Carbon Peak Scenario Simulation of Manufacturing Carbon Emissions in Northeast China: Perspective of Structure Optimization

Abstract

1. Introduction

2. Literature Review and Research Hypothesis

2.1. Literature Review

2.1.1. Research on the Impact of Structure Optimization on Carbon Emissions

2.1.2. Prediction and Simulation Research of Carbon Emissions

2.2. Research Hypothesis

2.2.1. The Performance of Manufacturing Structure Optimization on Carbon Emission Reduction

2.2.2. Manufacturing Carbon Emission Reduction Performance under Various Scenarios

3. Materials and Methods

3.1. Methods

3.1.1. Spatial Econometric Model

3.1.2. Machine Learning Models

3.2. Variable Selection

3.2.1. Explained Variable

3.2.2. Core Explanatory Variables

3.2.3. Control Variables

3.3. Data Sources

4. Results

4.1. Empirical Analysis of the Impact of Manufacturing Structure Optimization on Carbon Emissions

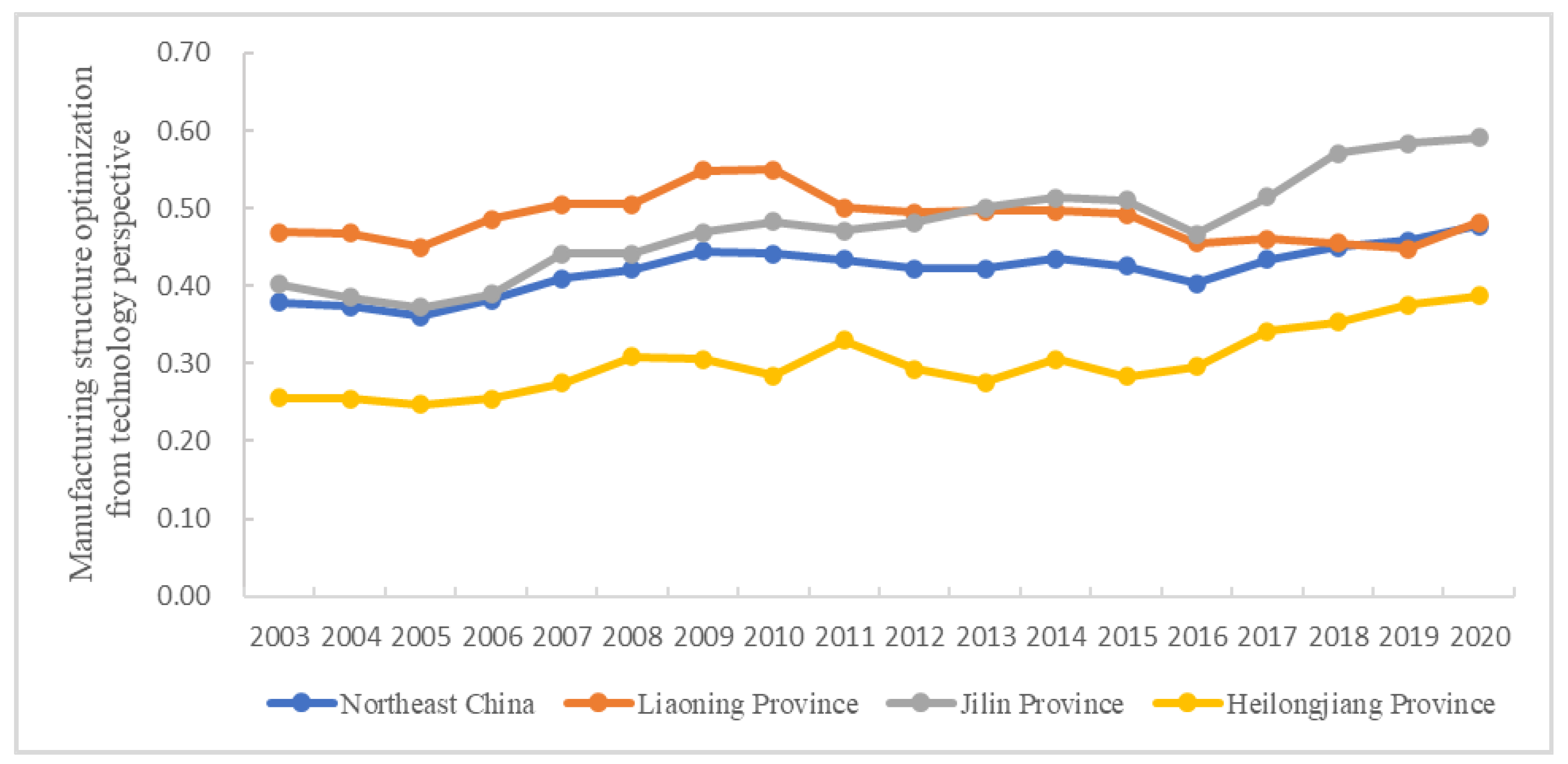

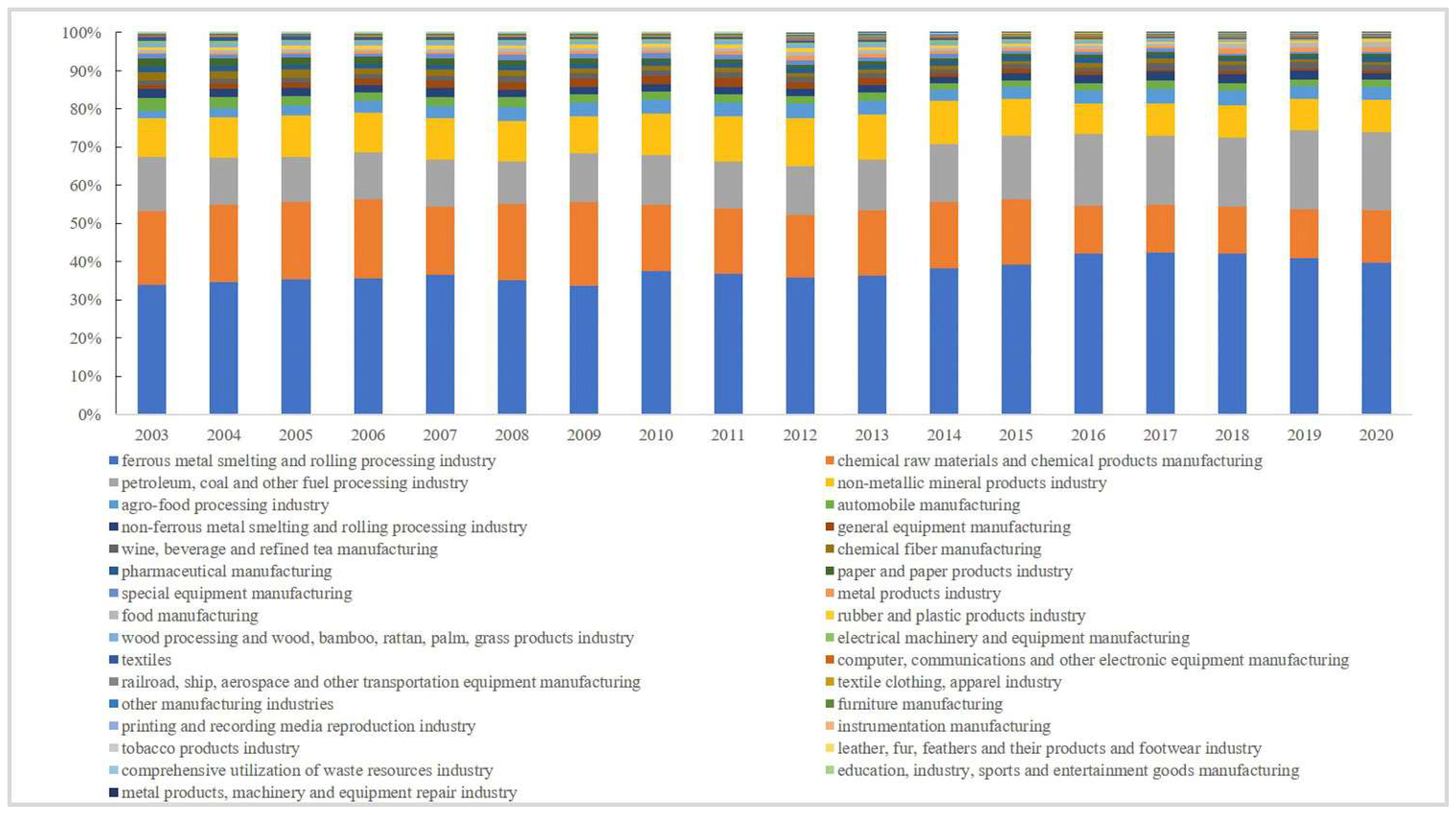

4.1.1. Analysis of Manufacturing Structure Optimization and Carbon Emission Characteristics in Northeast China

4.1.2. Analysis of the Impact of Manufacturing Structure Optimization on Carbon Emissions in Northeast China

4.2. Carbon Peak Scenario Simulation of Manufacturing Carbon Emissions from the Perspective of Structure Optimization

4.2.1. Scenario Setting

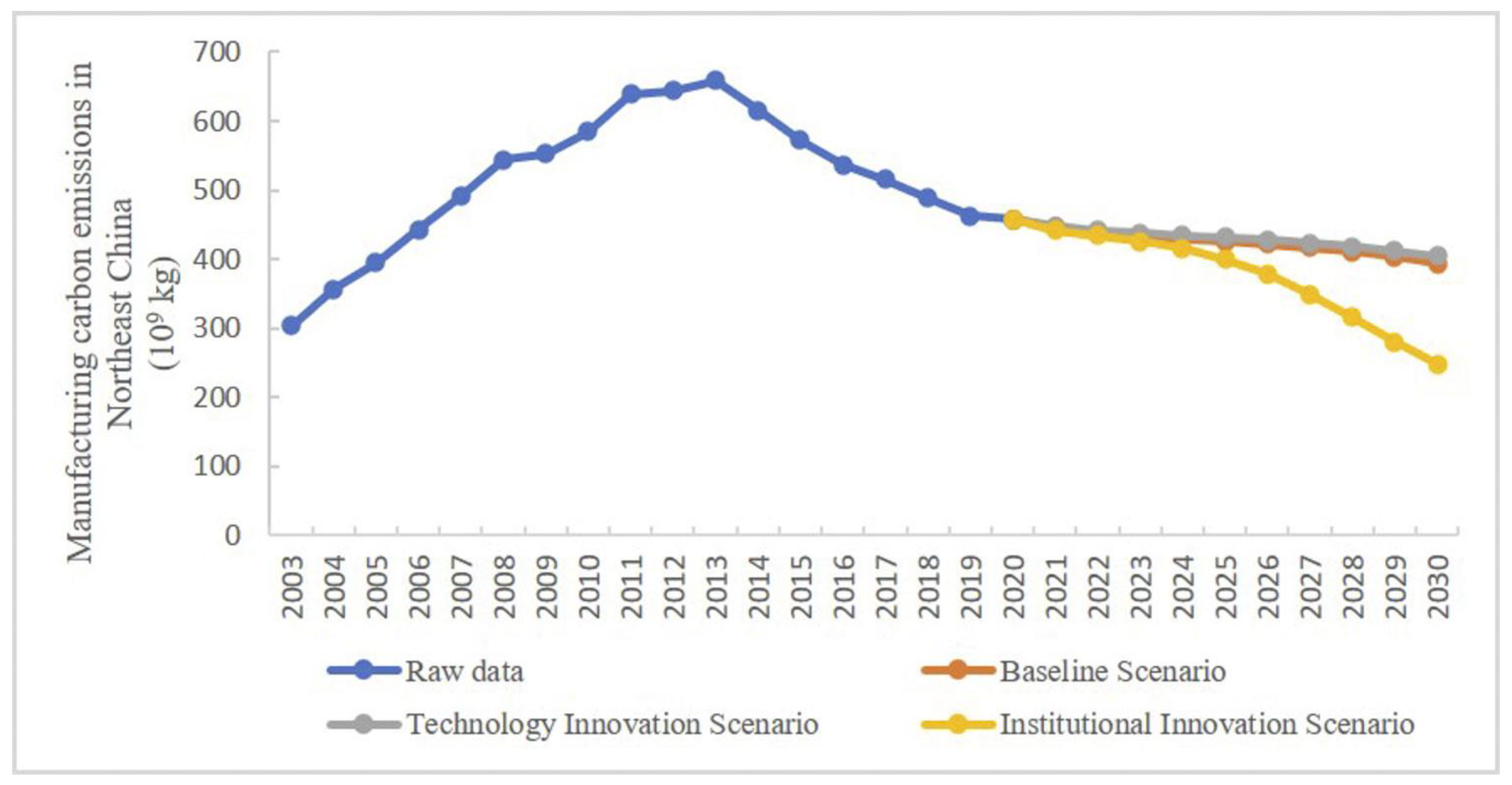

4.2.2. Scenario Simulation

5. Discussion

5.1. Comparison of Research on Influencing Factors of Manufacturing Carbon Emissions

5.2. Comparison of Research on Prediction and Simulation of Manufacturing Carbon Emissions

5.3. Policy Recommendations to Promote Manufacturing Structure Optimization and Carbon Emission Reduction

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Spatial Weight Matrix | Model | Test Method | Statistics | p-Value |

|---|---|---|---|---|

| Geographic adjacency | SEM | Lagrange multiplier | 1.717 | 0.190 |

| Robust Lagrange multiplier | 2.134 | 0.144 | ||

| SLM | Lagrange multiplier | 27.744 *** | 0.000 | |

| Robust Lagrange multiplier | 28.160 *** | 0.000 | ||

| Geographic distance | SEM | Lagrange multiplier | 5.580 ** | 0.018 |

| Robust Lagrange multiplier | 0.146 | 0.702 | ||

| SLM | Lagrange multiplier | 36.763 *** | 0.000 | |

| Robust Lagrange multiplier | 31.328 *** | 0.000 | ||

| Economic geographic distance | SEM | Lagrange multiplier | 1.796 | 0.180 |

| Robust Lagrange multiplier | 2.116 | 0.146 | ||

| SLM | Lagrange multiplier | 23.144 *** | 0.000 | |

| Robust Lagrange multiplier | 23.464 *** | 0.000 |

| Spatial Weight Matrix | Model Comparison | LR Statistics | p-Value |

|---|---|---|---|

| Geographic adjacency | SDM and SLM | 32.810 *** | 0.000 |

| SDM and SEM | 35.850 *** | 0.000 | |

| Geographic distance | SDM and SLM | 32.600 *** | 0.000 |

| SDM and SEM | 34.090 *** | 0.000 | |

| Economic geographic distance | SDM and SLM | 28.620 *** | 0.000 |

| SDM and SEM | 31.190 *** | 0.000 |

| Spatial Weight Matrix | Chi-Square Statistics | p-Value |

|---|---|---|

| Geographic adjacency | −680.520 | - |

| Geographic distance | 339.890 *** | 0.000 |

| Economic geographic distance | −19.290 | - |

| Variables | Regional Fixed Effects | Time Fixed Effects | Double Fixed Effects |

|---|---|---|---|

| ST | 0.252 *** | 0.721 *** | 0.196 ** |

| (2.79) | (8.07) | (2.12) | |

| L | 0.114 *** | 0.215 *** | 0.117 *** |

| (4.27) | (10.79) | (4.45) | |

| P | 0.313 *** | 0.394 *** | 0.305 *** |

| (11.87) | (21.58) | (11.67) | |

| EI | 0.530 *** | 0.835 *** | 0.501 *** |

| (14.60) | (21.31) | (13.31) | |

| ES | −0.063 | −0.402 *** | −0.084 |

| (−0.45) | (−5.33) | (−0.57) | |

| TI | 0.050 ** | 0.055 *** | 0.057 *** |

| (2.48) | (2.89) | (2.83) | |

| ER | 0.102 | 0.417 *** | 0.133 * |

| (1.39) | (4.86) | (1.81) | |

| W × ST | −0.294 | 1.093 ** | −1.154 *** |

| (−1.04) | (2.33) | (−2.94) | |

| W × L | 0.116 | −0.465 *** | 0.240 * |

| (1.40) | (−3.25) | (1.65) | |

| W × P | 0.125 | −0.594 *** | 0.034 |

| (1.50) | (−4.21) | (0.25) | |

| W × EI | 0.057 | −0.688 *** | 0.163 |

| (0.43) | (−2.76) | (0.80) | |

| W × ES | −2.004 *** | −8.772 *** | −2.952 *** |

| (−2.79) | (−14.70) | (−2.69) | |

| W × TI | −0.078 ** | 0.494 *** | 0.053 |

| (−2.13) | (4.08) | (0.49) | |

| W × ER | 0.315 | 1.471 *** | 0.461 |

| (1.49) | (3.07) | (1.41) | |

| rho | 0.457 *** | −0.406 *** | −0.161 ** |

| (5.86) | (−3.10) | (−2.08) | |

| sigma2_e | 0.020 *** | 0.064 *** | 0.019 *** |

| (17.64) | (19.32) | (17.74) | |

| 0.804 | 0.728 | 0.849 | |

| Log-L | 333.774 | −59.139 | 361.324 |

| Spatial Weight Matrix | Model | Test Method | Statistics | p-Value |

|---|---|---|---|---|

| Geographic adjacency | SEM | Lagrange multiplier | 4.033 *** | 0.045 |

| Robust Lagrange multiplier | 0.298 | 0.585 | ||

| SLM | Lagrange multiplier | 24.801 *** | 0.000 | |

| Robust Lagrange multiplier | 21.066 *** | 0.000 | ||

| Geographic distance | SEM | Lagrange multiplier | 7.657 *** | 0.006 |

| Robust Lagrange multiplier | 0.100 | 0.752 | ||

| SLM | Lagrange multiplier | 31.109 *** | 0.000 | |

| Robust Lagrange multiplier | 23.553 *** | 0.000 | ||

| Economic geographic distance | SEM | Lagrange multiplier | 1.820 | 0.177 |

| Robust Lagrange multiplier | 1.755 | 0.185 | ||

| SLM | Lagrange multiplier | 22.286 *** | 0.000 | |

| Robust Lagrange multiplier | 22.221 *** | 0.000 |

| Spatial Weight Matrix | Model Comparison | LR Statistics | p-Value |

|---|---|---|---|

| Geographic adjacency | SDM and SLM | 32.970 *** | 0.000 |

| SDM and SEM | 35.420 *** | 0.000 | |

| Geographic distance | SDM and SLM | 20.770 *** | 0.004 |

| SDM and SEM | 22.070 *** | 0.003 | |

| Economic geographic distance | SDM and SLM | 13.070 *** | 0.007 |

| SDM and SEM | 15.730 *** | 0.003 |

| Spatial Weight Matrix | Chi-Square Statistics | p-Value |

|---|---|---|

| Geographic adjacency | −144.060 | - |

| Geographic distance | 119.160 *** | 0.000 |

| Economic geographic distance | −48.910 | - |

| Variables | Regional Fixed Effects | Time Fixed Effects | Double Fixed Effects |

|---|---|---|---|

| SE | −0.354 *** | 0.520 *** | −0.360 *** |

| (−3.47) | (5.18) | (−3.62) | |

| L | 0.123 *** | 0.244 *** | 0.136 *** |

| (4.70) | (12.04) | (5.25) | |

| P | 0.301 *** | 0.419 *** | 0.303 *** |

| (11.36) | (21.52) | (11.56) | |

| EI | 0.495 *** | 0.830 *** | 0.494 *** |

| (13.76) | (19.62) | (13.78) | |

| ES | −0.130 | −0.575 *** | −0.240 * |

| (−0.94) | (−6.68) | (−1.68) | |

| TI | 0.025 | 0.030 | 0.032 |

| (1.23) | (1.52) | (1.55) | |

| ER | 0.153 ** | 0.355 *** | 0.164 ** |

| (2.08) | (3.80) | (2.18) | |

| W × SE | 0.985 ** | 0.295 | 0.261 |

| (2.15) | (0.44) | (0.49) | |

| W × L | 0.122 | −0.455 *** | 0.259 * |

| (1.55) | (−2.86) | (1.81) | |

| W × P | 0.105 | −0.510 *** | 0.106 |

| (1.23) | (−3.43) | (0.78) | |

| W × EI | 0.055 | −0.954 *** | 0.276 |

| (0.42) | (−3.67) | (1.41) | |

| W × ES | −1.340 * | −8.000 *** | −2.761 ** |

| (−1.87) | (−12.75) | (−2.55) | |

| W × TI | −0.048 | 0.446 *** | 0.110 |

| (−1.31) | (3.54) | (1.03) | |

| W × ER | 0.337 | 1.178 ** | 0.270 |

| (1.53) | (2.43) | (0.79) | |

| rho | 0.449 *** | −0.285 ** | −0.124 |

| (5.75) | (−2.17) | (−0.90) | |

| sigma2_e | 0.019 *** | 0.070 *** | 0.019 *** |

| (17.65) | (18.80) | (17.74) | |

| 0.747 | 0.737 | 0.779 | |

| Log-L | 336.609 | −76.862 | 359.947 |

Appendix B

| Variables | Model 1 | Model 2 | Model 3 |

|---|---|---|---|

| TI | 0.098 *** | −0.005 | 0.100 *** |

| (5.71) | (−0.79) | (5.85) | |

| ST | 0.350 *** | ||

| (3.09) | |||

| L | 0.236 *** | 0.047 *** | 0.220 *** |

| (11.46) | (6.46) | (10.39) | |

| P | 0.533 *** | 0.067 *** | 0.510 *** |

| (24.64) | (8.86) | (22.35) | |

| EI | 0.833 *** | 0.023 | 0.825 *** |

| (18.02) | (1.44) | (17.93) | |

| ES | −0.085 | −0.107 *** | −0.047 |

| (−0.96) | (−3.45) | (−0.53) | |

| ER | −0.182 * | 0.126 *** | −0.225 ** |

| (−1.70) | (3.34) | (−2.11) | |

| Cons | 2.191 *** | −0.065 | 2.214 *** |

| (12.31) | (−1.04) | (12.51) | |

| 0.848 | 0.503 | 0.851 | |

| Bootstrap test | [−0.006, 0.003] | ||

| Variables | Model 1 | Model 2 | Model 3 |

|---|---|---|---|

| TI | 0.098 *** | 0.021 *** | 0.087 *** |

| (5.71) | (3.74) | (5.06) | |

| SE | 0.549 *** | ||

| (4.62) | |||

| L | 0.236 *** | 0.044 *** | 0.212 *** |

| (11.46) | (6.40) | (10.13) | |

| P | 0.533 *** | 0.057 *** | 0.502 *** |

| (24.64) | (7.90) | (22.48) | |

| EI | 0.833 *** | 0.065 *** | 0.797 *** |

| (18.02) | (4.24) | (17.28) | |

| ES | −0.085 | 0.313 *** | −0.257 *** |

| (−0.96) | (10.66) | (−2.71) | |

| ER | −0.182 * | 0.206 *** | −0.295 *** |

| (−1.70) | (5.81) | (−2.73) | |

| Cons | 2.191 *** | −0.630 *** | 2.537 *** |

| (12.31) | (−10.67) | (13.32) | |

| 0.848 | 0.512 | 0.853 | |

| Bootstrap test | [0.006, 0.021] | ||

| Variables | Model 1 | Model 2 | Model 3 |

|---|---|---|---|

| ER | −0.182 * | 0.126 *** | −0.225 ** |

| (−1.70) | (3.34) | (−2.11) | |

| ST | 0.350 *** | ||

| (3.09) | |||

| L | 0.236 *** | 0.047 *** | 0.220 *** |

| (11.46) | (6.46) | (10.39) | |

| P | 0.533 *** | 0.067 *** | 0.510 *** |

| (24.64) | (8.86) | (22.35) | |

| EI | 0.833 *** | 0.023 | 0.825 *** |

| (18.02) | (1.44) | (17.93) | |

| ES | −0.085 | −0.107 *** | −0.047 |

| (−0.96) | (−3.45) | (−0.53) | |

| TI | 0.098 *** | −0.005 | 0.100 *** |

| (5.71) | (−0.79) | (5.85) | |

| Cons | 2.191 *** | −0.065 | 2.214 *** |

| (12.31) | (−1.04) | (12.51) | |

| 0.848 | 0.503 | 0.851 | |

| Bootstrap test | [0.011, 0.089] | ||

| Variables | Model 1 | Model 2 | Model 3 |

|---|---|---|---|

| ER | −0.182 * | 0.206 *** | −0.295 *** |

| (−1.70) | (5.81) | (−2.73) | |

| SE | 0.549 *** | ||

| (4.62) | |||

| L | 0.236 *** | 0.044 *** | 0.212 *** |

| (11.46) | (6.40) | (10.13) | |

| P | 0.533 *** | 0.057 *** | 0.502 *** |

| (24.64) | (7.90) | (22.48) | |

| EI | 0.833 *** | 0.065 *** | 0.797 *** |

| (18.02) | (4.24) | (17.28) | |

| ES | −0.085 | 0.313 *** | −0.257 *** |

| (−0.96) | (10.66) | (−2.71) | |

| TI | 0.098 *** | 0.021 *** | 0.087 *** |

| (5.71) | (3.74) | (5.06) | |

| Cons | 2.191 *** | −0.630 *** | 2.537 *** |

| (12.31) | (−10.67) | (13.32) | |

| 0.848 | 0.512 | 0.853 | |

| Bootstrap test | [0.053, 0.174] | ||

References

- Li, M. Energy China; Shanghai Education Press: Shanghai, China, 2020; pp. 1–32. [Google Scholar]

- BP. bp World Energy Statistics Yearbook; Royal Dutch/Shell Group of Companies: London, UK, 2022; p. 15. [Google Scholar]

- Lin, B.; Liu, X.; Zou, C.; Liu, X. Resource tax reform: An analysis of resource economics with coal as an example. China Soc. Sci. 2012, 2, 58–78+206. [Google Scholar]

- Yu, B. How does industrial restructuring improve regional energy efficiency—An empirical examination based on two dimensions of magnitude and quality. Financ. Econ. Res. 2017, 43, 86–97. [Google Scholar]

- Chen, C.; Li, G.; Yang, X. The Road to New Industrialization of the Northeast Old Industrial Base; Northeast Normal University Press: Changchun, China, 2004; pp. 71–92. [Google Scholar]

- Oosterhaven, J.; Broersma, L. Sector Structure and Cluster Economies: A Decomposition of Regional Labour Productivity. Reg. Stud. 2007, 41, 631–659. [Google Scholar] [CrossRef]

- Rahman, M.M.; Kashem, M.A. Carbon emissions, energy consumption and industrial growth in Bangladesh: Empirical evidence from ARDL cointegration and Granger causality analysis. Energy Policy 2017, 110, 600–608. [Google Scholar] [CrossRef]

- Zhao, R.; Qiu, Z. A Review of Research on the Relationship between Industrial Structure and Carbon Emissions. Econ. J. 2014, 10, 110–113. [Google Scholar]

- Deng, G.; Han, J.; Zhang, Z. Dynamic evolution of industrial structure upgrading, international trade and carbon emissions of energy consumption. Soft Sci. 2018, 32, 35–38, 48. [Google Scholar]

- Wu, C. A study on the synergistic effects of low-carbon economic development in China. Manag. World 2021, 37, 105–117. [Google Scholar]

- Wang, R.; Ci, H.; Zhang, T.; Tang, Y.; Wei, J.; Yang, H.; Feng, G.; Yan, Z. Spatial-Temporal Evolution Characteristics of In-dustrial Carbon Emissions in China’s Most Developed Provinces from 1998–2013: The Case of Guangdong. Energies 2023, 16, 2249. [Google Scholar] [CrossRef]

- Nicholson, S.R.; Rorrer, N.A.; Carpenter, A.C.; Beckham, G.T. Manufacturing energy and greenhouse gas emissions associated with plastics consumption. Joule 2021, 5, 673–686. [Google Scholar] [CrossRef]

- Li, Z.; Shao, S.; Shi, X.; Sun, Y.; Zhang, X. Structural transformation of manufacturing, natural resource dependence, and carbon emissions reduction: Evidence of a threshold effect from China. J. Clean. Prod. 2019, 206, 920–927. [Google Scholar] [CrossRef]

- Wang, X.; Zhang, L.; Qin, Y.; Zhang, J. Spatial and temporal evolution of carbon emissions from high-carbon manufacturing industries in China and its drivers. Resour. Sci. 2020, 42, 323–333. [Google Scholar]

- Zhang, X.; Tang, X.; Zhou, S. Research on the optimization and adjustment of manufacturing industry structure under the multiple constraints of environment, economy and employment—Taking Northeast China as an example. Econ. Syst. Reform 2019, 3, 86–93. [Google Scholar]

- Yang, Y.; He, F.; Ji, J.; Liu, X. Peaking Carbon Emissions in a Megacity through Economic Restructuring: A Case Study of Shenzhen, China. Energies 2022, 15, 6932. [Google Scholar] [CrossRef]

- Xu, X.; Ren, X.; Chang, Z. Big data and green development. China Ind. Econ. 2019, 4, 5–22. [Google Scholar]

- Tang, X.; Zhang, X.; Li, Y. A study on the optimal adjustment of China’s manufacturing industry structure—Based on the perspective of multiple constraints of low carbon, employment and economic growth. Explor. Econ. Issues 2018, 1, 147–154. [Google Scholar]

- Wang, Y.; Bi, Y.; Wang, E. Scenario projections of industrial carbon emission peaking and assessment of emission reduction potential in China. China Popul. Resour. Environ. 2017, 27, 131–140. [Google Scholar]

- Du, K.; Li, J. Towards a green world: How do green technology innovations affect total-factor carbon productivity. Energy Policy 2019, 131, 240–250. [Google Scholar] [CrossRef]

- Shao, S.; Zhang, X.; Zhao, X. Empirical decomposition and peak paths of carbon emissions in China’s manufacturing industry -generalized Dixie index decomposition and dynamic scenario analysis. China Ind. Econ. 2017, 348, 44–63. [Google Scholar]

- Liu, J.; Zhao, J. Research on carbon emission prediction of buildings based on system dynamics. Sci. Technol. Manag. Res. 2018, 38, 219–226. [Google Scholar]

- Wang, H.; Xiao, L.; Liao, B. System dynamics-based simulation of carbon reduction pathways in China. J. Natural Resour. 2022, 37, 1352–1369. [Google Scholar] [CrossRef]

- Han, N.; Luo, X. Carbon emission peaking projections and emission reduction potential in Beijing, Tianjin and Hebei from a multi-scenario perspective. J. Natural Resour. 2022, 37, 1277–1288. [Google Scholar] [CrossRef]

- Tang, W.; Cui, L.; Zheng, S.; Hu, W. Multi-Scenario Simulation of Land Use Carbon Emissions from Energy Consumption in Shenzhen, China. Land 2022, 11, 1673. [Google Scholar] [CrossRef]

- Xu, G.; Schwarz, P.; Yang, H. Determining China’s CO2 emissions peak with a dynamic nonlinear artificial neural network approach and scenario analysis. Energy Policy 2019, 128, 752–762. [Google Scholar] [CrossRef]

- Hu, Z.; Gong, X.; Liu, H. A study on carbon emission prediction of household consumption in western cities based on BP model--Xi’an city as an example. Arid Zone Resour. Environ. 2020, 34, 82–89. [Google Scholar]

- Marjanović, V.; Milovančević, M.; Mladenović, I. Prediction of GDP growth rate based on carbon dioxide (CO2) emissions. J. CO2 Util. 2016, 16, 212–217. [Google Scholar] [CrossRef]

- Liu, C.; Wang, Z.; Yuan, C. Impact of autonomous technological innovation on industrial carbon emissions and trend prediction under structural perspective. China Popul.-Resour. Environ. 2022, 32, 12–21. [Google Scholar]

- Moran, P.A. Notes on continuous stochastic phenomena. Biometrika 1950, 37, 17–23. [Google Scholar] [CrossRef]

- Elhorst, J.P. Spatial Econometrics: From Cross-Sectional Data to Spatial Panels; Springer: Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2014; pp. 5–34. [Google Scholar]

- Fan, Q.; Hudson, D. A new method for constructing endogenous spatio-temporal weight matrix including variable time effects. Quantitat. Econo. Tech. Econ. Res. 2018, 35, 131–149. [Google Scholar]

- Lin, G.; Long, Z.; Wu, M. Spatial econometric empirical analysis of regional economic convergence in China: 1978–2002. Economics 2005, S1, 67–82. [Google Scholar]

- Rumelhart, D.E.; Hinton, G.E.; Williams, R.J. Learning re-presentations by back-propagating errors. Nature 1986, 323, 533–536. [Google Scholar] [CrossRef]

- Cortes, C.; Vapnik, V. Support-vector networks. Mach. Learn. 1995, 20, 273–297. [Google Scholar] [CrossRef]

- Breiman, L. Bagging Predictors; Technical Report; Statistics Department, University of California: Berkeley, CA, USA, 1994. [Google Scholar]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas Inventories; Japan Institute for Global Environmental Strategies: Kanagawa, Japan, 2006; pp. 6–35. [Google Scholar]

- GB/T 4754-2017; Industry Classification Standards for National Economic Activities. Standardization Administration of the People’s Republic of China: Beijing, China, 2017.

- Fu, Y.; Ye, X.; Wang, Z. Structural change of manufacturing industry and efficiency improvement of economic growth. Econ. Res. 2016, 51, 86–100. [Google Scholar]

- Shen, K.; Gong, J. Environmental pollution, technological progress and energy-intensive industries in China—An empirical analysis based on environmental total factor productivity. China Ind. Econ. 2011, 285, 25–34. [Google Scholar]

- Theil, H. Economics and Informtation Theory; North Holland Publishing Company: Amsterdam, The Netherlands, 1967; pp. 91–134. [Google Scholar]

- Tang, S.; Wu, X.; Zhu, J. Digital finance and corporate technology innovation—Structural characteristics, mechanism identi-fication and differences in effects under financial regulation. Manag. World 2020, 36, 52–66+9. [Google Scholar]

- Xu, J.; Cui, J. Low carbon cities and enterprise green technology innovation. China Ind. Econ. 2020, 12, 178–196. [Google Scholar]

- Li, H.; Zou, Q. Research on environmental regulation, resource endowment and urban industrial transformation—A compar-ative analysis based on resource-based cities and non-resource-based cities. Econ. Res. 2018, 53, 182–198. [Google Scholar]

- GB/T 2589-2020; General Rules for Calculating Comprehensive Energy Consumption. Standardization Administration of the People’s Republic of China: Beijing, China, 2020.

- Shao, S.; Fan, M.; Yang, L. Economic restructuring, green technological progress and low-carbon transformational development in China-an empirical examination based on the perspective of overall technological frontier and spatial spillover effects. Manag. World 2022, 38, 46–69. [Google Scholar]

- Zheng, S. Political cycles, five-year plans, and environmental pollution—The example of industrial sulfur dioxide emissions. Politic. Sci. Res. 2016, 2, 80–94. [Google Scholar]

- Lin, B.; Teng, Y. Decoupling of economic and carbon emission linkages: Evidence from manufacturing industry chains. J. Environ. Manag. 2022, 322, 116081. [Google Scholar] [CrossRef]

- Zhang, C.; Zhang, W.; Luo, W.; Gao, X.; Zhang, B. Analysis of Influencing Factors of Carbon Emissions in China’s Logistics Industry: A GDIM-Based Indicator Decomposition. Energies 2021, 14, 5742. [Google Scholar] [CrossRef]

- Liu, J.; Yang, Q.; Zhang, Y.; Xu, Y. Analysis of CO2 Emissions in China’s Manufacturing Industry Based on Extended Logarithmic Mean Division Index Decomposition. Sustainability 2019, 11, 226. [Google Scholar] [CrossRef]

- Fujimori, S.; Wu, W.; Doelman, J.; Frank, S.; Hristov, J.; Kyle, P.; Sands, R.; van Zeist, W.-J.; Havlik, P.; Domínguez, I.P.; et al. Land-based climate change mitigation measures can affect agricultural markets and food security. Nat. Food 2022, 3, 110–121. [Google Scholar] [CrossRef] [PubMed]

- Shao, S.; Xu, L.; Zhang, S. Can carbon emissions trading help achieve the “double carbon” target—Heterogeneous Evidence from the Supply Side and Consumption Side of Energy. J. Lanzhou Univ. (Soc. Sci. Ed.) 2022, 50, 27–40. [Google Scholar]

- Ren, B. Six strategies that need to be adhered to for the high-quality development of China’s manufacturing industry in the new era. J. Human 2019, 7, 31–38. [Google Scholar]

| Energy Type | Standard Coal Factor (kg Standard Coal/kg) | CO2 Emission Factor (kg CO2/kg) |

|---|---|---|

| Raw coal | 0.714 | 1.900 |

| Washed refined coal | 0.900 | 2.405 |

| Other washed coal | 0.286 | 0.764 |

| Coal products | 0.529 | 1.714 |

| Coke | 0.971 | 2.853 |

| Coke oven gas | 0.614 | 0.847 |

| Other gas | 0.357 | 0.801 |

| Other coking products | 1.300 | 3.833 |

| Crude oil | 1.429 | 3.017 |

| Gasoline | 1.471 | 2.925 |

| Kerosene | 1.471 | 3.033 |

| Diesel | 1.457 | 3.096 |

| Liquefied petroleum gas | 1.714 | 3.101 |

| Fuel oil | 1.429 | 3.171 |

| Refinery dry gas | 1.571 | 3.008 |

| Other petroleum products | 1.200 | 2.527 |

| Natural gas | 1.330 | 2.165 |

| Thermal power (equivalent) | 0.034 | 0.110 |

| Electricity (equivalent) | 0.123 | 0.777 |

| Category | Manufacturing Classification |

|---|---|

| High-technology manufacturing | chemical raw materials and chemical products manufacturing; pharmaceutical manufacturing; general equipment manufacturing; special equipment manufacturing; automobile manufacturing; railroad, ship, aerospace, and other transportation equipment manufacturing; electrical machinery and equipment manufacturing; computer, communications, and other electronic equipment manufacturing; instrumentation manufacturing; metal products, machinery, and equipment repair industry |

| Medium- technology manufacturing | petroleum, coal, and other fuel processing industry; chemical fiber manufacturing; rubber and plastic products industry; non-metallic mineral products industry; ferrous metal smelting and rolling processing industry; non-ferrous metal smelting and rolling processing industry; metal products industry; comprehensive utilization of waste resources industry |

| Low-technology manufacturing | agro-food processing industry; food manufacturing; wine, beverage, and refined tea manufacturing; tobacco products industry; textiles; textile clothing, apparel industry; leather, fur, feathers and their products, and footwear industry; wood processing and wood, bamboo, rattan, palm, and grass products industry; furniture manufacturing; paper and paper products industry; printing and recording media reproduction industry; education industry; sports and entertainment goods manufacturing; other manufacturing industries |

| Category | Manufacturing Classification |

|---|---|

| High-energy-consumption manufacturing | petroleum, coal, and other fuel processing industry; chemical raw materials and chemical products manufacturing; non-metallic mineral products industry; ferrous metal smelting and rolling processing industry; non-ferrous metal smelting and rolling processing industry |

| Medium-energy-consumption manufacturing | agro-food processing industry; food manufacturing; wine, beverage, and refined tea manufacturing; textiles; wood processing and wood, bamboo, rattan, palm, and grass products industry; paper and paper products industry; pharmaceutical manufacturing; chemical fiber manufacturing; rubber and plastic products industry; metal products industry; general equipment manufacturing |

| Low-energy-consumption manufacturing | Tobacco products industry; textile clothing, apparel industry; leather, fur, feathers and their products, and footwear industry; furniture manufacturing; printing and recording media reproduction industry; education industry; sports and entertainment goods manufacturing; special equipment manufacturing; automobile manufacturing; railroad, ship, aerospace, and other transportation equipment manufacturing; electrical machinery and equipment manufacturing; computer, communications, and other electronic equipment manufacturing; instrumentation manufacturing; other manufacturing; comprehensive utilization of waste resources industry; metal products, machinery, and equipment repair industry |

| Year | Geographic Adjacency | Geographic Distance | Economic Geographic Distance | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Moran’s I | Z-Value | p-Value | Moran’s I | Z-Value | p-Value | Moran’s I | Z-Value | p-Value | |

| 2003 | 0.147 * | 1.616 | 0.053 | 0.083 *** | 2.676 | 0.004 | 0.194 *** | 2.540 | 0.006 |

| 2004 | 0.135 * | 1.511 | 0.066 | 0.096 *** | 2.971 | 0.002 | 0.197 *** | 2.570 | 0.005 |

| 2005 | 0.112 * | 1.291 | 0.098 | 0.089 *** | 2.813 | 0.003 | 0.179 *** | 2.366 | 0.009 |

| 2006 | 0.173 ** | 1.857 | 0.032 | 0.137 *** | 3.962 | 0.000 | 0.216 *** | 2.788 | 0.003 |

| 2007 | 0.211 ** | 2.202 | 0.014 | 0.132 *** | 3.839 | 0.000 | 0.261 *** | 3.298 | 0.001 |

| 2008 | 0.166 ** | 1.796 | 0.036 | 0.109 *** | 3.291 | 0.001 | 0.222 *** | 2.863 | 0.002 |

| 2009 | 0.307 *** | 3.087 | 0.001 | 0.186 *** | 5.129 | 0.000 | 0.309 *** | 3.847 | 0.000 |

| 2010 | 0.352 *** | 3.491 | 0.000 | 0.207 *** | 5.611 | 0.000 | 0.315 *** | 3.924 | 0.000 |

| 2011 | 0.177 ** | 1.889 | 0.030 | 0.104 *** | 3.182 | 0.001 | 0.222 *** | 2.856 | 0.002 |

| 2012 | 0.303 *** | 3.045 | 0.001 | 0.167 *** | 4.683 | 0.000 | 0.296 *** | 3.697 | 0.000 |

| 2013 | 0.387 *** | 3.816 | 0.000 | 0.195 *** | 5.338 | 0.000 | 0.302 *** | 3.775 | 0.000 |

| 2014 | 0.304 *** | 3.053 | 0.001 | 0.159 *** | 4.488 | 0.000 | 0.259 *** | 3.281 | 0.001 |

| 2015 | 0.329 *** | 3.286 | 0.001 | 0.177 *** | 4.919 | 0.000 | 0.285 *** | 3.572 | 0.000 |

| 2016 | 0.137 * | 1.524 | 0.064 | 0.090 *** | 2.832 | 0.002 | 0.218 *** | 2.811 | 0.003 |

| 2017 | 0.112 * | 1.295 | 0.098 | 0.054 ** | 1.977 | 0.024 | 0.196 *** | 2.569 | 0.005 |

| 2018 | 0.063 | 0.849 | 0.198 | 0.056 ** | 2.026 | 0.021 | 0.170 ** | 2.263 | 0.012 |

| 2019 | 0.024 | 0.486 | 0.314 | 0.037 * | 1.572 | 0.058 | 0.133 ** | 1.848 | 0.032 |

| 2020 | 0.034 | 0.583 | 0.280 | 0.044 ** | 1.736 | 0.041 | 0.142 ** | 1.947 | 0.026 |

| Year | Geographic Adjacency | Geographic Distance | Economic Geographic Distance | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Moran’s I | Z-Value | p-Value | Moran’s I | Z-Value | p-Value | Moran’s I | Z-Value | p-Value | |

| 2003 | 0.020 | 0.454 | 0.325 | −0.007 | 0.523 | 0.301 | −0.012 | 0.194 | 0.423 |

| 2004 | 0.016 | 0.415 | 0.339 | −0.016 | 0.315 | 0.376 | −0.033 | −0.035 | 0.486 |

| 2005 | −0.012 | 0.164 | 0.435 | −0.028 | 0.029 | 0.489 | −0.062 | −0.374 | 0.354 |

| 2006 | −0.039 | −0.091 | 0.464 | −0.027 | 0.055 | 0.478 | −0.048 | −0.216 | 0.415 |

| 2007 | −0.010 | 0.182 | 0.428 | −0.004 | 0.597 | 0.275 | −0.014 | 0.180 | 0.428 |

| 2008 | 0.014 | 0.398 | 0.345 | 0.017 | 1.115 | 0.133 | −0.012 | 0.203 | 0.420 |

| 2009 | 0.043 | 0.668 | 0.252 | 0.028 * | 1.359 | 0.087 | 0.016 | 0.520 | 0.302 |

| 2010 | 0.108 | 1.256 | 0.105 | 0.055 ** | 1.995 | 0.023 | 0.054 | 0.946 | 0.172 |

| 2011 | 0.126 * | 1.401 | 0.081 | 0.058 ** | 2.082 | 0.019 | 0.069 | 1.120 | 0.131 |

| 2012 | 0.249 *** | 2.552 | 0.005 | 0.121 *** | 3.582 | 0.000 | 0.178 *** | 2.361 | 0.009 |

| 2013 | 0.207 ** | 2.167 | 0.015 | 0.090 *** | 2.829 | 0.002 | 0.117 ** | 1.665 | 0.048 |

| 2014 | 0.172 ** | 1.845 | 0.033 | 0.084 *** | 2.708 | 0.003 | 0.108 * | 1.566 | 0.059 |

| 2015 | 0.216 ** | 2.247 | 0.012 | 0.102 *** | 3.120 | 0.001 | 0.137 ** | 1.893 | 0.029 |

| 2016 | 0.237 *** | 2.441 | 0.007 | 0.112 *** | 3.367 | 0.000 | 0.168 ** | 2.245 | 0.012 |

| 2017 | 0.190 ** | 2.006 | 0.022 | 0.078 *** | 2.560 | 0.005 | 0.126 ** | 1.762 | 0.039 |

| 2018 | 0.158 ** | 1.717 | 0.043 | 0.069 *** | 2.348 | 0.009 | 0.094 * | 1.398 | 0.081 |

| 2019 | 0.172 ** | 1.850 | 0.032 | 0.084 *** | 2.687 | 0.004 | 0.107 * | 1.547 | 0.061 |

| 2020 | 0.147 * | 1.613 | 0.053 | 0.074 *** | 2.469 | 0.007 | 0.091 * | 1.364 | 0.086 |

| Year | Geographic Adjacency | Geographic Distance | Economic Geographic Distance | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Moran’s I | Z-Value | p-Value | Moran’s I | Z-Value | p-Value | Moran’s I | Z-Value | p-Value | |

| 2003 | 0.103 | 1.214 | 0.112 | 0.027 * | 1.338 | 0.090 | 0.192 *** | 2.524 | 0.006 |

| 2004 | 0.144 * | 1.593 | 0.056 | 0.043 ** | 1.716 | 0.043 | 0.200 *** | 2.613 | 0.005 |

| 2005 | 0.154 ** | 1.679 | 0.047 | 0.044 ** | 1.741 | 0.041 | 0.202 *** | 2.630 | 0.004 |

| 2006 | 0.118 * | 1.347 | 0.089 | 0.028 * | 1.367 | 0.086 | 0.198 *** | 2.582 | 0.005 |

| 2007 | 0.120 * | 1.366 | 0.086 | 0.031 * | 1.437 | 0.075 | 0.192 *** | 2.520 | 0.006 |

| 2008 | 0.110 | 1.281 | 0.100 | 0.019 | 1.151 | 0.125 | 0.166 ** | 2.183 | 0.015 |

| 2009 | 0.092 | 1.110 | 0.133 | 0.009 | 0.910 | 0.181 | 0.163 ** | 2.193 | 0.014 |

| 2010 | 0.122 * | 1.389 | 0.082 | 0.027 * | 1.339 | 0.090 | 0.178 *** | 2.365 | 0.009 |

| 2011 | 0.140 * | 1.549 | 0.061 | 0.028 * | 1.360 | 0.087 | 0.176 *** | 2.333 | 0.010 |

| 2012 | 0.144 * | 1.593 | 0.056 | 0.026 * | 1.323 | 0.093 | 0.162 ** | 2.176 | 0.015 |

| 2013 | 0.154 ** | 1.681 | 0.046 | 0.032 * | 1.458 | 0.073 | 0.175 ** | 2.320 | 0.010 |

| 2014 | 0.160 ** | 1.736 | 0.041 | 0.040 ** | 1.651 | 0.049 | 0.179 *** | 2.367 | 0.009 |

| 2015 | 0.156 ** | 1.700 | 0.045 | 0.045 ** | 1.769 | 0.039 | 0.182 *** | 2.409 | 0.008 |

| 2016 | 0.195 ** | 2.058 | 0.020 | 0.057 ** | 2.053 | 0.020 | 0.194 *** | 2.546 | 0.005 |

| 2017 | 0.196 ** | 2.066 | 0.019 | 0.056 ** | 2.030 | 0.021 | 0.199 *** | 2.596 | 0.005 |

| 2018 | 0.207 ** | 2.166 | 0.015 | 0.059 ** | 2.107 | 0.018 | 0.202 *** | 2.628 | 0.004 |

| 2019 | 0.231 *** | 2.388 | 0.008 | 0.072 *** | 2.421 | 0.008 | 0.210 *** | 2.727 | 0.003 |

| 2020 | 0.219 ** | 2.274 | 0.012 | 0.072 *** | 2.401 | 0.008 | 0.210 *** | 2.722 | 0.003 |

| ST | L | P | EI | ES | TI | ER | |

|---|---|---|---|---|---|---|---|

| Direct effect | 0.208 ** | 0.114 *** | 0.308 *** | 0.502 *** | −0.062 | 0.058 *** | 0.131 * |

| (2.20) | (4.49) | (12.25) | (13.36) | (−0.44) | (2.91) | (1.74) | |

| Indirect effect | −1.064 *** | 0.208 * | −0.005 | 0.086 | −2.560 ** | 0.034 | 0.409 |

| (−3.19) | (1.66) | (−0.04) | (0.54) | (−2.57) | (0.36) | (1.31) | |

| Total effect | −0.856 ** | 0.323 ** | 0.303 *** | 0.588 *** | −2.621 ** | 0.092 | 0.540 |

| (−2.42) | (2.54) | (2.64) | (3.66) | (−2.54) | (0.93) | (1.64) |

| SE | L | P | EI | ES | TI | ER | |

|---|---|---|---|---|---|---|---|

| Direct effect | −0.358 *** | 0.133 *** | 0.305 *** | 0.495 *** | −0.221 | 0.032 | 0.164 ** |

| (−3.49) | (5.31) | (12.09) | (13.71) | (−1.64) | (1.58) | (2.13) | |

| Indirect effect | 0.258 | 0.226 * | 0.064 | 0.195 | −2.385 ** | 0.090 | 0.235 |

| (0.54) | (1.80) | (0.56) | (1.26) | (−2.43) | (0.95) | (0.71) | |

| Total effect | −0.100 * | 0.360 *** | 0.369 *** | 0.690 *** | −2.606 ** | 0.122 | 0.398 |

| (−1.76) | (2.84) | (3.23) | (4.51) | (−2.55) | (1.22) | (1.13) |

| Variables | Baseline Scenario | Technology Innovation Scenario | Institutional Innovation Scenario |

|---|---|---|---|

| ST | 4.60% | 4.60% | 4.89% |

| SE | 1.78% | 1.84% | 2.26% |

| L | −8.43% | −8.43% | −8.43% |

| K | −2.43% | −2.43% | −2.43% |

| E | −1.02% | −1.02% | −1.02% |

| P | −3.78% | −3.78% | −3.78% |

| ES | −1.04% | −1.98% | −1.98% |

| TI | 0.47% | 3.56% | 0.47% |

| ER | 1.77% | 1.77% | 4.11% |

| Year | BP Model | SVM Model | RF Model |

|---|---|---|---|

| 2021 | 452.168 | 452.931 | 441.812 |

| 2022 | 446.848 | 449.870 | 441.812 |

| 2023 | 442.992 | 446.219 | 441.812 |

| 2024 | 440.045 | 442.979 | 441.006 |

| 2025 | 437.627 | 440.566 | 440.014 |

| 2026 | 435.466 | 438.898 | 439.395 |

| 2027 | 433.343 | 437.723 | 438.135 |

| 2028 | 431.062 | 436.831 | 436.113 |

| 2029 | 428.423 | 436.106 | 434.691 |

| 2030 | 425.201 | 435.522 | 434.691 |

| 0.974 | 0.918 | 0.823 | |

| 1748.965 | 2304.506 | 4123.421 | |

| 2.299 | 2.474 | 6.263 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, C.; Zhang, Y.; Yang, Y.; Gao, H. Carbon Peak Scenario Simulation of Manufacturing Carbon Emissions in Northeast China: Perspective of Structure Optimization. Energies 2023, 16, 5227. https://doi.org/10.3390/en16135227

Xu C, Zhang Y, Yang Y, Gao H. Carbon Peak Scenario Simulation of Manufacturing Carbon Emissions in Northeast China: Perspective of Structure Optimization. Energies. 2023; 16(13):5227. https://doi.org/10.3390/en16135227

Chicago/Turabian StyleXu, Caifen, Yu Zhang, Yangmeina Yang, and Huiying Gao. 2023. "Carbon Peak Scenario Simulation of Manufacturing Carbon Emissions in Northeast China: Perspective of Structure Optimization" Energies 16, no. 13: 5227. https://doi.org/10.3390/en16135227

APA StyleXu, C., Zhang, Y., Yang, Y., & Gao, H. (2023). Carbon Peak Scenario Simulation of Manufacturing Carbon Emissions in Northeast China: Perspective of Structure Optimization. Energies, 16(13), 5227. https://doi.org/10.3390/en16135227