Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle

Abstract

:1. Introduction

2. Methods

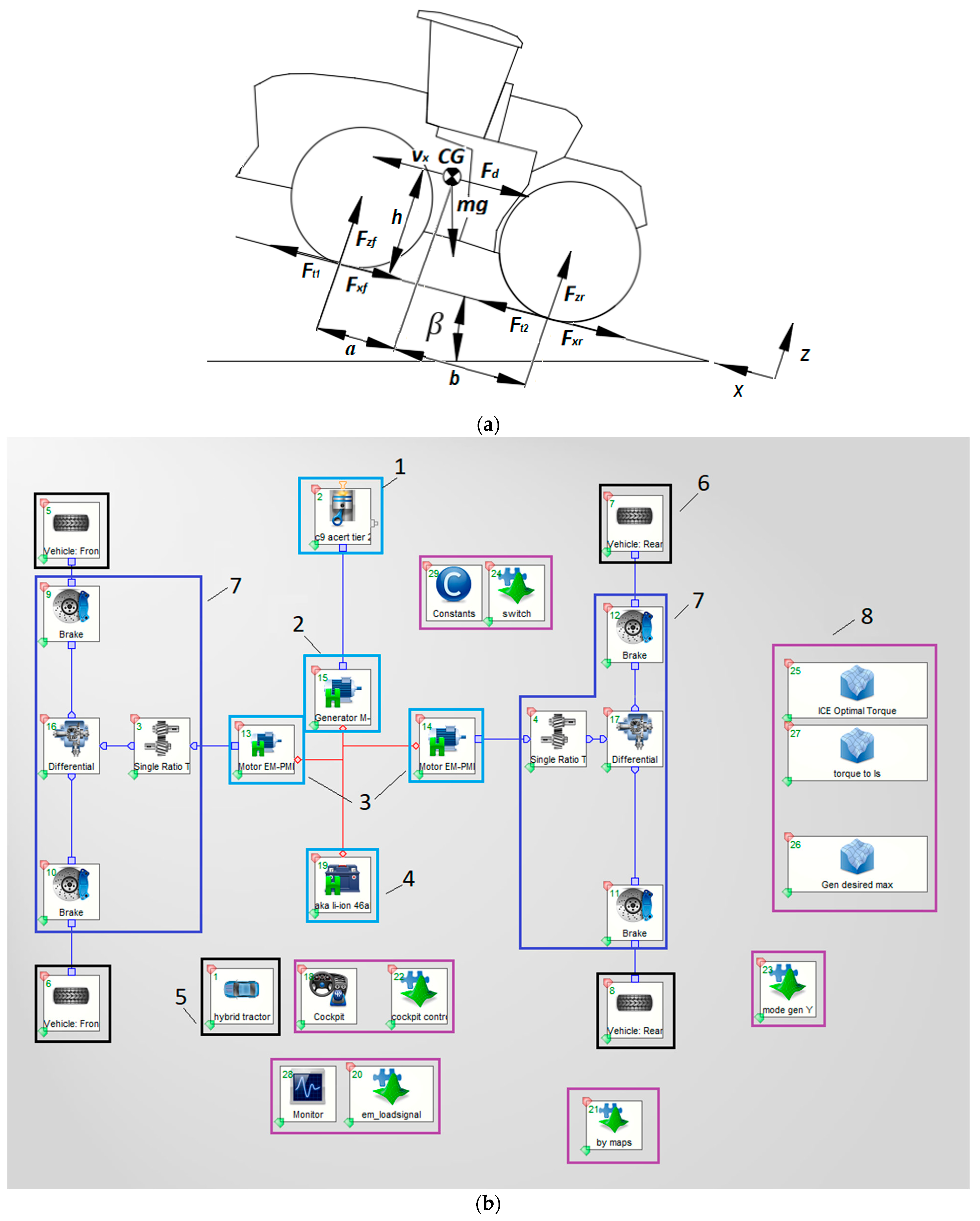

2.1. Vehicle Models

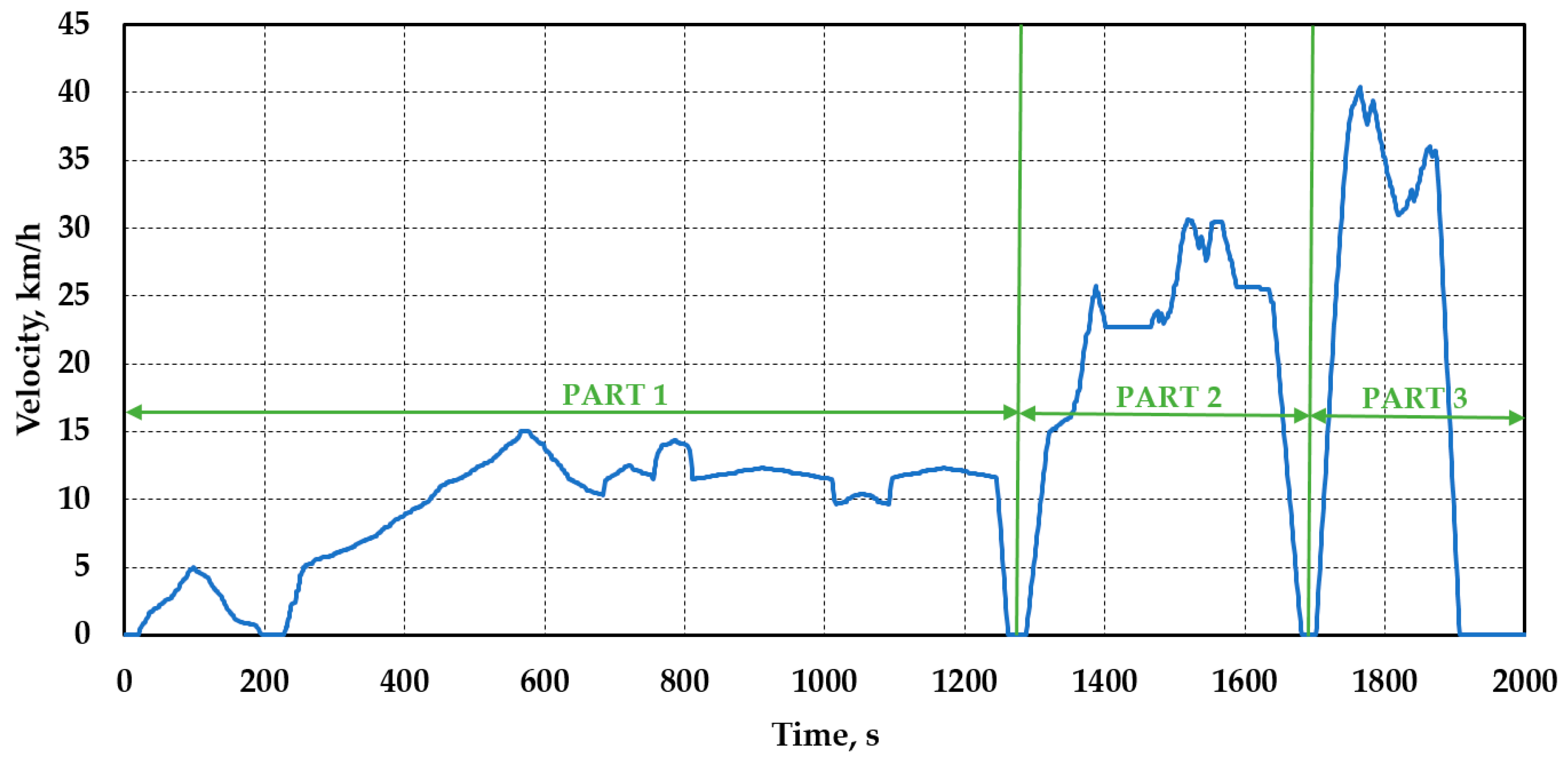

2.2. Hybrid Operational Cycle

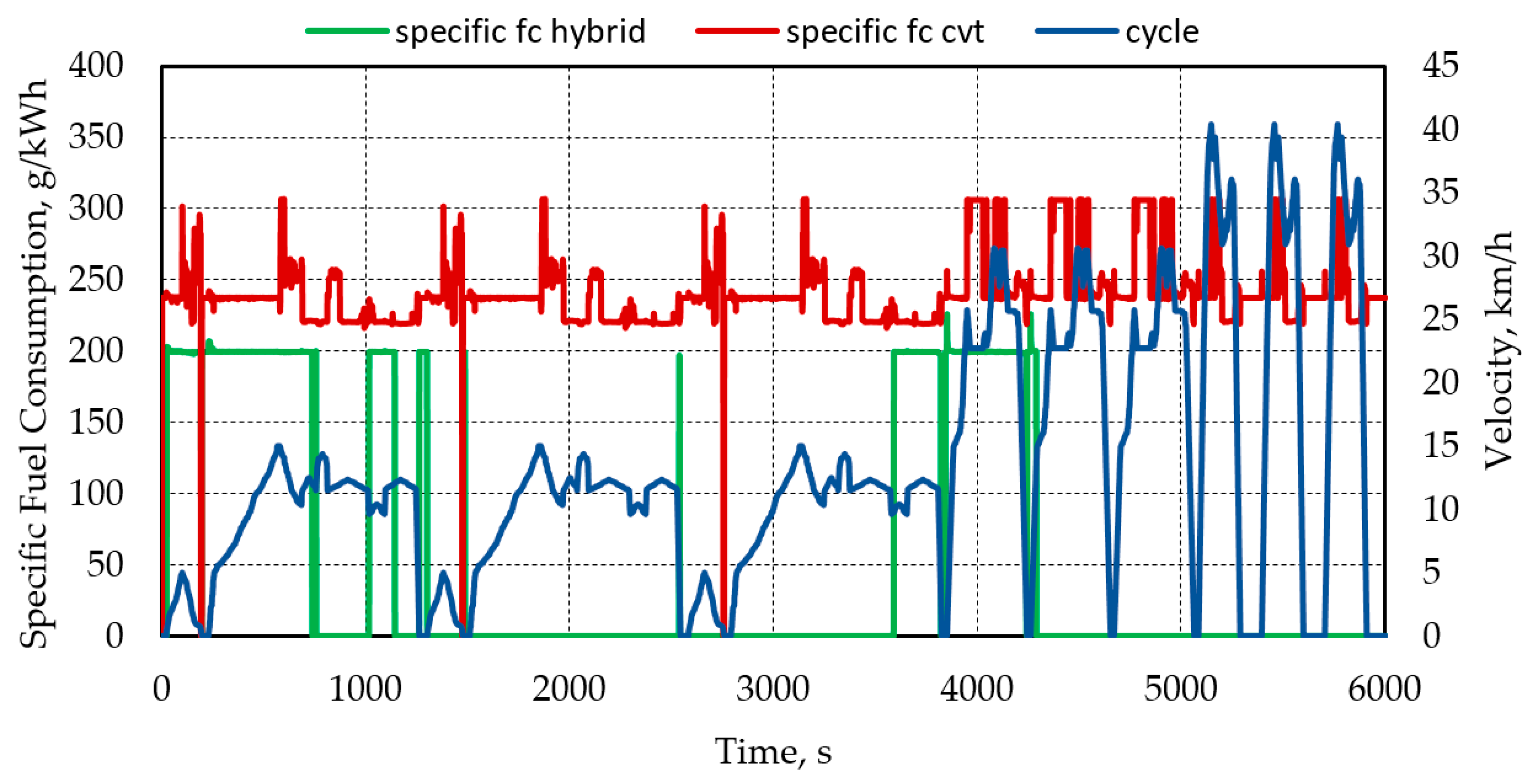

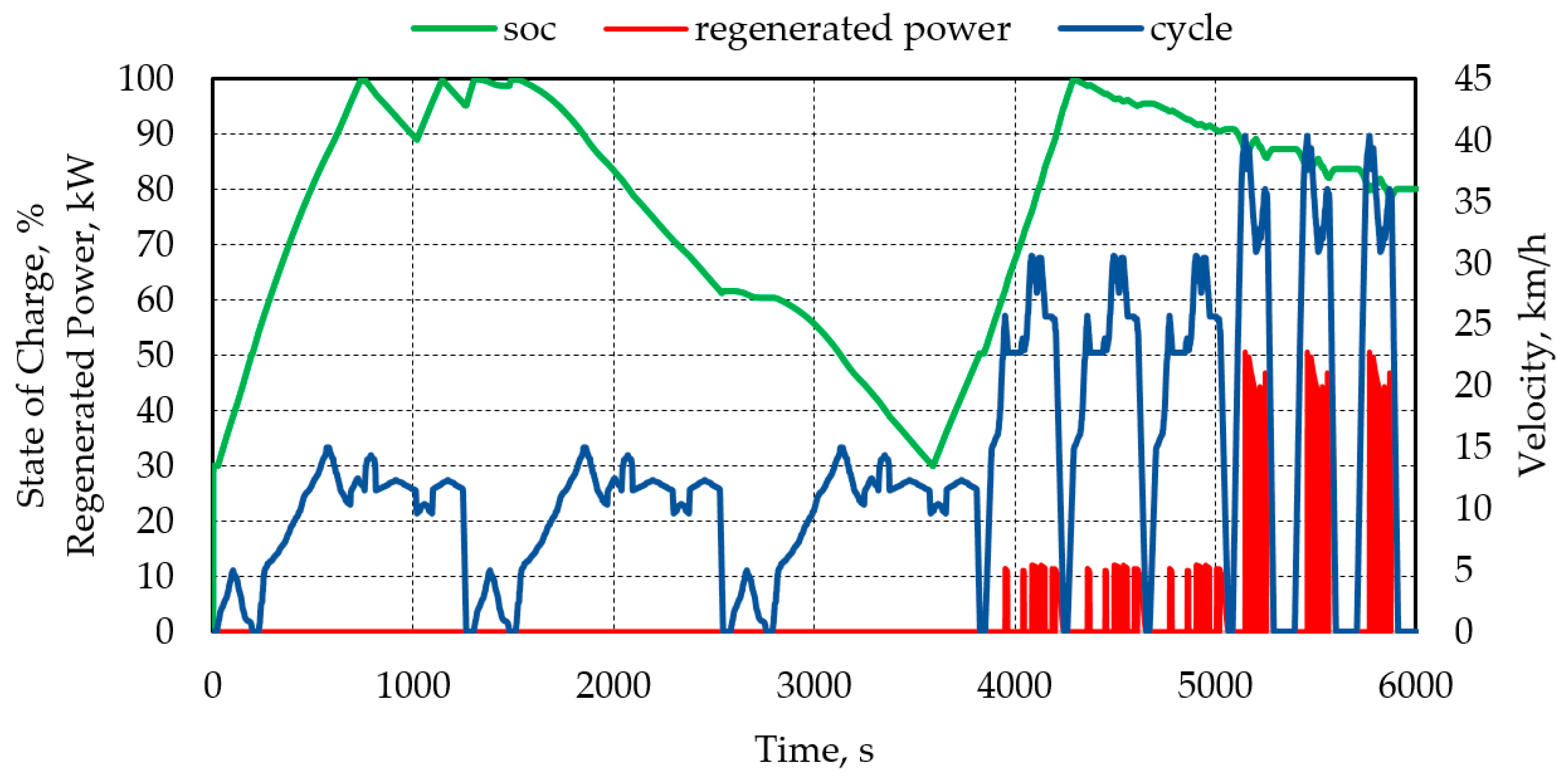

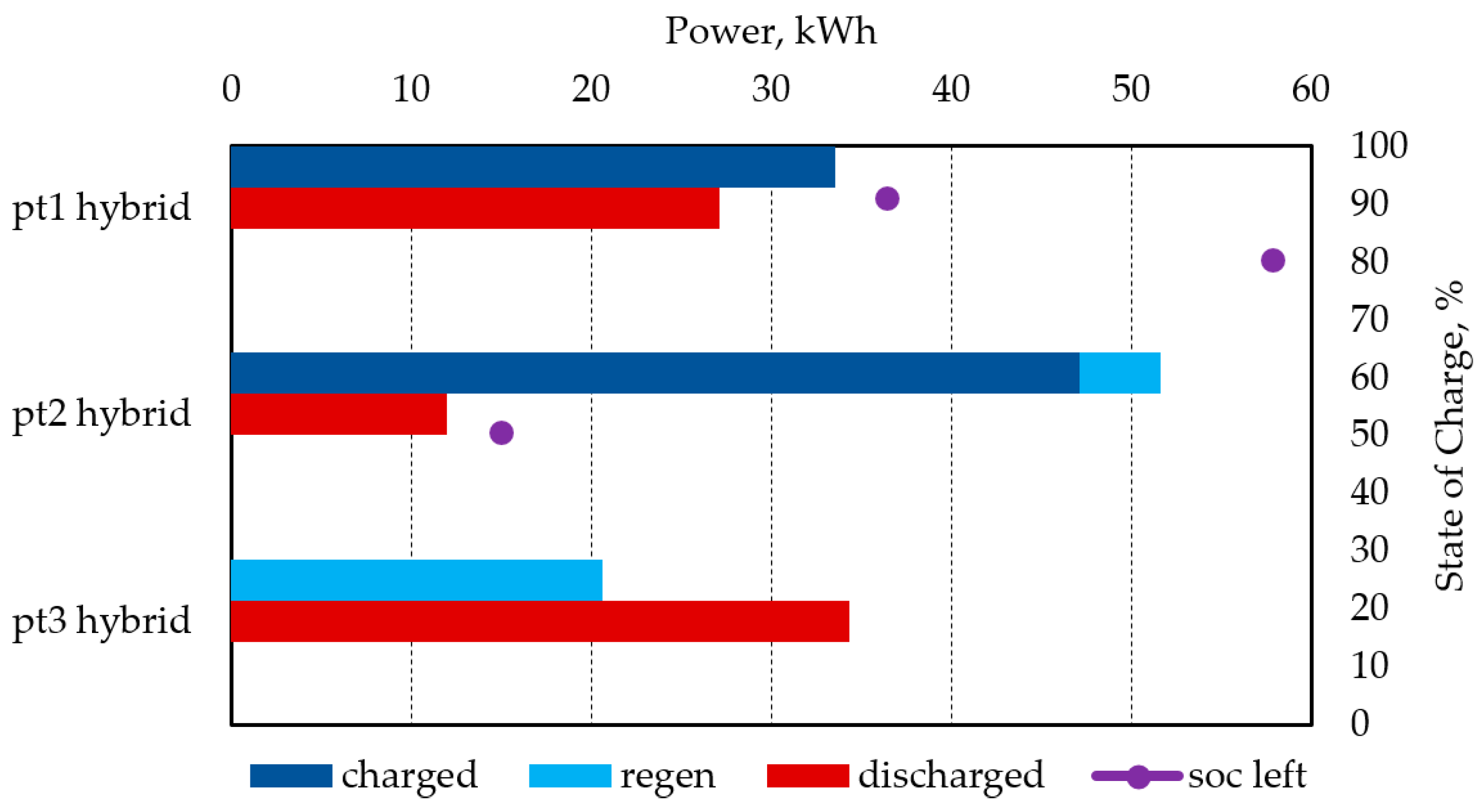

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sato, S.; Jiang, Y.J.; Russell, R.L.; Miller, J.W.; Karavalakis, G.; Durbin, T.D.; Johnson, K.C. Experimental driving performance evaluation of battery-powered medium and heavy duty all-electric vehicles. Int. J. Electr. Power Energy Syst. 2022, 141, 108100. [Google Scholar] [CrossRef]

- Troncon, D.; Alberti, L. Case of Study of the Electrification of a Tractor: Electric Motor Performance Requirements and Design. Energies 2020, 13, 2197. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Monsalve, G.; Cardenas, A.; Mousazadeh, H. Off-Road Electric Vehicles and Autonomous Robots in Agricultural Sector: Trends, Challenges, and Opportunities. Vehicles 2022, 4, 843–864. [Google Scholar] [CrossRef]

- Li, T.; Xie, B.; Li, Z.; Li, J. Design and optimization of a dual-input coupling powertrain system: A case study for electric tractors. Appl. Sci. 2020, 10, 1608. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.; Kim, Y.; Choi, C.; Chung, S.; Inoue, E.; Okayasu, T. Development of a Parallel Hybrid System for Agricultural Tractors. Bull. Fac. Agric. Kyushu Univ. 2017, 62, 137–144. [Google Scholar] [CrossRef]

- Moreda, G.P.; Munoz-Garcia, M.A.; Barreiro, P. High voltage electrification and agricultural machinery—A review. Energy Convers. Manag. 2016, 115, 117–131. [Google Scholar] [CrossRef]

- Un-Noor, F.; Wu, G.; Perugu, H.; Collier, S.; Yoon, S.; Barth, M.; Boriboonsomsin, K. Off-Road Construction and Agricultural Equipment Electrification: Review, Challenges, and Opportunities. Vehicles 2022, 4, 780–807. [Google Scholar] [CrossRef]

- Mocera, F.; Martelli, S.; Somà, A. State of the Art and Future Trends of Electrification in Agricultural Tractors. SAE Tech. Pap. 2022. [Google Scholar] [CrossRef]

- Kim, D.-M.; Benoliel, P.; Kim, D.-K.; Lee, T.H.; Park, J.W.; Hong, J.-P. Framework development of series hybrid powertrain design for heavy-duty vehicle considering driving conditions. IEEE Trans. Veh. Technol. 2019, 68, 6468–6480. [Google Scholar] [CrossRef]

- Kim, D.-M.; Lee, S.-G.; Kim, D.-K.; Park, M.-R.; Lim, M.-S. Sizing and optimization process of hybrid electric propulsion system for heavy-duty vehicle based on Gaussian process modeling considering traction motor characteristics. Renew. Sustain. Energy Rev. 2022, 161, 11228. [Google Scholar] [CrossRef]

- Feng, Y.; Dong, Z. Optimal energy management with balanced fuel economy and battery life for large hybrid electric mining truck. J. Power Sources 2020, 454, 227948. [Google Scholar] [CrossRef]

- Feng, Y.; Dong, Z. Comparative lifecycle costs and emissions of electrified powertrains for light-duty logistics trucks. Transp. Res. Part D: Transp. Environ. 2023, 117, 103672. [Google Scholar] [CrossRef]

- Lajunen, A.; Suomela, J. Evaluation of energy storage system requirements for hybrid mining loaders. IEEE Trans. Veh. Technol. 2012, 61, 3387–3393. [Google Scholar] [CrossRef]

- Yang, W.; Liang, J.; Yang, J.; Zhang, N. Investigation of a novel coaxial power-split hybrid powertrain for mining trucks. Energies 2018, 11, 172. [Google Scholar] [CrossRef] [Green Version]

- Ceraolo, M.; Lutzemberger, G. Heavy-duty hybrid transportation systems: Design, modeling, and energy management. In Hybrid Energy Systems, Hybrid Technologies for Power Generation; Lo Faro, M., Barbera, O., Giacoppo, G., Eds.; Academic Press: Cambridge, MA, USA, 2022; pp. 313–336. [Google Scholar] [CrossRef]

- Medževeprytė, U.K.; Makaras, R.; Lukoševičius, V.; Keršys, A. Evaluation of the Working Parameters of a Series-Hybrid Tractor under the Soil Work Conditions. Teh. Vjesn. 2022, 29, 45–50. [Google Scholar] [CrossRef]

- Medževeprytė, U.K.; Makaras, R.; Rimkus, A. Efficiency of an off-road heavy-duty series hybrid drive based on a modified world harmonized transient cycle. Transp. Probl. 2022, 17, 187–195. [Google Scholar] [CrossRef]

- Xie, S.; Peng, J.; He, H. Plug-in hybrid electric bus energy management based on stochastic model predictive control. Energy Procedia 2017, 105, 2672–2677. [Google Scholar] [CrossRef]

- Wu, Z.; Xie, B.; Li, Z.; Chi, R.; Ren, Z.; Du, Y.; Hirai, Y. Modelling and verification of driving torque management for electric tractor: Dual-mode driving intention interpretation with torque demand restriction. Biosyst. Eng. 2019, 182, 65–83. [Google Scholar] [CrossRef]

- Yang, H.; Sun, Y.; Xia, C.; Zhang, H. Research on Energy Management Strategy of Fuel Cell Electric Tractor Based on Multi-Algorithm Fusion and Optimization. Energies 2022, 15, 6389. [Google Scholar] [CrossRef]

- Wang, S.; Wu, X.; Zhao, X.; Wang, S.; Xie, B.; Song, Z.; Wang, D. Co-optimization energy management strategy for a novel dual-motor drive system of electric tractor considering efficiency and stability. Energy 2023, 281, 128074. [Google Scholar] [CrossRef]

- Rossi, C.; Pontara, D.; Falcomer, C.; Bertoldi, M.; Mandrioli, R. A hybrid–electric driveline for agricultural tractors based on an e-CVT power-split transmission. Energies 2021, 14, 6912. [Google Scholar] [CrossRef]

- Gupta, S.; Maity Sr, R.; Kulkarni Ceng, S. Modeling, Analysis and Experimental Validation of Tractor Architectures for Rural Electrification. In Proceedings of the 8th SAEINDIA International Mobility Conference & Exposition and Commercial Vehicle Engineering Congress 2013 (SIMCOMVEC), Chennai, India, 4–7 December 2013. [Google Scholar]

- Scolaro, E.; Alberti, L.; Barater, D. Electric Drives for Hybrid Electric Agricultural Tractors. In Proceedings of the 2021 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Modena, Italy, 8–9 April 2021; pp. 331–336. [Google Scholar] [CrossRef]

- Bouquain, D.; Blunier, B.; Miraoui, A. HEV series architectures evaluation: Modeling, simulation and experimentation. In Proceedings of the 2009 IEEE Vehicle Power and Propulsion Conference, Dearborn, MI, USA, 7–10 September 2009; pp. 584–591. [Google Scholar] [CrossRef]

- Xu, W.; Liu, M.; Xu, L.; Zhang, S. Energy Management Strategy of Hydrogen Fuel Cell/Battery/Ultracapacitor Hybrid Tractor Based on Efficiency Optimization. Appl. Sci. 2023, 13, 151. [Google Scholar] [CrossRef]

- Dou, H.; Wei, H.; Zhang, Y.; Ai, Q. Configuration Design and Optimal Energy Management for Coupled-Split Powertrain Tractor. Machines 2022, 10, 1175. [Google Scholar] [CrossRef]

- Zhu, Z.; Zeng, L.; Chen, L.; Zou, R.; Cai, Y. Fuzzy Adaptive Energy Management Strategy for a Hybrid Agricultural Tractor Equipped with HMCVT. Agriculture 2022, 12, 1986. [Google Scholar] [CrossRef]

- Goswami, G.; Tupitsina, A.; Jaiswal, S.; Nutakor, C.; Lindh, T.; Sopanen, J. Comparison of various hybrid electric powertrains for non-road mobile machinery using real-time multibody simulation. IEEE Access 2022, 10, 107631–107648. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V.; Somà, A. Comparative Analysis of Hybrid Electric Architectures for Specialized Agricultural Tractors. Energies 2022, 15, 1944. [Google Scholar] [CrossRef]

- Mocera, F.; Martini, V. Numerical performance investigation of a hybrid eCVT specialized agricultural tractor. Appl. Sci. 2022, 12, 2438. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. A Review of Hybrid Electric Architectures in Construction, Handling and Agriculture Machines. In New Perspectives on Electric Vehicles; IntechOpen: London, UK, 2021; Available online: https://books.google.lt/books?hl=lt&lr=&id=jtFuEAAAQBAJ&oi=fnd&pg=PA49&dq=A+Review+of+Hybrid+Electric+Architectures+in+Construction,+Handling+and+Agriculture+Machines&ots=SAjwcZEdoG&sig=-CM7MxMM5GWUCljNwY6ckThX3EY&redir_esc=y#v=onepage&q=A%20Review%20of%20Hybrid%20Electric%20Architectures%20in%20Construction%2C%20Handling%20and%20Agriculture%20Machines&f=false (accessed on 15 April 2023).

- Mocera, F. A Model-Based Design Approach for a Parallel Hybrid Electric Tractor Energy Management Strategy Using Hardware in the Loop Technique. Vehicles 2020, 3, 1–19. [Google Scholar] [CrossRef]

- Xu, L.; Liu, M.; Zhou, Z. Design of drive system for series hybrid electric tractor. Trans. CSAE 2014, 30, 11–18. [Google Scholar]

- Wang, X.; Huang, Y.; Wang, J. Study on Driver-Oriented Energy Management Strategy for Hybrid Heavy-Duty Off-Road Vehicles under Aggressive Transient Operating Condition. Sustainability 2023, 15, 7539. [Google Scholar] [CrossRef]

- Wen, C.-K.; Zhang, S.-L.; Xie, B.; Song, Z.-H.; Li, T.-H.; Jia, F.; Han, J.-G. Design and verification innovative approach of dual-motor power coupling drive systems for electric tractors. Energy 2022, 247, 123538. [Google Scholar] [CrossRef]

- Ueka, Y.; Yamashita, J.; Sato, K.; Doi, Y. Study on the Development of the Electric Tractor: Specifications and Traveling and Tilling Performance of a Prototype Electric Tractor. Eng. Agric. Environ. Food 2013, 6, 160–164. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, G.; Liu, M.; Yan, X.; Xu, L.; Shang, C. Research on Global Optimal Energy Management Strategy of Agricultural Hybrid Tractor Equipped with CVT. World Electr. Veh. J. 2023, 14, 127. [Google Scholar] [CrossRef]

- Cheng, Z.; Chen, Y.; Li, W.; Zhou, P.; Liu, J.; Li, L.; Chang, W.; Qian, Y. Optimization Design Based on I-GA and Simulation Test Verification of 5-Stage Hydraulic Mechanical Continuously Variable Transmission Used for Tractor. Agriculture 2022, 12, 807. [Google Scholar] [CrossRef]

- Fu, B.; Zhu, T.; Liu, J.; Zhao, Y.; Chen, J. Influencing Factors of Electric Vehicle Economy Based on Continuously Variable Transmission. Int. J. Automot. Technol. 2022, 23, 717–728. [Google Scholar] [CrossRef]

- Fu, B.; Zhu, T.; Liu, J.; Hu, X. Research on Clamping Force Control of CVT for Electric Vehicles Based on Slip Characteristics. Sensors 2022, 22, 2131. [Google Scholar] [CrossRef]

- Hu, J.; Xiao, F.; Peng, H.; Zhao, W. CVT discrete speed ratio optimizations based on energy efficiency for PHEV. Alex. Eng. J. 2022, 61, 4095–4105. [Google Scholar] [CrossRef]

- Wang, Q.; Frank, A.A. Plug-in HEV with CVT: Configuration, control, and its concurrent multi-objective optimization by evolutionary algorithm. Int. J. Automot. Technol. 2014, 15, 103–115. [Google Scholar] [CrossRef]

- Williamson, S.S.; Khaligh, A.; Oh, S.C.; Emadi, A. Impact of energy storage device selection on the overall drive train efficiency and performance of heavy-duty hybrid vehicles. In Proceedings of the 2005 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 7 September 2005; p. 10. [Google Scholar] [CrossRef]

- Kodjak, D.; Sharpe, B.; Delgado, O. Evolution of heavy-duty vehicle fuel efficiency policies in major markets. Mitig Adapt Strat. Glob. Change 2015, 20, 755–775. [Google Scholar] [CrossRef]

- Banjac, T.; Trenc, F.; Katrašnik, T. Energy conversion efficiency of hybrid electric heavy-duty vehicles operating according to diverse drive cycles. Energy Convers. Manag. 2009, 50, 2865–2878. [Google Scholar] [CrossRef]

- Giuliano, G.; Dessouky, M.; Dexter, S.; Fang, J.; Hu, S.; Miller, M. Heavy-duty trucks: The challenge of getting to zero. Transp. Res. Part D Transp. Environ. 2021, 93, 102742. [Google Scholar] [CrossRef]

- Rajamani, R. Longitudinal Vehicle Dynamics. In Vehicle Dynamics and Control. Mechanical Engineering Series; Springer: Boston, MA, USA, 2006; pp. 95–122. [Google Scholar] [CrossRef]

- Mocera, F.; Somà, A. Analysis of a parallel hybrid electric tractor for agricultural applications. Energies 2020, 13, 3055. [Google Scholar] [CrossRef]

- Steven, H. Development of a Worldwide Harmonised Heavy-Duty Engine Emissions Test Cycle. Final Report. April 2001. Available online: https://unece.org/DAM/trans/doc/2001/wp29grpe/TRANS-WP29-GRPE-42-inf02.pdf (accessed on 6 July 2023).

| Parameter | Value | Unit |

|---|---|---|

| Maximum Engine Power | 254 | kW |

| Continuous Alternator Power | 177 | kW |

| Peak Motor Torque | 1900 | Nm |

| Battery Capacity | 46 | Ah |

| Vehicle Mass | 12,600 | kg |

| Wheel Load | 3500 | kg |

| Vehicle Frontal Area | 7.75 | m2 |

| Wheelbase | 3.3 | m |

| Final Drive Ratio | 28 | - |

| Tire | 900/60 R38 | - |

| Cycle pt. | Rolling Resistance | Tire Friction |

|---|---|---|

| Part 1 | 0.09 | 0.6 |

| Part 2 | 0.02 | 0.6 |

| Part 3 | 0.02 | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Medževeprytė, U.K.; Makaras, R.; Lukoševičius, V.; Kilikevičius, S. Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle. Energies 2023, 16, 5379. https://doi.org/10.3390/en16145379

Medževeprytė UK, Makaras R, Lukoševičius V, Kilikevičius S. Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle. Energies. 2023; 16(14):5379. https://doi.org/10.3390/en16145379

Chicago/Turabian StyleMedževeprytė, Ugnė Koletė, Rolandas Makaras, Vaidas Lukoševičius, and Sigitas Kilikevičius. 2023. "Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle" Energies 16, no. 14: 5379. https://doi.org/10.3390/en16145379

APA StyleMedževeprytė, U. K., Makaras, R., Lukoševičius, V., & Kilikevičius, S. (2023). Application and Efficiency of a Series-Hybrid Drive for Agricultural Use Based on a Modified Version of the World Harmonized Transient Cycle. Energies, 16(14), 5379. https://doi.org/10.3390/en16145379