Thrust Coordinated Assignment and Ripple Suppression of a Multiple-Modular Permanent Magnet Linear Synchronous Motor Based on Model Predictive Thrust Control

Abstract

1. Introduction

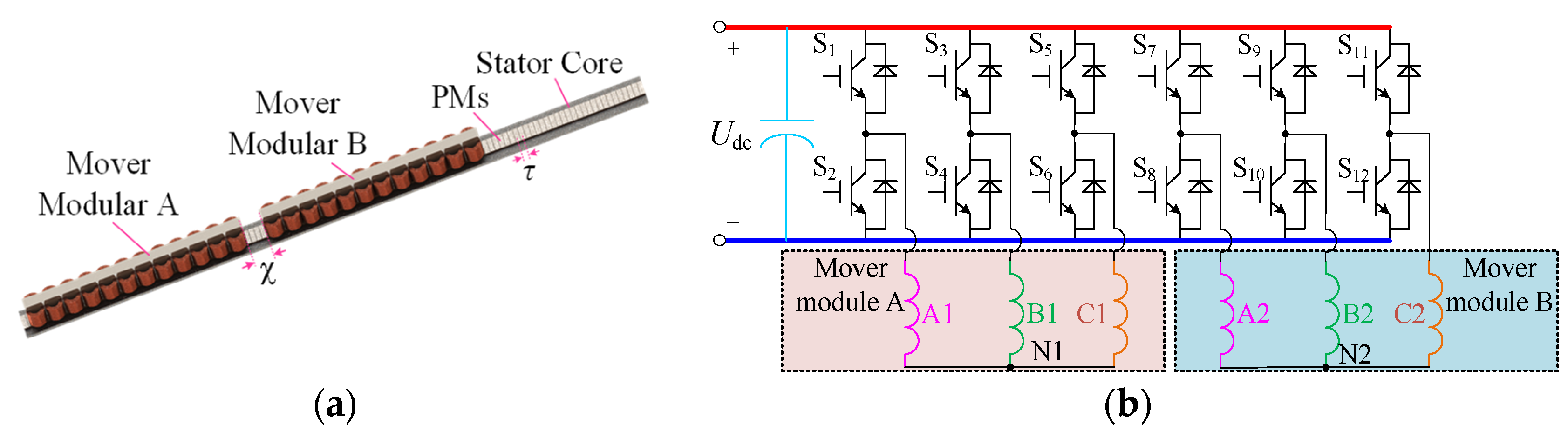

2. Topology and Multiple Operating Mode of the Multiple-Modular PMSLM

2.1. Topology of the MM-PMSLM Driving System

2.2. Multiple Operating Mode for Automated Warehousing

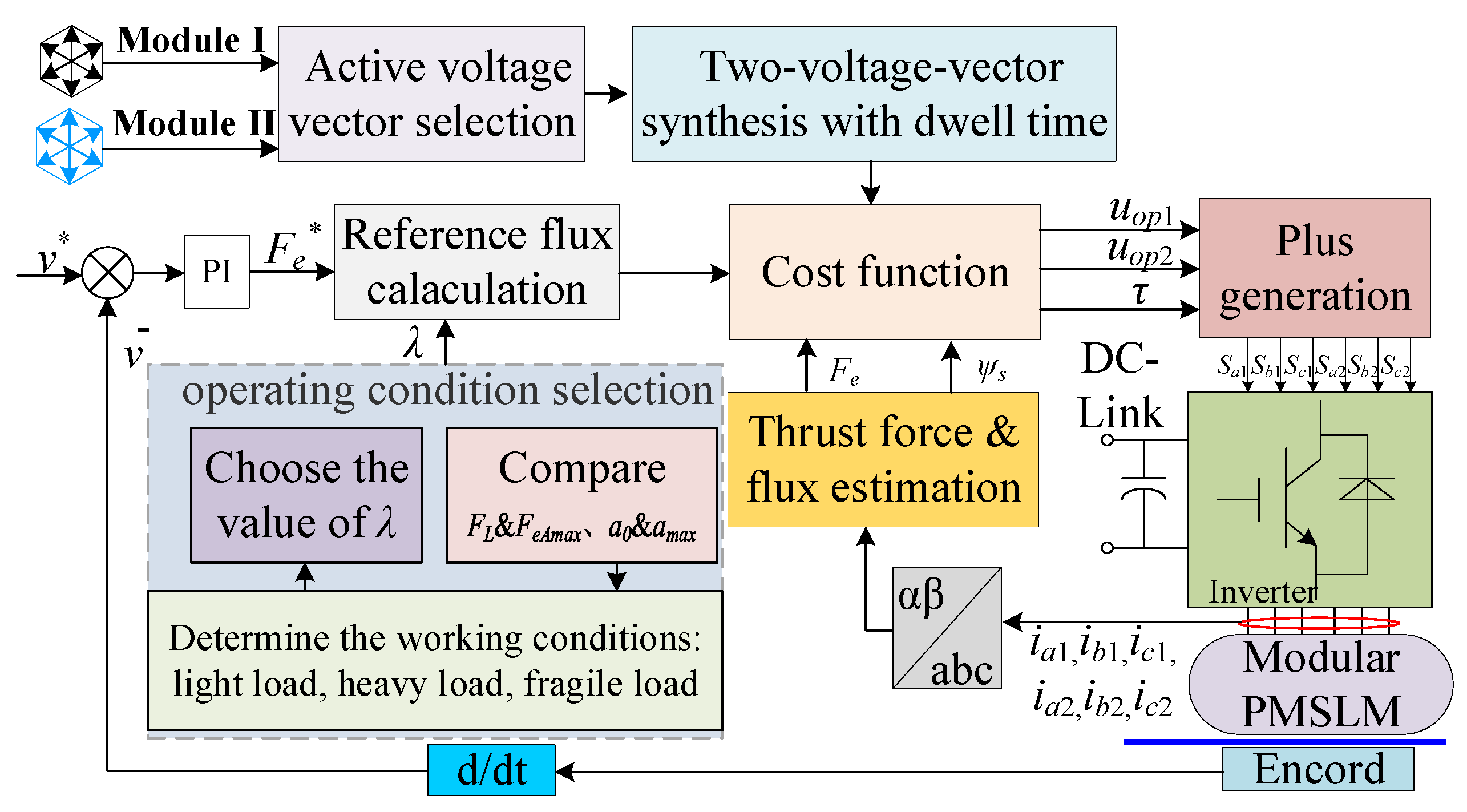

3. Model Predictive Thrust Force Control

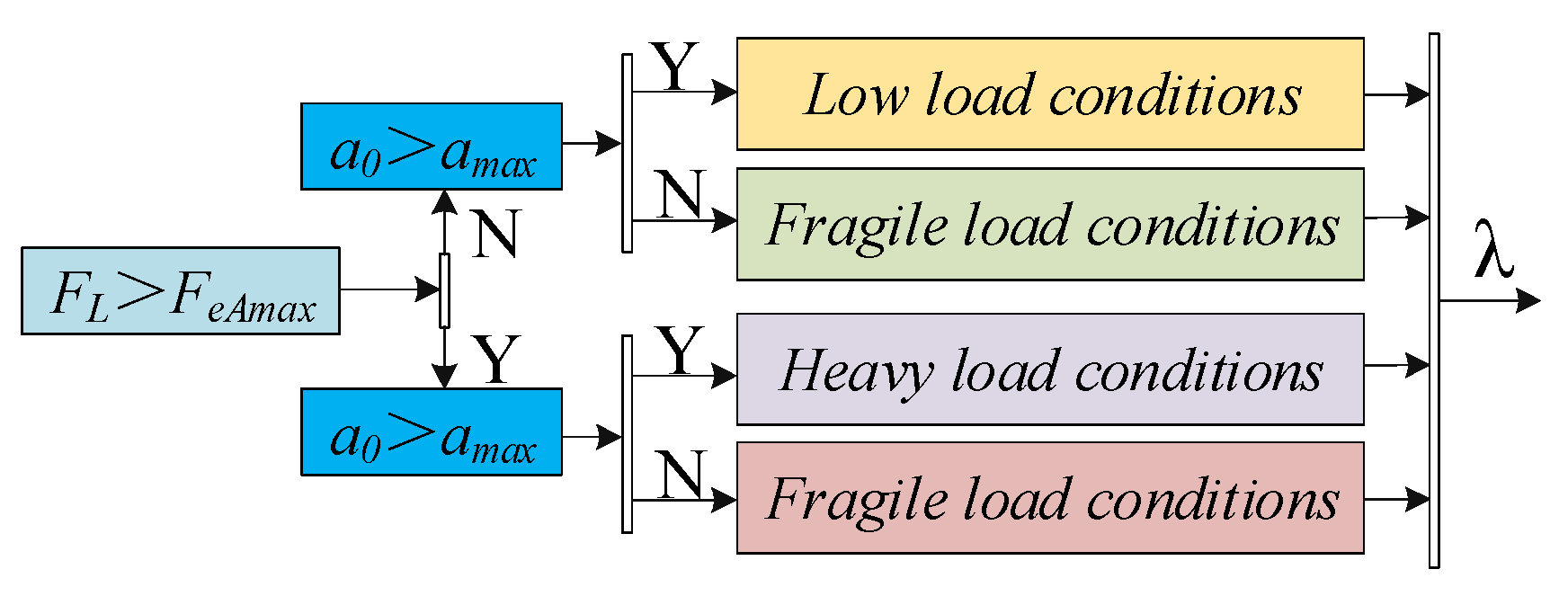

3.1. Selection Principle of λ in Different Conditions

- (1)

- Low load

- (2)

- Heavy load

- (3)

- Fragile load

3.2. Reference Flux Calculation and Current Prediction Model

3.3. Thrust Force and Flux Estimator and Cost Function

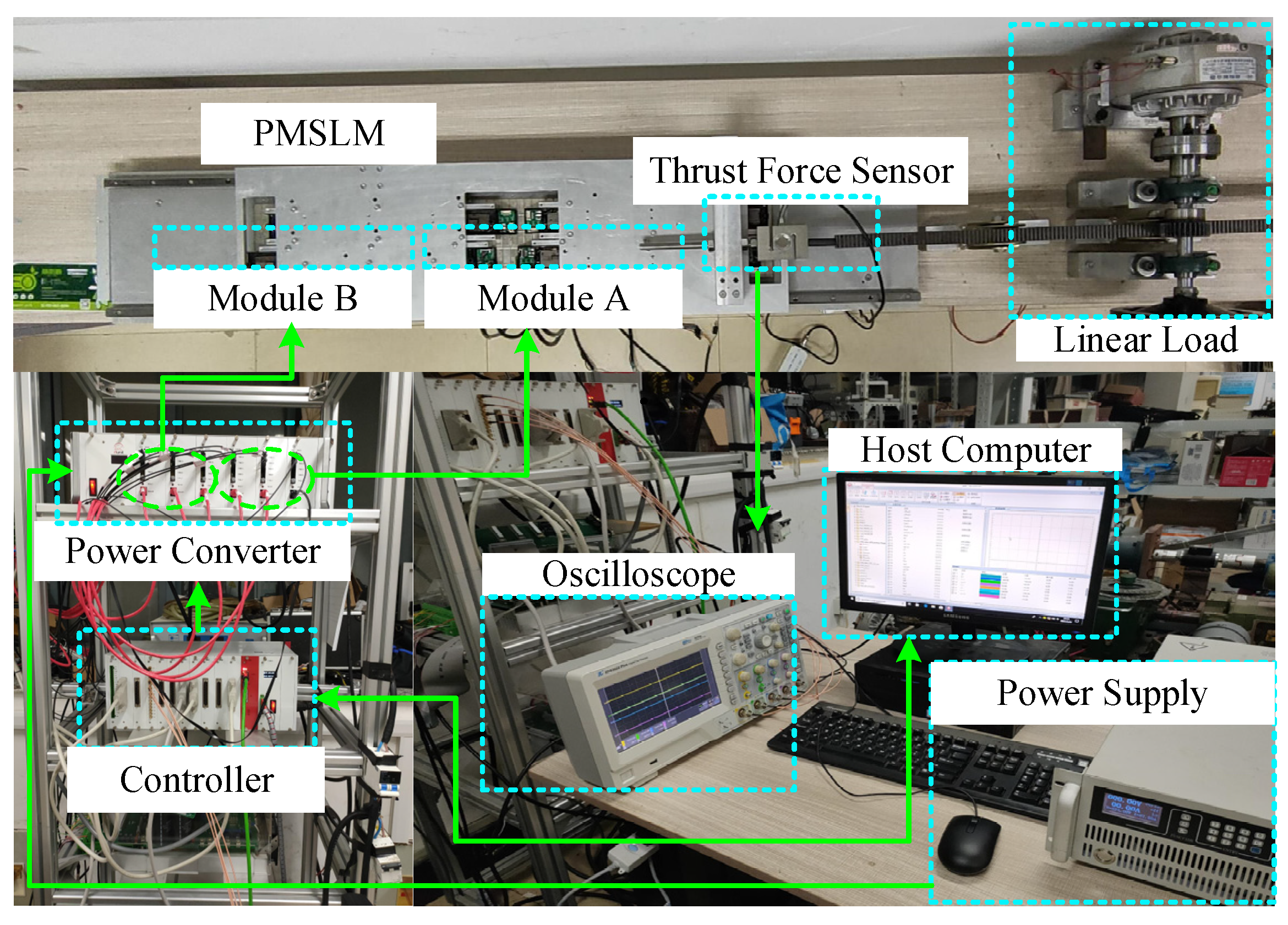

4. Experimental Verification

- (1)

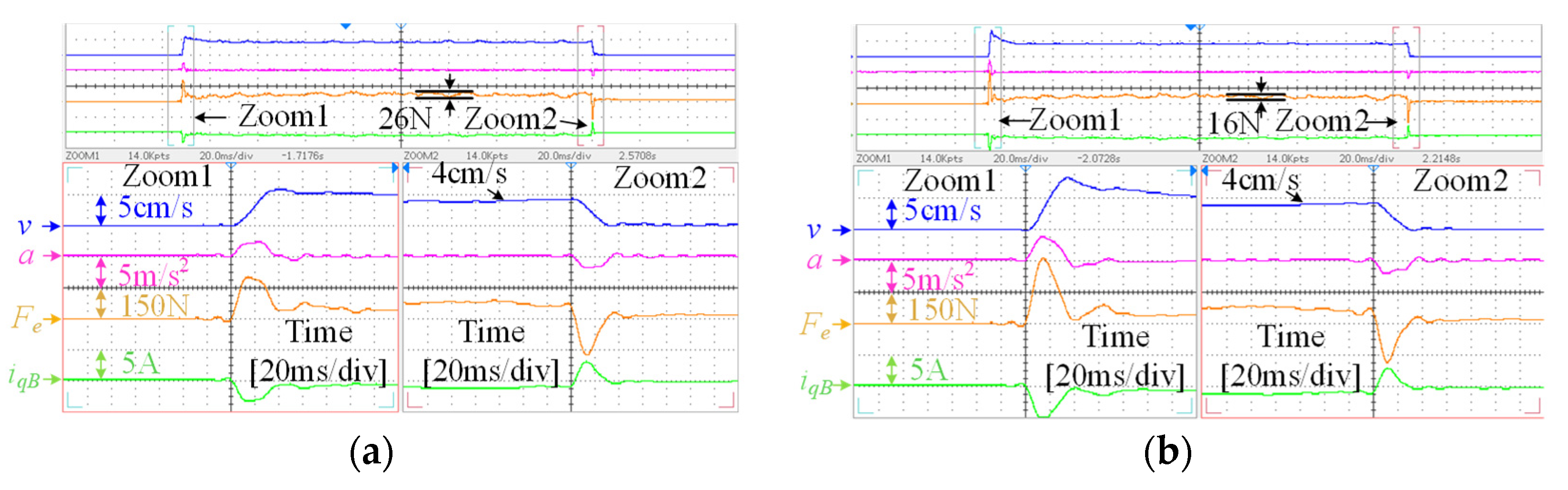

- Low load condition: Figure 6 shows the dynamic performance of the two control methods. The proposed method does not consider module utilization as well. The speed varies from 0 cm/s–4 cm/s–0 cm/s. The load force is set to 60 N. Due to the adopted MPTC control, the current response is better, and the acceleration and deceleration speeds are faster than those of the SVPWM control method. The thrust ripple of the proposed method is 26.7%, and that of the traditional SVPWM is 43.3%.

- (2)

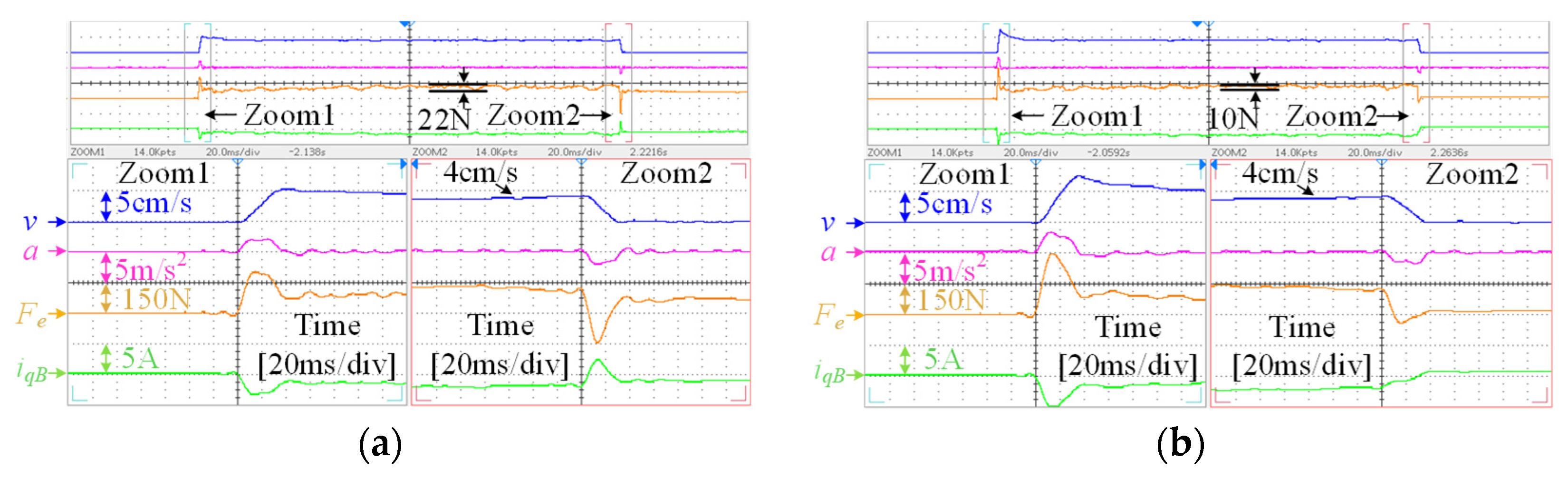

- Heavy load condition: Figure 7 shows the dynamic response of the two methods under heavy load. The speed varies from 0 cm/s–4 cm/s–0 cm/s. The reference load force is set to 100 N. To simulate heavy load conditions, α is increased accordingly. The thrust ripple of the proposed method is 10%, and that of the traditional SVPWM method is 22%.

- (3)

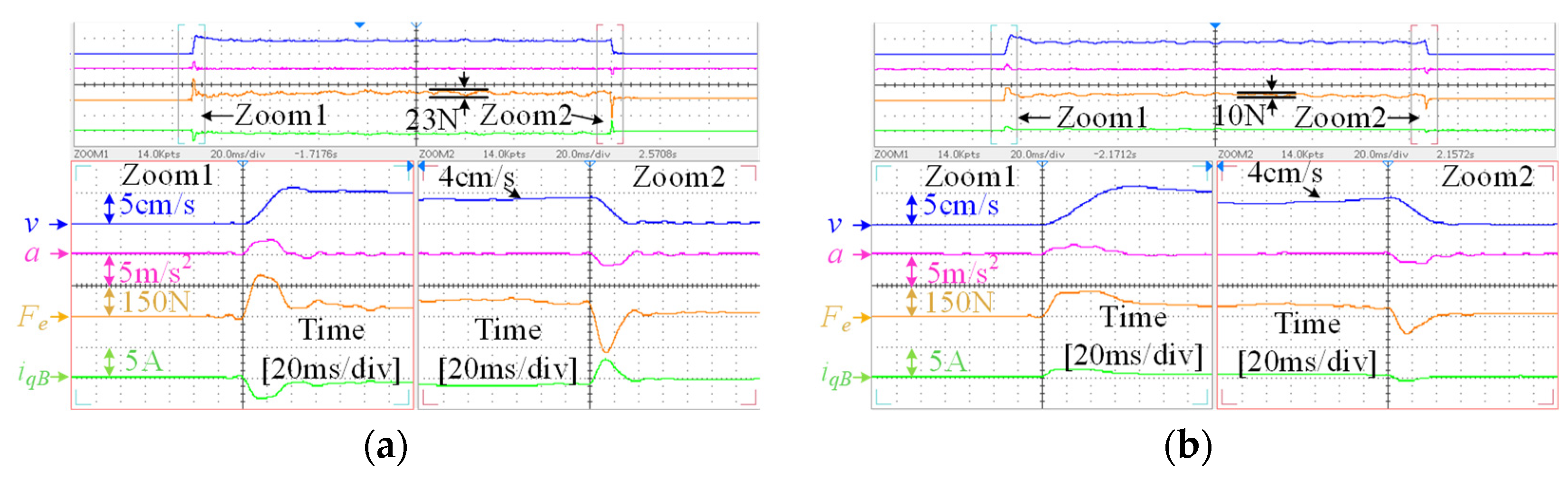

- Fragile load condition: The dynamic response of the two methods under the fragile load condition is shown in Figure 8. The speed varies from 0 cm/s–4 cm/s–0 cm/s. The load force is set to 60 N. The allowable maximum acceleration a0 is 1.8 m/s2. The maximum acceleration at the start is reduced from 2.5 m/s2 to 1.7 m/s2, and that at the stop is reduced from 2 m/s2 to 1.7 m/s2. The thrust ripple of the proposed method is 38.3%, and that of the traditional SVPWM method is 16.7%.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hu, H.; Liu, X.; Zhao, J.; Guo, Y. Analysis and Minimization of Detent End Force in Linear Permanent Magnet Synchronous Machines. IEEE Trans. Ind. Electron. 2017, 65, 2475–2486. [Google Scholar] [CrossRef]

- Xu, L.; Zhu, X.; Wu, W.; Fan, W.; Zhou, X.; Cai, X.; Quan, L. Flux-leakage design principle and multiple-operating conditions modeling of flux leakage controllable PM ma-chine considering driving cycles. IEEE Trans. Ind. Electron. 2022, 69, 8862. [Google Scholar] [CrossRef]

- Li, B.; Zhao, J.; Liu, X.; Guo, Y.; Hu, H.; Li, J. Detent force reduction of an arc-linear permanent magnet synchronous motor by using compensation windings. IEEE Trans. Ind. Electron. 2017, 64, 3001. [Google Scholar] [CrossRef]

- Yang, H.; Bai, Y.; Chien, Y. Generalized super-twisting sliding mode control of permanent magnet synchronous motor based on sinusoidal saturation function. IEICE Electron. Express 2022, 19, 20220066. [Google Scholar] [CrossRef]

- Xu, L.; Zhu, X.; Fan, W.; Zhang, C.; Zhang, L.; Quan, L. Comparative analysis and design of partitioned stator hybrid excitation axial flux switching PM motors for in-wheel traction applications. IEEE Trans. Energy Convers. 2022, 37, 1416. [Google Scholar] [CrossRef]

- Yoshitake, H.; Kamoshida, R.; Nagashima, Y. New Automated Guided Vehicle System Using Real-Time Holonic Scheduling for Warehouse Picking. IEEE Robot. Autom. Lett. 2019, 4, 1045–1052. [Google Scholar] [CrossRef]

- Zhang, F.; Shang, W.; Zhang, B.; Cong, S. Design optimization of redundantly actuated cable-driven parallel robots for automated warehouse system. IEEE Access 2020, 8, 56867. [Google Scholar] [CrossRef]

- Digani, V.; Sabattini, L.; Secchi, C. A probabilistic eulerian traffic model for the coordination of multiple AGVs in automatic warehouses. IEEE Rob. Autom. Lett. 2016, 1, 26. [Google Scholar] [CrossRef]

- Prakash, R.; Behera, L.; Mohan, S.; Jagannathan, S. Dual-Loop Optimal Control of a Robot Manipulator and Its Application in Warehouse Automation. IEEE Trans. Autom. Sci. Eng. 2020, 19, 262–279. [Google Scholar] [CrossRef]

- Lian, Y.; Xie, W.; Yang, Q.; Liu, Y.; Yang, Y.; Wu, A.G.; Eisaka, T. Improved coding landmark-based visual sensor position measurement and planning strategy for multi-warehouse automated guided vehicle. IEEE Trans. Instrum. Meas. 2022, 71, 3509316. [Google Scholar] [CrossRef]

- Basile, F.; Chiacchio, P.; Coppola, J. A Hybrid Model of Complex Automated Warehouse Systems—Part I: Modeling and Simulation. IEEE Trans. Autom. Sci. Eng. 2012, 9, 640–653. [Google Scholar] [CrossRef]

- Du, Y.; Mao, Y.; Xiao, F.; Zhu, X.; Sun, Y.; Quan, L. A Pole-Changing Doubly Salient Permanent Magnet Motor. IEEE Trans. Transp. Electrif. 2022, 8, 2479–2489. [Google Scholar] [CrossRef]

- Fu, D.; Zhao, X.; Yuan, H. High-precision motion control method for permanent magnet linear synchronous motor. IEICE Electron. Express 2021, 18, 20210097. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, L.; Zhu, X.; Du, Y.; Quan, L. Elimination of DC-Link Voltage Ripple in PMSM Drives with a DC-Split-Capacitor Converter. IEEE Trans. Power Electron. 2020, 36, 8141–8154. [Google Scholar] [CrossRef]

- Zhao, W.; Zheng, J.; Wang, J.; Liu, G.; Zhao, J.; Fang, Z. Design and Analysis of a Linear Permanent-Magnet Vernier Machine with Improved Force Density. IEEE Trans. Ind. Electron. 2015, 63, 2072–2082. [Google Scholar] [CrossRef]

- Bascetta, L.; Rocco, P.; Magnani, G. Force ripple compensation in linear motors based on closed-loop position-dependent identification. IEEE/ASME Trans. Mechatron. 2010, 15, 349. [Google Scholar] [CrossRef]

- Lim, C.S.; Rahim, N.A.; Hew, W.P.; Levi, E. Model Predictive Control of a Two-Motor Drive with Five-Leg-Inverter Supply. IEEE Trans. Ind. Electron. 2012, 60, 54–65. [Google Scholar] [CrossRef]

- Shi, X.; Lan, Y. Improved predictive position control for linear synchronous motor with disturbance observer. IEICE Electron. Express 2022, 19, 20220375. [Google Scholar] [CrossRef]

- Yao, B.; Hu, C.; Lu, L.; Wang, Q. Adaptive Robust Precision Motion Control of a High-Speed Industrial Gantry with Cogging Force Compensations. IEEE Trans. Control Syst. Technol. 2011, 19, 1149–1159. [Google Scholar] [CrossRef]

- Wang, Z.; Hu, C.; Zhu, Y.; He, S.; Yang, K.; Zhang, M. Neural Network Learning Adaptive Robust Control of an Industrial Linear Motor-Driven Stage with Disturbance Rejection Ability. IEEE Trans. Ind. Inform. 2017, 13, 2172–2183. [Google Scholar] [CrossRef]

- Marino, P.; Milano, M.; Vasca, F. Linear quadratic state feedback and robust neural network estimator for field-oriented-controlled induction motors. IEEE Trans. Ind. Electron. 1999, 46, 150. [Google Scholar] [CrossRef]

- Mandra, S.; Galkowski, K.; Rogers, E.; Rauh, A.; Aschemann, H. Performance-Enhanced Robust Iterative Learning Control with Experimental Application to PMSM Position Tracking. IEEE Trans. Control Syst. Technol. 2018, 27, 1813–1819. [Google Scholar] [CrossRef]

- Lin, Z.; Wang, J.; Howe, D. A Learning Feed-Forward Current Controller for Linear Reciprocating Vapor Compressors. IEEE Trans. Ind. Electron. 2010, 58, 3383–3390. [Google Scholar] [CrossRef]

- Tan, Q.; Huang, X.; Li, L.; Wang, M. Magnetic field analysis and flux barrier design for modular permanent magnet linear synchronous motor. IEEE Trans. Ind. Electron. 2020, 67, 3891. [Google Scholar] [CrossRef]

- Cao, R.; Cheng, M.; Zhang, B. Speed Control of Complementary and Modular Linear Flux-Switching Permanent-Magnet Motor. IEEE Trans. Ind. Electron. 2015, 62, 4056–4064. [Google Scholar] [CrossRef]

- Zhang, Z.; Tang, X.; Zhang, C.; Li, M. Comparative study on modular longitudinal and transverse flux-switching permanent magnet linear motor. IEEE Trans. Energy Convers. 2020, 35, 33. [Google Scholar] [CrossRef]

- Zhao, W.; Yao, T.; Xu, L.; Chen, X.; Song, X. Multi-objective optimization design of a modular linear permanent magnet vernier machine by combined approximation models and differential evolution. IEEE Trans. Ind. Electron. 2021, 68, 4634. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, M.; Ji, J.; Cao, R.; Du, Y.; Li, F. Design and analysis of a new fault-tolerant linear permanent-magnet motor for maglev transportation ap-plications. IEEE Trans. Appl. Supercond. 2012, 22, 5200204. [Google Scholar] [CrossRef]

- Basile, F.; Chiacchio, P.; Coppola, J. A Hybrid Model of Complex Automated Warehouse Systems—Part II: Analysis and Experimental Results. IEEE Trans. Autom. Sci. Eng. 2012, 9, 654–668. [Google Scholar] [CrossRef]

| Items | Start | Stop |

|---|---|---|

| Low load | I/III | I/III |

| Heavy load | III | II |

| Low and fragile load | II | II |

| Heavy and fragile load | III | II |

| Parameters | Values | Parameters | Values |

|---|---|---|---|

| Udc (V) | 24 | Ψf (Wb) | 0.006 |

| VN (m/s) | 0.2 | Ls (mH) | 4.0 |

| IN (A) | 5 | Rs (Ω) | 2.75 |

| Methods | Thrust Ripple (Low Load) | Thrust Ripple (Heavy Load) | Thrust Ripple (Fragile Load) |

|---|---|---|---|

| Conventional SVPWM | 26 N | 22 N | 23 N |

| Proposed methods | 16 N | 10 N | 10 N |

| Methods | Start Response Time (Low Load/Heavy Load/Fragile Load) | Stop Response Time (Low Load/Heavy Load/Fragile Load) |

|---|---|---|

| Conventional SVPWM | 24 ms/26 ms/24 ms | 30 ms/28 ms/30 ms |

| Proposed methods | 16 ms/18 ms/40 ms | 28 ms/32 ms/40 ms |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zuo, K.; Hong, Y.; Yang, J.; Xu, L.; Qi, H.; Li, B.; Liu, H.; Liu, L. Thrust Coordinated Assignment and Ripple Suppression of a Multiple-Modular Permanent Magnet Linear Synchronous Motor Based on Model Predictive Thrust Control. Energies 2023, 16, 5368. https://doi.org/10.3390/en16145368

Zuo K, Hong Y, Yang J, Xu L, Qi H, Li B, Liu H, Liu L. Thrust Coordinated Assignment and Ripple Suppression of a Multiple-Modular Permanent Magnet Linear Synchronous Motor Based on Model Predictive Thrust Control. Energies. 2023; 16(14):5368. https://doi.org/10.3390/en16145368

Chicago/Turabian StyleZuo, Kai, Yi Hong, Jin Yang, Lei Xu, Haitao Qi, Baolong Li, Hao Liu, and Luyuan Liu. 2023. "Thrust Coordinated Assignment and Ripple Suppression of a Multiple-Modular Permanent Magnet Linear Synchronous Motor Based on Model Predictive Thrust Control" Energies 16, no. 14: 5368. https://doi.org/10.3390/en16145368

APA StyleZuo, K., Hong, Y., Yang, J., Xu, L., Qi, H., Li, B., Liu, H., & Liu, L. (2023). Thrust Coordinated Assignment and Ripple Suppression of a Multiple-Modular Permanent Magnet Linear Synchronous Motor Based on Model Predictive Thrust Control. Energies, 16(14), 5368. https://doi.org/10.3390/en16145368