Abstract

There is a plethora of methods in the global literature that can be used to measure CO2 emissions from electrified transport. But are these methods reliable, and do they offer us a true view of how much exactly of this greenhouse gas is being produced by electric rail transport? We answer this question by proposing an improved CO2 emission estimation model based on cargo transport. Unlike other works, our studies include four crucial steps: (1) estimation of energy consumption in electrified rail cargo transport; (2) estimation of energy losses in the railway traction system and high voltage transmission lines; (3) CO2 emission estimation in traditional powerhouses; and (4) determination of the intensity of the CO2 emissions from electrified rail cargo transport. Based on our method, we concluded that the intensity of CO2 depends not only on the type of fossil fuel used for energy production but also on the parameters of the cargo train, such as its length and weight or the total number of wagon axles (which depend on wagon type). The achieved intensity of CO2 emissions in electrified rail cargo transport slightly varies from those reported in the global literature. Among the most important reasons responsible for this are the conditions under which these tests were conducted. Nevertheless, our results shed new light on how CO2 should be measured. We proved that the decarbonization of electrified rail cargo transport will never be possible without infrastructure modernization. In addition, based on a case study, we also delivered knowledge on how to reduce the environmental impact of electrified rail cargo transport.

1. Introduction

1.1. Background of the Problem of CO2 Emissions in Electrified Rail Cargo Transport

This paper presents a broader perspective on the issue of CO2 emissions in electrified rail cargo transportation.

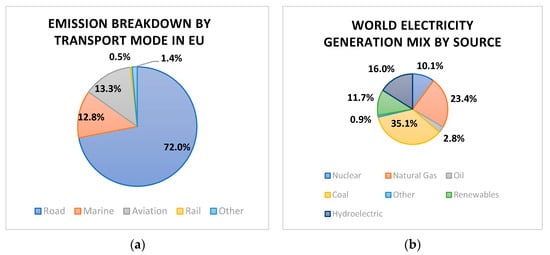

Carbon dioxide is a greenhouse gas (GHG) which is responsible for growing global temperatures [1]. Transport, which is one of the main sources of CO2 emissions, boosts the GDP on the one hand [2] and degrades the environment on the other [3]. Already, approximately 27% of GHG derives from the transport sector [4], so politicians and scientists around the world are paying attention to this topic [5,6,7]. At present, there is a debate on how to keep a fast pace of economic development with low environmental degradation that derives from this form of human activity [8]. Experts say that railway transport is the answer [9,10,11]. But there are still a few unresolved problems related to it. Over the decades, there have been a few manners of rail vehicle propulsion, i.e., steam, diesel, and electric propulsion. Contrary to steam propulsion in rail transportation, diesel and electric propulsion remain in use. For example, out of around 11 thousand locomotives currently operating in rail freight mainline services, 8150 are electric locomotives and the remaining 2850 are diesel locomotives. Thus, on average, around 75% of trains still use electric energy, and the other 25% use diesel. It is a very well-known fact that diesel has a negative impact on our planet [12,13]. This topic was addressed in publication [14]. However, taking into consideration that the energetic mix of many countries in the world is still mainly based on fossil fuels, it is easy to conclude that electric trains can also have a bad effect on the Earth. After all, only 28% of energy production comes from renewable sources (such as the sun, wind, and water) and about 72% from fossil fuels like gas, oil, uranium and coal [15]. The emission breakdown by transport mode in the EU and energy mix in the world are shown in Figure 1.

Figure 1.

(a) Emission breakdown by transport mode in the EU; (b) Energy Mix in the EU. Authors’ own scheme based on [15,16].

It is also worth noting that most politicians and scientists hastily perceive broadly understood electromobility as a manner for decarbonization and a remedy for global warming [17,18,19,20]. Only some of them found threats ensuing from the development of electromobility. Brief information about the defects of electromobility is contained in publications [19,21,22,23,24].

1.2. Research Aim, Contribution, General Consultation, and Article Structure

In general, the worldwide literature lacks an accurate model revealing how carbon dioxide is generated in electrified transport and how its quantity depends on transport conditions. Therefore, the main aim of this study was to propose an improved model of CO2 measurement. This model also provides an answer on how to receive a reliable CO2 emission factor that can be easily implemented in the cost–benefit analysis (CBA) when designing railway infrastructure.

To this end, we carried out several experiments based on electrified rail cargo transport. We chose this branch of transportation because the railway seems to be the most promising means of transportation in recent years.

Thus, our new model embraces the following stages:

- Stage of estimation of energy consumption in electrified rail cargo transport: this step discusses the group of methods for estimating energy consumption in electrified rail cargo transport. In the case study, we chose one method that, from our point of view, would be the best for further analyses.

- Stage of estimation of energy losses in the traction network and high-voltage (HV) transmission lines: this step describes various systems of the power transport network in Europe. Based on a literature review concerning this topic, we determined the level of energy losses in each system of power supply. In the case study, we took them into consideration. Finally, those losses had an influence on the final intensity of CO2 emissions.

- Stage of estimation of CO2 emissions in various types of powerhouses: this step discusses the topic of CO2 emissions from various types of fossil fuel powerhouses. It was emphasized that the production of CO2 depends on the type of fuel that is used to generate energy. In the case study, we showed that the final CO2 emission rate in electrified rail cargo transport differs depending on the type of energy source.

- Stage of determination of the CO2 emission intensity in electrified rail cargo transport: at this stage, we developed the final formula that could be used to estimate the carbon footprint intensity in electrified rail cargo transport. This formula was then implemented in the case study. On this basis, we prepared several graphs showing differences in CO2 emissions in various transport conditions for electrified rail cargo transport.

The case study concluded that the intensity of CO2 emissions from electrified rail cargo transport depends not only on the energy source but also on the parameters of the train and the type of traction network system. We also came to the conclusion that our results differ from those reported in the global literature. There are a few reasons for this phenomenon. Firstly, we conducted a case study based on intermodal trains, where trains are usually much lighter and have a different fleet of cars than bulk trains, etc. Secondly, our model has a different structure than any other model in the literature so far. It takes into account, among others, the energy losses in railway traction and transmission lines. Thirdly, we used different metric units to measure CO2 in electrified rail cargo transport: gCO2/gross-tkm (instead of traditional gCO2/tkm), which is useful in the new CBA for railway projects in the EU. In the new CBA, it is mandatory to show how the new railway line impacts the environment. This is achieved using a CO2 emission factor. Most of the CO2 emission factors available in the literature are based on metric units that refer to the net cargo weight (gCO2/tkm). However, initially, in the CBA, the weight of carried cargo is usually unknown, unlike the gross weight of the train. The gross weight of the train is the basic assumption needed in traffic analyses or to determine the required parameters of a railway line (such as design speed, axle loads, type of traction system, etc.). In this regard, one option to determine the environmental impact of the trains considered is to use a metric expressed in gCO2/gross-tkm. Once the value of this factor is known, it is enough to multiply the gross weight of the train, the distance of the route, and the emission factor expressed in gCO2/gross-tkm to obtain the size of the carbon footprint emitted by trains on the considered railway line. It is worth noting that the current emission factors in the literature are not equivalent to a factor expressed in gCO2/gross-tkm. To fill this gap, we prepared special equations (see Equations (13) and (15)).

Based on these studies, we also figured out that transport decarbonization is not possible without upgrading the railway and energetic infrastructure, but there are several ways to help reduce its environmental impact. These manners are discussed in detail in the last part of this article.

This paper is structured as follows: in Section 2, we discuss the research status of the field; in Section 3, we explain our new method for estimating CO2 emissions in electrified rail cargo transport; in Section 4, we show a case study and the main results based on it; and in Section 5, we discuss the received results and formulate final conclusions.

2. Literature Review

In recent years, electrified rail transport has gained many proponents who support initiatives involved with transport decarbonization. Overall, this mode of transport allows the cumulative carriage of passengers and commodities with a relatively milder environmental impact over long and medium distances than road transport [25,26]. Nevertheless, many experts believe that many steps must be taken to make railway transport emission-free. Therefore, scientists are still seeking optimization solutions that could help decrease the environmental impact of rail transport. In fact, those solutions are being tested on the basis of dynamics models that enable observation of CO2 emissions at the system level [27]. In the case of electrified rail transport, the process of estimating CO2 emissions usually takes into account the energy consumption, and it does not matter what type of carriage (passenger or cargo) is actually being considered [28].

2.1. Existing Methods for Estimating the Intensity of CO2 Emissions

Over the years, for the purpose of estimating the intensity of CO2 emissions in electrified rail transport, several models have been constructed [29].

- I.

- MEET (Methodologies for Estimating Emissions from Transport)

The MEET method was created by a group of experts in the 1990s in order to estimate carbon footprints in sea, rail, road, and air transport—both passenger and freight. At that time, very comprehensive research papers were published on it [30]. The MEET method is no longer as popular as the methods that were constructed a few years later.

In the MEET method, there are two models for estimating energy consumption that are necessary to estimate the carbon footprint. In the first approach, the consumed energy ( depends on the distance ( and average velocity between stops [30,31] (Formula (1)),

where —constants determined based on empirical observations. For cargo trains, experts assume the following values: and [29].

In the first approach, the consumed energy ( depends on the number of stops , maximal velocity of the route (, gravitation , trip altitude difference (), and traveled distance [29,30],

where —constants determined based on empirical observations. For cargo trains, experts assume the following values: , , 0.0845 [29].

To calculate the total energy consumption on the route , the following formula was implemented:

where —the maximal train payload.

- II.

- ARTEMIS (Assessment and Reliability of Transport Emission Models and Inventory Systems)

The ARTEMIS method was created in the first decade of the 21st century based on the MEET method. This method is much more popular than MEET and constitutes a reference for many works of science around the world [32,33]. Energy consumption () in the ARTEMIS method, which is used for estimating carbon footprints, follows the law of physics. The energy consumed in this method is proportional to the resistance forces that electric locomotives must overcome while driving [34,35] (Formula (4)):

where —rolling, aerodynamic, uphill, and acceleration resistance forces.

Taking into consideration the efficiency of the locomotive, the total energy consumption on the route is equal to

where —the efficiency of the locomotive.

Based on the ARTEMIS method, a publication on GHG emissions in Sweden and Finland was prepared, which analyzed road transport. In this article, the authors stated that the following factors have a main influence on the emission level: fuel quality, engine temperature, driving resistances and transmission losses [36]. It is worth noting that some factors presented above can also have an effect on the emission level of railway transport.

- III.

- ETW (EcoTransIT World)

The ETW method was created in order to estimate carbon footprints in sea, rail, road, and air transport [37,38]. The energy consumption () in this method results from an empirically determined formula:

where —parameter related to the trip altitude difference, —train gross mass.

Taking into consideration the efficiency of the locomotive, the total energy consumption for the given route is equal to

where —train space utilization rate.

In the case of the ETW method, there is a special tool that helps to estimate carbon footprint. Table 1 shows companies interested in using the ETW tool. According to the International Union of Railways (UIC), these are major players in the market that pursue a sustainable environmental policy.

Table 1.

List of companies using the ETW tool.

Moreover, an example of a publication in which the ETW method was used is [39]. There, the efficiency of transporting goods produced by chemical factories was assessed.

- IV.

- Mesoscopic

The Mesoscopic method was created by the authors of [40]. It is a hybrid of the ARTEMIS and ETW methods. In this method, formulas from the ARTEMIS method are used to calculate the energy needed to overcome the resistance forces, and formulas from the ETW method are used to calculate the energy needed to propel the locomotive. The formula for energy consumed during the train route is as follows:

where —power necessary to overcome aerodynamic, rolling and uphill resistance forces; —power needed for single train acceleration.

The equations for the individual elements of Equation (8) are presented beneath:

where —aerodynamic resistance factor; —air density; —locomotive front surface; —number of stops per 100 km; —altitude of area in the distance .

In addition,

where —aerodynamic and rolling resistance factors of locomotives and wagons; —surface rolling resistance factors; —number of axles in wagons of the z-type; —number of the z-type wagons.

The final formula for energy consumed on the train route is as follows:

For example, in the global literature, the Mesoscopic method was implemented in the context of the Vehicle Routing Problem [41] and for estimating the energy consumed by electric cars [42].

In general, the Mesoscopic method, unlike the MEET and ETW, does not contain any empirical parameters (e.g., Those parameters may be non-objective for a given type of train and can significantly affect the final results. In addition, this method includes an equation for the energy consumed during a single train acceleration. In the ARTEMIS method, the energy consumption during the train acceleration is calculated only from the value of the average acceleration over the whole train route. Therefore, the results received with the Mesoscopic method may be more accurate than the results obtained with the ARTEMIS method.

2.2. The Problem of Energy Losses in the Traction Network System

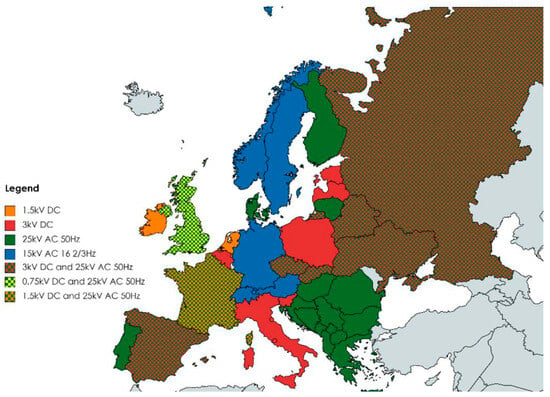

There are two general types of traction power supply systems in railway transport. There is talk of a Direct Current (DC) system and an Alternating Current (AC) system. These systems are divided into subsystems. Only in Europe are there 0.75, 1.5, and 3 kV DC power systems and 15 and 25 kV AC power systems (Figure 2).

Figure 2.

Distribution of traction power for railways in Europe. Source: [43].

The variety of power supply systems deepens the interoperability problems in railway transport in Europe and worldwide [44]. At present, many vehicles are equipped with components that enable the conversion of direct current into alternating current and vice versa. However, such vehicles are usually more expensive than traditional ones due to their complexity [45].

The energy losses in the traction network are a serious problem from an ecological and economic point of view. In the case of the DC system, the energy loss takes place in the following elements of the traction network: substations, traction cables, subsection power regulators, chokes, section cabin power regulators, and returnable cables. According to experts [46], on non-modernized railway lines, energy losses in the catenary can be equal to 11.5–12.8%, and on modernized ones, they constitute about 2.2–2.4% in the case of a DC system. The report of the publisher “Prokolej” reports energy losses of about 2.47% in the case of the AC system and 9.97% in the case of the DC system [47].

3. Materials and Methods

The following paper deals with the estimation of CO2 emissions in electrified rail cargo transport.

The main role in this process is played by the energy consumed by the locomotive engine. In the case of cargo transport, the energy needed to overcome the resistance forces depends on technical and organizational factors (which are discussed later). Knowing the actual energy demand of the locomotive for a given route and transport conditions, it is possible to estimate the amount of energy the power plant must produce. Due to the dominant share of fossil fuels in the global energetic mix, it was assumed that energy flowing in traction comes from traditional powerhouses. However, it is worth noting that before energy reaches the locomotive engine, some will be lost in certain elements of the railway traction system. Therefore, the energy production in the powerhouse is always higher than the actual demand for the locomotive.

Ultimately, the type of powerhouse affects the intensity of CO2 emissions. This is where the physical emission of carbon dioxide into the atmosphere takes place. Its intensity is closely correlated with the type of fuel, its calorific value, and the energy efficiency of the powerhouse.

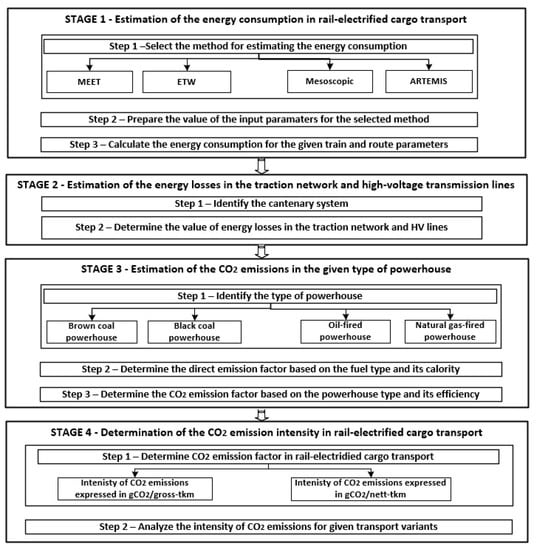

Taking into consideration everything that was already mentioned, a new model for estimating CO2 emission intensity in electrified rail cargo transport was developed and is presented in Figure 3.

Figure 3.

A new model for estimating CO2 emission intensity in electrified rail cargo: the authors’ own scheme.

The subsequent steps of this model are described below:

- I.

- Stage of estimation of the energy consumption in rail-electrified transport

At this stage, a decision must be made about the method chosen to estimate energy consumption. It may be chosen by one of the following methods:

- MEET (,

- ARTEMIS (,

- ETW (,

- Mesoscopic (.

Later, it is necessary to prepare all the required values of the parameters characteristic of a given method. Then, it is possible to calculate the energy consumed by a train. The energy consumed by a train was denoted as , where is the energy consumed by the train according to method number (i).

- II.

- Stage of estimation of energy losses in the traction network and HV transmission lines

At this stage, it is necessary to state the type of catenary system installed on the railway line. Then, the energy losses are measured using special devices. For the purposes of the case study, the following designations were introduced:

—the level of energy losses in an AC system and HV transmission lines,

—the level of energy losses in a DC system and HV transmission lines.

These losses increase the amount of energy retrieved from the powerhouse. Thus, they can have a considerable influence on the final intensity of CO2 emissions.

- III.

- Stage of estimation of CO2 emissions in the powerhouse

At this stage, it is necessary to recognize the type of powerhouse that provides energy and the type of fuel that is fired in it. In the second step, it is important to determine the calorific value of the fuel being considered. The calorific value signifies the amount of energy that can be produced from 1 kg of the of fuel. Based on it, the metric amount of energy generated from the fuel and the CO2 emissions produced from the k-type of fuel can be established. In the third step, the age of the powerhouse and its efficiency are determined. The powerhouses are divided into the following groups:

- of average age (,

- modern (),

- modernized (,

- old type (),

where —the age of powerhouse of the j-type fired by the k-type of fuel.

Finally, it is possible to estimate the intensity of CO2 emitted per unit of energy The following equation can be used for this purpose:

where —efficiency of a powerhouse of the j-type fired with the k-type of fuel. The efficiency of a powerhouse is understood as the quotient of energy delivered into the incineration process and energy on the output. It is worth mentioning that the low efficiency of powerhouses means that the energetic potential of fuel is only utilized in half or 1/3 of them.

- IV.

- Stage of determination of the CO2 emission intensity in electrified rail cargo transport

At this stage, it is mandatory to decide the factor in which the further analyses should be conducted. According to Figure 3, the intensity of CO2 emissions expressed in gross-tkm can be estimated based on the given equation,

where —intensity of CO2 emissions for a train of the of composition, for of variable, for method no. , for the of fuel and for the of powerhouse; —gross mass of the train. In the case of a cargo train,

where —weight of a wagon of the z-type, —total tare of containers, —total net weight of the goods.

It is enough to slightly modify Formula (13) to receive the intensity of CO2 emissions expressed in the traditional metric unit,

where —intensity of CO2 emission for a train of the of composition and for the of tested variables, for method no. (see Table 5), for the of fuel and for the of powerhouse.

Once the type of the emission factor is selected, further analyses can finally proceed. It is worth mentioning that they should be carried out for various transport variants in order to better understand the relationships between train parameters and CO2 emission levels.

4. Case Study and Results

4.1. The Scope of the Case Study

The intensity of the CO2 emissions in rail transport depends on many technical and organizational parameters. Generally, these parameters may vary depending on the type of transport. For example, bulk trains can be heavier than passenger trains or intermodal trains. On the other hand, intermodal trains may consist of wagons that have many more axles. From this point of view, a comparison of the carbon footprints of different types of trains is not representative. That is why, in this case study, it was decided to conduct the calculations only based on one type of train, i.e., intermodal trains.

In addition, due to the large number of graphs and analyses that needed to be prepared, it was decided to measure the intensity of the CO2 emissions only in the metric expressed in gCO2/gross-tkm. The test procedure is similar in both cases.

4.2. Algorithm Implementation, Calculations, and Results

4.2.1. Stage 1, Stage 2

Currently, two main types of intermodal trains are operating in Europe. The first type of train is a short train with a length of no more than 620 m (600 m without a locomotive). Such a short length of trains is the result of the lack of modernization of railway lines, stations, and intermodal terminals. However, the AGTC and TEN-T agreements oblige member states to modernize their infrastructure. Ultimately, after modernization, it should be possible to operate trains with a total length of 750 m (730 m without a locomotive) in all European countries [48]. Therefore, it was decided to consider two train lengths (620 and 750 m) in the context of CO2 emissions in this case study.

In addition, it is also worth noting that in Europe, there is a significant diversity of wagon fleets. In intermodal transport, the most popular types of wagons are 40′ and 80′. With this in mind, the estimation of CO2 emission intensity was carried out in four variants, (:

- , V1 (620 m, 80′)—variant no. I (train length 620 m, heterogeneous 80′ wagon set),

- , V2 (600 m, 40′)—variant no. II (train length 620 m, heterogeneous 40′ wagon set),

- , V3 (730 m, 80′)—variant no. III (train length 750 m, heterogeneous 80′ wagon set),

- , V4 (730 m, 40′)—variant no. IV (train length 750 m, heterogeneous 40′ wagon set).

For estimating the energy consumption of an electric locomotive in this case study, the Mesoscopic method was chosen. This method seems to be much more accurate and intuitive than any other method presented in this article. In addition, the Mesoscopic method is easy to implement and contains the largest number of parameters that can be controlled for the purposes of the case study. Therefore, more interesting and varied results can also be obtained.

In order to carry out calculations with this method, it was necessary to define the parameters of the train and its route (Table 2).

Table 2.

Parameters of the train and route.

Also here, the level of energy losses in the traction network and HV transmission lines was assumed. In this case study, they were equal to . Under normal conditions, they should be measured by special devices.

4.2.2. Stage 3

In this stage, based on data available on the Internet and the literature, information about fuel that may be fired in traditional powerhouses was prepared. Particular attention was paid to the calorific value of fuel, energy production, and direct CO2 emissions per 1 kg of the mentioned fuel. Only four types of fuel were considered in this case study (Table 3).

Table 3.

Type of fuel, its caloricity, energy potential, and direct CO2 emissions.

In the table below, data with specific group of powerhouses are presented, as well as their efficiency and the calculated CO2 emission factor (Table 4).

Table 4.

Types of power plants, its efficiency and emission level.

4.2.3. Stage 4

In the following stage, the impact of a specific type of powerhouse and the parameters of the route and trains were tested. The testing data set is presented in Table 5.

Table 5.

Tested parameters.

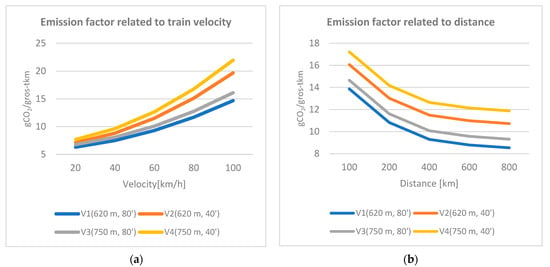

The calculations were carried out using Equations (8), (12), (13) and (15). Based on them, two exemplary graphs were prepared showing the intensity of CO2 emissions in relation to increasing distance and velocity (Figure 4).

Figure 4.

(a) Emission factor related to train velocity; (b) Emission factor related to distance.

Figure 4a shows that as the average velocity increases for the parameters posted in Table 5 (train with gross weight equal to 2200 tons, distance of route equal to 400 km, number of stops equal to 2/100 km), the amount of CO2 emitted to the atmosphere is exponentially growing for each variant. It turns out that the intensity of CO2 emissions ranges from 6.3 to 7.7 gCO2/gross-tkm at a train speed of 20 km/h and from 14.7 to 22 gCO2/gross-tkm at a train speed of 100 km/h.

In contrast, with similar parameters and a regular velocity (60 km/h), when the distance increases, it was observed that the intensity of CO2 emission decreases along with the increasing distance. Figure 4b shows that depending on the length of the train, CO2 emissions oscillate between 13.9 and 17.2 gCO2/gross-tkm on a distance equal to 100 km and between 8.5 and 11.9 gCO2/gross-tkm on a distance of 800 km.

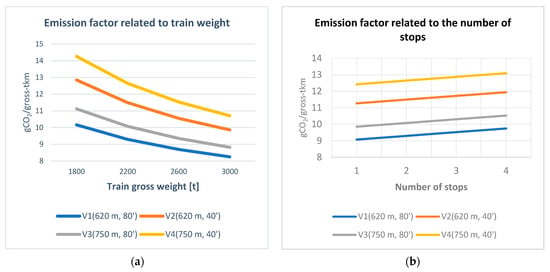

In the next step, the increase in the total weight of the train and the increase in the number of stops on the intensity of CO2 emissions were also analyzed (Figure 5).

Figure 5.

(a) Emission factor related to train gross weight; (b) Emission factor related to number of stops.

The emission curve in Figure 5a has a similar character as that in Figure 4b, where gross train weight is growing. For trains with a gross weight of 1800 tons, the intensity of CO2 emissions ranged from 10.1 to 14.3 gCO2/gross-tkm, and for trains with a gross weight of 3000 tons, from 8.25 to 10.7 gCO2/gross-tkm, respectively. In the case when the train stopped once per 100 km (Figure 5b), the intensity of CO2 emissions ranged from 9 to 12.4 gCO2/gross-tkm, and in the case when the train stopped four times per 100 km, the intensity of CO2 emissions ranged from 9.7 to 13 gCO2/gross-tkm.

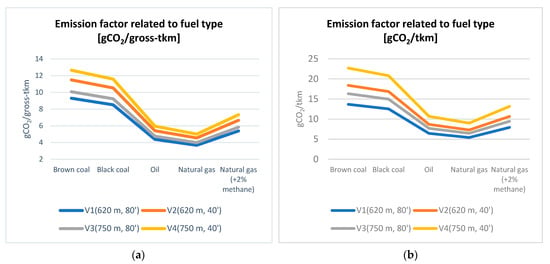

At the last level of the case study, the impact of fuel type on the intensity of CO2 emissions was examined (Figure 6).

Figure 6.

(a) Emission factor related to fuel type expressed in gCO2/gross-tkm; (b) Emission factor related to fuel type expressed in gCO2/tkm.

The most significant differences in the intensity of CO2 emissions were observed in Figure 6a,b. When producing energy from a brown coal-fired power plant, emissions fluctuated between 9.3 and 12.7 gCO2/gross-tkm; in the case of a black coal-fired power plant, emissions fluctuated between 8.5 and 11.5 gCO2/gross-tkm; in the case of an oil-fired power plant, they fluctuated between 4.4 and 5.95 gCO2/gross-tkm; in the case of a gas-fired power plant, they fluctuated between 3.7 and 5 gCO2/gross-tkm; and in the case of a gas-fired power plant (+2% methane lineage included), they fluctuated between 7.3 gCO2/gross-tkm. At once, the CO2 emission factor expressed in gCO2/tkm was correspondingly higher by 47% in V1 for each type of powerhouse, by 60–62% in V2, V3, and by 79.5% in V4.

5. Discussion

These analyses lead to the following observations:

- Firstly, the received results may be difficult to compare due to the high number of factors that may affect CO2 emissions. In general, in non-laboratory conditions, it is not possible to simultaneously measure the impact of various parameters on energy consumption or CO2 emissions.

- Secondly, based on the graph (Figure 4b), it is easy to come to the conclusion that rail transport is more environmentally friendly over long distances than over short distances.

- Thirdly, an increase in the average velocity of a train causes an exponential growth in CO2 emissions (Figure 4a), while the growth of train weight (Figure 5a) causes a decrease in its intensity. Apart from that, Figure 5b shows that the locomotive consumes a significant amount of energy during acceleration. This means that acceleration is a very energy-absorbing process.

- Fourthly, most analyses were conducted based on energy coming from black coal-fired power plants. In the case of other energy sources, the level of emissions varied significantly (Figure 6a,b). The lowest emissions were observed when energy was retrieved from gas- and oil-fired power plants. It means that this type of fuel has a good calorific value, and gaining energy from it causes fewer GHG emissions into the atmosphere than other fuels. The worst source of energy turned out to be a lignite-fired power plant because the fuel used in this type of object has a low calorific value and is the most polluted.

- Fifthly, the obtained results for railway transport slightly vary from those reported in the literature. For example, the UK government website reports the emission factor for railway freight transport equal to 27.5 gCO2/tkm [51]; the UIC documents reports —20 gCO2/tkm [52] (and similar values of emission factors can be found in publications [53,54]). On the other hand, the average CO2-emission factor proposed by McKinnon for the calculation of CO2-emission from rail freight transport is equal to 22 gCO2/tkm. This value was extrapolated based on emission factors coming from reliable sources across Europe [55,56,57] (see Table 6).

Table 6. Emission factor for rail freight transport.

Table 6. Emission factor for rail freight transport.

In this study, the emission factor for the average value of route and train parameters (Case 5) and for black coal powerhouse ranges from 12.5 to 20.8 gCO2/tkm (see Figure 6b). Comparing the values from this study with the values posted in Table 6, it may be found that the emission factors are almost the same in both cases. It is interesting that the authors of the report for the RailBaltica investment assumed the emission factor for rail operations fluctuates from 10.5 to 13.5 gCO2/gross-tkm [58]. For the average values in this study, the same factor ranged from 8.5 to 11.5 gCO2/gross-tkm. These differences are insignificant and may be the result of the conditions and methods in which those analyses were carried out, the type of cargo train, and train parameters such as gross weight, number of wagons and axles, speed, distance, etc. In this regard, for the CBA, it is safe to use an emission factor in the range of 10.5 to 11.5 gCO2/gross-tkm.

6. Concussions

Based on these studies, it is easy to conclude that decarbonization of rail-electrified transport is not possible as long as energy is still retrieved from traditional powerhouses. In the current geopolitical situation, a complete transition from fossil fuels to renewable energy is still unlikely. Therefore, transport probably needs to wait a little longer for decarbonization. Thankfully, there are several ways to mitigate the environmental impact of railway transport. The first method is to optimize the route parameters. For example, fewer stops consume less energy. From an ecological point of view, it is also worth arranging heavier trains than lighter ones, longer trains than shorter ones, and longer distances than shorter ones (>200 km). Unfortunately, here we return to the starting point. In order to arrange longer trains, it is necessary to modernize the railway infrastructure, as many terminals, cargo holds, and railway stations are still not able to handle 750 m trains. The second method is the modernization of the traction network and the powerhouses. At this level, more than 50–70% of energy is lost. The presented results suggest that states around the world should strive to modernize their railway and energy infrastructure. Without these efforts, rail-electrified transport is not fully environmentally friendly. It is worth noting that in the global literature, there is no place for a discussion on energy losses in traction networks and overhead lines in a situation where their modernization may be one of many ways to fight against global warming. The third option is the proper selection of wagon fleet for the transport task. It was noticed that the CO2 emission intensity is related to the type of wagon. Based on the conducted research, it was concluded that trains composed of 40-foot wagons produced about 10–15% more CO2 than trains composed of 80-foot wagons. This phenomenon may be responsible for the number of wagon axles and the weight of wagons, which have a significant influence on energy consumption. However, further research with other types of wagons and configurations is needed to fully understand the impact of these dependencies.

It is also worth noting that the emission factors for rail freight can vary widely between countries depending on the carbon intensity of their electrical power. Therefore, it is almost impossible to establish a representative emission factor for the whole of Europe [56].

Author Contributions

M.B. prepared the methodology, conducted formal analyses, prepared and wrote the original draft, and D.P. reviewed and edited the draft, provided supervision, and acquired funding. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Warsaw University of Technology, Faculty of Transport, through a grant number 7/2022 from the Scientific Council of the Discipline of Civil Engineering, Geodesy, and Transport.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study, in the collection, analysis, or interpretation of data, in the writing of the manuscript, or in the decision to publish the results.

References

- Handayani, R.D. Triyanto Seventh-Grade Students’ Conceptions of Climate Change, Global Warming, and the Greenhouse Effect. Annu. Set Environ. Prot. 2021, 70, 490–500. [Google Scholar] [CrossRef]

- Shafique, M.; Azam, A.; Rafiq, M.; Luo, X. Investigating the Nexus among Transport, Economic Growth and Environmental Degradation: Evidence from Panel ARDL Approach. Transp. Policy 2021, 109, 61–71. [Google Scholar] [CrossRef]

- Li, Y.; Du, Q.; Lu, X.; Wu, J.; Han, X. Relationship between the Development and CO2 Emissions of Transport Sector in China. Transp. Res. Part D Transp. Environ. 2019, 74, 1–14. [Google Scholar] [CrossRef]

- Aminzadegan, S.; Shahriari, M.; Mehranfar, F.; Abramović, B. Factors Affecting the Emission of Pollutants in Different Types of Transportation: A Literature Review. Energy Rep. 2022, 8, 2508–2529. [Google Scholar] [CrossRef]

- Jacyna, M.; Wasiak, M.; Lewczuk, K.; Karoń, G. Noise and Environmental Pollution from Transport: Decisive Problems in Developing Ecologically Efficient Transport Systems. J. Vibroengineering 2017, 19, 5639–5655. [Google Scholar] [CrossRef]

- Pyza, D. Systemy Przewozowe—Problemy Obsługi, Potencjał i Jego Utrzymanie; Oficyna Wydawnicza Politech: Warsaw, Poland, 2019; p. 235. ISBN 978-83-7814-881-4. [Google Scholar]

- Pyza, D.; Jacyna-Gołda, I.; Gołda, P.; Gołębiowski, P. Alternative Fuels and Their Impact on Reducing Pollution of the Natural Environment. Ann. Enivoron. Prot. 2018, 2, 819–836. [Google Scholar]

- Smith, M. Delivering the Goods: Executing Sustainable Transport Policy through Urban Planning in Merseyside (2001–2010). Plan. Perspect. 2020, 36, 515–534. [Google Scholar] [CrossRef]

- Ge, J.; Shi, W.; Wang, X. Policy Agenda for Sustainable Intermodal Transport in China: An Application of the Multiple Streams Framework. Sustainability 2020, 12, 3915. [Google Scholar] [CrossRef]

- Boehm, M.; Arnz, M.; Winter, J. The Potential of High-Speed Rail Freight in Europe: How Is a Modal Shift from Road to Rail Possible for Low-Density High Value Cargo? Eur. Transp. Res. Rev. 2021, 13, 4. [Google Scholar] [CrossRef]

- Regmi, M.B.; Hanaoka, S. Assessment of Modal Shift and Emissions along a Freight Transport Corridor Between Laos and Thailand. Int. J. Sustain. Transp. 2015, 9, 192–202. [Google Scholar] [CrossRef]

- RailTech.Com I Over Half of EU Locomotives Still Run on Diesel: The Road to Net Zero. Available online: https://www.railtech.com/rolling-stock/2023/05/09/over-50-of-eu-locomotives-still-run-on-diesel-the-road-to-net-zero/?gdpr=accept&gdpr=accept (accessed on 23 August 2023).

- Eurostat. Available online: https://ec.europa.eu/eurostat/databrowser/view/rail_eq_locon/default/table?lang=enhttps:%2F%2Fec.europa.eu%2Feurostat%2Fstatistics-ex-plained%2Findex.php%3Ftitle%3DTransport_equipment_statistics#Railway_transport_equipment:_more_electrical_energy.2C_fewer (accessed on 23 August 2023).

- Brzeziński, M.; Pyza, D. Carbon Dioxide Emission from Diesel Engine Vehicles in Intermodal Transport. Transport 2021, 36, 246–259. [Google Scholar] [CrossRef]

- Supapo, K.R.M.; Lozano, L.; Tabañag, I.D.F.; Querikiol, E.M. A Geospatial Approach to Energy Planning in Aid of Just Energy Transition in Small Island Communities in the Philippines. Appl. Sci. 2021, 11, 11955. [Google Scholar] [CrossRef]

- CO2 Emissions from Cars: Facts and Figures (Infographics)|News|European Parliament. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20190313STO31218/co2-emissions-from-cars-facts-and-figures-infographics (accessed on 23 August 2023).

- Bauer, L.; Beck, P.; Stütz, L.; Kley, M. Enhanced Efficiency Prediction of an Electrified Off-Highway Vehicle Transmission Utilizing Machine Learning Methods. Procedia Comput. Sci. 2021, 192, 417–426. [Google Scholar] [CrossRef]

- Di Chiara, L.; Ferres, F.; Bastarrica, F. Impact of Electromobility Deployment Scenarios in the Power System of Uruguay by 2028. In Proceedings of the 2021 IEEE URUCON, Montevideo, Uruguay, 24–26 November 2021; pp. 360–363. [Google Scholar] [CrossRef]

- Habib, K.; Hansdóttir, S.T.; Habib, H. Critical Metals for Electromobility: Global Demand Scenarios for Passenger Vehicles, 2015–2050. Resour. Conserv. Recycl. 2020, 154, 104603. [Google Scholar] [CrossRef]

- Lemme, R.F.F.; Arruda, E.F.; Bahiense, L. Optimization Model to Assess Electric Vehicles as an Alternative for Fleet Composition in Station-Based Car Sharing Systems. Transp. Res. Part D Transp. Environ. 2019, 67, 173–196. [Google Scholar] [CrossRef]

- Jerez, B.; Garcés, I.; Torres, R. Lithium Extractivism and Water Injustices in the Salar de Atacama, Chile: The Colonial Shadow of Green Electromobility. Polit. Geogr. 2021, 87, 102382. [Google Scholar] [CrossRef]

- Yang, H.; Ma, Q.; Wang, Z.; Cai, Q.; Xie, K.; Yang, D. Safety of Micro-Mobility: Analysis of E-Scooter Crashes by Mining News Reports. Accid. Anal. Prev. 2020, 143, 105608. [Google Scholar] [CrossRef] [PubMed]

- Golovanov, N.; Marinescu, A. Electromobility and Climate Change. In Proceedings of the 2019 8th International Conference on Modern Power Systems, MPS 2019, Cluj Napoca, Romania, 21–23 May 2019. [Google Scholar] [CrossRef]

- Plewa, F.; Strozik, G. Energy and Environmental Implications of Electromobility Implementation in Poland. IOP Conf. Ser. Earth Environ. Sci. 2019, 261, 012042. [Google Scholar] [CrossRef]

- Janic, M.; Vleugel, J. Estimating Potential Reductions in Externalities from Rail–Road Substitution in Trans-European Freight Transport Corridors. Transp. Res. Part D Transp. Environ. 2012, 17, 154–160. [Google Scholar] [CrossRef]

- Zając, M. The Analysis of Selected Factors Improving the Cargo Susceptibility to Modal Shift. Energies 2022, 15, 8811. [Google Scholar] [CrossRef]

- Golightly, D.; Gamble, C.; Palacin, R.; Pierce, K. Multi-Modelling for Decarbonisation in Urban Rail Systems. Urban Rail Transit 2019, 5, 254–266. [Google Scholar] [CrossRef]

- Janić, M. Multicriteria Evaluation of Intermodal (Rail/Road) Freight Transport Corridors. Logist. Sustain. Transp. 2020, 11, 1–23. [Google Scholar] [CrossRef]

- Heinold, A. Comparing Emission Estimation Models for Rail Freight Transportation. Transp. Res. Part D Transp. Environ. 2020, 86, 102468. [Google Scholar] [CrossRef]

- Hickman, J.A. (Ed.) Project Report SE/491/98 Methodology for Calculating Transport Emissions and Energy Consumption; Deliverable 22 for the Project MEET (Methodologies for Estimating Air Pollutant Emissions from Transport); Transport Research Laboratory: Berkshire, UK, 1999. [Google Scholar]

- Heinold, A.; Meisel, F. Emission Rates of Intermodal Rail/Road and Road-Only Transportation in Europe: A Comprehensive Simulation Study. Transp. Res. Part D Transp. Environ. 2018, 65, 421–437. [Google Scholar] [CrossRef]

- Wang, H.; Fu, L.; Chen, J. Developing a High-Resolution Vehicular Emission Inventory by Integrating an Emission Model and a Traffic Model: Part 2—A Case Study in Beijing. J. Air Waste Manag. Assoc. 2012, 60, 1471–1475. [Google Scholar] [CrossRef]

- García, V.F.; María, D.; Vidal, R.; Daniel, N.; Cordero, G.; Dilara, D.P. Evaluation and Improvement of Road Vehicle Pollutant Emission Factors Based on Instantaneous Emissions Data Processing. Ph.D. Thesis, Jaume I University, Castelló de la Plana, Spain, 2014. [Google Scholar]

- Heinold, A.; Meisel, F. Emission Limits and Emission Allocation Schemes in Intermodal Freight Transportation. Transp. Res. Part E Logist. Transp. Rev. 2020, 141, 101963. [Google Scholar] [CrossRef]

- Lindgreen, E.B.G.; Sorenson, S.C. Simulation of Energy Consumption and Emissions from Rail Traffic; Technical University of Denmark: Lyngby, Denmark, 2005; pp. 343–354. [Google Scholar]

- Andre, M.; Keller, M.; Gadrat, M.; Sjodin, A. The ARTEMIS European Tools for Estimating the Pollutant Emissions from Road Transport and Their Application in Sweden and France. In Proceedings of the 17th International Conference’ Transport and Air Pollution, Graz, Austria, 2008; Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=399e8ff96aad8c28ebf79e2414d869203f9c768b (accessed on 11 July 2023).

- Wild, P. Recommendations for a Future Global CO2-Calculation Standard for Transport and Logistics. Transp. Res. Part D Transp. Environ. 2021, 100, 103024. [Google Scholar] [CrossRef]

- EcoTransIT World Initiative (EWI). Ecological Transport Information Tool for Worldwide Transports; EcoTransIT World Initiative (EWI): Berne, Switzerland; Hannover, Germany; Heidelberg, Germany, 2019. [Google Scholar]

- Cichosz, M.; Nowicka, K.; Ocicka, B. Efektywne Planowanie Transportu Multimodalnego. Przem. Chem. 2018, 97, 1421. [Google Scholar] [CrossRef]

- Kirschstein, T.; Meisel, F. GHG-Emission Models for Assessing the Eco-Friendliness of Road and Rail Freight Transports. Transp. Res. Part B Methodol. 2015, 73, 13–33. [Google Scholar] [CrossRef]

- Zhou, Y.; Lee, G.M. A Lagrangian Relaxation-Based Solution Method for a Green Vehicle Routing Problem to Minimize Greenhouse Gas Emissions. Sustainability 2017, 9, 776. [Google Scholar] [CrossRef]

- Zhang, R.; Yao, E. Mesoscopic Model Framework for Estimating Electric Vehicles’ Energy Consumption. Sustain. Cities Soc. 2019, 47, 101478. [Google Scholar] [CrossRef]

- Kampczyk, A.; Rombalska, K. Configuration of the Geometric State of Railway Tracks in the Sustainability Development of Electrified Traction Systems. Sensors 2023, 23, 2817. [Google Scholar] [CrossRef]

- Arboleya, P.; Diaz, G.; Coto, M. Unified Ac/Dc Power Flow for Traction Systems: A New Concept. IEEE Trans. Veh. Technol. 2012, 61, 2421–2430. [Google Scholar] [CrossRef]

- Stobiecki, A.; Dudek, R. Układy Napędowe Wielosystemowych Pojazdów Trakcyjnych. Masz. Elektr. Zesz. Probl. 2018, 2, 7–13. [Google Scholar]

- Chrabąszcz, I.; Kierzyk, M.; Prusak, J.; Markowski, Paweł. Analiza Strat Energii w Układzie Zasilania Wybranego Odcinka Trakcji Elektrycznej DC Po Jego Modernizacji. Eksploatacja 2018, 25, 38–43. [Google Scholar]

- Janusz, B.; Krzysztof, F.; Marek, K.; Jakub, M.; Artur, R. Porównanie Systemów Zasilania Kolejowej Sieci Trakcyjnej; Fundacja “Pro Kolej”: Warszawa, Poland, 2020; Available online: https://prokolej.org/wp-content/uploads/2022/10/Raport-3-25kV.pdf (accessed on 5 August 2023).

- Pyza, D.; Piątek, M. Wybrane Aspekty Projektowania Terminali Intermodalnych. Pr. Nauk. Politech. Warsz. Transp. 2017, 119, 389–399. [Google Scholar]

- PKP Cargo Katalog Wagonów PKP. Available online: https://www.pkpcargo.com/media/244882/pkp_cargo_katalog_03072018.pdf (accessed on 26 January 2020).

- Graus, W.H.J.; Voogt, M.; Worrell, E. International Comparison of Energy Efficiency of Fossil Power Generation. Energy Policy 2007, 35, 3936–3951. [Google Scholar] [CrossRef]

- Dataportal.orr.gov.uk Rail Emissions April 2021 to March 2022. Available online: https://dataportal.orr.gov.uk/media/2112/rail-emissions-2021-22.pdf (accessed on 23 August 2023).

- UIC Energy Consumption and CO2 Emissions. Available online: https://uic.org/IMG/pdf/2012_uic-iea_railway_handbook_web_high.pdf (accessed on 23 August 2023).

- Rizet, C.; Cruz, C.; Mbacké, M. Reducing Freight Transport CO2 Emissions by Increasing the Load Factor. Procedia-Soc. Behav. Sci. 2012, 48, 184–195. [Google Scholar] [CrossRef]

- Witaszek, M.; Witaszek, K. Comparison of Air Pollutants Emissions for Different Modes of Transport. Available online: https://repolis.bg.polsl.pl/Content/20411/Porownanie_emisji.pdf (accessed on 7 July 2023).

- Mckinnon, A.; Piecyk, M. Measuring and Managing CO2 Emissions of European Chemical Transport. In Proceedings of the Workshop Inland Navigation CO2 Emissions, Strasbourg, France, 12 April 2011. [Google Scholar]

- ECTA Guidelines for Measuring and Managing CO2 Emission from Freight Transport Operations. Available online: https://www.ecta.com/wp-content/uploads/2021/03/ECTA-CEFIC-GUIDELINE-FOR-MEASURING-AND-MANAGING-CO2-ISSUE-1.pdf (accessed on 23 August 2023).

- Mckinnon, A. CO2 Emissions from Freight Transport: An Analysis of UK Data. In Proceedings of the Logistics Research Network-2007 Conference Global Supply Chains, Edinburgh, UK, January 2007; Available online: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=fe8c34454596287cb19a9eab912201cfd23211f8 (accessed on 15 July 2023).

- Piterina, O.; Masharsky, A. Energy Consumption of Rail Baltica Project: Regional Aspects of Environmental Impact. Econ. Cult. 2019, 16, 148–160. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).