Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle

Abstract

1. Introduction

2. Methods

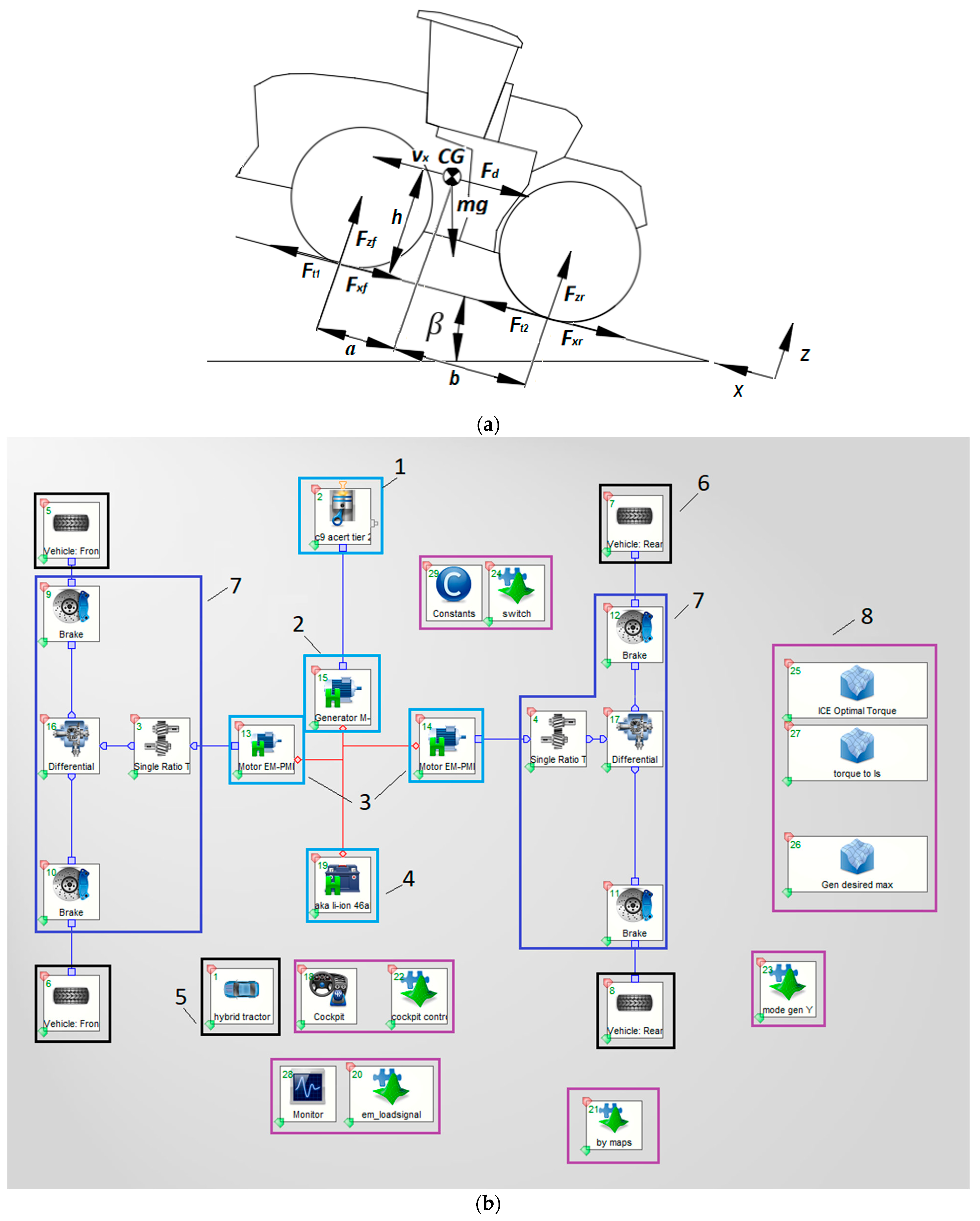

2.1. Vehicle Models

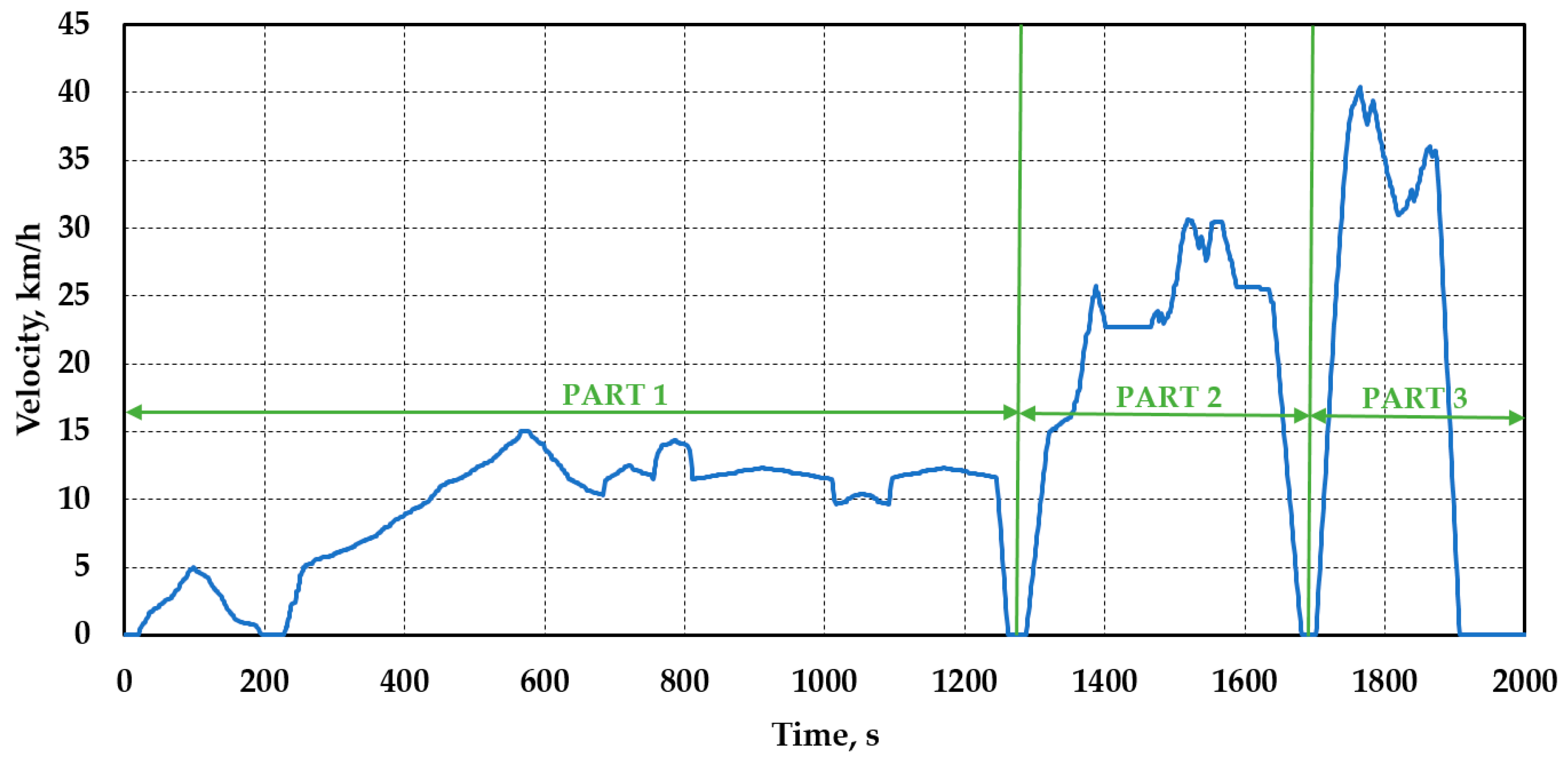

2.2. Hybrid Operational Cycle

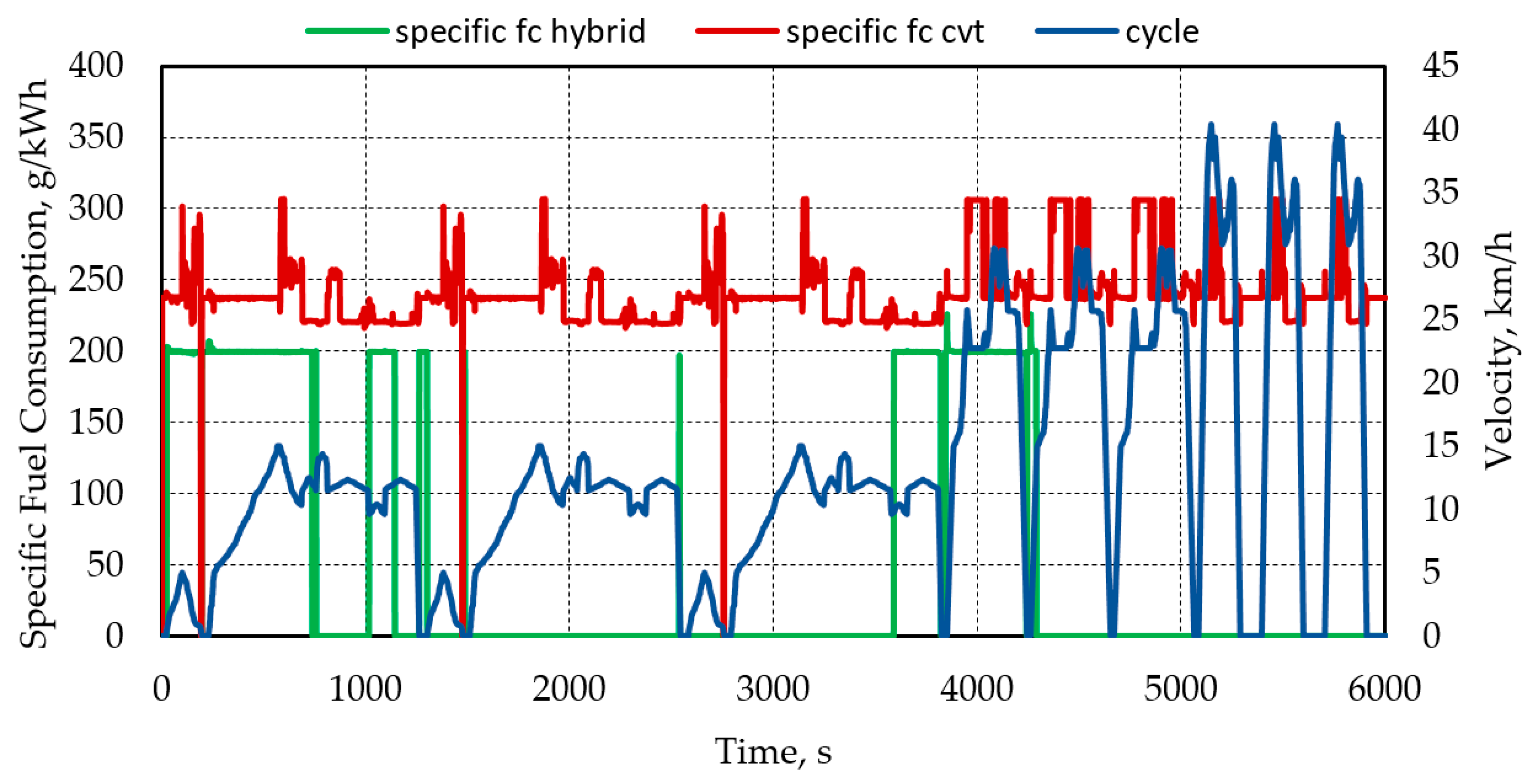

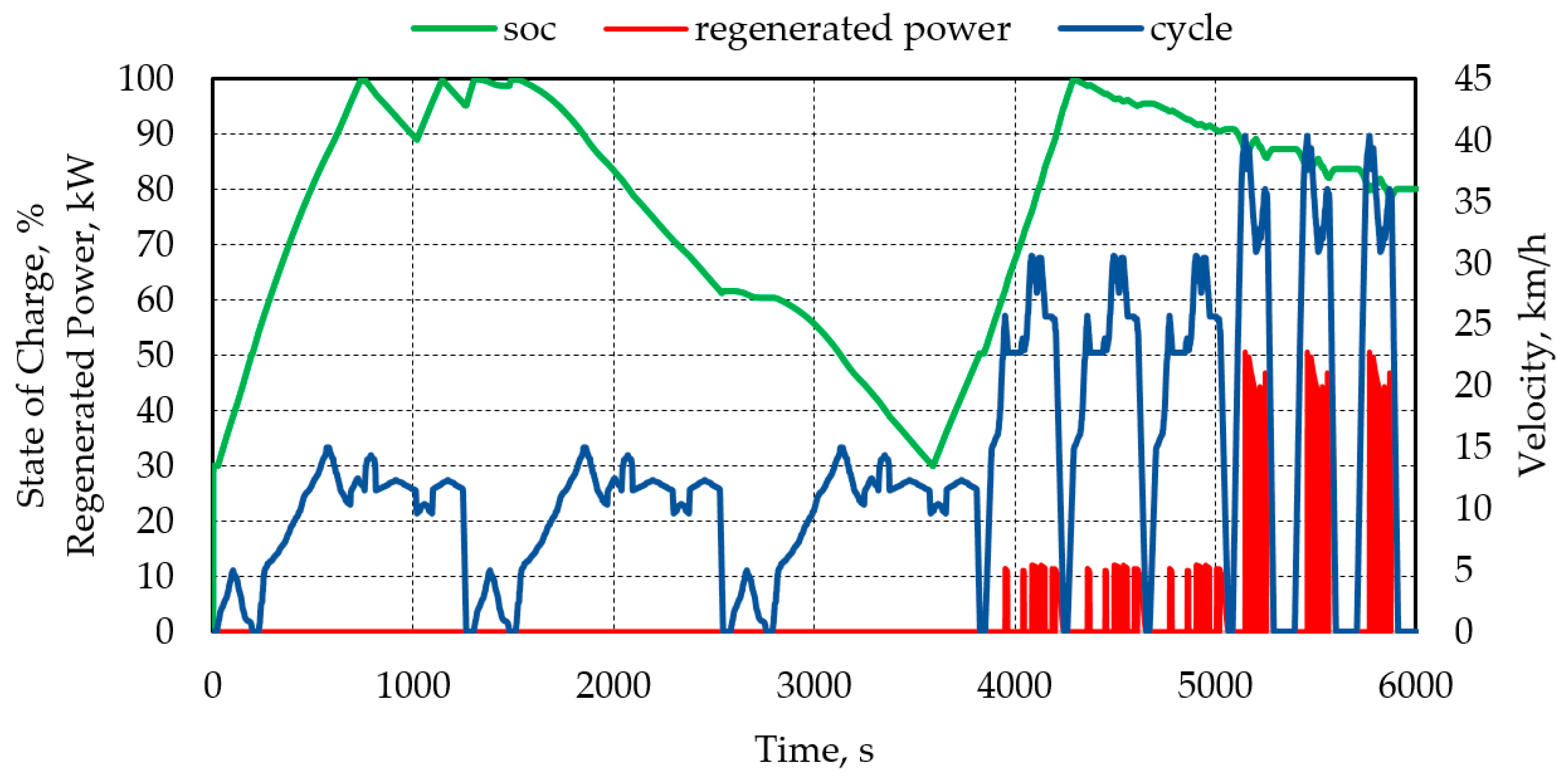

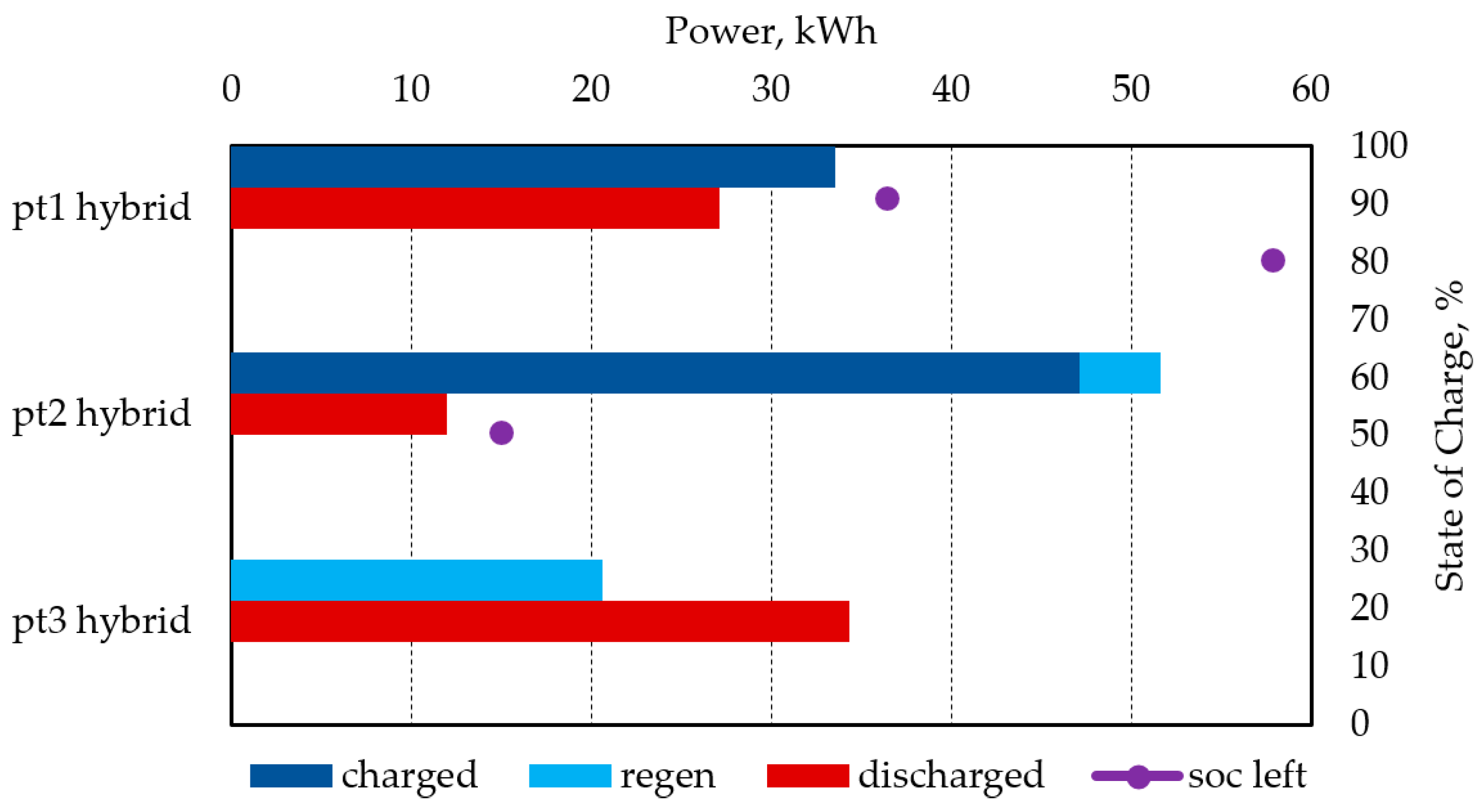

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sato, S.; Jiang, Y.J.; Russell, R.L.; Miller, J.W.; Karavalakis, G.; Durbin, T.D.; Johnson, K.C. Experimental driving performance evaluation of battery-powered medium and heavy duty all-electric vehicles. Int. J. Electr. Power Energy Syst. 2022, 141, 108100. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L. Case of Study of the Electrification of a Tractor: Electric Motor Performance Requirements and Design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Monsalve, G.; Cardenas, A.; Mousazadeh, H. Off-Road Electric Vehicles and Autonomous Robots in Agricultural Sector: Trends, Challenges, and Opportunities. Vehicles 2022, 4, 843–864. [Google Scholar] [CrossRef]

- Li, T.; Xie, B.; Li, Z.; Li, J. Design and optimization of a dual-input coupling powertrain system: A case study for electric tractors. Appl. Sci. 2020, 10, 1608. [Google Scholar] [CrossRef]

- Lee, D.; Kim, Y.; Choi, C.; Chung, S.; Inoue, E.; Okayasu, T. Development of a Parallel Hybrid System for Agricultural Tractors. Bull. Fac. Agric. Kyushu Univ. 2017, 62, 137–144. [Google Scholar] [CrossRef]

- Moreda, G.P.; Munoz-Garcia, M.A.; Barreiro, P. High voltage electrification and agricultural machinery—A review. Energy Convers. Manag. 2016, 115, 117–131. [Google Scholar] [CrossRef]

- Un-Noor, F.; Wu, G.; Perugu, H.; Collier, S.; Yoon, S.; Barth, M.; Boriboonsomsin, K. Off-Road Construction and Agricultural Equipment Electrification: Review, Challenges, and Opportunities. Vehicles 2022, 4, 780–807. [Google Scholar] [CrossRef]

- Mocera, F.; Martelli, S.; Somà, A. State of the Art and Future Trends of Electrification in Agricultural Tractors. SAE Tech. Pap. 2022. [Google Scholar] [CrossRef]

- Kim, D.-M.; Benoliel, P.; Kim, D.-K.; Lee, T.H.; Park, J.W.; Hong, J.-P. Framework development of series hybrid powertrain design for heavy-duty vehicle considering driving conditions. IEEE Trans. Veh. Technol. 2019, 68, 6468–6480. [Google Scholar] [CrossRef]

- Kim, D.-M.; Lee, S.-G.; Kim, D.-K.; Park, M.-R.; Lim, M.-S. Sizing and optimization process of hybrid electric propulsion system for heavy-duty vehicle based on Gaussian process modeling considering traction motor characteristics. Renew. Sustain. Energy Rev. 2022, 161, 11228. [Google Scholar] [CrossRef]

- Feng, Y.; Dong, Z. Optimal energy management with balanced fuel economy and battery life for large hybrid electric mining truck. J. Power Sources 2020, 454, 227948. [Google Scholar] [CrossRef]

- Feng, Y.; Dong, Z. Comparative lifecycle costs and emissions of electrified powertrains for light-duty logistics trucks. Transp. Res. Part D: Transp. Environ. 2023, 117, 103672. [Google Scholar] [CrossRef]

- Lajunen, A.; Suomela, J. Evaluation of energy storage system requirements for hybrid mining loaders. IEEE Trans. Veh. Technol. 2012, 61, 3387–3393. [Google Scholar] [CrossRef]

- Yang, W.; Liang, J.; Yang, J.; Zhang, N. Investigation of a novel coaxial power-split hybrid powertrain for mining trucks. Energies 2018, 11, 172. [Google Scholar] [CrossRef]

- Ceraolo, M.; Lutzemberger, G. Heavy-duty hybrid transportation systems: Design, modeling, and energy management. In Hybrid Energy Systems, Hybrid Technologies for Power Generation; Lo Faro, M., Barbera, O., Giacoppo, G., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 313–336. [Google Scholar] [CrossRef]

- Medževeprytė, U.K.; Makaras, R.; Lukoševičius, V.; Keršys, A. Evaluation of the Working Parameters of a Series-Hybrid Tractor under the Soil Work Conditions. Teh. Vjesn. 2022, 29, 45–50. [Google Scholar] [CrossRef]

- Medževeprytė, U.K.; Makaras, R.; Rimkus, A. Efficiency of an off-road heavy-duty series hybrid drive based on a modified world harmonized transient cycle. Transp. Probl. 2022, 17, 187–195. [Google Scholar] [CrossRef]

- Xie, S.; Peng, J.; He, H. Plug-in hybrid electric bus energy management based on stochastic model predictive control. Energy Procedia 2017, 105, 2672–2677. [Google Scholar] [CrossRef]

- Wu, Z.; Xie, B.; Li, Z.; Chi, R.; Ren, Z.; Du, Y.; Hirai, Y. Modelling and verification of driving torque management for electric tractor: Dual-mode driving intention interpretation with torque demand restriction. Biosyst. Eng. 2019, 182, 65–83. [Google Scholar] [CrossRef]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on Energy Management Strategy of Fuel Cell Electric Tractor Based on Multi-Algorithm Fusion and Optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X.; Zhao, X.; Wang, S.; Xie, B.; Song, Z.; Wang, D. Co-optimization energy management strategy for a novel dual-motor drive system of electric tractor considering efficiency and stability. Energy 2023, 281, 128074. [Google Scholar] [CrossRef]

- Rossi, C.; Pontara, D.; Falcomer, C.; Bertoldi, M.; Mandrioli, R. A hybrid–electric driveline for agricultural tractors based on an e-CVT power-split transmission. Energies 2021, 14, 6912. [Google Scholar] [CrossRef]

- Gupta, S.; Maity Sr, R.; Kulkarni Ceng, S. Modeling, Analysis and Experimental Validation of Tractor Architectures for Rural Electrification. In Proceedings of the 8th SAEINDIA International Mobility Conference & Exposition and Commercial Vehicle Engineering Congress 2013 (SIMCOMVEC), Chennai, India, 4–7 December 2013. [Google Scholar]

- Scolaro, E.; Alberti, L.; Barater, D. Electric Drives for Hybrid Electric Agricultural Tractors. In Proceedings of the 2021 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Modena, Italy, 8–9 April 2021; pp. 331–336. [Google Scholar] [CrossRef]

- Bouquain, D.; Blunier, B.; Miraoui, A. HEV series architectures evaluation: Modeling, simulation and experimentation. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–10 September 2009; pp. 584–591. [Google Scholar] [CrossRef]

- Xu, W.; Liu, M.; Xu, L.; Zhang, S. Energy Management Strategy of Hydrogen Fuel Cell/Battery/Ultracapacitor Hybrid Tractor Based on Efficiency Optimization. Appl. Sci. 2023, 13, 151. [Google Scholar] [CrossRef]

- Dou, H.; Wei, H.; Zhang, Y.; Ai, Q. Configuration Design and Optimal Energy Management for Coupled-Split Powertrain Tractor. Machines 2022, 10, 1175. [Google Scholar] [CrossRef]

- Zhu, Z.; Zeng, L.; Chen, L.; Zou, R.; Cai, Y. Fuzzy Adaptive Energy Management Strategy for a Hybrid Agricultural Tractor Equipped with HMCVT. Agriculture 2022, 12, 1986. [Google Scholar] [CrossRef]

- Goswami, G.; Tupitsina, A.; Jaiswal, S.; Nutakor, C.; Lindh, T.; Sopanen, J. Comparison of various hybrid electric powertrains for non-road mobile machinery using real-time multibody simulation. IEEE Access 2022, 10, 107631–107648. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V.; Somà, A. Comparative Analysis of Hybrid Electric Architectures for Specialized Agricultural Tractors. Energies 2022, 15, 1944. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V. Numerical performance investigation of a hybrid eCVT specialized agricultural tractor. Appl. Sci. 2022, 12, 2438. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. A Review of Hybrid Electric Architectures in Construction, Handling and Agriculture Machines. In New Perspectives on Electric Vehicles; IntechOpen: London, UK, 2021; Available online: https://books.google.lt/books?hl=lt&lr=&id=jtFuEAAAQBAJ&oi=fnd&pg=PA49&dq=A+Review+of+Hybrid+Electric+Architectures+in+Construction,+Handling+and+Agriculture+Machines&ots=SAjwcZEdoG&sig=-CM7MxMM5GWUCljNwY6ckThX3EY&redir_esc=y#v=onepage&q=A%20Review%20of%20Hybrid%20Electric%20Architectures%20in%20Construction%2C%20Handling%20and%20Agriculture%20Machines&f=false (accessed on 15 April 2023).

- Mocera, F. A Model-Based Design Approach for a Parallel Hybrid Electric Tractor Energy Management Strategy Using Hardware in the Loop Technique. Vehicles 2020, 3, 1–19. [Google Scholar] [CrossRef]

- Xu, L.; Liu, M.; Zhou, Z. Design of drive system for series hybrid electric tractor. Trans. CSAE 2014, 30, 11–18. [Google Scholar]

- Wang, X.; Huang, Y.; Wang, J. Study on Driver-Oriented Energy Management Strategy for Hybrid Heavy-Duty Off-Road Vehicles under Aggressive Transient Operating Condition. Sustainability 2023, 15, 7539. [Google Scholar] [CrossRef]

- Wen, C.-K.; Zhang, S.-L.; Xie, B.; Song, Z.-H.; Li, T.-H.; Jia, F.; Han, J.-G. Design and verification innovative approach of dual-motor power coupling drive systems for electric tractors. Energy 2022, 247, 123538. [Google Scholar] [CrossRef]

- Ueka, Y.; Yamashita, J.; Sato, K.; Doi, Y. Study on the Development of the Electric Tractor: Specifications and Traveling and Tilling Performance of a Prototype Electric Tractor. Eng. Agric. Environ. Food 2013, 6, 160–164. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, G.; Liu, M.; Yan, X.; Xu, L.; Shang, C. Research on Global Optimal Energy Management Strategy of Agricultural Hybrid Tractor Equipped with CVT. World Electr. Veh. J. 2023, 14, 127. [Google Scholar] [CrossRef]

- Cheng, Z.; Chen, Y.; Li, W.; Zhou, P.; Liu, J.; Li, L.; Chang, W.; Qian, Y. Optimization Design Based on I-GA and Simulation Test Verification of 5-Stage Hydraulic Mechanical Continuously Variable Transmission Used for Tractor. Agriculture 2022, 12, 807. [Google Scholar] [CrossRef]

- Fu, B.; Zhu, T.; Liu, J.; Zhao, Y.; Chen, J. Influencing Factors of Electric Vehicle Economy Based on Continuously Variable Transmission. Int. J. Automot. Technol. 2022, 23, 717–728. [Google Scholar] [CrossRef]

- Fu, B.; Zhu, T.; Liu, J.; Hu, X. Research on Clamping Force Control of CVT for Electric Vehicles Based on Slip Characteristics. Sensors 2022, 22, 2131. [Google Scholar] [CrossRef]

- Hu, J.; Xiao, F.; Peng, H.; Zhao, W. CVT discrete speed ratio optimizations based on energy efficiency for PHEV. Alex. Eng. J. 2022, 61, 4095–4105. [Google Scholar] [CrossRef]

- Wang, Q.; Frank, A.A. Plug-in HEV with CVT: Configuration, control, and its concurrent multi-objective optimization by evolutionary algorithm. Int. J. Automot. Technol. 2014, 15, 103–115. [Google Scholar] [CrossRef]

- Williamson, S.S.; Khaligh, A.; Oh, S.C.; Emadi, A. Impact of energy storage device selection on the overall drive train efficiency and performance of heavy-duty hybrid vehicles. In Proceedings of the 2005 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 7 September 2005; p. 10. [Google Scholar] [CrossRef]

- Kodjak, D.; Sharpe, B.; Delgado, O. Evolution of heavy-duty vehicle fuel efficiency policies in major markets. Mitig Adapt Strat. Glob. Change 2015, 20, 755–775. [Google Scholar] [CrossRef]

- Banjac, T.; Trenc, F.; Katrašnik, T. Energy conversion efficiency of hybrid electric heavy-duty vehicles operating according to diverse drive cycles. Energy Convers. Manag. 2009, 50, 2865–2878. [Google Scholar] [CrossRef]

- Giuliano, G.; Dessouky, M.; Dexter, S.; Fang, J.; Hu, S.; Miller, M. Heavy-duty trucks: The challenge of getting to zero. Transp. Res. Part D Transp. Environ. 2021, 93, 102742. [Google Scholar] [CrossRef]

- Rajamani, R. Longitudinal Vehicle Dynamics. In Vehicle Dynamics and Control. Mechanical Engineering Series; Springer: Boston, MA, USA, 2006; pp. 95–122. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Analysis of a parallel hybrid electric tractor for agricultural applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Steven, H. Development of a Worldwide Harmonised Heavy-Duty Engine Emissions Test Cycle. Final Report. April 2001. Available online: https://unece.org/DAM/trans/doc/2001/wp29grpe/TRANS-WP29-GRPE-42-inf02.pdf (accessed on 6 July 2023).

| Parameter | Value | Unit |

|---|---|---|

| Maximum Engine Power | 254 | kW |

| Continuous Alternator Power | 177 | kW |

| Peak Motor Torque | 1900 | Nm |

| Battery Capacity | 46 | Ah |

| Vehicle Mass | 12,600 | kg |

| Wheel Load | 3500 | kg |

| Vehicle Frontal Area | 7.75 | m2 |

| Wheelbase | 3.3 | m |

| Final Drive Ratio | 28 | - |

| Tire | 900/60 R38 | - |

| Cycle pt. | Rolling Resistance | Tire Friction |

|---|---|---|

| Part 1 | 0.09 | 0.6 |

| Part 2 | 0.02 | 0.6 |

| Part 3 | 0.02 | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medževeprytė, U.K.; Makaras, R.; Lukoševičius, V.; Kilikevičius, S. Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle. Energies 2023, 16, 5379. https://doi.org/10.3390/en16145379

Medževeprytė UK, Makaras R, Lukoševičius V, Kilikevičius S. Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle. Energies. 2023; 16(14):5379. https://doi.org/10.3390/en16145379

Chicago/Turabian StyleMedževeprytė, Ugnė Koletė, Rolandas Makaras, Vaidas Lukoševičius, and Sigitas Kilikevičius. 2023. "Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle" Energies 16, no. 14: 5379. https://doi.org/10.3390/en16145379

APA StyleMedževeprytė, U. K., Makaras, R., Lukoševičius, V., & Kilikevičius, S. (2023). Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle. Energies, 16(14), 5379. https://doi.org/10.3390/en16145379