Research on Stability Control of Shields at Working Face with Large Dip Angle

Abstract

1. Introduction

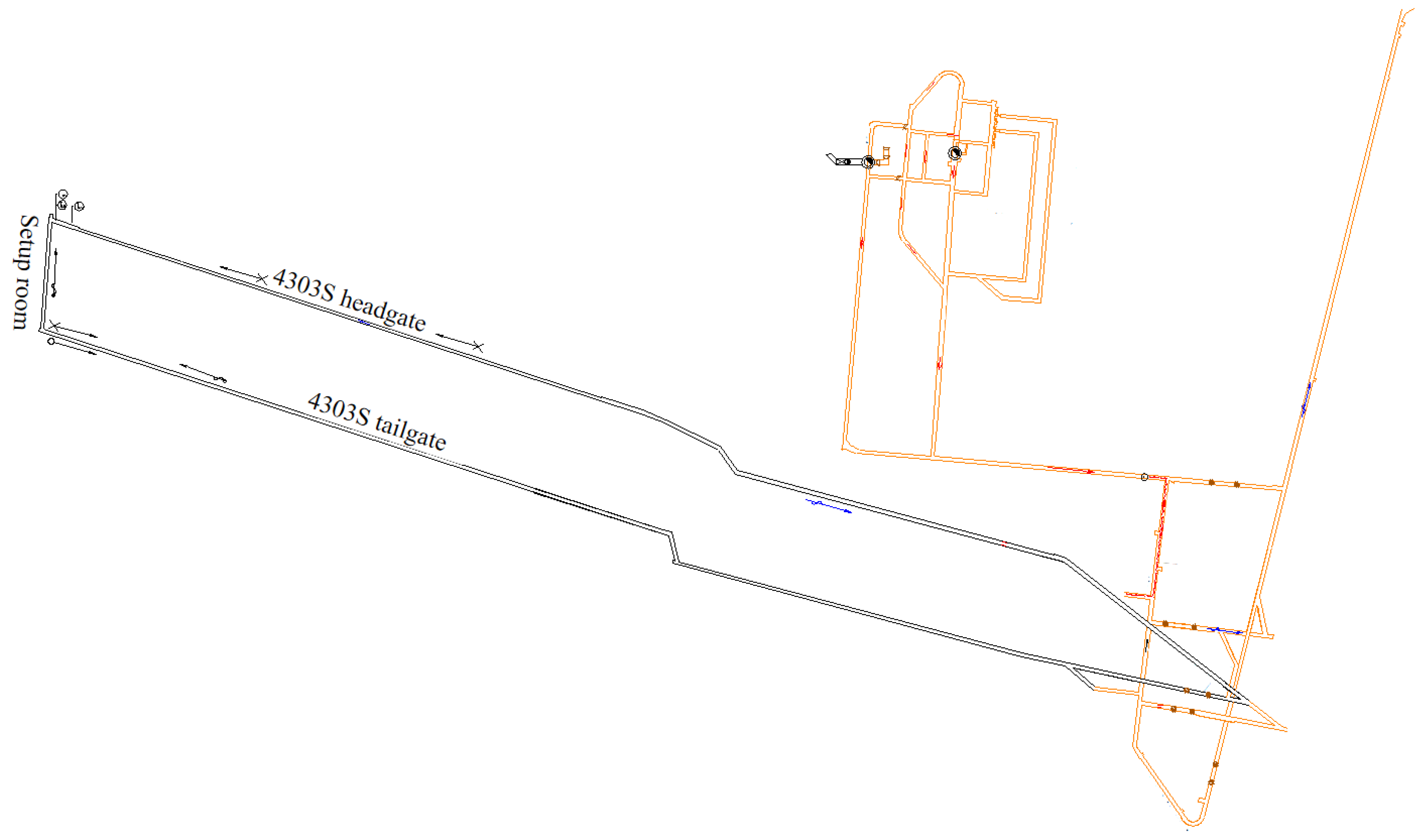

2. Engineering Background

2.1. The Panel

2.2. Occurrence of the Coal Seam

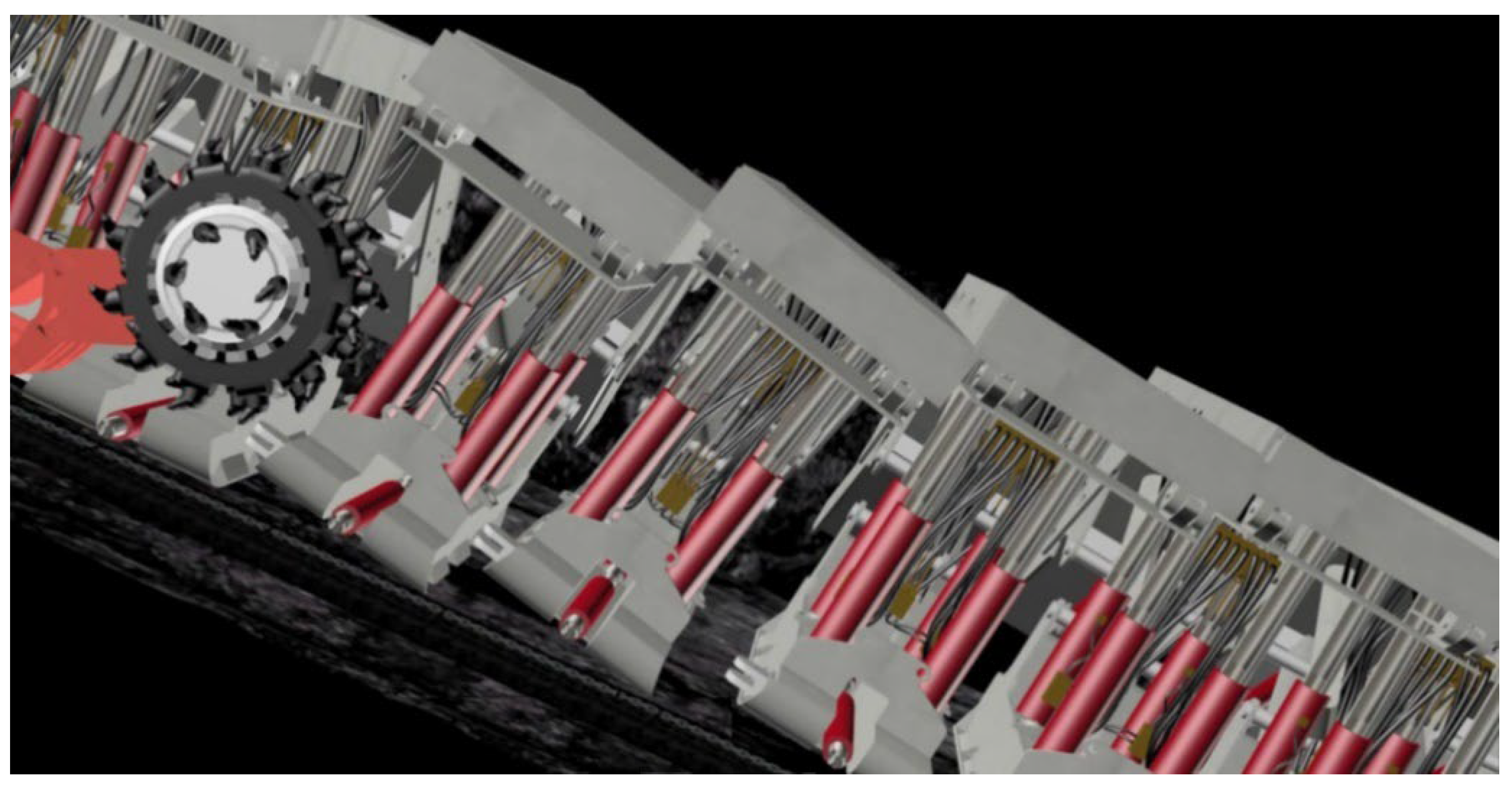

3. Mining Technology

4. Stability Analysis of Hydraulic Supports and Conveyor

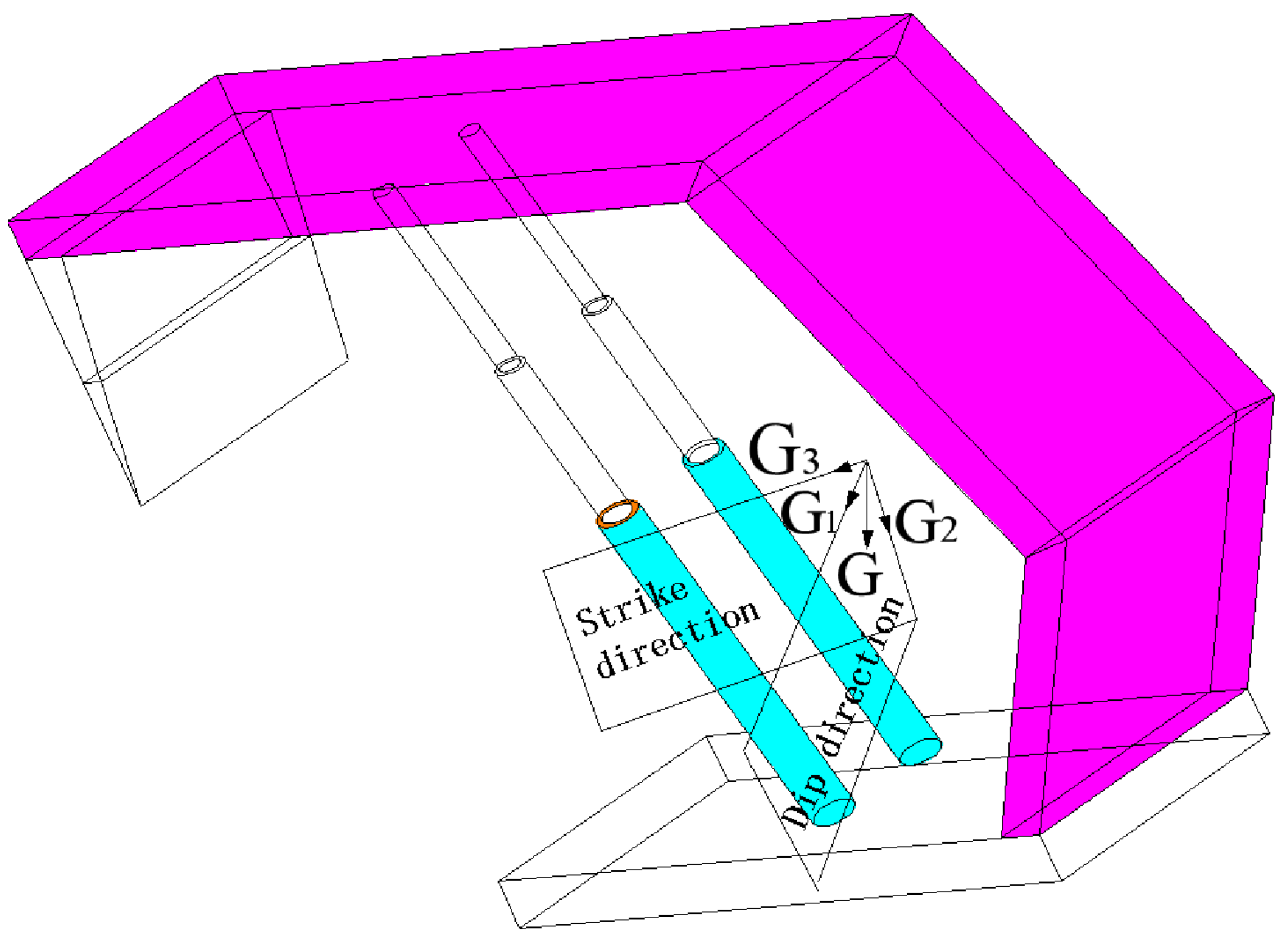

4.1. Mechanical Model of “Support and Surrounding Rock”

4.2. Mechanical Analysis of Support along the Dip

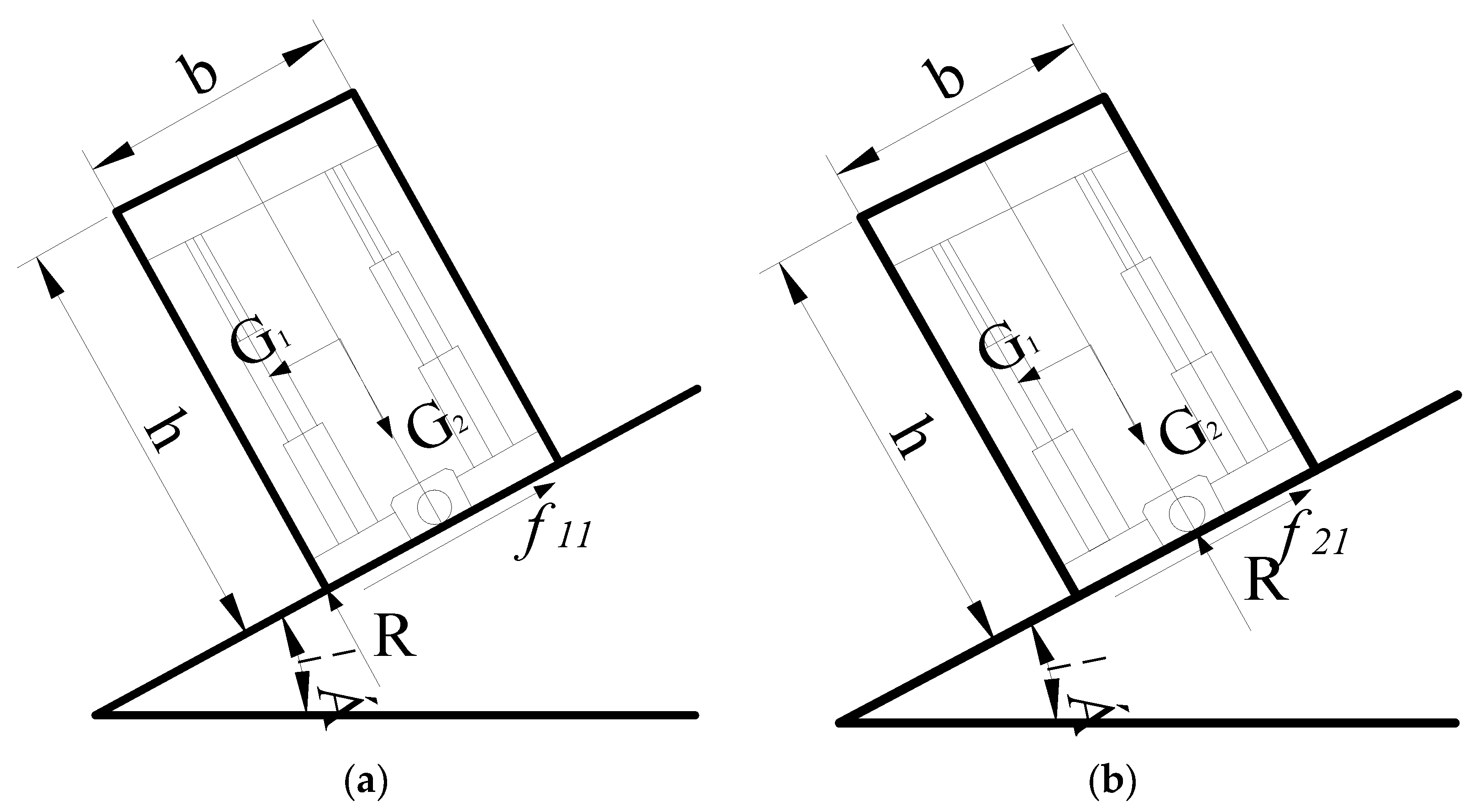

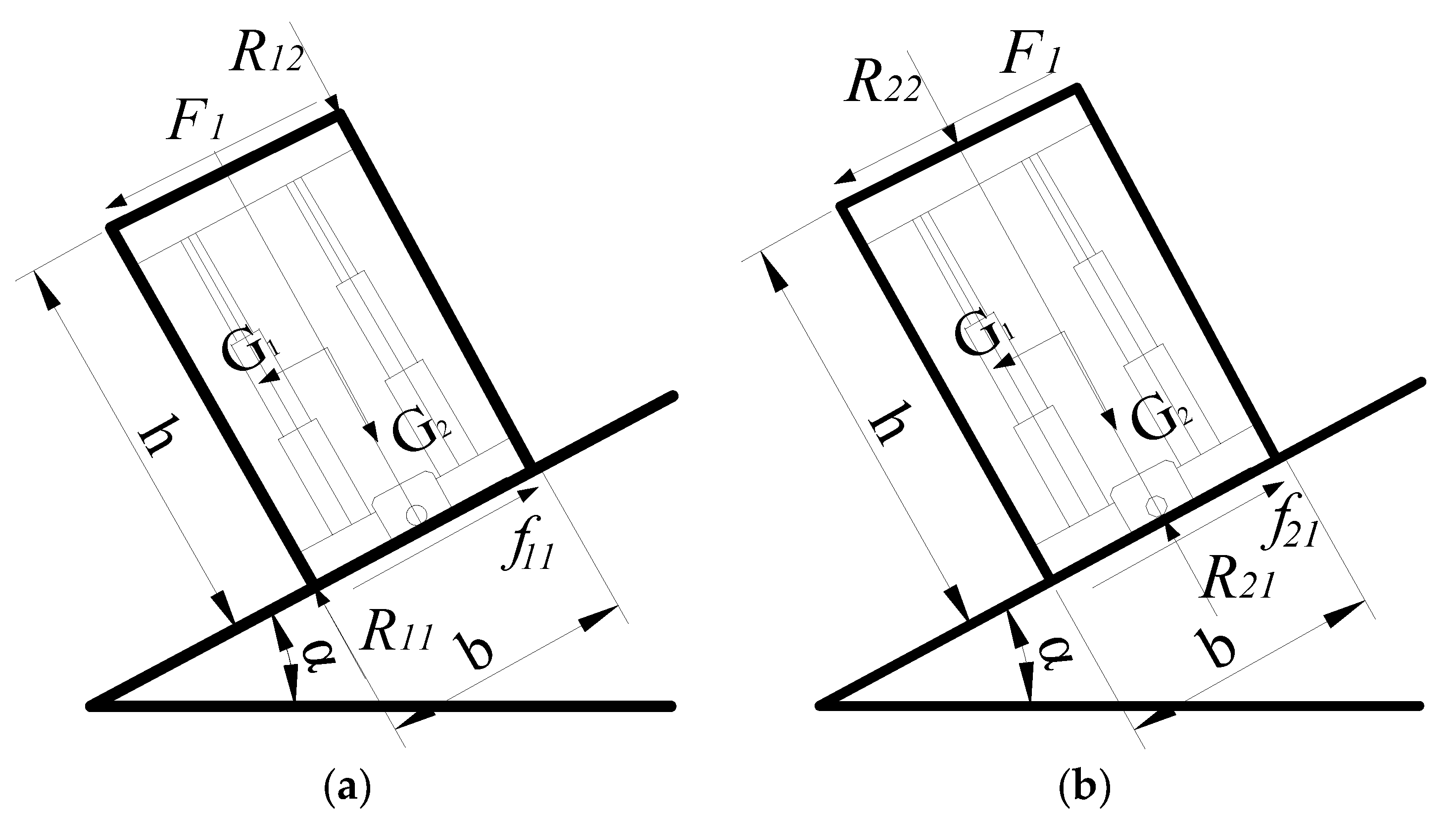

- (1)

- Free state mechanical analysis of the support

- (2)

- Analysis of support tipping model

- (3)

- Analysis of support slip model

- (4)

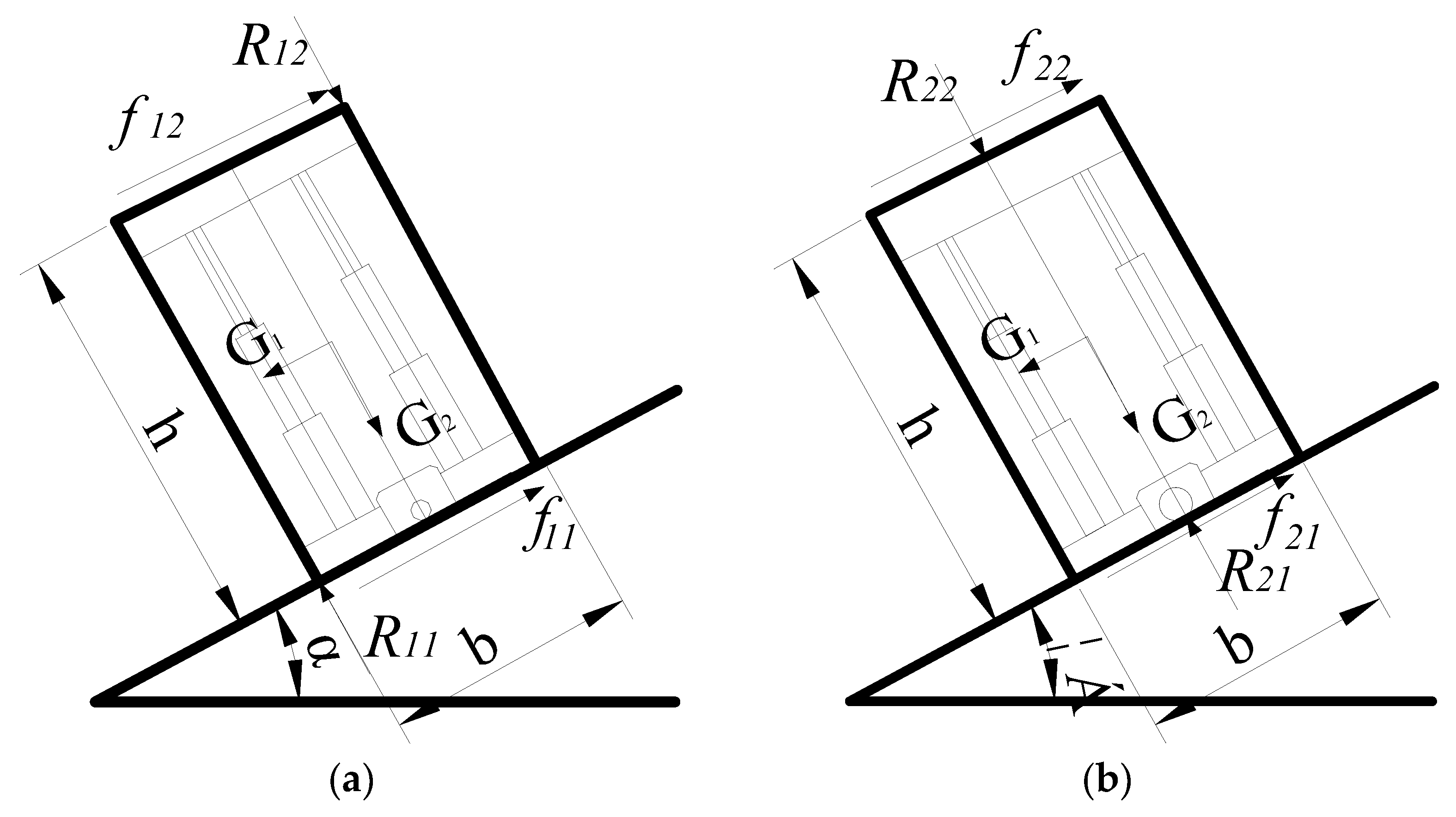

- Mechanical analysis of support working state

- where G—gravity on the support, kN;

- R12—Working resistance, kN.

4.3. Stability Analysis of Support in Special Period

- (1)

- According to Figure 6a, the force analysis of the support tipping model in working state can be obtained in this way:

- (2)

- The critical state of the support sliding model is shown in Figure 6b:

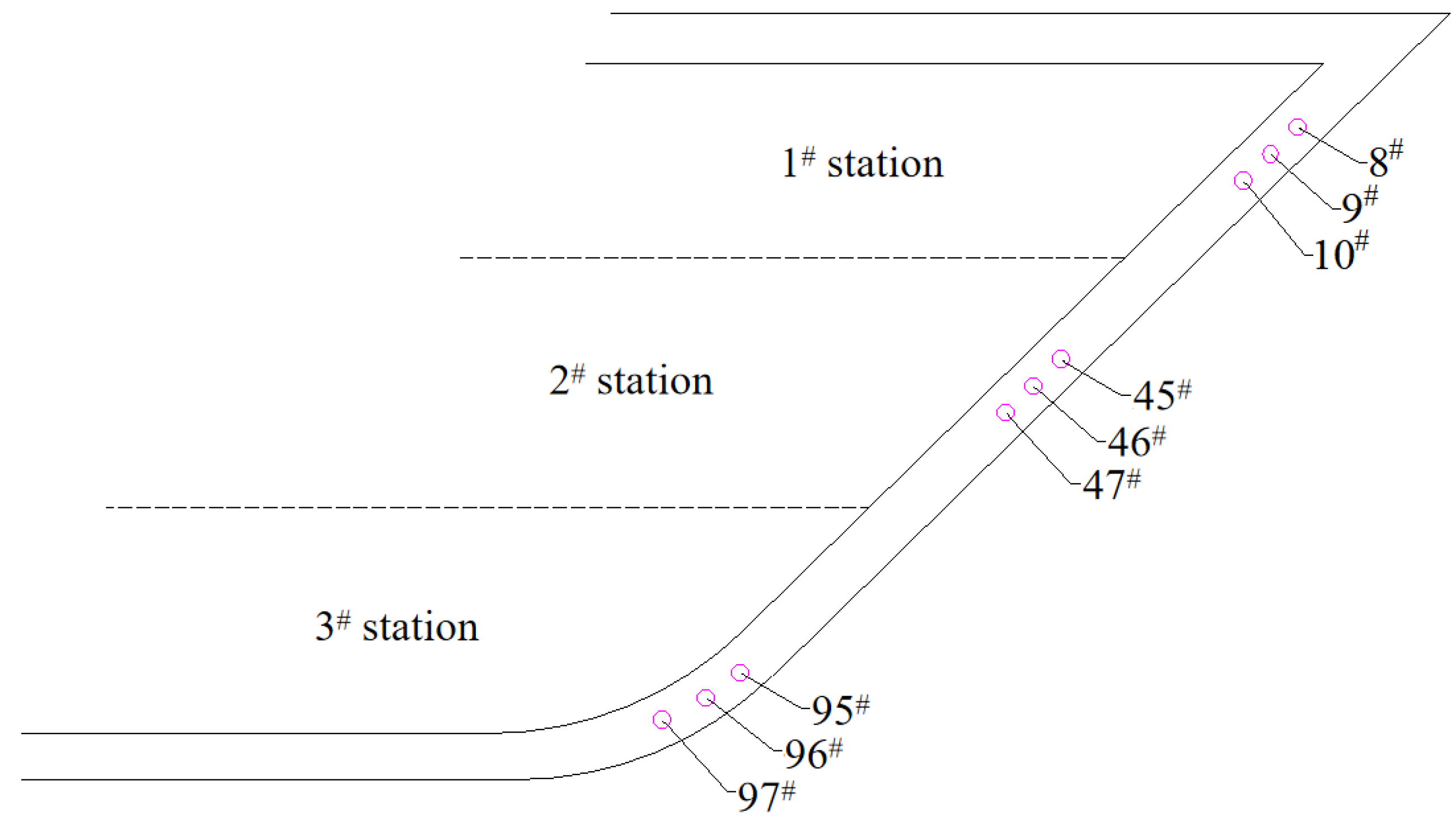

5. Field Monitoring

6. Stability Assurance Technology for Equipment with Large Dip Angle

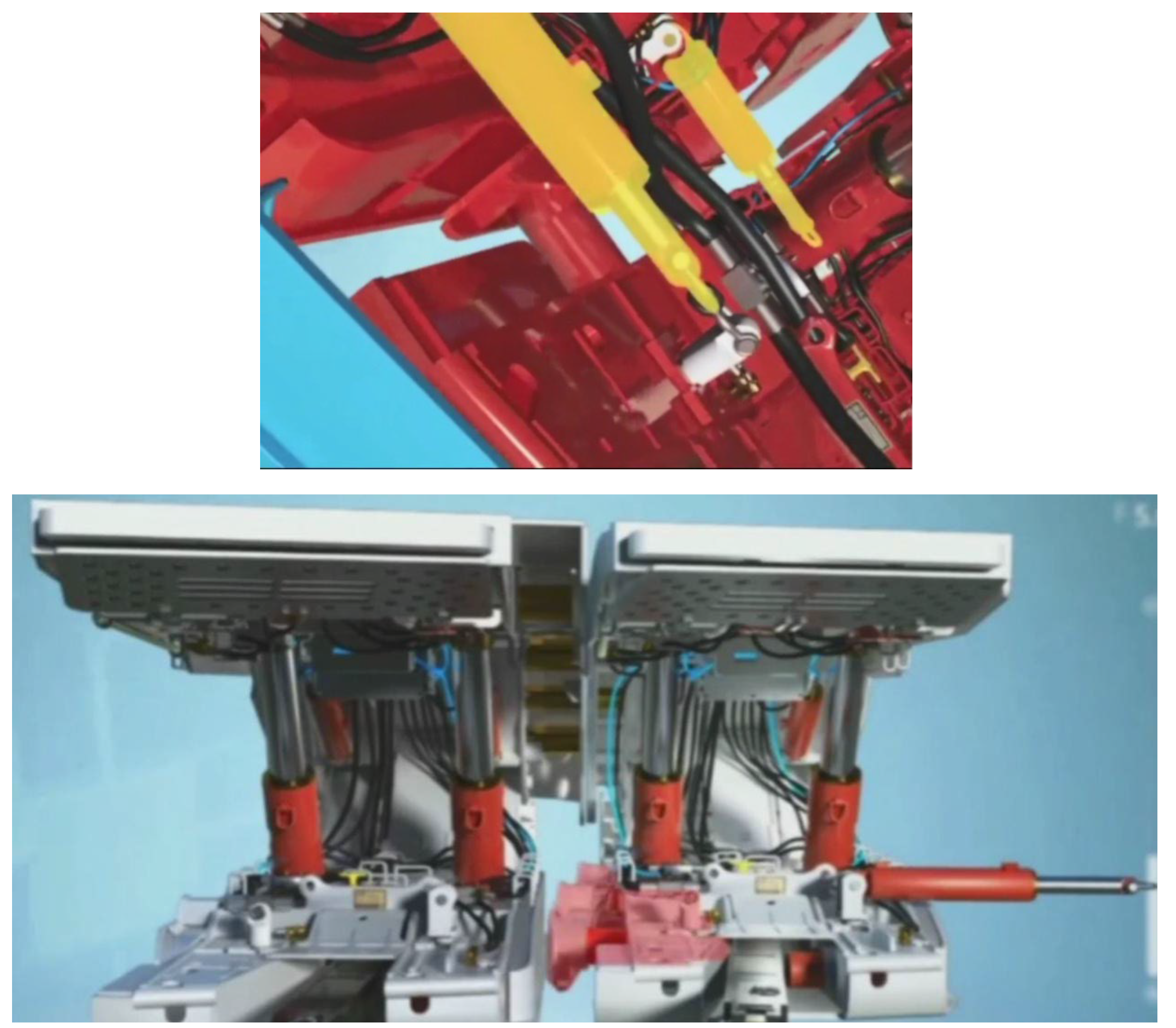

6.1. The Main Measures of Support Anti-Tipping

- (1)

- Ensure that there is no gap in the canopy of the support, so that it has no space to tip over; the side shield jack and the side push spring make the canopy more seamless, and always maintain enough correcting force to prevent tipping.

- (2)

- Add an adjusting jack between the adjacent supports, as shown in the Figure 9. When the support tips, the adjacent support supporting the roof is used as the fulcrum, and the position of the bracket is adjusted with the jack.

- (3)

- Add base adjusting jacks between the adjacent supports to restrict the tipping of a single support as shown in Figure 10. The effect of adding base adjusting jack is equivalent to connecting two supports together to become one. The width of the support is doubled, and its anti-tipping ability is greatly increased.

- (4)

- Add metal mesh between the canopy and the roof, because the friction coefficient between the metal mesh and the support is small, which can release the energy of the roof sliding (in a large angle working face roof-support-floor system, the roof has a sliding trend; in the support and the original contact mode of the roof, the support has to prevent the roof sliding force, so that the support bears part of the roof sliding energy and it brings a great threat to the stability of the support tipping) and enhances the stability of the support, while not destroying the integrity of the roof.

6.2. Support Anti-Slip Technology

- (1)

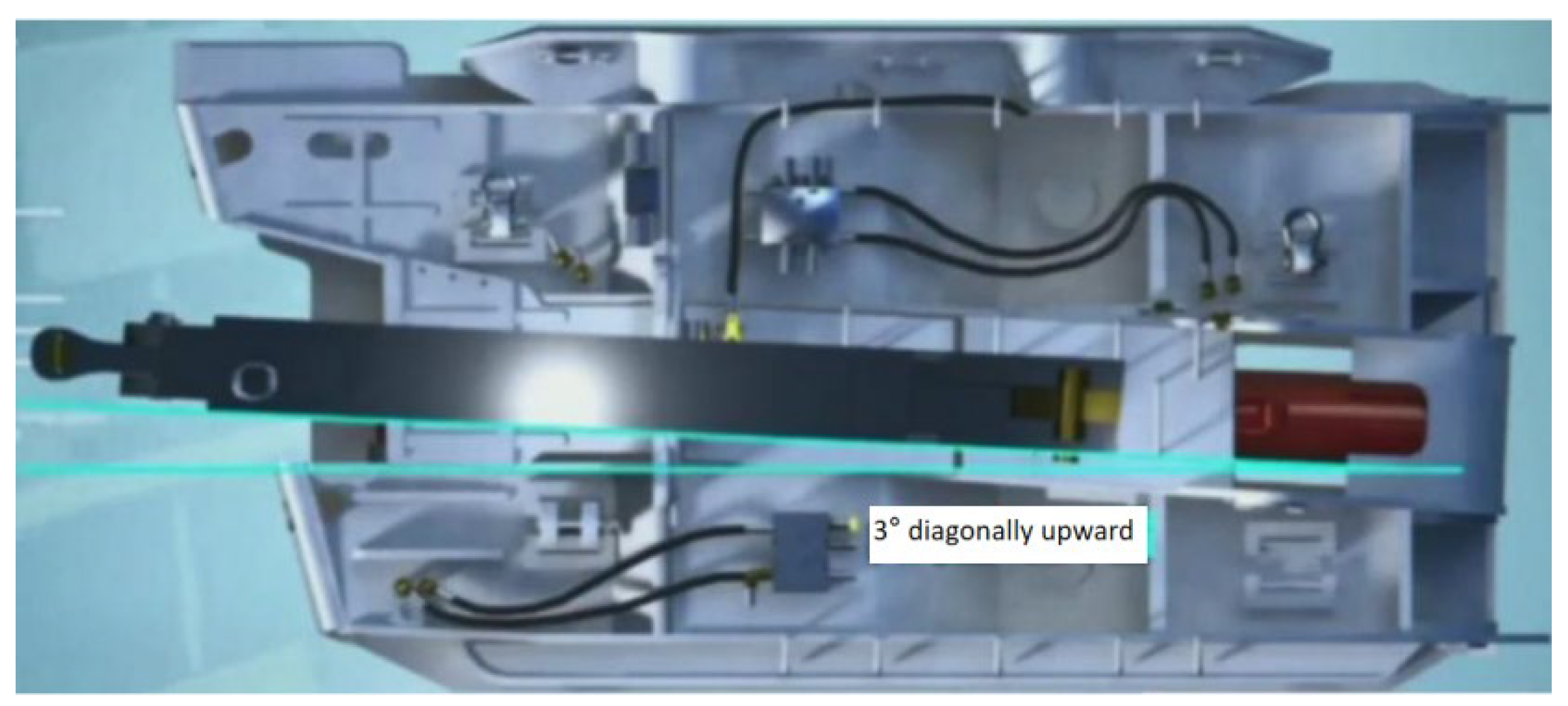

- The conveyor pushing rod is guided through the whole process, the gap between the push rod and the base is controlled in 10~20 mm, and the pushing device is arranged 3° diagonally upward to control the sliding rod angle (Figure 11).

- (2)

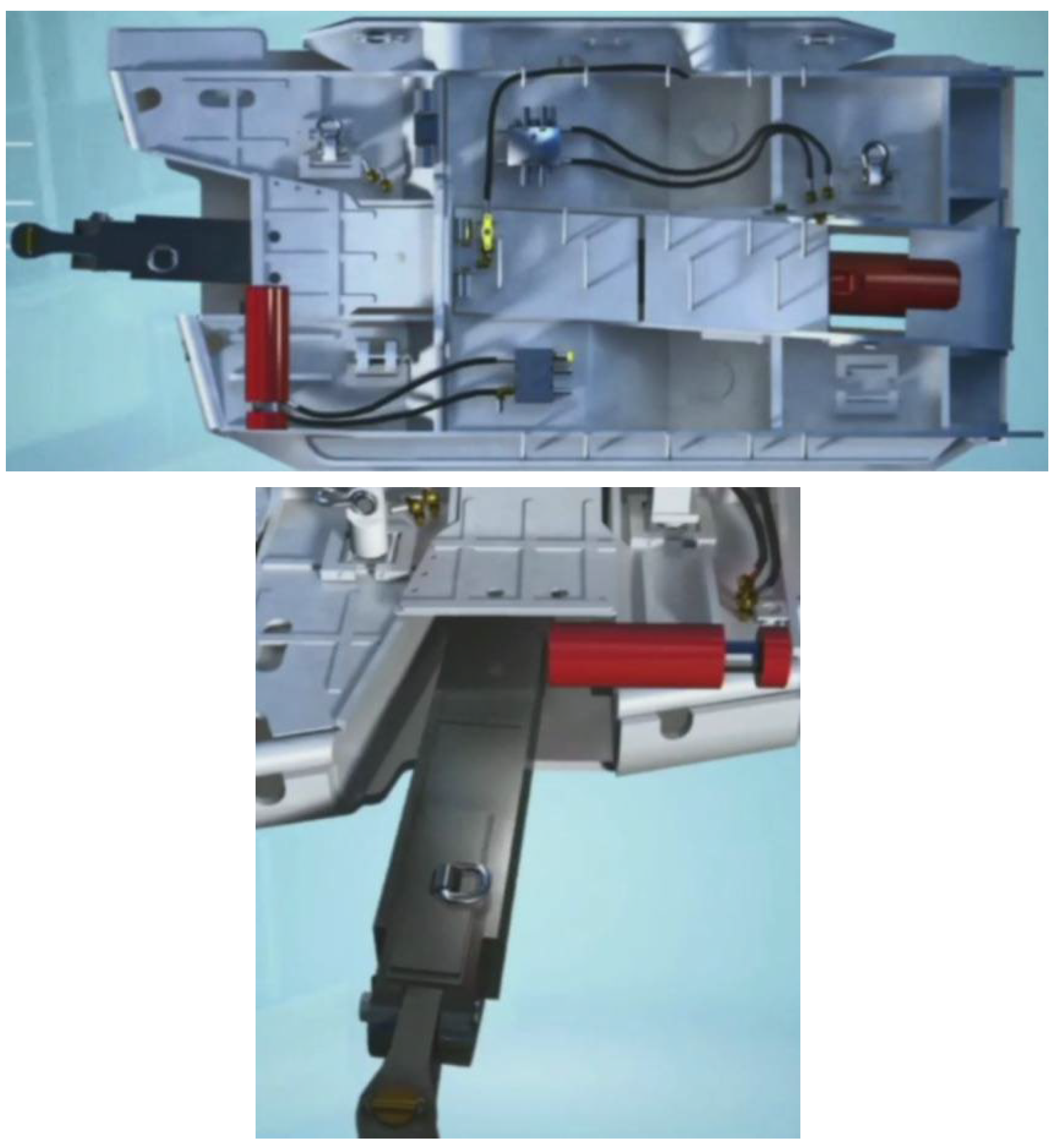

- Add the pushing rod limiting jack to limit the swing angle of the push rod (Figure 12).

- (3)

- Anti-slip jacks are set between adjacent support bases, the support with initial support force is used as the fulcrum, the position of the adjacent support is adjusted, and the cable stayed oil cylinder is installed and connected with the guide connecting device (Figure 13).

- (4)

- The support moves from the bottom to the top along the working face starting from the second support, then moving the first support and the third frame, and on and on all the way the top.

7. Discussion

8. Conclusions

- (1)

- On the basis of considering the influence of coal seam strike angles on the inclined stability of support and inclined angles on the inclined stability of support, a mechanical model of “support-surrounding rock” is established. Through the mechanical calculation and analysis of the free state and working state of the working face support, it is concluded that the critical tipping angle of the support in the free state is 27.8°, and the critical slip angle is 16°. The support is more prone to slip in the free state.

- (2)

- Failure slip will occur on the floor. When the trend and rate of roof collapse are different from the trend and rate of failure slip on the floor, it will cause the instability of the “floor-support-roof” system on the working face, resulting in disastrous accidents.

- (3)

- With the increase in tangential component force and the decrease in normal component force, the working load received by the supporting system of the working face becomes smaller, the external load causing the instability of the supporting system increases, and it is easy for the support slip, fall, and tilt.

- (4)

- A series of shield stability control anti-fall and anti-slip technologies of intelligent working face supports with a large dip angle is conducive to ensuring the stability of mine support and improving safety.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kulakov, V.N. Stress state in the face region of a steep coal bed. J. Min. Sci. 1995, 31, 02047661. [Google Scholar] [CrossRef]

- Hahn, H.; Hintze, W.; Treumann, H. Safety and Technological Aspects of Black Powder. Propellants Explos. Pyrotech. 1980, 5, 129–134. [Google Scholar] [CrossRef]

- Singh, T.N.; Gehi, L.D. State behavior during mining of steeply dipping thick seams—A case study. In Proceedings of the 27th International Symposium on Thick Seam Mining, Dhanbad, India, 19–21 November 1992; pp. 311–315. [Google Scholar]

- Feng, G.; Wang, P.; Zhao, J.; Wang, Z. A Coal Burst Mitigation Strategy for Gateroad in Mining of Deep Inclined Longwall Panels at Huafeng Coal Mine. Shock. Vib. 2018, 2018, 5929785. [Google Scholar]

- Zhao, J.; Wang, P.; Su, Y. An Innovative Longwall Mining Technology in Tangshan Coal Mine, China. Minerals 2017, 7, 14. [Google Scholar] [CrossRef]

- Feng, G.; Wang, P.; Chugh, Y.P. A New Gob-Side Entry Layout for Longwall Top Coal Caving. Energies 2018, 11, 1292. [Google Scholar] [CrossRef]

- Alejano, L.R.; Ramírez-Oyanguren, P.; Taboada, J. FDM predictive methodology for subsidence due to flat and inclined coal seam mining. Int. J. Rock Mech. Min. Sci. 1999, 36, 475–491. [Google Scholar] [CrossRef]

- Feng-hai, M.A.; Li, S.; Dun, L.I. Numerical simulation analysis of covering rock strata as mining steep-inclined coal seam under fault movement. Trans. Nonferrous Met. Soc. China 2011, 21, s556–s561. [Google Scholar]

- Ching, J.; Yang, Z.; Shiau, J.; Chen, J. Estimation of rock pressure during an excavation/cut in sedimentary rocks with inclined bedding planes. Struct. Saf. 2013, 41, 11–19. [Google Scholar] [CrossRef]

- Xin, Y.; Gou, P.; Ge, F. Analysis of stability of support and surrounding rock in mining top coal of inclined coal seam. Int. J. Min. Sci. Technol. 2014, 24, 63–68. [Google Scholar] [CrossRef]

- Lin, Y.; Hong, Y.; Zheng, S.; Zhang, Y. Failure modes of openings in a steeply bedded rock mass. Rock Mech. Rock Eng. 1984, 17, 113–119. [Google Scholar]

- Gao, W. Study on the width of the non-elastic zone in inclined coal pillar for strip mining. Int. J. Rock Mech. Min. Sci. 2014, 72, 304–310. [Google Scholar]

- Huang, X. Physical model test and numerical analysis on the behavior of stratified rock masses during underground excavation. Int. J. Rock Mech. Min. Sci. 2012, 49, 134–147. [Google Scholar]

- Das, A.J.; Mandal, P.K.; Bhattacharjee, R.; Roy, L.B. Evaluation of stability of underground workings for exploitation of an inclined coal seam by the ubiquitous joint model. Int. J. Rock Mech. Min. Sci. 2017, 93, 101–114. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Paul, P.S.; Sinha, R.K. Generalised Analytical Models for the Strength of the Inclined as well as the Flat Coal Pillars using Rock Mass Failure Criterion. Rock Mech. Rock Eng. 2019, 52, 3921–3946. [Google Scholar] [CrossRef]

- Das, A.J.; Mandal, P.K.; Paul, P.S.; Sinha, R.K.; Tewari, S. Assessment of the Strength of Inclined Coal Pillars through Numerical Modelling based on the Ubiquitous Joint Model. Rock Mech. Rock Eng. 2019, 52, 3691–3717. [Google Scholar] [CrossRef]

- Foroughi, M.H. Some Aspects of Coal Pillar Stability in Inclined Coal Seams. Ph.D. Thesis, University of New South Wales, Sydney, NSW, Australia; p. 273.

- Jessu, K.V.; Spearing, A.J.S. Performance of inclined pillars with a major discontinuity. Int. J. Min. Sci. Technol. 2019, 29, 437–443. [Google Scholar] [CrossRef]

- Jessu, K.V.; Spearing, A.J.; Sharifzadeh, M. Mostafa Sharifzadeh. Laboratory and Numerical Investigation on Strength Performance of Inclined Pillars. Energies 2018, 11, 3229. [Google Scholar] [CrossRef]

- Sun, J.; Wang, L.G.; Tang, F.R. Micro-seismic monitoring failure characteristics of inclined coal seam floor. Rock Soil. Mech. 2011, 32, 1589–1594. [Google Scholar]

- Wang, Z.; Dou, L.; Wang, G. Coal Burst Induced by Horizontal Section Mining of a Steeply Inclined, Extra-Thick Coal Seam and Its Prevention: A Case Study from Yaojie No. 3 Coal Mine, China. Shock. Vib. 2019, 2019, 8469019. [Google Scholar] [CrossRef]

- Çelik, A.; Özçelik, Y. Investigation of the effect of caving height on the efficiency of the longwall top coal caving production method applied in inclined and thick coal seams by physical modeling. Int. J. Rock Mech. Min. Sci. 2023, 162, 105304. [Google Scholar] [CrossRef]

- Çelik, A. Investigation of Longwall Caving Method Efficiency in Inclined Thick Coal Seams by Physical Modelling. Ph.D. Thesis, The Graduate School of Science and Engineering, Hacettepe University, Ankara, Turkey, 2022. [Google Scholar]

- Çelik, A.; Özçelik, Y. Investigation of the effects of coal seam slope and top coal drawn height on top coal recovery ratio in longwall top coal caving method applied in steep inclined thick coal seams. Arab. J. Geosci. 2022, 15, 181. [Google Scholar] [CrossRef]

- Tu, H.; Tu, S.; Yuan, Y.; Bai, Q. Present situation of fully mechanized mining technology for steeply inclined coal seams in China. Arab. J. Geosci. 2015, 8, 4485–4494. [Google Scholar] [CrossRef]

- Klishin, S.V.; Klishin, V.I.; Opruk, G.Y. Modeling coal discharge in mechanized steep and thick coal mining. J. Min. Sci. 2013, 49, 932–940. [Google Scholar] [CrossRef]

- Kostyuk, S.; Bedarev, N.; Lyubimov, O.; Kovalyov, N. Searching for the Optimal Parameters of the Thick Steep Seams‘ Under-Level Development. E3S Web Conf. 2018, 41, 01002. [Google Scholar] [CrossRef]

- Klishin, V.I.; Klishin, S.V. Coal Extraction From Thick Flat And Steep Beds. J. Min. Sci. 2010, 46, 149–159. [Google Scholar] [CrossRef]

- Selyukov, A.; Gerasimov, A.; Grishin, V. The Results of Mining and Geometric Analysis in Open Pit Mining of Promising Kuzbass Coal Deposits with Block System. E3S Web Conf. 2020, 174, 01020. [Google Scholar] [CrossRef]

- Rak, Z. Mechanised sublevel caving systems for winning thick and steep hard coal beds. In International Mining Forum 2010: Mine Safety and Efficient Exploitation Facing Challenges of the 21 Century; CRC Press: Boca Raton, FL, USA, 2010; pp. 361–370. [Google Scholar]

- Kolesnikov, V.; Katsubin, A.; Martyanov, V.; Dobrov, A. Features of the Excavation and Loading Equipment of Various Types in the Development of Inclined and Steep Beds. E3S Web Conf. 2019, 105, 01023. [Google Scholar] [CrossRef]

- Jawed, M.; Sinha, R.K. Design of rhombus coal pillars and support for roadway stability and mechanizing loading of face coal using SDLs in a steeply inclined thin coal seam—A technical feasibility study. Arab. J. Geosci. 2018, 11, 415. [Google Scholar] [CrossRef]

- Kumar, R.; Mandal, P.K.; Ghosh, N.; Das, A.J.; Banerjee, G. Design of stable parallelepiped coal pillars considering geotechnical uncertainties. Rock Mech. Rock Eng. 2023. [Google Scholar] [CrossRef]

- Duc, T.P.; Tuan, A.P.; Vitcalov, V.; Le Quang, P. Justification of spatially-planned solutions and determination of the dimension block in the working of the medium thick inclined coal seams with the room and pillar system. E3S Web Conf. 2018, 41, 01024. [Google Scholar]

- Zhao, P.; Zhuo, R.; Li, S.; Shu, C.M.; Jia, Y.; Lin, H.; Chang, Z.; Ho, C.; Bin, L.; Xiao, P. Fractal characteristics of methane migration channels in inclined coal seams. Energy 2021, 225, 120127. [Google Scholar] [CrossRef]

- Nikitenko, M.S.; Malakhov, Y.V.; Neogi, B.; Chakraborty, P.; Banerjee, D. Robotic complex for the development of thick steeply-inclined coal seams and ore deposits. IOP Conf. Ser. Earth Environ. Sci. 2017, 84, 012002. [Google Scholar] [CrossRef]

- Asadi, A.; Shahriar, K.; Goshtasbi, K.; Najm, K. Development of a new mathematical model for prediction of surface subsidence due to inclined coal-seam mining. J. S. Afr. Inst. Min. Metall. 2005, 105, 15–20. [Google Scholar]

- Erdem, B.; Duran, Z. A model for extended bench casting in dipping coal seam. J. Sci. Ind. Res. 2007, 66, 435–443. [Google Scholar]

- Eremin, M.; Peryshkin, A.; Esterhuizen, G.; Pavlova, L.; Fryanov, V. Numerical analysis of pillar stability in longwall mining of two adjacent panels of an inclined coal seam. Appl. Sci. 2022, 12, 11028. [Google Scholar] [CrossRef]

- Dudek, M.; Tajduś, K. FEM for prediction of surface deformations induced by flooding of steeply inclined mining seams. Geomech. Energy Environ. 2021, 28, 100254. [Google Scholar] [CrossRef]

- Vu, T.T. Solutions to prevent face spall and roof falling in fully mechanized longwall at underground mines, Vietnam. Min. Miner. Depos. 2022, 16, 127–134. [Google Scholar] [CrossRef]

- Shavarskyi, I.; Falshtynskyi, V.; Dychkovskyi, R.; Akimov, O.; Sala, D.; Buketov, V. Management of the longwall face advance on the stress-strain state of rock mass. Min. Miner. Depos. 2022, 16, 78–85. [Google Scholar] [CrossRef]

- Smoliński, A.; Malashkevych, D.; Petlovanyi, M.; Rysbekov, K.; Lozynskyi, V.; Sai, K. Research into Impact of Leaving Waste Rocks in the Mined-Out Space on the Geomechanical State of the Rock Mass Surrounding the Longwall Face. Energies 2022, 15, 9522. [Google Scholar] [CrossRef]

- Malashkevych, D.; Petlovanyi, M.; Sai, K.; Zubko, S. Research into the coal quality with a new selective mining technology of the waste rock accumulation in the mined-out area. Min. Miner. Depos. 2022, 16, 103–114. [Google Scholar] [CrossRef]

- Satsuk, T.P.; Sharyakov, V.A.; Sharyakova, O.L.; Kovalev, D.A.; Vorob’ev, A.A.; Makarova, E.I. Automatic Voltage Stabilization of an Electric Rolling Stock Catenary System. Russ. Electr. Engin. 2021, 92, 349. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Ilyushin, Y.V. The Development of the Toxic and Flammable Gases Concentration Monitoring System for Coalmines. Energies 2022, 15, 8917. [Google Scholar] [CrossRef]

| Level Name | +750 m level | Name of Mining District | Fourth mining district |

| Elevation on the surface | 1238.1~1244.2 m | Elevation underground | 993.8~759.2 m |

| Position of the panel | On the northeast of the surface industrial sites. | ||

| The influence of mining on the surface facilities | The corresponding ground position of the working face is a semi-fixed dune without buildings, and the working face has no influence on the ground buildings during the mining period. | ||

| Location | To the east of the panel is the 4304S panel, and to the west is the coal pillar protected by the zone of oxidized zone. To the south is the protective coal pillar of the ancient Great Wall, and to the north is the setup room of the 4303 (W) panel | ||

| Seam No. | 3 Upper | Thickness of Coal Seam (m) | 1.8~2.4 | Inclination (°) | 33~42 |

| 2.1 | 37.5 | ||||

| Texture of coal seam | complex | Hardness | soft | Coal types | Gas coal |

| Recoverable index (%) | 0.98 | Variable coefficient (%) | 25.98 | Degree of stability | Stabilization |

| Type No. | ZFS5000/17/34 | Accommodated Dip Angle | ≥20° |

| Working resistance | 4650 kN | Opening width | 1700~3400 mm |

| Center to center spacing | 1500 mm | Moving distance for each step | 600 mm |

| Pump station pressure | 31.5 MPa | Mode of operation | Local operation |

| Type No. | ZFG5600/18/33 | Adaptation to seam dip | ≥20° |

| Working resistance | 5600 kN | Support height | 1800~3300 mm |

| Center distance of support | 1500 mm | Moving distance for each step | 600 mm |

| Pump station pressure | 31.5 Mpa | Mode of operation | Local operation |

| Cutting Height (m) | |||

| Angle of Mining Downdip (updip) (°) | 2.8 | 3 | 3.2 |

| 5 | 27.8 | 26.1 | 24.7 |

| 10 | 26.5 | 24.8 | 23.2 |

| 15 | 24.2 | 22.2 | 20.4 |

| 20 | 20.3 | 17.9 | 15.5 |

| 25 | 13.5 | 9.3 | 2.6 |

| Angles of mining downdip (updip)/(°) | 5 | 10 | 15 | 20 | 25 |

| Support inclined critical slip/(°) | 16.0 | 13.5 | 7.4 | Slippage | Slippage |

| Items | Time | Time Interval/ Day | Stress /MPa | Periodic Weighting Interval/m | |

|---|---|---|---|---|---|

| No. | |||||

| 8# | April 21 | 6 | 21~27 | 18 | |

| April 26 | 5 | 15 | |||

| April 31 | 5 | 15 | |||

| 9# | April 23 | 5 | 22~26 | 15 | |

| April 29 | 6 | 18 | |||

| May 3 | 5 | 15 | |||

| 10# | April 26 | 5 | 26~30 | 15 | |

| April 30 | 4 | 12 | |||

| Items | Time | Time Interval /Day | Stress /MPa | Periodic Weighting Interval/m | |

|---|---|---|---|---|---|

| No. | |||||

| 45# | May 17 | 5 | 23~29 | 15 | |

| May 23 | 6 | 18 | |||

| May 27 | 4 | 12 | |||

| 46# | May 19 | 7 | 26~29 | 21 | |

| May 25 | 6 | 18 | |||

| May 30 | 5 | 15 | |||

| 47# | May 21 | 6 | 27~31 | 18 | |

| May 24 | 3 | 9 | |||

| Items | Time | Time Interval /Day | Stress /MPa | Periodic Weighting Interval/m | |

|---|---|---|---|---|---|

| No. | |||||

| 95# | May 19 | 5 | 19~24 | 15 | |

| May 23 | 4 | 12 | |||

| May 27 | 4 | 12 | |||

| 96# | May 22 | 5 | 21~23 | 15 | |

| May 26 | 4 | 12 | |||

| May 31 | 5 | 15 | |||

| 97# | May 24 | 3 | 23~26 | 9 | |

| May 28 | 4 | 12 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, B.; Wang, P. Research on Stability Control of Shields at Working Face with Large Dip Angle. Energies 2023, 16, 5813. https://doi.org/10.3390/en16155813

Shi B, Wang P. Research on Stability Control of Shields at Working Face with Large Dip Angle. Energies. 2023; 16(15):5813. https://doi.org/10.3390/en16155813

Chicago/Turabian StyleShi, Bao, and Pengfei Wang. 2023. "Research on Stability Control of Shields at Working Face with Large Dip Angle" Energies 16, no. 15: 5813. https://doi.org/10.3390/en16155813

APA StyleShi, B., & Wang, P. (2023). Research on Stability Control of Shields at Working Face with Large Dip Angle. Energies, 16(15), 5813. https://doi.org/10.3390/en16155813