Feasibility Investigation of Attitude Control with Shape Memory Alloy Actuator on a Tethered Wing

Abstract

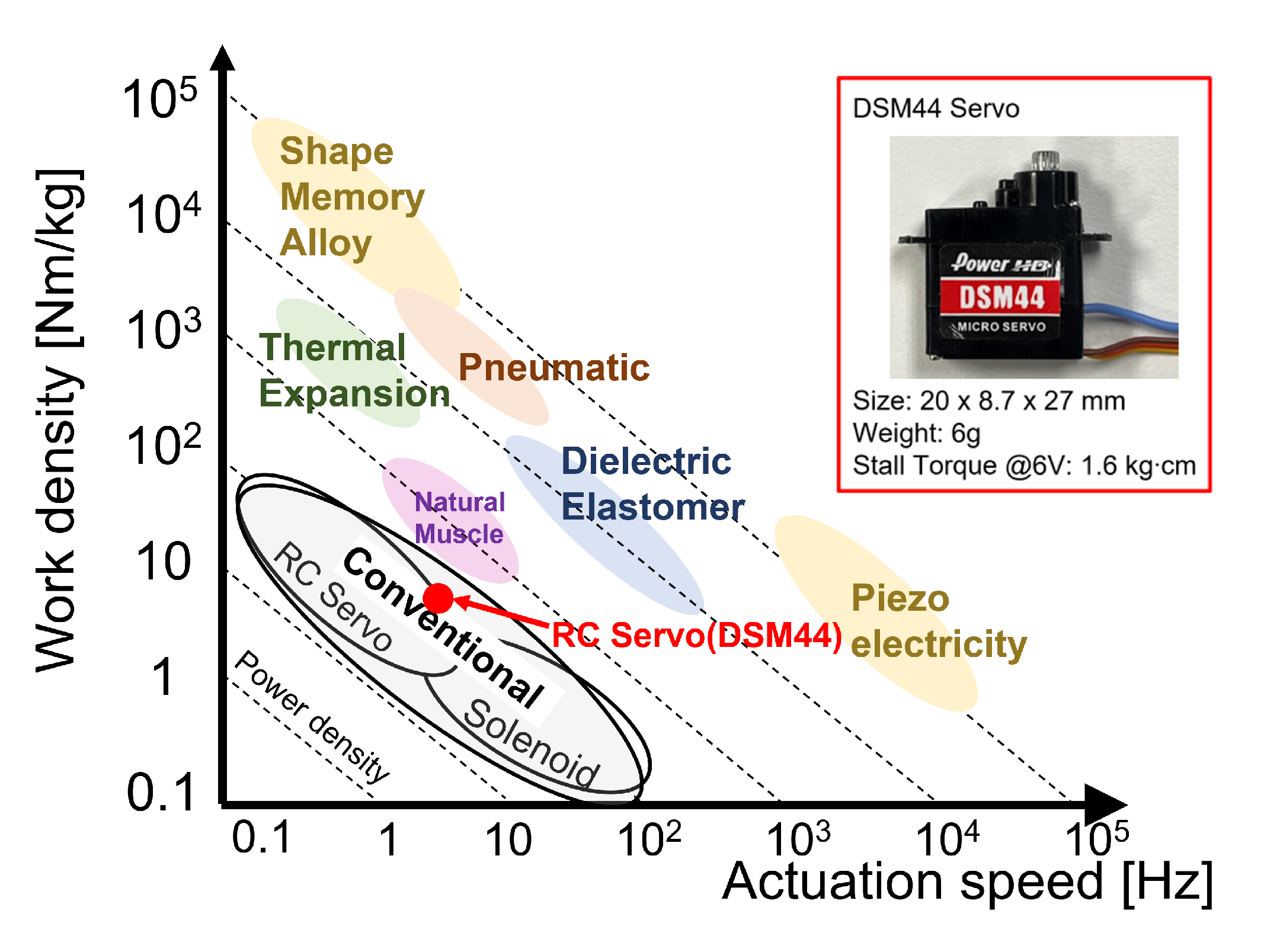

1. Introduction

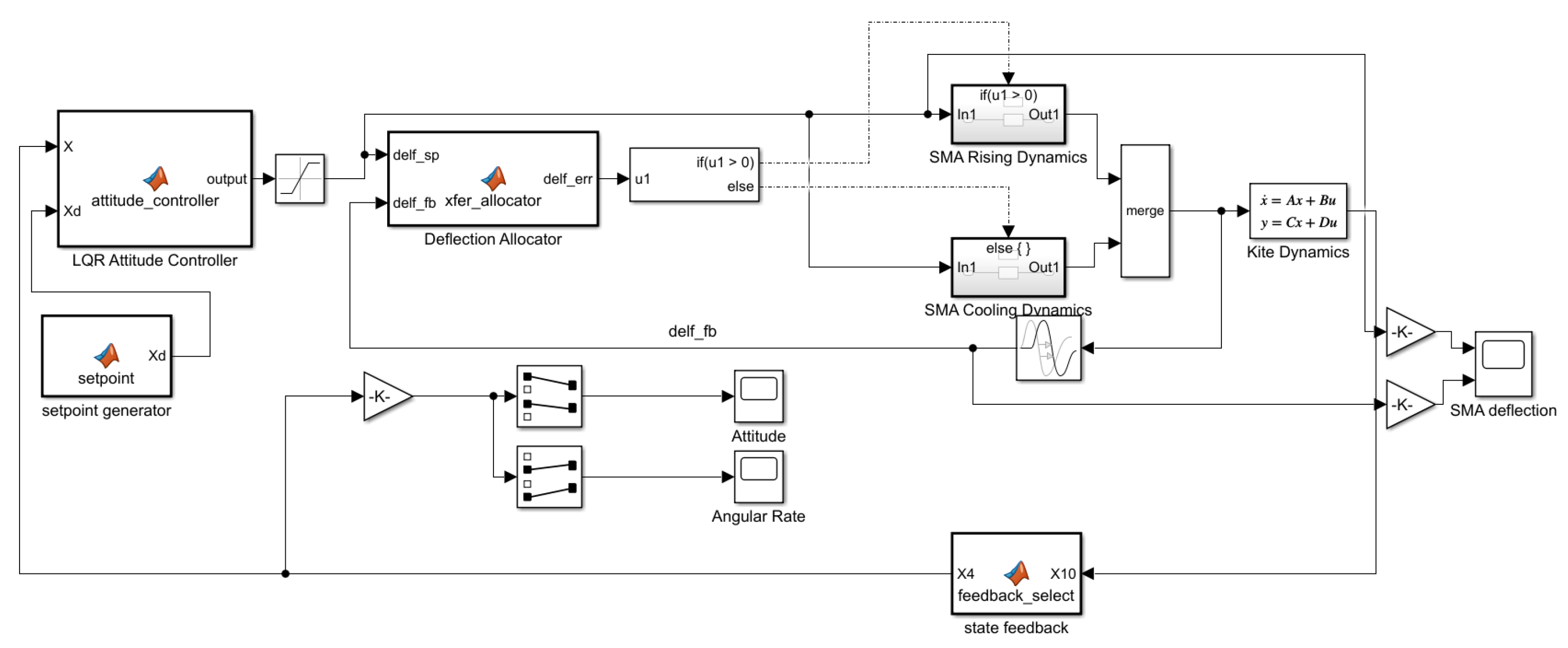

2. Stability Augmentation System of the Proof of Concept Kite

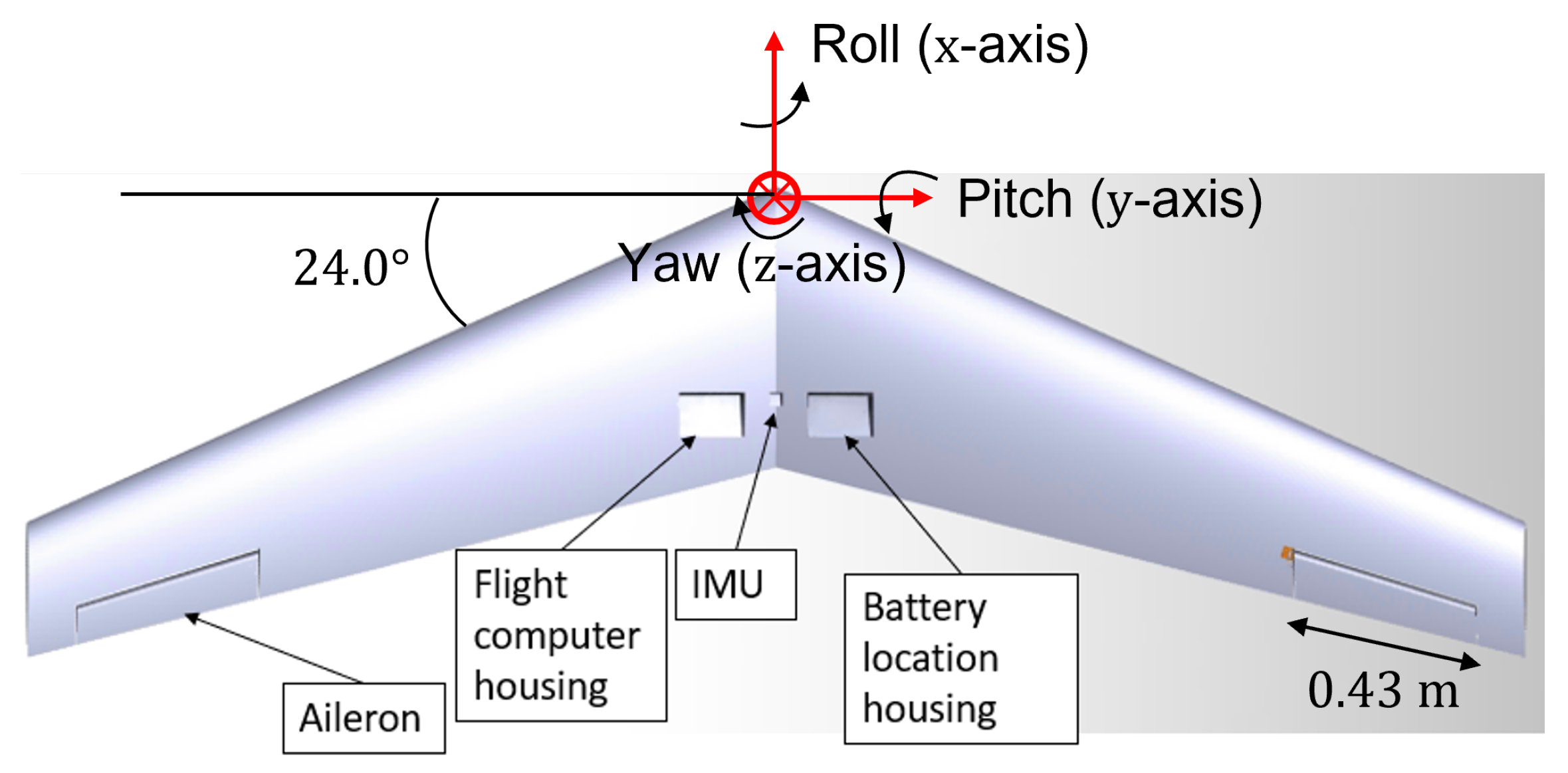

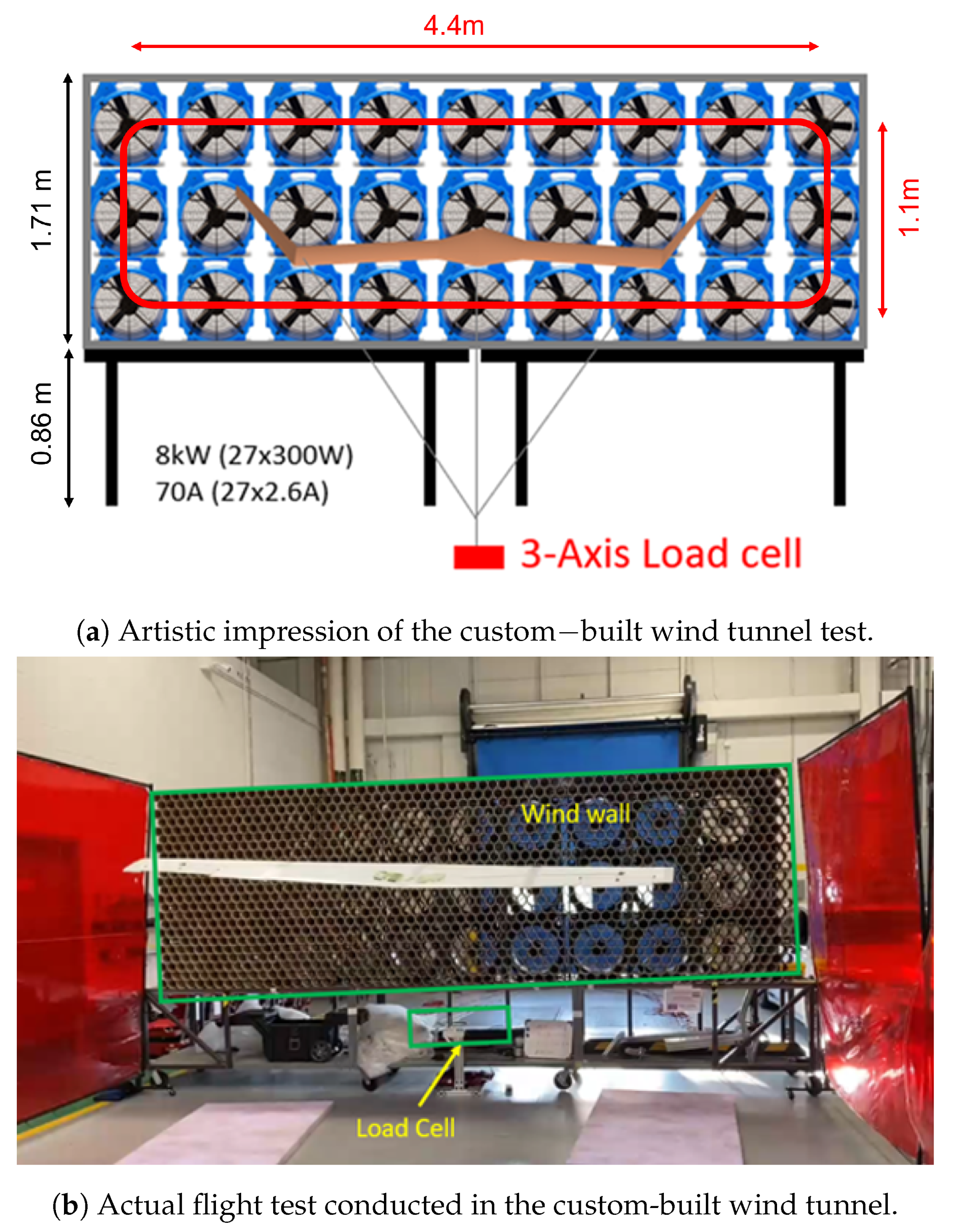

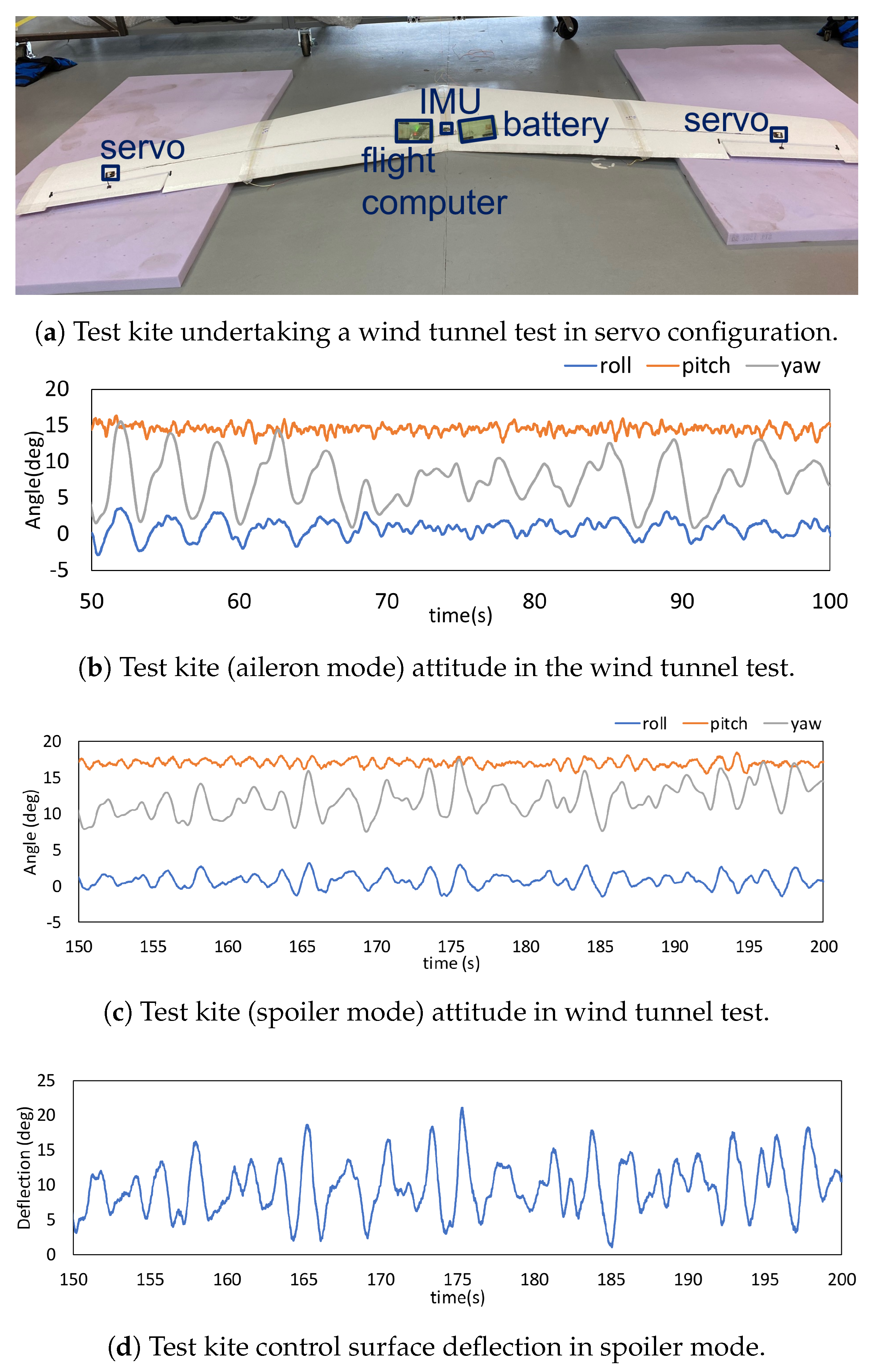

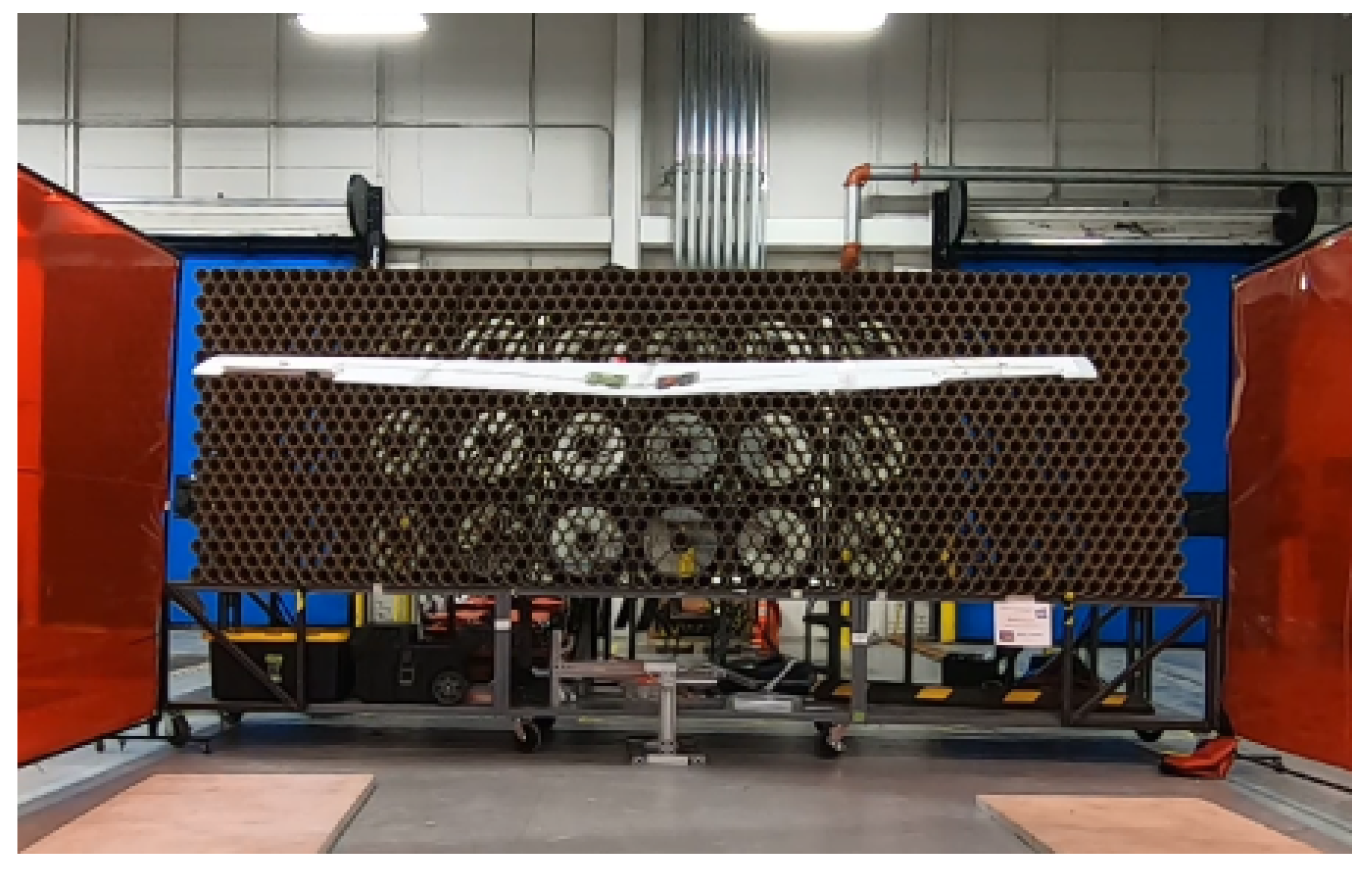

2.1. Test Platform and Prior Tests

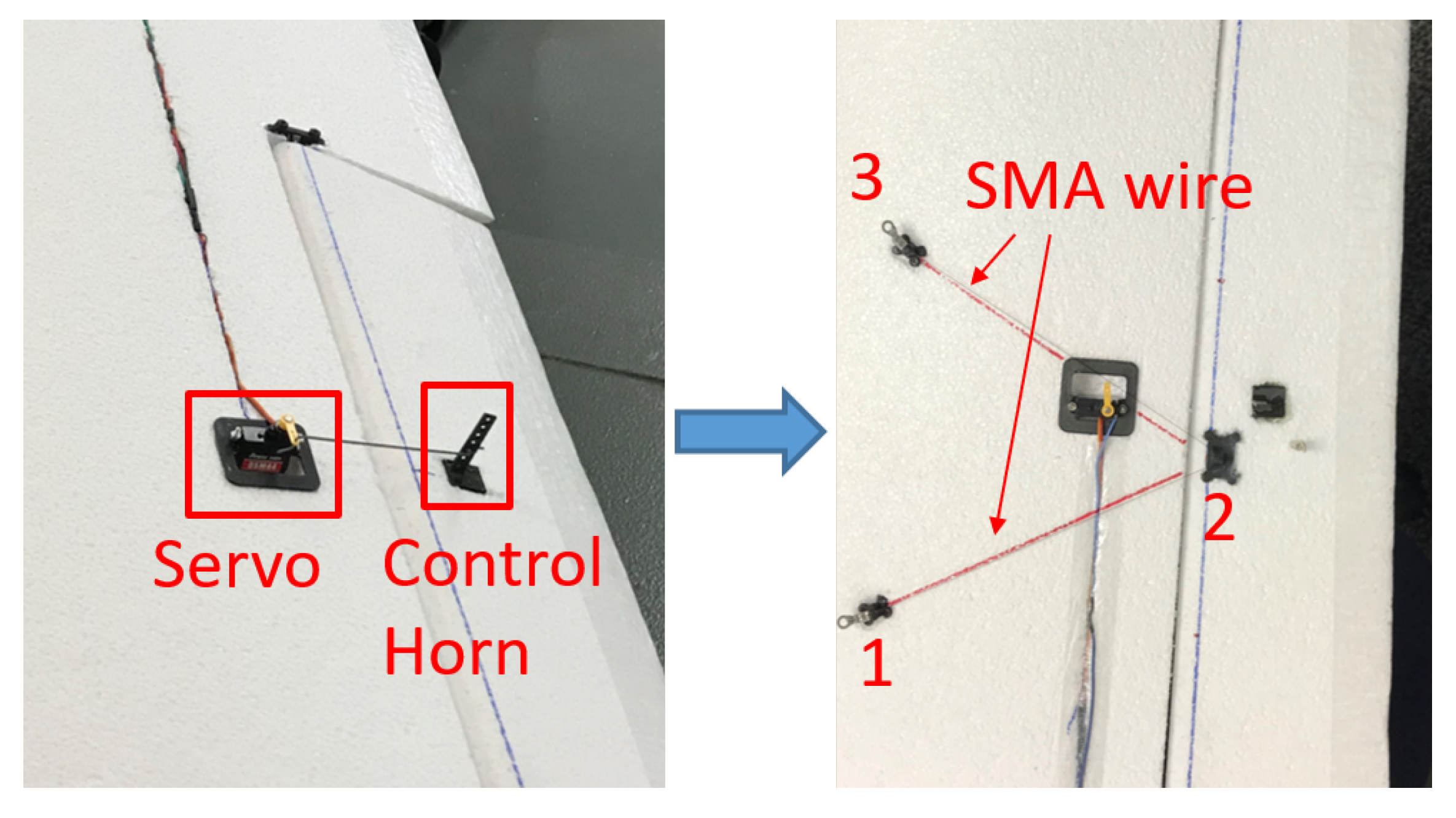

2.2. SMA Actuation Configuration

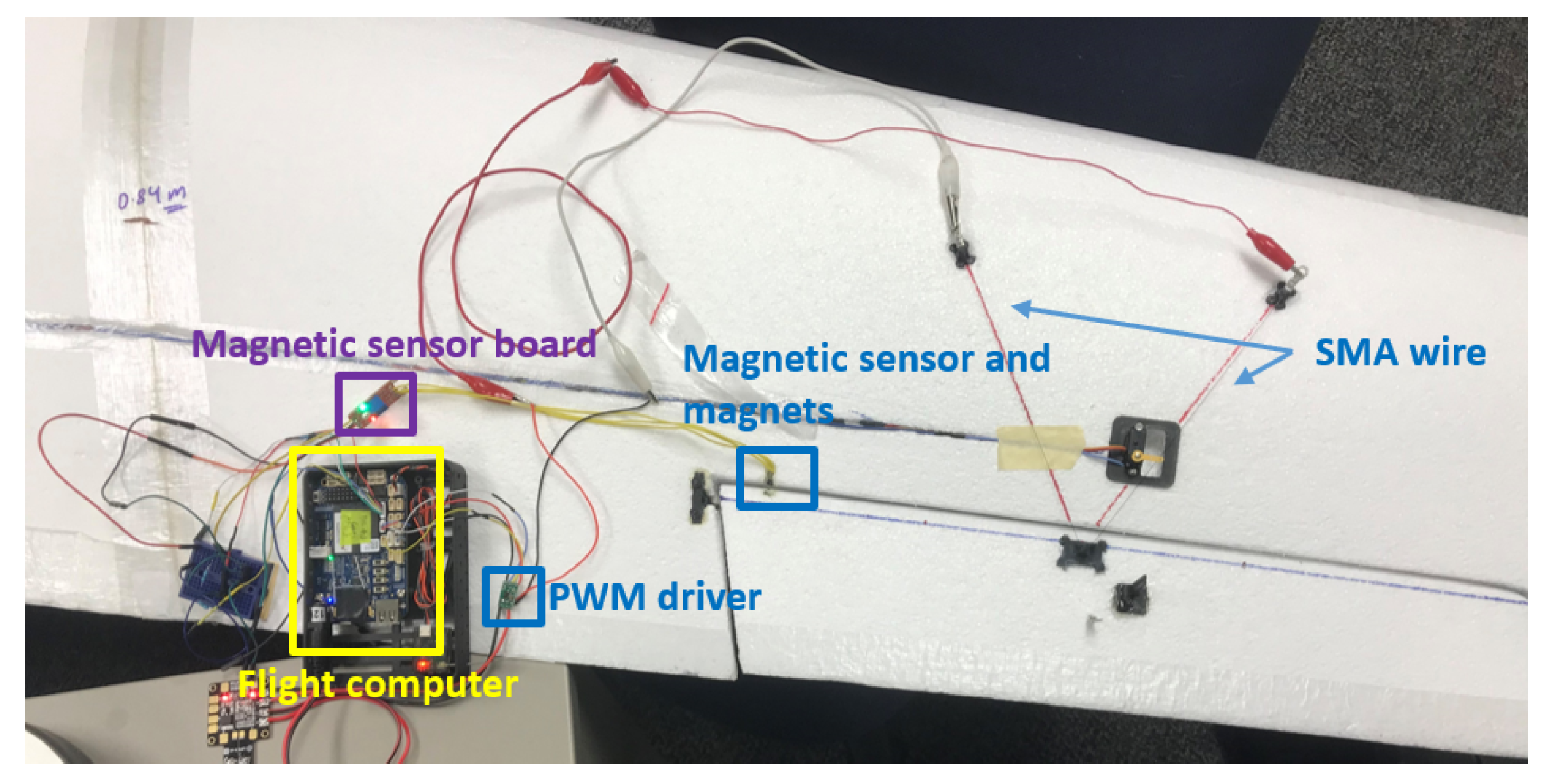

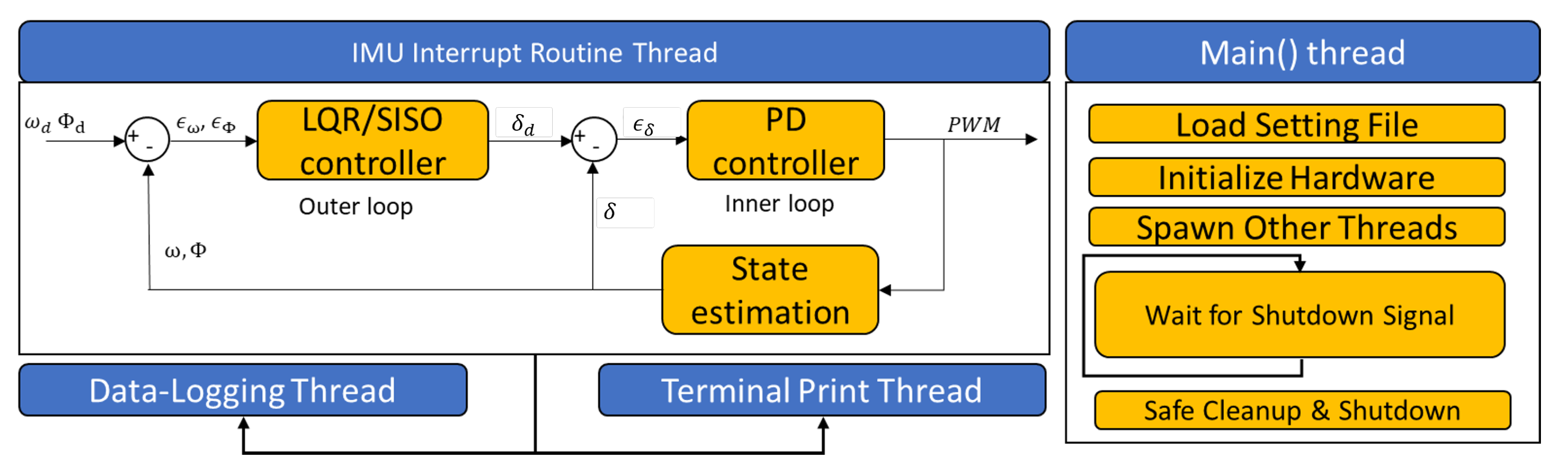

2.3. Kite Avionics and Flight Controller

3. Iterative Design and Test of the SMA Actuator

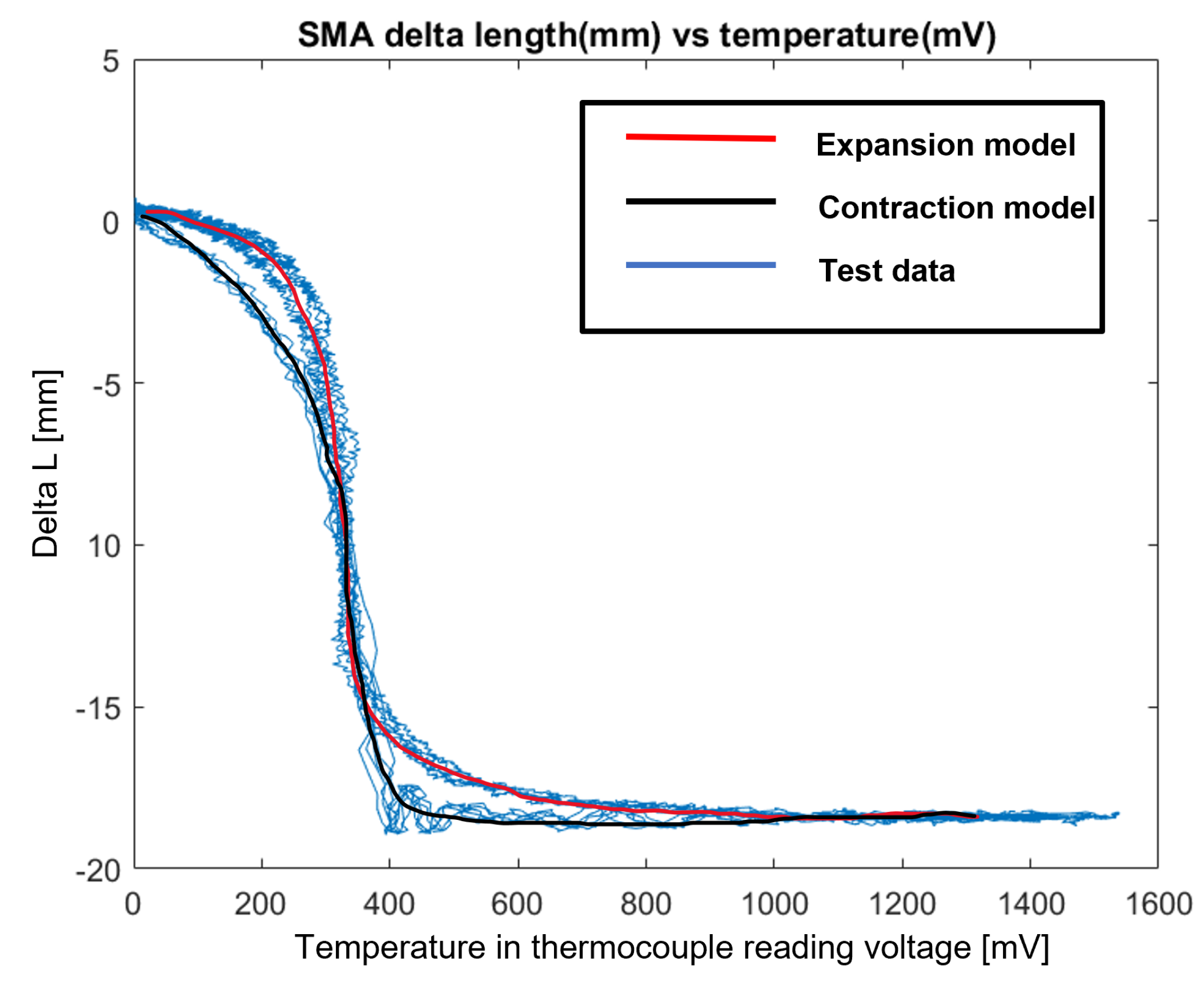

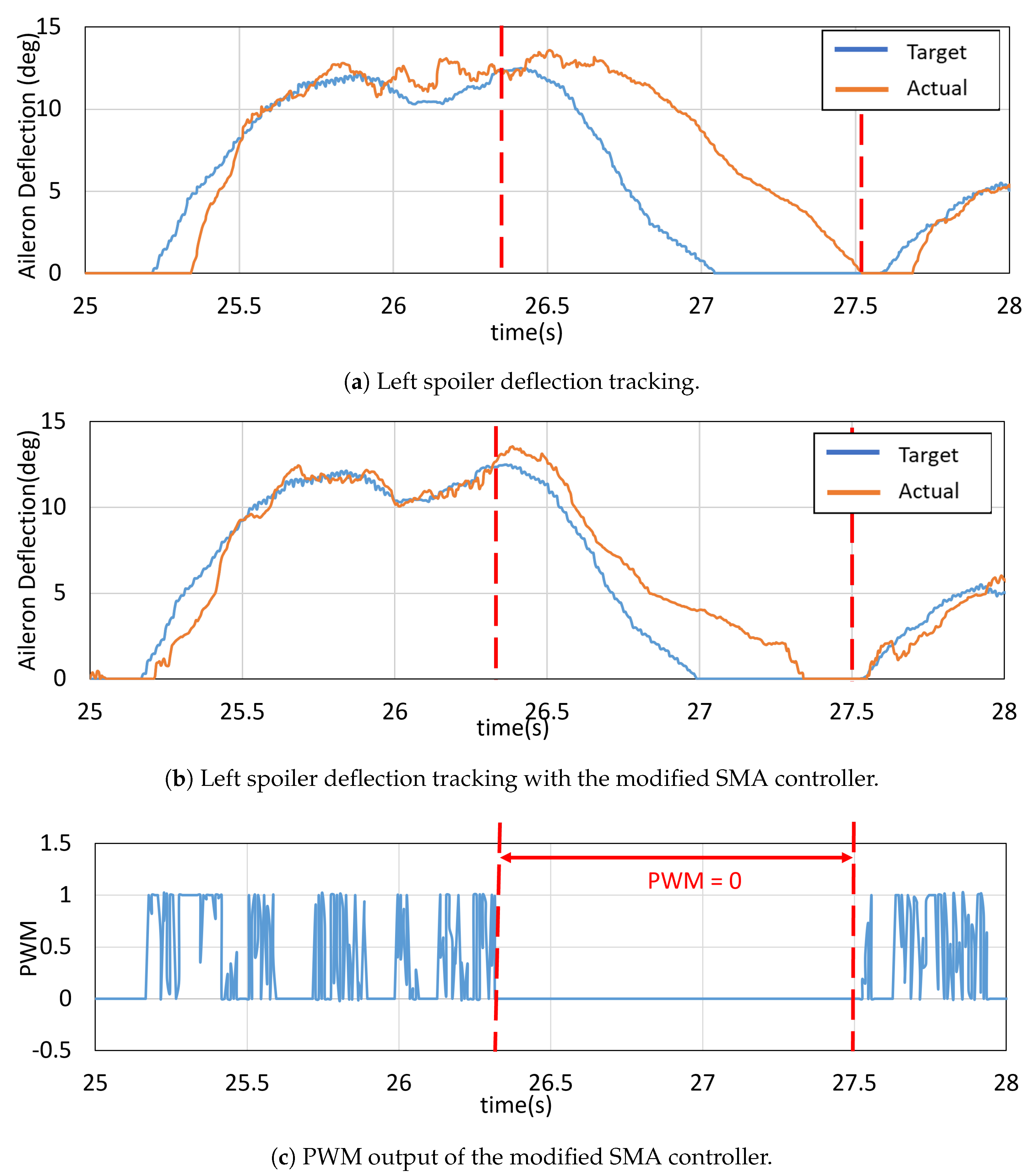

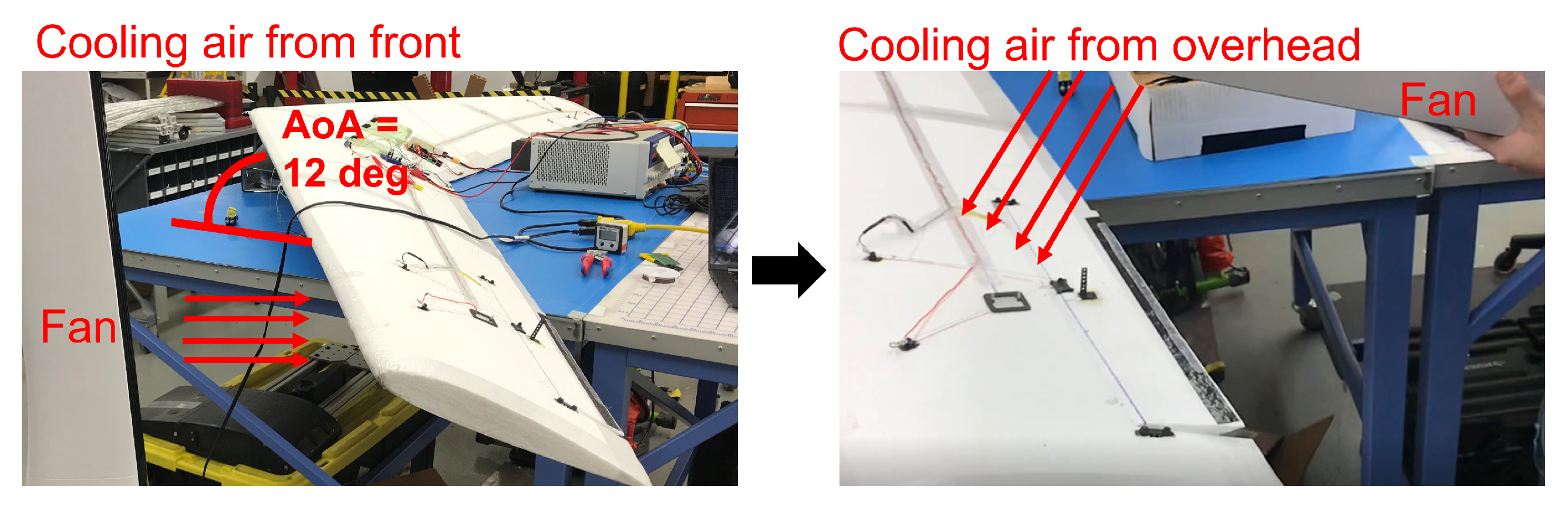

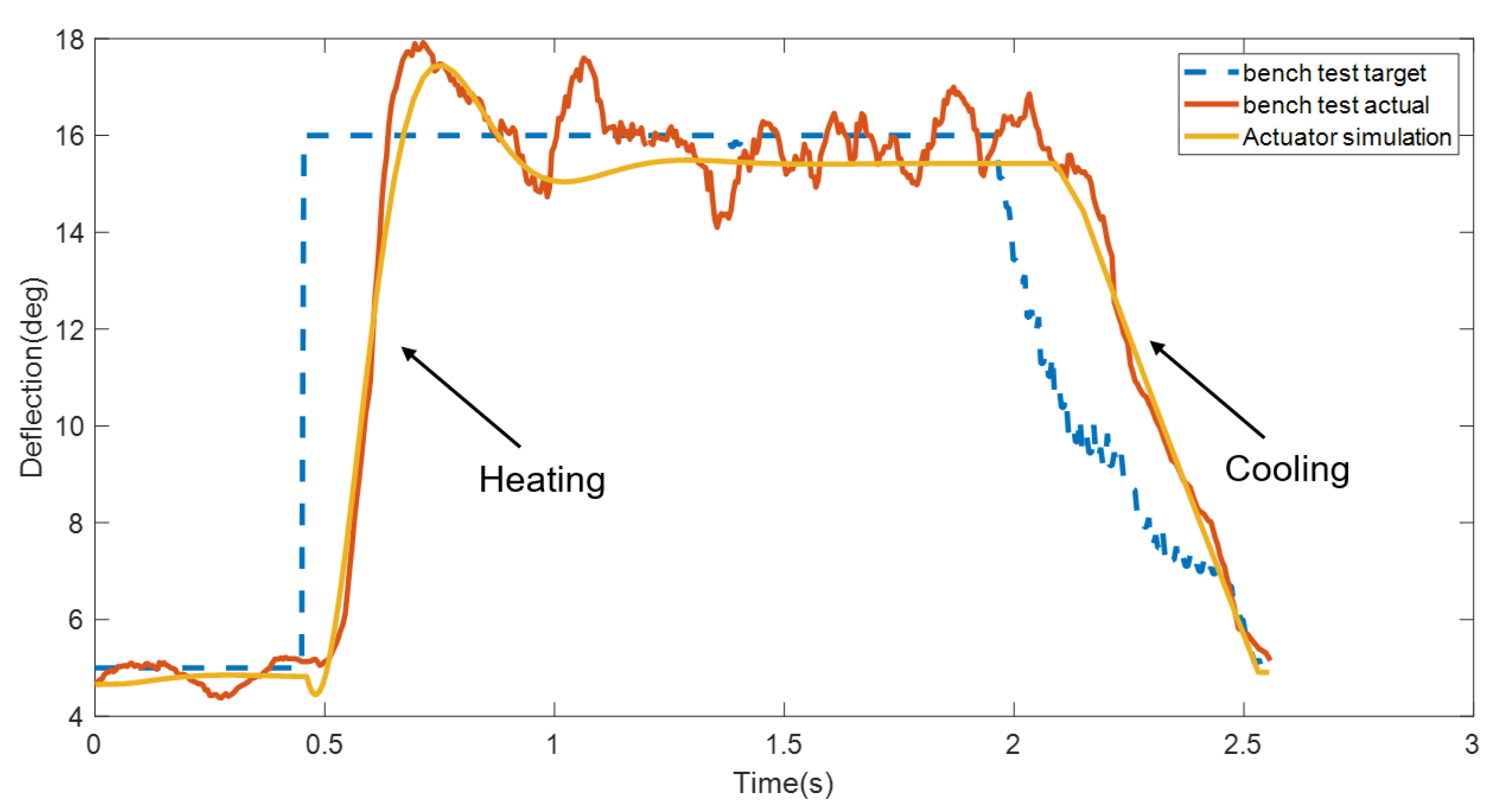

3.1. Prototype SMA Actuator Tests and Improvements

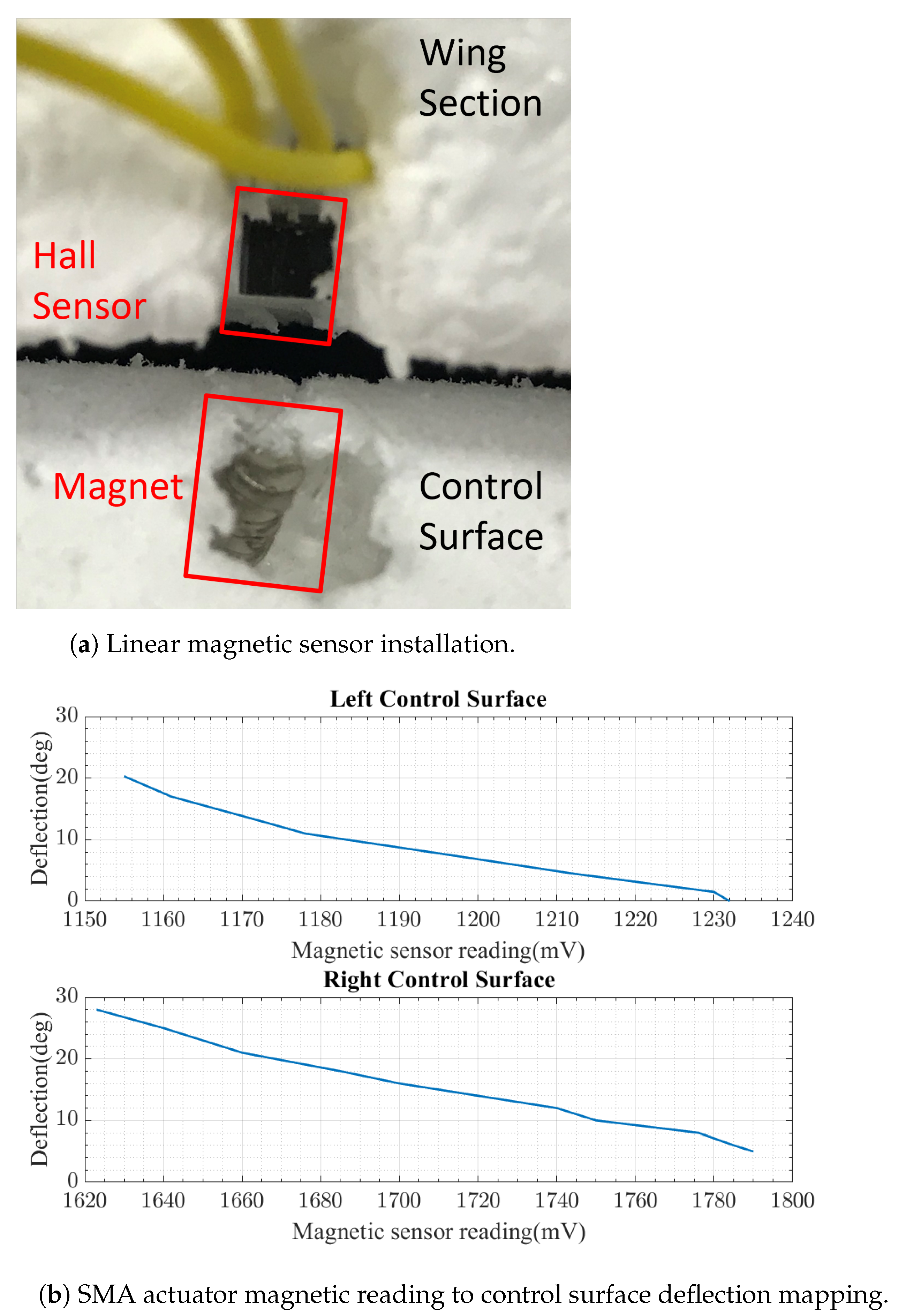

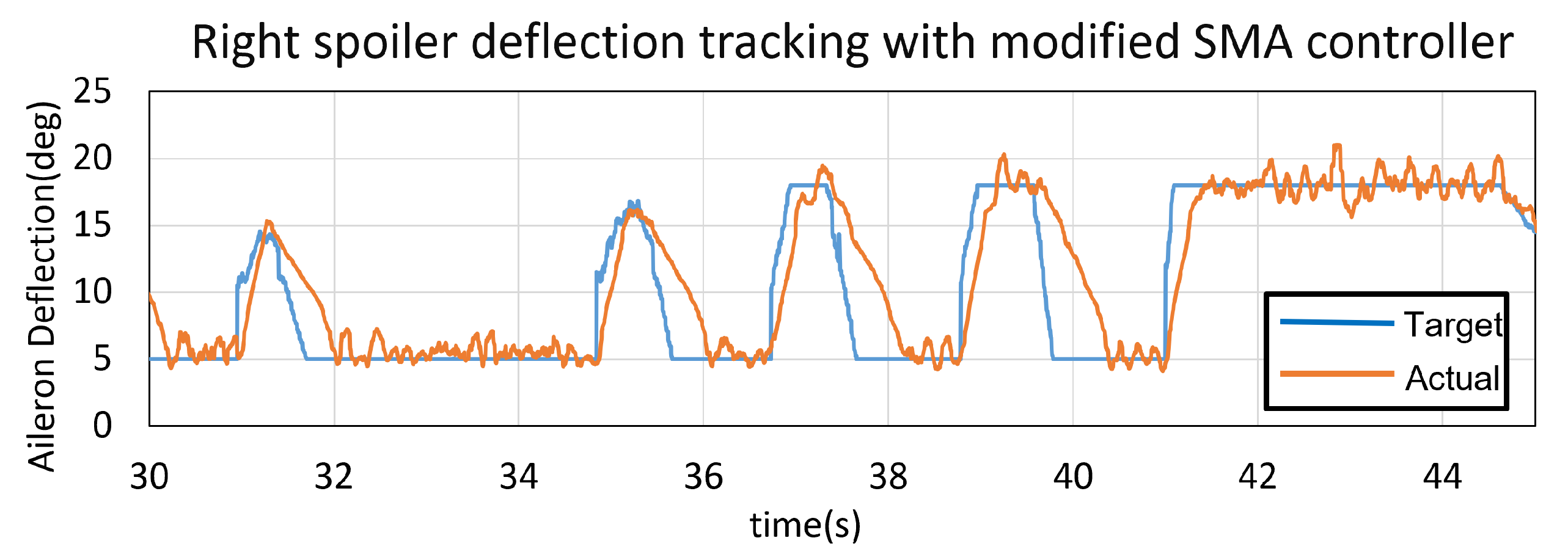

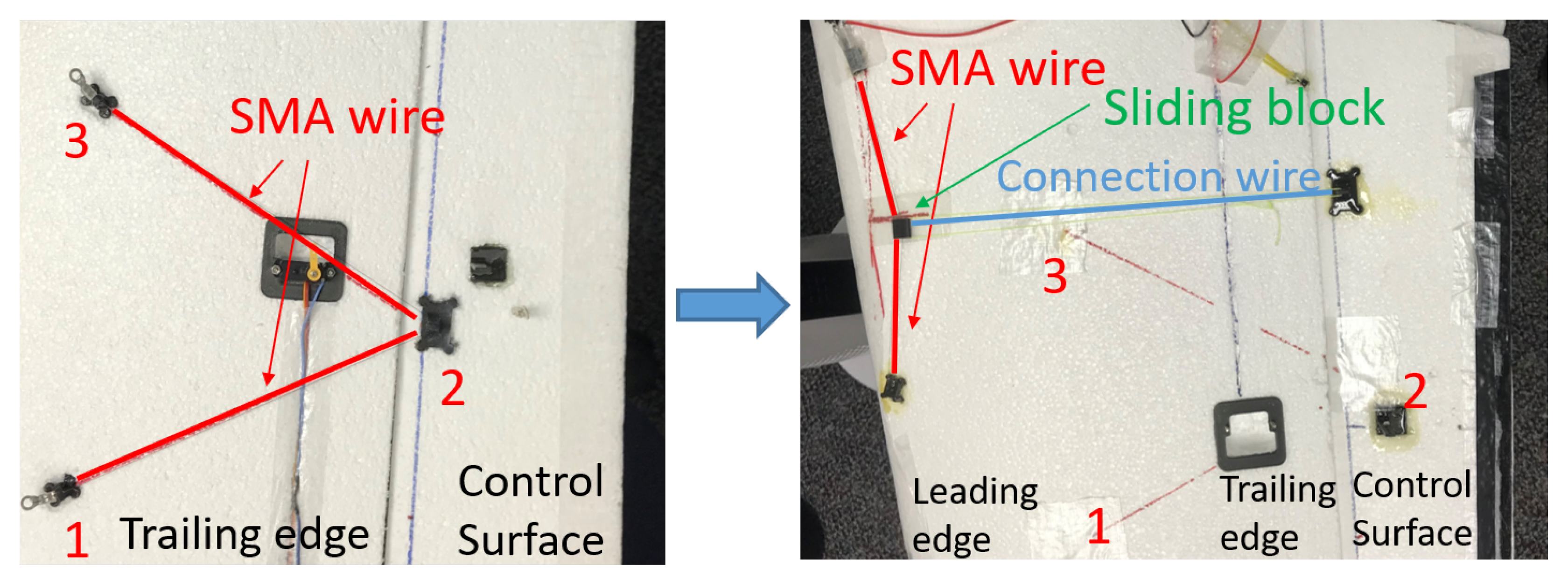

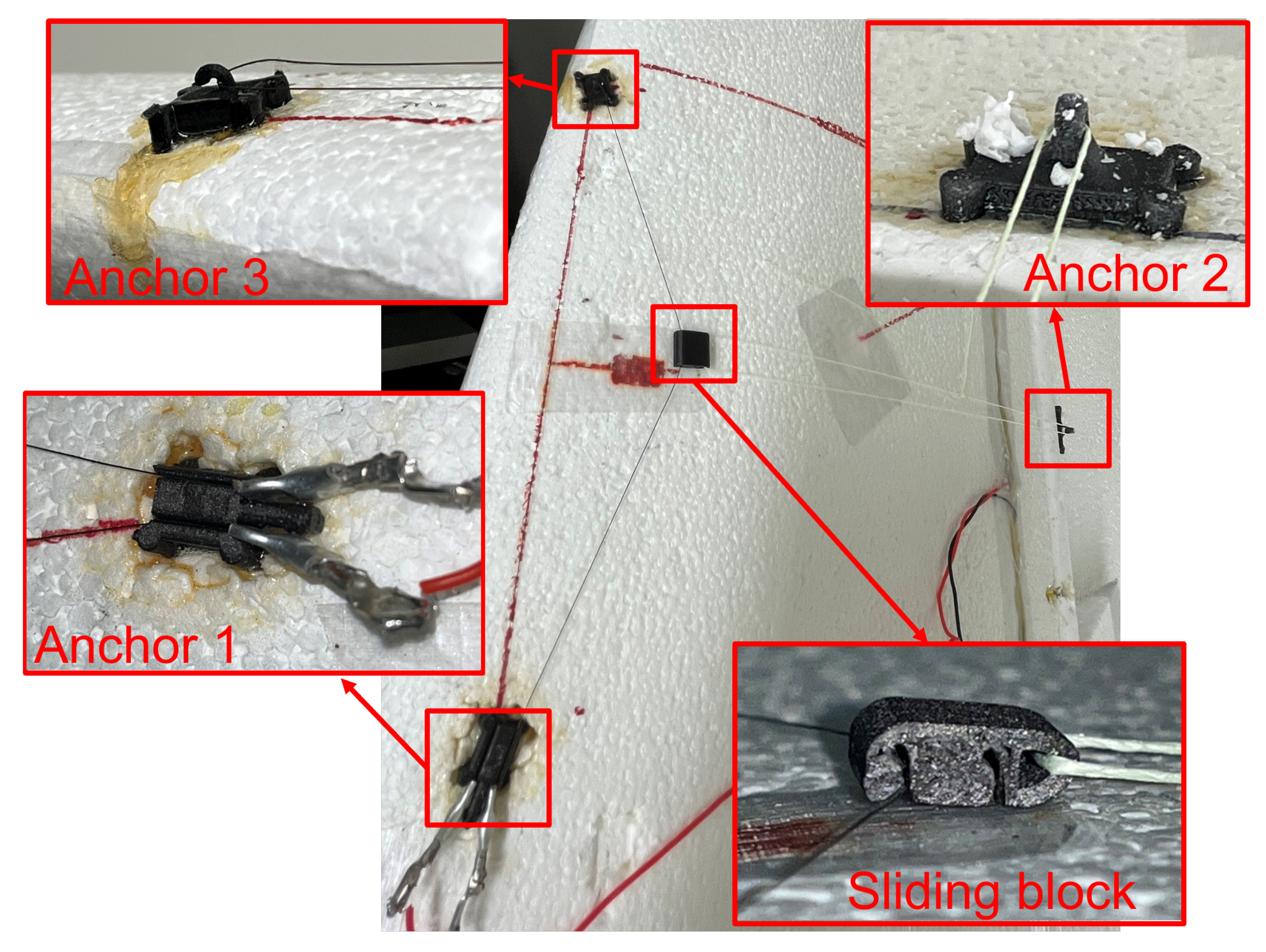

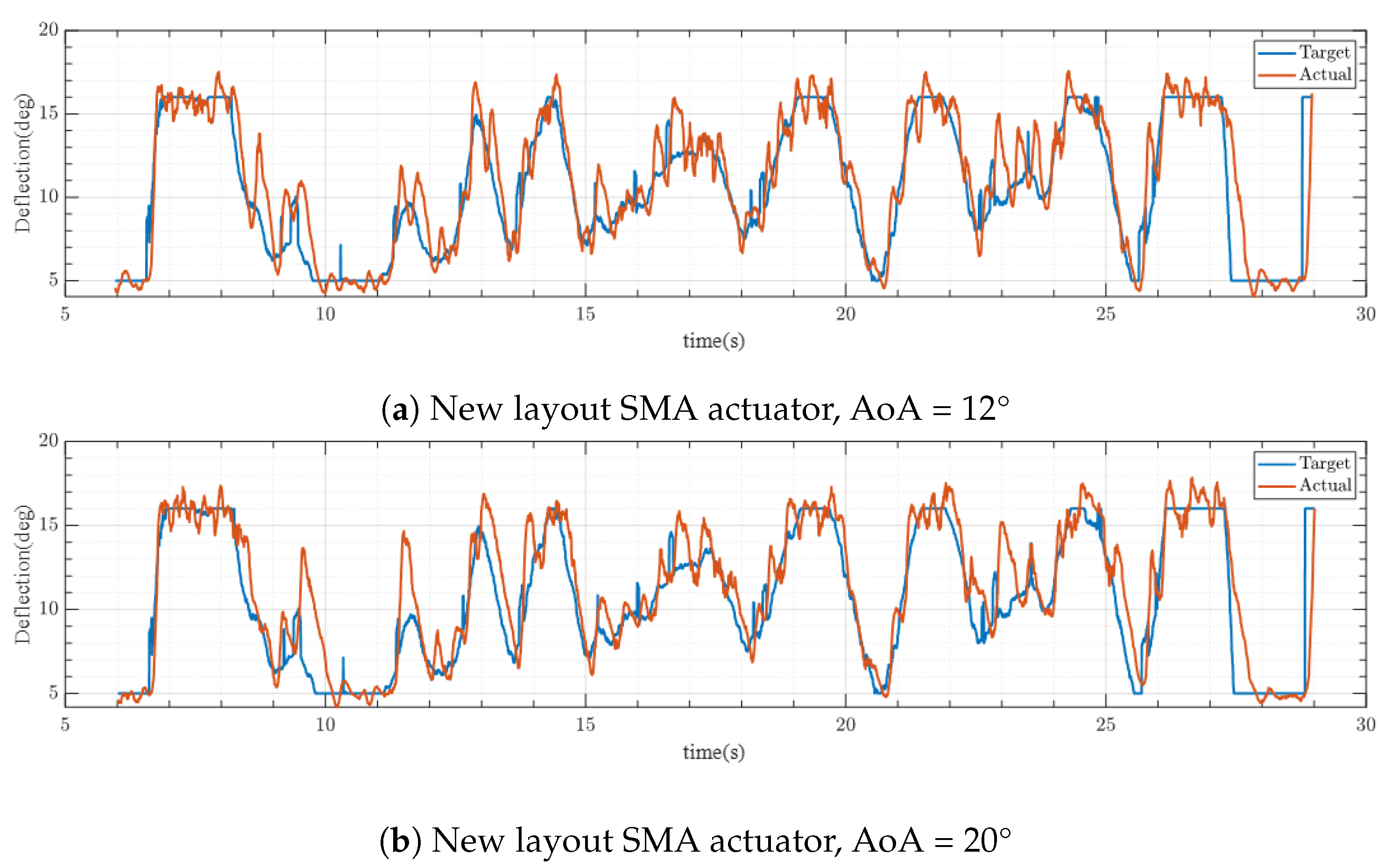

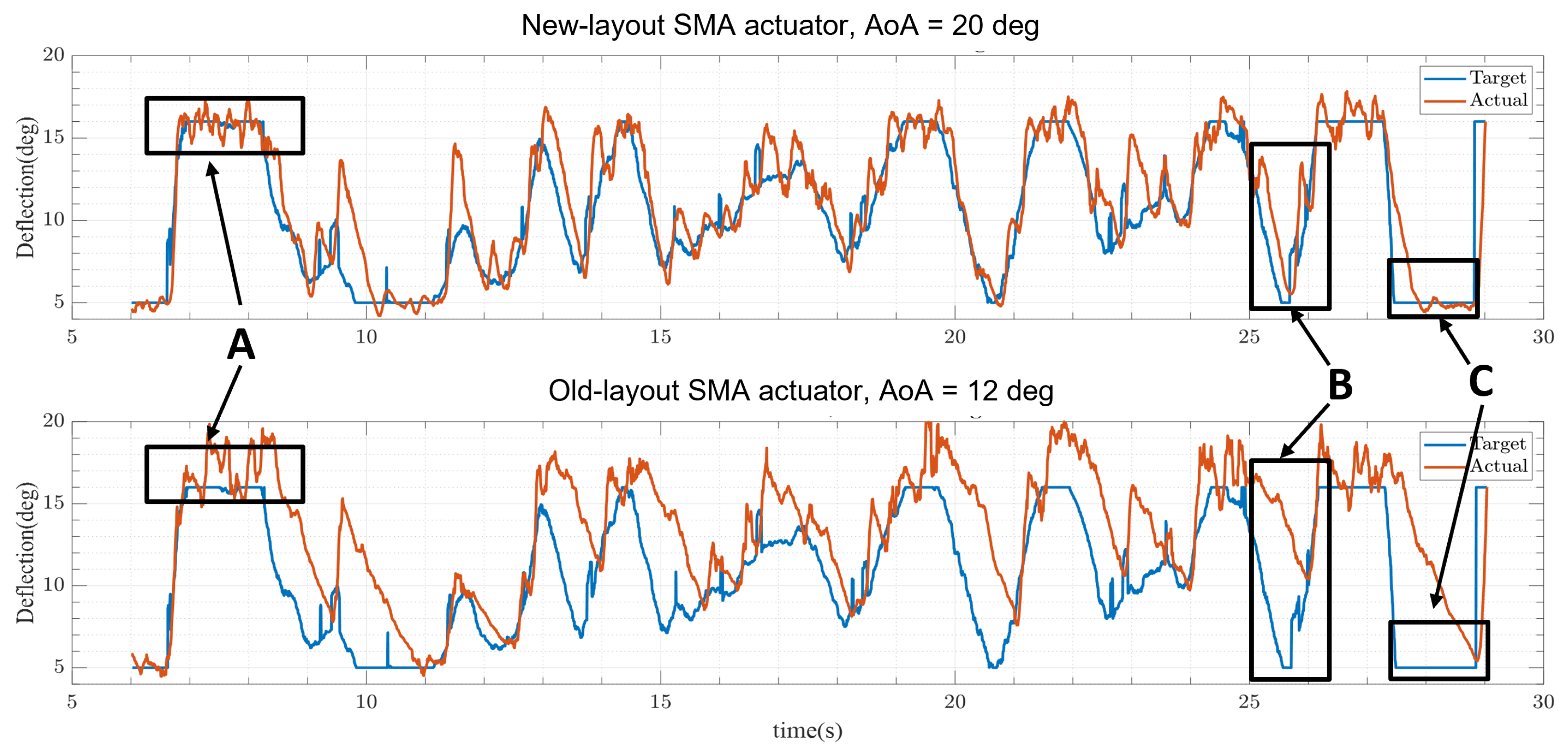

3.2. New Layout SMA Actuator

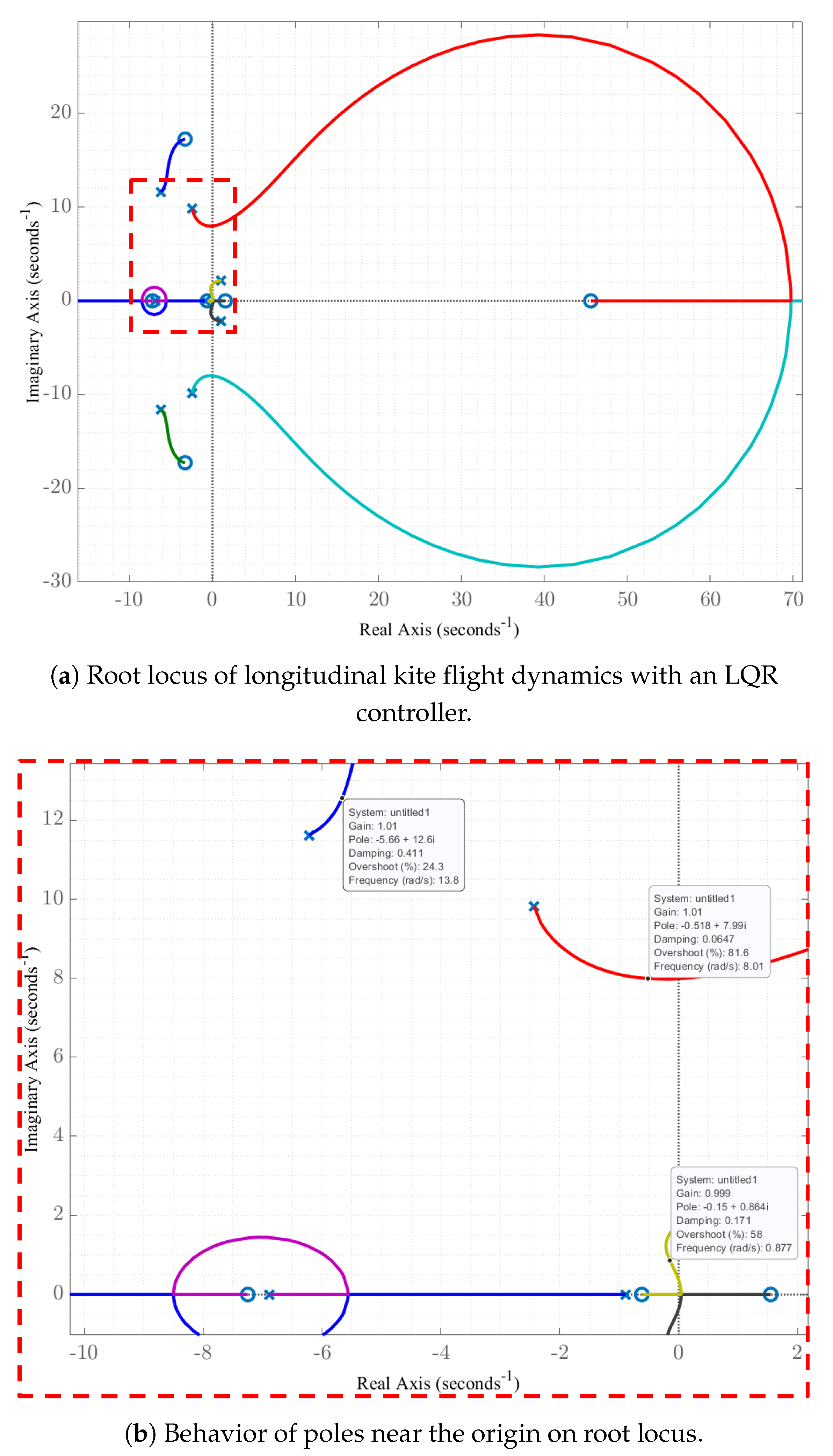

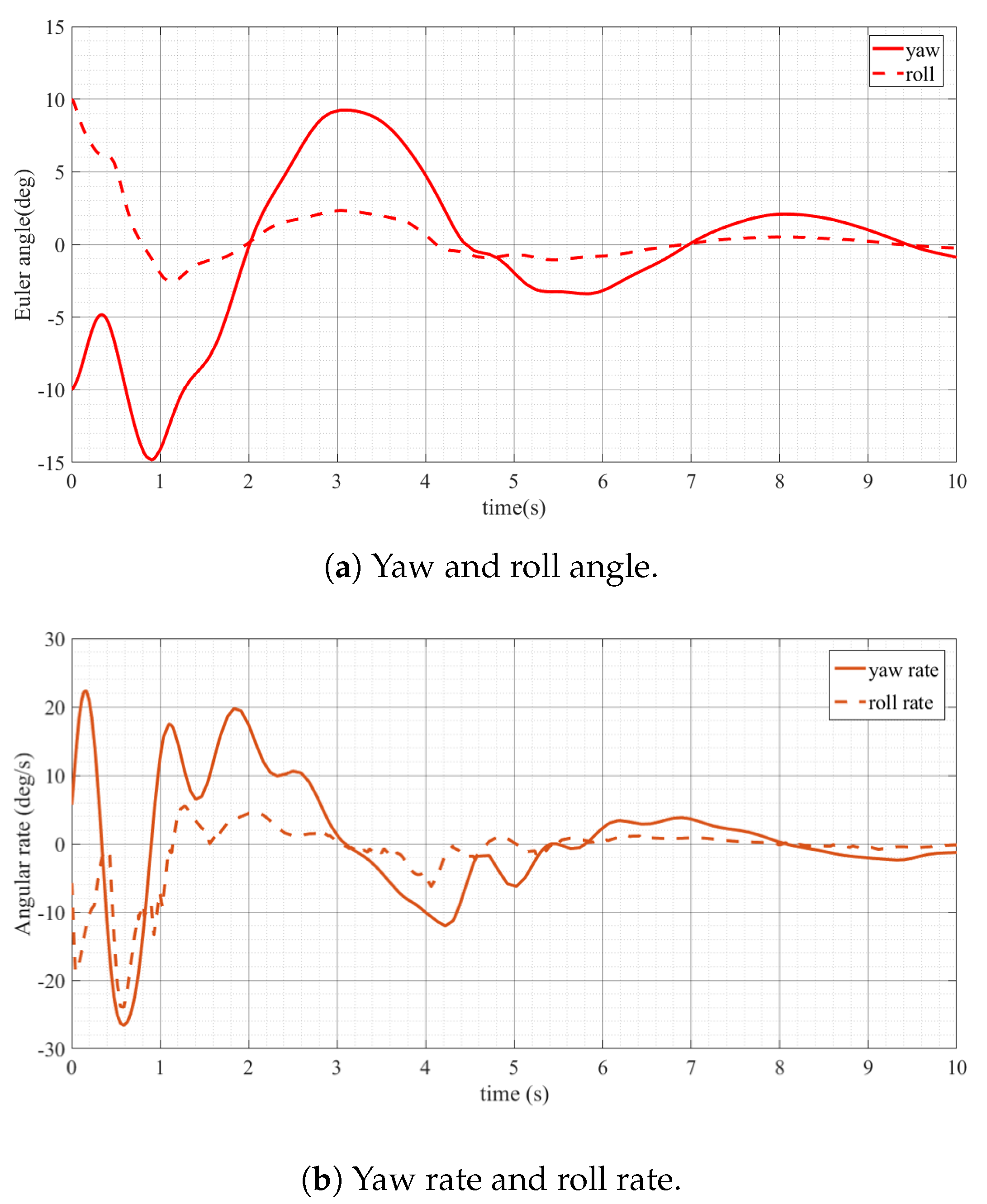

3.3. New Layout SMA Actuator Incorporated Flight Dynamics Model

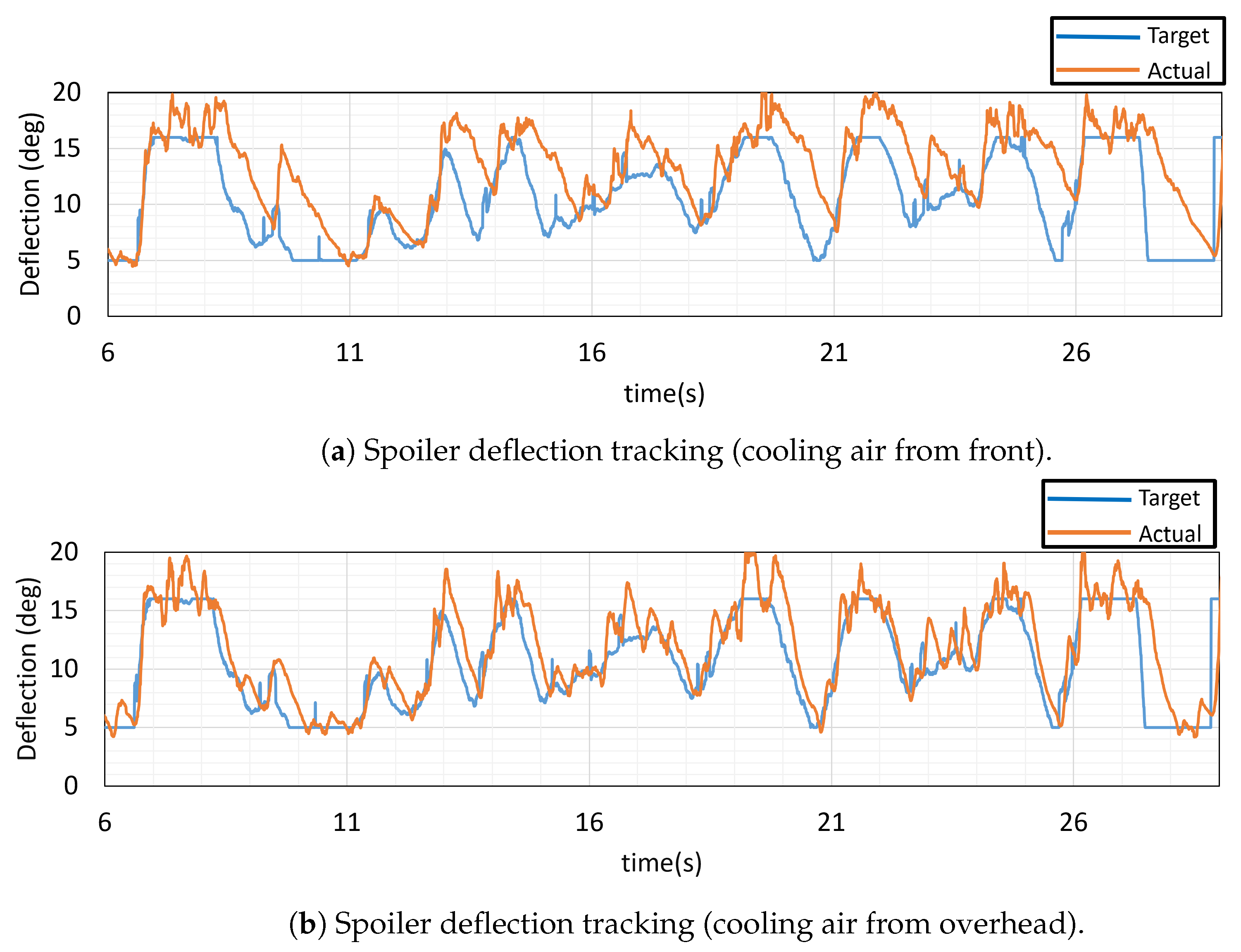

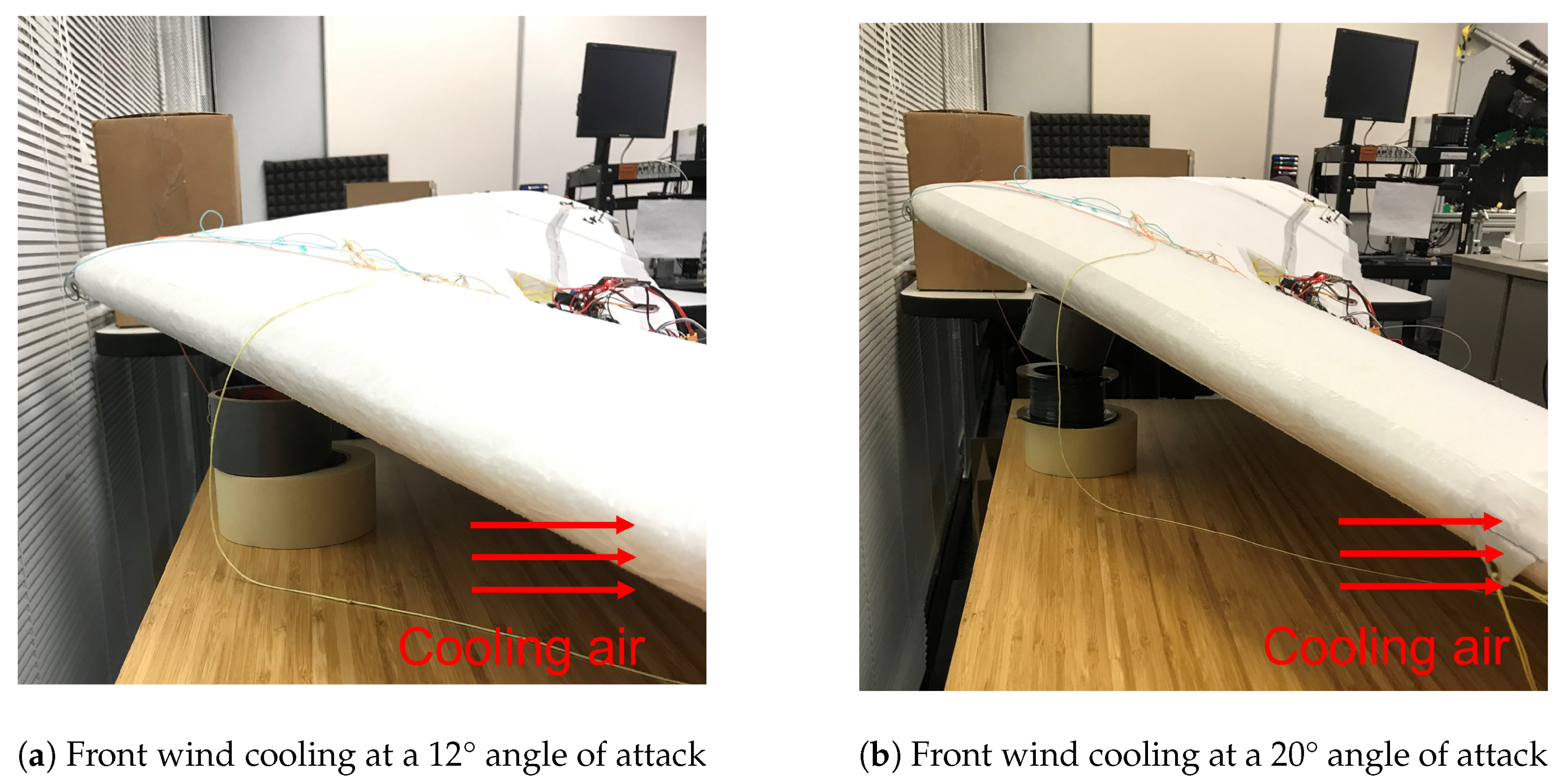

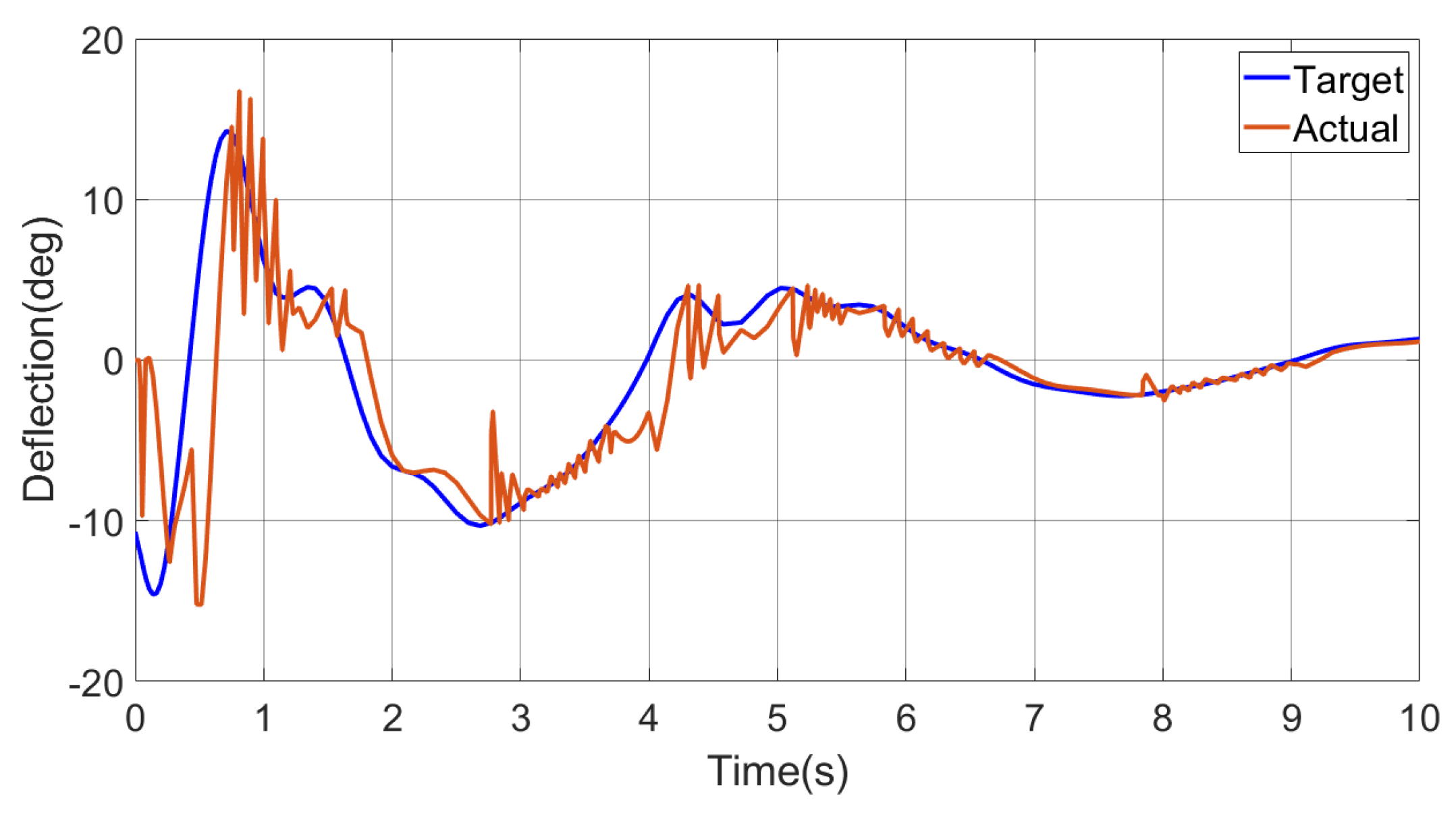

3.4. Flight Test with the New Layout SMA Actuator

4. Conclusions and Future Work

- 1.

- The improved SMA actuators, controlled by an in-house developed attitude controller, successfully stabilized the kite in the presence of turbulent wind.

- 2.

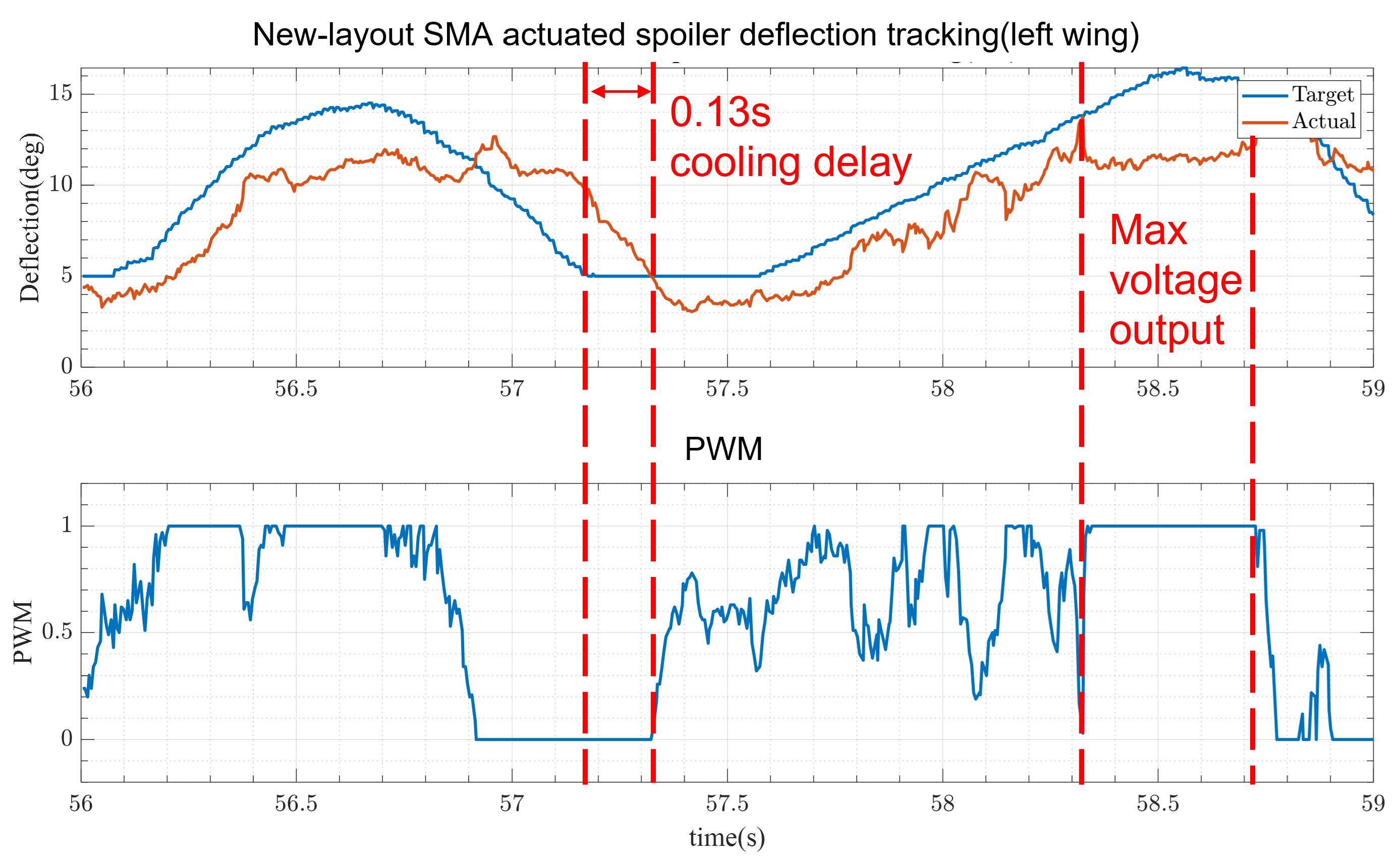

- The SMA actuator’s responsiveness and accuracy are comparable to a servo motor. However, because of the SMA actuator’s sensitivity to ambient cooling conditions, it is rather challenging to always achieve such quick and precise deflections.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Itakura, E. Save from Future Japan Social Crises! “Mothership” Project. In Proceedings of the Airborne Wind Energy Conference 2019, Glasgow, Scotland, 15–16 October 2019. [Google Scholar]

- Nam, T.; Vahid, O.; Gupta, R.; Kapania, R.K. High Altitude Airborne Wind Energy. In Proceedings of the AIAA Scitech 2021 Forum, Virtual Event, 11–15 January 2021; p. 1815. [Google Scholar]

- Gupta, R.; Zhu, Y.; Nam, T. Flight Dynamics, Control Law Design, and Flight Tests of Kite. In Proceedings of the AIAA AVIATION 2021 FORUM, Virtual Event, 2–6 August 2021; p. 2462. [Google Scholar]

- Zhu, Y.; Gupta, R.; Aris, A.; Nam, T. Development and Testing of the Flight Control System for a Tethered Wing. In Proceedings of the AIAA Scitech 2022 Forum, San Diego, CA, USA, 3–7 January 2022; p. 2049. [Google Scholar]

- Gupta, R.; Zhu, Y.; Nam, T.; Tsukada, T.; Fukagawa, T.; Itakura, E. Cross Wind Flight Dynamics Modeling of Tethered Kite. In Proceedings of the AIAA Scitech 2022 Forum, San Diego, CA, USA, 3–7 January 2022; p. 0136. [Google Scholar]

- Woods, B.K.; Fincham, J.H.; Friswell, M.I. Aerodynamic modelling of the fish bone active camber morphing concept. In Proceedings of the RAeS Applied Aerodynamics Conference, Bristol, UK, 22–24 July 2014; Volume 2224. [Google Scholar]

- Rivero, A.E.; Weaver, P.M.; Cooper, J.E.; Woods, B.K. Parametric structural modelling of fish bone active camber morphing aerofoils. J. Intell. Mater. Syst. Struct. 2018, 29, 2008–2026. [Google Scholar] [CrossRef]

- Meguid, S.; Su, Y.; Wang, Y. Complete morphing wing design using flexible-rib system. Int. J. Mech. Mater. Des. 2017, 13, 159–171. [Google Scholar] [CrossRef]

- Zekry, D.A.; Nam, T.; Gupta, R.; Zhu, Y.; Wissa, A.A. Covert-inspired flaps: An experimental study to understand the interactions between upperwing and underwing covert feathers. Bioinspir. Biomimetics 2023, 18, 046021. [Google Scholar] [CrossRef]

- Tang, Y.; Qin, L.; Li, X.; Chew, C.M.; Zhu, J. A frog-inspired swimming robot based on dielectric elastomer actuators. In Proceedings of the 2017 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Vancouver, BC, Canada, 24–28 September 2017; IEEE: Piscataway Township, NJ, USA, 2017; pp. 2403–2408. [Google Scholar]

- Lin, P.W.; Liu, C.H. Bio-inspired soft proboscis actuator driven by dielectric elastomer fluid transducers. Polymers 2019, 11, 142. [Google Scholar] [CrossRef] [PubMed]

- Tang, Y.; Chi, Y.; Sun, J.; Huang, T.H.; Maghsoudi, O.H.; Spence, A.; Zhao, J.; Su, H.; Yin, J. Leveraging elastic instabilities for amplified performance: Spine-inspired high-speed and high-force soft robots. Sci. Adv. 2020, 6, eaaz6912. [Google Scholar] [CrossRef] [PubMed]

- Ricotti, L.; Trimmer, B.; Feinberg, A.W.; Raman, R.; Parker, K.K.; Bashir, R.; Sitti, M.; Martel, S.; Dario, P.; Menciassi, A. Biohybrid actuators for robotics: A review of devices actuated by living cells. Sci. Robot. 2017, 2, eaaq0495. [Google Scholar] [CrossRef] [PubMed]

- Liang, W.; Liu, H.; Wang, K.; Qian, Z.; Ren, L.; Ren, L. Comparative study of robotic artificial actuators and biological muscle. Adv. Mech. Eng. 2020, 12, 1687814020933409. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, L.; Liu, Y.; Leng, J. Review of dielectric elastomer actuators and their applications in soft robots. Adv. Intell. Syst. 2021, 3, 2000282. [Google Scholar] [CrossRef]

- Rich, S.I.; Wood, R.J.; Majidi, C. Untethered soft robotics. Nat. Electron. 2018, 1, 102–112. [Google Scholar] [CrossRef]

- Pololu. Power HD High-Speed Digital Micro Servo DSM44. 2023. Available online: https://www.pololu.com/product/2142 (accessed on 27 February 2023).

- Fichera, S.; Isnardi, I.; Mottershead, J.E. High-bandwidth morphing actuator for aeroelastic model control. Aerospace 2019, 6, 13. [Google Scholar] [CrossRef]

- Hunter, I.W.; Hollerbach, J.M.; Ballantyne, J. A comparative analysis of actuator technologies for robotics. Robot. Rev. 1991, 2, 299–342. [Google Scholar]

- Kota, S.; Hetrick, J.A.; Osborn, R.; Paul, D.; Pendleton, E.; Flick, P.; Tilmann, C. Design and application of compliant mechanisms for morphing aircraft structures. In Smart Structures and Materials 2003: Industrial and Commercial Applications of Smart Structures Technologies; SPIE: Bellingham, DC, USA, 2003; Volume 5054, pp. 24–33. [Google Scholar]

- Shintake, J.; Rosset, S.; Schubert, B.; Floreano, D.; Shea, H. UAVs Flex Their Artificial Muscles. 2021. Available online: https://spectrum.ieee.org/uavs-flex-their-artificial-muscles (accessed on 27 February 2023).

- Kim, J.; Kim, J.W.; Kim, H.C.; Zhai, L.; Ko, H.U.; Muthoka, R.M. Review of soft actuator materials. Int. J. Precis. Eng. Manuf. 2019, 20, 2221–2241. [Google Scholar] [CrossRef]

- Plante, J.S.; Dubowsky, S. Large-scale failure modes of dielectric elastomer actuators. Int. J. Solids Struct. 2006, 43, 7727–7751. [Google Scholar] [CrossRef]

- Citro, M.; Coco, S. Fatigue behavior of Shape Memory Alloy wires actuated at high speed. In Proceedings of the ACTUATOR 2022, International Conference and Exhibition on New Actuator Systems and Applications, Mannheim, Germany, 28–30 June 2022; VDE: Frankfurt am Main, Germany, 2022; pp. 1–4. [Google Scholar]

- Motzki, P.; Gorges, T.; Kappel, M.; Schmidt, M.; Rizzello, G.; Seelecke, S. High-speed and high-efficiency shape memory alloy actuation. Smart Mater. Struct. 2018, 27, 075047. [Google Scholar] [CrossRef]

- Mabe, J.H.; Calkins, F.T.; Ruggeri, R.T. Full-scale flight tests of aircraft morphing structures using SMA actuators. In Proceedings of the Active and Passive Smart Structures and Integrated Systems 2007, San Diego, CA, USA, 19–22 March 2007; International Society for Optics and Photonics: Bellingham, DC, USA, 2007; Volume 6525, p. 65251C. [Google Scholar]

- Calkins, F.T.; Mabe, J.H. Shape Memory Alloy Based Morphing Aerostructures. J. Mech. Des. 2010, 132, 111012. [Google Scholar] [CrossRef]

- Yuchen, C.; Xing, S.; Jiefeng, L.; Jinjin, C. Nonlinear hysteresis identification and compensation based on the discrete Preisach model of an aircraft morphing wing device manipulated by an SMA actuator. Chin. J. Aeronaut. 2019, 32, 1040–1050. [Google Scholar]

- Simpson, A.; Jacob, J.; Smith, S. Flight control of a UAV with inflatable wings with wing warping. In Proceedings of the 24th AIAA Applied Aerodynamics Conference, San Francisco, CA, USA, 5–8 June 2006; p. 2831. [Google Scholar]

- Brennison, M.; Barrett, R.; Kerth, L. Development and flight test of a shape memory alloy actuator flight control system. In Active and Passive Smart Structures and Integrated Systems 2010; SPIE: Bellingham, DC, USA, 2010; Volume 7643, pp. 887–900. [Google Scholar]

- Song, H.; Kubica, E.; Gorbet, R. Resistance modelling of SMA wire actuators. In Proceedings of the International Workshop on Smart Materials, Structures & NDT in Aerospace Conference, Montreal, QC, Canada, 2–4 November 2011. [Google Scholar]

- Courtney, T.H. Mechanical Behavior of Materials; Waveland Pr Inc.: Boston, MA, USA, 2005. [Google Scholar]

- Zhang, D.; Zhao, X.; Han, J.; Li, X.; Zhang, B. Active modeling and control for shape memory alloy actuators. IEEE Access 2019, 7, 162549–162558. [Google Scholar] [CrossRef]

- Sayyaadi, H.; Zakerzadeh, M.R. Position control of shape memory alloy actuator based on the generalized Prandtl–Ishlinskii inverse model. Mechatronics 2012, 22, 945–957. [Google Scholar] [CrossRef]

- Jayender, J.; Patel, R.V.; Nikumb, S.; Ostojic, M. Modeling and control of shape memory alloy actuators. IEEE Trans. Control. Syst. Technol. 2008, 16, 279–287. [Google Scholar] [CrossRef]

- Hannen, J.C.; Crews, J.H.; Buckner, G.D. Indirect intelligent sliding mode control of a shape memory alloy actuated flexible beam using hysteretic recurrent neural networks. Smart Mater. Struct. 2012, 21, 085015. [Google Scholar] [CrossRef]

- Kha, N.B.; Ahn, K.K. Position control of shape memory alloy actuators by using self tuning fuzzy PID controller. In Proceedings of the 2006 1ST IEEE Conference on Industrial Electronics and Applications, Singapore, 24–26 May 2006; IEEE: Piscataway Township, NJ, USA, 2006; pp. 1–5. [Google Scholar]

- Nakshatharan, S.S.; Dhanalakshmi, K.; Ruth, D.J.S. Fuzzy based sliding surface for shape memory alloy wire actuated classical super-articulated control system. Appl. Soft Comput. 2015, 32, 580–589. [Google Scholar] [CrossRef]

- Nikdel, N.; Nikdel, P.; Badamchizadeh, M.A.; Hassanzadeh, I. Using neural network model predictive control for controlling shape memory alloy-based manipulator. IEEE Trans. Ind. Electron. 2013, 61, 1394–1401. [Google Scholar] [CrossRef]

- Etkin, B.; Reid, L.D. Dynamics of Flight: Stability and Control; John Wiley & Sons: Hoboken, NJ, USA, 1995. [Google Scholar]

- WITMOTION. WT61P. 2022. Available online: https://www.wit-motion.com/6-axis/witmotion-wt61-6-axis-ahrs-sensor-digital.html (accessed on 27 February 2023).

- Nelson, R.; Yoder, M.; Lechner, D.; Casner, D.; Agar, D.; Govostes, R. Librobotcontrol, Software Package, Version 1.0. 2015. Available online: https://github.com/beagleboard/librobotcontrol (accessed on 24 February 2022).

- Grigorie, T.L.; Popov, A.V.; Botez, R.M.; Mamou, M.; Mébarki, Y. A Morphing Wing used Shape Memory Alloy Actuators New Control Technique with Bi-positional and PI Laws Optimum Combination—Part 1: Design Phase. In Proceedings of the ICINCO, Funchal, Portugal, 15–18 June 2010. [Google Scholar]

- Liu, S.H.; Huang, T.S.; Yen, J.Y. Tracking control of shape-memory-alloy actuators based on self-sensing feedback and inverse hysteresis compensation. Sensors 2009, 10, 112–127. [Google Scholar] [CrossRef] [PubMed]

- Senthilkumar, P.; Dayananda, G.; Umapathy, M.; Shankar, V. Experimental evaluation of a shape memory alloy wire actuator with a modulated adaptive controller for position control. Smart Mater. Struct. 2011, 21, 015015. [Google Scholar] [CrossRef]

- Dunbar, B. NASA Tests New Alloy to Fold Wings in Fligh. 2020. Available online: https://www.nasa.gov/centers/armstrong/feature/nasa-tests-new-alloy-to-fold-wings-in-flight.html (accessed on 20 March 2023).

- Jeong, J.; Hyeon, K.; Han, J.; Park, C.H.; Ahn, S.Y.; Bok, S.K.; Kyung, K.U. Wrist assisting soft wearable robot with stretchable coolant vessel integrated SMA muscle. IEEE/ASME Trans. Mechatronics 2021, 27, 1046–1058. [Google Scholar] [CrossRef]

| Test Kite Geometric Parameters | |

|---|---|

| Wing Area (m2) | 1.6 |

| Span (m) | 3.4 |

| MAC (m) | 0.5 |

| Dihedral (deg) | 5.0 |

| Leading Edge Sweep (Deg) | 24.0 |

| Test Kite Control Surface Geometric Parameters | |

| Span (m) | 0.43 |

| Root Chord (m) | 0.11 |

| Tip Chord (m) | 0.09 |

| Area (m2) | 0.04 |

| Control Surface Deflection (deg) | Hinge Moment (Nm) |

|---|---|

| 5 | 0.0113 |

| 10 | 0.0220 |

| 15 | 0.0300 |

| 20 | 0.0389 |

| 25 | 0.0473 |

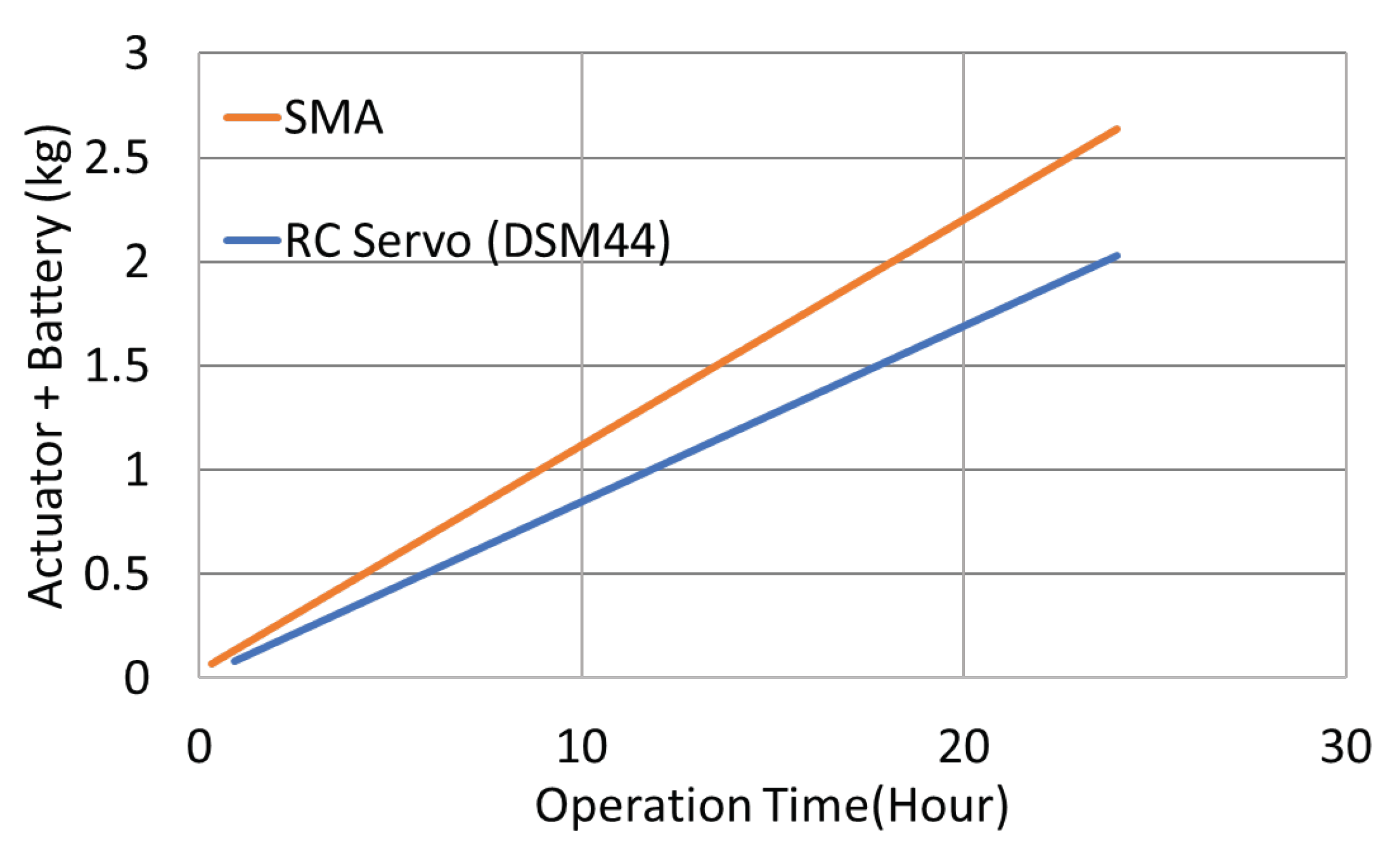

| Servo Configuration | SMA Configuration | ||

|---|---|---|---|

| Component | Mass (g) | Component | Mass (g) |

| Servo | 12 | SMA wire | 1 |

| 2S battery | 56 | 4S battery | 63 |

| Driver circuit | 9 | Driver circuit | 2 |

| Magnetic sensor | N/A | Magnetic Sensor | 6 |

| Total | 77 | Total | 72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Tsuruta, R.; Gupta, R.; Nam, T. Feasibility Investigation of Attitude Control with Shape Memory Alloy Actuator on a Tethered Wing. Energies 2023, 16, 5691. https://doi.org/10.3390/en16155691

Zhu Y, Tsuruta R, Gupta R, Nam T. Feasibility Investigation of Attitude Control with Shape Memory Alloy Actuator on a Tethered Wing. Energies. 2023; 16(15):5691. https://doi.org/10.3390/en16155691

Chicago/Turabian StyleZhu, Yufei, Ryohei Tsuruta, Rikin Gupta, and Taewoo Nam. 2023. "Feasibility Investigation of Attitude Control with Shape Memory Alloy Actuator on a Tethered Wing" Energies 16, no. 15: 5691. https://doi.org/10.3390/en16155691

APA StyleZhu, Y., Tsuruta, R., Gupta, R., & Nam, T. (2023). Feasibility Investigation of Attitude Control with Shape Memory Alloy Actuator on a Tethered Wing. Energies, 16(15), 5691. https://doi.org/10.3390/en16155691