Replacement Scenarios of LPG Boilers with Air-to-Water Heat Pumps for a Production Manufacturing Site

Abstract

:1. Introduction

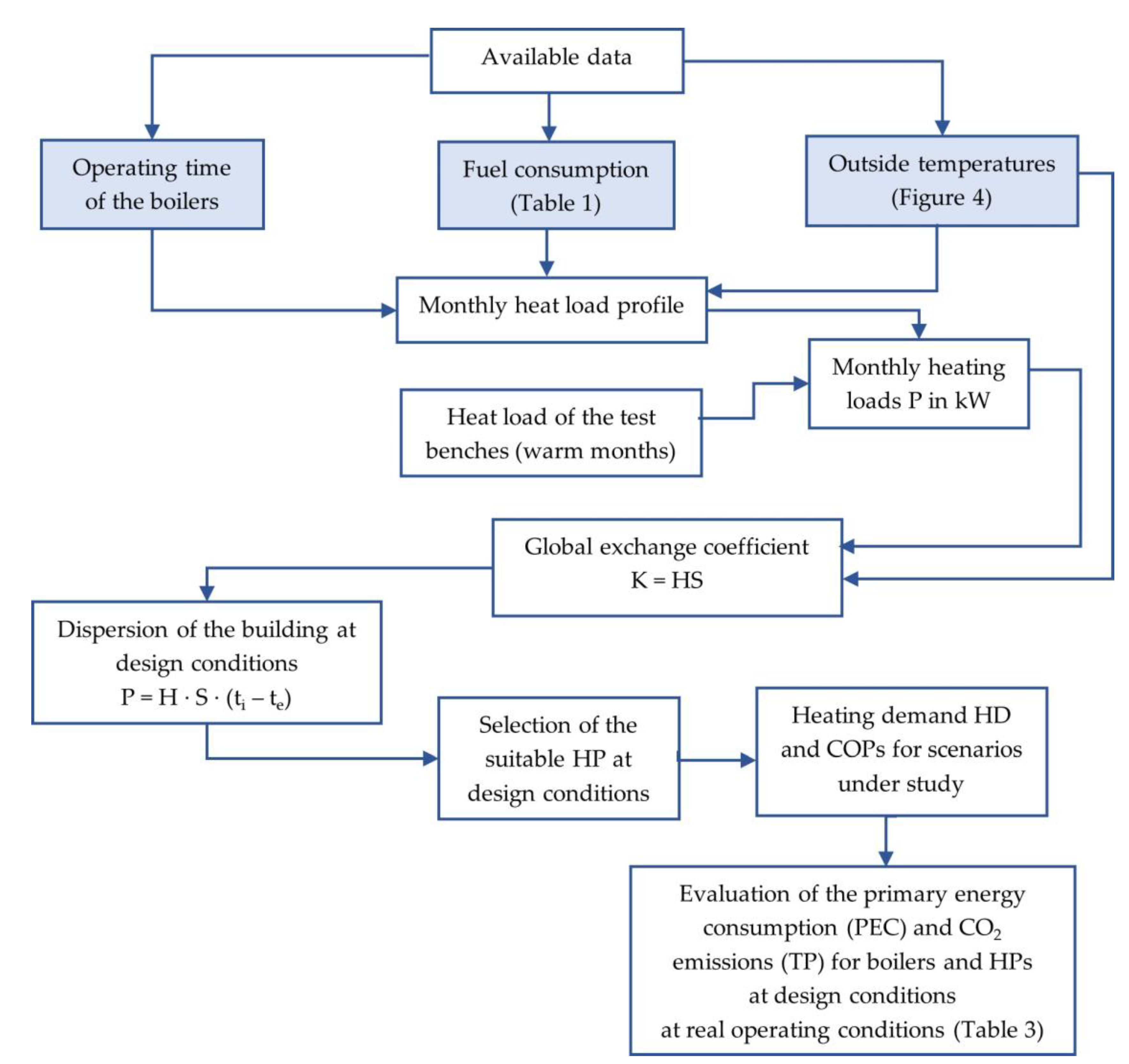

2. Materials and Methods

- (1)

- Selection of the HP from the design conditions

- (2)

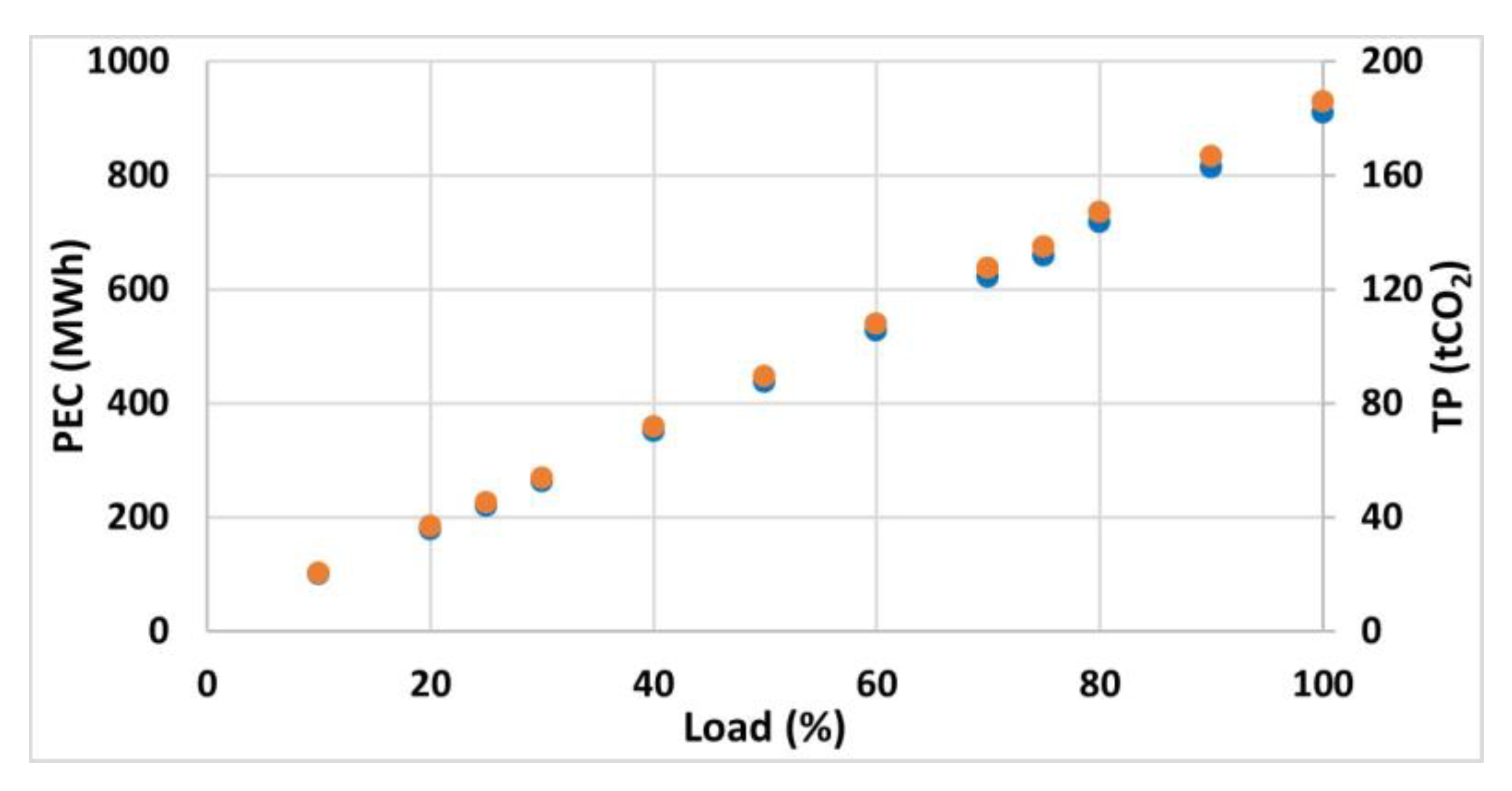

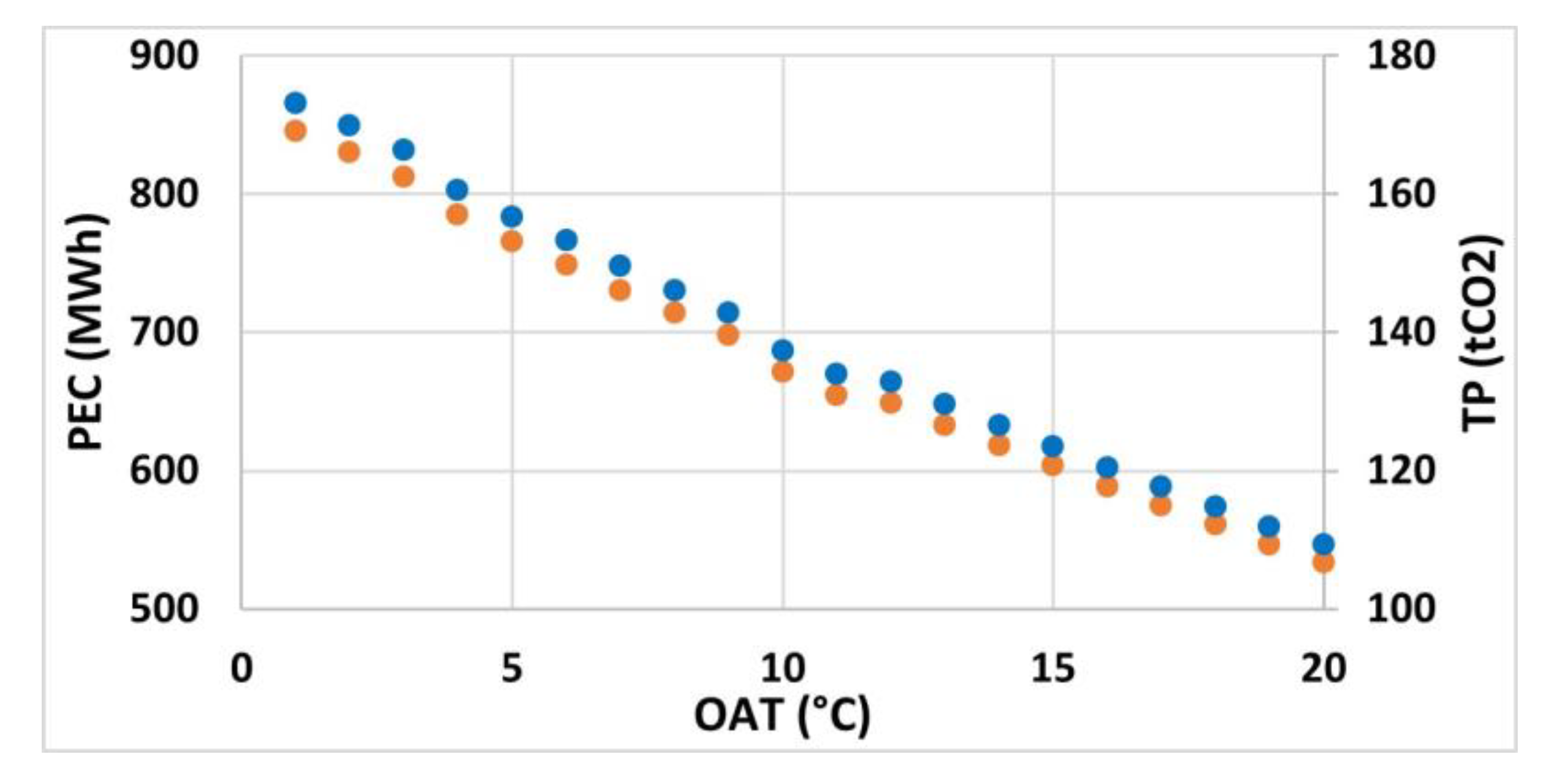

- Evaluation of primary energy consumption and CO2 production for the boilers and the HP.

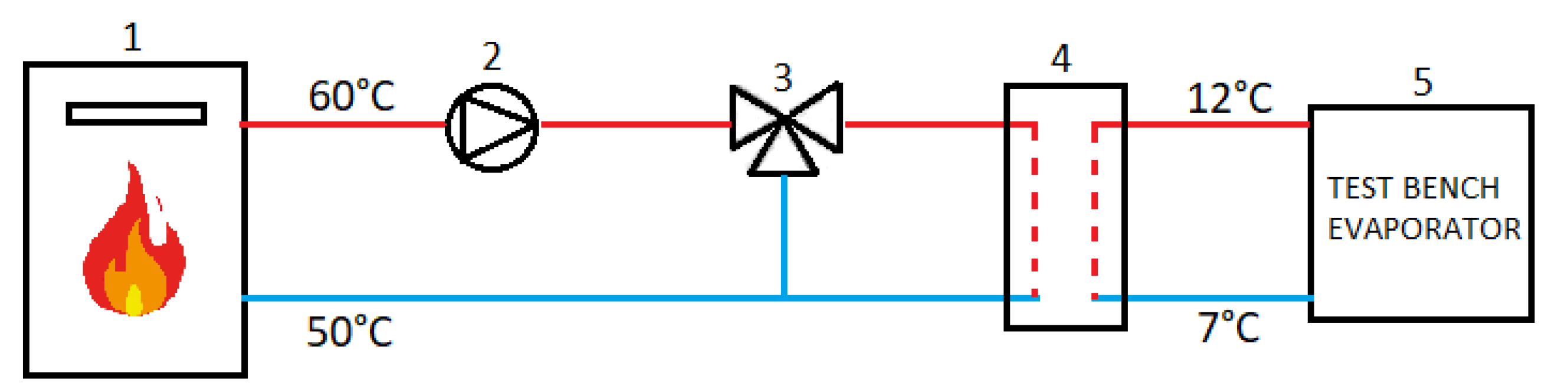

2.1. Description of the Case Study

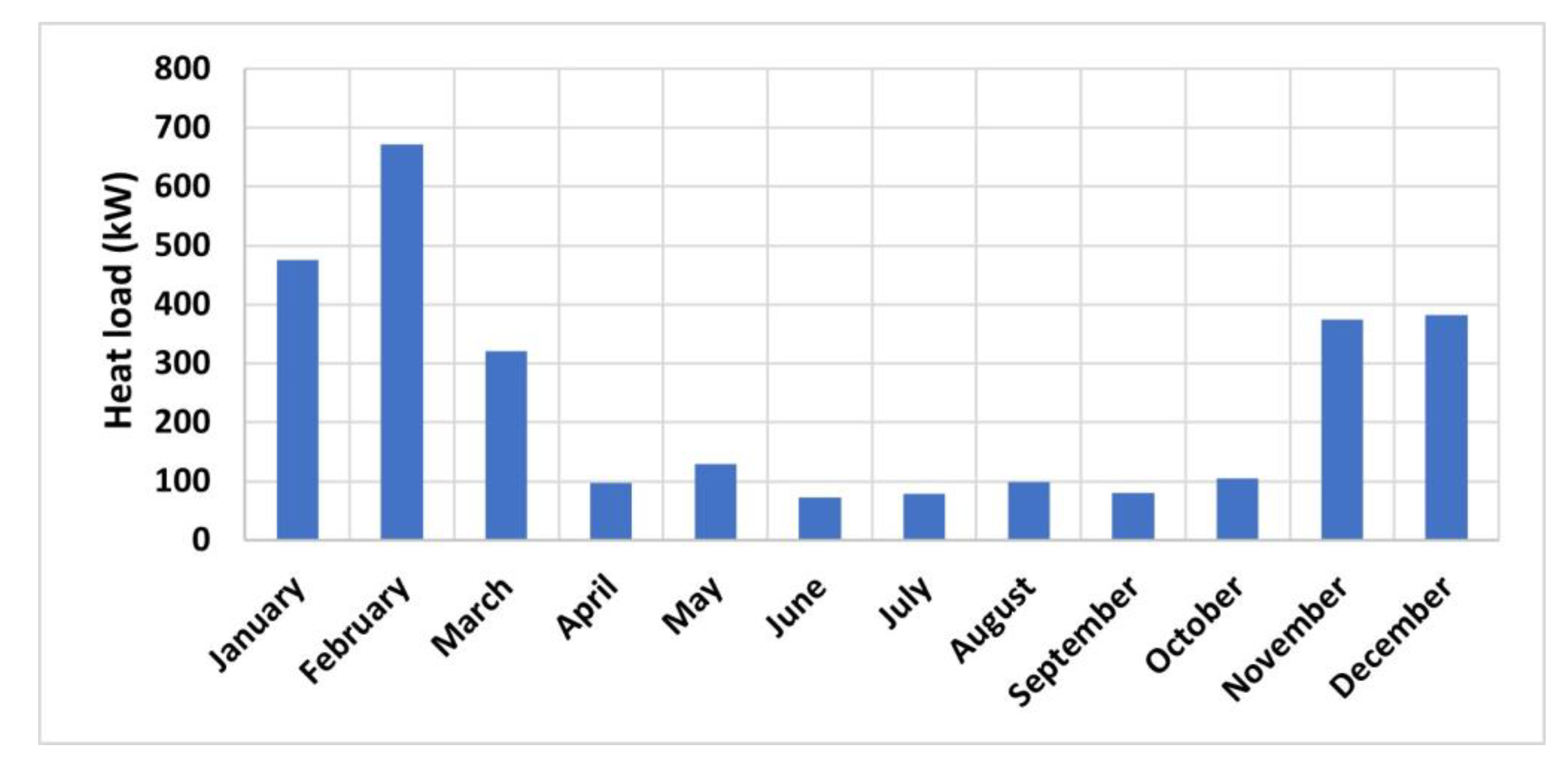

2.2. Evaluation of the Monthly Heat Load and Temperature Profiles

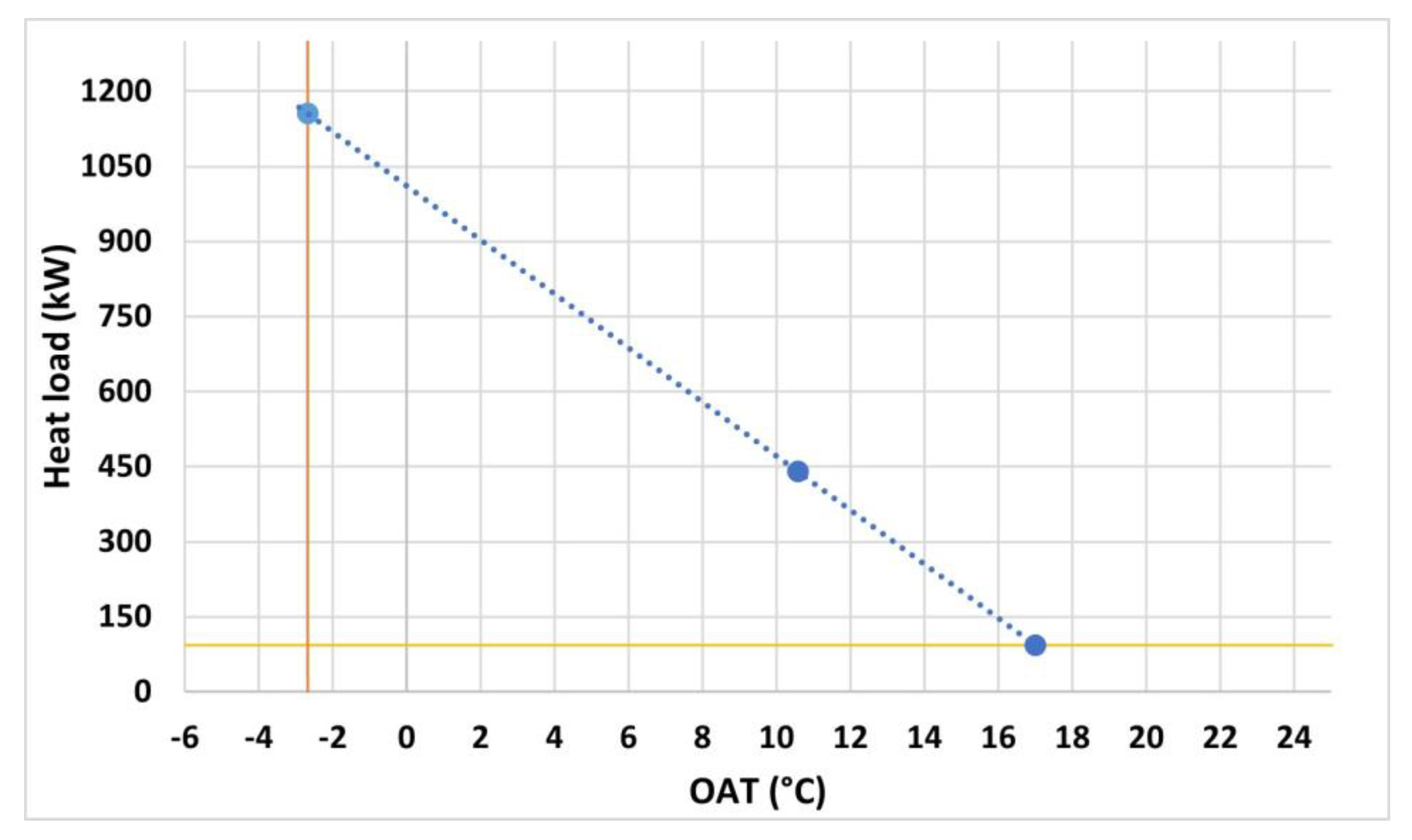

2.3. Selection of the Suitable Heat Pump

- (1)

- The first point is (17 °C; 0 kW), at which point generally the free thermal inputs cancel out the power requirement for space heating of most buildings, with the indoor temperature being equal to 20 °C.

- (2)

- The second point (10.6 °C; 440 kW) is given by the average seasonal temperature and the average seasonal power use during the heating period; the average seasonal power can be deduced as the ratio between the seasonal fuel consumption, expressed in kWh, and the heating period, expressed in hours.

3. Results

3.1. Design Conditions Scenario

3.2. Scenario of Real Operating Conditions

4. Discussion

Economic Considerations

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee, and the Committee of the Regions. The European Green Deal; European Commission: Brussels, Belgium, 2019; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A52019DC0640 (accessed on 13 March 2023).

- The International Energy Agency, IEA. Global Status Report. 2017. Available online: https://globalabc.org/sites/default/files/2020-09/2017%20GlobalABC%20GSR%20.pdf (accessed on 12 March 2023).

- The European Partnership for Energy and the Environment, EPEE. Decarbonising Heating & Cooling in Europe. Available online: https://epeeglobal.org/wp-content/uploads/2022/01/Decarbonising-heating-and-cooling-EPEE_One_Pager.pdf (accessed on 12 March 2023).

- Leung, J. Decarbonizing US Buildings. Center for Climate and Energy Solutions, 2018. Available online: https://www.c2es.org/wp-content/uploads/2018/06/innovation-buildings-background-brief-07-18.pdf (accessed on 13 March 2023).

- Lin, B.; Liu, H. CO2 emissions of China’s commercial and residential buildings: Evidence and reduction policy. Build. Environ. 2015, 92, 418–431. [Google Scholar] [CrossRef]

- Carella, A.; D’Orazio, A. The heat pumps for better air quality. Sustain. Cities Soc. 2021, 75, 103314. [Google Scholar] [CrossRef] [PubMed]

- Caputo, A. Istituto Superiore per la Protezione e la Ricerca Ambientale ISPRA, Indicatori di Efficienza e Decarbonizzazione del Sistema Energetico Nazionale e del Settore Elettrico; Higher Institute for Environmental Protection and Research—ISPRA: Rome, Italy, 2022; pp. 1–108. (In Italian) [Google Scholar]

- Minuto, F.D.; Lazzeroni, P.; Borchiellini, R.; Olivero, S.; Bottaccioli, L.; Lanzini, A. Modeling technology retrofit scenarios for the conversion of condominium into an energy community: An Italian case study. J. Clean. Prod. 2021, 282, 124536. [Google Scholar] [CrossRef]

- Jadwiszczak, P.; Jurasz, J.; Kazmierczak, B.; Niemierka, E.; Zheng, W. Factors Shaping A/W Heat Pumps CO2 Emissions—Evidence from Poland. Energies 2021, 14, 1576. [Google Scholar] [CrossRef]

- Carella, A.; Del Ferraro, L.; D’Orazio, A. Air/Water Heat Pumps in Existing Heating and Hot Water Systems for Better Urban Air Quality and Primary Energy Savings: Scenarios of Two Italian Cities. Energies 2022, 16, 377. [Google Scholar] [CrossRef]

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review of buildings’ energy consumption information. Energy Build. 2008, 40, 394–398. [Google Scholar] [CrossRef]

- Gradziuk, P.; Siudek, A.; Klepacka, A.; Florkowski, W.; Trocewicz, A.; Skorokhod, I. Heat Pump Installation in Public Buildings: Savings and Environmental Benefits in Underserved Rural Areas. Energies 2022, 15, 7903. [Google Scholar] [CrossRef]

- Dongellini, M.; Naldi, C.; Morini, G.L. Seasonal performance evaluation of electric air-to-water heat pump systems. Appl. Therm. Eng. 2015, 90, 1072–1081. [Google Scholar] [CrossRef]

- Katipamula, S.; O’Neal, D.L. A part load factor for heat pump derived from laboratory measurements. Energy Build. 1992, 19, 125–132. [Google Scholar] [CrossRef]

- Mouzeviris, G.A.; Papakostas, K.T. Study on Air-to-Water Heat Pumps Seasonal Performances for Heating in Greece. Energies 2022, 15, 279. [Google Scholar] [CrossRef]

- Rossi di Schio, E.; Ballerini, V. The scope of an air source heat pump: Comparison between on-off and inverter heat pump. JP J. Heat Mass Transf. 2021, 24, 79–86. [Google Scholar] [CrossRef]

- UNI TR 10349-2:2016; Heating and Cooling of Buildings—Climatic Data—Part 2: Data for Design Load. UNI—Ente Italiano di Normazione: Milan, Italy, 2016.

- IlMeteo. Available online: https://www.ilmeteo.it/portale/archivio-meteo/Cecchina/2022 (accessed on 3 March 2023).

- UNI EN 12831:2018; Energy Performance of Buildings—Method for Calculation of the Design Heat Load—Part 1: Space Heating Load. UNI—Ente Italiano di Normazione: Milan, Italy, 2018.

- Socal, L.; Soma, F. La Firma Energetica. Available online: https://www.progetto2000web.com/assets/repository/p2000/pdf/p2000-36.pdf (accessed on 23 March 2023).

- Mota-Babiloni, A.; Navarro-Esbrí, J.; Makhnatch, P.; Molés, F. Refrigerant R32 as lower GWP working fluid in residential air conditioning systems in Europe and the USA. Renew. Sust. Energ. Rev. 2017, 80, 1031–1042. [Google Scholar] [CrossRef]

- United Nations Framework Convention on Climate Change UNFCCC, National Inventory of CO2 Emission Coefficients. Available online: https://www.assolombarda.it/servizi/ambiente/informazioni/ets-tabella-parametri-standard-nazionali (accessed on 14 March 2023).

- UNI EN 14825:2019; Air Conditioners, liquid Chilling Packages and Heat Pumps, with Electrically Driven Compressors, for Space Heating and Cooling—Testing and Rating at Part Load Conditions and Calculation of Seasonal Performance. UNI—Ente Italiano di Normazione: Milan, Italy, 2019.

- UNI EN 13284-1:2017; Stationary Source Emissions—Determination of Low Range Mass Concentration of Dust—Part 1: Manual Gravimetric Method. UNI—Ente Italiano di Normazione: Milan, Italy, 2017.

- UNI EN 15058:2017; Stationary Source Emissions—Determination of the Mass Concentration of Carbon Monoxide—Standard Reference Method: Non-Dispersive Infrared Spectrometry. UNI—Ente Italiano di Normazione: Milan, Italy, 2017.

- UNI EN 14792:2017; Stationary Source Emissions—Determination of Mass Concentration of Nitrogen Oxides—Standard Reference Method: Chemiluminescence. UNI—Ente Italiano di Normazione: Milan, Italy, 2017.

- UNI EN 14791:2017; Stationary Source Emissions—Determination of Mass Concentration of Sulfur Oxides—Standard Reference Method. UNI—Ente Italiano di Normazione: Milan, Italy, 2017.

- Koumi Ngoh, S.; Epessé Missé, S.; Moungnutou Mfetoum, I. Environmental and economic assessment of switching from heavy fuel oil to natural gas in industrial boilers and furnaces: Case of Cameroon, a low-income country. Front. Energy Res. 2022, 10, 1053576. [Google Scholar] [CrossRef]

- Shibata, N.; Sierra, F.; Hagras, A. Integration of LCA and LCCA through BIM for optimized decision-making when switching from gas to electricity services in dwellings. Energy Build. 2023, 288, 113000. [Google Scholar] [CrossRef]

- Neumann, G.; Schropp, E.; Gaderer, M. Life Cycle Assessment of an Air-Source Heat Pump and a Condensing Gas Boiler Using an Attributional and a Consequential Approach. Procedia CIRP 2022, 105, 351–356. [Google Scholar] [CrossRef]

- MISE, Ministry of Economic Development. DM 16-02-2016. Update of the Framework for the Promotion of Small-Scale Interventions to Increase Energy Efficiency and for the Production of Thermal Energy from Renewable Sources. Available online: https://www.gazzettaufficiale.it/eli/id/2016/03/02/16A01548/sg (accessed on 20 April 2023).

- Desideri, U.; Krayem, A.; Thorin, E. The Unprecedented Natural Gas Crisis in Europe: Investigating the Causes and Consequences with a Focus on Italy. Energies 2023, 16, 5954. [Google Scholar] [CrossRef]

| Month | Consumption (m3) | Consumption (L) |

|---|---|---|

| January | 7708 | 29,291 |

| February | 10,210 | 38,797 |

| March | 5547 | 21,079 |

| April | 1582 | 6012 |

| May | 2133 | 8105 |

| June | 1195 | 4541 |

| July | 1262 | 4796 |

| August | 1708 | 6490 |

| September | 1336 | 5077 |

| October | 1707 | 6487 |

| November | 6214 | 23,613 |

| December | 6462 | 24,556 |

| Total | 47,064 | 178,844 |

| Month | HC, kW | OAT, °C | COP | PI, kW |

|---|---|---|---|---|

| January | 238.0 | 7.6 | 3.289 | 71.4 |

| February | 335.9 | 10.0 | 3.392 | 99.0 |

| March | 160.3 | 9.9 | 3.449 | 45.5 |

| April | 48.8 | 13.6 | 3.253 | 15.1 |

| May | 64.3 | 20.7 | 3.884 | 16.5 |

| June | 36.0 | 26.1 | 4.379 | 8.2 |

| July | 39.0 | 27.9 | 4.600 | 8.5 |

| August | 49.4 | 26.7 | 3.981 | 12.3 |

| September | 40.2 | 22.6 | 3.494 | 11.5 |

| October | 52.7 | 19.1 | 3.586 | 14.9 |

| November | 187.2 | 13.5 | 3.742 | 50.0 |

| December | 191.2 | 11.9 | 3.612 | 52.9 |

| Month | Primary Energy Needs, kWh | CO2 Emissions, kg CO2 | ||

|---|---|---|---|---|

| Boilers | Heat Pumps | Boilers | Heat Pumps | |

| January | 193,460 | 75,879 | 45,735 | 15,532 |

| February | 256,248 | 97,454 | 60,579 | 19,949 |

| March | 139,225 | 52,074 | 32,914 | 10,659 |

| April | 39,705 | 15,746 | 9387 | 3223 |

| May | 53,535 | 17,781 | 12,656 | 3640 |

| June | 29,992 | 8836 | 7090 | 1809 |

| July | 31,674 | 8883 | 7488 | 1818 |

| August | 42,868 | 13,891 | 10,134 | 2843 |

| September | 33,531 | 12,380 | 7927 | 2534 |

| October | 42,843 | 15,412 | 10,128 | 3155 |

| November | 155,960 | 53,766 | 36,870 | 11,006 |

| December | 162,185 | 57,924 | 38,342 | 11,857 |

| Total | 1,181,226 | 430,025 | 279,249 | 88,026 |

| Pollutant | Concentration (mg/Nm3) | Limit Value (mg/Nm3) |

|---|---|---|

| Dust | 1.4 ± 0.5 | 10 |

| CO | <4.6 | 150 |

| NO2 | 112 ± 4.1 | 350 |

| SO2 | <3.5 | 35 |

| Prices 2022 | Prices 2023 | |||

|---|---|---|---|---|

| Design Conditions | Real Operating Conditions | Design Conditions | Real Operating Conditions | |

| Without incentive | 12 y 302 d | 8 y 363 d | / | 29 y 288 d |

| With incentive | 4 y 261 d | 4 y 35 d | / | 9 y 274 d |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carella, A.; Del Ferraro, L.; D’Orazio, A. Replacement Scenarios of LPG Boilers with Air-to-Water Heat Pumps for a Production Manufacturing Site. Energies 2023, 16, 6233. https://doi.org/10.3390/en16176233

Carella A, Del Ferraro L, D’Orazio A. Replacement Scenarios of LPG Boilers with Air-to-Water Heat Pumps for a Production Manufacturing Site. Energies. 2023; 16(17):6233. https://doi.org/10.3390/en16176233

Chicago/Turabian StyleCarella, Alberta, Luca Del Ferraro, and Annunziata D’Orazio. 2023. "Replacement Scenarios of LPG Boilers with Air-to-Water Heat Pumps for a Production Manufacturing Site" Energies 16, no. 17: 6233. https://doi.org/10.3390/en16176233

APA StyleCarella, A., Del Ferraro, L., & D’Orazio, A. (2023). Replacement Scenarios of LPG Boilers with Air-to-Water Heat Pumps for a Production Manufacturing Site. Energies, 16(17), 6233. https://doi.org/10.3390/en16176233