1. Introduction

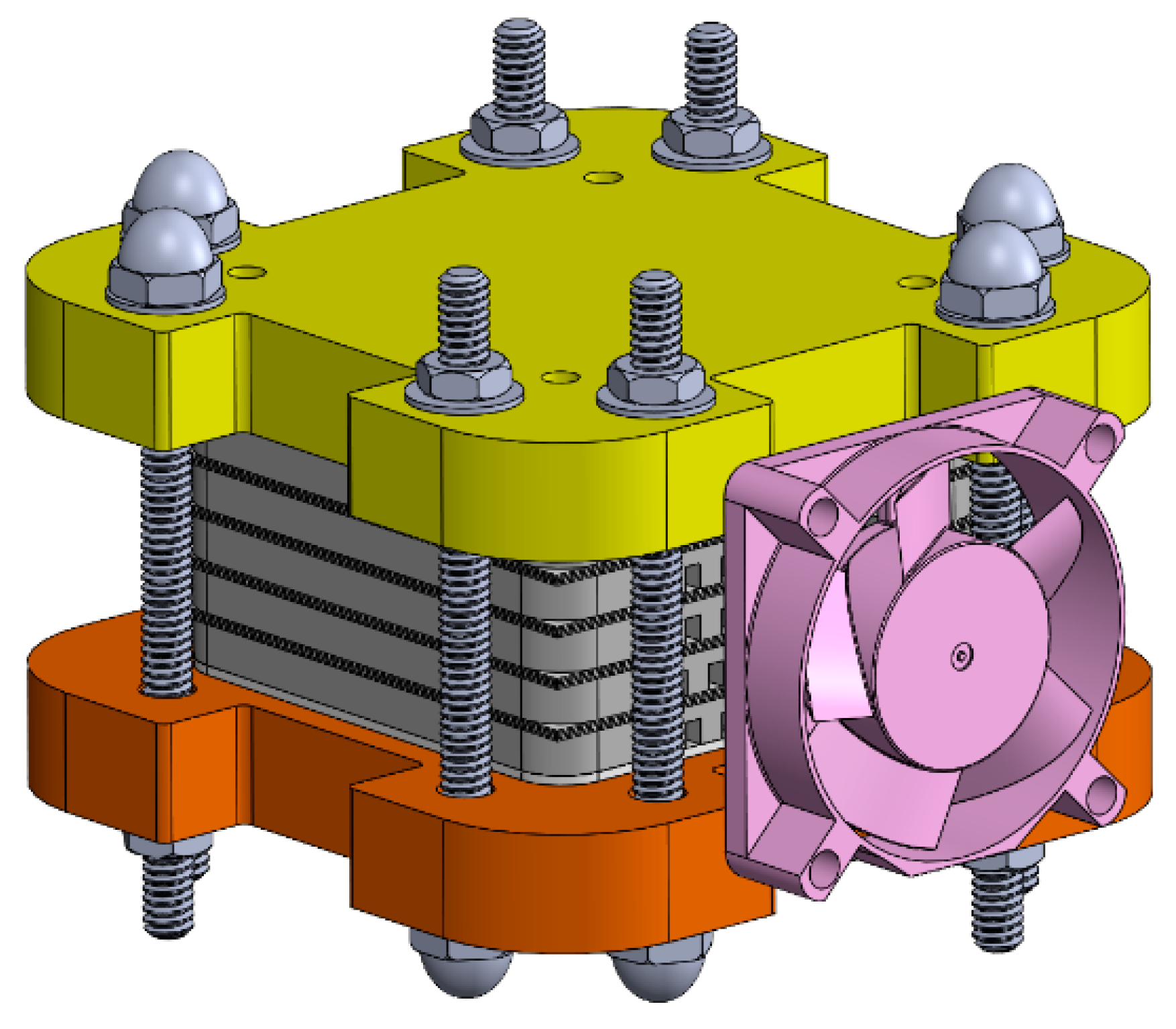

An electrochemical energy conversion device known as a proton exchange membrane fuel cell (PEMFC) uses the chemical reaction between hydrogen and oxygen to produce electricity. An anode, a cathode, and a proton exchange membrane are sandwiched between them in these fuel cells. Fuel cells were firstly developed as single cells and later adapted to a stack configuration to set their power rating according to the load they are connected to. A PEMFC stack configuration is shown in

Figure 1.

The proton exchange membrane, a solid, semi-permeable polymer that selectively permits protons (hydrogen ions) to pass through while blocking electrons, is the essential component of PEMFCs. Hydrogen gas is sent to the anode of the fuel cell, where it splits into protons and electrons. The electrons are compelled to move through an external circuit, creating an electric current, while the protons migrate through the membrane to the cathode. The only consequence of this process is water, which is created at the cathode when protons and electrons mix with oxygen molecules [

1,

2,

3].

PEMFCs provide a number of benefits over other fuel cell types, including a short start-up time, high power density, and a relatively low operating temperature. They are, therefore, seen as prospective contenders for a variety of applications, including stationary power generation, portable power sources, and electric vehicles, where clean and effective energy conversion is crucial.

Due to its multiple operational and environmental advantages, proton exchange membrane fuel cells (PEMFCs) are crucial in the context of clean energy and sustainable transportation [

4,

5]:

PEMFCs are zero-emission energy sources since they produce electricity through an electrochemical reaction that only results in the byproduct of water. This contrasts with traditional combustion engines, which emit greenhouse gases and air pollutants that contribute to climate change and air quality degradation.

High energy conversion efficiency: PEMFCs have higher energy conversion efficiency compared to internal combustion engines, as they directly convert chemical energy into electrical energy without the intermediate step of heat generation. This leads to lower energy waste and better fuel utilization, further contributing to their sustainability.

Renewable hydrogen: The hydrogen used as fuel in PEMFCs can be produced from renewable sources such as solar, wind, and hydroelectric power through water electrolysis. This makes hydrogen a sustainable and renewable energy carrier, which can be utilized in PEMFCs for clean power generation.

Decarbonizing transportation: The application of PEMFCs in electric vehicles (EVs) can contribute to decarbonizing the transportation sector, which is one of the major sources of greenhouse gas emissions. Fuel cell electric vehicles (FCEVs) are more appropriate for some uses than battery electric vehicles (BEVs), such as long-haul haulage and heavy-duty vehicles, due to their greater driving range and quicker refueling periods.

Grid stability and energy storage: PEMFCs, particularly when coupled with renewable energy sources, can assist with grid stability by offering distributed power generation and acting as energy storage devices. They can contribute to a more flexible and resilient energy infrastructure by storing excess electricity generated during times of low demand and releasing it back to the grid during times of peak demand.

The performance, cost, and durability are the three main issues that PEMFC technology must overcome in order to be widely adopted and successfully used in a variety of applications. Performance-wise, elements such as the conductivity of the proton exchange membrane, the potency of the electrochemical reaction catalysts, and the mass movement inside the fuel cell all have an impact on the efficiency and power density of PEMFCs. Enhancements in these areas are necessary to achieve improved performance [

6,

7,

8,

9,

10].

In terms of durability, PEMFCs have a propensity to deteriorate over time as a result of elements such membrane thinning, catalyst deterioration, and carbon corrosion. Their commercial success depends on ensuring their long-term stability and reliability, especially in sectors such as transportation where extended lifetimes are necessary. Last but not least, a major obstacle to the adoption of PEMFCs is their high cost, particularly the platinum-based catalysts employed in the oxygen reduction cycle. Making PEMFCs more competitive with alternative energy conversion technologies requires the development of low-cost materials and production techniques [

11].

In order to address these issues, the paper’s main objective is to examine recent developments in PEMFC technology, which include cutting-edge approaches, creative designs, and unique materials. This paper reviews the most recent research in areas such as advanced membrane materials, novel catalysts for oxygen reduction reactions, innovative flow field designs, and degradation mitigation strategies in order to shed light on the current state of PEMFC technology and the potential for further advancements to improve their performance, durability, and cost-effectiveness.

2. Advanced Membrane Materials

The performance and lifetime of polymer electrolyte membrane fuel cells (PEMFCs) have been increased by increasing the conductivity and durability of polymer electrolyte membrane materials. Researchers have been looking into new materials and designs to address the drawbacks of conventional perfluorosulfonic acid (PFSA) membranes, such as nafion, which are infamous for their high costs and subpar performance at high temperatures and low humidity [

12]. The cell membrane is usual fitted to a plastic gasket to ensure tightness when the cell is assembled, which ensures no oxygen and hydrogen leakage occurs when the cell is operated, as can be seen in

Figure 2.

The creation of alternative polymer chemistries, such as hydrocarbon-based and aromatic polymers, which can provide superior mechanical stability, enhanced thermal resistance, and lower prices as compared to conventional PFSA membranes, is one strategy. Under certain operating conditions, these alternative polymers might also show higher proton conductivity, which would improve the fuel cell performance. Another field of study focuses on the inclusion of inorganic components into the polymer matrix, such as metal–organic frameworks (MOFs), zeolites, and nanoparticles. The conductivity, tensile strength, and thermal stability of the membrane can all be enhanced by these hybrid materials, also referred to as nanocomposite membranes. The inorganic components may also serve as water retention agents, improving the performance in low-humidity environments [

13].

Furthermore, researchers have been developing thin-film composite membranes, which consist of a thin, highly conductive layer supported by a mechanically robust substrate. These composite membranes can achieve high proton conductivity while maintaining excellent mechanical properties, addressing the trade-off between conductivity and mechanical strength typically observed in conventional membranes. The introduction of novel materials in PEMFCs can significantly impact the overall performance of the fuel cell by addressing the limitations of conventional components and providing enhanced properties that contribute to improved efficiency, power density, and durability [

14].

In the case of advanced polymer electrolyte membranes, the use of alternative polymers and composite materials can lead to better proton conductivity under a wider range of operating conditions, such as elevated temperatures and low humidity. This improved conductivity directly translates to higher fuel cell efficiency and power output. Additionally, the enhanced mechanical and thermal stability of these novel membranes can contribute to longer lifetimes and improved reliability, reducing the maintenance and replacement costs. Regarding novel catalysts, particularly non-platinum group metal (non-PGM) catalysts, their development can substantially reduce the cost of fuel cell components while maintaining, or even surpassing, the performance of traditional platinum-based catalysts. This cost reduction can make PEMFCs more economically competitive with other energy conversion technologies. Moreover, some novel catalysts exhibit higher resistance to poisoning by impurities and improved long-term stability, further contributing to the durability and performance of the fuel cell [

15].

For both the anode and cathode sides, the implementation of innovative flow field designs can also positively impact the overall performance of PEMFCs. On the contrary, a blowing air fan can also be used to provide fresh air on the cathode side of the cell. As seen in

Figure 3, it has been experimentally proven during lab experiments that there is a jump in fuel cell performance when the blowing fan unit is activated.

It is evidently clear that research institutes and industry have opted to use CFD simulation software packages to predict the effectiveness of fuel cells. Not all cases require experimentation, and simulations can also decrease the development costs.

On the cathode side of the membrane, straight flow channels are used to guide the flow blown by the fan onto the surface of the membrane; the flow channels are provided with both a diverging and converging cross-sections as shown in

Figure 4. This ensures that the flowing air charge is entrained partially over the membrane until it is consumed. The selected number of channels is intentionally distributed over the membrane area.

Consequently, by optimizing the mass transport of hydrogen and oxygen, enhancing water management, and reducing flooding, these designs can lead to improved reactant distribution and the more efficient removal of byproducts, ultimately resulting in higher power density and better fuel utilization.

Notably, the evolution in membrane materials has revolutionized the PEMFC domain, augmenting the fuel cells’ efficiency and reliability. Novel polymers and composite materials have superseded conventional PFSA membranes, enhancing the proton conductivity and thermal resilience, resulting in an improved power output and longer cell lifespan. This shift has also led to significant reductions in maintenance and replacement expenses. Additionally, the advent of non-PGM catalysts, offering similar or superior performance to traditional platinum-based catalysts at a fraction of the cost, promotes a more economically sustainable approach. These catalysts also boast higher resistance to contamination and long-term stability, thereby extending the fuel cells’ durability.

In parallel, breakthroughs in flow field designs, such as the inclusion of a blowing air fan and diverging–converging flow channels, have advanced the overall PEMFC performance by optimizing the reactant distribution and byproduct removal. The increasing utilization of CFD simulations has led to accelerated development by allowing performance predictions and design optimization at lower costs. However, despite these advancements, challenges persist. The extensive testing of new materials under realistic conditions, further cost reductions, and continuous enhancements of the fuel cell efficiency and power density are essential areas for ongoing research. In essence, while significant strides have been made, relentless innovation is required to fully harness the potential of PEMFCs.

3. Novel Catalysts for Oxygen Reduction Reaction (ORR)

The recent advancements in oxygen reduction reaction (ORR) catalysts have predominantly focused on the development of non-platinum group metal (non-PGM) catalysts. The motivation behind this research is to overcome the drawbacks of traditional platinum-based catalysts, which are expensive, scarce, and susceptible to poisoning by impurities, such as carbon monoxide. Regarding the path to reach this kind of enhancement, during the experimentation phase of the fuel cell, polarization curves are plotted with the purpose of comparing the cells’ performance with other commercially used cells. Once the modified fuel cell performance is identified and proven to be positive, more focus is on the voltage losses in the form of activation and concentration, and these values can be extracted from the polarization plot.

One promising class of non-PGM catalysts comprises metal–nitrogen–carbon (M-N-C) materials, which are composed of transition metals, such as iron, cobalt, or nickel, coordinated with nitrogen atoms in a carbon matrix. These catalysts have shown remarkable ORR activity and stability, making them attractive alternatives to platinum-based catalysts. The recent research in M-N-C catalysts has focused on optimizing their composition, structure, and synthesis methods to further improve their performance and durability [

16].

Another area of interest is the development of heteroatom-doped carbon materials, such as nitrogen-doped carbon nanotubes or graphene. Due to the presence of heteroatoms, which alter the electronic structure of the carbon lattice and produce active sites for the oxygen reduction reaction, these materials have increased ORR activity. To enhance these materials’ ORR performance, researchers have been looking into various doping strategies and the impacts of various heteroatoms. As prospective ORR catalysts, perovskites, spinels, and layered materials, which are transition metal oxides and chalcogenides, have also been investigated. These materials have strong catalytic activity and stability, and they can be combined with other materials such as carbon supports or conductive polymers to further improve their performance through compositional adjustments, nanostructuring, or a combination of both.

In order to create feasible substitutes for conventional platinum-based catalysts for the oxygen reduction reaction (ORR) in PEMFCs, substantial research has been done on the performance and long-term stability of non-platinum group metal (non-PGM) catalysts. Performance-wise, several non-PGM catalysts, such as metal–nitrogen–carbon (M-N-C) materials, have demonstrated encouraging ORR activity, which in some circumstances approaches or even exceeds that of platinum-based catalysts. Their catalytic performance has been further enhanced by the optimization of these materials’ composition, structure, and production techniques. In contrast to their platinum-based equivalents, the performance of non-PGM catalysts may be more susceptible to the operating circumstances, such as the temperature and humidity [

17,

18,

19,

20].

Non-PGM catalysts typically display variable levels of durability when it comes to long-term stability. While some substances, such as M-N-C catalysts, have shown good stability when used in fuel cells, other substances may degrade more quickly due to factors such as metal leaching or structural changes. It is important to note that catalysts made without PGMs are typically more resistant to impurity poisoning, such as carbon monoxide poisoning, which is a common problem with catalysts made with platinum. Non-PGM catalysts have a number of benefits over conventional platinum-based catalysts, including lower costs, less vulnerability to poisoning, and the possibility for equivalent or better performance. However, the operational conditions and material-specific characteristics may have a greater impact on their performance and long-term stability. In order to make non-PGM catalysts a feasible substitute for platinum-based catalysts in PEMFCs, the ongoing research and development efforts are concentrated on addressing these issues and improving their performance and robustness [

21].

Recent advancements in the development of non-platinum group metal (non-PGM) catalysts, particularly in metal-nitrogen-carbon (M-N-C) materials and heteroatom-doped carbon materials, have shown promising alternatives to traditional platinum-based catalysts for the oxygen reduction reaction (ORR) in PEMFCs. While providing considerable benefits such as cost reductions and resistance to impurity poisoning, these new catalysts offer equivalent or superior performance in some cases. The optimization of these materials’ composition, structure, and synthesis methods, along with the exploration of different doping strategies, has further contributed to their performance and durability. Nonetheless, the influence of the operational conditions on non-PGM catalysts’ performance and their long-term stability due to issues such as metal leaching or structural changes remains a concern. As such, continued research and development efforts are crucial to overcome these challenges, thereby making non-PGM catalysts viable substitutes for platinum-based catalysts in PEMFCs.

4. Innovative Flow Field Designs

The distribution of reactants, the removal of byproducts, and the control of heat and water within the fuel cell are all directly influenced by the flow field design, which is crucial to the performance and longevity of PEMFCs. Enhancing mass transportation, improving water management, and reducing performance losses due to reactant maldistribution and floods can all be accomplished by optimizing the flow field design. PEMFCs frequently employ conventional flow field designs including serpentine and parallel flow patterns. A simple classical design of a flow field bipolar plate for hydrogen gas fuel is one example as shown in

Figure 5 [

22].

To further improve the performance and longevity of the fuel cells, researchers are looking into novel designs. Interdigitated, wavy, and bio-inspired patterns are a few cutting-edge flow field designs that aim to improve mass transportation and water management. For instance, the interdigitated flow field design encourages forced convection within the fuel cell, improving the reactant distribution and enhancing byproduct elimination. Comparing this concept to conventional flow field designs, a higher power density and better fuel utilization may be achieved. On the other hand, wavy flow field designs create turbulence within the channels, which enhances mass transportation while improving heat and water management. The efficiency and durability of the device may be harmed by pressure loss and the development of hot spots inside the fuel cell, which can be reduced by these designs [

23].

Bio-inspired flow field designs, such as those based on the branching patterns found in nature, can lead to enhanced performance and reduced vulnerability to localized deterioration via a more uniform reactant distribution and efficient byproduct elimination. In recent years, new flow field designs have been released in an effort to improve water management in PEMFCs, reduce flooding, and improve mass transit. These innovative patterns aim to overcome the shortcomings of traditional flow field designs including serpentine and parallel flow fields while enhancing the performance and durability [

24].

One such design uses interdigitated flow fields, which alternate between intake and outlet channels to force convection inside the fuel cell. This layout encourages a better reactant distribution and improved byproduct elimination, which results in increased power density, improved fuel efficiency, and decreased flooding problems. Channels having sinusoidal or undulating patterns are used in wavy flow field designs to create turbulence within the flow channels. This turbulence promotes a more equal temperature distribution and prevents the development of hot spots, which improves the heat and water management for mass transportation. Additionally, the wavy form can lessen flooding and pressure drops, making the fuel cell operation more effective [

25,

26,

27].

Branching or fractal designs are examples of bio-inspired flow field patterns that resemble the vascular networks of plants or the circulatory systems of animals. Over the whole active surface of the fuel cell, these patterns offer a more uniform reactant distribution and effective byproduct removal. This even distribution can help improve water management, lower the risk of localized flooding, and increase the performance and durability. Interdigitated, wavy, and bio-inspired flow field designs have the potential to improve water management in PEMFCs, decrease floods, and increase mass transportation. These ground-breaking innovations have the potential to improve the fuel cell performance, byproduct removal, heat and water management, and performance by increasing the durability and fuel efficiency.

5. Strategies for Mitigating Degradation Mechanisms

The performance and durability of proton exchange membrane fuel cells (PEMFCs) can be negatively impacted by a variety of degradation mechanisms. Carbon corrosion, catalyst deterioration, and membrane thinning are the main modes of degradation. Membrane thinning results from the chemical and mechanical breakdown of the polymer electrolyte membrane that divides the anode and cathode compartments. Reactive radicals such as hydroxyl and peroxide species that can break polymer chains and result in a loss of mechanical integrity can arise, which can lead to chemical degradation. Mechanical deterioration can be brought on by the membrane expanding and contracting as a result of changes in temperature and humidity, which can result in pinholes and cracks. The membrane becomes less effective at preventing electron transfer between the anode and cathode as it becomes thinner, which increases the fuel cell resistance and lowers the efficiency.

Another significant issue with PEMFCs is catalyst deterioration, which can affect the fuel cell’s performance and electrochemical activity. The active surface area that is available for the electrochemical processes is decreased by particle agglomeration, dissolution, and migration in platinum-based catalysts, which are frequently utilized in PEMFCs. Impurities such as carbon monoxide that adsorb onto the active sites and stop the oxygen reduction reaction can also poison the catalysts.

The carbon-based materials employed as supports for the catalysts and gas diffusion layers in PEMFCs are subject to carbon corrosion, a deterioration mechanism. Due to the existence of reactive oxygen species and the potential cycling observed during fuel cell operation, carbon corrosion is a possibility. The catalyst particles may separate or aggregate as the carbon support corrodes, resulting in a loss of the active surface area and a decline in fuel cell performance. Additionally, the gas diffusion layer’s deterioration may lead to less efficient gas transport and higher electrical resistance.

Carbon corrosion, catalyst deterioration, and membrane thinning are the main degrading processes that influence PEMFCs. It is critical to find methods for reducing their effects and boosting the overall reliability of PEMFC technology because these mechanisms have the potential to adversely affect the performance, efficiency, and durability of the fuel cells. In recent years, a great deal of research has been devoted to reducing the degradation processes in PEMFCs, with the goal of improving the performance and longevity of the fuel cells through the development of cutting-edge materials and operational techniques.

Researchers have created innovative polymer electrolyte membranes with enhanced chemical and mechanical resilience to solve membrane thinning. Modified perfluorosulfonic acid (PFSA) polymers with strengthened side chains, hydrocarbon-based polymers with improved chemical stability, or composite membranes with inorganic fillers or nanofibers for improved mechanical strength are a few examples of these cutting-edge materials. In addition, operational tactics such as regulating the operating temperature and humidity can lessen the mechanical stress on the membrane and slow down the rate of degradation.

By creating more stable catalyst materials and support structures, catalyst degradation can be reduced. For instance, scientists have investigated the usage of core–shell systems, in which the core is made of a more stable metal, such as gold or palladium, and the outside layer is made of platinum. While maintaining a high level of electrochemical activity, this arrangement can assist in reducing particle agglomeration and dissolution. Alternative non-PGM catalysts, such as metal–nitrogen–carbon (M-N-C) materials, can also provide increased stability and toxin tolerance. The endurance of the catalyst layer can be further improved by the creation of carbon supports that are more corrosion-resistant, such as graphitized carbon or carbon nanotubes.

The use of more corrosion-resistant materials, such as carbon materials with better graphitization or the incorporation of protective coatings, can reduce carbon corrosion in the gas diffusion layer and catalyst supports. Operational strategies can also help to reduce the creation of reactive oxygen species and delay the rate of carbon corrosion, such as adopting more stable operating conditions or avoiding high potentials during startup and shutdown.

Recent advances in reducing the degradation processes in PEMFCs have been made possible by the development of cutting-edge materials, including novel polymer electrolyte membranes, more stable catalysts, and corrosion-resistant carbon supports, as well as operational strategies that help minimize the effects of degradation. These advances have made PEMFCs more reliable, efficient, and practical for a wide range of applications.

5.1. Mechanisms of Degradation

Degradation in PEMFCs usually occurs due to a variety of factors that can be grouped into three major categories: mechanical degradation, chemical degradation, and thermal degradation. Mechanical degradation is often caused by the cyclic loading and unloading of the fuel cell, leading to stress build-up in the membrane. This can result in micro-cracks and eventual failure of the cell.

Chemical degradation is primarily attributed to the interaction of the membrane material with the chemicals used within the fuel cell. The membrane may be oxidized, hydrolyzed, or otherwise chemically altered, leading to a decrease in its ionic conductivity and mechanical strength. Thermal degradation typically occurs due to excessive heat generated during operation. This can lead to the evaporation of water necessary for proton conduction, ultimately leading to the breakdown of the proton exchange membrane.

In addition, catalyst degradation is another significant factor that affects the longevity and performance of PEMFCs. It typically involves the dissolution, agglomeration, or corrosion of catalyst particles (usually platinum), which ultimately reduces the active surface area for the electrochemical reaction. Carbon corrosion, which involves the oxidation of the carbon support in the catalyst layer, is a major cause of PEMFC performance loss. The electro-oxidation of carbon can lead to a loss of can catalyst support and thinning of the catalyst layer, both of which reduce the active area for the electrochemical reaction.

5.2. Strategies to Mitigate Degradation

Several strategies have been proposed to mitigate the degradation of PEMFCs. For mechanical degradation, improving the mechanical properties of the membrane by using more robust materials or reinforcing existing materials could be an effective strategy. Chemical degradation could be mitigated by using more chemically stable materials or optimizing the chemical composition of the membrane and catalyst layers. To prevent thermal degradation, effective heat management systems should be implemented.

Catalyst degradation can be reduced by using more stable materials, such as non-noble metal catalysts or alloy catalysts, which exhibit better resistance to dissolution and agglomeration. The mitigation strategies for carbon corrosion involve using corrosion-resistant support materials such as titanium carbide or carbon nanotubes instead of traditional carbon black.

The mitigation of degradation mechanisms in proton exchange membrane fuel cells (PEMFCs) poses a significant challenge in the pursuit of optimizing their performance, efficiency, and durability. The dominant degradation factors—membrane thinning, catalyst deterioration, and carbon corrosion—are being tackled using innovative materials and operational techniques. Advanced polymer electrolyte membranes, for instance, have shown increased chemical and mechanical resilience against thinning. Innovative catalyst structures, such as core–shell systems, or non-PGM catalysts, such as M-N-C materials, are also showing promise in reducing catalyst degradation. Additionally, adopting corrosion-resistant carbon materials and operational strategies to avoid the creation of reactive oxygen species can potentially limit carbon corrosion. These measures not only hold promise to boost the overall reliability of PEMFCs but also their suitability for a wider spectrum of applications. Nevertheless, ongoing research and development efforts are essential to refine these strategies and uncover more robust, efficient, and practical solutions to mitigate the effects of these degradation processes in PEMFCs.

6. System-Level Optimization and Integration

For PEMFC components to achieve outstanding performance, efficiency, and durability in real-world applications, system integration and tuning are necessary. The interactions between a multitude of components, including the membrane, catalysts, gas diffusion layers, and flow field plates, as well as the balance of plant components, such as pumps, valves, and heat exchangers, affect how well a fuel cell system performs. Each component must work efficiently and in concert with the other components as a result of good system-level optimization and integration, which raises the dependability and performance as a whole.

To optimize each component’s performance while avoiding deterioration processes, operating parameters such as the temperature, humidity, and pressure can be altered at the system level. By maintaining an ideal temperature, which can also help improve the membrane conductivity, catalyst activity, and water management, for example, the rate of mechanical and chemical degradation can be slowed down. The connections between PEMFC components and subsystems must be carefully taken into account while integrating PEMFC components at the system level. For example, by properly combining the gas diffusion layers and flow field plates to enhance the reactant distribution, heat management, and water removal, a more uniform and efficient operation can be attained.

Optimizing and integrating PEMFC components at the system level can also lead to cost reductions by decreasing overdesign, simplifying the system complexity, and improving manufacturing practices. PEMFC technology could consequently become more economical than existing energy conversion techniques and find widespread application in a number of industries, including transportation, stationary power generation, and portable power sources.

It is essential to integrate and optimize PEMFC components at the system level in order to increase the overall performance, efficiency, and durability of the fuel cells. By carefully examining the interactions between components and subsystems, it is possible to build fuel cell systems that function effectively and synergistically, which could ultimately leads to the success of PEMFC technology in a number of applications. There are innovative ways to raise the overall system performance, reliability, and durability of PEMFCs, including the development of new materials, component design optimization, and the application of cutting-edge control strategies.

The creation of novel materials including bipolar plates, improved polymer electrolyte membranes, corrosion-resistant gas diffusion layers, and membranes with improved conductivity and stability is one method. By addressing important degradation causes and boosting the effectiveness of the electrochemical reactions, these materials can significantly improve the performance, dependability, and lifetime of the fuel cell.

Another strategy is component design optimization, which uses state-of-the-art flow field designs to enhance the heat dissipation, mass transfer, and water management. It is possible to obtain a more uniform reactant distribution, reduce flooding, and assure effective heat and water management by optimizing the design of components such as the gas diffusion layers and flow field plates, which will increase the performance and durability.

To improve the durability, dependability, and overall performance of the system, advanced control strategies can also be used. These tactics might include the application of model-based control algorithms, machine learning methodologies, or adaptive control approaches that track the operating circumstances and modify the system parameters in real-time. These control solutions can aid in maintaining optimal performance and reducing the effects of degradation processes by continuously responding to changes in the operating environment and proactively controlling possible difficulties.

A fuel cell system’s ability to perform diagnostics and prognostics can also enable condition-based maintenance and the early identification of possible faults. The system can identify anomalies, such as increased resistance or decreased electrochemical activity, and take corrective action to stop further deterioration or failure by keeping an eye on the health of the fuel cell stack and its constituent parts.

The creation of new materials, component design optimization, and the use of cutting-edge control techniques are examples of creative ways to improve the overall system performance, dependability, and durability in PEMFCs. These techniques can be used to build fuel cell systems that are more effective, dependable, and robust and can suit the needs of diverse applications, from stationary power generation to transportation.

7. Discussion and Conclusions

The main contribution of this article is that it highlights the improvements and developments made in PEMFC technology with the intention of overcoming its main drawbacks, including the cost, performance, and durability. These developments include the creation of novel catalysts that are more effective and long-lasting, advanced membrane materials with improved conductivity and stability, creative flow field designs that improve mass transport and water management, and techniques to lessen degradation mechanisms. Additionally, the significance of integrating and optimizing PEMFC parts at the system level has been underlined, as well as the potential advantages of putting modern control methods and diagnostics into practice.

These discoveries have important significance for the PEMFC technology’s future, since they help remove obstacles to its widespread adoption and commercialization. These developments make fuel cell technology more competitive with alternative energy conversion technologies by steadily enhancing the performance, efficiency, and robustness of PEMFCs while lowering costs. The success of PEMFCs in a variety of applications, including transportation, stationary power generation, and portable power sources, depends on this development.

It is impossible to overestimate the significance of the ongoing research and development activities in PEMFC technology, as these efforts are essential for gaining the widespread acceptance of fuel cells in a variety of applications. PEMFCs have the potential to play a key role in addressing the world’s energy and transportation demands as the demand for clean, sustainable energy sources rises. In order to make PEMFCs more competitive with alternative energy conversion choices, it is imperative to address the major issues PEMFCs face, such as their performance, durability, and cost. Continuous research and development efforts aid in resolving these problems. Fuel cell systems can become more efficient, trustworthy, and long-lasting through the development of advanced control methods and diagnostics, along with continual improvements in materials, component design, and system integration.

Furthermore, by enabling the discovery of more affordable materials, manufacturing techniques, and system designs, ongoing research and development can aid in lowering the costs related to PEMFC technology. PEMFCs will be easier to use and more appealing to a wider range of customers as a result of falling prices, which will speed up their adoption in industries such as transportation, stationary power generation, and portable power solutions.

In order to keep ahead of new difficulties and seize new possibilities, it is also crucial to maintain research and development initiatives. PEMFC systems must be able to satisfy the unique requirements of various applications while maintaining high performance, efficiency, and reliability as technology advances and new applications are developed.

In conclusion, the potential of PEMFC technology to address current issues, reduce costs, and promote the broad use of fuel cells in a variety of applications makes it crucial to continue research and development efforts in this area. These initiatives promote not only the development of PEMFC technology but also the global shift to a clean and sustainable energy future.

In order to provide a comprehensive overview of the current state of PEMFCs, we have compiled a table summarizing the performance of recent PEMFCs, both those employing platinum group metals (PGMs) and non-PGMs catalysts. While PGMs, particularly platinum-based catalysts, are currently more active and common in PEMFC technology, they can suffer from degradation and are typically more expensive. In contrast, non-PGM catalysts can provide cost and durability advantages, albeit generally with lesser activity. The following

Table 1 outlines key parameters such as the power density, operating temperature, durability, and efficiency for each of these fuel cells, providing an insight into their comparative performances.