currently available as a set of Excel spreadsheets.

The Dispa-SET model was created to tackle the unit commitment problem and provide a short-term operating plan for large-scale power systems [150]. To achieve this, the model employs binary variables to signify the start-up and shut-down decisions for generation units, and continuously allocates total power demand among available generation units to minimize overall system costs. To ensure fast solving, the model is expressed as a Mixed-Integer Linear Program (MILP) and features a compact formulation designed specifically for large, interconnected power systems. The open-source nature of the model, which can be easily modified by users with limited programming knowledge, enhances its transparency, reproducibility, and visibility.

The ELMOD family encompasses a series of spatial optimization models that employ a bottom-up approach to find the cost-minimizing or welfare-maximizing dispatch of the European electricity sector, taking into account technical characteristics of generation units and flows in the high-voltage transmission network [151]. These models have versatile applications, such as market design, congestion management, and investments in electricity infrastructures. The ELMOD family was developed in 2006 and has been extended, updated, and implemented at DIW Berlin and TU Berlin. The family comprises four models, namely the original ELMOD for Europe, ELMOD-DE for Germany, stELMOD, a stochastic multi-market model with rolling planning, and dynELMOD, a multi-period investment model projecting up to 2050. The models differ in their level of detail and scope, and all require the use of GAMS.

Ficus is a MILP model that has been specifically designed to optimize a multi-commodity energy system for a factory [152]. The model’s primary objective is to determine the most cost-effective energy system that can meet the energy demands of various commodities, such as electricity and heat, based on the given demand time-series. Ficus considers the time-series cost of external commodities and peak demand charges with a configurable timebase for each commodity. Additionally, ficus allows for the deactivation of specific equations, which transforms the model into a linear programming model without integer variables. The model supports multiple-input and multiple-output energy conversion technologies with load-dependent efficiencies. The model’s capabilities enable factories to optimize their energy usage and reduce costs, making it a valuable tool for capacity expansion planning and unit commitment in local energy systems.

FlexiGIS is a tool that is designed to promote flexibility in Geographic Information Systems (GIS) [153]. One of its notable features is its ability to extract, filter, and classify geo-referenced energy infrastructure in urban areas. This capability is achieved by simulating local electricity consumption and power generation from renewable energy sources, and allocating the necessary decentralized energy storage in urban settings. Additionally, the program is able to systematically evaluate various self-consumption scenarios and analyze the characteristics and benefits of flexibility technologies in promoting higher autarky levels in cities. It should be noted that the urban energy infrastructure extracted is largely based on data from OpenStreetMap.

LEAP 2020 is software for energy policy analysis and climate change mitigation assessment developed by the Stockholm Environment Institute [154]. Its flexible and user-friendly features have made it a widely adopted tool by various stakeholders, including government agencies, academics, non-governmental organizations, consulting companies, and energy utilities across 190 countries globally. The platform’s versatility enables it to track energy consumption, production, and resource extraction in all sectors of an economy, including both energy and non-energy sector greenhouse gas emissions and local/regional air pollutants and short-lived climate pollutants (SLCPs). LEAP supports various modeling methodologies, and it is utilized at various scales ranging from cities and states to national, regional, and global applications. LEAP’s ease of use, especially in developing countries, has enabled the creation of energy and emissions scenarios, which serve as a basis for their reporting to the United Nations Framework Convention on Climate Change (UNFCCC). LEAP’s low initial data requirements compared to other modeling tools have made it an attractive option for scenario analysis and policy evaluation.

LUSYM is a state-of-the-art MILP for a deterministic security-constrained unit commitment model [155]. Its formulation is both concise and rigorous, incorporating a diverse range of constraints such as power plant limitations, renewable curtailment, flexible load, storage units, transmission grid constraints, spinning reserve constraints, and planned outage scheduling modules. The model is programmed in Gams and solved using the latest releases of either Cplex or Gurobi MIP solver. LUSYM’s efficacy has been validated by benchmarking simulations, which illustrate that it is comparable in terms of optimality and run time to current commercial unit commitment models, while also being able to accurately replicate historically recorded generation data.

MEDEAS is a tool designed to assist policy makers in achieving a low-carbon and sustainable energy system by 2050 through comprehensive eight-work packages [156]. The work packages comprise management and coordination, data collection, the exploration of various scenarios and pathways, the construction and implementation of the MEDEAS model, the cross-comparison of models, the evaluation of the model’s results, the analysis of environmental and technological impacts, policy analysis, and the dissemination of results. The project aims to achieve efficient management, identify data requirements, simulate different scenarios and temporal evolutions, construct and evaluate the MEDEAS model, and analyze and implement policies. The MEDEAS model focuses on selected case studies and scenarios, simulating various pathways for the EU’s future economic development under different energy systems while conducting sensitivity analyses for energy return on energy investment (EROI) under different scenarios. The policy analysis will investigate the effectiveness of top-down and bottom-up strategies to reduce emissions by 2050. The project plans to disseminate its findings to increase visibility and impact at the national and international levels.

The open energy modeling framework (oemof) is a suite of open-source Python libraries that enable energy system modeling [157]. These libraries have been leveraged to develop various tools, including Multi-Vector Simulator (MVS), Model Template for Residential Energy Supply Systems (MTRESS), Offgridders, Wärmetool, renpassGIS, and Spreadsheet Energy System Model Generator (SESMG), to facilitate energy system design and optimization. The primary goal of these tools is to simplify the modeling process and enable users to assess the economic and environmental performance of various energy supply options. Each tool has its unique characteristics, such as the ability to evaluate local sector-coupled energy systems, optimize and evaluate local electricity systems, and facilitate stakeholder comparisons of different heating technologies.

The OSeMOSYS model was developed to address the limited availability of energy planning tools to researchers and energy planners in developing countries [158]. Existing models often require significant investment in terms of resources, training, and software purchases. OSeMOSYS offers a comprehensive optimization model for long-term energy planning that requires less time and has a smaller learning curve than established energy system models. This makes it accessible to a wide range of stakeholders in the energy market, including students, government specialists, and researchers in developing countries, without the need for upfront financial investment. Developing human capacity in energy modeling is crucial for countries experiencing rising emissions, resource consumption, and energy service demand. OSeMOSYS is a valuable tool for experienced energy researchers to conduct sophisticated analyses and obtain insights.

Pandapower is a novel open-source network calculation program used for power systems analysis [159]. The tool aims to bridge the gap between commercial and open-source power systems analysis tools by leveraging the functionalities of two widely used libraries: pandas and PYPOWER. Pandapower provides an extensive power system model library, improved power flow solver, and other power systems analysis functions. It is designed to enable the automation of analysis and optimization in power systems, with a specific focus on the static analysis of three-phase power systems. By offering features that are typically available only in commercial power system analysis tools, such as user-friendly interfaces and detailed model libraries, pandapower facilitates the development of sophisticated analyses and optimization. However, the tool’s inability to analyze unsymmetrical power lines common in North American feeder designs remains a limitation.

PowerGAMA is a simulation tool that enables the high-level analysis of renewable energy integration in large power systems [160]. It optimizes the generation dispatch based on marginal costs and takes into account the variable power availability of solar, hydro, and wind generators, as well as the variability of demand. The tool employs a flow-based approach, which determines the power flow in the AC grid using physical power flow equations. PowerGAMA also considers the use of energy storage by generators with energy storage, such as hydro power and concentrated solar power. However, the tool does not include power market intricacies, leading to an overestimation of the ability to accommodate significant amounts of variable renewable energy. Despite this simplification of the real power system, PowerGAMA has proved useful in guiding grid development planning and evaluating the impacts of new generation and interconnections.

PowerNet is an optimization model that simulates Unit Commitment and Economic Dispatch in large-scale power systems [161]. The model represents a power system as a set of nodes, including power plants, substations, and import/export stations. PowerNet employs a Direct Current (DC) network with N-1 criterion to calculate power flow, balancing modeling accuracy with data and computational requirements. Additionally, PowerNet can incorporate information about variable renewable resources, including hydro, wind, and solar power, into the UC/ED process. The model also accounts for the impact of droughts on the generation of dispatchable thermal units, which are dependent on freshwater availability. These distinctive features of PowerNet make it suitable for tackling problems in the water–energy nexus domain that investigate the impact of water availability on electricity supply and demand.

PyPSA is a tool designed to model energy systems’ operation and optimal investment over multiple time periods [162]. It was developed by the Frankfurt Institute for Advanced Studies and provides models for the unit commitment of conventional and renewable generators, storage units, and all combinations of direct and alternating current electricity networks. PyPSA is also capable of coupling electricity to other energy sectors such as gas, heating, and transport. Moreover, PyPSA is licensed under the GNU General Public License Version 3, allowing users to inspect, use and modify the code. PyPSA has already been widely used by more than a dozen research institutes and companies worldwide and has been expanded to be used in grid planning tools.

REopt is a versatile energy planning tool that enables clients to achieve their energy performance goals and cost savings targets by optimizing the integration of multiple technologies [163]. It employs an integrated approach to minimize energy costs by considering various factors, such as electricity and thermal consumption, resource availability, complex tariff structures, incentives, and interconnection limits. Using a mixed integer linear program, REopt recommends an optimal mix of conventional and renewable energy sources, as well as energy storage technologies, and provides a cost-optimal dispatch strategy for operating them at maximum economic efficiency. The tool can be customized to address a range of energy optimization scenarios, including policy, microgrid, and operational energy applications. Throughout the energy planning process, from agency-level screening and macro planning to project development and energy asset operation, the platform provides techno-economic decision support analysis.

RETScreen is a publicly available software tool that enables users to assess the economic viability of renewable energy and energy-efficient technologies [164]. The software facilitates the comparison of a “proposed case” with a “base case” to determine the economic balance between the costs and savings associated with the technologies under consideration. RETScreen can analyze project feasibility over a 50-year time horizon with monthly or yearly time-steps, thereby accommodating individual projects or global-scale analyses. The software has been applied to a range of renewable energy projects worldwide, including solar water heating in Lebanon, solar PV in Egypt, and wind farm development in Algeria. RETScreen’s five-step analysis includes energy, cost, greenhouse gas analysis, financial summary, and sensitivity and risk analysis, with applicability across all energy sectors except transport.

SAM is a versatile and freely available software tool that has been developed to facilitate informed decision-making within the renewable energy industry [165]. Specifically, SAM offers financial modeling support for a range of renewable energy applications, including both residential and commercial projects that feature on-site renewable energy systems, as well as power purchase agreement projects that generate revenue by feeding energy back into the grid. As such, SAM can be leveraged by diverse stakeholders seeking to assess the financial and technical feasibility of various renewable energy initiatives.