Studies on Flow Characteristics of Gas–Liquid Multiphase Pumps Applied in Petroleum Transportation Engineering—A Review

Abstract

1. Introduction

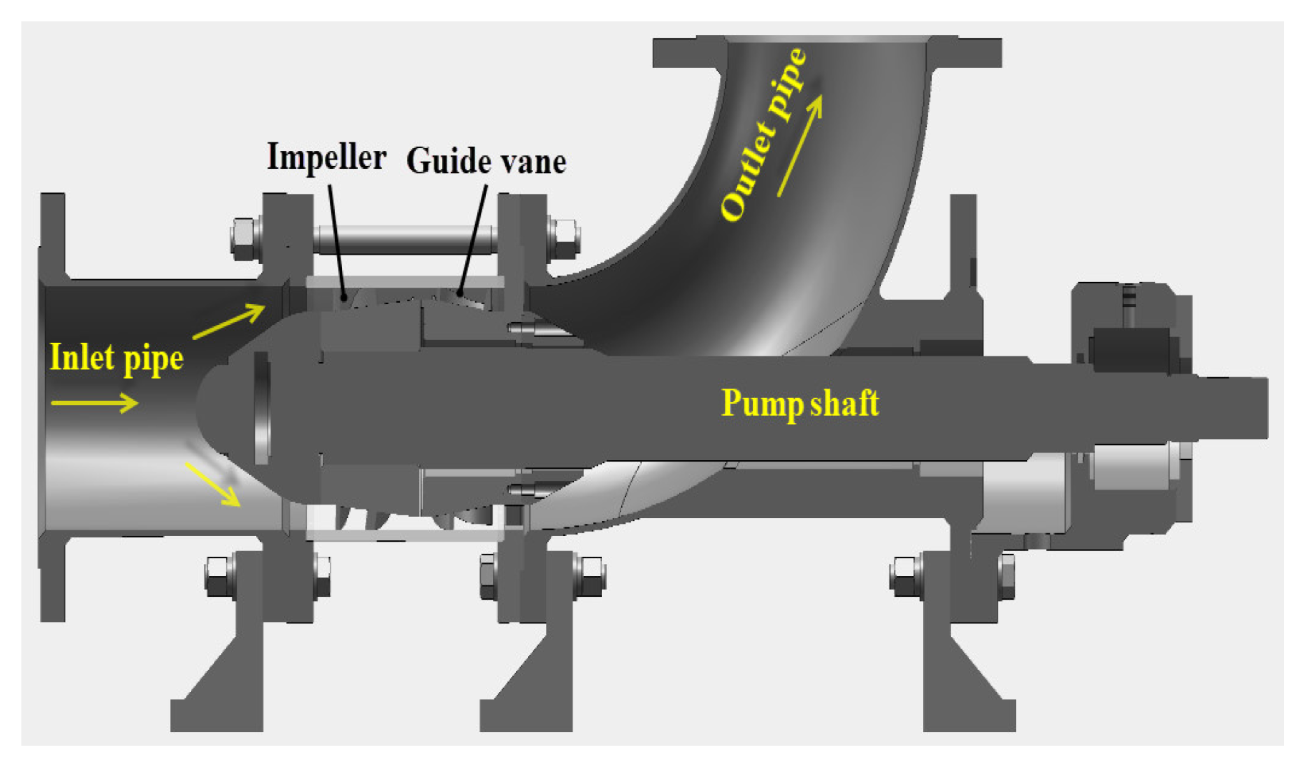

2. Multiphase Pump Type

| United States | Britain | Germany | Japan | China | Russia |

|---|---|---|---|---|---|

| Screw pump | Screw pump | Screw pump | Centrifugal pump | Screw pump | Screw pump |

| Liquid-ring pump | Axial pump | Vortex pump | Vortex pump | Liquid-ring pump | Liquid-ring pump |

| Centrifugal pump | / | / | Screw pump | / | / |

| Types | Multiphase Pump | |

|---|---|---|

| Merit | Defect | |

| Screw pump | High pressure (up to (5~12) × 105 Pa) High efficiency (20~50%) Large discharge capacity Simple structure | Small oil–gas ratio (up to 20) Easy temperature rise Sensitive to solid particles High manufacturing requirements High price |

| Liquid-ring pump | Large oil–gas ratio (up to 10~1000) Insensitive to solid particles Low price | Low pressure Low efficiency Small discharge capacity (120~600 m3/h) |

| Axial pump | Large discharge capacity (1500 m3/h) High efficiency Simple structure High pressure with a few units | Small oil–gas ratio (up to 10) performance deteriorates with the increased oil–gas ratio |

| Centrifugal pump | High pressure Large discharge capacity Simple structure Easy manufacturing Low price High efficiency | Small gas–liquid ratio |

| Vortex pump | Large discharge capacity | Small gas–liquid ratio (up to 10) Low efficiency Complex structure |

3. Experimental Studies of Multiphase Pumps

3.1. Energy Performance Testing

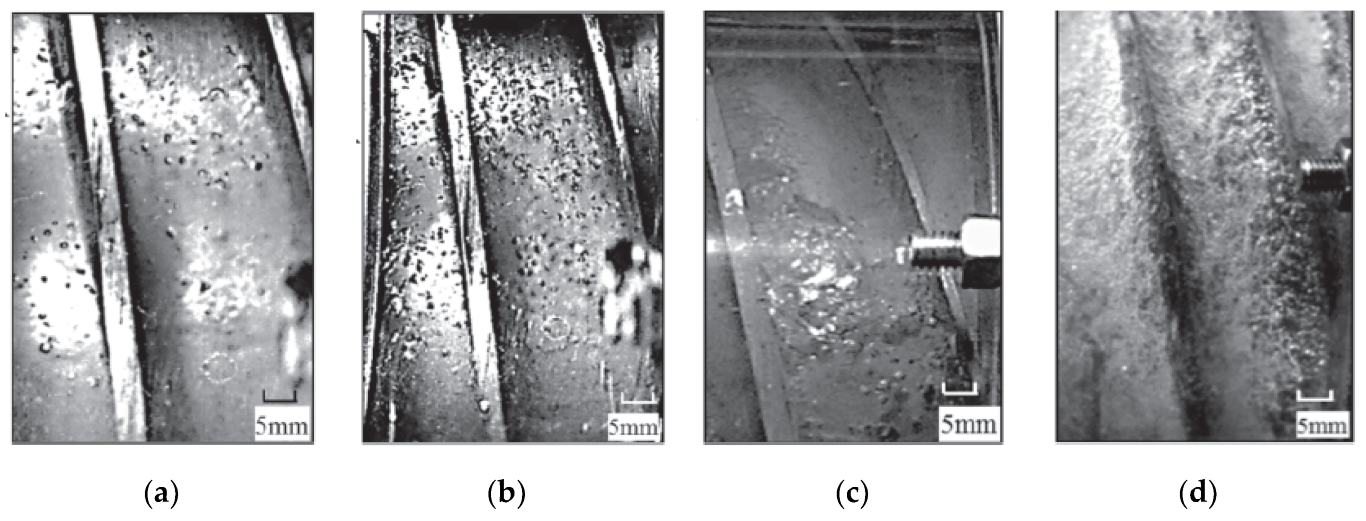

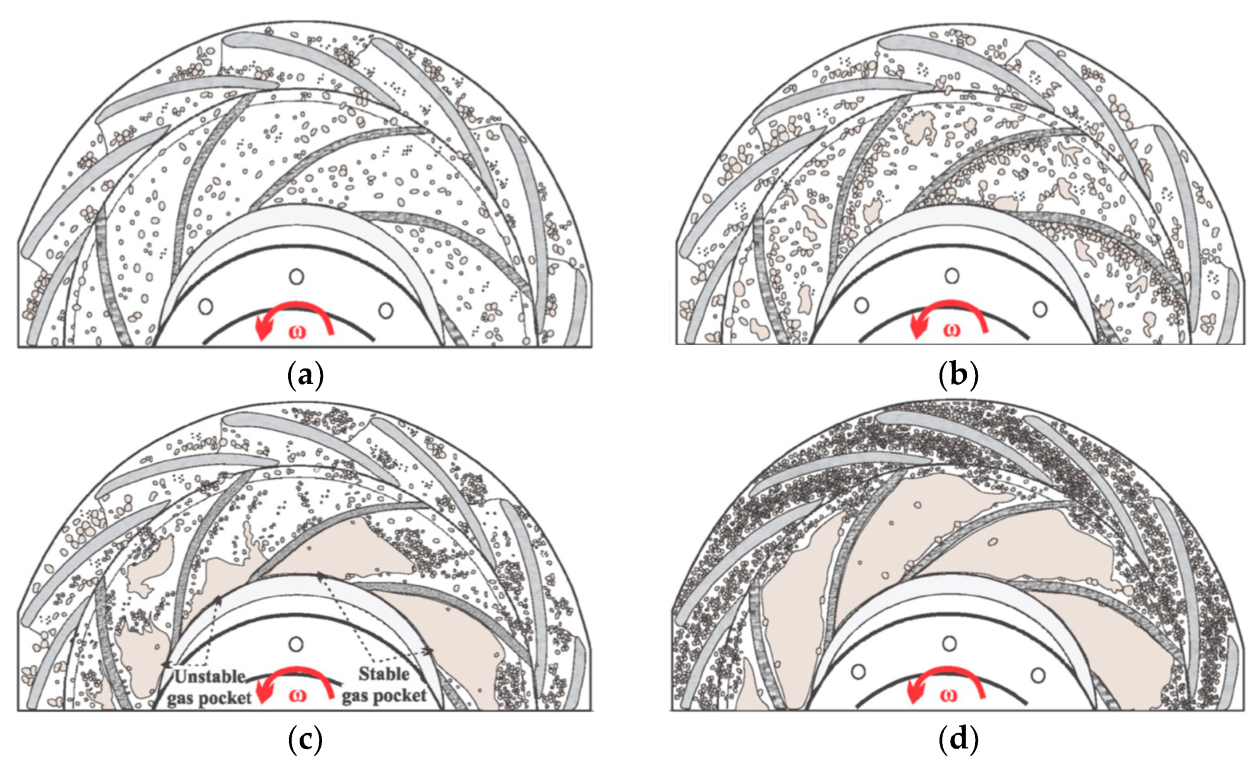

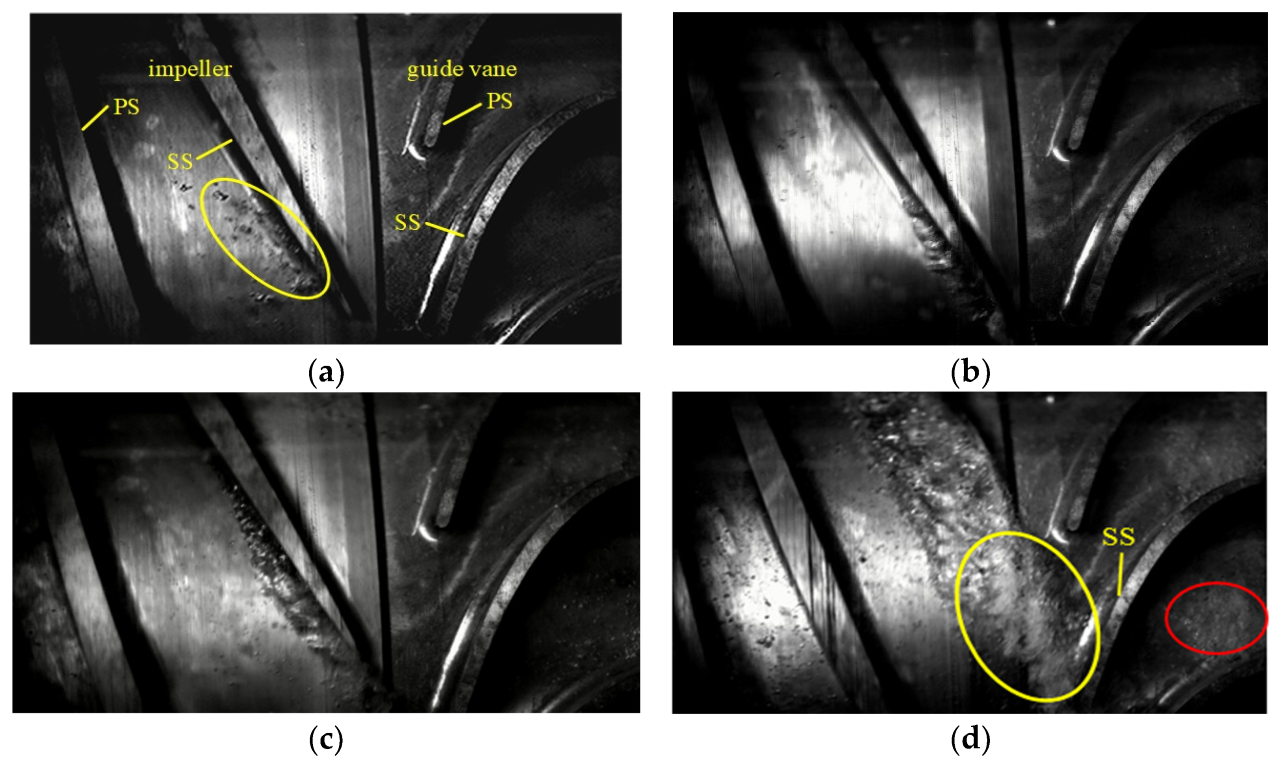

3.2. Flow Patterns

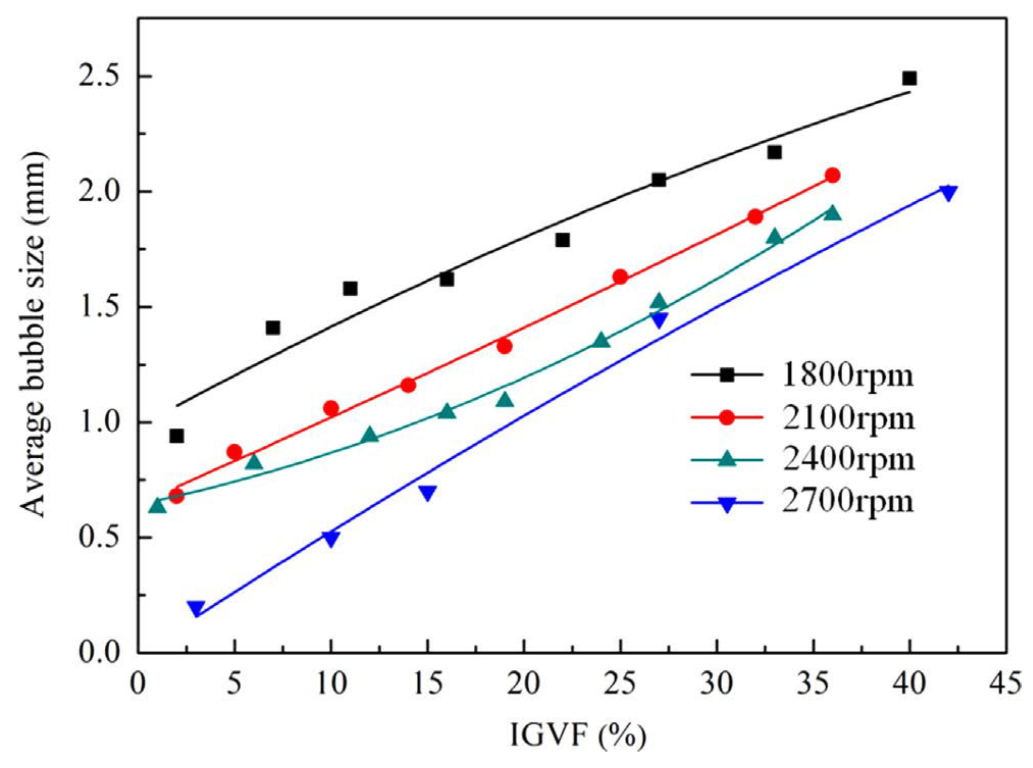

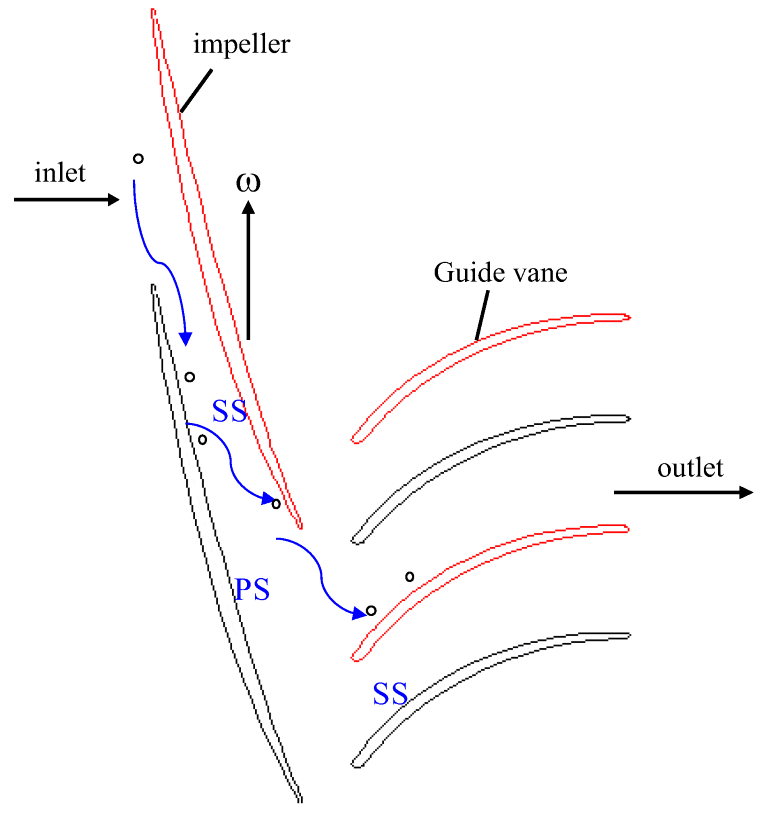

3.3. Bubble Motion

4. Numerical Methods on Flow Mechanism

4.1. Turbulence Model

| Turbulence Model | Author | Object | Main Conclusion |

|---|---|---|---|

| k-ε | Zhu et al. (2017) [68] | Three-stage centrifugal ESP | The relationship between bubble size and GVF is determined. |

| He et al. (2020) [57] | Centrifugal pump | There is a great scattering of the void fraction at high-rotation speeds. | |

| Caridad et al. (2008) [55] | Centrifugal pump | The gas pocket increases hydraulic losses. | |

| Pineda et al. (2016) [56] | Centrifugal ESP | The head decreases at higher gas flow rates and lower intake pressures. | |

| RNG k-ε | Ma et al. (2020) [58] | Reciprocating multiphase pump | The instantaneous two-phase distribution and fluctuation characteristics at high GVFs are determined. |

| Liu et al. (2020) [59] | Three-stage helico-axial multiphase pump | Increases in viscosity and blade height as well as decreases in flow rate increase turbulent kinetic energy. | |

| SST k-ω | Kim et al. (2015) [60] | Helico-axial multiphase pump | Hydrodynamic performance is improved by an optimization design method. |

| Yu et al. (2015) [27] | Axial multiphase pump | Drag force is dominant and turbulent dispersion force can be neglected. | |

| Stel et al. (2015) [61] | Mixed-type ESP | Pressure difference and flow pattern are obtained at different flow rates. | |

| Pervaiz et al. (2022) [62] | Centrifugal pump | Turbulence increases with the increase in GVF in the impeller. | |

| Shu et al. (2022) [63] | Helico-axial multiphase pump | The relationship between vorticity and enstrophy dissipation rate is obtained. |

4.2. Turbulence Model Two-Phase Flow Model

| Numerical Methods | Two-Phase Flow Model | Feature | Disadvantage |

|---|---|---|---|

| Euler–Lagrange method | Discrete phase model [70] | The velocity and motion trajectory of the discrete phase are easily obtained. | Suitable for IGVF of less than 10% and very low computational efficiency. |

| Euler–Euler method | Homogeneous model [72] | The two media are equivalent to a pure substance. | Ignored the phase interaction and large calculation error. |

| Diffusion model [71] | The average motion and diffusion motion are considered. | Not applicable for large diffusion speed. | |

| Two-fluid model [27,73,74] | Each medium has its conservation equations, and phase interactions are considered. | Low calculation efficiency and difficulty in convergence. |

| Items | Symbol | Expression |

|---|---|---|

| Drag | FD | |

| Lift | FL | |

| Added mass force | FA | |

| Turbulent dispersion force | FT | |

| Basset force | FB | |

| Magnus force | FM | |

| Staffman force | FS | |

| Inertia force | Fi | |

| Pressure difference force | Fp |

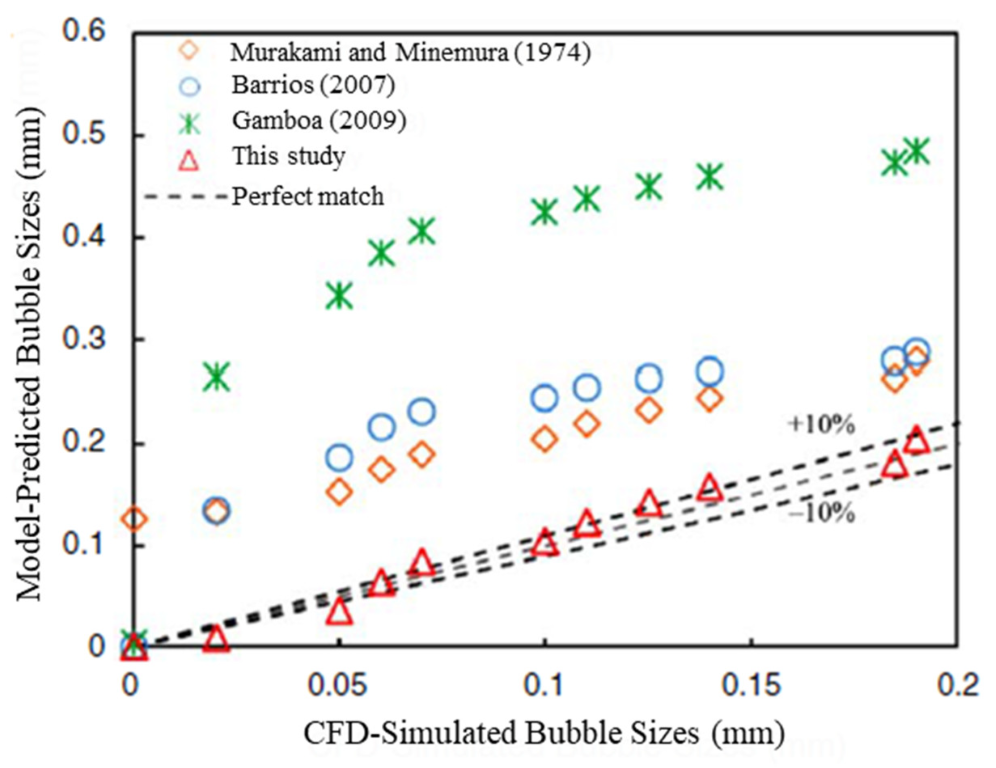

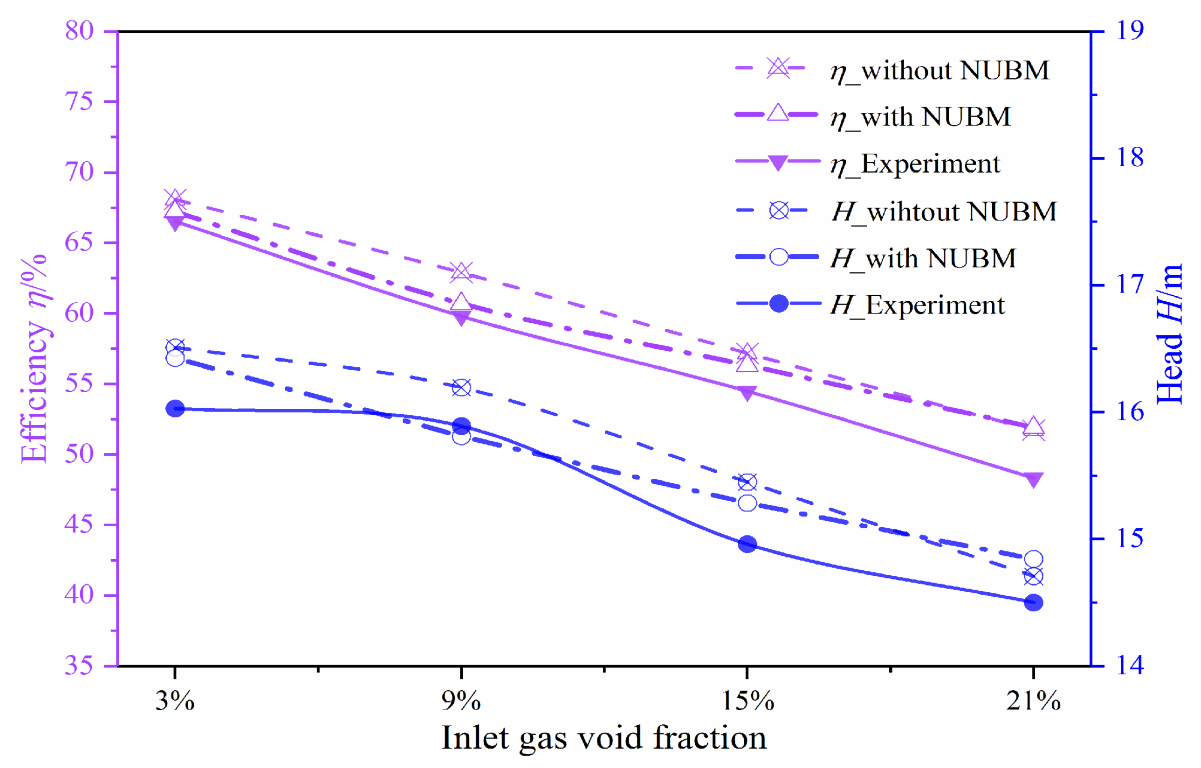

4.3. Bubble Balance Model

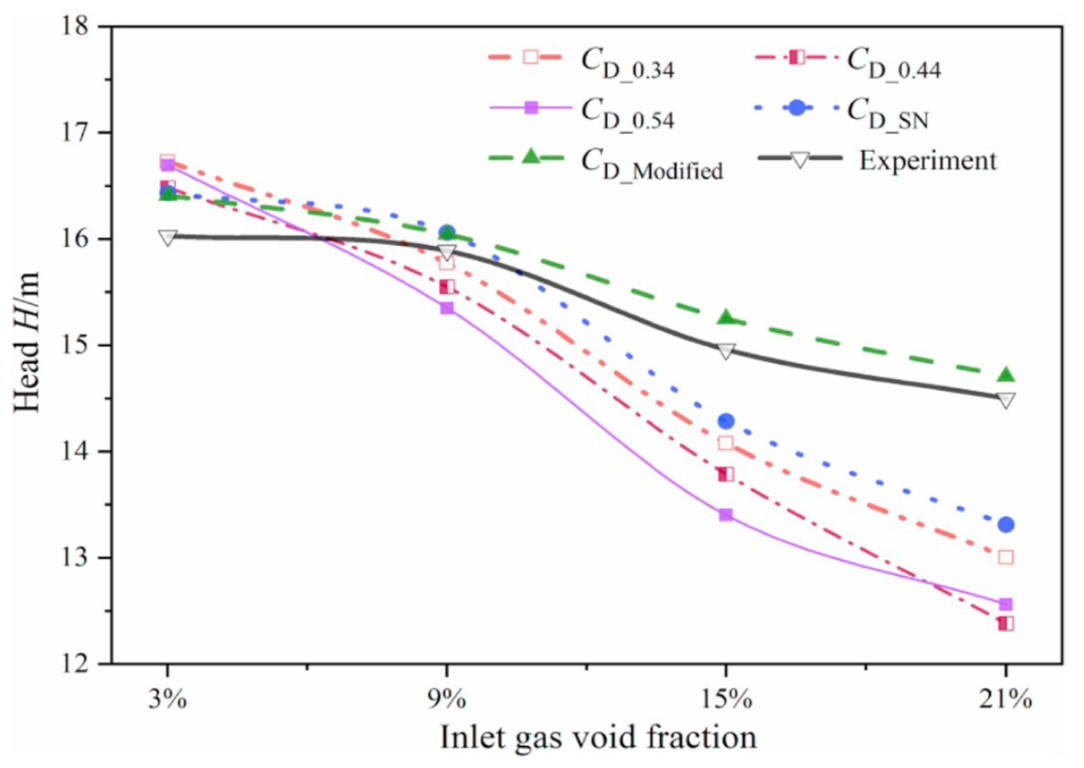

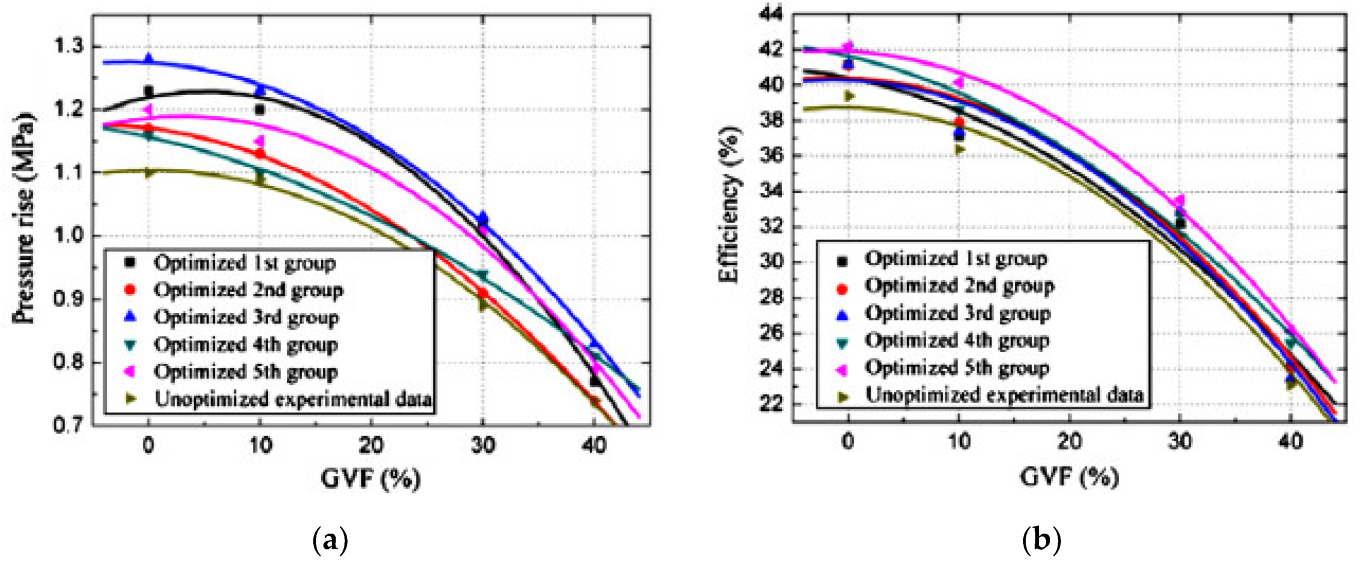

5. CFD Analysis of Energy Performance

6. CFD Analysis of Flow Characteristic

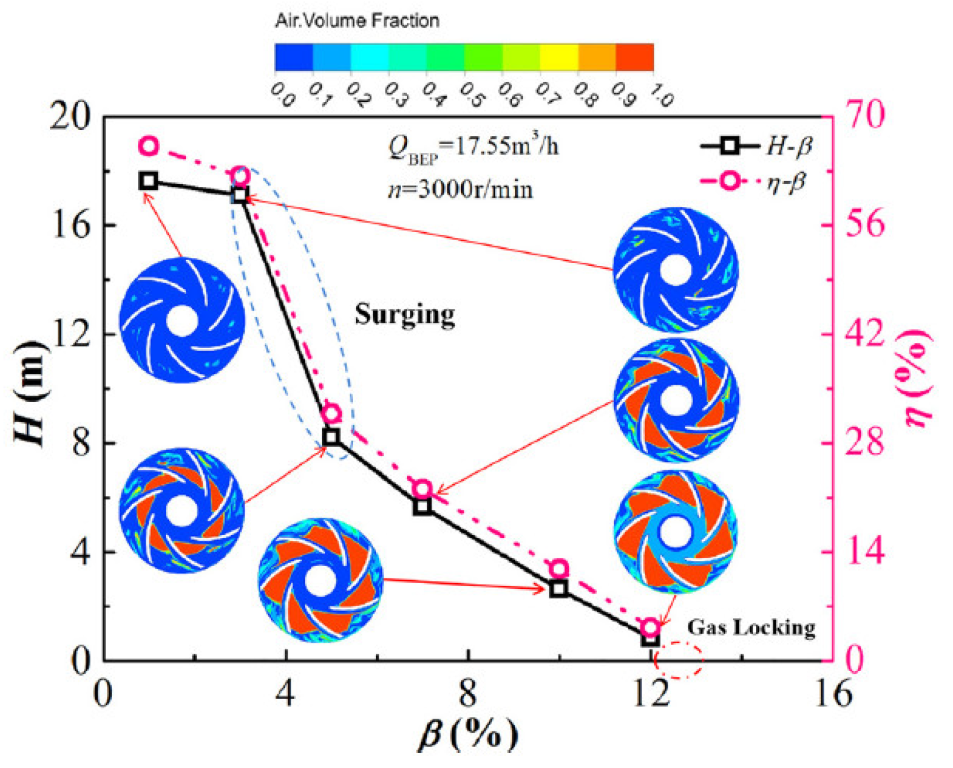

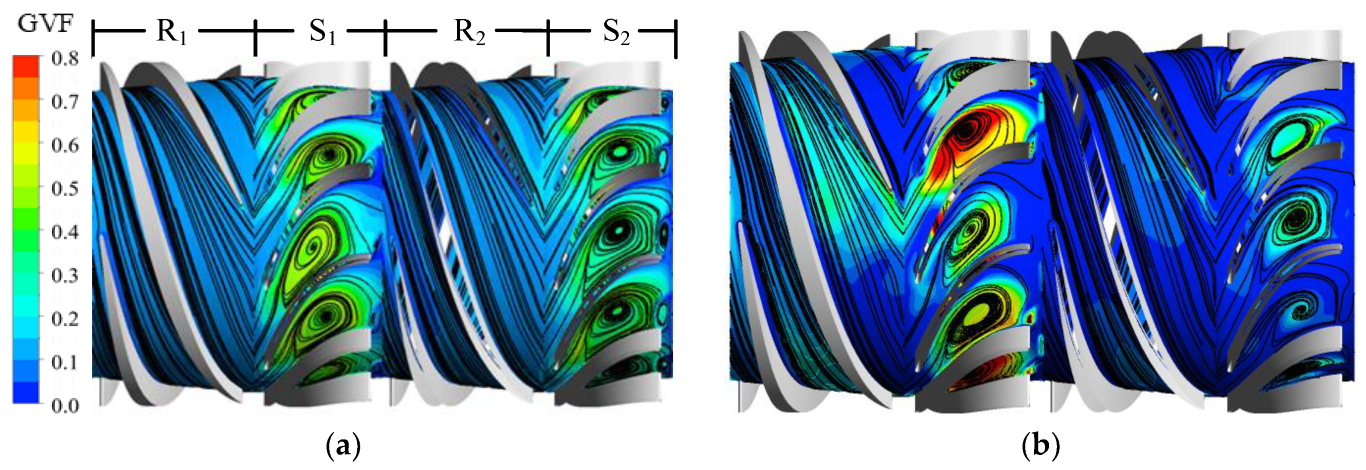

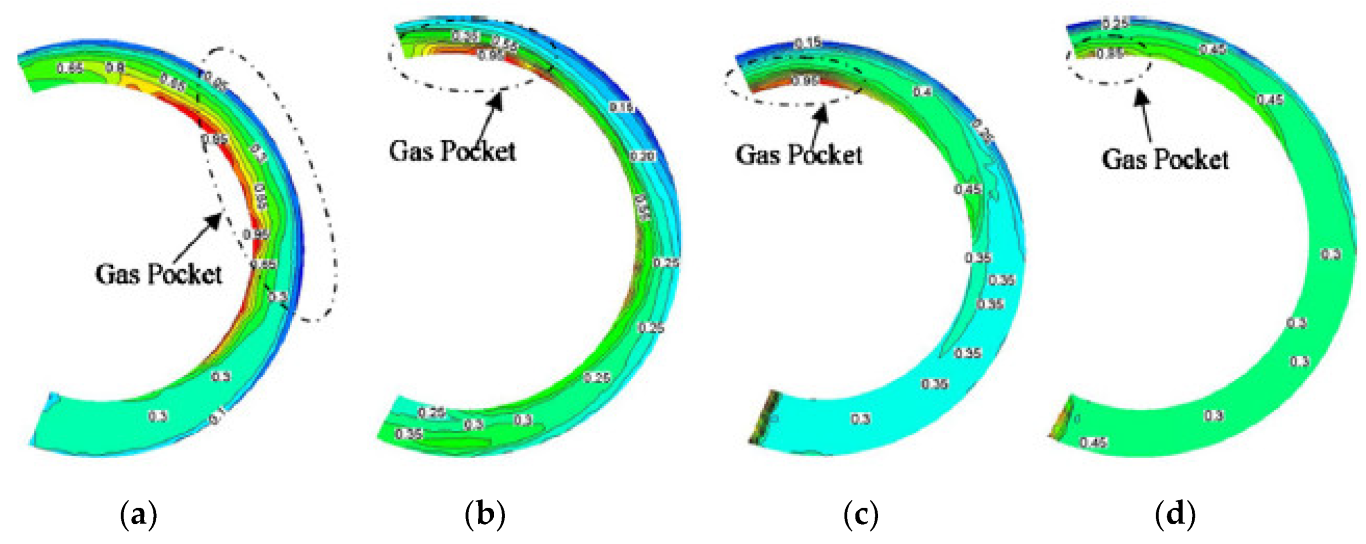

6.1. Gas Distribution Law

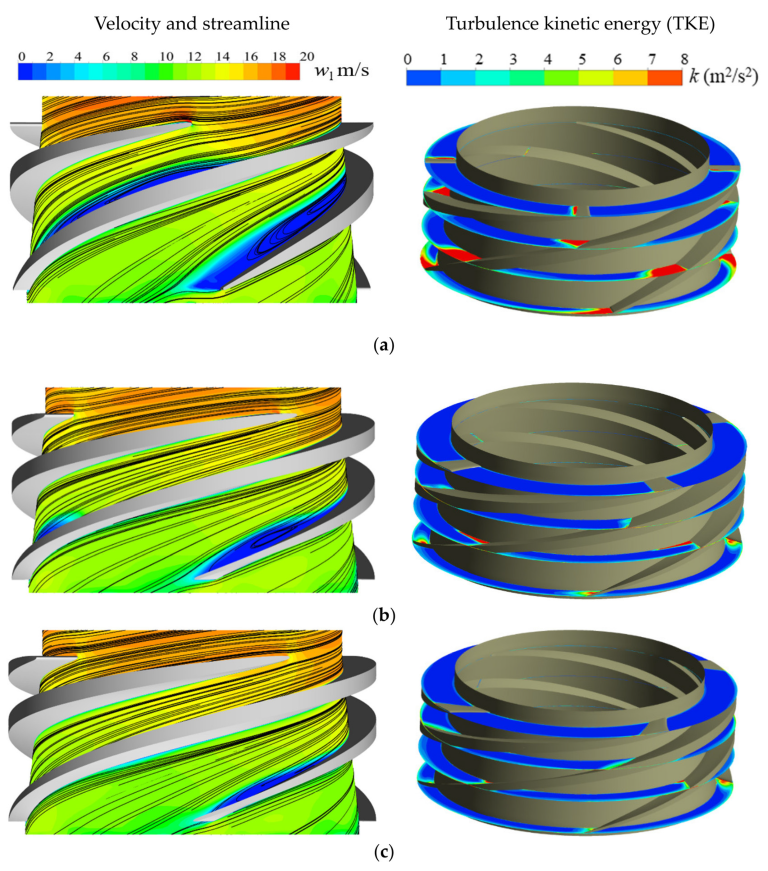

6.2. Vorticity Characteristics

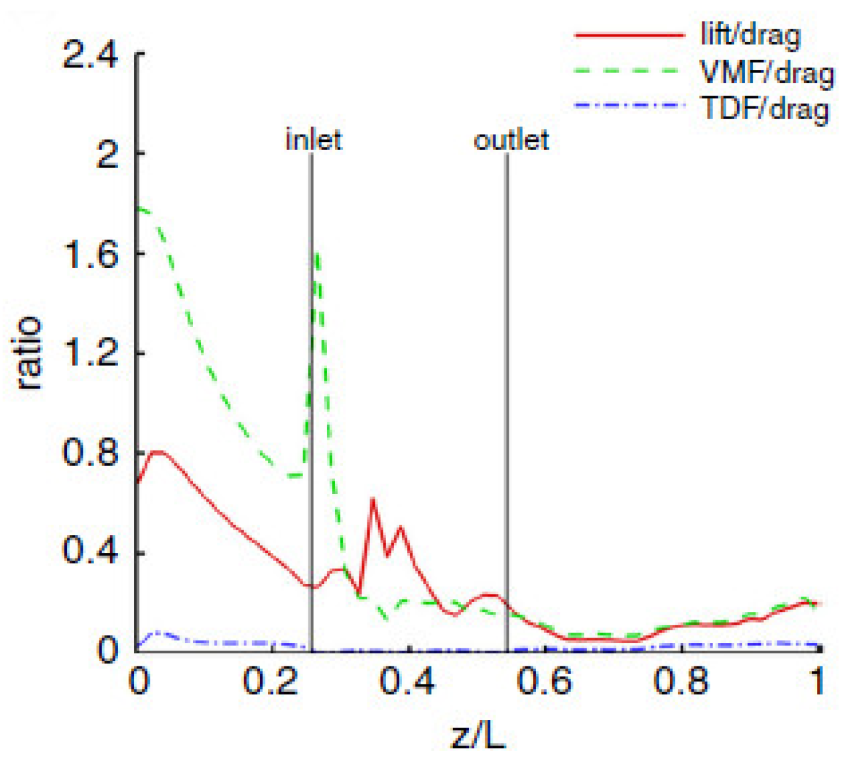

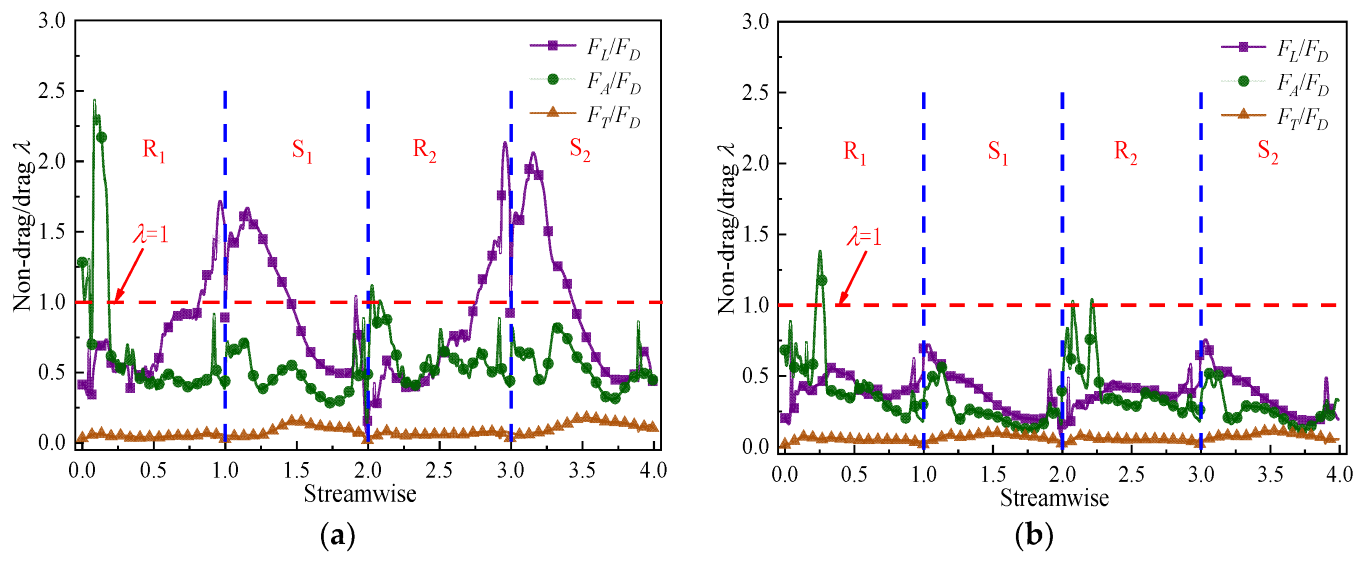

6.3. Phase Interaction Characteristics

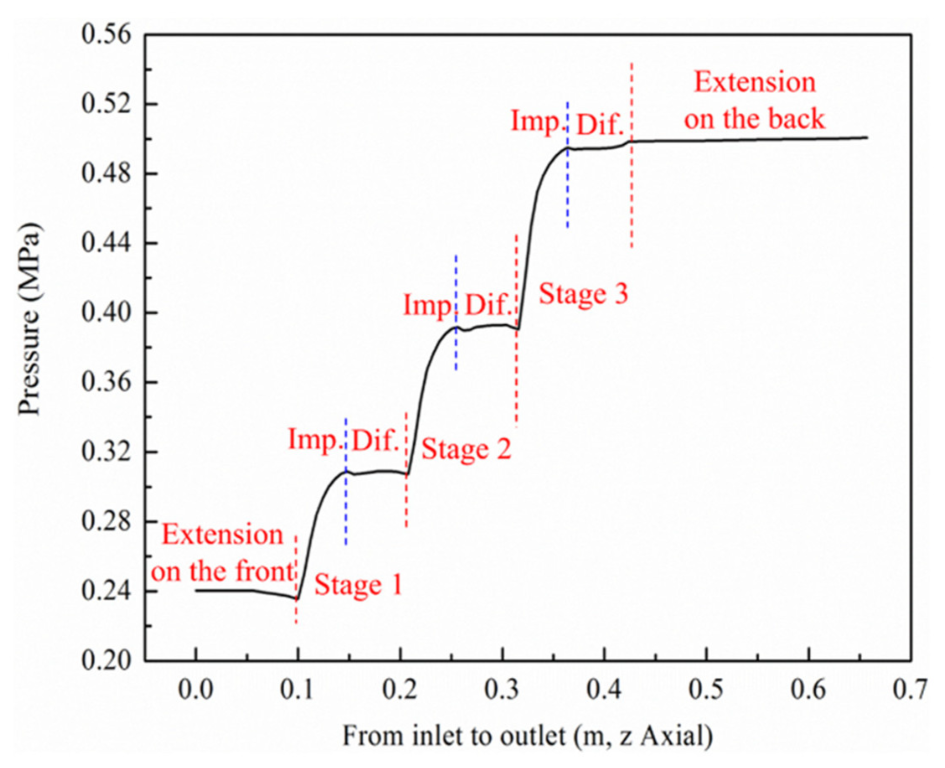

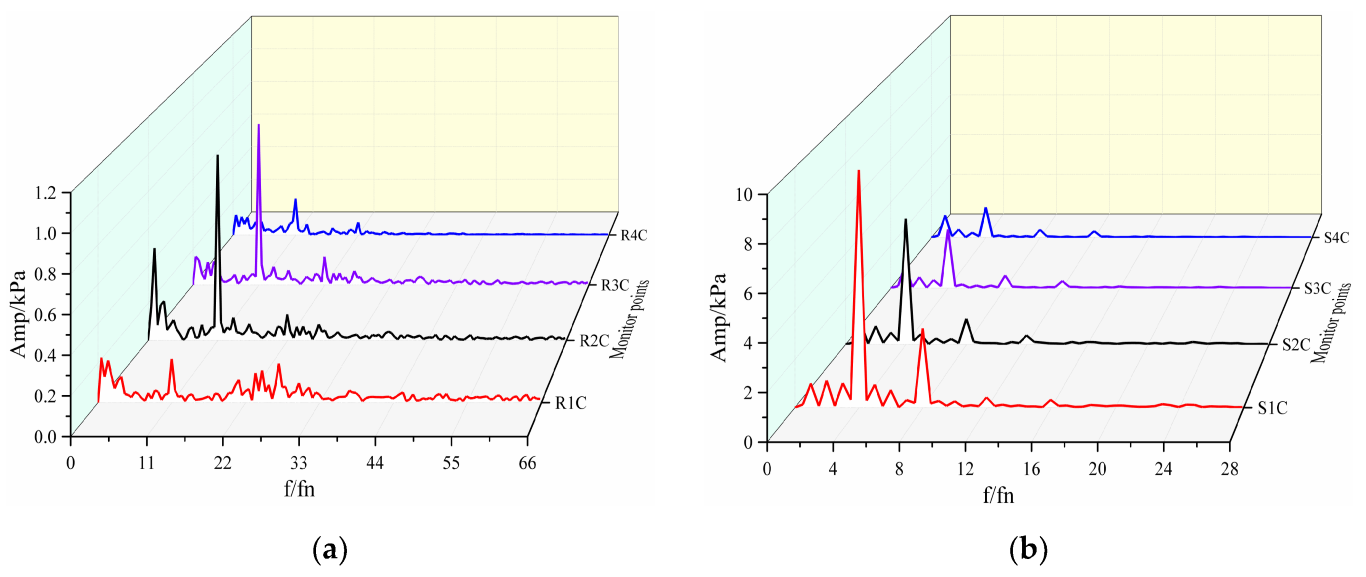

6.4. Pressure Fluctuation Characteristics

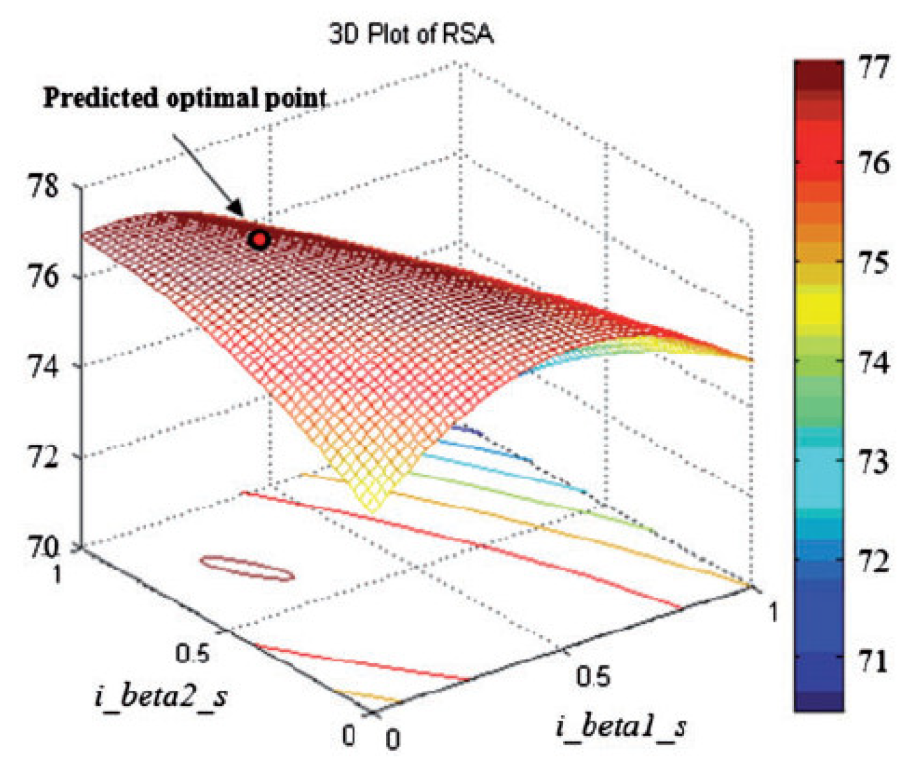

7. Flow Improvement Strategy of Multiphase Pump

7.1. Indirect Control Strategy of Gas–Liquid Flow

7.2. Direct Control Strategy of Gas–Liquid Flow

8. Summary of the Investigated Literature, Important Findings and Future Directions

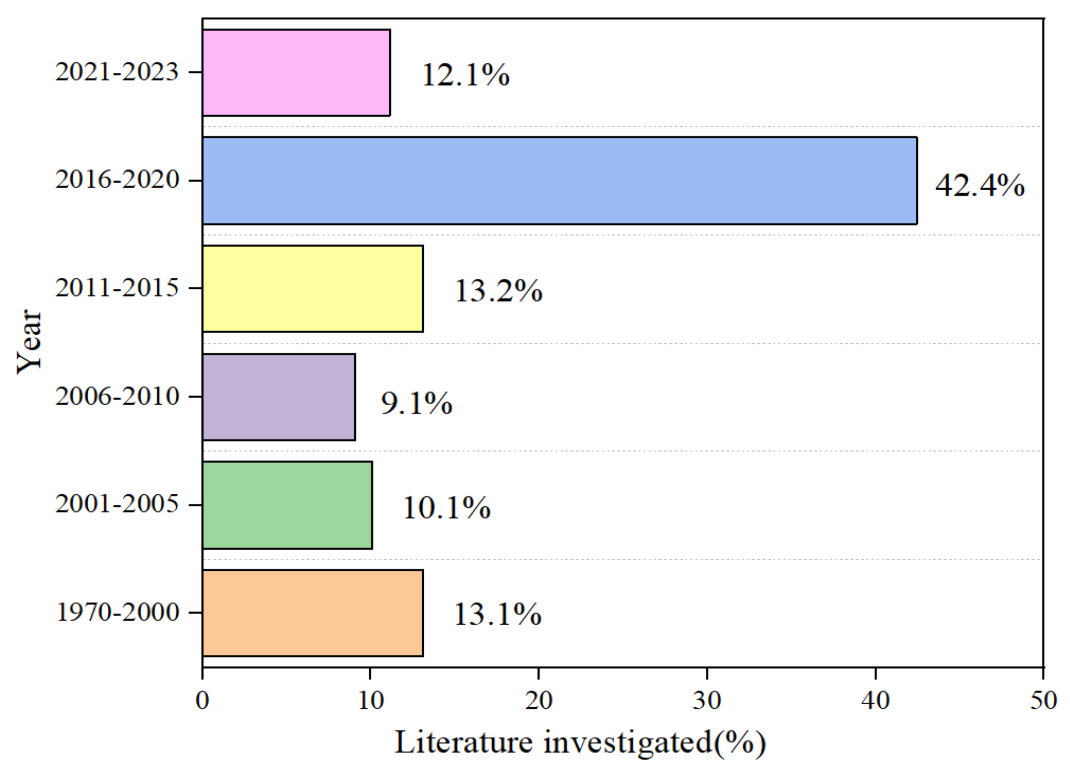

- In this article, about 67.7% of the surveyed literature belongs to 2011–2023, 19.2% belongs to 2001–2010 and 13.1% belongs to the year before 2000. The annual distribution of the literature is shown in Figure 28;

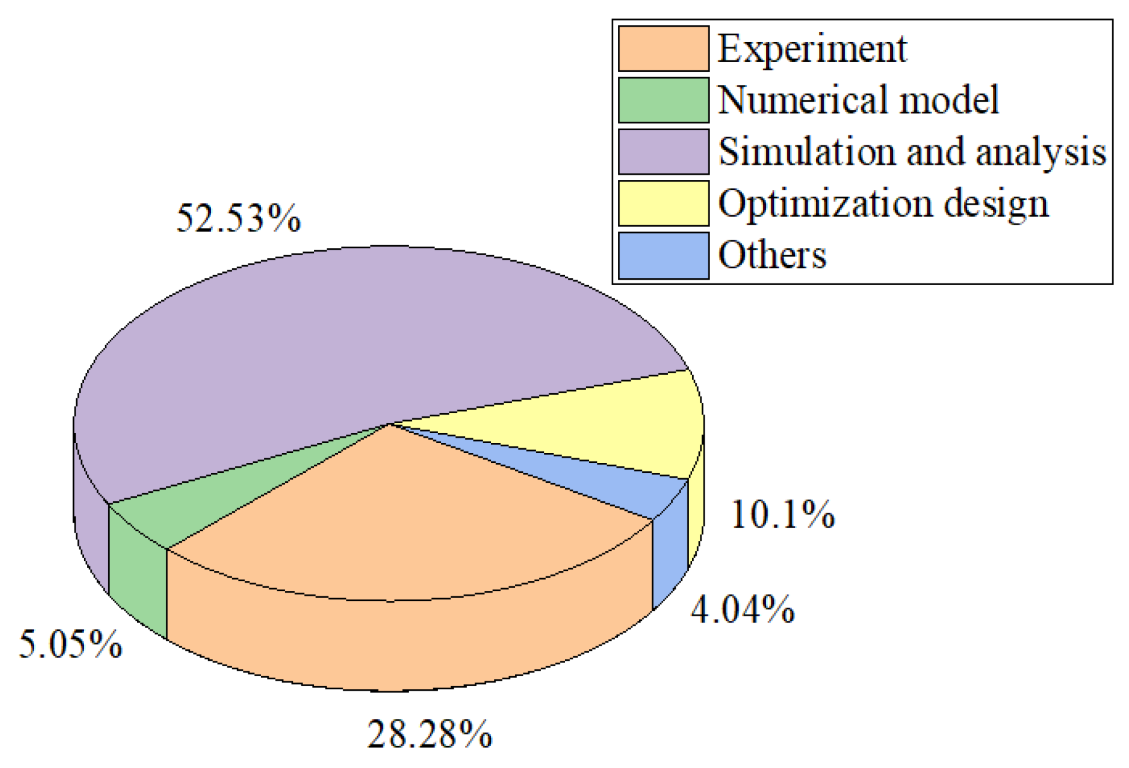

- To have a comprehensive understanding of the current research on multiphase pumps, the types of the investigated literature are summarized in Figure 29, which includes experiment, numerical model development, CFD simulation and analysis and optimization design;

- Various results of the multiphase pump including performance, bubble distribution, vorticity, phase interaction and pressure fluctuation have been obtained. However, there is no single review article that discusses a comprehensive research overview of the gas–liquid multiphase pump.

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dale, S. BP Statistical Review of World Energy; BP Plc: London, UK, 2021. [Google Scholar]

- Verde, W.M.; Biazussi, J.; Porcel, C.E.; Estevam, V.; Tavares, A.; Neto, S.J.A.; Rocha, P.S.D.M.; Bannwart, A.C. Experimental investigation of pressure drop in failed Electrical Submersible Pump (ESP) under liquid single-phase and gas-liquid two-phase flow. In Proceedings of the 17th Brazilian Congress of Thermal Sciences and Engineering, Águas de Lindóia, Brazil, 25–28 November 2018. [Google Scholar]

- Liu, M.; Tan, L.; Cao, S. Method of dynamic mode decomposition and reconstruction with application to a three-stage multiphase pump. Energy 2020, 208, 118343. [Google Scholar] [CrossRef]

- Suh, J.-W.; Kim, J.-W.; Choi, Y.-S.; Joo, W.-G.; Lee, K.-Y. Development of numerical Eulerian-Eulerian models for simulating multiphase pumps. J. Pet. Sci. Eng. 2018, 162, 588–601. [Google Scholar] [CrossRef]

- Falcimaigne, J.; Brac, J.; Charron, Y.; Pagnier, P.; Vilagines, R. Multiphase pumping: Achievements and perspectives. Oil Gas Sci. Technol. 2002, 57, 99–107. [Google Scholar] [CrossRef]

- Shi, Y.; Zhu, H.; Zhang, J.; Zhang, J.; Zhao, J. Experiment and numerical study of a new generation three-stage multiphase pump. J. Pet. Sci. Eng. 2018, 169, 471–484. [Google Scholar] [CrossRef]

- Yang, X.; Hu, C.; Hu, Y.; Qu, Z. Theoretical and experimental study of a synchronal rotary multiphase pump at very high inlet gas volume fractions. Appl. Therm. Eng. 2017, 110, 710–719. [Google Scholar] [CrossRef]

- Liu, P.; Patil, A.; Morrison, G. Multiphase Flow Performance Prediction Model for Twin-Screw Pump. J. Fluids Eng. 2018, 140, 031103. [Google Scholar] [CrossRef]

- Räbiger, K.; Maksoud, T.; Ward, J.; Hausmann, G. Theoretical and experimental analysis of a multiphase screw pump, handling gas–liquid mixtures with very high gas volume fractions. Exp. Therm. Fluid Sci. 2008, 32, 1694–1701. [Google Scholar] [CrossRef]

- Feng, C.; Yueyuan, P.; Ziwen, X.; Pengcheng, S. Thermodynamic performance simulation of a twin-screw multiphase pump. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2001, 215, 157–163. [Google Scholar] [CrossRef]

- Cao, S.; Peng, G.; Yu, Z. Hydrodynamic design of rotodynamic pump impeller for multiphase pumping by combined ap-proach of inverse design and CFD analysis. J. Fluids Eng. 2005, 127, 330–338. [Google Scholar] [CrossRef]

- Li, Y.; Yu, Z.; Zhang, W.; Yang, J.; Ye, Q. Analysis of bubble distribution in a multiphase rotodynamic pump. Eng. Appl. Comput. Fluid Mech. 2019, 13, 551–559. [Google Scholar] [CrossRef]

- Suh, J.-W.; Kim, J.-H.; Choi, Y.-S.; Joo, W.-G.; Lee, K.-Y. A study on numerical optimization and performance verification of multiphase pump for offshore plant. Proc. Inst. Mech. Eng. Part A J. Power Energy 2017, 231, 382–397. [Google Scholar] [CrossRef]

- Shi, J.; Tao, S.; Shi, G.; Song, W. Effect of Gas Volume Fraction on the Energy Loss Characteristics of Multiphase Pumps at Each Cavitation Stage. Water 2021, 13, 2293. [Google Scholar] [CrossRef]

- Dupoiron, M. The Effect of Gas on Multi-Stage Mixed-Flow Centrifugal Pumps. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2017. [Google Scholar]

- Sato, S.; Furukawa, A.; Takamatsu, Y. Air-water two-phase flow performance of centrifugal pump impellers with various blade angles. JSME Int. J. Ser. B 1996, 39, 223–229. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, S.; Li, Y.; Zhu, H.; Zhang, Y. Visualization study of gas–liquid two-phase flow patterns inside a three-stage rotodynamic multi-phase pump. Exp. Therm. Fluid Sci. 2016, 70, 125–138. [Google Scholar] [CrossRef]

- Barrios, L.; Prado, M.G. Experimental visualization of two-phase flow inside an electrical submersible pump stage. J. Energy Resour. Technol. 2011, 133, 042901. [Google Scholar] [CrossRef]

- Neumann, M.; Schäfer, T.; Bieberle, A.; Hampel, U. An Experimental Study on the Gas Entrainment in Horizontally and Vertically Installed Centrifugal Pumps. J. Fluids Eng. 2016, 138, 091301. [Google Scholar] [CrossRef]

- Verde, W.M.; Biazussi, J.L.; Sassim, N.A.; Bannwart, A.C. Experimental study of gas-liquid two-phase flow patterns within centrifugal pumps impellers. Exp. Therm. Fluid Sci. 2017, 85, 37–51. [Google Scholar] [CrossRef]

- He, D.; Li, R.; Zhang, Z.; Sun, S.; Guo, P. Gas–Liquid Two-Phase Flow Pattern Identification of a Centrifugal Pump Based on SMOTE and Artificial Neural Network. Micromachines 2021, 13, 2. [Google Scholar] [CrossRef] [PubMed]

- Qiaorui, S.; Ali, A.; Biaobiao, W.; Wang, P.; Bois, G.; Jianping, Y.; Kubar, A.A. Numerical study on gas-liquid two phase flow characteristic of multistage electrical sub-mersible pump by using a novel multiple-size group (MUSIG) model. Phys. Fluids 2022, 34, 1–21. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Xu, Y.; Cao, S. Optimization design method of multi-stage multiphase pump based on Oseen vortex. J. Pet. Sci. Eng. 2020, 184, 106532. [Google Scholar] [CrossRef]

- Parikh, T.; Mansour, M.; Thévenin, D. Investigations on the effect of tip clearance gap and inducer on the transport of air-water two-phase flow by centrifugal pumps. Chem. Eng. Sci. 2020, 218, 115554. [Google Scholar] [CrossRef]

- Zhu, J.J.; Zhang, H.Q. Numerical study on Electrical-Submersible-Pump two-phase performance and bubble-size Modeling. SPE Prod. Oper. 2017, 32, 267–278. [Google Scholar] [CrossRef]

- Yu, Z.; Zhu, B.; Cao, S.; Liu, Y. Effect of Virtual Mass Force on the Mixed Transport Process in a Multiphase Rotodynamic Pump. Adv. Mech. Eng. 2014, 6, 958352. [Google Scholar] [CrossRef]

- Yu, Z.; Zhu, B.; Cao, S. Interphase force analysis for air-water bubbly flow in a multiphase rotodynamic pump. Eng. Comput. 2015, 32, 2166–2180. [Google Scholar] [CrossRef]

- Liu, M.; Cao, S.; Cao, S.L. Numerical analysis for interphase forces of gas-liquid flow in a multiphase pump. Eng. Com-Putations 2018, 35, 2386–2402. [Google Scholar] [CrossRef]

- Ricardo, D.M.M.; Jiménez, G.E.C.; Ferreira, J.V.; Meirelles, P.S. Multiphase gas-flow model of an electrical submersible pump. Oil Gas Sci. Technol.-Rev. D IFP Energ. Nouv. 2018, 73, 29. [Google Scholar] [CrossRef]

- Taguchi, G. Design of Experiment; Maruzen: Tokyo, Japan, 1976. [Google Scholar]

- Bonaiuti, D.; Zangeneh, M. On the Coupling of Inverse Design and Optimization Techniques for the Multiobjective, Multipoint Design of Turbomachinery Blades. J. Turbomach. 2009, 131, 021014. [Google Scholar] [CrossRef]

- Suh, J.-W.; Choi, Y.-S.; Kim, J.-H.; Joo, W.-G.; Lee, K.-Y. Multi-Objective Optimization of the Hydrodynamic Performance of the Second Stage of a Multi-Phase Pump. Energies 2017, 10, 1334. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, B.; Wang, Z.; Wang, F. Optimization design for an impeller of the multiphase rotodynamic pump handling gas-liquid two-phase flow. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 236, 1544–1557. [Google Scholar] [CrossRef]

- Ping, L.G. Research and development in the oil gas mixture pump technology at home and abroad. J. East China Shipbuild. Inst. 2000, 14, 83–87. (In Chinese) [Google Scholar] [CrossRef]

- Paladino, E.E.; de Cerqueira, R.F.; Weise, J.; Lavoratti, T.C.; Caetano, E.F. Theoretical and experimental analysis of multiphase twin-screw pumps op-erating in serial arrangement. J. Pet. Sci. Eng. 2022, 216, 1–20. [Google Scholar] [CrossRef]

- Qian, T.; Zhang, Y. Screw optimization for performance enhancement of a twin-screw pump. Curr. Res. Protein Chem. 1990, 228, 159–166. [Google Scholar]

- Zhang, W.W.; Zhu, B.S.; Yu, Z.Y. Numerical study on pressure fluctuation in a multiphase rotodynamic pump with different inlet gas void fractions. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; Volume 405. [Google Scholar] [CrossRef]

- Xu, Y.; Cao, S.; Sano, T.; Wakai, T.; Reclari, M. Experimental Investigation on Transient Pressure Characteristics in a Helico-Axial Multiphase Pump. Energies 2019, 12, 461. [Google Scholar] [CrossRef]

- Zhao, L.; Chang, Z.; Zhang, Z.; Huang, R.; He, D. Visualization of gas-liquid flow pattern in a centrifugal pump impeller and its influence on the pump performance. Meas. Sens. 2021, 13, 100033. [Google Scholar] [CrossRef]

- Bratu, C. Two-phase pump transient behaviour. Soc. Pet. Eng. 1995, 30660, 247–261. [Google Scholar]

- Barrios, L.; Prado, M.G. Modeling two-phase flow inside an electrical submersible pump stage. J. Energy Resour. Technol. 2011, 133, 042902. [Google Scholar] [CrossRef]

- Samaras, V.; Margaris, D. Two-phase flow regime maps for air-lift pump vertical upward gas–liquid flow. Int. J. Multiph. Flow 2005, 31, 757–766. [Google Scholar] [CrossRef]

- Julia, J.E.; Hibiki, T. Flow regime transition criteria for two-phase flow in a vertical annulus. Int. J. Heat Fluid Flow 2011, 32, 993–1004. [Google Scholar] [CrossRef]

- Simonnet, M.; Gentric, C.; Olmos, E.; Midoux, N. CFD simulation of the flow field in a bubble column reactor: Importance of the drag force formulation to describe regime transitions. Chem. Eng. Process. Process. Intensif. 2008, 47, 1726–1737. [Google Scholar] [CrossRef]

- Truman, C.R. Discussion: “A theoretical study on air bubble motion in a centrifugal pump impeller” (Minemura, Kiyoshi, and Murakami, Mitsukiyo, 1980, ASME J. Fluids Eng., 102, pp. 446–453). J. Fluids Eng. 1980, 102, 454–455. [Google Scholar] [CrossRef][Green Version]

- Murakami, M.; Minemura, K. Effects of entrained air on the performance of centrifugal pumps: 2nd Report, Effects of number of blades. Bull. JSME 1974, 17, 1286–1295. [Google Scholar] [CrossRef]

- Cubas, J.M.; Stel, H.; Ofuchi, E.M.; Neto, M.A.M.; Morales, R.E. Visualization of two-phase gas-liquid flow in a radial centrifugal pump with a vaned diffuser. J. Pet. Sci. Eng. 2020, 187, 106848. [Google Scholar] [CrossRef]

- Qian, H.; Mou, J.; Wu, D.; Ren, Y.; Zheng, S.; Zhu, Z. Experimental investigation on the gas-liquid flow patterns in a centrifugal pump during self-priming process. AIP Adv. 2020, 10, 015136. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, S.; Zhu, H.; Zhang, Y. Experimental investigation of the flow at the entrance of a rotodynamic multiphase pump by visualization. J. Pet. Sci. Eng. 2015, 126, 254–261. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, B.; Yu, Z. Characteristics of bubble motion and distribution in a multiphase rotodynamic pump. J. Pet. Sci. Eng. 2020, 193, 107435. [Google Scholar] [CrossRef]

- Franke, M. Aspects of Numerical Simulation of Turbomachinery Flows. 2009. Available online: https://elib.dlr.de/62007/ (accessed on 15 August 2023).

- Huang, S.; Su, X.; Guo, J.; Yue, L. Unsteady numerical simulation for gas-liquid two-phase flow in self-priming process of cen-trifugal pump. Energy Convers. Manag. 2014, 85, 694–700. [Google Scholar] [CrossRef]

- Li, C.; Luo, X.; Feng, J.; Zhu, G.; Xue, Y. Effects of Gas-Volume Fractions on the External Characteristics and Pressure Fluctuation of a Multistage Mixed-Transport Pump. Appl. Sci. 2020, 10, 582. [Google Scholar] [CrossRef]

- Caridad, J.; Asuaje, M.; Kenyery, F.; Tremante, A.; Aguillón, O. Characterization of a centrifugal pump impeller under two-phase flow conditions. J. Pet. Sci. Eng. 2008, 63, 18–22. [Google Scholar] [CrossRef]

- Pineda, H.; Biazussi, J.; López, F.; Oliveira, B.; Carvalho, R.D.; Bannwart, A.C.; Ratkovich, N. Phase distribution analysis in an Electrical Submersible Pump (ESP) inlet handling water–air two-phase flow using Computational Fluid Dynamics (CFD). J. Pet. Sci. Eng. 2016, 139, 49–61. [Google Scholar] [CrossRef]

- He, D.; Ge, Z.; Bai, B.; Guo, P.; Luo, X. Gas–Liquid Two-Phase Performance of Centrifugal Pump Under Bubble Inflow Based on Computational Fluid Dynamics–Population Balance Model Coupling Model. J. Fluids Eng. 2020, 142, 081402. [Google Scholar] [CrossRef]

- Ma, Y.; Chen, Y.; Zhang, S. Numerical study on void fraction wave of reciprocating multiphase pumps with high gas rates based on real gas models. Eng. Appl. Comput. Fluid Mech. 2020, 14, 607–621. [Google Scholar] [CrossRef]

- Liu, M.; Tan, L.; Cao, S. Influence of viscosity on energy performance and flow field of a multiphase pump. Renew. Energy 2020, 162, 1151–1160. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, H.C.; Kim, J.H.; Choi, Y.S.; Yoon, J.Y.; Yoo, I.S.; Choi, W.C. Improvement of hydrodynamic performance of a multiphase pump using design of experiment techniques. J. Fluids Eng. 2015, 137, 081301. [Google Scholar] [CrossRef]

- Stel, H.; Sirino, T.; Ponce, F.J.; Chiva, S.; Morales, R.E.M. Numerical investigation of the flow in a multistage electric submersible pump. J. Pet. Sci. Eng. 2015, 136, 41–54. [Google Scholar] [CrossRef]

- Pervaiz, S.S.; Hasan, A.; Dol, S.S.; Gadala, M.S. Numerical investigation of turbulence production under two-phase flow in a simulation of electrical submersible pump performance. J. Fluids Eng. 2022, 1, 011015. [Google Scholar] [CrossRef]

- Shu, Z.K.; Shi, G.T.; Dan, Y.; Wang, B.X.; Tan, X. Enstrophy dissipation of the tip leakage vortex in a multiphase pump. Phys. Fluids 2022, 34, 033310. [Google Scholar] [CrossRef]

- Zhang, W.; Hu, L.; Li, H.; Zhu, B.; Wang, F. Numerical analysis of bubble size effect in a gas-liquid two-phase rotodynamic pump by using a bubble coalescence and collapse model. Chem. Eng. Res. Des. 2023, 191, 617–629. [Google Scholar] [CrossRef]

- Launder, B.E.; Spalding, D.B. Lectures in Mathematical Model of Turbulence; Academic Press: Cambridge, MA, USA, 1972. [Google Scholar]

- Yakhot, V.; Orszag, S.A.; Thangam, S.; Gatski, T.B.; Speziale, C.G. Development of turbulence models for shear flows by a double expansion technique. Phys. Fluids A Fluid Dyn. 1992, 4, 1510–1520. [Google Scholar] [CrossRef]

- Menter, F.R. Two-equation eddy-viscosity turbulence models for engineering applications. AIAA J. 1994, 32, 1598–1605. [Google Scholar] [CrossRef]

- Barrios, L.J. Visualization and Modeling of Multiphase Performance Inside an Electrical Submersible Pump; The University of Tulsa: Tulsa, OK, USA, 2007. [Google Scholar]

- Pessoa, R.; Prado, M. Two-Phase Flow Performance for Electrical Submersible Pump Stages. SPE Prod. Facil. 2003, 18, 13–27. [Google Scholar] [CrossRef]

- Wang, Z.; Deng, Y.; Pan, Y.; Jin, Y.; Huang, F. Experimentally investigating the flow characteristics of airlift pumps operating in gas-liquid-solid flow. Exp. Therm. Fluid Sci. 2019, 112, 109988. [Google Scholar] [CrossRef]

- Lin, Z.H. Vortex Shedding Characteristics and Engineering Application of Gas-Liquid Two-Phase Flow; Chemical Industry Press: Beijing, China, 2001. (In Chinese) [Google Scholar]

- Liu, D.Y. Fluid Dynamics of Two-Phase Systems; Higher Education Press: Beijing, China, 1993. [Google Scholar]

- Zhang, J.; Li, Y.; Cai, S.; Zhu, H.; Zhang, Y. Investigation of gas–liquid two-phase flow in a three-stage rotodynamic multiphase pump via numerical simulation and visualization experiment. Adv. Mech. Eng. 2016, 8, 1687814016642669. [Google Scholar] [CrossRef]

- Benhmidene, A.; Chaouachi, B.; Bourouis, M.; Gabsi, S. Numerical Prediction of Flow Patterns in Bubble Pumps. J. Fluids Eng. 2011, 133, 1–8. [Google Scholar] [CrossRef]

- Ofuchi, E.M.; Stel, H.; Sirino, T.; Vieira, T.S.; Ponce, F.J.; Chiva, S.; Morales, R.E.M. Numerical investigation of the effect of viscosity in a multistage electric submersible pump. Eng. Appl. Comput. Fluid Mech. 2017, 11, 258–272. [Google Scholar] [CrossRef]

- Murakami, M.; Minemura, K. Effects of entrained air on the performance of a centrifugal pump: 1st report, performance and flow conditions. Bull. JSME 1974, 17, 1047–1055. [Google Scholar] [CrossRef]

- Gamboa, J. Prediction of the Transition in Two-Phase Performance of an Electrical Submersible Pump; The University of Tulsa: Tulsa, OK, USA, 2009. [Google Scholar]

- Lane, G.; Schwarz, M.; Evans, G. Numerical modelling of gas–liquid flow in stirred tanks. Chem. Eng. Sci. 2005, 60, 2203–2214. [Google Scholar] [CrossRef]

- Zhang, W.; Yu, Z.; Li, Y. Application of a non-uniform bubble model in a multiphase rotodynamic pump. J. Pet. Sci. Eng. 2018, 173, 1316–1322. [Google Scholar] [CrossRef]

- Liu, P.; Morrison, G.; Patil, A. Experimental and Analytical Investigation of a Novel Multistage Twin-Screw Pump. J. Energy Resour. Technol. 2019, 141, 1–25. [Google Scholar] [CrossRef]

- Zhang, W.; Xie, X.; Zhu, B.; Ma, Z. Analysis of phase interaction and gas holdup in a multistage multiphase rotodynamic pump based on a modified Euler two-fluid model. Renew. Energy 2021, 164, 1496–1507. [Google Scholar] [CrossRef]

- Sahand, P.; Sujan, G.; Gerald, M. Two-phase flow characterization in a split vane impeller Electrical Submersible Pump. J. Pet. Sci. Eng. 2017, 148, 82–93. [Google Scholar]

- Yan, D.; Kovacevic, A.; Tang, Q.; Rane, S.; Zhang, W. Numerical modelling of twin-screw pumps based on computational fluid dynamics. AR-CHIVE Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 231, 1989–1996. [Google Scholar] [CrossRef]

- Zhu, J.; Zhu, H.; Zhang, J.; Zhang, H.-Q. A numerical study on flow patterns inside an electrical submersible pump (ESP) and comparison with visualization experiments. J. Pet. Sci. Eng. 2019, 173, 339–350. [Google Scholar] [CrossRef]

- Fu, W.-S.; Lai, Y.-C.; Li, C.-G. Estimation of turbulent natural convection in horizontal parallel plates by the Q criterion. Int. Commun. Heat Mass Transf. 2013, 45, 41–46. [Google Scholar] [CrossRef]

- Hunt, J.; Wray, A.A.; Moin, P. Eddies, Streams, and Convergence Zones in Turbulent Flows; Center for Turbulence Research: Stanford, CA, USA, 1988. [Google Scholar]

- Liu, Y.; Tan, L.; Liu, M.; Hao, Y.; Xu, Y. Influence of prewhirl angle and axial distance on energy performance and pressure fluctuation for a centrifugal pump with inlet guide vanes. Energies 2017, 10, 695. [Google Scholar] [CrossRef]

- González, J.; Parrondo, J.; Santolaria, C.; Blanco, E. Steady and Unsteady Radial Forces for a Centrifugal Pump with Impeller to Tongue Gap Variation. J. Fluids Eng. 2006, 128, 454–462. [Google Scholar] [CrossRef]

- Majidi, K. Numerical Study of Unsteady Flow in a Centrifugal Pump. J. Turbomach. 2005, 127, 805–814. [Google Scholar] [CrossRef]

- Feng, J.; Luo, X.; Guo, P.; Wu, G. Influence of tip clearance on pressure fluctuations in an axial flow pump. J. Mech. Sci. Technol. 2016, 30, 1603–1610. [Google Scholar] [CrossRef]

- Xie, C.; Tang, F.; Zhang, R.; Zhou, W.; Zhang, W.; Yang, F. Numerical calculation of axial-flow pump’s pressure fluctuation and model test analysis. Adv. Mech. Eng. 2018, 10, 1687814018769775. [Google Scholar] [CrossRef]

- Shuai, Z.-J.; Li, W.-Y.; Zhang, X.-Y.; Jiang, C.-X.; Li, F.-C. Numerical Study on the Characteristics of Pressure Fluctuations in an Axial-Flow Water Pump. Adv. Mech. Eng. 2014, 6, 565061. [Google Scholar] [CrossRef]

- Miyabe, M.; Maeda, H.; Umeki, I.; Jittani, Y. Unstable head-flow characteristic generation mechanism of a low specific speed mixed flow pump. J. Therm. Sci. 2006, 15, 115–120. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, B.; Yu, Z.; Yang, C. Numerical study of pressure fluctuation in the whole flow passage of a low specific speed mixed-flow pump. Adv. Mech. Eng. 2017, 9, 1687814017707651. [Google Scholar] [CrossRef]

- Xu, Y.; Tan, L.; Liu, Y.; Cao, S. Pressure fluctuation and flow pattern of a mixed-flow pump with different blade tip clearances under cavitation condition. Adv. Mech. Eng. 2017, 9, 1687814017696227. [Google Scholar] [CrossRef]

- Shi, G.-T.; Liu, Z.-K.; Xiao, Y.-X.; Tang, X.-L.; Liu, X.-B. Pressure fluctuation characteristics in the pressurization unit of a multiphase pump. J. Hydrodyn. 2021, 33, 1230–1241. [Google Scholar] [CrossRef]

- Zhang, W.; Yu, Z.; Li, Y.; Yang, J.; Ye, Q. Numerical analysis of pressure fluctuation in a multiphase rotodynamic pump with air–water two-phase flow. Oil Gas Sci. Technol. Rev. d’IFP Energies Nouv. 2019, 74, 18. [Google Scholar] [CrossRef]

- Zhang, J.; Zhu, H.; Yang, C.; Li, Y.; Wei, H. Multi-objective shape optimization of helico-axial multiphase pump impeller based on NSGA-II and ANN. Energy Convers. Manag. 2011, 52, 538–546. [Google Scholar] [CrossRef]

- Zhang, W.; Zhu, B.; Zi, D.; Ma, Z.; Wang, F. Transportability improvement of a gas-liquid rotodynamic pump using the two-step mul-ti-objective optimization strategy. Front. Energy Res. 2022, 10, 900182. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhang, W.; Hu, L.; Zhu, B.; Wang, F. Studies on Flow Characteristics of Gas–Liquid Multiphase Pumps Applied in Petroleum Transportation Engineering—A Review. Energies 2023, 16, 6292. https://doi.org/10.3390/en16176292

Li H, Zhang W, Hu L, Zhu B, Wang F. Studies on Flow Characteristics of Gas–Liquid Multiphase Pumps Applied in Petroleum Transportation Engineering—A Review. Energies. 2023; 16(17):6292. https://doi.org/10.3390/en16176292

Chicago/Turabian StyleLi, Huichuang, Wenwu Zhang, Liwei Hu, Baoshan Zhu, and Fujun Wang. 2023. "Studies on Flow Characteristics of Gas–Liquid Multiphase Pumps Applied in Petroleum Transportation Engineering—A Review" Energies 16, no. 17: 6292. https://doi.org/10.3390/en16176292

APA StyleLi, H., Zhang, W., Hu, L., Zhu, B., & Wang, F. (2023). Studies on Flow Characteristics of Gas–Liquid Multiphase Pumps Applied in Petroleum Transportation Engineering—A Review. Energies, 16(17), 6292. https://doi.org/10.3390/en16176292