Performance Improvement of Permanent-Magnet-Synchronous Motors through Rotor Shape Optimization of Marine Blowing System with High-Speed Rotation

Abstract

:1. Introduction

2. Characteristics of Air-Conditioning and Blowing Systems and Motor

2.1. Air-Conditioning and Blowing Systems for Ships

2.2. Basic Specifications of Motors for Air-Conditioning and Blowing Systems

3. Additional Protrusion Model Considering High-Speed Rotation

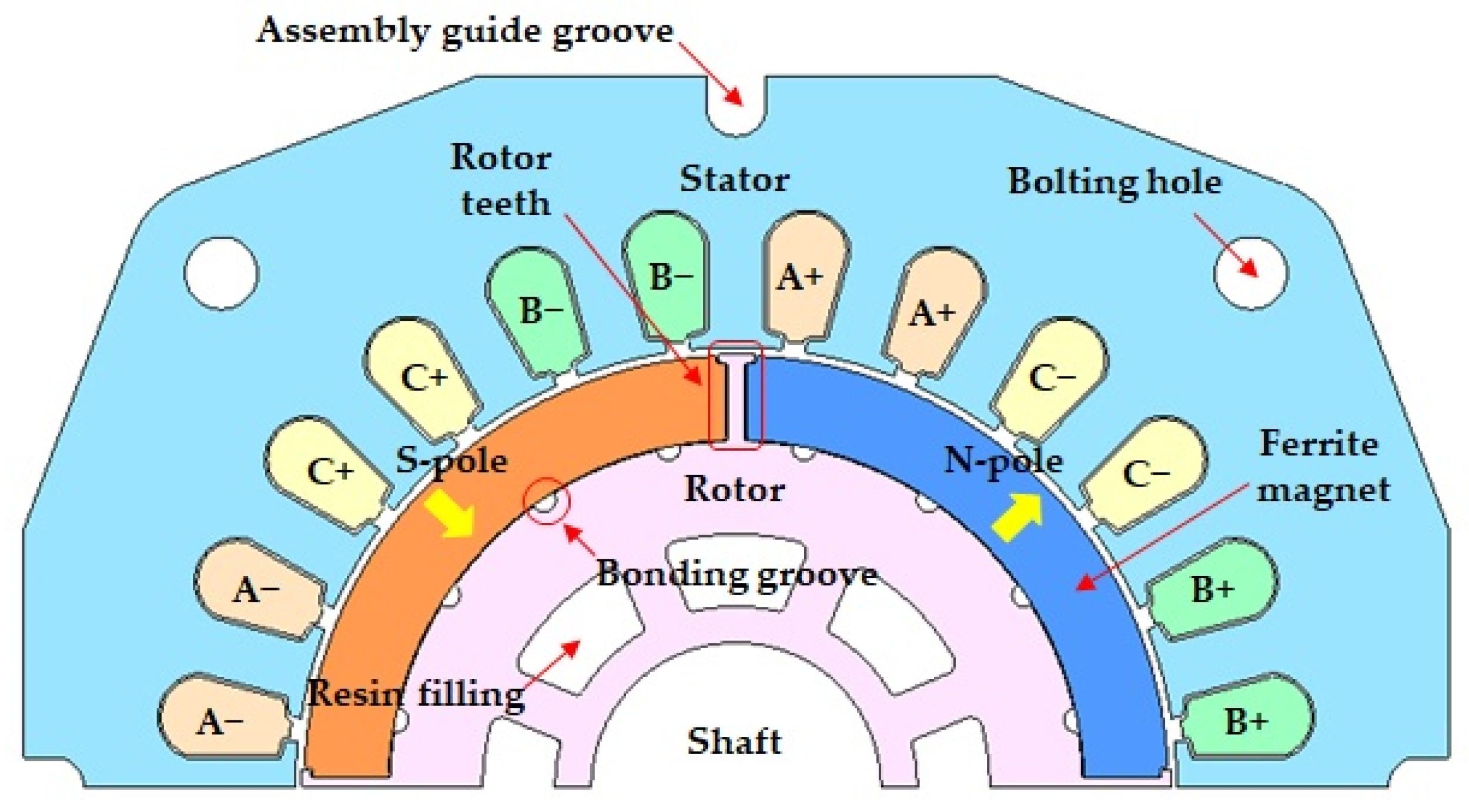

3.1. Basic Model Selection and Structural Characteristics

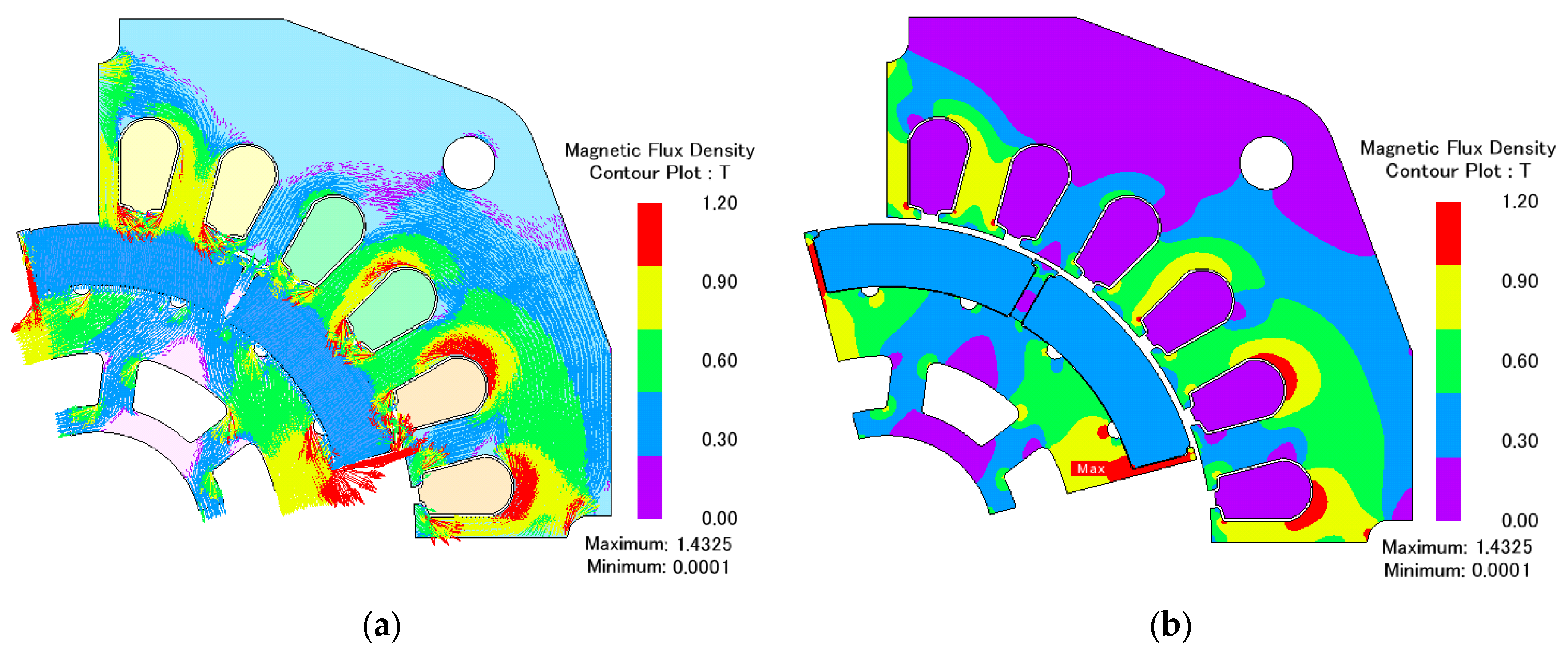

3.2. Characteristic Analysis at No Load

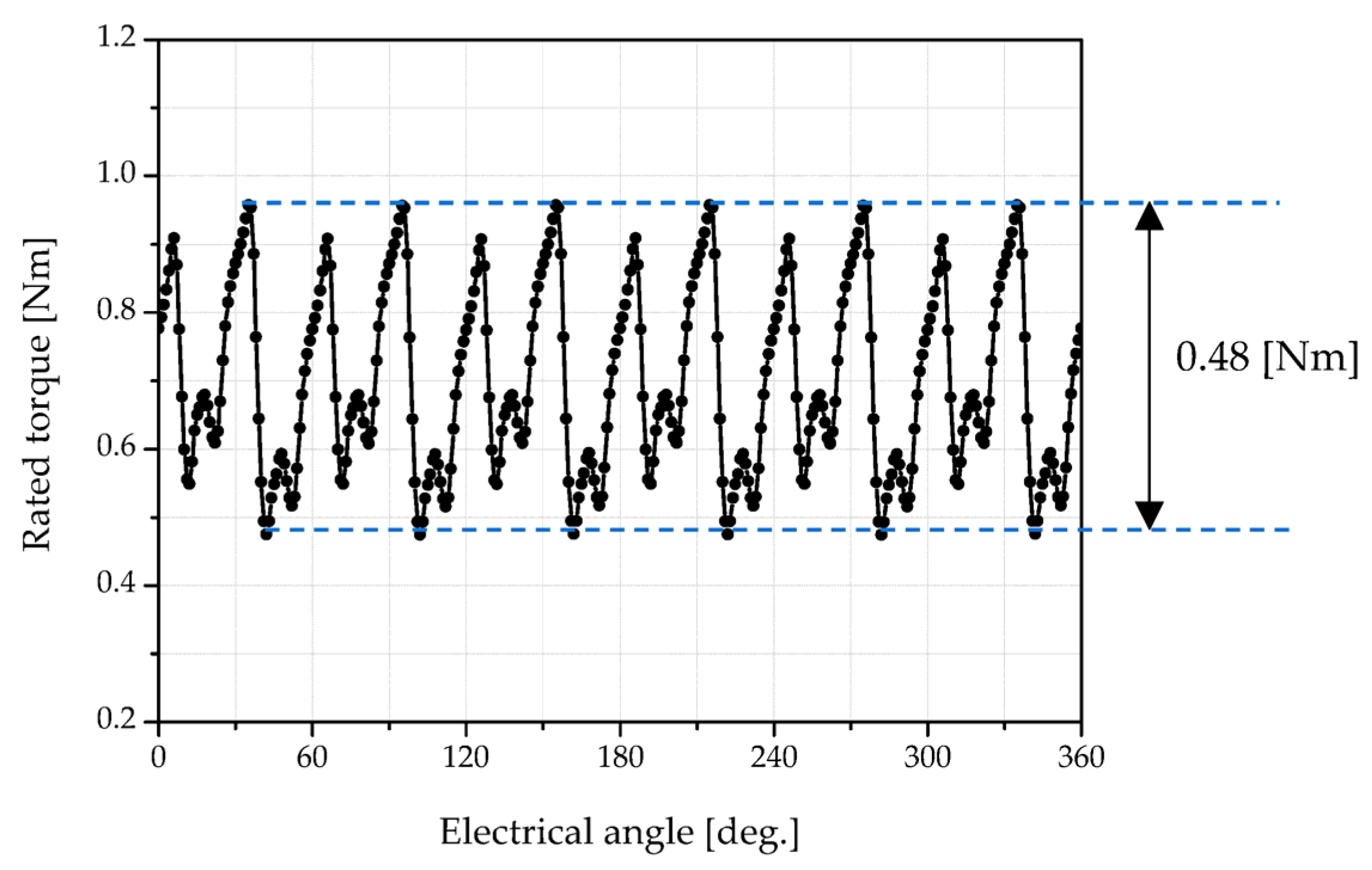

3.3. Characteristic Analysis at Rated Load

4. Optimization for Proposed Model

4.1. Optimization Process and Design Parameters Setting

4.2. Characteristic Analysis for Setting Objective Function and Design of Experiment

- -

- Bond application area: increased by more than 10 [%] compared with the basic model;

- -

- Cogging torque at no load: less than 0.2 [Nm];

- -

- THD of back EMF at no load: 38.6 [%] or less;

- -

- Torque ripple at load: minimized;

- -

- Efficiency at load: maximum (>90.9 [%]).

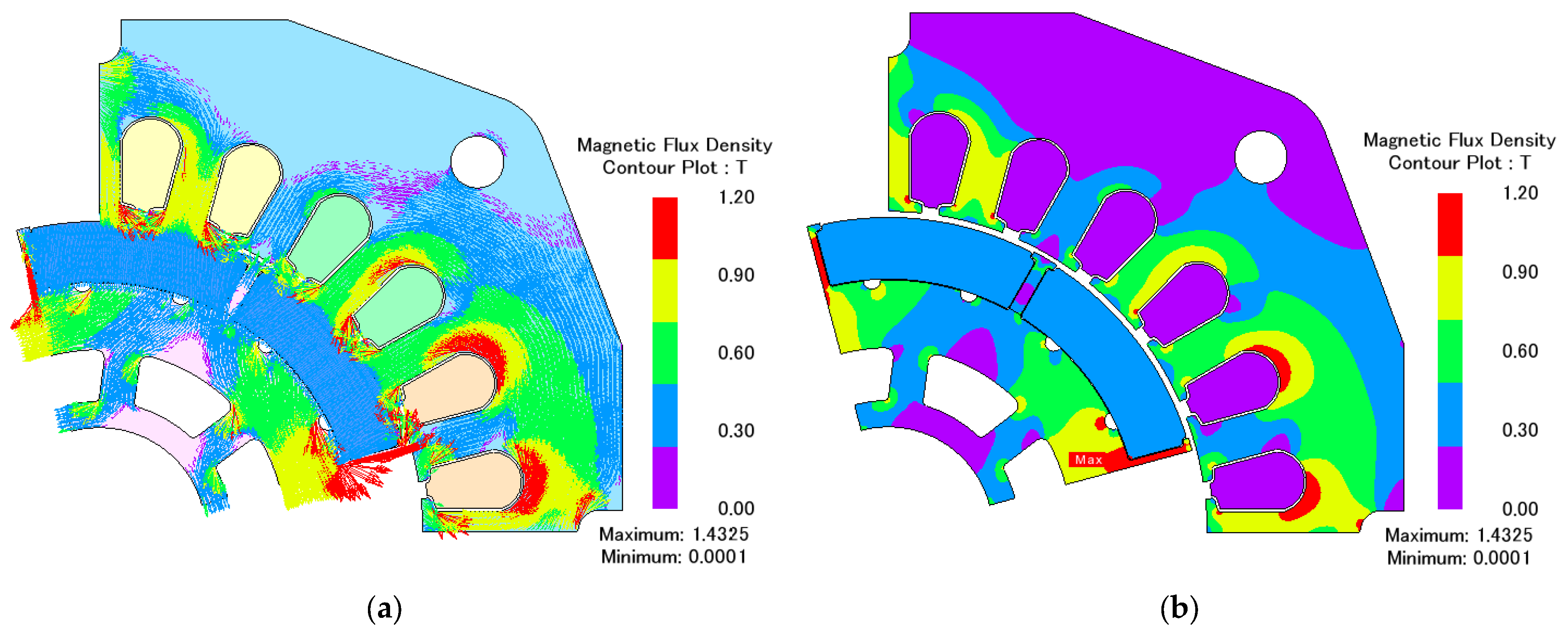

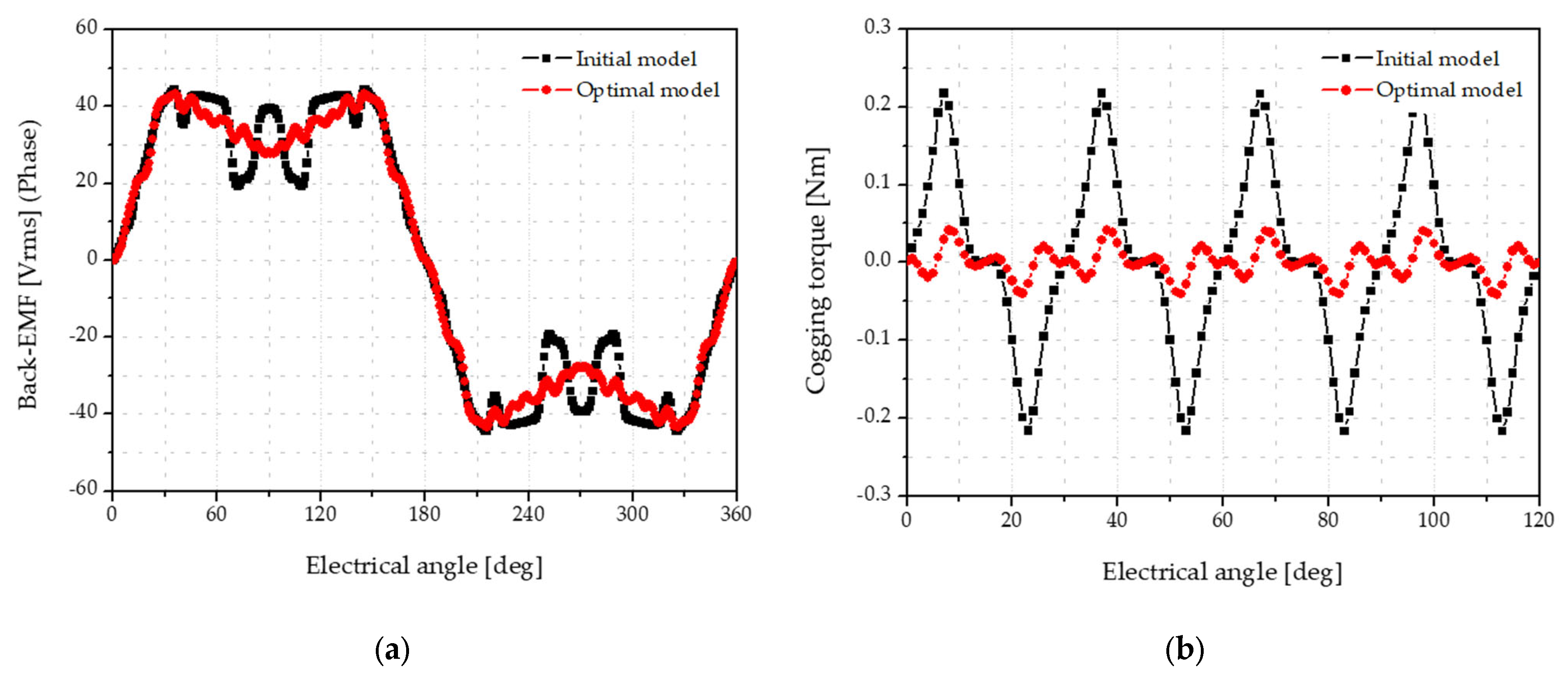

4.3. Characteristic Analysis of Optimal Model

4.4. Excitation Source Analysis of Torque Ripple

5. Stress and Natural Vibration Mode Analysis of Rotor Structure

5.1. Stress Analysis of Rotor Structure

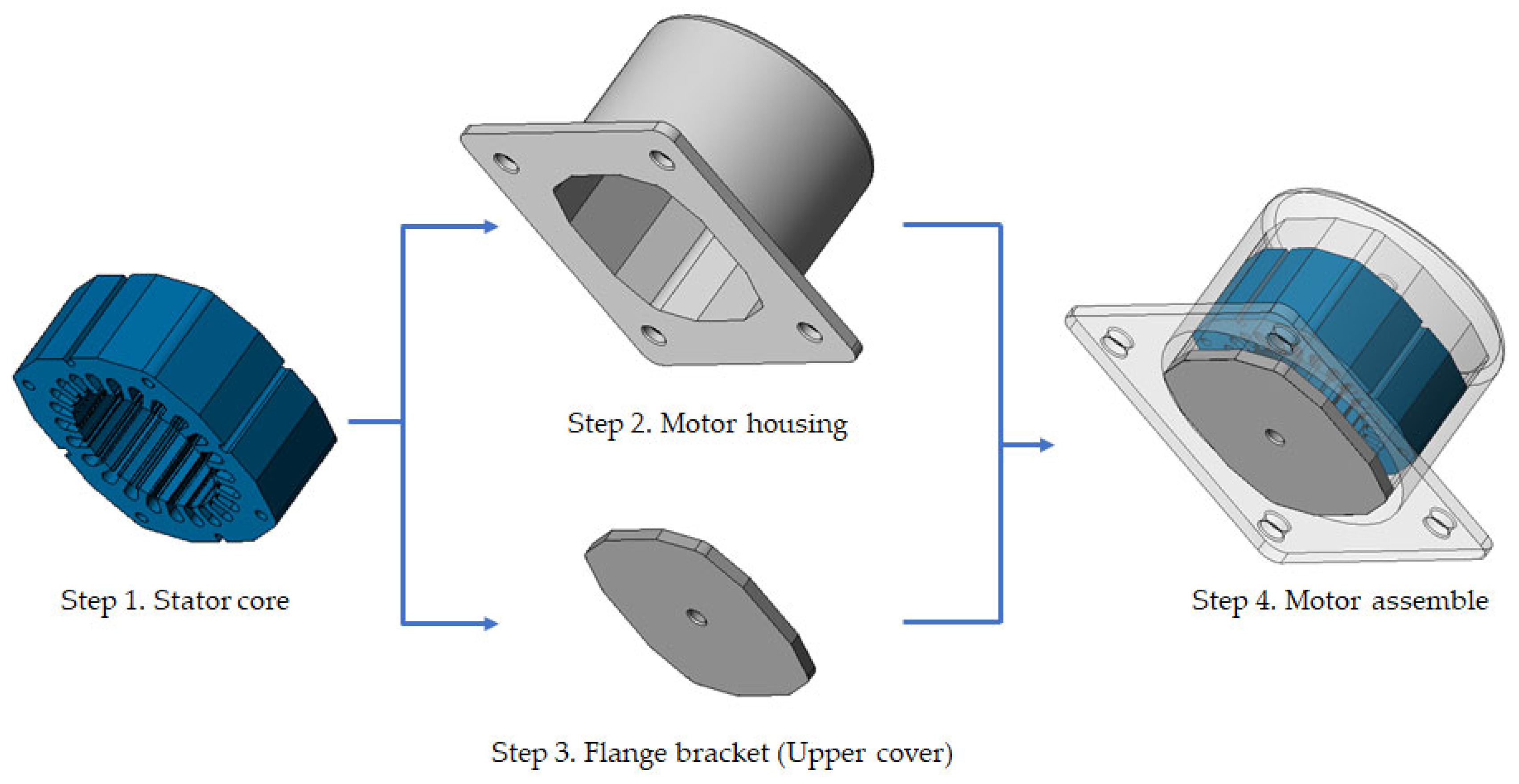

5.2. Natural Vibration Mode Analysis (Stator and Case Part)

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ajioka, Y.; Ohno, K. Electric Propulsion Systems for Ships. Hitachi Rev. 2013, 62, 231. [Google Scholar]

- Ma, F.; Qi, L.; Ye, S.; Chen, Y.; Xiao, H.; Li, S. Research on Fault Diagnosis Algorithm of Ship Electric Propulsion Motor. Appl. Sci. 2023, 13, 4064. [Google Scholar] [CrossRef]

- Yu, C.; Qi, L.; Sun, J.; Jiang, C.; Su, J.; Shu, W. Fault Diagnosis Technology for Ship Electrical Power System. Energies 2022, 15, 1287. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, Y.; Zhao, X.; Hu, Q.; Liu, D. Fuzzy wavelet network intelligent predictive controller for vacuum injection molding. Comput. Integr. Manuf. Syst. 2010, 16, 2647–2652. [Google Scholar]

- Hu, Y. Model Predictive Torque Control Strategy for Marine Permanent Magnet Synchronous Propulsion Motor. Master’s Thesis, Wuhan University of Technology, Wuhan, China, 2019. [Google Scholar]

- Zhang, L.; Yang, M. Fault diagnosis of permanent magnet synchronous motor based on mixup-LSTM. Electr. Switch. 2022, 60, 58–62. [Google Scholar]

- Xue, S.; He, Q.; Pan, J.; Huang, X. Research on dynamic eccentricity fault diagnosis method of permanent magnet synchronous motor based on GA-SVM. Zuhe Jichuang Yu Zidonghua Jiagong Jishu 2022, 99–103. [Google Scholar]

- Sifang, Z.; Qiang, S.; Yanming, Z.; Wei, Z. Mechanical fault detection of permanent magnet synchronous motor based on improved DFA and LDA. J. Beijing Inst. Technol. 2023, 43, 61–69. [Google Scholar] [CrossRef]

- Niu, H.C.; Zhao, M.L.; Qin, F.Z. Study on the Ship Electric Propulsion System and Its Development. In Proceedings of the 7th International Conference on Applied Science, Engineering and Technology (ICASET 2017), Qingdao, China, 29–30 July 2017; Atlantis Press: Amsterdam, The Netherlands, 2017; pp. 212–216. [Google Scholar] [CrossRef]

- Jeong, C.-L.; Kim, Y.-K.; Hur, J. Optimized Design of PMSM With Hybrid-Type Permanent Magnet for Improving Performance and Reliability. IEEE Trans. Ind. Appl. 2019, 55, 4692–4701. [Google Scholar] [CrossRef]

- You, Y.-M.; Chung, D.-W. Optimal Design of a Permanent Magnet Synchronous Motor to Improve Torque and Demagnetization Characteristics. J. Magn. 2017, 22, 423–429. [Google Scholar] [CrossRef]

- Dong, J.N.; Huang, Y.K.; Jin, L.; Lin, H.Y. Comparative Study of Surface-Mounted and Interior Permanent-Magnet Motors for High-Speed Applications. IEEE Trans. Appl. Supercond. 2016, 26, 1–4. [Google Scholar] [CrossRef]

- Hong, J.; Wang, S.; Yang, Z. Comparison of electromagnetic excited vibration for SPM and IPM motors. In Proceedings of the 2017 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017; pp. 1–8. [Google Scholar] [CrossRef]

- Pellegrino, G.; Vagati, A.; Guglielmi, P.; Boazzo, B. Performance Comparison Between Surface-Mounted and Interior PM Motor Drives for Electric Vehicle Application. IEEE Trans. Ind. Electron. 2012, 59, 803–811. [Google Scholar] [CrossRef] [Green Version]

- Ahn, J.H.; Han, C.; Kim, C.W.; Choi, J.Y. Rotor Design of High-Speed Permanent Magnet Synchronous Motors Considering Rotor Magnet and Sleeve Materials. IEEE Trans. Appl. Supercond. 2018, 28, 1–4. [Google Scholar] [CrossRef]

- Chu, G.; Dutta, R.; Rahman, M.F.; Lovatt, H.; Sarlioglu, B. Analytical Calculation of Maximum Mechanical Stress on the Rotor of Interior Permanent-Magnet Synchronous Machines. IEEE Trans. Ind. Appl. 2020, 56, 1321–1331. [Google Scholar] [CrossRef]

- Du, G.; Xu, W.; Zhu, J.; Huang, N. Rotor Stress Analysis for High-Speed Permanent Magnet Machines Considering Assembly Gap and Temperature Gradient. IEEE Trans. Energy Convers. 2019, 34, 2276–2285. [Google Scholar] [CrossRef]

- Li, W.; Qiu, H.; Zhang, X.; Cao, J.; Zhang, S.; Yi, R. Influence of Rotor-Sleeve Electromagnetic Characteristics on High Speed Permanent-Magnet Generator. IEEE Trans. Ind. Electron. 2014, 61, 3030–3037. [Google Scholar] [CrossRef]

- Yang, Y.; Castano, S.M.; Yang, R.; Kasprzak, M.; Bilgin, B.; Sathyan, A.; Dadkhah, H.; Emadi, A. Design and Comparison of Interior Permanent Magnet Motor Topologies for Traction Applications. IEEE Trans. Transp. Electrif. 2017, 3, 86–97. [Google Scholar] [CrossRef]

- Kim, B.-C.; Lee, J.-H.; Kang, D.-W. A Study on the Effect of Eddy Current Loss and Demagnetization Characteristics of Magnet Division. IEEE Trans. Appl. Supercond. 2020, 30, 1–5. [Google Scholar] [CrossRef]

- Fengge, Z.; Guanghui, D.; Tianyu, W.; Guangwei, L. Review on Development and Design of High Speed Machines. Trans. Chin. Electrotech. Soc. 2016, 31, 1–18. [Google Scholar]

- Liu, G.; Liu, M.; Zhang, Y.; Wang, H.; Gerada, C. High-Speed Permanent Magnet Synchronous Motor Iron Loss Calculation Method Considering Multiphysics Factors. IEEE Trans. Ind. Electron. 2020, 67, 5360–5368. [Google Scholar] [CrossRef]

- Zhang, Y.; McLoone, S.; Cao, W.; Qiu, F.; Gerada, C. Power Loss and Thermal Analysis of a MW High-Speed Permanent Magnet Synchronous Machine. IEEE Trans. Energy Convers. 2017, 32, 1468–1478. [Google Scholar] [CrossRef] [Green Version]

- Du, G.; Huang, N.; He, H.; Lei, G.; Zhu, J. Parameter Design for a High-Speed Permanent Magnet Machine Under Multiphysics Constraints. IEEE Trans. Energy Convers. 2020, 35, 2025–2035. [Google Scholar] [CrossRef]

- Fang, H.; Li, D.; Qu, R.; Li, J.; Wang, C.; Song, B. Rotor Design and Eddy-Current Loss Suppression for High-Speed Machines With a Solid-PM Rotor. IEEE Trans. Ind. Appl. 2019, 55, 448–457. [Google Scholar] [CrossRef]

- Qi, Z.; Zhang, Y.; Yu, S.; Xu, Z. Design and Analysis of a 30 kW, 30,000 r/min High-Speed Permanent Magnet Motor for Compressor Application. Energies 2022, 15, 3923. [Google Scholar] [CrossRef]

- Qin, X.-F.; Shen, J.-X. Multi-Physics Design of High-Speed Large-Power Permanent Magnet Synchronous Motor. In Proceedings of the 2020 Fifteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 10–12 September 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Kirtley, J.L.; Banerjee, A.; Englebretson, S. Motors for Ship Propulsion. Proc. IEEE 2015, 103, 2320–2332. [Google Scholar] [CrossRef]

- Deb, K. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef] [Green Version]

- Ohnishi, T.; Takahashi, N. Optimal design of efficient IPM motor using finite element method. IEEE Trans. Magn. 2000, 36, 3537–3539. [Google Scholar] [CrossRef] [Green Version]

- Rahman, M.M.; Kim, K.-T.; Hur, J. Design and Optimization of Neodymium-Free SPOKE-Type Motor with Segmented Wing-Shaped PM. IEEE Trans. Magn. 2014, 50, 865–868. [Google Scholar] [CrossRef]

- Parasiliti, F.; Villani, M.; Lucidi, S.; Rinaldi, F. Finite-Element-Based Multiobjective Design Optimization Procedure of Interior Permanent Magnet Synchronous Motors for Wide Constant-Power Region Operation. IEEE Trans. Ind. Electron. 2012, 59, 2503–2514. [Google Scholar] [CrossRef]

- You, Y.-M.; Yoon, K.-Y. Multi-Objective Optimization of Permanent Magnet Synchronous Motor for Electric Vehicle Considering Demagnetization. Appl. Sci. 2021, 11, 2159. [Google Scholar] [CrossRef]

- Yoon, K.Y.; Hwang, K.Y. Optimal Design of Spoke-Type IPM Motor Allowing Irreversible Demagnetization to Minimize PM Weight. IEEE Access 2021, 9, 65721–65729. [Google Scholar] [CrossRef]

- Hwang, K.Y.; Jo, J.H.; Kwon, B.I. A Study on Optimal Pole Design of Spoke-Type IPMSM With Concentrated Winding for Reducing the Torque Ripple by Experiment Design Method. IEEE Trans. Magn. 2009, 45, 4712–4715. [Google Scholar] [CrossRef]

- Yoon, K.; Kwon, B. Optimal Design of a New Interior Permanent Magnet Model Using a Flared-Shape Arrangement of Ferrite Magnets. IEEE Trans. Magn. 2016, 52, 1–4. [Google Scholar] [CrossRef]

- Song, T.; Zhang, Z.; Liu, H.; Hu, W. Multi-objective optimisation design and performance comparison of permanent magnet synchronous motor for EVs based on FEA. IET Electr. Power Appl. 2019, 13, 1157–1166. [Google Scholar] [CrossRef]

- Hong, G.; Wei, T.; Ding, X. Multi-objective Optimal Design of Permanent Magnet Synchronous Motor for High Efficiency and High Dynamic Performance. IEEE Access 2018, 6, 23568–23581. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, X.; Gerada, C.; Zhang, H.; Liu, C.; Wang, Y. Multi-Physics and Multi-Objective Optimization of a High Speed PMSM for High Performance Applications. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- PIDOTECH Inc. PIAnO User ’s Manuals and Tutorials; PIDOTECH Inc.: Seoul, Republic of Korea, 2019. [Google Scholar]

- Mallin, L.R.; Barrans, S.M. A Review of the High-speed Permanent Magnet Rotor Stress Analysis used for Automotive Air-handling Machines. Eur. J. Eng. Technol. Res. 2020, 5, 448–456. [Google Scholar] [CrossRef]

- Zhao, N.; Liu, W. Loss Calculation and Thermal Analysis of Surface-Mounted PM Motor and Interior PM Motor. IEEE Trans. Magn. 2015, 51, 1–4. [Google Scholar] [CrossRef]

- Pu, T.; Du, G.; Tong, J.; Huang, N.; Li, N.; Xu, W. Comparison of Rotor Strength of Various Rotor Structures for Ultra-high speed Permanent Magnet Synchronous Motor. In Proceedings of the 2021 IEEE 4th Student Conference on Electric Machines and Systems (SCEMS), Huzhou, China, 1–3 December 2021; pp. 1–6. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, X.; Gao, Q.; Li, Y. Rotor Strength Analysis of Ultra-High Speed Permanent Magnet synchronous Motor. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Xie, Y.; Xia, Y.; Li, Z.; Li, F. Analysis of Modal and Vibration Reduction of an Interior Permanent Magnet Synchronous Motor. Energies 2019, 12, 3427. [Google Scholar] [CrossRef] [Green Version]

| Item | Unit | Basic SPM Model | |

|---|---|---|---|

| Stator slot/Rotor pole | — | 24/4 | |

| Output power (10 % margin consideration) | W | 1100 | |

| Rated speed | rpm | 15,000 | |

| Air gap | mm | 0.7 | |

| Stator | Inner diameter/Stack | mm | 73.0/50.0 |

| Material | — | 35PN270 | |

| Rotor | Outer diameter/Stack | mm | 71.6/50.0 |

| Material | mm | 35PN270 | |

| Magnet | Outer, inner diameter/Magnet thickness | mm | 71.6, 57.6/7.0 |

| Material/Grade/Maker | — | Ferrite/9BE/Hitachi metals | |

| Winding | Diameter/Turns/Number of parallel circuits | — | Φ1.1/20 turns/four parallel |

| Material | — | Copper | |

| Item | Unit | Basic SPM model | ||

|---|---|---|---|---|

| No load | Back EMF | Vrms | 33.4 | |

| THD | % | 38.6 | ||

| Cogging-torque ripple | Nm | 0.43 | ||

| Rated load | Rated speed | rpm | 15,000 | |

| Rated torque | Average | Nm | 0.70 | |

| Ripple (peak-to-peak) | Nm | 0.48 | ||

| Current (Phase) | Arms | 23.8 | ||

| Output power | W | 1098.7 | ||

| Loss | Copper | W | 40.5 | |

| Iron | W | 69.7 | ||

| Efficiency | % | 90.9 | ||

| Bond area | mm3 | 15,426.3 | ||

| No. | x1 | x2 | x3 | Y1 | Y2 | Y3 | Y4 | Y5 |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.4 | 1.1 | 6.8 | 15,687.8 | 0.38 | 41.9 | 0.52 | 90.5 |

| 2 | 0.9 | 1.5 | 5.0 | 15,667.7 | 0.43 | 39.1 | 0.49 | 90.8 |

| 3 | 0.6 | 0.8 | 13.9 | 16,817.0 | 0.18 | 35.4 | 0.27 | 91.1 |

| 4 | 1.0 | 1.7 | 28.2 | 18,077.2 | 0.24 | 39.6 | 0.38 | 90.4 |

| 5 | 1.4 | 0.7 | 15.7 | 16,703.9 | 0.18 | 45.8 | 0.37 | 90.1 |

| 6 | 0.6 | 1.8 | 10.4 | 16,390.4 | 0.21 | 37.7 | 0.36 | 91.0 |

| 7 | 0.7 | 2.0 | 22.9 | 17,650.6 | 0.18 | 37.7 | 0.44 | 90.8 |

| 8 | 1.5 | 1.6 | 24.6 | 17,534.8 | 0.21 | 46.9 | 0.56 | 89.6 |

| 9 | 0.9 | 0.5 | 17.0 | 17,059.5 | 0.16 | 38.7 | 0.33 | 90.9 |

| 10 | 0.8 | 1.0 | 25.6 | 17,954.8 | 0.22 | 36.8 | 0.44 | 90.8 |

| 11 | 1.2 | 1.9 | 12.1 | 16,335.7 | 0.17 | 45.9 | 0.33 | 89.9 |

| 12 | 1.1 | 0.6 | 8.6 | 16,027.5 | 0.31 | 43.2 | 0.51 | 90.4 |

| 13 | 1.1 | 1.3 | 17.5 | 16,983.1 | 0.11 | 42.5 | 0.31 | 90.4 |

| 14 | 0.5 | 1.4 | 19.3 | 17,403.4 | 0.04 | 34.4 | 0.27 | 91.1 |

| 15 | 1.3 | 0.9 | 24.2 | 17,617.5 | 0.18 | 43.2 | 0.52 | 90.3 |

| Design Variables | Unit | Basic Model | Optimal Model | Difference |

|---|---|---|---|---|

| Width | mm | 1.5 | 0.5 | −1.0 |

| Thickness | mm | 0.77 | 1.40 | +0.63 |

| Angle | deg. | 4.78 | 18.20 | +13.42 |

| Objective Function | Unit | Basic Model | Optimal Model | Difference |

|---|---|---|---|---|

| Y1 (Bond application area) | mm2 | 15,426.3 | 17,283.8 | +12.1 [%] |

| Y2 (Cogging torque) | Nm | 0.430 | 0.076 | −82.3 [%] |

| Y3 (THD of back EMF) | % | 38.6 | 34.4 | −4.19 |

| Y4 (Torque ripple) | Nm | 0.480 | 0.261 | −45.6 [%] |

| Y5 (Efficiency) | % | 90.9 | 91.1 | +0.22 |

| Item | Unit | Basic Model | Optimal Model | Difference | ||

|---|---|---|---|---|---|---|

| No load | Back EMF | Vrms | 33.4 | 32.8 | −1.8 [%] | |

| THD | % | 38.6 | 34.5 | −4.1 [%] | ||

| Cogging-torque ripple | Nm | 0.43 | 0.08 | −81.0 [%] | ||

| Rated load | Rated speed | rpm | 15,000 | 15,000 | — | |

| Torque | Average | Nm | 0.70 | 0.70 | — | |

| Ripple | Nm | 0.482 (69.0 [%]) | 0.256 (36.7 [%]) | −46.9 [%] | ||

| Current (Phase) | Arms | 23.8 | 23.8 | — | ||

| Output power | W | 1098.7 | 1,098.3 | — | ||

| Loss | Copper | W | 40.6 | 40.6 | — | |

| Iron | W | 69.7 | 66.1 | −5.2 [%] | ||

| Efficiency | % | 90.9 | 91.1 | +0.2 [%] | ||

| Mode | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Frequency | 0 | 500 | 1k | 1.5k | 2.0k | 2.5k | 3.0k | 3.5k | 4.0k |

| Magnitude | 0.6993 | 0 | 0.000658 | 0 | 0.00031 | 0 | 0.053986 | 0 | 0 |

| Order | Stator Tooth | Rotor Pole | Mechanical Rotation Freq. | Electrical Rotating Freq. | Cogging Torque | Torque Ripple |

| 24.0 X | 4.0 X | 1.0 X | 2.0 X | 24.0 X | 12.0 X | |

| 12.0 f | 2.0 f | 0.5 f | 1.0 f | 12.0 f | 6.0 f | |

| 1st | 6000 Hz | 1000 Hz | 250 Hz | 500 Hz | 6000 Hz | 3000 Hz |

| JS Standard | Thickness [mm] | Tensile Strength [N/mm2] | Yield point [MPa] |

|---|---|---|---|

| 35PN230 | 0.35 | 535 | 393 |

| Maker | Grade | Tensile Strength at Break [N/mm2] | Bond Application Area per Magnet [mm2] | Yield Point [Mpa] (min) |

|---|---|---|---|---|

| LOCTITE | 331 | 11 | 2160.48 | 2376.5 |

| Mode | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

|---|---|---|---|---|---|---|---|---|---|

| Frequency [Hz] | 713.9 | 815.0 | 820.7 | 1573.3 | 1576.0 | 1636.4 | 2278.4 | 3716.2 | 3719.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, K.-Y.; Lee, S.-T. Performance Improvement of Permanent-Magnet-Synchronous Motors through Rotor Shape Optimization of Marine Blowing System with High-Speed Rotation. Energies 2023, 16, 5486. https://doi.org/10.3390/en16145486

Yoon K-Y, Lee S-T. Performance Improvement of Permanent-Magnet-Synchronous Motors through Rotor Shape Optimization of Marine Blowing System with High-Speed Rotation. Energies. 2023; 16(14):5486. https://doi.org/10.3390/en16145486

Chicago/Turabian StyleYoon, Keun-Young, and Sang-Taek Lee. 2023. "Performance Improvement of Permanent-Magnet-Synchronous Motors through Rotor Shape Optimization of Marine Blowing System with High-Speed Rotation" Energies 16, no. 14: 5486. https://doi.org/10.3390/en16145486

APA StyleYoon, K.-Y., & Lee, S.-T. (2023). Performance Improvement of Permanent-Magnet-Synchronous Motors through Rotor Shape Optimization of Marine Blowing System with High-Speed Rotation. Energies, 16(14), 5486. https://doi.org/10.3390/en16145486