Abstract

In this paper, the performance and emission characteristics of a diesel engine were investigated with varying ratios of tung oil-based biodiesel blends (B10, B20, and B50) and neat diesel under different operating conditions. The experimental results showed that the addition of biodiesel blends had different effects on engine power and torque depending on the blend ratio. B10 displayed a slight increase in power and torque, which increased by 1.9% and 6.6%. At the same time, B20 and B50 showed declines slightly. The fuel consumption rate increased slightly with an increasing percentage of biodiesel added. In general, all the blends exhibited significantly lower emissions of CO, NOX, HC, and smoke compared to neat diesel. B10 displayed the most notable reduction of CO emissions, with a 42.86% decrease at medium to high loads. NOX emissions of tung oil-based biodiesel blends were reduced at all load conditions except for B50. In addition, HC emissions were all reduced, especially for B20, which led to a 27.54% reduction at 50% load. Among all the tested blends, B50 showed the greatest decrease in smoke emissions of 38.05% compared to neat diesel at 2000 rpm. The research concluded that using biodiesel fuels from renewable resources, such as tung oil, presents a promising environmentally friendly alternative fuel option.

1. Introduction

As car ownership in China continues to rise rapidly, automobile exhaust emissions of harmful substances like CO, NOX, and PM have become the primary sources of urban air pollution, posing significant threats to human health. As we strive to enhance the quality of life and boost prosperity, one of the most significant challenges is meeting the ever-increasing demand for energy. Despite ongoing efforts to transition to alternative energy sources, it is apparent that fossil fuel-based internal combustion engines (ICEs) will remain the primary power source for energy and transportation in the foreseeable future [1,2,3]. However, as concerns about global environmental deterioration grow, the exhaust emissions from ICEs, such as carbon monoxide (CO), oxides of nitrogen (NOX), carbon dioxide (CO2), and hydrocarbons (HC) are increasingly subject to stringent regulations [4,5,6]. In order to promote the use of alternative fuels and address environmental concerns, major advanced and emerging economies have carried out a series of regulations [7,8,9]. As a green and environmentally friendly oxygenated fuel, biodiesel can effectively reduce the CO, NOX, and PM emissions of diesel engines. In addition, it can curb the increasing trend of automobile emission pollution as soon as possible and significantly improve the air quality of cities in China. Because of this, biodiesel has attracted more and more attention from scholars.

Biofuel is a newly developed fuel derived from biological materials that can exist in solid, liquid, and gaseous forms. As a promising renewable energy source, biodiesel offers excellent environmental protection characteristics, such as good cold start and lubrication performance, reduced greenhouse gas emissions, and potential opportunities for sustainable economic growth [10]. On the other hand, it is essential to consider the physicochemical properties of biodiesel, given its unique composition and properties. The higher kinematic viscosity of biodiesel improves the combustion quality of fuel [11,12], and the higher flash point makes the storage, treatment and transportation safer [13,14,15]. The cetane number (CN) influences the ignition quality of the fuel and is a measure of the ignition timing in the combustion chamber [16]. Overall, biodiesel has higher CN than pure diesel. Higher CN usually indicates a shorter ignition delay and earlier combustion, which is conducive to the smooth operation of the engine [17,18]. The biodegradability and low toxicity of plant biofuels have rendered them a desirable and practical substitute for diesel fuel [19,20].

Based on the above, biodiesel can play a significant role in reducing environmental pollution, leading countries worldwide to explore oils with suitable properties for producing biodiesel. Among the many options, the Tung tree is a valuable woody oil tree species in China [21]. Known for its high seed oil content, it is considered one of the four major woody oil tree species. Tung oil, also known as “China wood oil” [22], is extracted by pressing the seeds of the tung tree [23]. China tung tree species not only have a variety but also high yield and good oil quality. The oil content of absolute dried tung seed is more than 50%, and the oil content of absolute dried tung kernel can be as high as 68%. In the context of the country’s vigorous biomass energy development, biodiesel preparation from tung oil has great practical significance in today’s increasing energy shortage. The high value and wide use of tung oil have attracted the attention of many countries. Its special chemical structure and active chemical properties have aroused the interest of many chemists who are committed to the study of tung oil chemistry.

The performance and emission characteristics of an engine fueled with biodiesel have been the subject of extensive research by scholars and experts alike. Researchers have investigated the combustion performance of various types of biodiesel fuels, seeking to identify potential benefits and limitations. Ahmad Muhsin Ithnin et al. [24] studied the combustion performance and emission analysis of diesel engines fueled with low-grade diesel emulsified fuel. Additionally, they found that the W/D formed from low-grade diesel is a potential alternative fuel, which could result in greener exhaust emissions and reduced fuel use without worsening its performance. Osmano Souza Valente et al. [25] investigated the fuel consumption and emissions of diesel generators fueled with soybean biodiesel and castor oil. The results showed that the specific fuel consumption increased with the increase of biodiesel content in the fuel. Compared with diesel, biodiesel blends showed higher carbon dioxide emissions at low loads and lower carbon dioxide emissions at high loads. HC emissions were usually higher. The research conducted by Özer Can [26] examines the exhaust emissions, combustion characteristics, and performance of a diesel engine that utilizes blends of biodiesel derived from waste oil. The results indicated that with the increase of biodiesel, NOX emissions increased by 8.7%, while smoke emissions decreased, and CO2 emissions increased slightly.

The feasibility of biodiesel production from tung oil was studied by Ji-Yeon Park et al. [27]. When methanol and tung oil were mixed at the optimum molar ratio, the acid value decreased [28,29]. Despite the fact that eleostearic acid, the primary constituent of tung oil, resulted in low oxidation stability as determined by the Rancimat method, the cold filter plugging point (CFPP) was satisfactory. Qiong Shang et al. [30] studied the chemical properties of tung oil biodiesel, and its mixture with neat diesel were studied. The effect of transesterification temperature on the performance of tung oil-based biodiesel was studied. Biodiesel was produced by the transesterification of benzene oil with methanol. It was observed that the tung oil-based biodiesel exhibited a low CFPP of −19 °C and a higher kinematic viscosity (KV) of 7.070 mm2/s as per the property analysis. Moreover, an increase in acid value (AV), KV, and CFPP was noted with increasing storage time. Nevertheless, the stability of the tung oil-based biodiesel could be improved by blending it with neat diesel, and a storage time of one month did not affect the ability of B20 or lower blends to meet the ASTM D7467 specification. Additionally, these blends were found to be more stable compared to pure tung oil biodiesel.

There are many studies on the combustion and emissions performance of different types of biological diesel, as well as a certain study of the feasibility and chemical properties of tung oil-based biological diesel. However, there is a lack of research on the emission characteristics of tung oil-based biodiesel. There is no literature report on the emission of engines burning tung oil-based biodiesel. Based on this, this study aims to fill this gap by investigating the performance and emission characteristics of an engine fueled with tung oil-based biodiesel under varying blend ratios. In the present experiment, an analysis of those was investigated using three different portions of tung oil-based biodiesel (10%, 20% and 50%) blended with neat diesel on a single-cylinder agricultural diesel engine. The test of speed characteristic, load characteristic, exhaust smoke and exhaust gas emissions were conducted on the test ZS1115 GM diesel engine. The results were studied and analyzed, and the potential for future use of tung oil-based biodiesel was explored. The study aims to provide valuable data to promote the use of biodiesel, which can assist in sustainable development and reduce emissions. By exploring the potential of this alternative fuel in diesel engines, this study contributes to the ongoing efforts to transition to alternative energy sources and address environmental concerns.

2. Experiments

This section is a description of experimental testing, including the physicochemical properties of biodiesel, experimental apparatus, and experimental setup. In addition, a comprehensive account of the initial and boundary conditions for laboratory experiments is provided.

2.1. Preparation and Properties of Biodiesel

The biodiesel used in this experiment is produced by the transesterification method, which is one of the better and most widely used biodiesel production methods. The transesterification method refers to the method of synthesizing biodiesel by transesterification reaction using various oils and fats and short-chain alcohols as raw materials, acids, alkalis, enzymes, etc., as catalysts or without using catalysts under supercritical conditions. A variety of low molecular weight alcohols can be used for transesterification reactions, such as methanol, ethanol, propanol, etc. However, the most commonly used is methanol due to its low cost and fuel properties, such as its polarity and short carbon chain, which can quickly react with fatty acid glycerides. In this paper, using tung oil as raw material and NaOH as the catalyst, biodiesel was prepared by transesterification reaction with methanol [31].

The main performance Indexes and chemical and physical properties of tung oil-based biodiesel were compared with neat diesel, as shown in Table 1. It shows the important characteristics of tung oil-based biodiesel and neat diesel. The following characteristics of biodiesel and neat diesel were determined in Zhonghe Energy Co., Ltd., Ningxiang, China.

Table 1.

Chemical and physical properties of tung oil-based biodiesel and neat diesel [32,33,34,35,36].

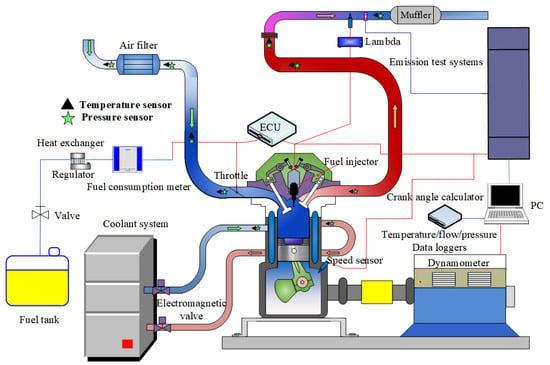

2.2. Experimental Setup and Test Engine

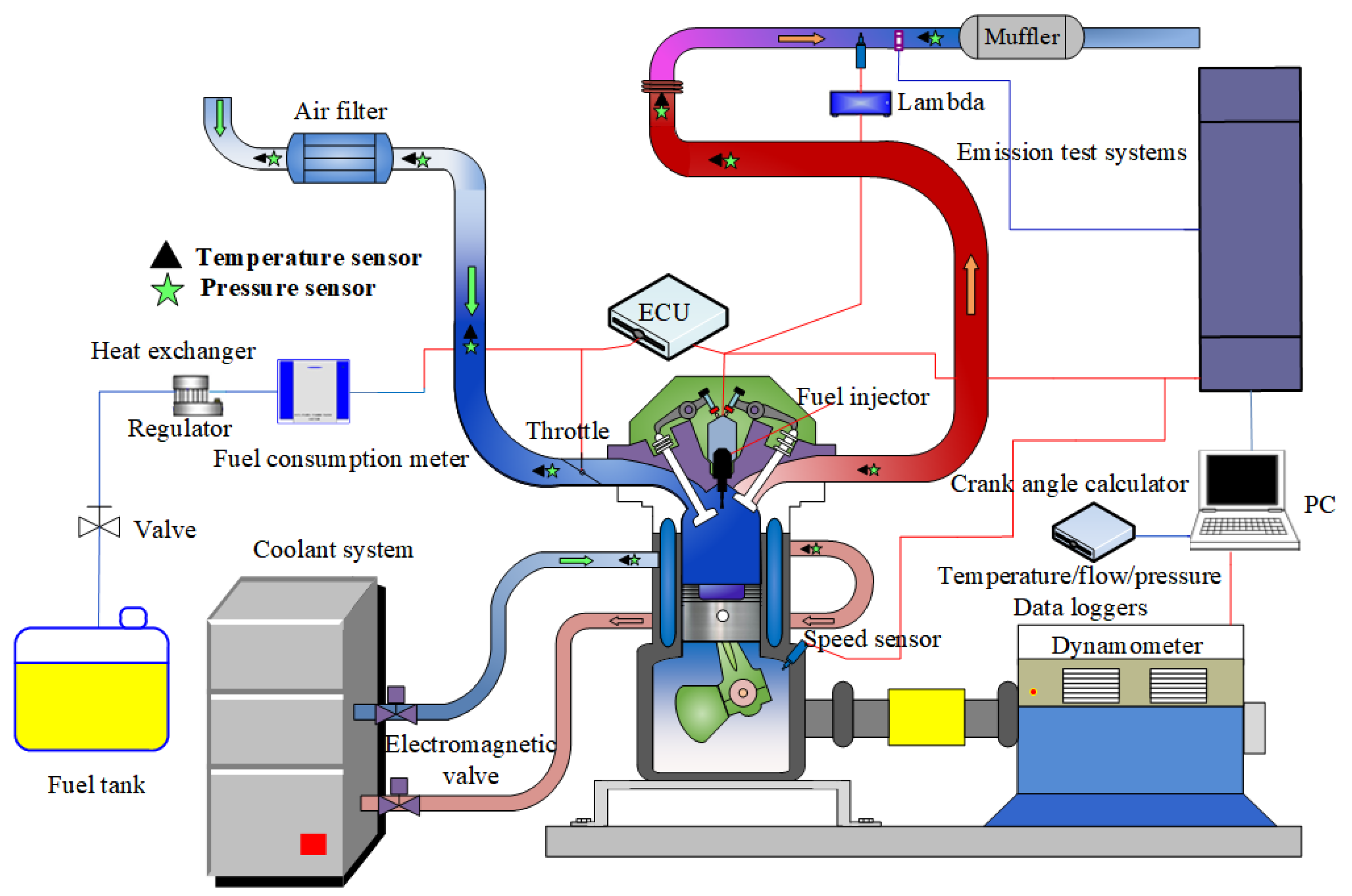

The test was carried out on a 14.71 kW single-cylinder, four-stroke and water-cooled diesel engine. Table 2 shows the technical specifications of the engine. Figure 1 shows a schematic diagram of the experimental apparatus for diesel engines and instrumentation systems. To determine and measure the performance characteristics and emissions of biodiesel-fueled engines, diesel engines are equipped with the necessary measuring instruments. All instruments, such as a fuel consumption measuring device, exhaust gas analyzer, energy meter, ammeter, thermal load resistance, heat exchanger and digital thermometer, are equipped on the engine bench.

Table 2.

Main engine paraments.

Figure 1.

The schematic diagram of the experimental apparatus for diesel engines and instrumentation systems.

Exhaust gas emission analyzers are used to measure emissions, such as unburned hydrocarbons (HC), nitrogen oxides (NOX), and carbon monoxide (CO). The measurement method of the exhaust gas analyzer and its measurement range, experimental percentage uncertainty, data measurement accuracy and further technical details of the engine and dynamometer are given in Table 3.

Table 3.

The specifications of instruments and equipment.

To ensure the accuracy and reliability of the results obtained, three repeat tests were conducted. Each test was performed under the same conditions to minimize the impact of external factors on the measurements. The measurements were carried out using a range of high-precision instruments that were carefully calibrated before each experiment to minimize measurement errors. Table 3 provides detailed information about the measurement properties, including their specifications and uncertainty levels. The measuring instruments used in the experiments were chosen based on their suitability for the specific parameters being measured, and their accuracy and precision were verified through rigorous calibration procedures. By following strict measurement protocols and carefully selecting the appropriate measuring instruments, we aimed to minimize the potential sources of error and obtain reliable data. Overall, the experimental setup and measurement procedures were designed with utmost care to ensure that the results obtained were accurate and meaningful. The overall uncertainty of experiments was calculated using Equation (1) as follows [37]:

The overall uncertainty of experiments.

2.3. Experimental Test Conditions

In order to guarantee the accuracy of experimental results, all laboratory experiments were conducted under identical operating conditions. Additionally, calibration was performed on all measuring instruments employed to record output data. The level of uncertainty for every device was analyzed and documented in Table 3. Furthermore, ambient conditions were monitored periodically both before and during experiments to ensure consistency throughout the tests. The test laboratory recorded the temperature, relative humidity, and density of the surrounding air. Sufficient warm-up time was given to the engine to ensure that it attained optimal operating temperatures, such as an engine oil temperature within the range of 77–84 °C. The test conditions of the following experiments are shown in the corresponding figures for each experiment in the results and discussion section.

3. Results and Discussions

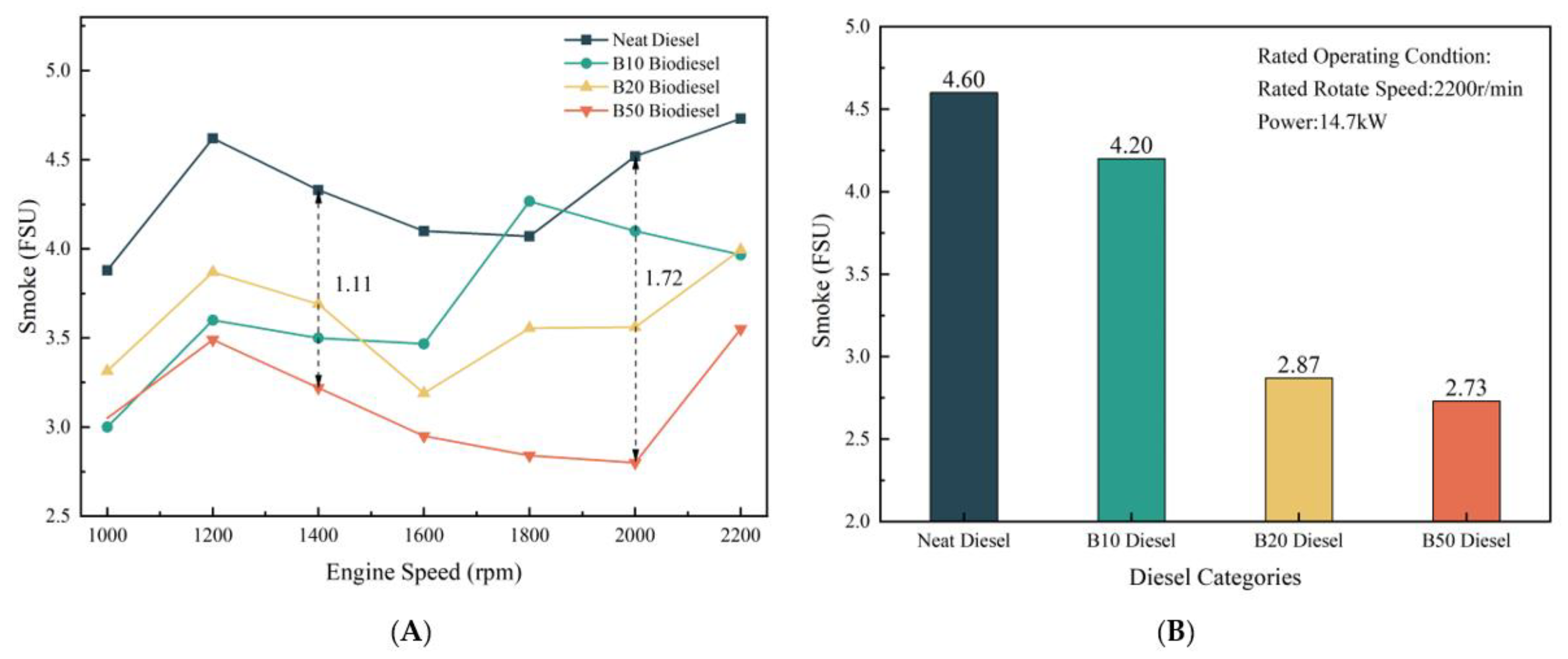

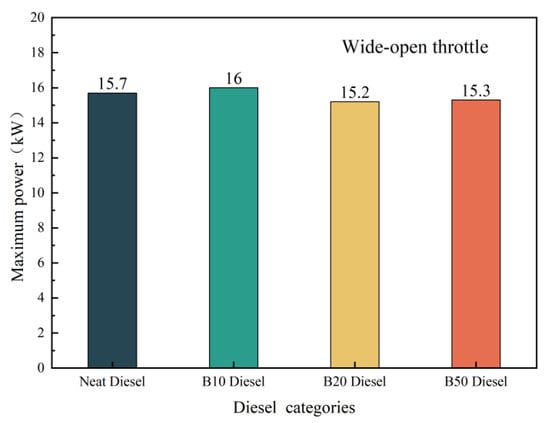

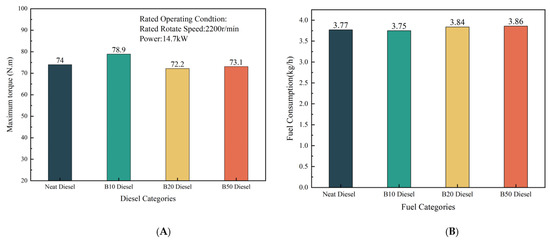

3.1. Load Characteristics and External Characteristics

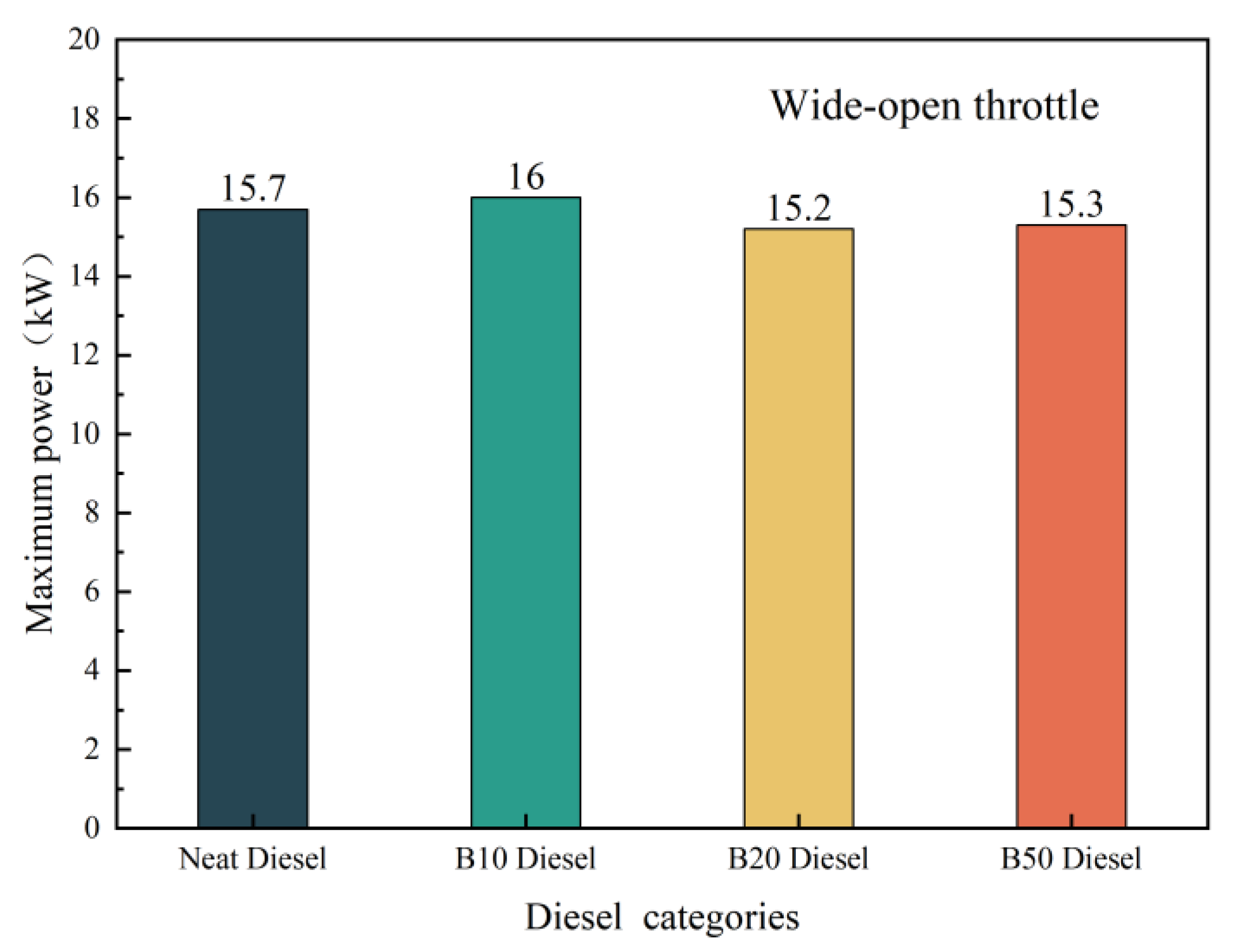

This experimental study investigated the speed characteristics, load characteristics, exhaust smoke, and gas pollutant emissions of different proportions of tung oil-based biodiesel (B10, B20, B50) and neat diesel fuel on the ZS1115GM diesel engine. The study also analyzed the influencing factors of these characteristics. Figure 2 and Figure 3 are the economic power of tung oil-based biodiesel. The maximum power, fuel consumption, maximum torque and smoke of biodiesel with different proportions of biodiesel under different conditions were studied.

Figure 2.

Maximum power compared to biodiesel blends.

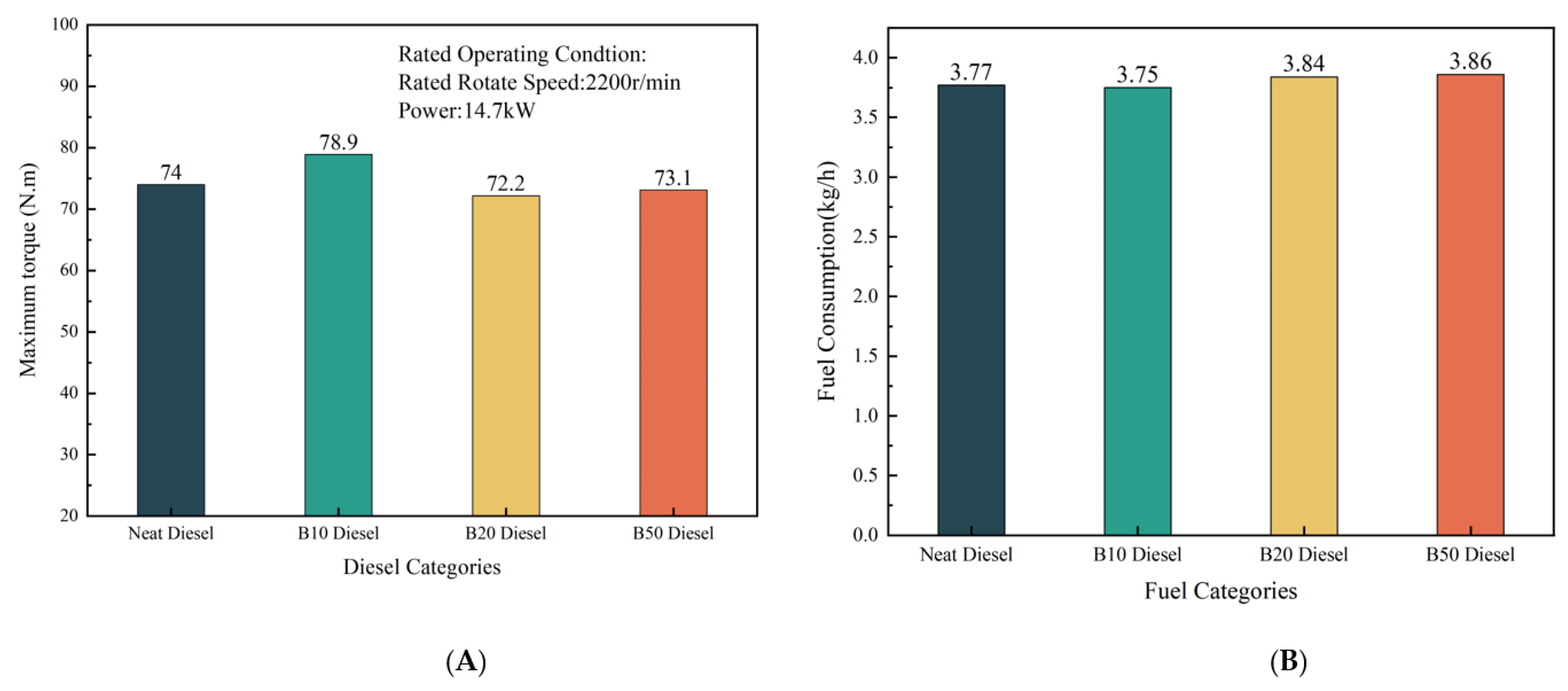

Figure 3.

The maximum torque and fuel consumption compared to biodiesel blends. (A) Maximum torque; (B) Fuel Consumption.

Figure 2 shows the maximum power when the throttle is fully open. It can be seen from the diagram that the maximum power and torque of B20 are the smallest and B10 the largest. Compared with the power of neat diesel, B10 increased by 1.9%, and B20 and B50 decreased by 3.2% and 2.5%, respectively. When a small amount of tung oil-based biodiesel is added, ignition performance is improved due to its higher cetane number than pure diesel and a slight increase in oxygen content, thus increasing combustion efficiency. In addition, the diesel engine is a single-cylinder agricultural diesel engine that does not have a high-pressure common rail electric injection system, and combustion performance has a significant impact on this diesel engine. The ignition performance plays a dominant role in the economic performance of the diesel engine in small proportions. Therefore, B10 exhibited a slight increase in power and torque over neat diesel. Additionally, according to our research, there is only a slight increase in power and torque. However, when a large proportion of biodiesel is added, the calorific value, density, and viscosity of biodiesel significantly decrease, and these factors play a significant role in the performance, leading to a reduction in economic power. Consequently, the output power of the diesel engine slightly decreases after incorporating a significant amount of biodiesel [38].

Our results show that a small amount of blended tung oil-based biodiesel has no effect on the performance of older single-cylinder diesel engines without expensive fuel injection systems and can even be slightly improved, indicating the application scenarios of tung oil-based biodiesel.

The maximum torque when the speed is 2200 rpm and the power is 14.7 kW under the rated condition in Figure 3A, and the fuel consumption at the maximum torque are compared in Figure 3B as can be seen from the figure, the highest maximum torque is achieved when using B10. Compared to running with pure diesel, the engine fueled with B10 shows nearly 6.6% torque increment, and B10 increased nearly by 6.6%. However, maximum torque was reduced by 2.4% and 1.2% compared to the run with pure diesel if B20 and B50 were used. As can be seen, with the proportion of biodiesel increasing, the fuel consumption rate became higher. At high RPM, the brake thermal efficiency (BTE) of the engine will decrease due to poor air–fuel mixing and poor injection. In addition, the increased proportion of biodiesel, resulting in increased viscosity and density, will lead to increased fuel consumption.

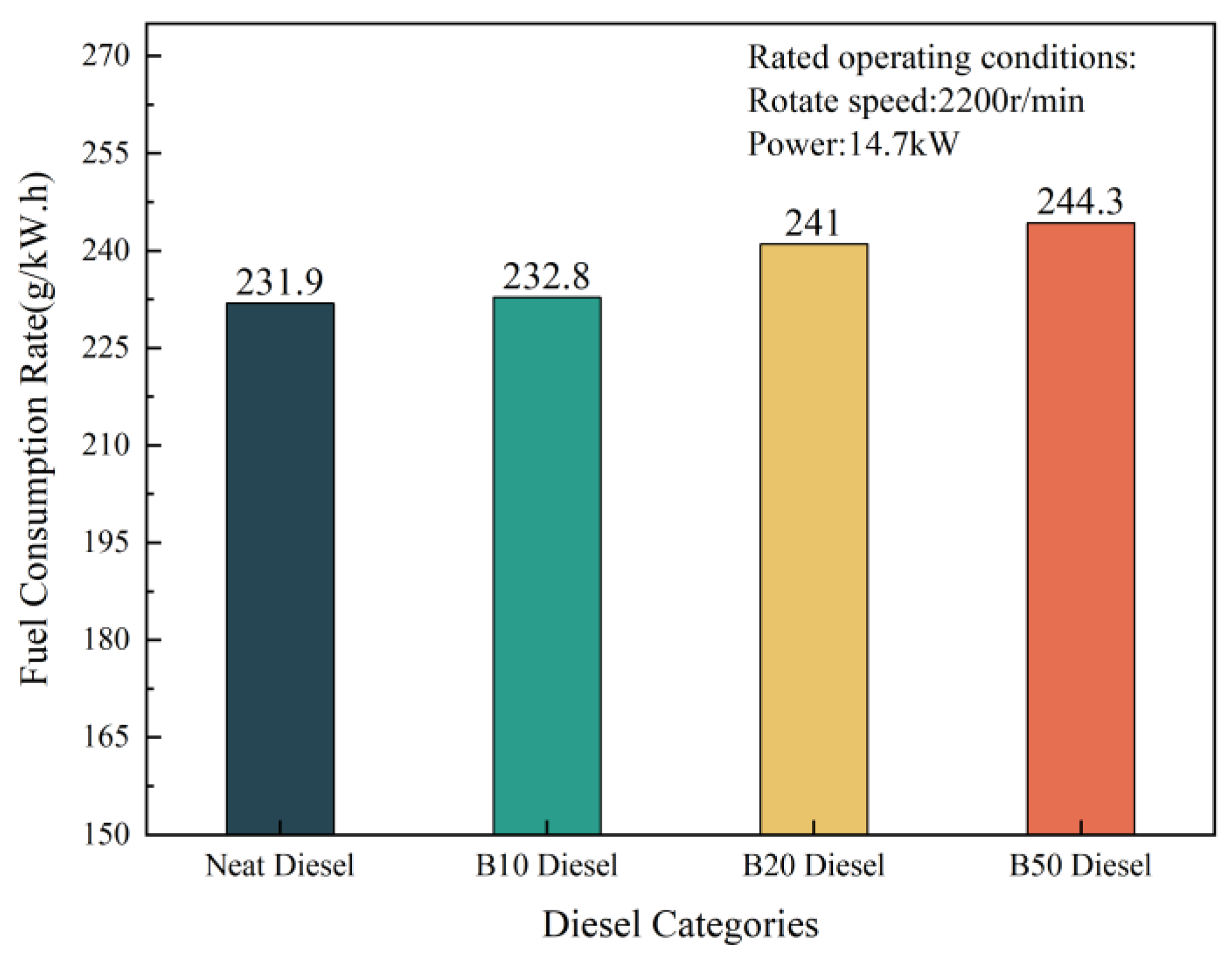

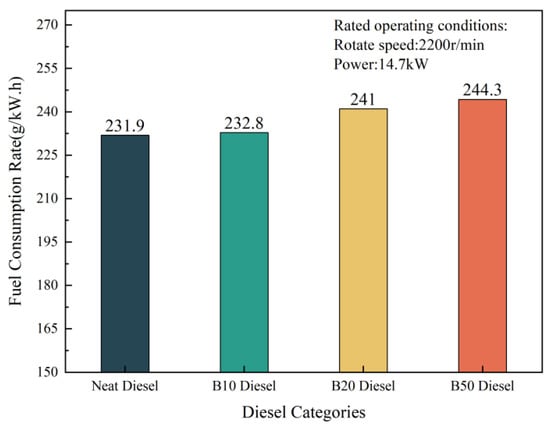

The fuel consumption rate at 2200 rpm and 14.7 kW under rated conditions have been presented in Figure 4. As shown in the figure, the fuel consumption rate increases with the increased mixing ratio. The fuel consumption rate of B10 is 0.9 g/kW·h higher than that of neat diesel. The fuel consumption rate of B50 increases the most, which is close to 5.3%. Such behavior can be attributed to the high viscosity, high residual carbon value, high cetane number and low calorific value of biodiesel compared to those of petrochemical diesel [39]. The energy released by the same volume of diesel biodiesel blended fuel is lower than that of petrochemical diesel. At the same time, the thermal polymerization of biodiesel molecules leads to incomplete combustion, and more carbon deposits are formed in the diesel engine, which greatly increases the friction resistance and affects the performance of the diesel engine. The low volatility of biodiesel will affect spray evaporation, thus inhibiting mixing. Insufficient mixing results in the deterioration of combustion and instability of the diesel engine [40] and a reduction in the brake thermal efficiency (BTE) of diesel [41,42]. Therefore, the fuel consumption rate of biodiesel increases, and the economic performance decreases, especially when B50 is used as fuel.

Figure 4.

Fuel Consumption Rate compared to biodiesel blends.

3.2. Emission Characteristic

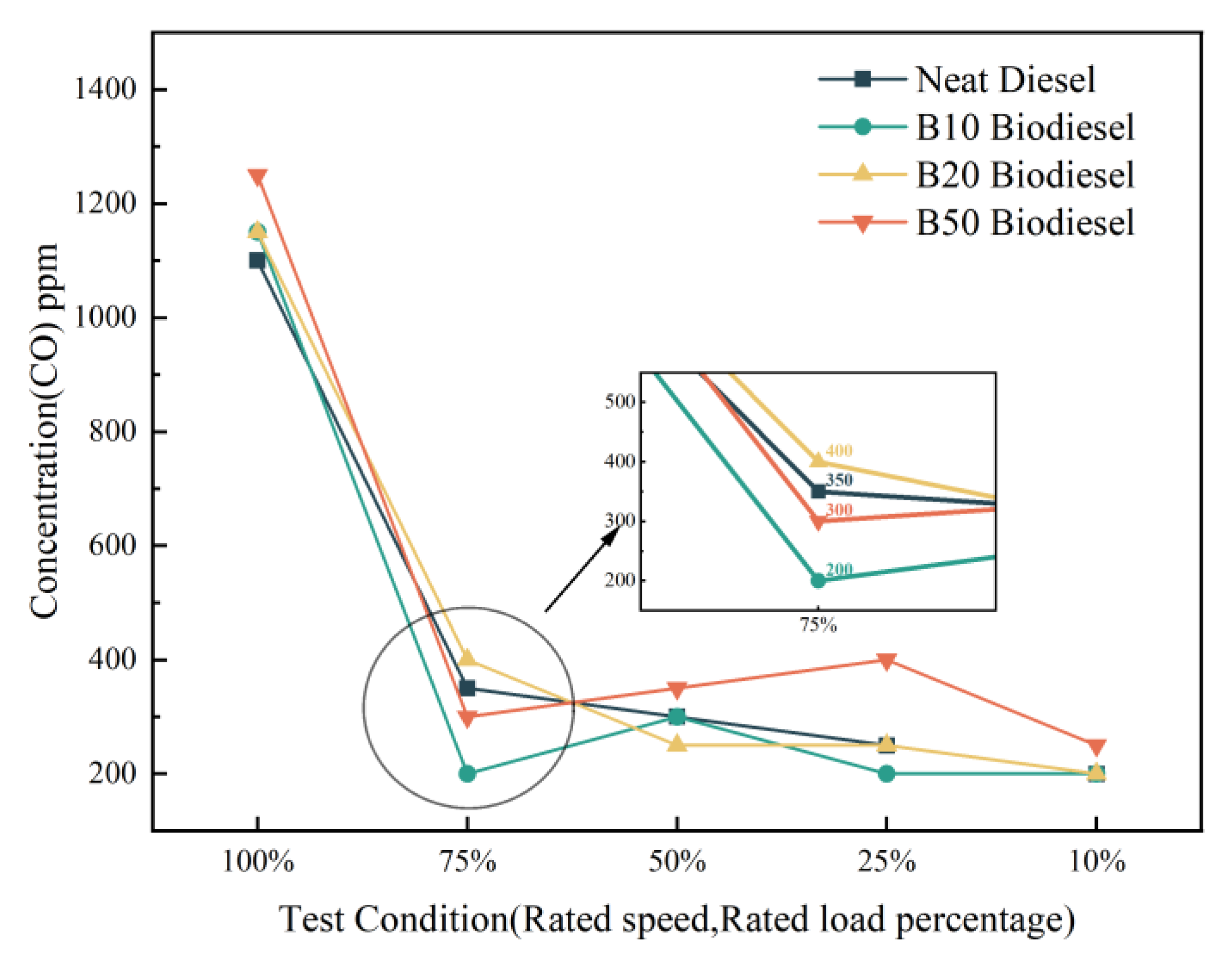

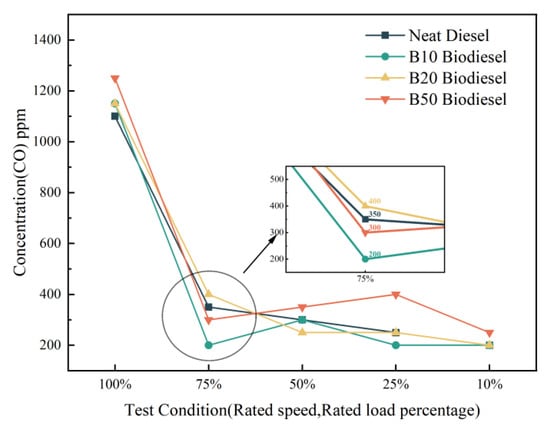

The changes in gas phase exhaust pollutants and soot under different mixing ratios and operation conditions are demonstrated in Figure 5, Figure 6, Figure 7 and Figure 8. The CO emissions at rated speed and different rated loads are represented in Figure 5. It can be seen that B10 has the most obvious effect on reducing CO emissions under different loads. Diesel has the most CO emissions at 100% rated load. CO emissions decrease sharply when the load reduces from 100% to 75%, while CO emissions from 75% to 10% rated load fluctuate little. When the engine operates at 100% load, the fuel consumption is significantly high. This is evident from Figure 5, where the concentrated mixture’s incomplete combustion due to insufficient oxygen leads to a rapid surge in CO emissions. In particular, the CO-specific emissions of B10 decreased by 42.86% at 75% load compared to neat diesel, while that of B50 increased by 60% at 25% load. The formation of CO is primarily influenced by oxygen concentration and serves as an indicator of complete combustion. At loads exceeding 20%, the high combustion temperature within the cylinder results from significant fuel injection. At this time, the oxygen concentration is the main influencing factor of CO formation. The neat conventional fuel itself does not contain oxygen, while the oxygen-containing characteristics of biodiesel itself improve the anoxic condition and reduce CO emissions. When the load is less than 20%, compared to that of diesel oil, the higher viscosity of biodiesel [43,44] has caused difficult fuel atomization and incomplete combustion. An increase in CO formation may be attributed to this factor [45].

Figure 5.

CO Emissions at different rated loads.

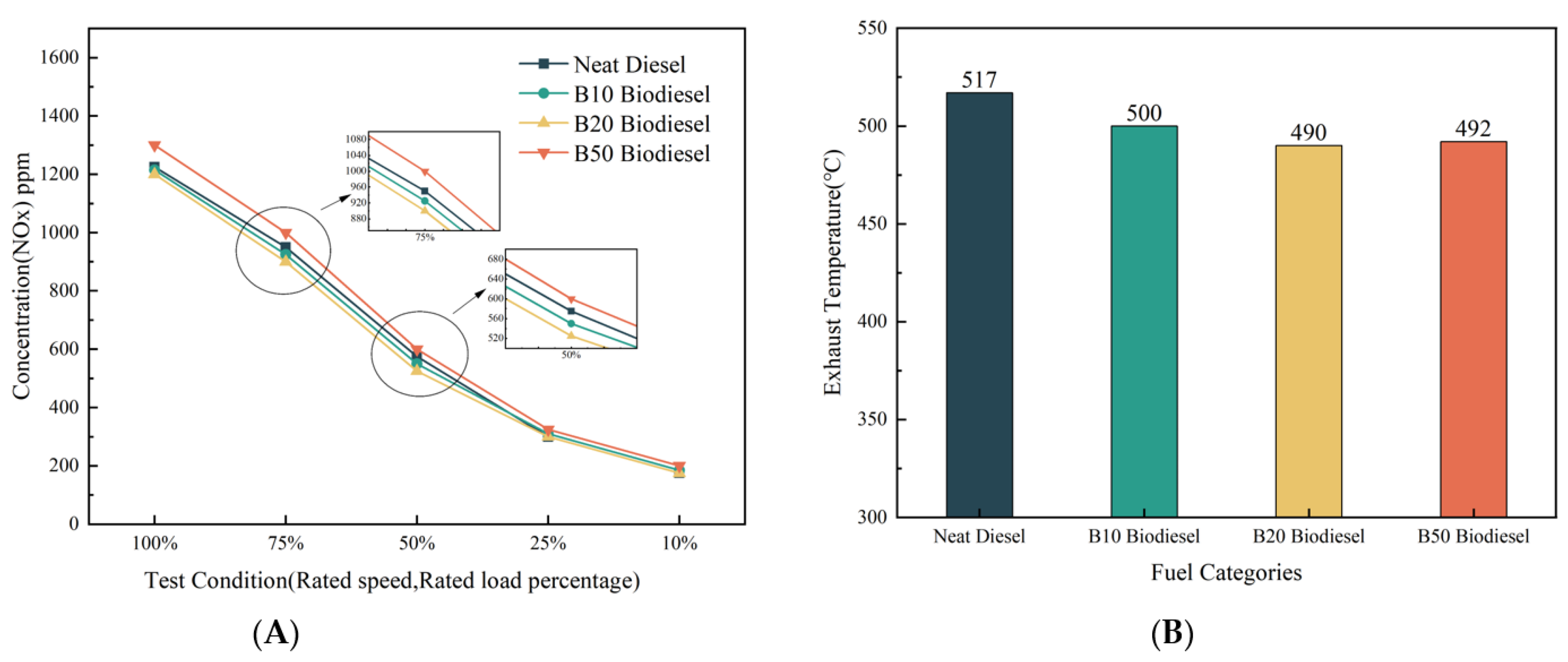

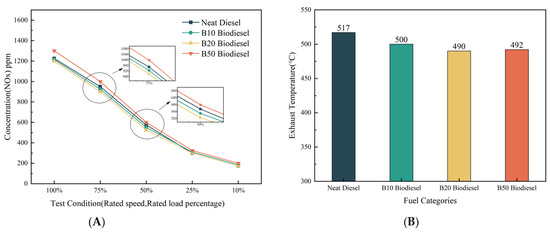

Figure 6.

NOX Emissions at different rated loads and Exhaust Temperatures compared to biodiesel blends. (A) Concentration (NOX); (B) Exhaust temperature.

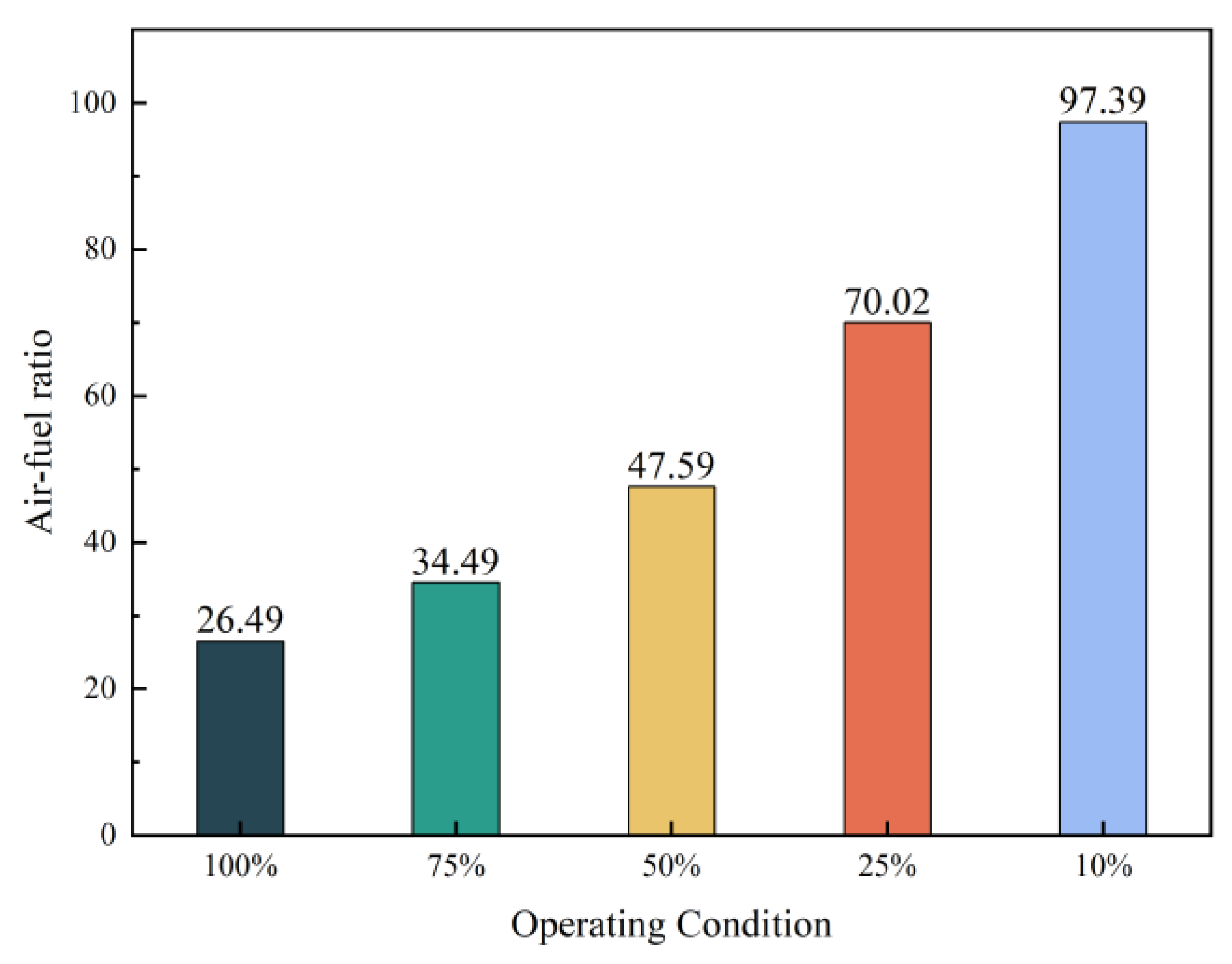

Figure 7.

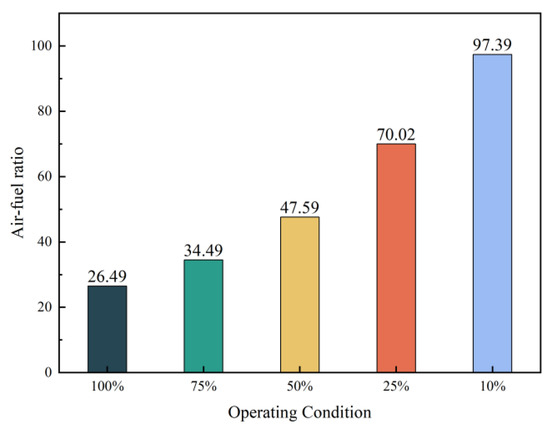

The air–fuel ratio at different rated loads.

Figure 8.

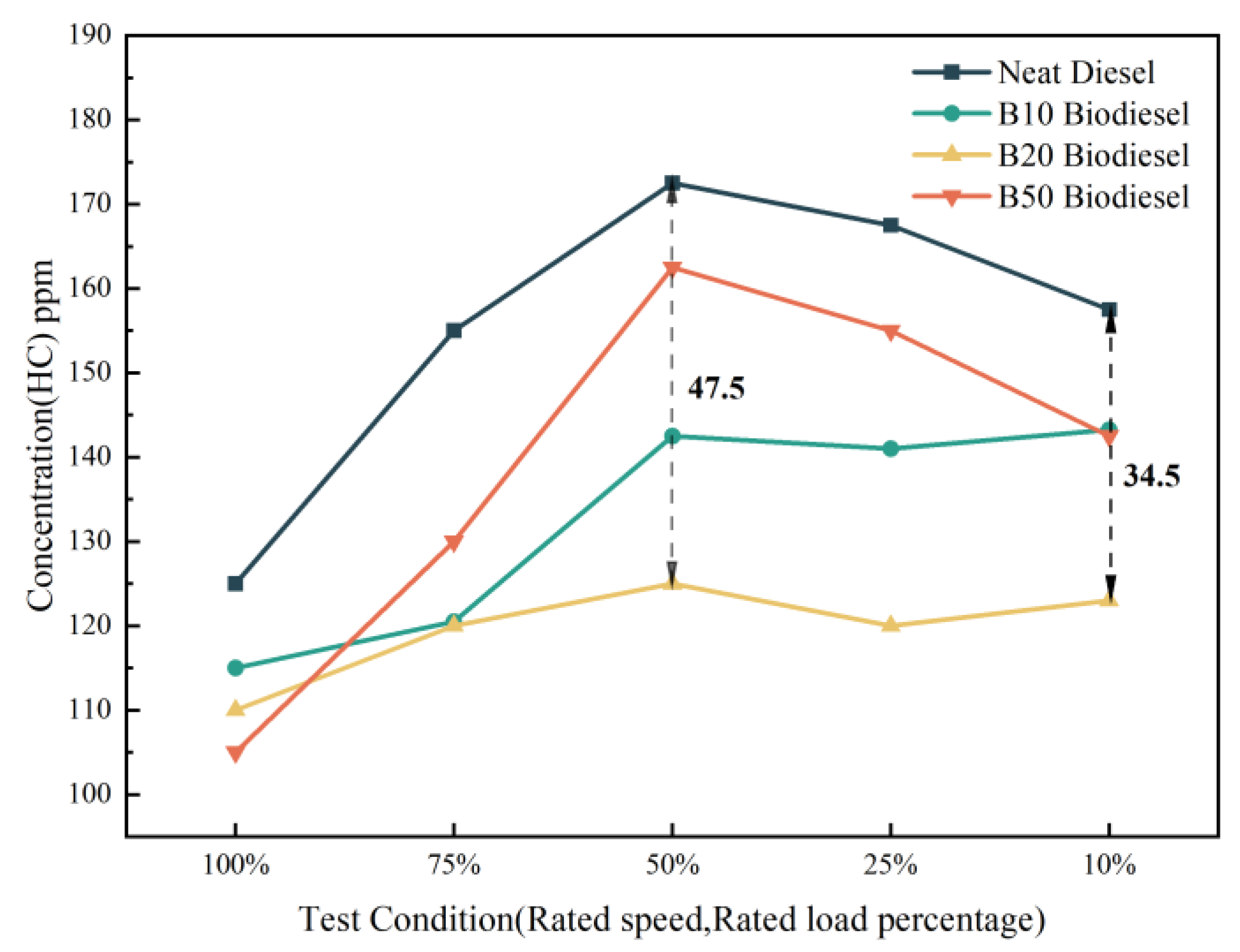

HC Emissions at different rated loads.

Figure 6 demonstrates the NOX emissions under different rated loads at rated speed and the exhausted temperature at 100% load. Except for B50, increasing the tung oil mixing ratio results in lower NOX emission under the same engine load. Conversely, as the rated load decreases, NOX emissions also decrease. The emission curves when the load is 50% and 75% are shown in the figure, which can clearly see the above situation. However, B50 has higher NOX emissions than B20. The reason for the lower increase in oxygen content, when blended in a smaller proportion, lies in the inherent characteristics of biodiesel. Its high cetane number and low aromatic content naturally lead to a reduction in combustion temperature. This reduction in temperature leads to a decrease in NOX emissions. When adding a large proportion, the excess oxygen in the mixed fuel causes the atmosphere of NOX generation. In addition, due to the low calorific value of biodiesel, the combustion temperature of the higher proportion of mixed fuel may decrease, and the exhaust temperature of B50 increases, as shown in Figure 6B. The combined effect of these three factors may lead to an increase in NOX emissions of the higher proportion of mixed fuel [45,46,47]. Additionally, the air–fuel ratio under different loads is shown in Figure 7. When the diesel engine load increases, the fuel supply increases and the air–fuel ratio gradually decreases. As the air–fuel ratio decreases, NOX emissions increase. When the air–fuel ratio gradually increases, the air increases and the temperature in the cylinder decreases; thereby, NOX emissions decrease.

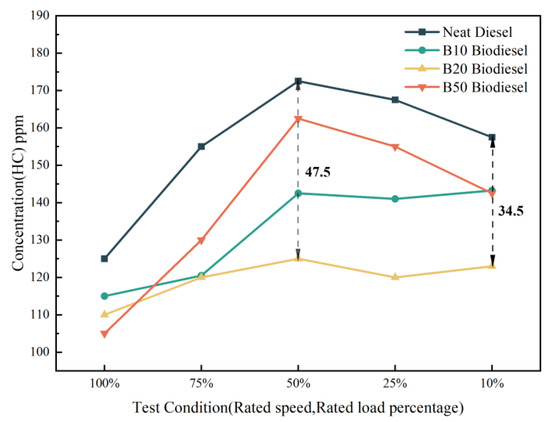

Figure 8 illustrates the HC emission at rated speed and different rated loads. As the load decreases, HC emissions increase first and then decrease. When the load is 50%, HC emissions reach the maximum. When the load is 100%, HC emissions are minimal. The most obvious is that when the load is 50%, the HC emission of B20 is reduced by 27.54 % compared with neat diesel. In addition, HC-specific emissions of tung oil-based biodiesel blends were all reduced, especially for B20, which decreased by 21.90% at 10% load. However, overall, the B20 shows the best performance, with the most significant reduction in HC emissions. With a low blend ratio, the fuel-bonded oxygen improves mixture quality, thus more complete combustion and less HC and particulate emissions.

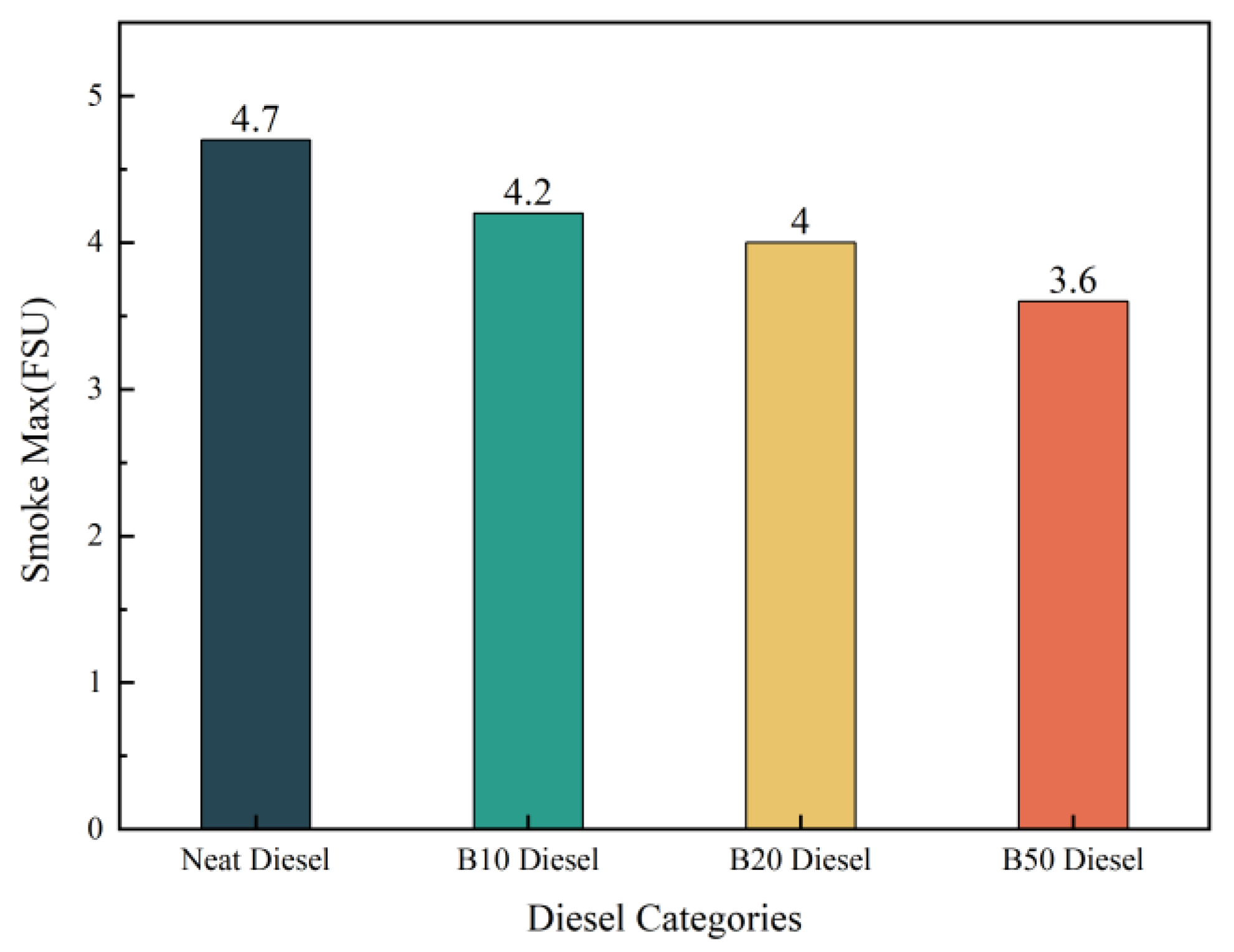

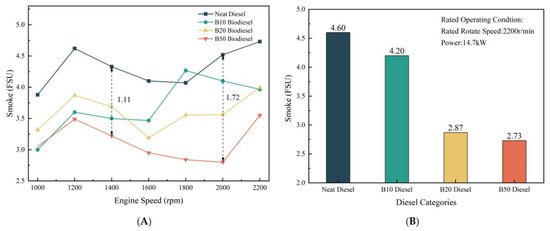

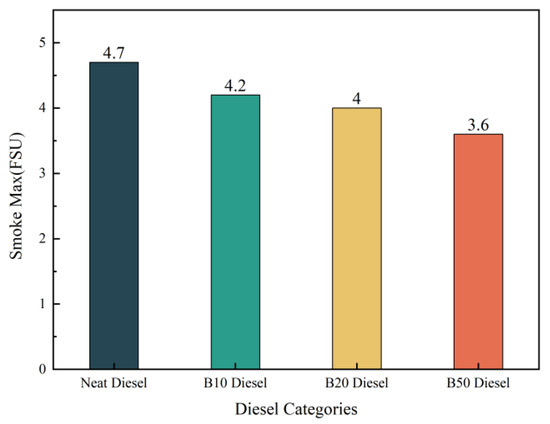

Figure 9A exhibits the change in the smoke emission of tung oil-based biodiesel with different speeds of rated power. As can be seen from the figure, usually at 1200 r/min and 2200 r/min, smoke emission is the highest. B20 and B50 smoke emission for ordinary biodiesel has a significant reduction. In particular, Smoke emissions decreased with an increasing percentage of tung oil added, especially for B50, which decreased by 38.05% at 2000 rpm. Figure 9B shows the change of smoke of different biodiesel at the same speed. In rated working conditions, the smoke degree (FSU) decreases sequentially with the increase in the proportion of tung oil. B50 is reduced the most, reducing by nearly 41% at a speed of 2200 rpm and power of 14.7 kW. Figure 10 shows the maximum smoke from different biodiesels.

Figure 9.

Smoke at different speeds compared to biodiesel blends. (A) Smoke at different speeds compared to biodiesel blends; (B) Smoke of different biodiesel in rated working conditions.

Figure 10.

Maximum smoke of different diesel blends.

First of all, biodiesel contains fewer aromatic hydrocarbons. In general, the higher the aromatic hydrocarbons contained in the fuel, the greater its smoke. The emission of soot from biodiesel is lower compared to pure diesel because the smoke produced by the fuel decreases with increasing amounts of alkanes. In addition, biodiesel is an oxygenated fuel (oxygen content of 10%); in the fuel combustion process, oxygen atoms play a role in fuel. Especially in areas with high fuel concentration, after the fuel is oxygenated, the fuel can be burned more completely. It can reduce soot emissions. Additionally, smoke reduces as the ambient temperature decreases [48,49,50,51].

Detailed comparative data can be seen in the following tables. Table 4 contains the emissions, specific emissions, specific emission reductions, and specific emission reduction rates of various exhaust gases under different rated loads. Table 4 and Table 5 are a comparison of the economic power of different biodiesel (B20), which shows the power and BSFC.

Table 4.

The emissions, specific emissions, specific emission reductions and specific emission reduction rates of various exhaust gases.

Table 5.

Comparison of the economic power of different biodiesel (B20).

4. Conclusions

Biodiesel was prepared from tung oil by conventional transesterification. The major physical and chemical properties of biodiesels and their combined blends were tested by ASTM standards. The performance and emission characteristics of 10%, 20% and 50% tung oil-based biodiesel blends were studied on a single-cylinder direct injection diesel engine. Based on the above research, the following conclusions can be drawn on it:

- (1)

- In terms of economy and power performance, compared with the use of neat diesel, the maximum power at full load is 16 kW for B10, which is 1.9% higher than neat diesel. In terms of torque, the B10 increased by almost 6.6%. However, the B20 and B50 decreased by 2.4% and 1.2%, respectively. The fuel consumption rate of B50 increases the most, and it increases by nearly 5.3%. This is mostly due to the calorific value of biodiesel, cetane number and other parameters that are quite different from diesel.

- (2)

- From the analysis of exhaust emission of the blends, it has been found that the NOX emissions blend decreases as increasing the proportion of tung oil-based except B50. B10 has the most obvious effect on reducing CO emissions at different rated loads. B20 shows the best performance with the most significant reduction in HC emissions. Biodiesel fuel reduces exhaust emissions, such as CO, HC, and NOX; the CO-specific emissions of B10 decreased by 42.86% at 75% load compared to neat diesel, while that of B50 increased by 60% at 25% load. Compared to neat diesel, NOX-specific emissions of tung oil-based biodiesel blends were reduced at all load conditions except for B50. In addition, HC-specific emissions of tung oil-based biodiesel blends were all reduced, especially for B20 decreased by 22.15% at 10% load.

- (3)

- When burning biodiesel, the exhaust smoke of biodiesel is significantly reduced. B50 is reduced the most, reducing by nearly 41%. This is because biodiesel contains fewer aromatic hydrocarbons, and biodiesel is an oxygen-containing fuel during fuel combustion.

The results show that if tung oil-based biodiesel is burned on the engine, the fuel injection system should be optimized to improve SFC and exhaust emissions. Further research could focus on enhancing the stability of the fuel, reducing NOX emissions and exploring uncontrolled emissions, such as smoke and particulate matter. This study contributes to the existing knowledge of the combustion and emission performance of biodiesel and provides valuable data to support the promotion and application of biodiesel in the context of environmental protection and emission reduction. However, it is important to note that the study was conducted under specific operating conditions, and further research is needed to evaluate the performance and emission characteristics of tung oil-based biodiesel blends under different engine conditions and long-term durability tests.

One of the main implications of our research is that tung oil-based biodiesel blends have the potential to significantly reduce the emissions of harmful pollutants, such as carbon dioxide, nitrogen oxides, and particulate matter. This is particularly important given the negative impact that these pollutants have on both human health and the environment. However, despite the many potential benefits of using biodiesel, there are also numerous barriers that need to be overcome in order to fully realize its potential. These include issues related to cost, infrastructure, and public perception. In order to address these challenges, it will be necessary to develop new policies and strategies that support the widespread adoption of biodiesel as a viable and sustainable alternative to traditional fossil fuels.

In conclusion, our research provides valuable insights into the potential of tung oil-based biodiesel blends to positively impact sustainable development in the energy and transportation sectors. By addressing the barriers to adoption and developing new policies and strategies, we can work towards creating a cleaner and more sustainable future for all.

Author Contributions

Conceptualization, Z.M., F.Z. and Z.C.; Methodology, J.L.; Software, Z.M.; Validation, Z.M.; Formal analysis, J.Y.; Investigation, Z.M. and D.H.; Data curation, D.H.; Writing—original draft, Z.M.; Writing—review & editing, J.F. and X.D.; Supervision, K.Y.; Project administration, F.Z.; Funding acquisition, F.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research work is sponsored by the Hunan Provincial Department of Education Project, China (21B0273), the Scientific Innovation Fund for Postgraduates of Central South University of Forestry and Technology (2022CX02072) and Hunan Provincial Natural Science Foundation of China (2023JJ41056).

Data Availability Statement

Not applicable.

Acknowledgments

The authors appreciate the reviewers and the editor for their careful reading and many constructive comments and suggestions on improving the manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| AV | Acid value |

| BSFC | Brake Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| B10 | 10% Tung oil, 90% 0# diesel |

| B20 | 20% Tung oil, 80% 0# diesel |

| B50 | 50% Tung oil, 50% 0# diesel |

| CFPP | Cold filter plugging point |

| CN | Cetane number |

| EGR | Exhaust Gas Recirculation |

| KV | Kinematic viscosity |

| NOX | Oxides of nitrogen |

| Φ | Equivalence ratio |

References

- Wang, B.; Wang, Z.; Shuai, S.; Yang, H.; Wang, J. Combustion and emission characteristics of Multiple Premixed Compression Ignition (MPCI) fuelled with naphtha and gasoline in wide load range. Energy Convers. Manag. 2014, 88, 79–87. [Google Scholar] [CrossRef]

- Tang, C.; Zhang, Y.; Huang, Z. Progress in combustion investigations of hydrogen enriched hydrocarbons. Renew. Sustain. Energy Rev. 2014, 30, 195–216. [Google Scholar] [CrossRef]

- Zhao, L.; Moiz, A.A.; Som, S.; Fogla, N.; Bybee, M.; Wahiduzzaman, S.; Mirzaeian, M.; Millo, F.; Kodavasal, J. Examining the role of flame topologies and in-cylinder flow fields on cyclic variability in spark-ignited engines using large-eddy simulation. Int. J. Engine Res. 2018, 19, 886–904. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, J.; Liu, B.; Zeng, K.; Yu, J.; Jiang, D. Combustion characteristics of a direct-injection engine fueled with natural gas–hydrogen blends under different ignition timings. Fuel 2007, 86, 381–387. [Google Scholar] [CrossRef]

- Huang, Y.; Hong, G.; Huang, R. Effect of injection timing on mixture formation and combustion in an ethanol direct injection plus gasoline port injection (EDI+ GPI) engine. Energy 2016, 111, 92–103. [Google Scholar] [CrossRef]

- Pei, Y.; Qin, J.; Li, X.; Zhang, D.; Wang, K.; Liu, Y. Experimental investigation on free and impingement spray fueled with methanol, ethanol, isooctane, TRF and gasoline. Fuel 2017, 208, 174–183. [Google Scholar] [CrossRef]

- Bae, C.; Kim, J. Alternative fuels for internal combustion engines. Proc. Combust. Inst. 2017, 36, 3389–3413. [Google Scholar] [CrossRef]

- Awad, O.I.; Mamat, R.; Ali, O.M.; Sidik, N.C.; Yusaf, T.; Kadirgama, K.; Kettner, M. Alcohol and ether as alternative fuels in spark ignition engine: A review. Renew. Sustain. Energy Rev. 2018, 82, 2586–2605. [Google Scholar] [CrossRef]

- Chen, Z.; Zhang, F.; Xu, B.; Zhang, Q.; Liu, J. Influence of methane content on a LNG heavy-duty engine with high compression ratio. Energy 2017, 128, 329–336. [Google Scholar] [CrossRef]

- Lee, S.; Speight, J.G.; Loyalka, S.K. (Eds.) Handbook of Alternative Fuel Technologies; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Mofijur, M.; Masjuki, H.H.; Kalam, M.A.; Atabani, A.E. Evaluation of biodiesel blending, engine performance and emissions characteristics of Jatropha curcas methyl ester: Malaysian perspective. Energy 2013, 55, 879–887. [Google Scholar] [CrossRef]

- Liaquat, A.M.; Masjuki, H.H.; Kalam, M.A.; Fattah, I.R. Impact of biodiesel blend on injector deposit formation. Energy 2014, 72, 813–823. [Google Scholar] [CrossRef]

- Jayed, M.H.; Masjuki, H.H.; Kalam, M.A.; Mahlia TM, I.; Husnawan, M.; Liaquat, A.M. Prospects of dedicated biodiesel engine vehicles in Malaysia and Indonesia. Renew. Sustain. Energy Rev. 2011, 15, 220–235. [Google Scholar] [CrossRef]

- Lim, S.; Teong, L.K. Recent trends, opportunities and challenges of biodiesel in Malaysia: An overview. Renew. Sustain. Energy Rev. 2010, 14, 938–954. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Aziz, A.A. High quality biodiesel and its diesel engine application: A review. Renew. Sustain. Energy Rev. 2010, 14, 1999–2008. [Google Scholar] [CrossRef]

- Imtenan, S.; Varman, M.; Masjuki, H.H.; Kalam, M.A.; Sajjad, H.; Arbab, M.I.; Fattah, I.R. Impact of low temperature combustion attaining strategies on diesel engine emissions for diesel and biodiesels: A review. Energy Convers. Manag. 2014, 80, 329–356. [Google Scholar] [CrossRef]

- Ming, C.; Fattah, I.R.; Chan, Q.N.; Pham, P.X.; Medwell, P.R.; Kook, S.; Yeoh, G.H.; Hawkes, E.R.; Masri, A.R. Combustion characterization of waste cooking oil and canola oil based biodiesels under simulated engine conditions. Fuel 2018, 224, 167–177. [Google Scholar] [CrossRef]

- Rahman SM, A.; Fattah IM, R.; Maitra, S.; Mahlia TM, I. A ranking scheme for biodiesel underpinned by critical physicochemical properties. Energy Convers. Manag. 2021, 229, 113742. [Google Scholar] [CrossRef]

- Umar, M.; Ji, X.; Kirikkaleli, D.; Alola, A.A. The imperativeness of environmental quality in the United States transportation sector amidst biomass-fossil energy consumption and growth. J. Clean. Prod. 2021, 285, 124863. [Google Scholar] [CrossRef]

- Torkashvand, M.; Hasan-Zadeh, A.; Torkashvand, A. Mini Review on Importance, Application, Advantages and Disadvantages of Biofuels. J. Mater. Environ. Sci. 2022, 13, 612–630. [Google Scholar]

- Blackmon, G.H. The tung-oil industry. Bot. Rev. 1943, 9, 1–40. [Google Scholar] [CrossRef]

- Qi, D.H.; Yang, K.; Zhang, D.; Chen, B. Combustion and emission characteristics of diesel-tung oil-ethanol blended fuels used in a CRDI diesel engine with different injection strategies. Appl. Therm. Eng. 2017, 111, 927–935. [Google Scholar] [CrossRef]

- Chen, Y.H.; Chen, J.H.; Chang, C.Y.; Chang, C.C. Biodiesel production from tung (Vernicia montana) oil and its blending properties in different fatty acid compositions. Bioresour. Technol. 2010, 101, 9521–9526. [Google Scholar] [CrossRef] [PubMed]

- Ithnin, A.M.; Ahmad, M.A.; Bakar MA, A.; Rajoo, S.; Yahya, W.J. Combustion performance and emission analysis of diesel engine fuelled with water-in-diesel emulsion fuel made from low-grade diesel fuel. Energy Convers. Manag. 2015, 90, 375–382. [Google Scholar] [CrossRef]

- Valente, O.S.; Da Silva, M.J.; Pasa VM, D.; Belchior CR, P.; Sodre, J.R. Fuel consumption and emissions from a diesel power generator fuelled with castor oil and soybean biodiesel. Fuel 2010, 89, 3637–3642. [Google Scholar] [CrossRef]

- Can, Ö. Combustion characteristics, performance and exhaust emissions of a diesel engine fueled with a waste cooking oil biodiesel mixture. Energy Convers. Manag. 2014, 87, 676–686. [Google Scholar] [CrossRef]

- Park, J.Y.; Kim, D.K.; Wang, Z.M.; Lu, P.; Park, S.C.; Lee, J.S. Production and characterization of biodiesel from tung oil. In Biotechnology for Fuels and Chemicals, Proceedings of the Twenty-Ninth Symposium on Biotechnology for Fuels and Chemicals, Denver, CO, USA, 29 April–2 May 2007; Humana Press: Totowa, NJ, USA, 2008; pp. 627–635. [Google Scholar]

- Kilic, G.; Sungur, B.; Topaloglu, B.; Ozcan, H. Experimental analysis on the performance and emissions of diesel/butanol/biodiesel blended fuels in a flame tube boiler. Appl. Therm. Eng. 2018, 130, 195–202. [Google Scholar] [CrossRef]

- Sungur, B.; Topaloglu, B.; Namli, L.; Ozcan, H.; Ozbey, M. Combustion performance and emissions of diesel/biodiesel blended fuels in a residential reverse flame boiler. Int. J. Glob. Warm. 2017, 13, 183–196. [Google Scholar] [CrossRef]

- Shang, Q.; Jiang, W.; Lu, H.; Liang, B. Properties of Tung oil biodiesel and its blends with neat diesel. Bioresour. Technol. 2010, 101, 826–828. [Google Scholar] [CrossRef]

- Deshmane, V.G.; Adewuyi, Y.G. Synthesis and kinetics of biodiesel formation via calcium methoxide base catalyzed transesterification reaction in the absence and presence of ultrasound. Fuel 2013, 107, 474–482. [Google Scholar] [CrossRef]

- GB/T 2540-1981; Petroleum Products—Determination of Density by Pycnometer. AQSIQ: Beijing, China, 1981.

- GB/T 264-2008; Petroleum Products—Determination of Acid or Base Number—Color-Indicator Titration Method. SAC: Beijing, China, 2008.

- SH/T 0246-2009; Determination of Total Sulfur in Crude Oil and Petroleum Products—Ultraviolet Fluorescence Method. SINOPEC: Beijing, China, 2009.

- EN 14112-2003; Determination of the Oxidation Stability of Fatty Acid Methyl Esters (FAME) for Use as Diesel Fuel—Accelerated Oxidation Method. CEN: Brussels, Belgium, 2003.

- ASTM D6584-2021; Standard Test Method for the Determination of Free and Total Glycerin in Biodiesel Blends by Gas Chromatography (External Standard Method). ASTM International: West Conshohocken, PA, USA, 2021.

- Razzaq, L.; Mujtaba, M.A.; Soudagar ME, M.; Ahmed, W.; Fayaz, H.; Bashir, S.; Rizwanul Fattah, I.M.; Ong, H.C.; Shahapurkar, K.; Afzal, A.; et al. Engine performance and emission characteristics of palm biodiesel blends with graphene oxide nanoplatelets and dimethyl carbonate additives. J. Environ. Manag. 2021, 282, 111917. [Google Scholar] [CrossRef]

- Cardone, M.; Prati, M.V.; Rocco, V.; Seggiani, M.; Senatore, A.; Vitolo, S. Brassica carinata as an alternative oil crop for the production of biodiesel in Italy: Engine performance and regulated and unregulated exhaust emissions. Environ. Sci. Technol. 2002, 36, 4656–4662. [Google Scholar] [CrossRef] [PubMed]

- Genbao, L.; Longbao, Z.; Deming, J. Effects of Biodiesel Blended Fuel on the Combustion and Emissions of DI Diesel Engines. Diesel Engine 2004, 2, 17–20. [Google Scholar]

- Goering, C.E.; Schwab, A.W.; Daugherty, M.J.; Pryde, E.H.; Heakin, A.J. Fuel properties of eleven vegetable oils. Trans. ASAE 1982, 25, 1472–1477. [Google Scholar] [CrossRef]

- Mujtaba, M.A.; Kalam, M.A.; Masjuki, H.H.; Gul, M.; Soudagar ME, M.; Ong, H.C.; Ahmed, W.; Atabani, A.E.; Razzaq, L.; Yusoff, M. Comparative study of nanoparticles and alcoholic fuel additives-biodiesel-diesel blend for performance and emission improvements. Fuel 2020, 279, 118434. [Google Scholar] [CrossRef]

- Wategave, S.P.; Banapurmath, N.R.; Sawant, M.S.; Soudagar ME, M.; Mujtaba, M.A.; Afzal, A.; Sadhik Basha, J.; Alazwari, M.A.; Safaei, M.R.; Elfasakhany, A.; et al. Clean combustion and emissions strategy using reactivity controlled compression ignition (RCCI) mode engine powered with CNG-Karanja biodiesel. J. Taiwan Inst. Chem. Eng. 2021, 124, 116–131. [Google Scholar] [CrossRef]

- Alptekin, E.; Canakci, M. Determination of the density and the viscosities of biodiesel–diesel fuel blends. Renew. Energy 2008, 33, 2623–2630. [Google Scholar] [CrossRef]

- Candeia, R.A.; Silva, M.C.D.; Carvalho Filho, J.R.; Brasilino, M.G.A.; Bicudo, T.C.; Santos, I.M.G.; Souza, A.G. Influence of soybean biodiesel content on basic properties of biodiesel–diesel blends. Fuel 2009, 88, 738–743. [Google Scholar] [CrossRef]

- Heywood, J.B. Internal Combustion Engine Fundamentals; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Hu, S.; Deng, B.; Wu, D.; Hou, K. Energy flow behavior and emission reduction of a turbo-charging and EGR non-road diesel engine equipped with DOC and DPF under NRTC (non-road transient cycle). Fuel 2021, 305, 121571. [Google Scholar] [CrossRef]

- Duan, X.; Xu, Z.; Sun, X.; Deng, B.; Liu, J. Effects of injection timing and EGR on combustion and emissions characteristics of the diesel engine fuelled with acetone–butanol–ethanol/diesel blend fuels. Energy 2021, 231, 121069. [Google Scholar] [CrossRef]

- Miyamoto, N.; Ogawa, H.; Nurun, N.M.; Obata, K.; Arima, T. Smokeless, low NOX, high thermal efficiency, and low noise diesel combustion with oxygenated agents as main fuel. SAE Trans. 1998, 107, 171–177. [Google Scholar]

- Westbrook, C.K.; Pitz, W.J.; Curran, H.J. Chemical kinetic modeling study of the effects of oxygenated hydrocarbons on soot emissions from diesel engines. J. Phys. Chem. A 2006, 110, 6912–6922. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Dai, J.; Li, Y.; Lee, T.H. Optical investigation on combustion and soot formation characteristics of isopropanol-butanol-ethanol (IBE)/diesel blends. Energy Sci. Eng. 2021, 9, 2311–2320. [Google Scholar] [CrossRef]

- Feng, R.; Hu, X.; Li, G.; Sun, Z.; Ye, M.; Deng, B. Exploration on the emissions and catalytic reactors interactions of a non-road diesel engine through experiment and system level simulation. Fuel 2023, 342, 127746. [Google Scholar] [CrossRef]

- Qi, D.H.; Geng, L.M.; Chen, H.; Bian, Y.Z.; Liu, J.; Ren, X.C. Combustion and performance evaluation of a diesel engine fueled with biodiesel produced from soybean crude oil. Renew. Energy 2009, 34, 2706–2713. [Google Scholar] [CrossRef]

- Senatore, A.; Cardone, M.; Rocco, V.; Prati, M.V. A Comparative Analysis of Combustion Process in DI Diesel Engine Fueled with Biodiesel and Diesel Fuel; SAE International: Warrendale, PA, USA, 2000; pp. 1–691. [Google Scholar]

- Canakci, M.; Van Gerpen, J.H. Comparison of engine performance and emissions for petroleum diesel fuel, yellow grease biodiesel, and soybean oil biodiesel. Trans. ASAE 2003, 46, 937. [Google Scholar] [CrossRef]

- Ozsezen, A.N.; Canakci, M.; Turkcan, A.; Sayin, C. Performance and combustion characteristics of a DI diesel engine fueled with waste palm oil and canola oil methyl esters. Fuel 2009, 88, 629–636. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).