Insights into the Fusion Correction Algorithm for On-Board NOx Sensor Measurement Results from Heavy-Duty Diesel Vehicles

Abstract

:1. Introduction

| Publication Year | Key Advances | Main Authors |

|---|---|---|

| 2004 | The measurement delay and cross sensitivity of NOx sensors were investigated. | Hofmann et al. [11] |

| 2009 | A data fusion algorithm was developed to account for the temperature and NH3 slip effects on NOx measurement. | Giampà et al. [12] |

| 2010 | A measurement method using zirconia-based potentiometric lambda sensors was presented to distinguish exhaust gas components accurately. | Fischer et al. [13] |

| 2015 | A mixed-potential electrochemical gas sensor with a three-dimensional three-phase boundary was investigated to detect NO2 at elevated temperatures. | Liu et al. [15] |

| 2016 | An adaptive-network-based fuzzy inference system was used to develop an algorithm that corrected the NOx sensor readings. | Wang et al. [14] |

| 2020 | A method based on an LSTM network for temperature and humidity compensation of the on-board NOx sensors was proposed. | Huang et al. [17] |

| 2021 | A formula for on-board NOx correction to ambient humidity and temperature was fitted using a big data approach. | Li et al. [18] |

2. Research Method

2.1. Experimental Facilities

2.2. Data Processing and Segmentation

2.3. MLP-RFR Fusion Correction Model

2.3.1. Delay Correction Model for the OBNS Measurement (Time Alignment)

2.3.2. Correction Model of Concentration Deviation for OBNS Measurement

2.4. Optimisation and Performance Evaluation of the Machine Learning Models

3. Results and Discussion

3.1. Analysis of the OBNS Measurement Characteristics

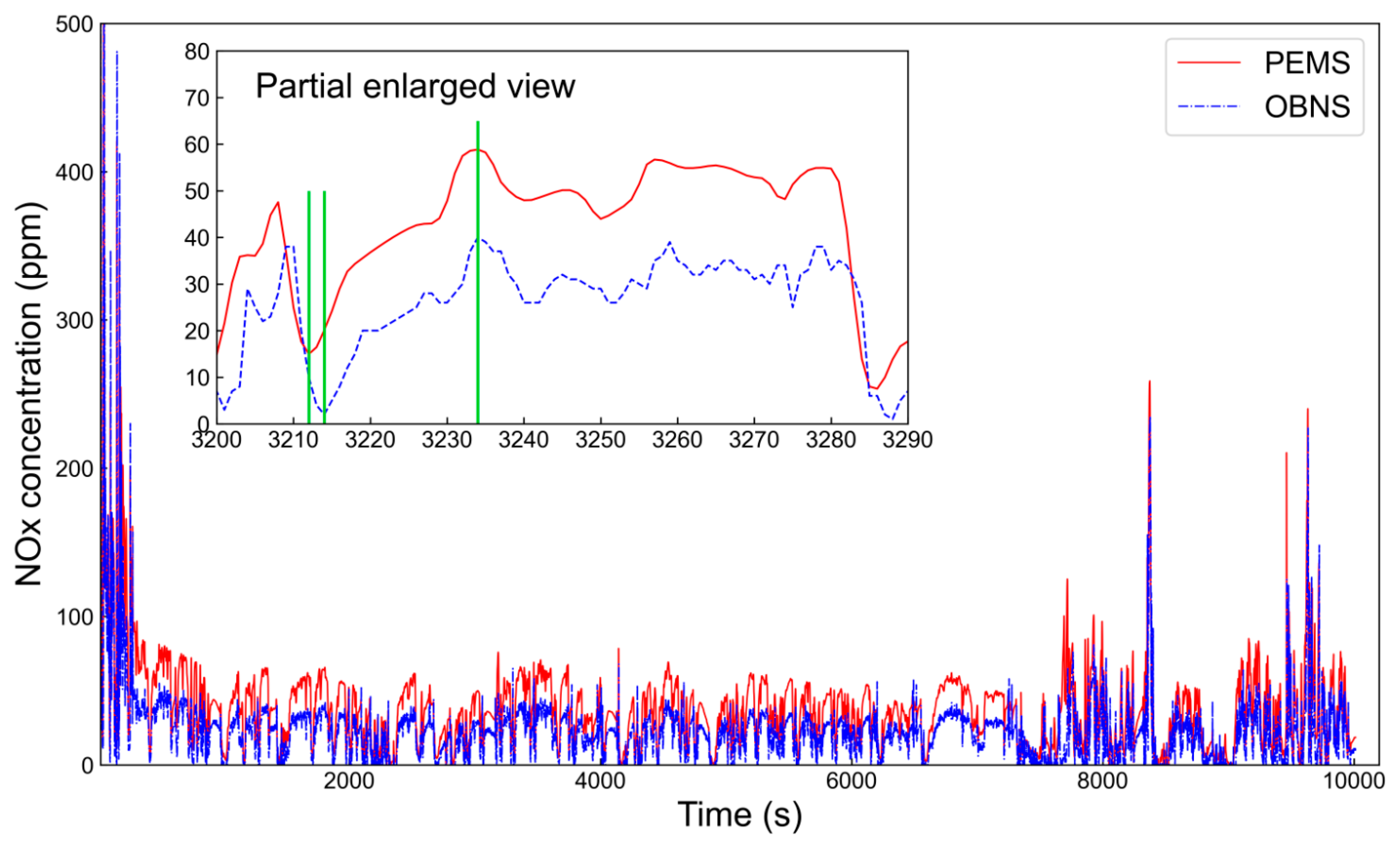

3.2. Delay Correction for the OBNS Measurement

3.3. Correction of the Concentration Deviation for the OBNS Measurement

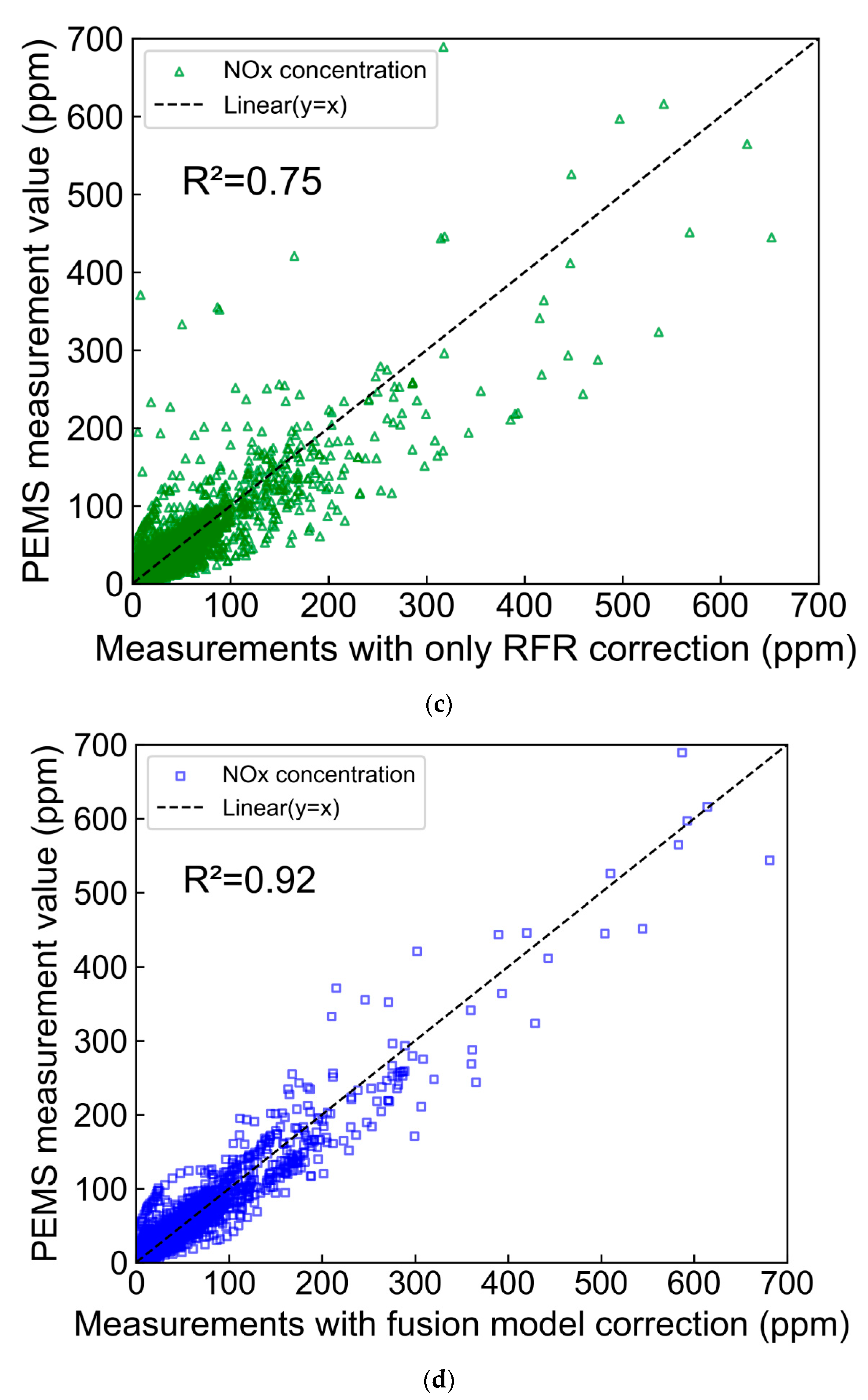

3.4. Evaluation of the MLP-RFR Fusion Algorithm Performance

4. Conclusions and Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CAN | Controller Area Network |

| CLD | Chemiluminescence Detection |

| GPS | Global Positioning System |

| LSTM | Long Short-Term Memory |

| MLP | Multilayer Perceptron |

| MSE | Mean Square Error |

| NDUV | Nondispersive Ultraviolet |

| NOx | Nitrogen Oxide |

| OBD | On-Board Diagnostics |

| OBNS | On-board Nitrogen Oxide Sensors |

| PEMS | Portable Emission Measurement System |

| Coefficient of Determination | |

| RF | Random Forest |

| RFR | Random Forest Regression |

| SCR | Selective Catalytic Reduction |

| SVM | Support Vector Machine |

| XGBoost | eXtreme Gradient Boosting |

References

- Li, X.; Ai, Y.; Ge, Y.; Qi, J.; Feng, Q.; Hu, J.; Porter, W.C.; Miao, Y.; Mao, H.; Jin, T. Integrated effects of SCR, velocity, and Air-fuel Ratio on gaseous pollutants and CO2 emissions from China V and VI heavy-duty diesel vehicles. Sci. Total Environ. 2022, 811, 152311. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, J.; Liu, H.; Li, Y.; Li, T.; Sun, K.; Wang, T. A fuel-consumption based window method for PEMS NOx emission calculation of heavy-duty diesel vehicles: Method description and case demonstration. J. Environ. Manag. 2023, 325, 116446. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Yin, H.; Wang, J.; Hao, C.; Xu, X.; Wang, Y.; Yang, Z.; Hao, L.; Tan, J.; Wang, X.; et al. China 6 moving average window method for real driving emission evaluation: Challenges, causes, and impacts. J. Environ. Manag. 2022, 319, 115737. [Google Scholar] [CrossRef]

- Sharp, C.A.; Feist, M.D.; Laroo, C.A.; Spears, M.W. Determination of PEMS Measurement Allowances for Gaseous Emissions Regulated Under the Heavy-Duty Diesel Engine In-Use Testing Program: Part 3—Results and Validation. SAE Int. J. Fuels Lubr. 2009, 2, 407–421. [Google Scholar] [CrossRef]

- Zheng, X.; Wu, Y.; Zhang, S.; Hu, J.; Zhang, K.M.; Li, Z.; He, L.; Hao, J. Characterizing particulate polycyclic aromatic hydrocarbon emissions from diesel vehicles using a portable emissions measurement system. Sci. Rep. 2017, 7, 10058. [Google Scholar] [CrossRef]

- Mądziel, M. Liquefied Petroleum Gas-Fuelled Vehicle CO2 Emission Modelling Based on Portable Emission Measurement System, On-Board Diagnostics Data, and Gradient-Boosting Machine Learning. Energies 2023, 16, 2754. [Google Scholar] [CrossRef]

- Jaworski, A.; Lejda, K.; Mądziel, M.; Ustrzycki, A. Assessment of the emission of harmful car exhaust components in real traffic conditions. IOP Conf. Ser. Mater. Sci. Eng. 2018, 421, 042031. [Google Scholar] [CrossRef]

- Cheng, Y.; He, L.; He, W.; Zhao, P.; Wang, P.; Zhao, J.; Zhang, K.; Zhang, S. Evaluating on-board sensing-based nitrogen oxides (NOX) emissions from a heavy-duty diesel truck in China. Atmos. Environ. 2019, 216, 116908. [Google Scholar] [CrossRef]

- Zhang, S.; Wu, Y.; Hu, J.; Huang, R.; Zhou, Y.; Bao, X.; Fu, L.; Hao, J. Can Euro V Heavy-Duty Diesel Engines, Diesel Hybrid and Alternative Fuel Technologies Mitigate NOX Emissions? New Evidence from On-Road Tests of Buses in China. Appl. Energy 2014, 132, 118–126. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, P.; He, L.; Yang, Y.; Liu, B.; He, W.; Cheng, Y.; Liu, Y.; Liu, S.; Hu, Q.; et al. On-board monitoring (OBM) for heavy-duty vehicle emissions in China: Regulations, early-stage evaluation, and policy recommendations. Sci. Total Environ. 2020, 731, 139045. [Google Scholar] [CrossRef]

- Hofmann, L.; Rusch, K.; Fischer, S.; Lemire, B. Onboard Emissions Monitoring on a HD Truck with an SCR System Using Nox Sensors; SAE Transactions; SAE International: Warrendale, PA, USA, 2004; pp. 559–572. [Google Scholar] [CrossRef]

- Giampà, A.; Petri, E.; Saponara, S.; Terreni, P. Sensor Modeling and Fusion Algorithms for NOx Measures towards Zero Emissions Vehicles. In Proceedings of the 2009 IEEE International Workshop on Robotic and Sensors Environments, Lecco, Italy, 6–7 November 2009; IEEE: Piscataway, NJ, USA, 2009; pp. 151–156. [Google Scholar]

- Fischer, S.; Pohle, R.; Farber, B.; Proch, R.; Kaniuk, J.; Fleischer, M.; Moos, R. Method for Detection of NOx in Exhaust Gases by Pulsed Discharge Measurements Using Standard Zir-conia-Based Lambda Sensors. Sens. Actuators B Chem. 2010, 147, 780–785. [Google Scholar] [CrossRef]

- Wang, Y.-Y.; Zhang, H.; Wang, J. NOx Sensor Reading Correction in Diesel Engine Selective Catalytic Reduction System Applications. IEEE/ASME Trans. Mechatron. 2016, 21, 460–471. [Google Scholar] [CrossRef]

- Liu, F.; Guan, Y.; Dai, M.; Zhang, H.; Guan, Y.; Sun, R.; Liang, X.; Sun, P.; Liu, F.; Lu, G. High-Performance Mixed-Potential Type NO2 Sensors Based on Three-Dimensional TPB and Co3V2O8 Sensing Electrode. Sens. Actuators B Chem. 2015, 216, 121–127. [Google Scholar] [CrossRef]

- Bhardwaj, A.; Bae, H.; Namgung, Y.; Lim, J.; Song, S.J. Influence of sintering temperature on the physical, electrochemical and sensing properties of α-Fe2O3-SnO2 nanocomposite sensing electrode for a mixed-potential type NOx sensor. Ceram. Int. 2019, 45, 2309–2318. [Google Scholar] [CrossRef]

- Huang, A.; Lyu, Y.; Guo, Z.; Zhao, X. A Temperature and Humidity Compensation Method for On-Board NOx Sensors with LSTM Network. In Proceedings of the 2020 International Conference on Sensing, Measurement & Data Analytics in the Era of Artificial Intelligence (ICSMD), Xi’an, China, 15–17 October 2020; IEEE: Piscataway, NJ, USA, 2020. [Google Scholar] [CrossRef]

- Li, P.; Lü, L. Research on a China 6b heavy-duty diesel vehicle real-world engine out NOx emission deterioration and ambient correction using big data approach. Environ. Sci. Pollut. Res. 2022, 29, 6949–6976. [Google Scholar] [CrossRef]

- Flores Fernández, A.; Sánchez Morales, E.; Botsch, M.; Facchi, C.; García Higuera, A. Generation of Correction Data for Autonomous Driving by Means of Machine Learning and On-Board Diagnostics. Sensors 2023, 23, 159. [Google Scholar] [CrossRef]

- Chastko, K.; Adams, M. Assessing the accuracy of long-term air pollution estimates produced with temporally adjusted short-term observations from unstructured sampling. J. Environ. Manag. 2019, 240, 249–258. [Google Scholar] [CrossRef]

- Just, A.C.; De Carli, M.M.; Shtein, A.; Dorman, M.; Lyapustin, A.; Kloog, I. Correcting Measurement Error in Satellite Aerosol Optical Depth with Machine Learning for Modeling PM2.5 in the Northeastern USA. Remote Sens. 2018, 10, 803. [Google Scholar] [CrossRef]

- Kim, Y.-H.; Ha, J.-H.; Yoon, Y.; Kim, N.-Y.; Im, H.-H.; Sim, S.; Choi, R.K.Y. Improved Correction of Atmospheric Pressure Data Obtained by Smartphones through Machine Learning. Comput. Intell. Neurosci. 2016, 2016, 9467878. [Google Scholar] [CrossRef]

- Lee, W.M. Getting Started with Scikit-Learn for Machine Learning. In Python® Machine Learning; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2019; pp. 93–117. [Google Scholar] [CrossRef]

- Yin, Y.; Jang-Jaccard, J.; Xu, W.; Singh, A.; Zhu, J.; Sabrina, F.; Kwak, J. IGRF-RFE: A Hybrid Feature Selection Method for MLP-Based Network Intrusion De-tection on UNSW-NB15 Dataset. J. Big Data 2023, 10, 15. [Google Scholar] [CrossRef]

- Anushiya, R.; Lavanya, V. A new deep-learning with swarm based feature selection for intelligent intrusion detection for the Internet of things. Meas. Sens. 2023, 26, 100700. [Google Scholar] [CrossRef]

- Bakro, M.; Kumar, R.R.; Alabrah, A.; Ashraf, Z.; Ahmed, M.N.; Shameem, M.; Abdelsalam, A. An Improved Design for a Cloud Intrusion Detection System Using Hybrid Features Selection Approach with ML Classifier; IEEE Access: Piscataway, NJ, USA, 2023. [Google Scholar]

- Taud, H.; Mas, J.F. Multilayer Perceptron (MLP). In Geomatic Approaches for Modeling Land Change Scenarios; Springer: Berlin/Heidelberg, Germany, 2018; pp. 451–455. [Google Scholar]

- Wong, T.-T. Performance evaluation of classification algorithms by k-fold and leave-one-out cross validation. Pattern Recognit. 2015, 48, 2839–2846. [Google Scholar] [CrossRef]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A Simple Way to Prevent Neural Networks from Overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Syarif, I.; Prugel-Bennett, A.; Wills, G. SVM Parameter Optimization using Grid Search and Genetic Algorithm to Improve Classification Performance. TELKOMNIKA (Telecommun. Comput. Electron. Control) 2016, 14, 1502. [Google Scholar] [CrossRef]

| Facility | Manufacturer and Model | Measurement Range | Precision (Steady State) |

|---|---|---|---|

| OBNS | BOSCH EGS-NX2 | 0–90 ppm: ±10 ppm | |

| 0–2750 ppm | 91–1500 ppm: ±8% rel. | ||

| 1501–2750 ppm: ±12% rel. | |||

| PEMS | AVL M.O.V.E. | 0–5000 ppm (NO) | 0–5000 ppm: ±2% rel. (NO) |

| 0–2500 ppm (NO2) | 0–2500 ppm: ±2% rel. (NO2) |

| Symbol Variable | Symbolic Meaning | Model Affiliation |

|---|---|---|

| MA30 | Moving average of 30 s window of raw measurements from OBNS | Classification Model |

| STD30 | Standard deviation of 30 s window of raw measurements from OBNS | |

| Lag_t | Actual delay of in-vehicle NOx sensor | |

| Lag_OBNS | Measurement delay correction data for OBNS | Regression Model |

| MA5 | Moving average of Lag_OBNS over a 5 s window | |

| MA10 | Moving average of Lag_OBNS over a 10 s window | |

| STD5 | Standard deviation of Lag_OBNS over a 5 s window | |

| STD10 | Standard deviation of Lag_OBNS over a 10 s window | |

| PEMS | PEMS measurement value |

| Algorithms | For Problem Types |

|---|---|

| Decision tree | Regression, classification |

| Support vector machine (SVM) | Regression, classification |

| Naive Bayes | Classification |

| MLP network | Regression, classification |

| Random forest (RF) | Regression, classification |

| Classification Algorithms | Average Cross-Validation Accuracy (%) | Training Time (s) |

|---|---|---|

| Decision tree | 32.8 | 0.3 |

| Naive Bayes | 23.9 | 0.05 |

| SVC | 40.8 | 51.0 |

| XGBoost | 37.8 | 24.3 |

| MLP | 43.4 | 9.1 |

| Regression Algorithms | MSE | R2 | Training Time (s) |

|---|---|---|---|

| MLP | 108.53 | 0.919 | 17.7 |

| Decision tree | 103.90 | 0.922 | 4.5 |

| XGBoost | 105.37 | 0.921 | 25.3 |

| RFR | 102.91 | 0.923 | 7.7 |

| Type | Measurement Error |

|---|---|

| Corrected values using the MLP-RFR fusion algorithm | 0–50 ppm: ±4.1 ppm (abs) |

| 50–100 ppm: ±6.1 ppm (abs) 50–100 ppm: ±9.3% (rel.) | |

| 100–150 ppm: ±27.2 ppm (abs) 100–150 ppm: ±22.4% (rel.) | |

| 150–200 ppm: ±30.6 ppm (abs) 150–200 ppm: ±18.1% (rel.) | |

| 200–300 ppm: ±41.1 ppm (abs) 200–300 ppm: ±17.5% (rel.) | |

| >300 ppm: ±72.0 ppm (abs) >300 ppm: ±15.9% (rel.) | |

| OBNS original measurement values | 0–50 ppm: ±12.1 ppm (abs) |

| 50–100 ppm: ±25.6 ppm (abs) 50–100 ppm: ±41.5% (rel.) | |

| 100–150 ppm: ±42.8 ppm (abs) 100–150 ppm: ±34.9% (rel.) | |

| 150–200 ppm: ±63.6 ppm (abs) 150–200 ppm: ±37.0% (rel.) | |

| 200–300 ppm: ±89.0 ppm (abs) 200–300 ppm: ±37.4% (rel.) | |

| >300 ppm: ±214.4 ppm (abs) >300 ppm: ±45.5% (rel.) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, C.; Pei, Y.; Liu, C.; Bai, X.; Jing, X.; Zhang, F.; Qin, J. Insights into the Fusion Correction Algorithm for On-Board NOx Sensor Measurement Results from Heavy-Duty Diesel Vehicles. Energies 2023, 16, 6082. https://doi.org/10.3390/en16166082

Wu C, Pei Y, Liu C, Bai X, Jing X, Zhang F, Qin J. Insights into the Fusion Correction Algorithm for On-Board NOx Sensor Measurement Results from Heavy-Duty Diesel Vehicles. Energies. 2023; 16(16):6082. https://doi.org/10.3390/en16166082

Chicago/Turabian StyleWu, Chunling, Yiqiang Pei, Chuntao Liu, Xiaoxin Bai, Xiaojun Jing, Fan Zhang, and Jing Qin. 2023. "Insights into the Fusion Correction Algorithm for On-Board NOx Sensor Measurement Results from Heavy-Duty Diesel Vehicles" Energies 16, no. 16: 6082. https://doi.org/10.3390/en16166082