Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil

Abstract

1. Introduction

- Measure the emissions of nitrogen oxides, particulate matter, carbon monoxide, and hydrocarbons from an engine running on waste lard oil biodiesel at various engine loads and speeds.

- Contrast the emissions of an engine running on waste lard oil biodiesel with those of a standard diesel engine.

- Examine the influence of engine load and speed on the emissions of a waste lard oil biodiesel-powered engine.

2. Literature Review

2.1. Effects of Biodiesel on Engine Emissions

2.2. Knowledge Gaps and Research Needs

3. Methodology

3.1. Experimental Setup and Materials

3.2. Fuel Preparation

3.3. Properties of Biodiesel

4. Results

4.1. Emission Characteristics

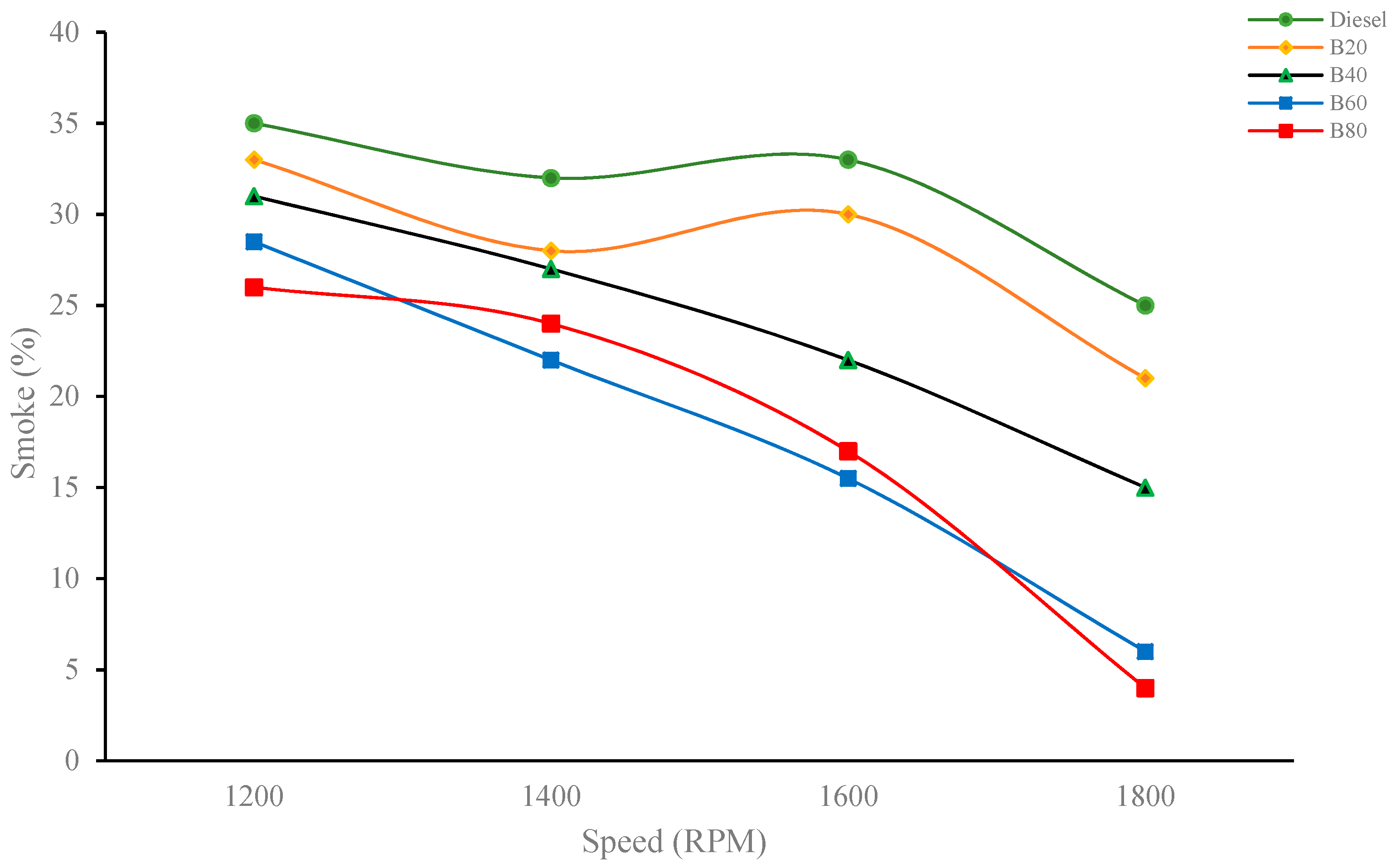

4.1.1. Variation of Particulate Matter (PM) Compound with Engine Speed

4.1.2. Variation of NOX Emissions with Engine Speed

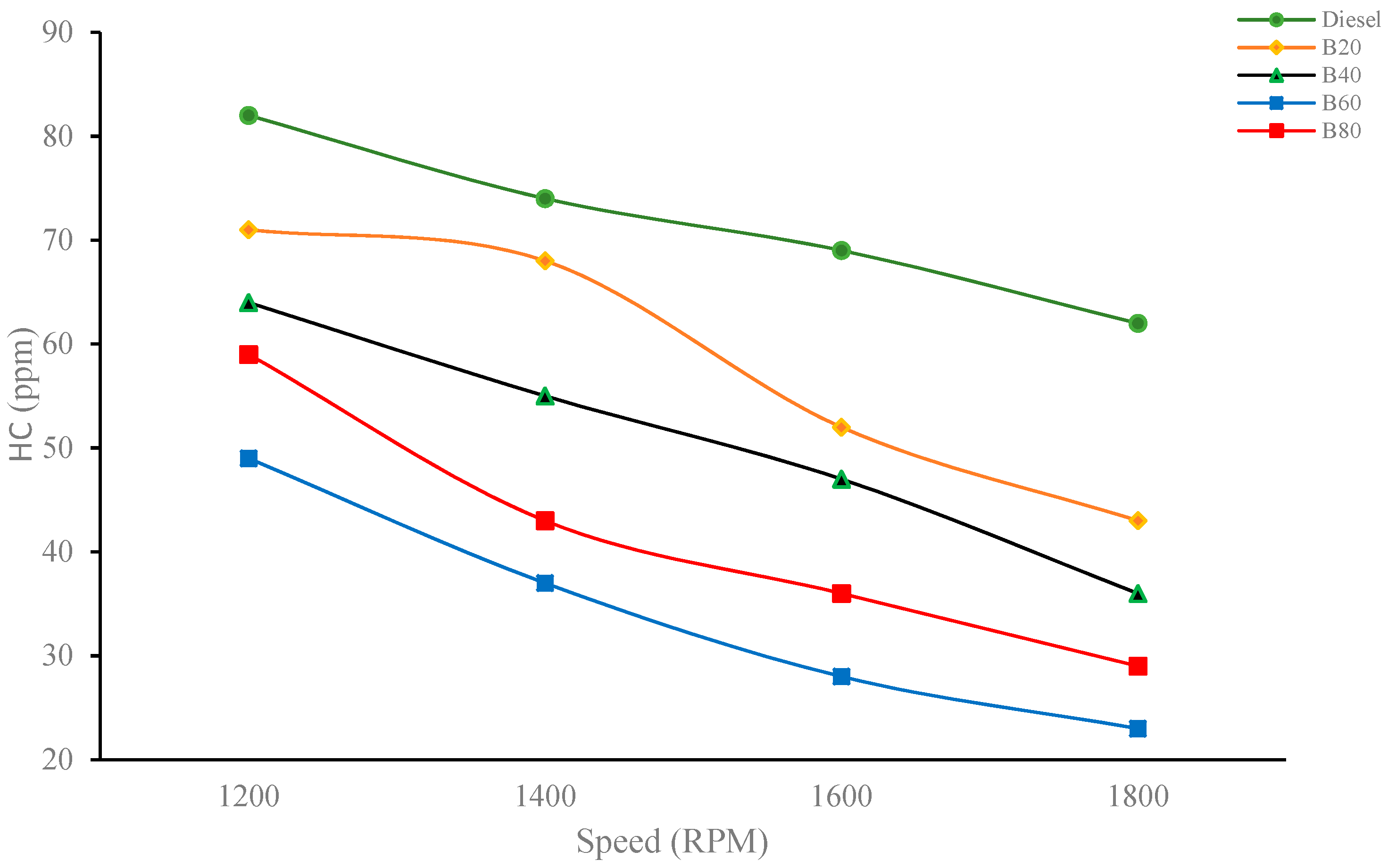

4.1.3. Variation of HC Emissions with Engine Speed

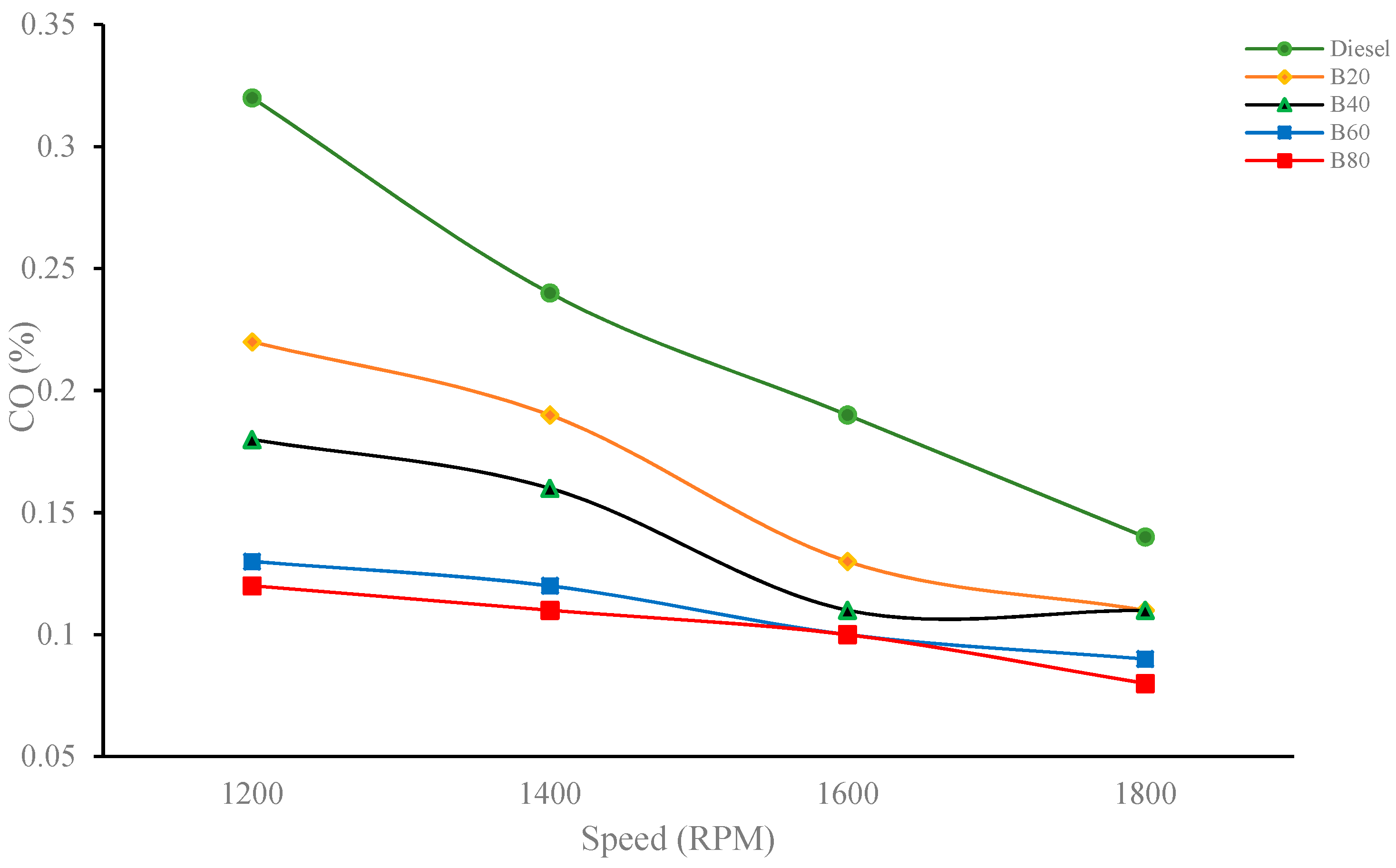

4.1.4. Variation of CO Emissions with Engine Speed

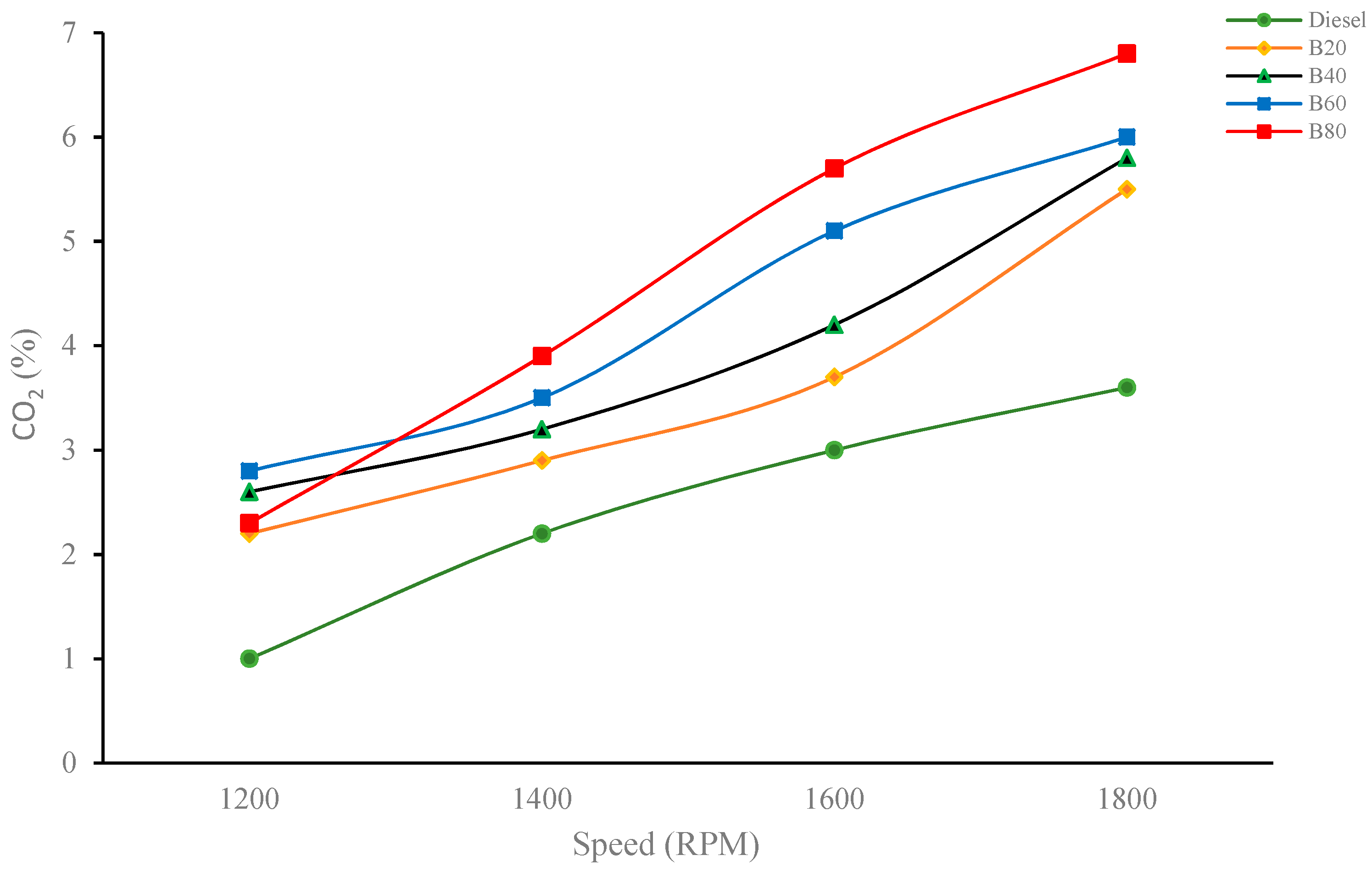

4.1.5. Variation of CO2 Emissions with Engine Speed

4.2. Performance Characteristics

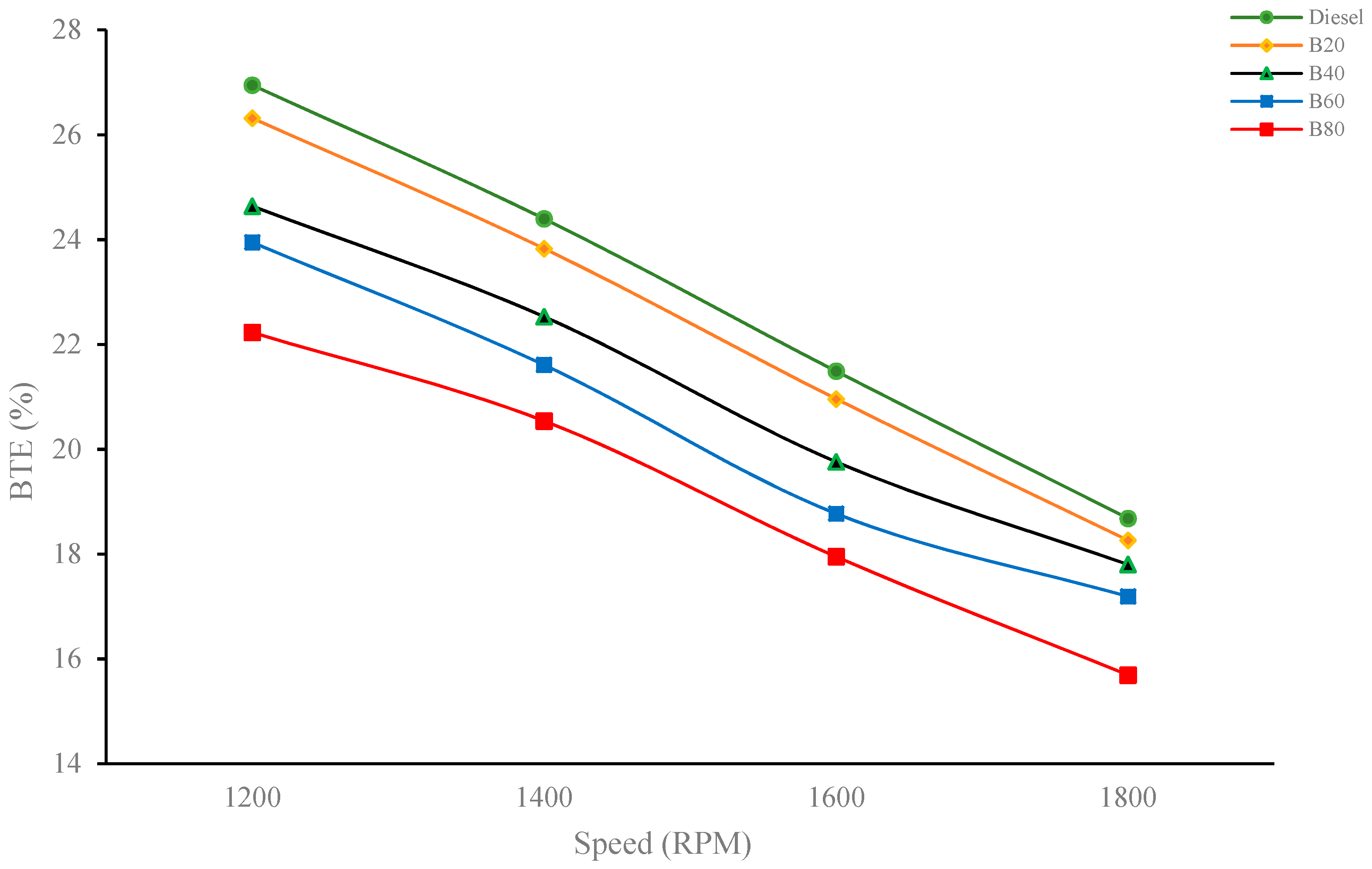

Effects on Brake Thermal Efficiency

5. Conclusions

- Increasing the fraction of biodiesel in diesel blends can reduce PM emissions significantly, with PM emissions dropping as the percentage of biodiesel in a fuel mix increases.

- Increasing engine speed reduces HC emissions in all biodiesel mixes by improving fuel atomization and vaporization.

- Biodiesel mixes may provide greater benefits at higher engine speeds, with the most visible improvements occurring at above 1800 rpm.

- As the percentage of biodiesel blend increases, CO emissions fall at all engine speeds, with the most notable variations noted at 1800 rpm.

- The amount of biodiesel in a mix might affect NOx emissions, with higher biodiesel content potentially resulting in higher NOx emissions due to the higher oxygen content of biodiesel.

- The BTE of waste lard biodiesel decreases with an increasing biodiesel proportion in a fuel mix, most likely due to biodiesel’s higher viscosity and lower calorific value compared to diesel fuel.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| PPM | Parts Per Million |

| RPM | Revolutions Per Minute |

| CI | Compression Ignition |

| IC | Internal Combustion |

| BP | Brake Power |

| KOH | Potassium Hydroxide |

| NaOH | Sodium Hydroxide |

| BSFC | Brake Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| EGR | Exhaust Gas Recirculation |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| HC | Hydrocarbon |

| NOX | Nitrogen Oxide |

References

- Khujamberdiev, R.; Cho, H.M. Biodiesel Raw Material Characterization and its Production Process-A Review. Nat. Vol. Essent. Oils 2021, 8, 12112–12120. [Google Scholar]

- Gumahin, A.C.; Galamiton, J.M.; Allerite, M.J.; Kaur, M. Response surface optimization of biodiesel yield from pre-treated waste oil of rendered pork from a food processing industry. Bioresour. Bioprocess. 2019, 6, 48. [Google Scholar] [CrossRef]

- El-Dalatony, M.M.; Sharma, P.; Hussein, E.E. Pig- and vegetable-cooked waste oils as feedstock for biodiesel, biogas, and biopolymer production. Biomass Conv. Bioref. 2022, 1–11. [Google Scholar] [CrossRef]

- Halek, F.; Kavousi-Rahim, A. Influence of Antioxidant Addition on the Emissions of a Diesel Engine by Using Waste Cooking Oil Biodiesel. Energy Environ. 2018, 29, 732–741. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Sharma, S.; Sharma, P.K.; Jhalani, A. A review on feedstocks, production processes, and yield for different generations of biodiesel. Fuel 2020, 262, 116553. [Google Scholar] [CrossRef]

- Almazrouei, M.; Elagroudy, S.; Janajreh, I. Transesterification of waste cooking oil: Quality assessment via thermogravimetric analysis. Innov. Sol. Energ. Transit. 2019, 158, 2070–2076. [Google Scholar] [CrossRef]

- Tang, Y.; Gu, X.; Chen, G. 99% yield biodiesel production from rapeseed oil using benzyl bromide–CaO catalyst. Environ. Chem. Lett. 2013, 11, 203–208. [Google Scholar] [CrossRef]

- Kaur, M.; Ali, A. Lithium ion impregnated calcium oxide as nano catalyst for the biodiesel production from karanja and jatropha oils. Renew. Energy 2011, 36, 2866–2871. [Google Scholar] [CrossRef]

- Bet-Moushoul, E.; Farhadi, K.; Mansourpanah, Y.; Nikbakht, A.M.; Molaei, R.; Forough, M. Application of CaO-based/Au nanoparticles as heterogeneous nanocatalysts in biodiesel production. Fuel 2016, 164, 119–127. [Google Scholar] [CrossRef]

- Öner, C.; Altun, Ş. Biodiesel production from inedible animal tallow and an experimental investigation of its use as alternative fuel in a direct injection diesel engine. Appl. Energy 2009, 86, 2114–2120. [Google Scholar] [CrossRef]

- Sathiyagnanam, A.P.; Vijayaraj, K.; Saravanan, C.G. Biodiesel Production from Waste Pork Lard and an Experimental Investigation of its Use as an Alternate Fuel in a DI Diesel Engine. Int. J. Mech. Eng. Robot. Res. 2021, 1, 176–191. [Google Scholar]

- Santana, J.C.C.; Miranda, A.C.; Souza, L.; Yamamura, C.L.K.; Coelho, D.D.F.; Tambourgi, E.B.; Berssaneti, F.T.; Ho, L.L. Clean production of biofuel from waste cooking oil to reduce emissions, fuel cost, and respiratory disease hospitalizations. Sustainability 2021, 13, 9185. [Google Scholar] [CrossRef]

- Srinivasan, G.R.; Jambulingam, R.; Gacem, A.; Ahmad, A.; Bhutto, J.K.; Yadav, K.K.; Mezni, A.; Alharbi, O.K.R.; Islam, S.; Ahn, Y.; et al. Effect of Fuel Preheating on Engine Characteristics of Waste Animal Fat-Oil Biodiesel in Compression Ignition Engine. Polymers 2022, 14, 3896. [Google Scholar] [CrossRef] [PubMed]

- Madhu, S.; Leo, G.L.; Prathap, P.; Devarajan, Y.; Jayabal, R. Effective utilization of waste pork fat as a potential alternate fuel in CRDI research diesel engine–Waste reduction and consumption technique. Process. Saf. Environ. Protect. 2023, 172, 815–824. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K.; Senthil Kumar, M.; Ramasamy, A.; Patel, D.; Balasubramanian, S.; Balakrishnan, S. An investigation on CI engine characteristics using pork lard methyl ester at various injection pressures and injection timings. Int. J. Green. Energy 2019, 16, 834–846. [Google Scholar] [CrossRef]

- Mandal, A.; Cho, H.M.; Chauhan, B.S. ANN Prediction of Performance and Emissions of CI Engine Using Biogas Flow Variation. Energies 2021, 14, 2910. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Inda, C.S.; Sharma, S.; Sharma, P.K.; Jhalani, A. A comprehensive review of biodiesel production from waste cooking oil and its use as fuel in compression ignition engines: 3rd generation cleaner feedstock. J. Clean. Prod. 2021, 307, 127299. [Google Scholar] [CrossRef]

- Wu, G.; Ge, J.C.; Choi, N.J. A comprehensive review of the application characteristics of biodiesel blends in diesel engines. Appl. Sci. 2020, 10, 8015. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Gupta, T. Performance, emission and combustion characteristics of waste plastic oil and its blends with diesel fuel. J. Renew. Sustain. Energy 2015, 7, 023129. [Google Scholar]

- Varatharajan, K.; Cheralathan, M.; Velraj, R. Mitigation of NOx emissions from a jatropha biodiesel fuelled DI diesel engine using antioxidant additives. Fuel 2011, 90, 2721–2725. [Google Scholar] [CrossRef]

- Song, J.; Cheenkachorn, K.; Wang, J.; Perez, J.; Boehman, A.L.; Young, P.J.; Waller, F.J. Effect of oxygenated fuel on combustion and emissions in a light-duty turbo diesel engine. Energy Fuels 2002, 16, 294–301. [Google Scholar] [CrossRef]

- Sharma, V.; Duraisamy, G.; Cho, H.M.; Arumugam, K. Production, combustion and emission impact of bio-mix methyl ester fuel on a stationary light duty diesel engine. J. Clean. Prod. 2019, 233, 147–159. [Google Scholar] [CrossRef]

- Janarthanam, H.; Kachupalli, S.R.S.R.; Jayapalan, S.K.; Subbiah, G.; Mani, P.; Velkumar, M.; Adithya, S.S. Emission and performance analysis of thermochemical conversion of bio-oil using waste animal fat. AIP Conf. Proc. 2020, 2311, 020020. [Google Scholar]

- Vali, R.H.; Hoang, A.T.; Wani, M.M.; Pali, H.S.; Balasubramanian, D.; Arıcı, M.; Said, Z.; Nguyen, X.P. Optimization of variable compression ratio diesel engine fueled with Zinc oxide nanoparticles and biodiesel emulsion using response surface methodology. Fuel 2022, 323, 124290. [Google Scholar] [CrossRef]

| Parameters | Description |

|---|---|

| Engine type | Horizontal, 4-stroke |

| Manufacturer | Daedong Korea Ltd. |

| Rated Power Output (kW) | 7.4 |

| Engine cooling | Water-cooled |

| Number of cylinders | 1 |

| Stroke length (mm) | 95 |

| Bore (mm) | 95 |

| Compression Ratio | 21 |

| Displacement (cc) | 673 |

| Injection pressure (kg/cm−2) | 200 |

| Exhaust Emission | Range | Resolution | Accuracy and Uncertainties |

|---|---|---|---|

| CO | 0.00–10.00 | % | ±0.01% |

| HC | 0–10,000 | ppm | ±1 ppm |

| CO2 | 0.0–20.0 | % | ±0.1% |

| O2 | 0.00–25.00 | % | ±0.1% |

| NOx | 0–5000 | ppm | ±1 ppm |

| Smoke | 0–100 | % | ±0.05% |

| Thermocouple (K-Type) | 0–1200 | ℃ | ±0.1 °C |

| Property | ASTM Standard | Diesel | Lard biodiesel | B20 | B40 | B60 | B80 |

|---|---|---|---|---|---|---|---|

| Density (kg/m3) | 800–880 | 820 | 816 | 821 | 833 | 841 | 859 |

| Viscosity at 40 °C (cSt) | 1.9–6 | 2.87 | 4.63 | 2.62 | 3.81 | 4.99 | 6.17 |

| Flash Point (°C) | >130 | 58 | 88 | 85 | 89 | 95 | 103 |

| Cetane Number | 48–65 | 48.7 | 65 | 52 | 58 | 62 | 65 |

| Calorific Value (Mj/kg) | >35 | 45.51 | 40.21 | 44.18 | 43.95 | 41.76 | 40.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khujamberdiev, R.; Cho, H. Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil. Energies 2023, 16, 5489. https://doi.org/10.3390/en16145489

Khujamberdiev R, Cho H. Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil. Energies. 2023; 16(14):5489. https://doi.org/10.3390/en16145489

Chicago/Turabian StyleKhujamberdiev, Ramozon, and Haengmuk Cho. 2023. "Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil" Energies 16, no. 14: 5489. https://doi.org/10.3390/en16145489

APA StyleKhujamberdiev, R., & Cho, H. (2023). Impact of Biodiesel Blending on Emission Characteristics of One-Cylinder Engine Using Waste Swine Oil. Energies, 16(14), 5489. https://doi.org/10.3390/en16145489