Fuel-Saving-Oriented Collaborative Driving Strategy for Commercial Vehicles Based on Driving Style Recognition

Abstract

:1. Introduction

2. Fuel-Saving-Oriented Collaborative Driving System

3. Desired Speed Prediction Based on Driving Style

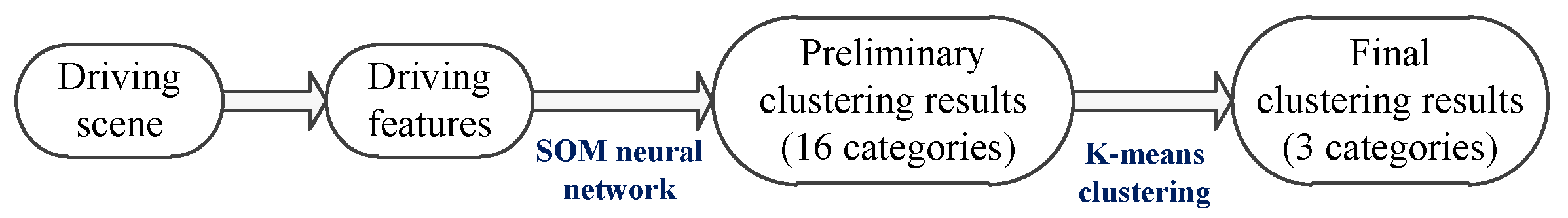

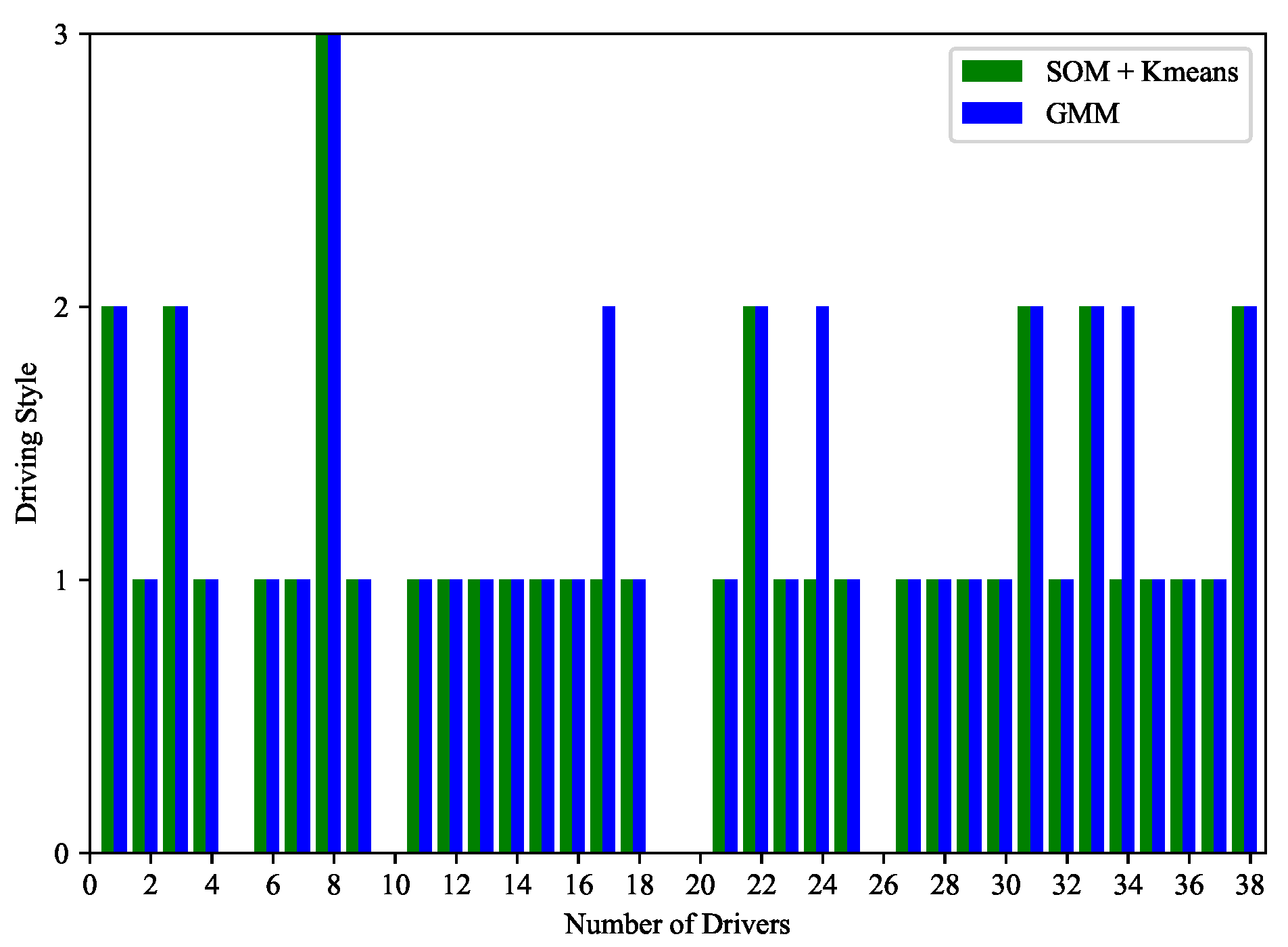

3.1. Driver Style Recognition Model

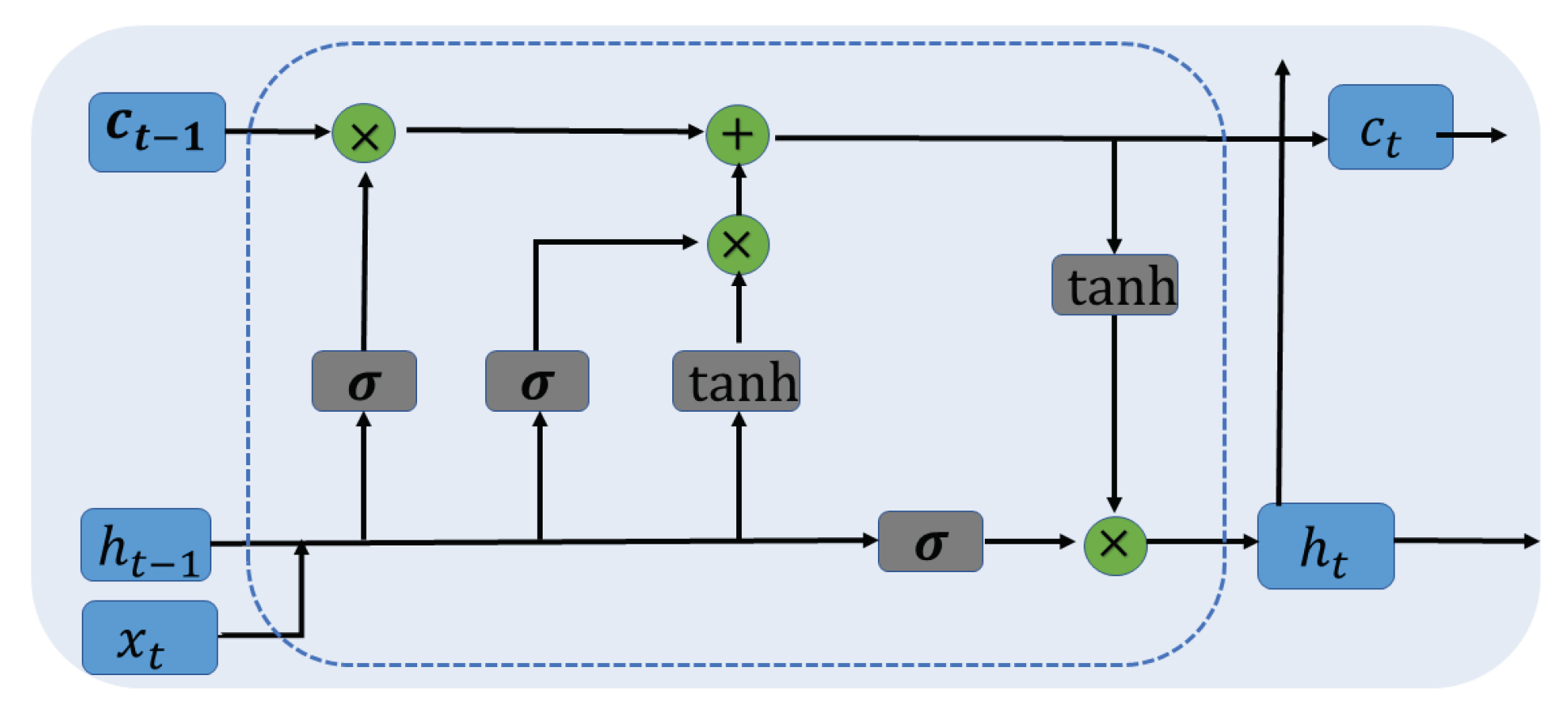

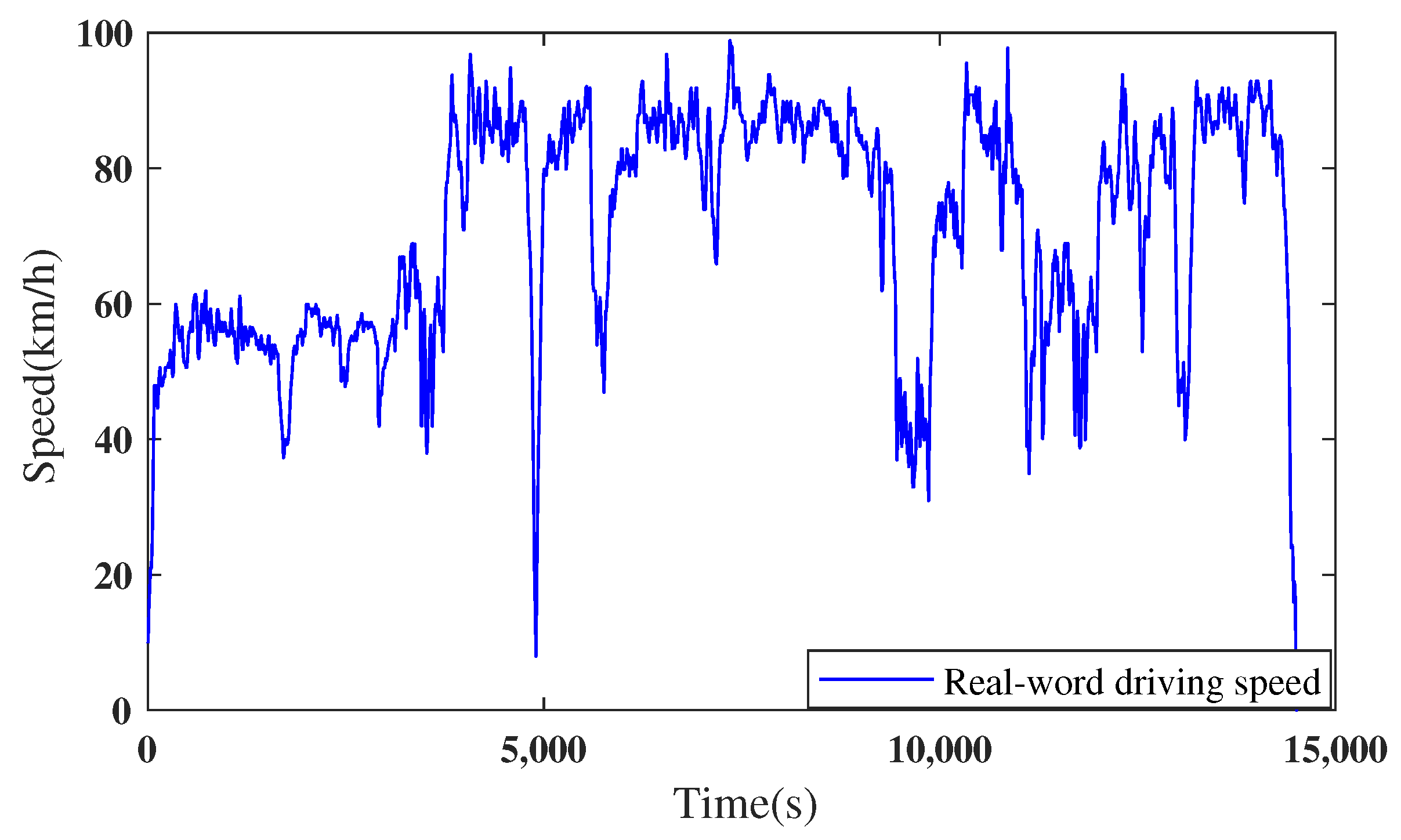

3.2. Vehicle Speed Prediction Method

4. Design of the MPC-Based Optimal Controller

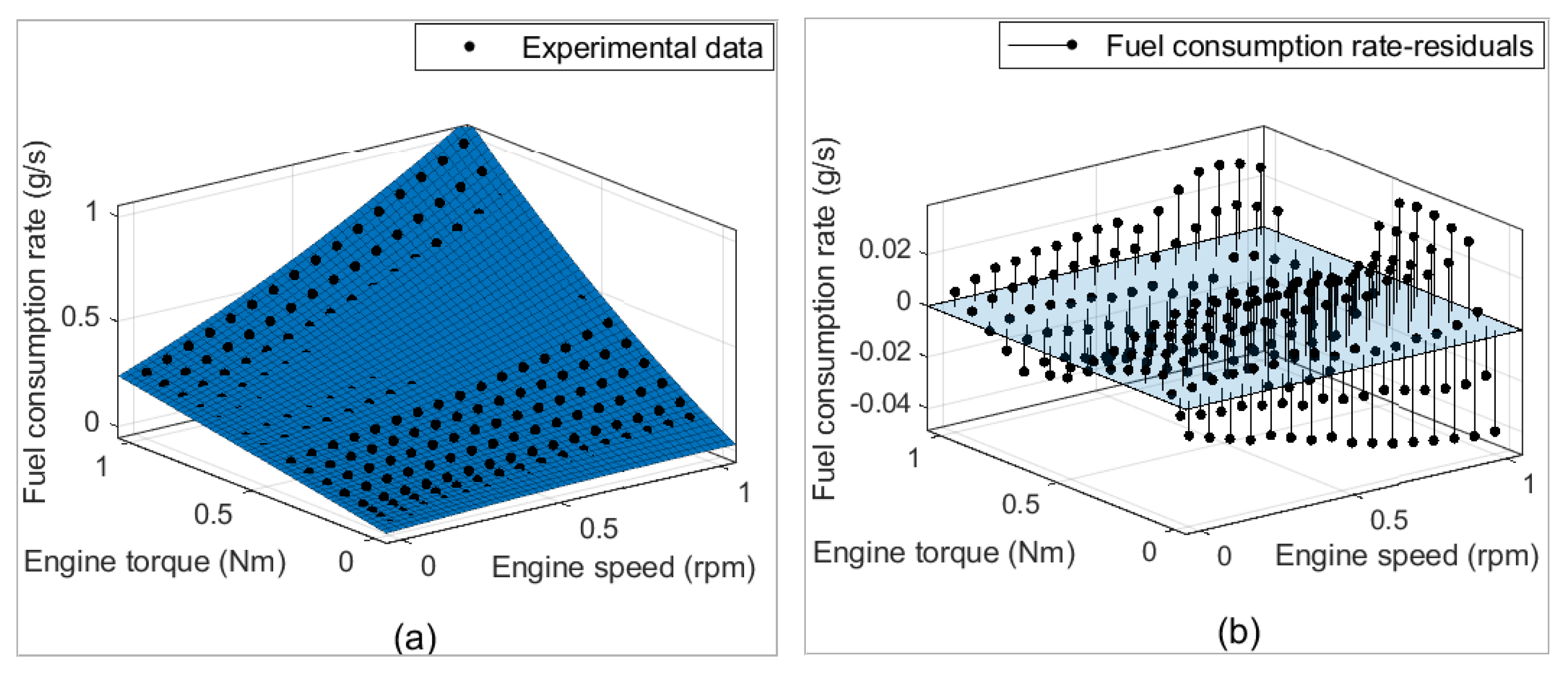

4.1. System Modeling of Commercial Vehicles

4.2. Formulation of Multi-Objective Function

4.2.1. Minimizing the Tracking Error of the Driver’s Desired Speed

4.2.2. Minimizing Fuel Consumption

4.2.3. Minimizing Engine Torque Ripple

4.3. Predictive Equation

4.4. Solution of the Optimization Problem

5. Human–Machine Collaboration

6. Results and Discussion

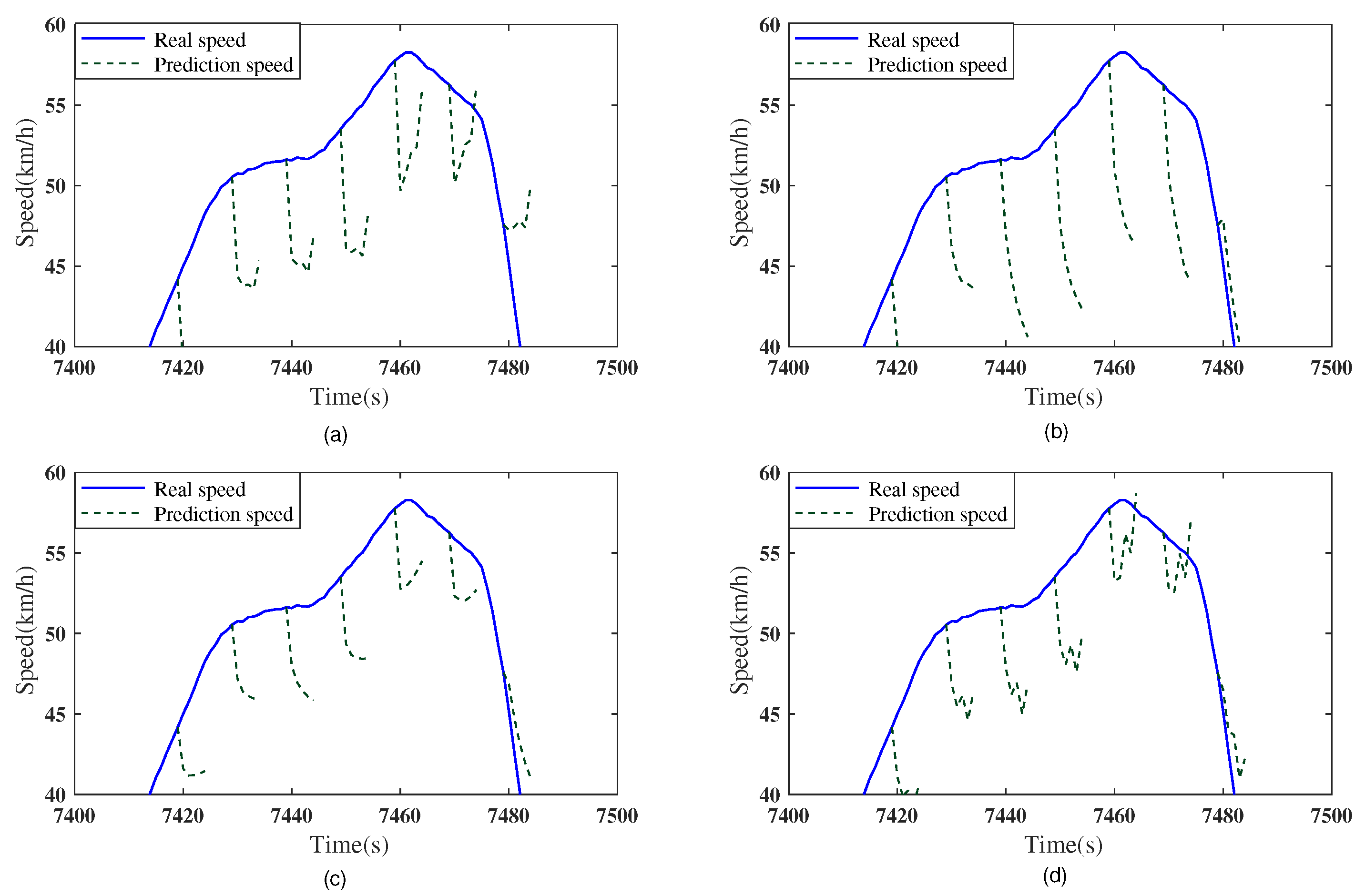

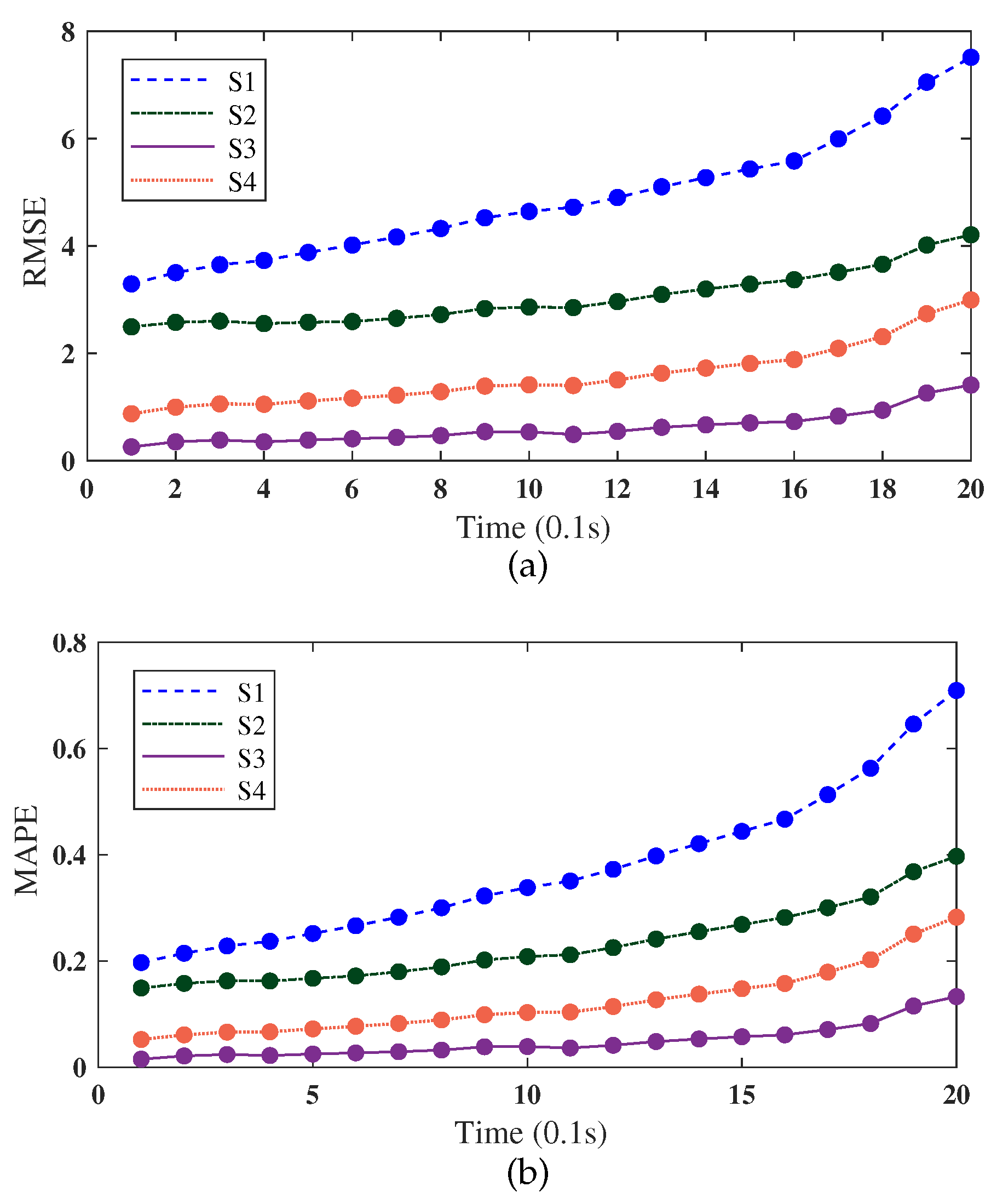

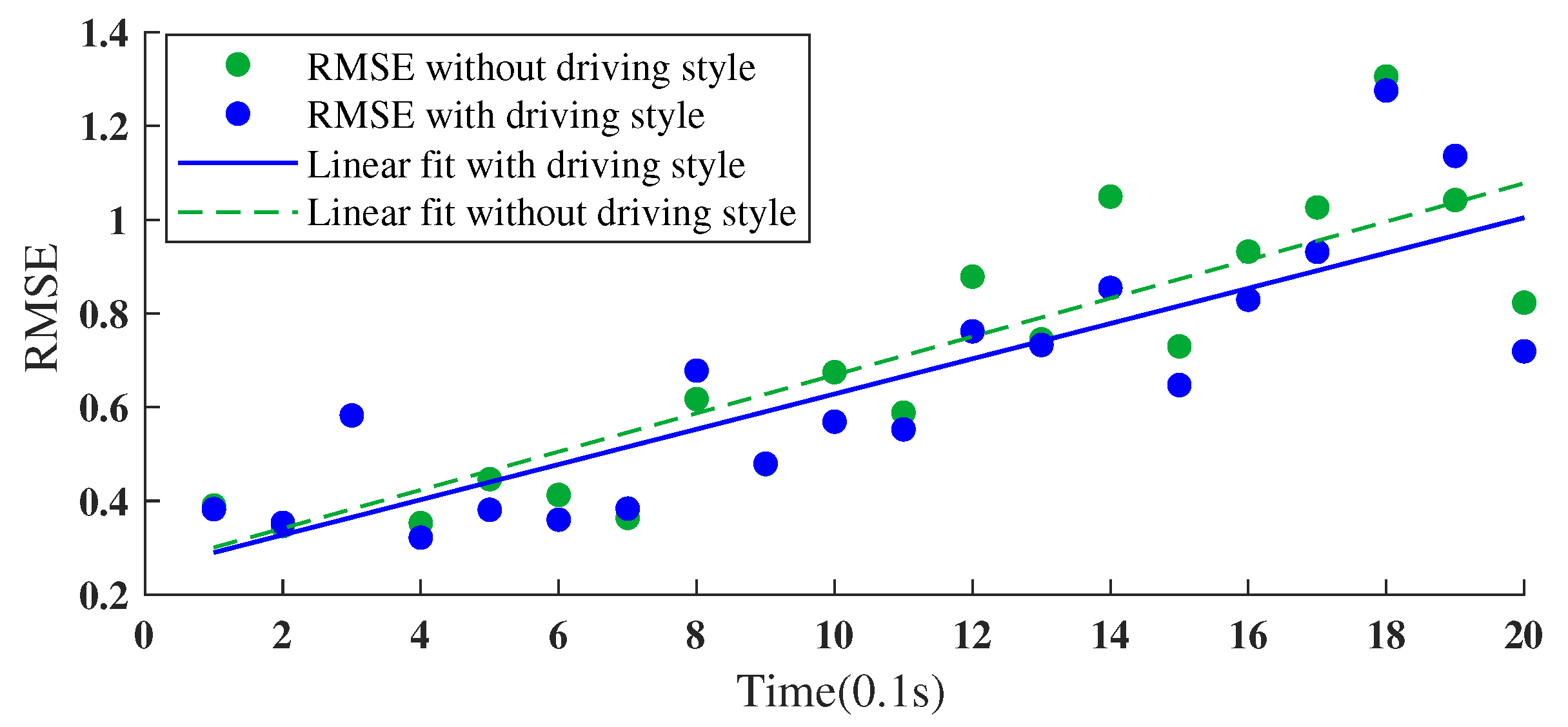

6.1. Vehicle Speed Prediction

6.1.1. Input Feature Selection

6.1.2. Effect of Driving Style on Velocity Prediction

- Without driving style feature:

- With driving style feature:

6.2. Evaluation on Fuel-Saving Performance

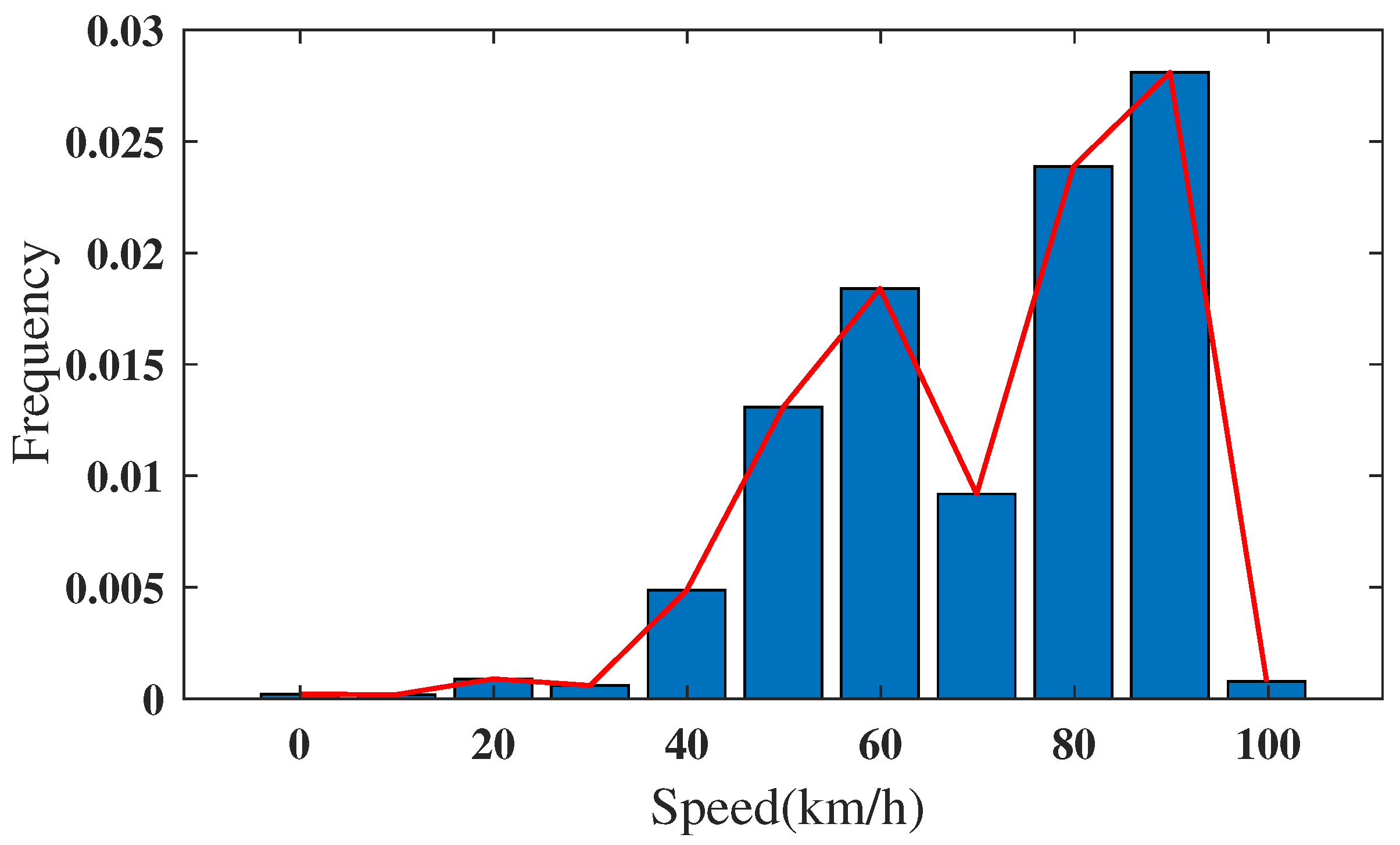

6.2.1. Speed Range Selection

6.2.2. Comparison of Performance in the High-Speed Range

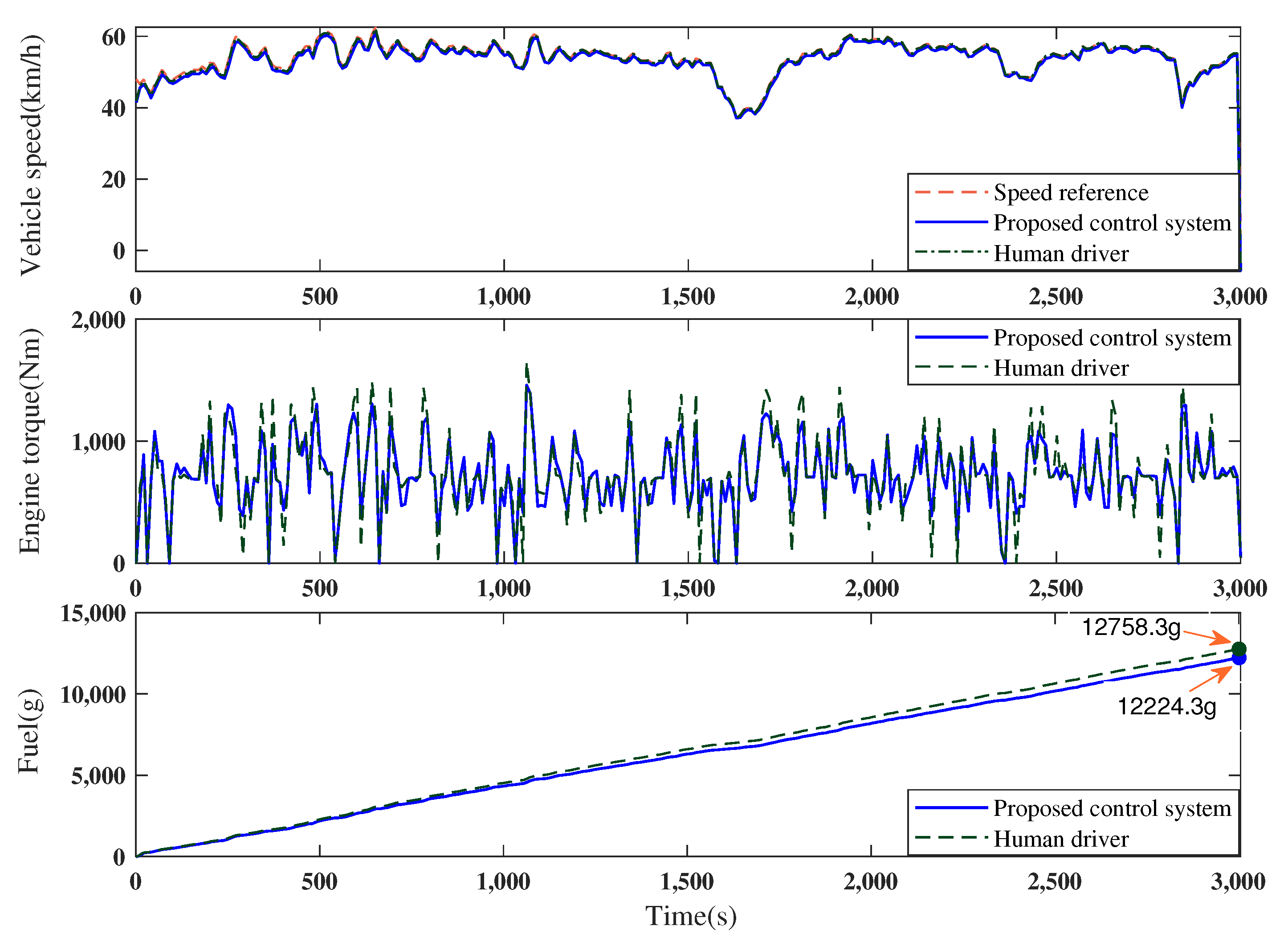

6.2.3. Comparison of Performance in the Medium-Speed Range Range

7. Conclusions

- The style recognition experiments show that the proposed SOM+K-means model, which has the recognition consistency of 90.9% with the GMM model, is accurate enough to recognize the driving styles of different drivers.

- The comparative experiments of the vehicle speed prediction indicate that the inclusion of the driving style feature in the input enhances the overall prediction accuracy compared to the scenario without the introduction of the driving style input.

- The fuel-saving evaluation simulation reveals that the human–machine collaborative driving controller saves 3–4% more fuel than human drivers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Delgado, O.; Rodríguez, F.; Muncrief, R. Fuel efficiency technology in european heavy-duty vehicles: Baseline and potential for the 2020–2030 time frame. Communications 2017, 49, 847129–848102. [Google Scholar]

- Karlsson, I.; Rootzen, J.; Johnsson, F.; Erlandsson, M. Achieving net-zero carbon emissions in construction supply chains–A multidimensional analysis of residential building systems. Dev. Built Environ. 2021, 8, 100059. [Google Scholar] [CrossRef]

- Li, H.; Zhu, D.; Shang, L.; Fan, P. Research on an energy management strategy and energy optimisation of hydraulic hybrid power mining trucks. Int. J. Veh. Des. 2021, 85, 246–273. [Google Scholar] [CrossRef]

- Na, X.; Cebon, D. Quantifying fuel-saving benefit of low-rolling-resistance tyres from heavy goods vehicle in-service operations. Transp. Res. Part D Transp. Environ. 2022, 113, 103501. [Google Scholar] [CrossRef]

- Kawajiri, K.; Kobayashi, M.; Sakamoto, K. Lightweight materials equal lightweight greenhouse gas emissions?: A historical analysis of greenhouse gases of vehicle material substitution. J. Clean. Prod. 2020, 253, 119805. [Google Scholar] [CrossRef]

- McTavish, S.; McAuliffe, B. Improved aerodynamic fuel savings predictions for heavy-duty vehicles using route-specific wind simulations. J. Wind. Eng. Ind. Aerodyn. 2021, 210, 104528. [Google Scholar] [CrossRef]

- Zarrinkolah, M.T.; Hosseini, V. Methane slip reduction of conventional dual-fuel natural gas diesel engine using direct fuel injection management and alternative combustion modes. Fuel 2023, 331, 125775. [Google Scholar] [CrossRef]

- Jia, C.; Zhou, J.; He, H.; Li, J.; Wei, Z.; Li, K.; Shi, M. A novel energy management strategy for hybrid electric bus with fuel cell health and battery thermal-and health-constrained awareness. Energy 2023, 271, 127105. [Google Scholar] [CrossRef]

- Hou, S.; Yin, H.; Pla, B.; Gao, J.; Chen, H. Real-time energy management strategy of a fuel cell electric vehicle with global optimal learning. IEEE Trans. Transp. Electrif. 2023, 16, 2645. [Google Scholar] [CrossRef]

- Chu, H.; Guo, L.; Gao, B.; Chen, H.; Bian, N.; Zhou, J. Predictive cruise control using high-definition map and real vehicle implementation. IEEE Trans. Veh. Technol. 2018, 67, 11377–11389. [Google Scholar] [CrossRef]

- Liang, J.; Feng, J.; Fang, Z.; Lu, Y.; Yin, G.; Mao, X.; Wu, J.; Wang, F. An energy-oriented torque-vector control framework for distributed drive electric vehicles. IEEE Trans. Transp. Electrif. 2023. [Google Scholar] [CrossRef]

- Yang, L.; Bian, Y.; Zhao, X.; Ma, J.; Wu, Y.; Chang, X.; Liu, X. Experimental research on the effectiveness of navigation prompt messages based on a driving simulator: A case study. Cogn. Technol. Work. 2021, 23, 439–458. [Google Scholar] [CrossRef]

- Rohani, M. Bus Driving Behaviour and Fuel Consumption. Ph.D. Thesis, University of Southampton, Southampton, UK, 2012. [Google Scholar]

- Loman, M.; Šarkan, B.; Skrúcanỳ, T. Comparison of fuel consumption of a passenger car depending on the driving style of the driver. Transp. Res. Procedia 2021, 55, 458–465. [Google Scholar] [CrossRef]

- Zhao, X.; Wu, Y.; Rong, J.; Zhang, Y. Development of a driving simulator based eco-driving support system. Transp. Res. Part C Emerg. Technol. 2015, 58, 631–641. [Google Scholar] [CrossRef]

- Tu, R.; Xu, J.; Li, T.; Chen, H. Effective and acceptable eco-driving guidance for human-driving vehicles: A review. Int. J. Environ. Res. Public Health 2022, 19, 7310. [Google Scholar] [CrossRef] [PubMed]

- Gonder, J.; Earleywine, M.; Sparks, W. Analyzing vehicle fuel saving opportunities through intelligent driver feedback. SAE Int. J. Passeng. Cars-Electron. Electr. Syst. 2012, 5, 450–461. [Google Scholar] [CrossRef]

- Xing, Y.; Lv, C.; Cao, D.; Hang, P. Toward human-vehicle collaboration: Review and perspectives on human-centered collaborative automated driving. Transp. Res. Part C Emerg. Technol. 2021, 128, 103199. [Google Scholar] [CrossRef]

- Marcano, M.; Díaz, S.; Pérez, J.; Irigoyen, E. A review of shared control for automated vehicles: Theory and applications. IEEE Trans. Hum.-Mach. Syst. 2020, 50, 475–491. [Google Scholar] [CrossRef]

- Kowol, P.; Nowak, P.; Banaś, W.; Bagier, P.; Lo Sciuto, G. Haptic Feedback Remote Control System for Electric Mechanical Assembly Vehicle Developed to Avoid Obstacles. J. Intell. Robot. Syst. 2023, 107, 41. [Google Scholar] [CrossRef]

- Noubissie Tientcheu, S.I.; Du, S.; Djouani, K. Review on Haptic Assistive Driving Systems Based on Drivers’ Steering-Wheel Operating Behaviour. Electronics 2022, 11, 2102. [Google Scholar] [CrossRef]

- Liu, J.; Dai, Q.; Guo, H.; Guo, J.; Chen, H. Human-oriented online driving authority optimization for driver-automation shared steering control. IEEE Trans. Intell. Veh. 2022, 7, 863–872. [Google Scholar] [CrossRef]

- Erlien, S.M.; Fujita, S.; Gerdes, J.C. Shared steering control using safe envelopes for obstacle avoidance and vehicle stability. IEEE Trans. Intell. Transp. Syst. 2015, 17, 441–451. [Google Scholar] [CrossRef]

- Chu, H.; Guo, L.; Yan, Y.; Gao, B.; Chen, H. Self-learning optimal cruise control based on individual car-following style. IEEE Trans. Intell. Transp. Syst. 2021, 22, 6622–6633. [Google Scholar] [CrossRef]

- Chu, H.; Zhuang, H.; Wang, W.; Na, X.; Guo, L.; Zhang, J.; Gao, B.; Chen, H. A Review of Driving Style Recognition Methods From Short-Term and Long-Term Perspectives. IEEE Trans. Intell. Veh. 2023. [Google Scholar] [CrossRef]

- Lian, J.; Wang, X.r.; Li, L.h.; Zhou, Y.f.; Yu, S.z.; Liu, X.j. Plug-in HEV energy management strategy based on SOC trajectory. Int. J. Veh. Des. 2020, 82, 1–17. [Google Scholar] [CrossRef]

- Zhang, B.; Yu, W.; Jia, Y.; Huang, J.; Yang, D.; Zhong, Z. Predicting vehicle trajectory via combination of model-based and data-driven methods using Kalman filter. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2023, 09544070231161846. [Google Scholar] [CrossRef]

- Ammoun, S.; Nashashibi, F. Real time trajectory prediction for collision risk estimation between vehicles. In Proceedings of the 2009 IEEE 5th International Conference on Intelligent Computer Communication and Processing, Cluj-Napoca, Romania, 27–29 August 2009; pp. 417–422. [Google Scholar]

- Shen, H.; Wang, Z.; Zhou, X.; Lamantia, M.; Yang, K.; Chen, P.; Wang, J. Electric Vehicle Velocity and Energy Consumption Predictions Using Transformer and Markov-Chain Monte Carlo. IEEE Trans. Transp. Electrif. 2022, 8, 3836–3847. [Google Scholar] [CrossRef]

- Daugherty, P.R.; Wilson, H.J. Human + Machine: Reimagining Work in the Age of AI; Harvard Business Press: Boston, MA, USA, 2018. [Google Scholar]

- Liu, J.; Guo, H.; Song, L.; Dai, Q.; Chen, H. Driver-automation shared steering control for highly automated vehicles. Sci. China Inf. Sci. 2020, 63, 63. [Google Scholar] [CrossRef]

- Mosharafian, S.; Razzaghpour, M.; Fallah, Y.P.; Velni, J.M. Gaussian process based stochastic model predictive control for cooperative adaptive cruise control. In Proceedings of the 2021 IEEE Vehicular Networking Conference (VNC), Ulm, Germany, 10–12 November 2021; pp. 17–23. [Google Scholar]

- Mulder, M.; Abbink, D.A.; Boer, E.R. Sharing control with haptics: Seamless driver support from manual to automatic control. Hum. Factors 2012, 54, 786–798. [Google Scholar] [CrossRef]

- Brandt, T.; Sattel, T.; Bohm, M. Combining haptic human-machine interaction with predictive path planning for lane-keeping and collision avoidance systems. In Proceedings of the 2007 IEEE Intelligent Vehicles Symposium, Istanbul, Turkey, 13–15 June 2007; pp. 582–587. [Google Scholar]

- Li, R.; Li, Y.; Li, S.E.; Burdet, E.; Cheng, B. Driver-automation indirect shared control of highly automated vehicles with intention-aware authority transition. In Proceedings of the 2017 IEEE Intelligent Vehicles Symposium (IV), Angeles, CA, USA, 11–14 June 2017; pp. 26–32. [Google Scholar]

- Flemisch, F.; Heesen, M.; Hesse, T.; Kelsch, J.; Schieben, A.; Beller, J. Towards a dynamic balance between humans and automation: Authority, ability, responsibility and control in shared and cooperative control situations. Cogn. Technol. Work. 2012, 14, 3–18. [Google Scholar] [CrossRef]

| Driving Scenario | Feature | |

|---|---|---|

| Low speed | Accelerating | Acceleration |

| Speed | ||

| Maintenance | Speed | |

| Accelerator pedal | ||

| Jerk | ||

| Medium speed | Accelerating | Acceleration |

| Maintenance | Acceleration | |

| High speed | Accelerating | Acceleration |

| Jerk | ||

| Maintenance | Speed | |

| Acceleration | ||

| Jerk | ||

| Brake pedal | ||

| Variable | Spe | Dri-Sty | Acc | Rela-Spe | Rela-Dis |

|---|---|---|---|---|---|

| S1 | * | * | |||

| S2 | * | * | * | ||

| S3 | * | * | * | ||

| S4 | * | * | * |

| Variable | Spe | Rela-Spe | Dri-Sty |

|---|---|---|---|

| S3 | * | * | * |

| S5 | * | * |

| Method Conditions | High-Speed Range | Medium-Speed Range |

|---|---|---|

| Driver | 27,754.6 g | 12,758.3 g |

| Proposed control system | 26,897.4 g | 12,224.3 g |

| Fuel saving rate | 3.04% | 4.1% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chu, H.; Li, Z.; Wang, J.; Hong, J. Fuel-Saving-Oriented Collaborative Driving Strategy for Commercial Vehicles Based on Driving Style Recognition. Energies 2023, 16, 6163. https://doi.org/10.3390/en16176163

Chu H, Li Z, Wang J, Hong J. Fuel-Saving-Oriented Collaborative Driving Strategy for Commercial Vehicles Based on Driving Style Recognition. Energies. 2023; 16(17):6163. https://doi.org/10.3390/en16176163

Chicago/Turabian StyleChu, Hongqing, Zongxuan Li, Jialin Wang, and Jinlong Hong. 2023. "Fuel-Saving-Oriented Collaborative Driving Strategy for Commercial Vehicles Based on Driving Style Recognition" Energies 16, no. 17: 6163. https://doi.org/10.3390/en16176163