Optimization of Welding Process of Geomembranes in Biodigesters Using Design of Factorial Experiments

Abstract

:1. Introduction

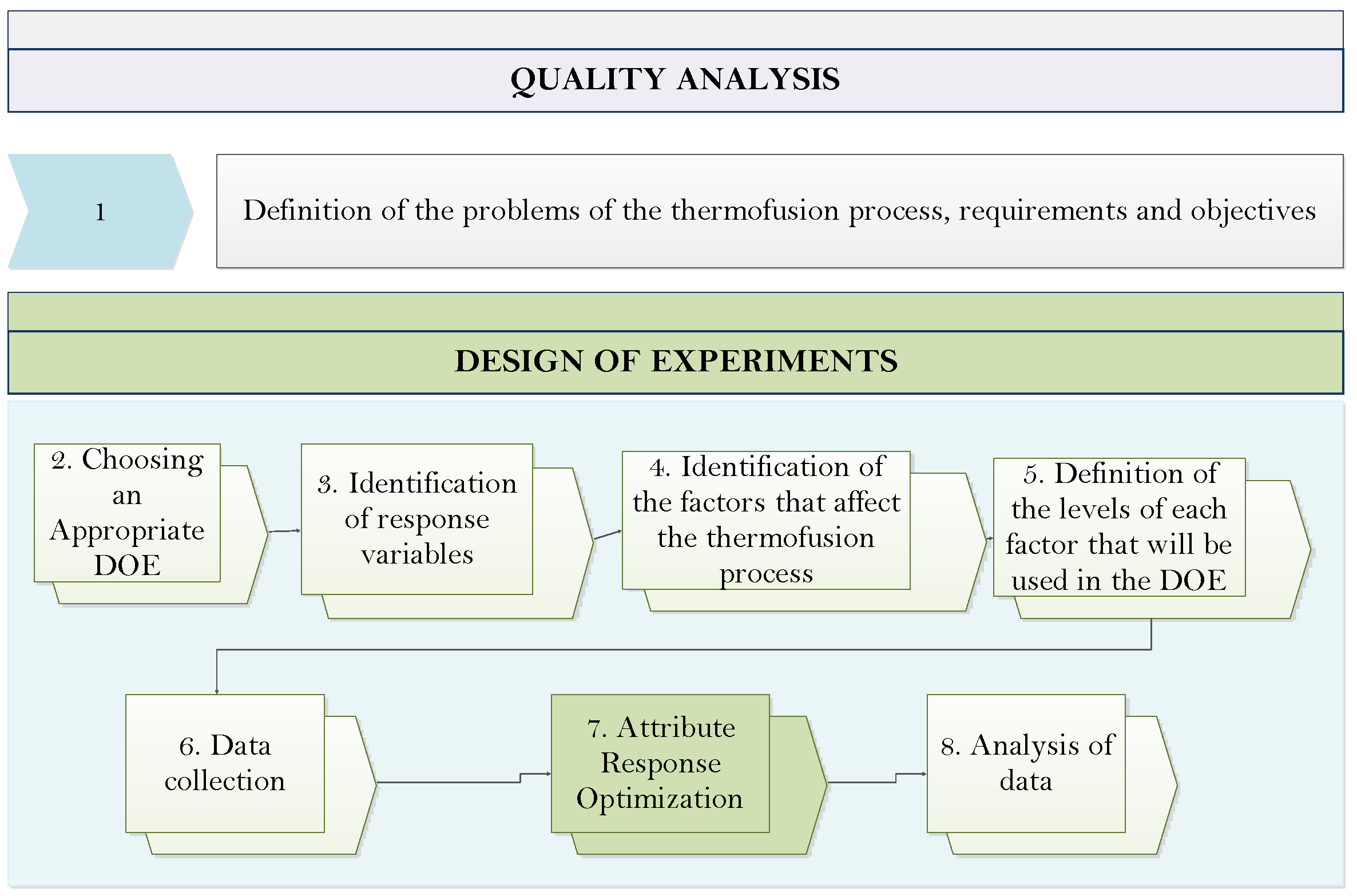

2. Materials and Methods

- Uneven heating: Uneven heating of the geomembrane can lead to weak spots and gaps in the fusion seam, which can compromise the integrity of the liner or containment system. This can be caused by a variety of factors, such as a dirty or damaged heating element or improper temperature control.

- Contamination: Contamination of the geomembrane surface can prevent a proper fusion between the two layers. This can occur when the surfaces are not properly cleaned or when debris, moisture, or other foreign substances are present.

- Inadequate fusion of the geomembrane layers: If the welding parameters are not set correctly for the geomembrane material, thickness, and ambient conditions, this can lead to inadequate fusion of the geomembrane layers. Welding parameters, such as temperature and speed, play a crucial role in achieving a proper weld joint.

- 4

- Poor alignment: If the geomembrane sheets are not properly aligned before the fusion process, it can lead to an imperfect seam or even complete failure.

- 5

- Operator error: Improper handling of the welding equipment or lack of training can also lead to problems during the thermofusion process.

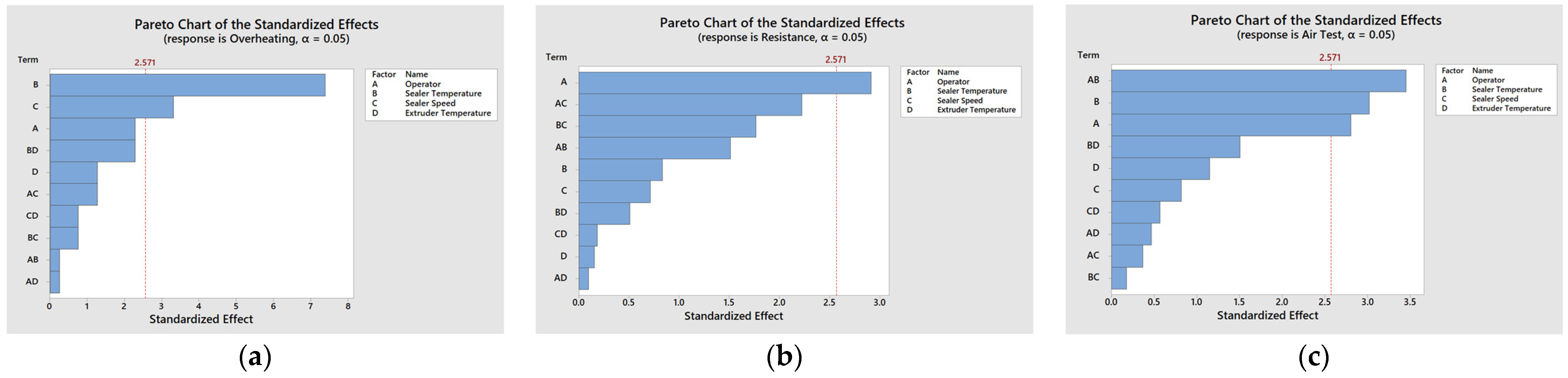

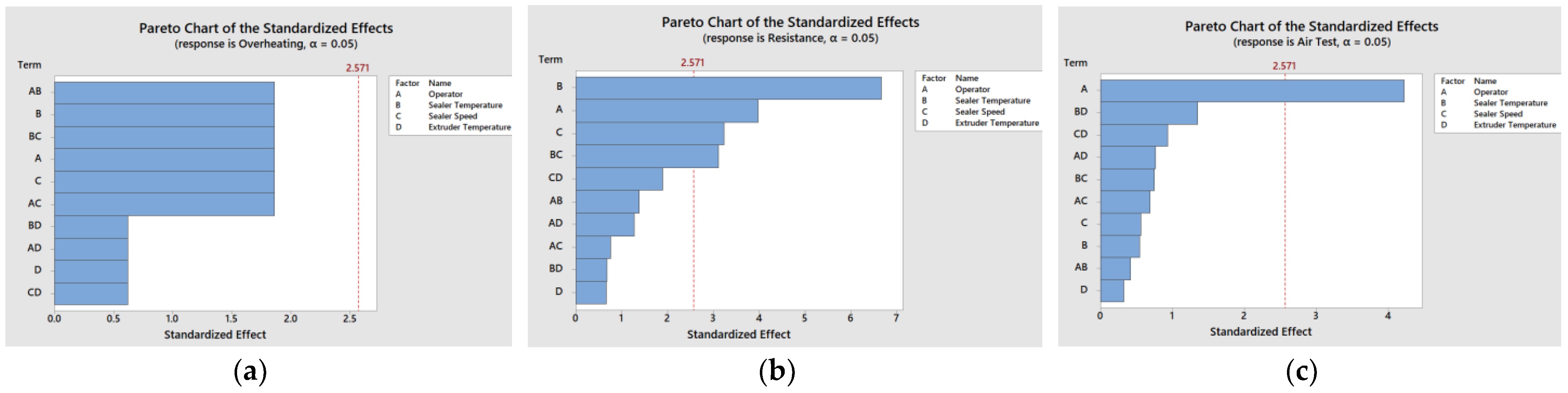

- Analysis of significant factors and interactions in DOEs: The analysis of significant factors and interactions involved determining which factors have a statistically significant impact on the response variable and how they interact with each other. The Pareto chart is a graphical tool used in the analysis of significant factors in the design of experiments (DOE) [37]. It is particularly useful in identifying and prioritizing the most influential factors affecting a response variable based on their relative importance.

- Interaction effects analysis: In addition to the main effects, interactions between factors are also examined. Interaction effects occur when the effect of one factor on the response variable depends on the level or presence of another factor. Interaction effects can be additive, synergistic, or antagonistic. By including interaction terms in the statistical model, researchers can evaluate the significance and strength of these interactions.

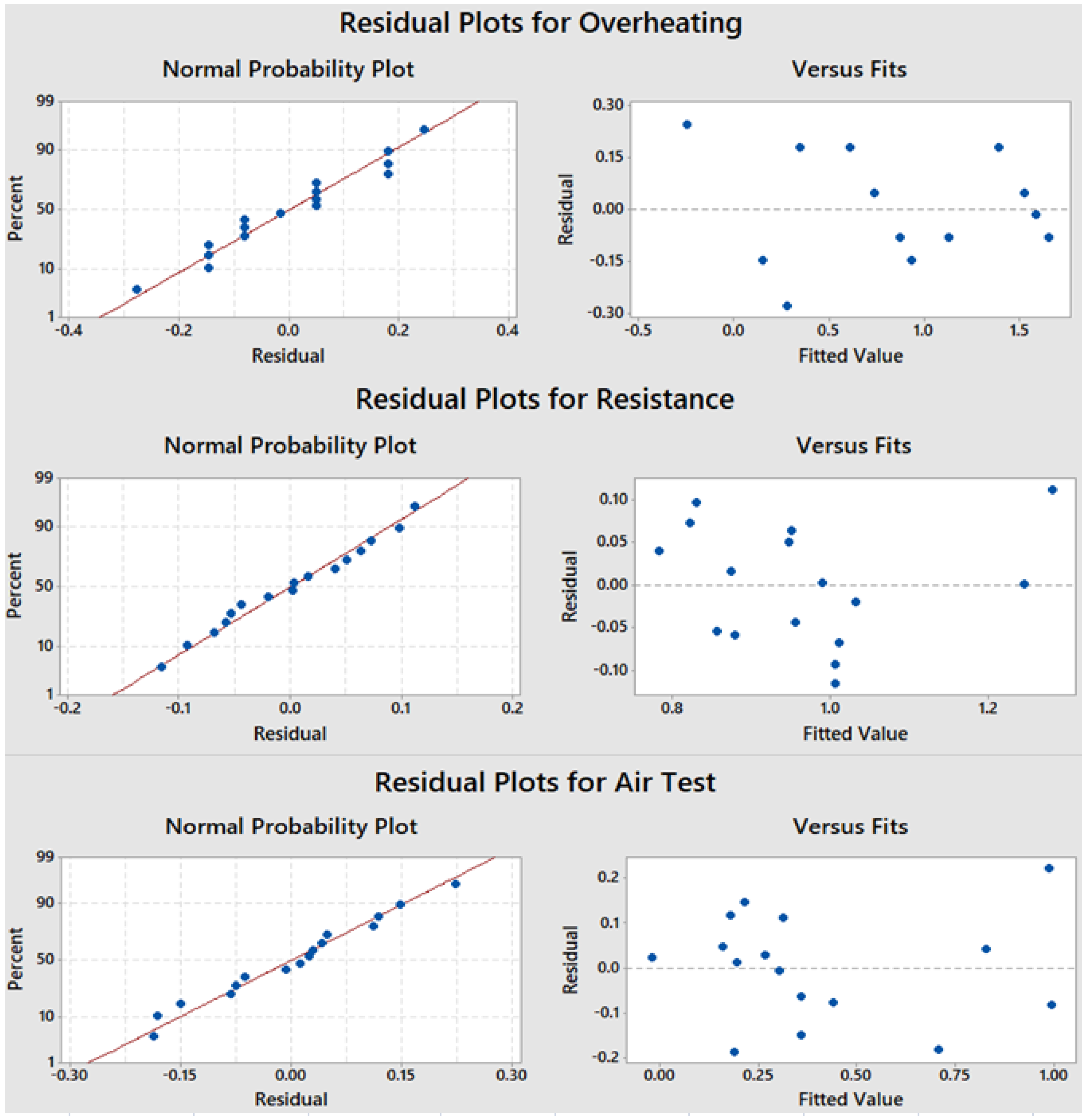

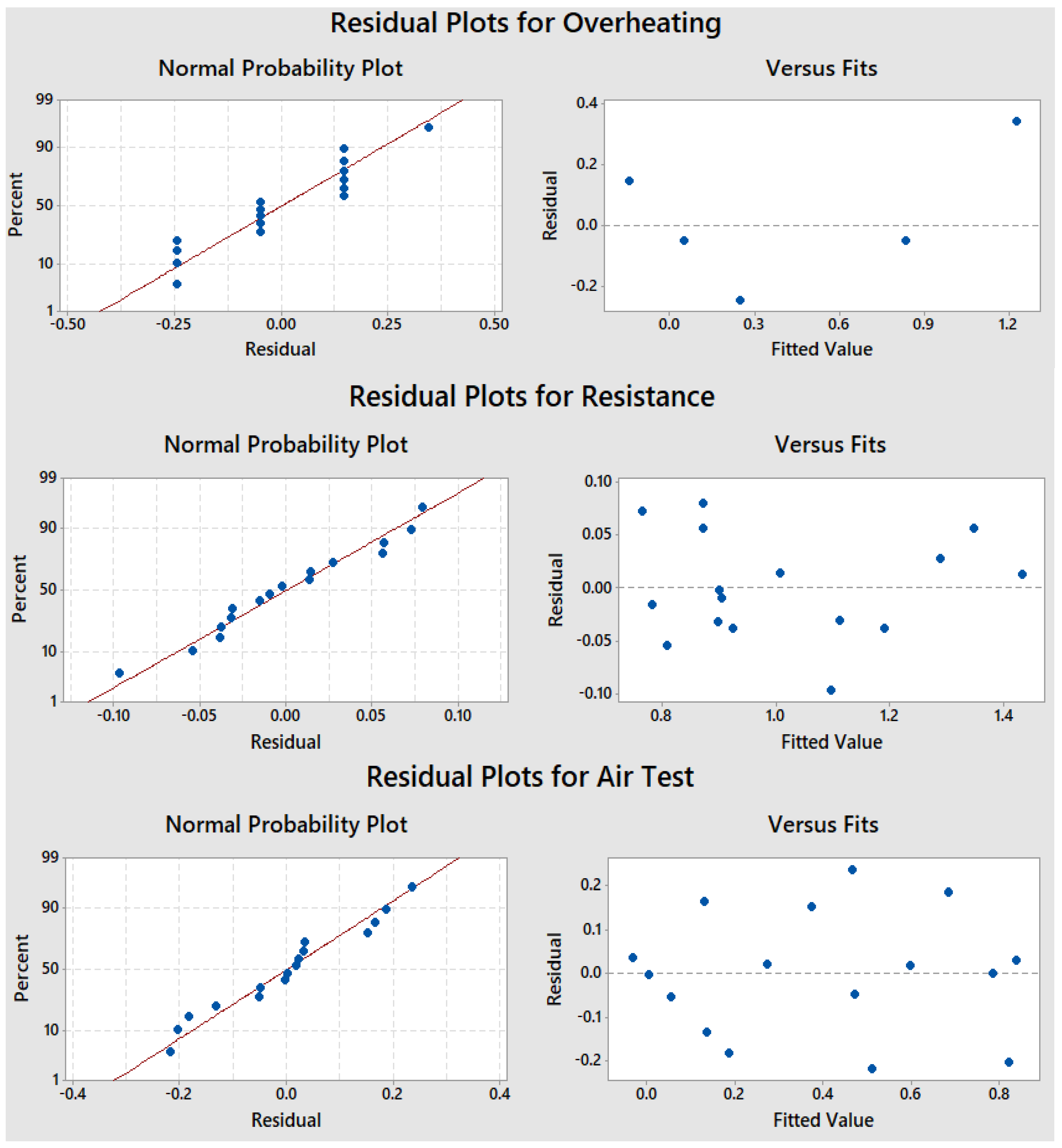

- Verification of assumptions in statistical analysis: involves checking for normality, constant variance, and independence of the data. Normality refers to the data following a normal distribution, while constant variance means that the variability of the response variable is consistent across all levels of factors. Independence indicates that observations or data points are not correlated or dependent on each other. These assumptions are crucial for valid statistical inference. The normal probability plot is used to test these assumptions.

- Optimization of the response variables of the model: It involves finding the combination of factors or input variables that maximizes or minimizes the response variable(s) based on the objectives of the study. The goal is to identify the optimal settings or conditions that lead to the desired outcome.

3. Results

3.1. Analysis of Significant Factors and Interactions

3.2. Verification of Assumption

3.3. Optimization of Model

O × VS − 0.00218 O × TE − 0.00327 TS × VS + 0.000327 TS × TE + 0.00654 VS × TE

O × VS + 0.00040 O × TE + 0.00351 TS × VS + 0.000034 TS × TE − 0.00074 VS × TE

0.076 O × VS − 0.00320 O × TE + 0.00060 TS × VS + 0.000172 TS × TE − 0.00388 VS × TE

TS + 0.589 O × VS + 0.0065 O × TE

− 0.00982 TS × VS− 0.000109 T S × TE + 0.0065 VS × TE

O × TS + 0.0658 O × VS − 0.00363 O × TE − 0.00445 TS × VS + 0.000032 TS × TE− 0.00541 VS × TE

TS − 0.166 O × VS + 0.00613 O × TE + 0.00302 TS × VS − 0.000180 TS × TE +

0.00752 VS × TE

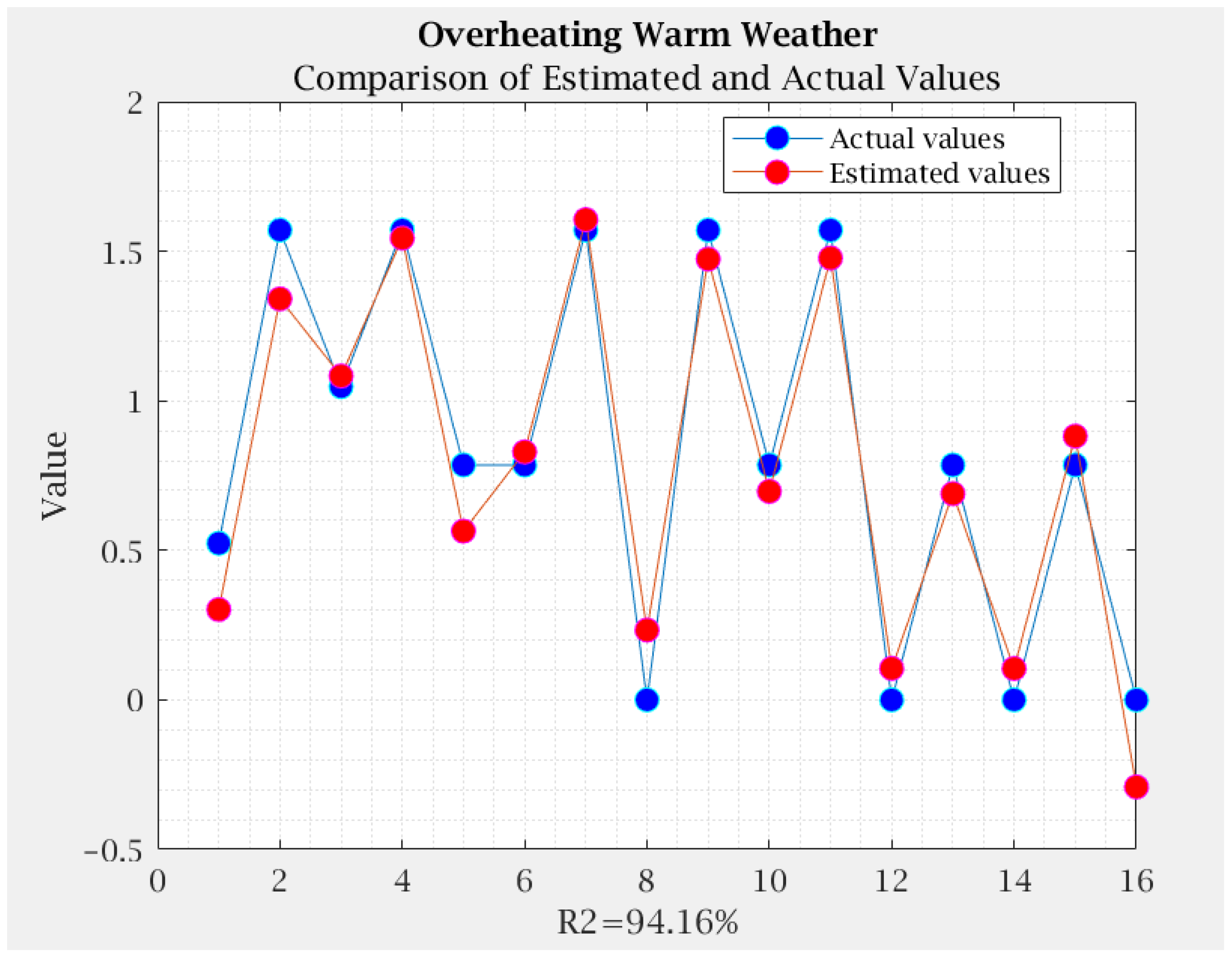

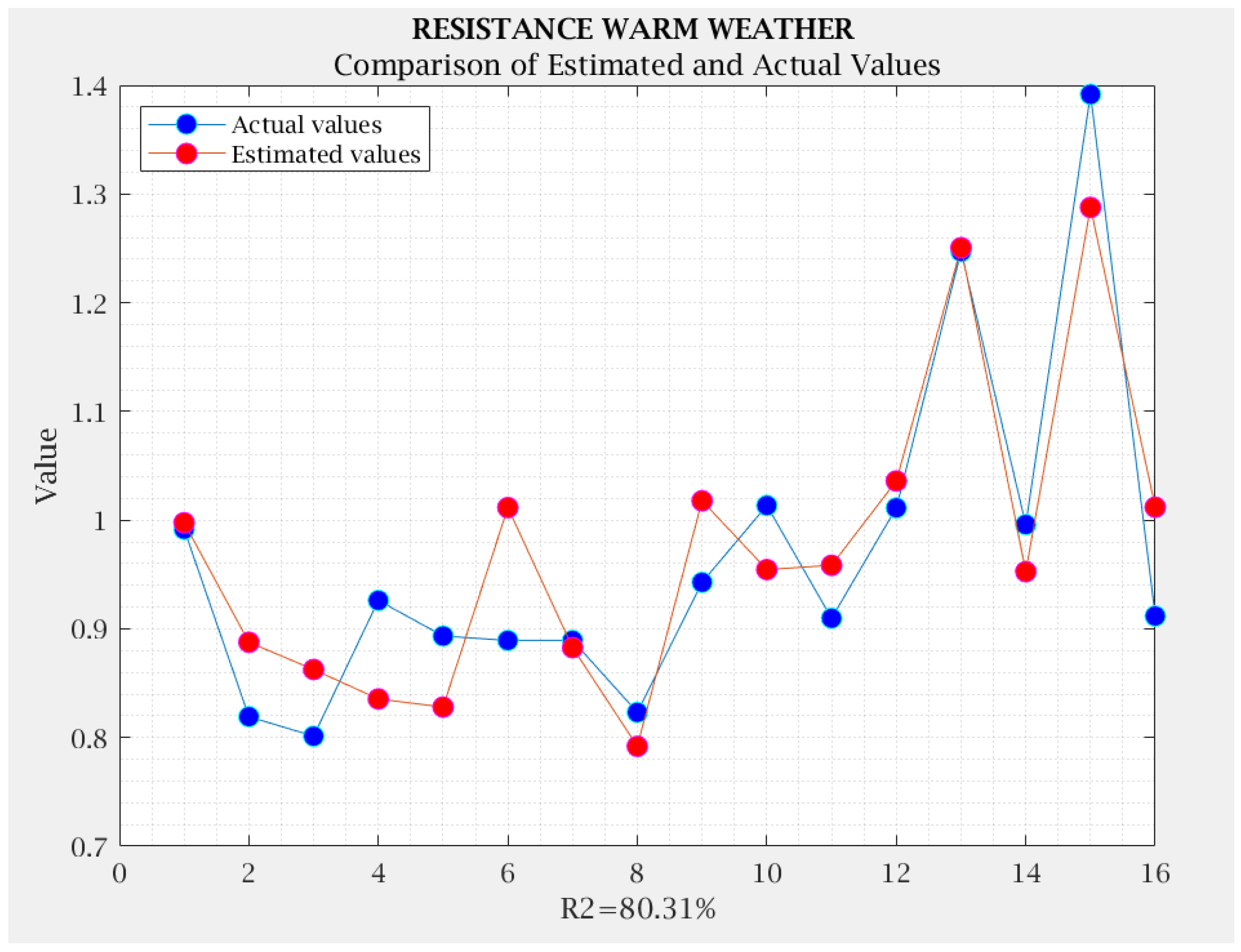

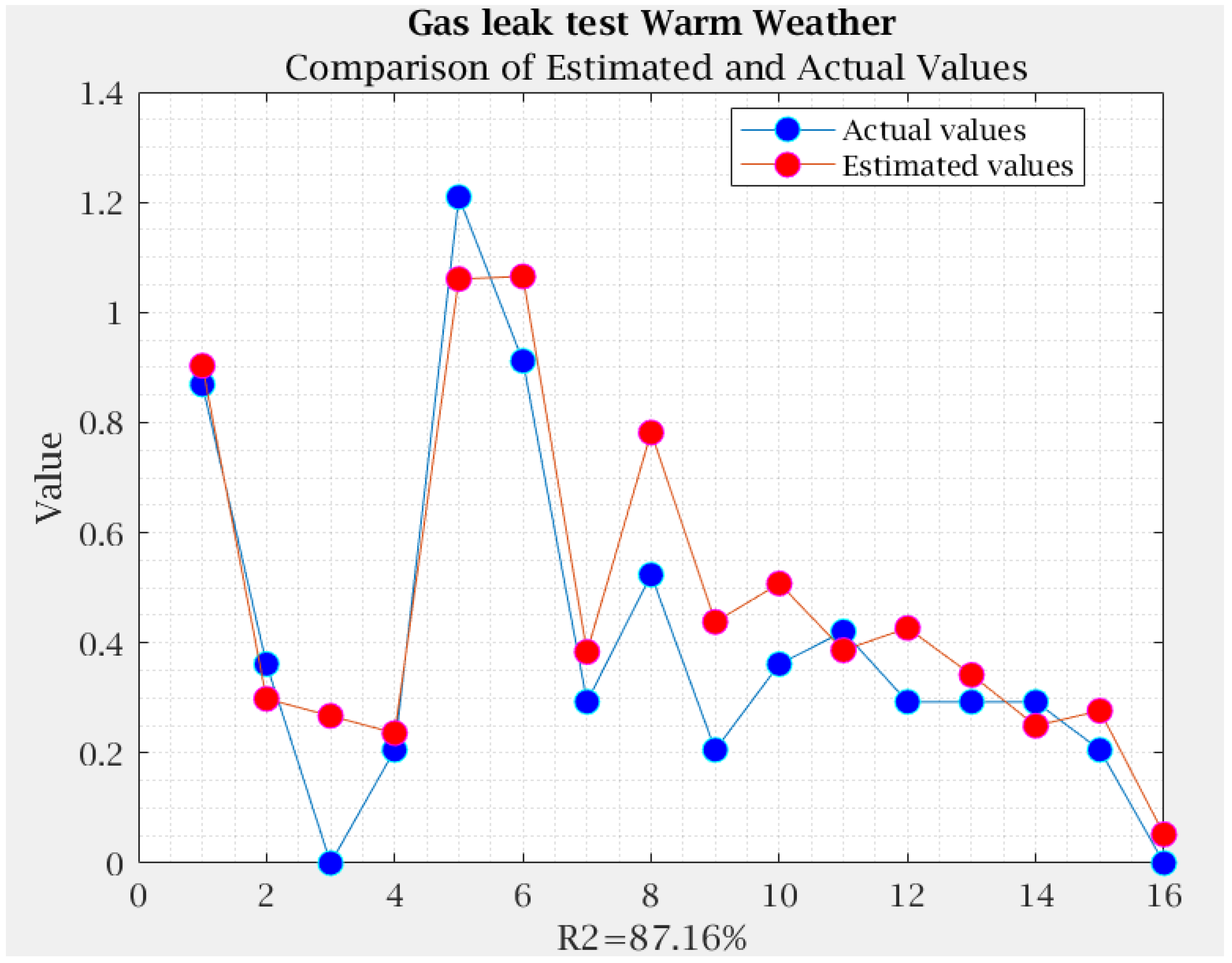

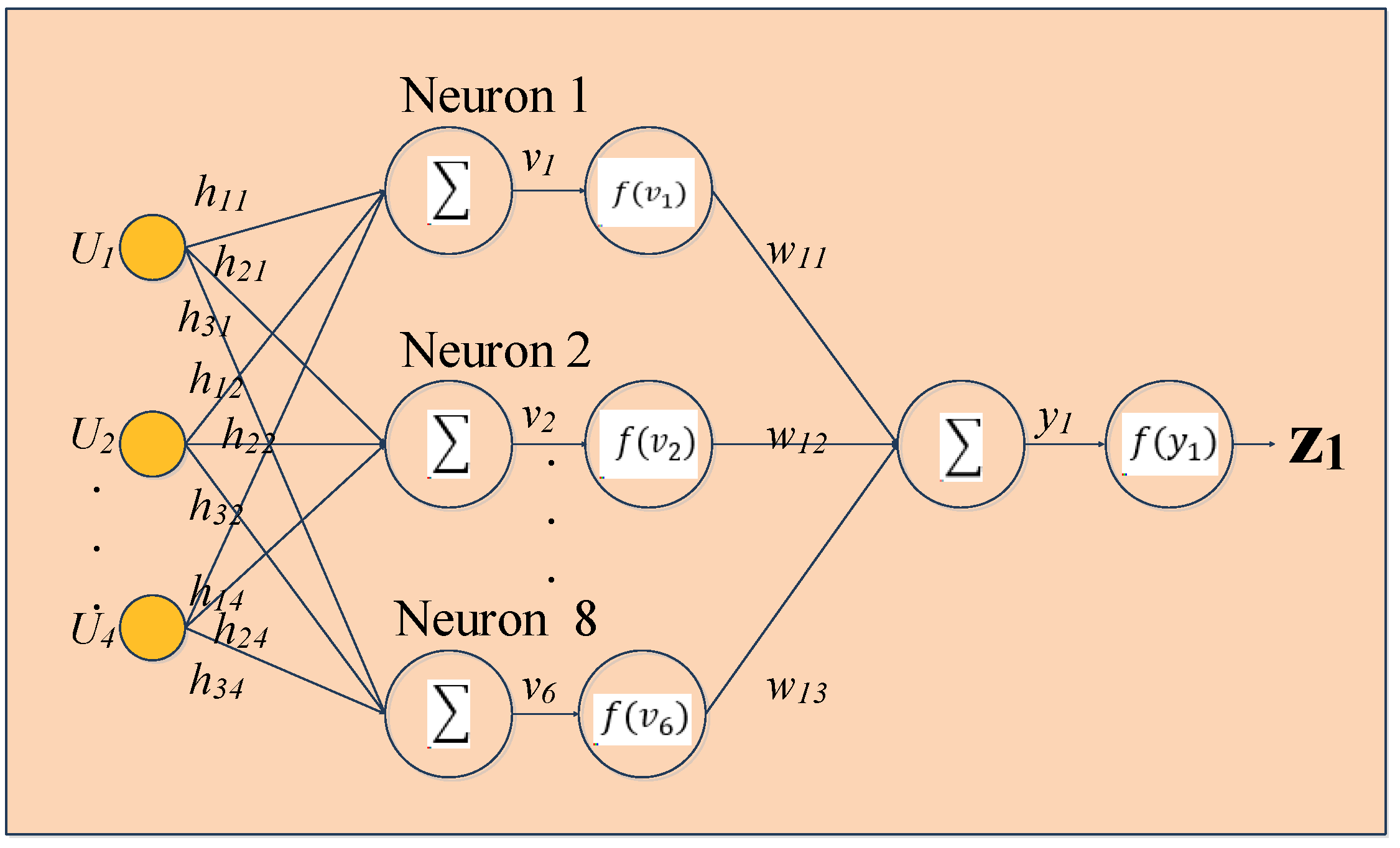

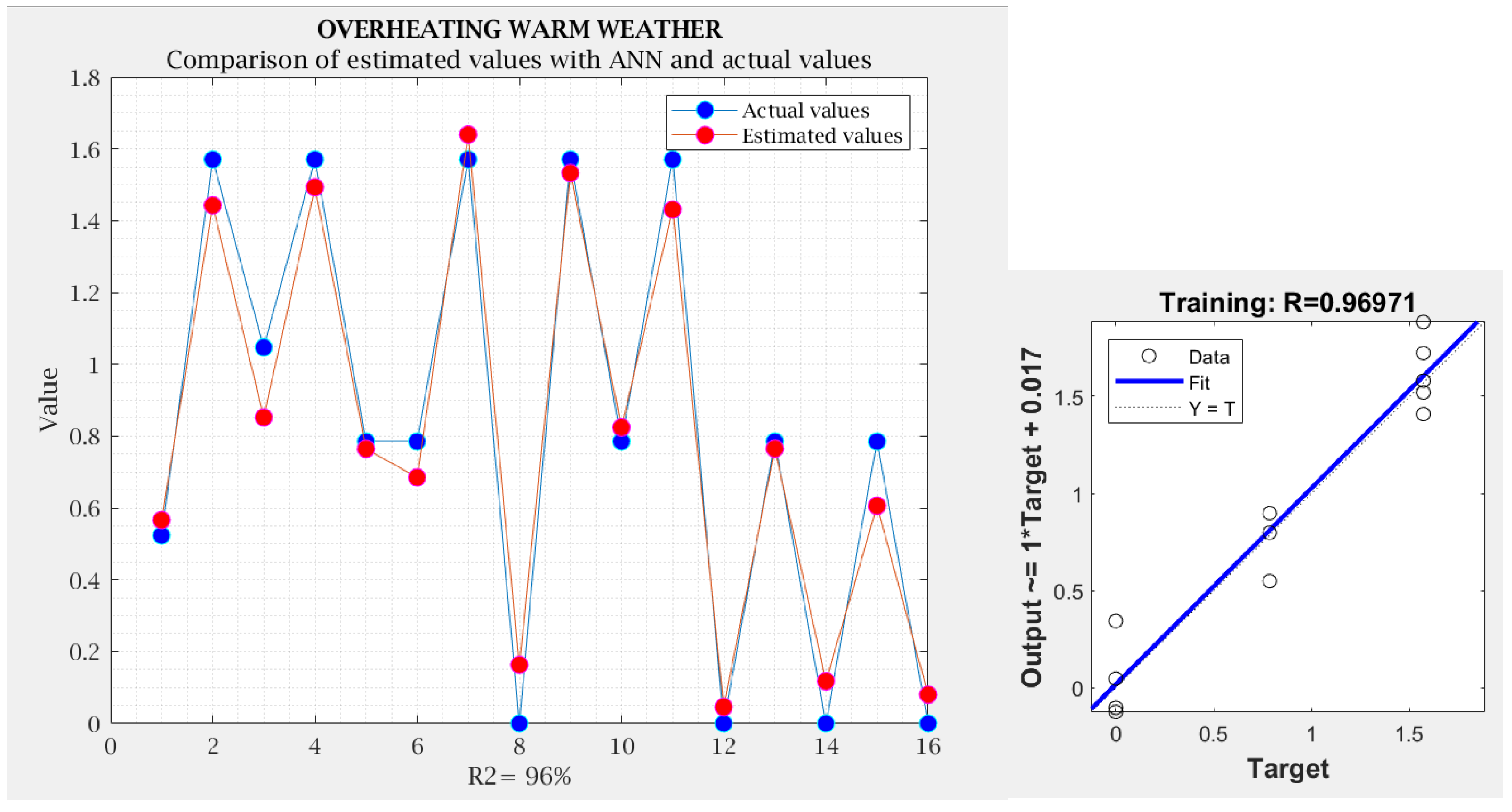

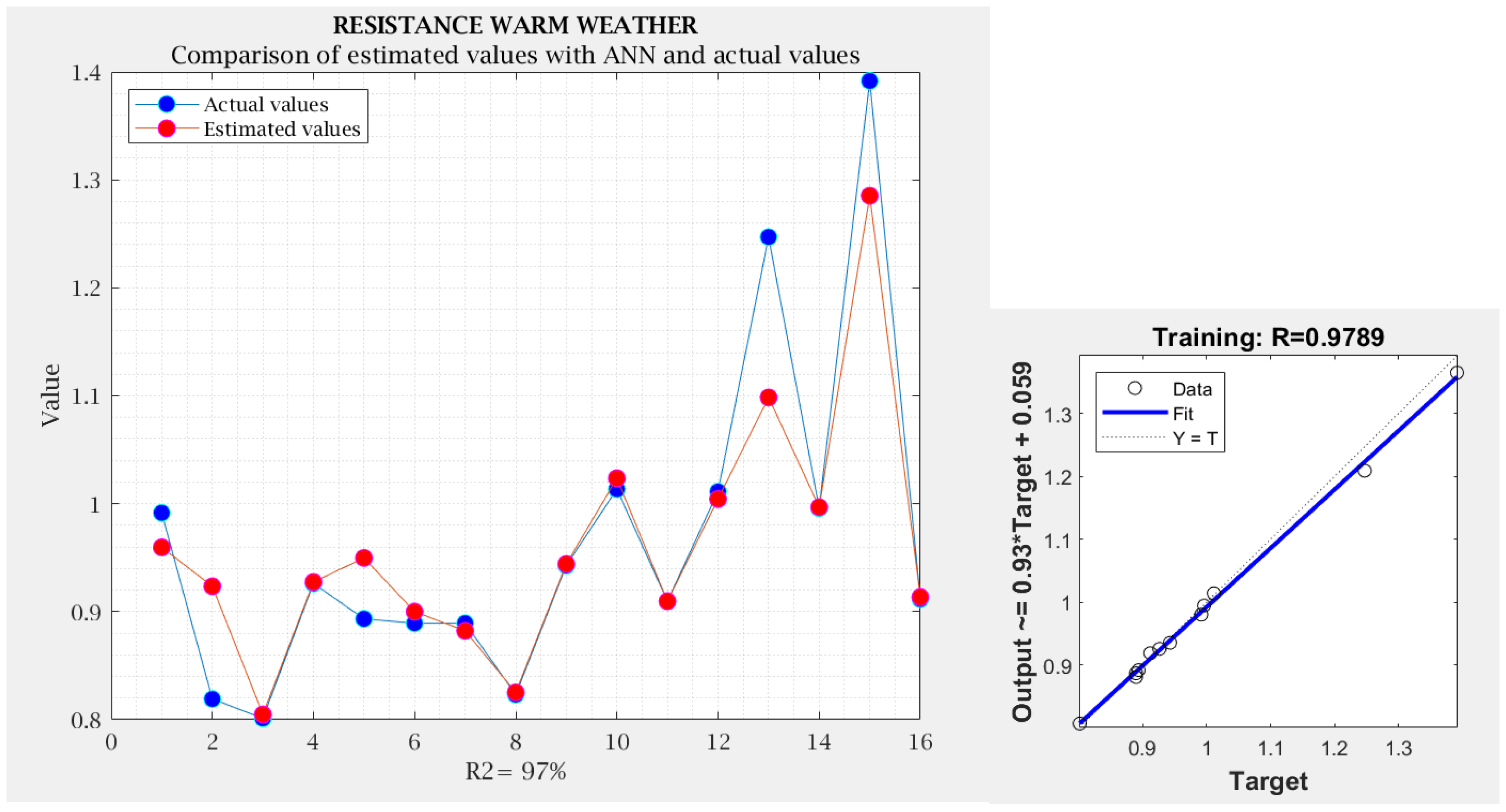

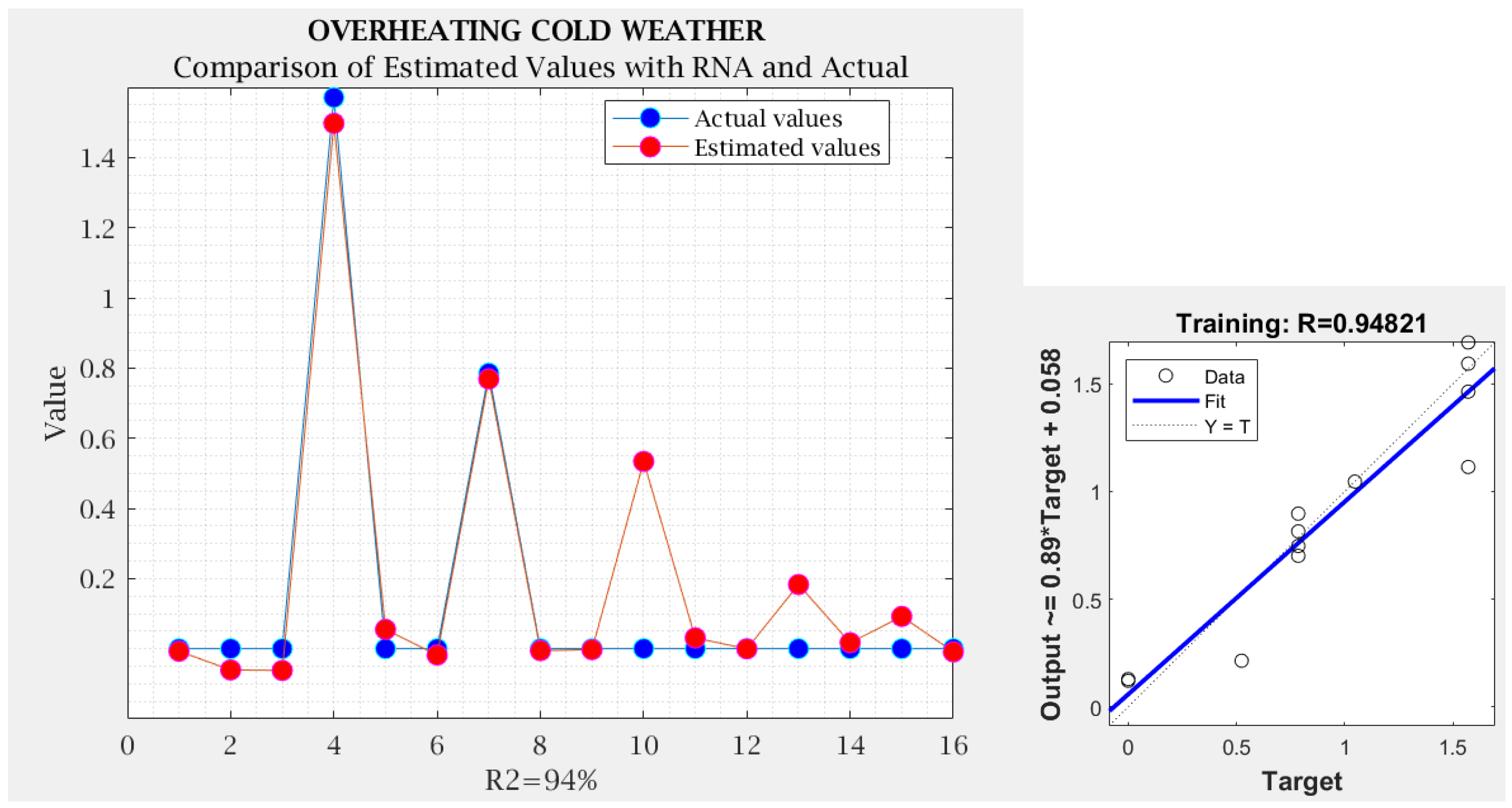

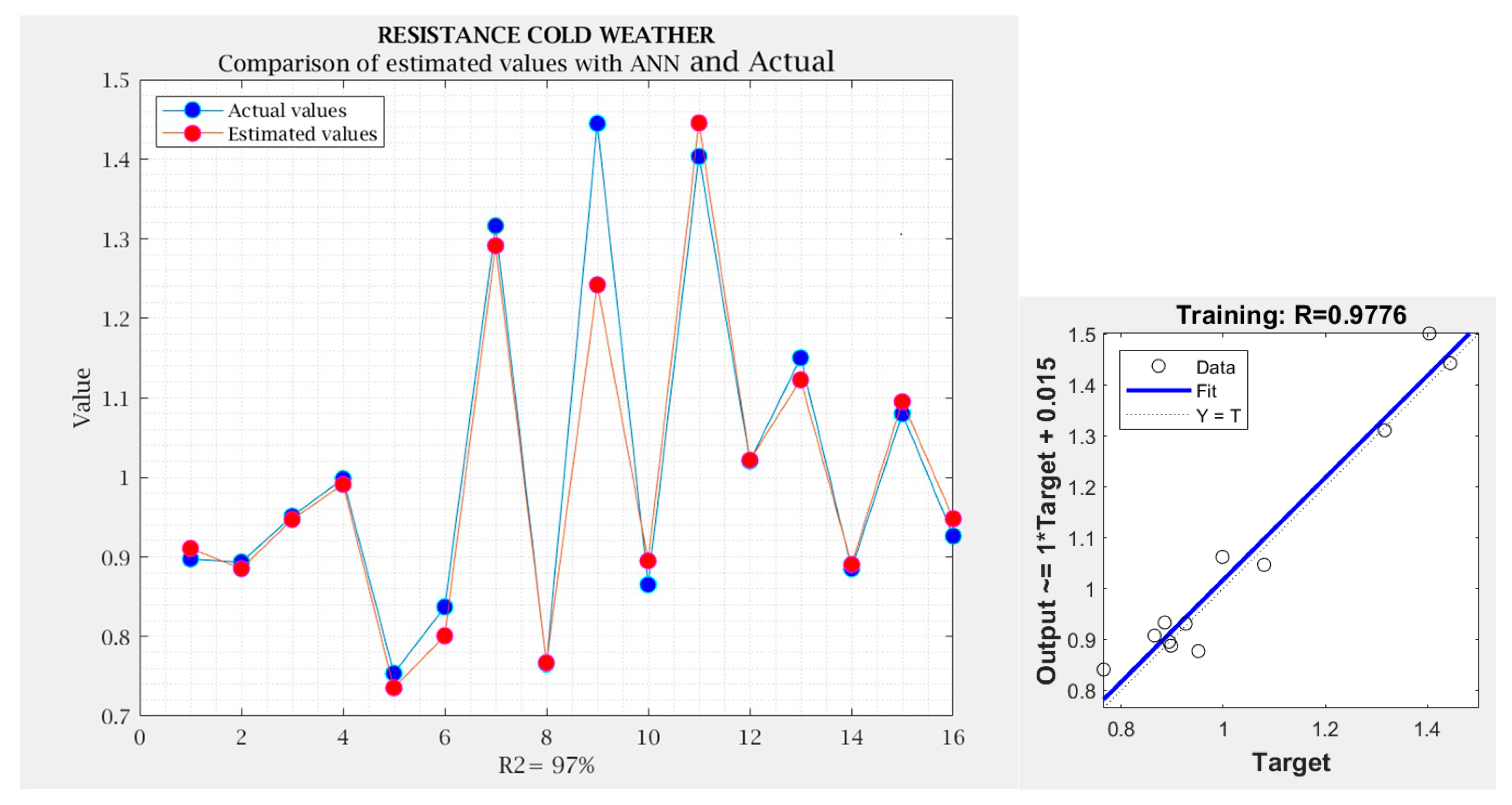

3.4. Comparative Analysis with Neural Networks

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Francey, W.; Rowe, R.K. Importance of thickness reduction and squeeze-out Std-OIT loss for HDPE geomembrane fusion seams. Geotext. Geomembr. 2023, 51, 30–42. [Google Scholar] [CrossRef]

- Cahyani, D.; Haryanto, A.; A Putra, G.; Fil’aini, R.; Marpaung, D.S.S. Life cycle assessment of biogas digester in small scale tapioca industry. IOP Conf. Ser. Earth Environ. Sci. 2019, 258, 012017. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Pastor, A.; Valderrama, P.; Atencio, E. Process Water Management and Seepage Control in Tailings Storage Facilities: Engineered Environmental Solutions Applied in Chile and Peru. Water 2023, 15, 196. [Google Scholar] [CrossRef]

- Valentin, C.A.; da Silva, J.L.; Kobelnik, M.; Ribeiro, C.A. Thermoanalytical and dynamic mechanical analysis of commercial geomembranes used for fluid retention of leaching in sanitary landfills. J. Therm. Anal. Calorim. 2019, 136, 471–481. [Google Scholar] [CrossRef]

- Shared Risk Trust. General Diagnosis of the Situation of Biodigestion Systems in Mexico; Federal Bureau of Agriculture, Animal Breeding and Rural Development: Mexico City, Mexico, 2010. [Google Scholar]

- Camarena-Martinez, R.; Lizarraga-Morales, R.A.; Baeza-Serrato, R. Classification of Geomembranes as Raw Material for Defects Reduction in the Manufacture of Biodigesters Using an Artificial Neuronal Network. Energies 2021, 14, 7345. [Google Scholar] [CrossRef]

- Zhang, L.; Bouazza, A.; Rowe, R.K.; Scheirs, J. Effect of welding parameters on properties of HDPE geomembrane seams. Geosynth. Int. 2017, 24, 408–418. [Google Scholar] [CrossRef]

- Gassner, F.; Fairhead, G. Field leakage rates of geosynthetic lined facilities. In Proceedings of the 10th International Geosynthetics Conference (DGGT), Berlin, Germany, 21–25 September 2014. [Google Scholar]

- Kasemiire, A.; Avohou, H.T.; De Bleye, C.; Sacre, P.-Y.; Dumont, E.; Hubert, P.; Ziemons, E. Design of experiments and design space approaches in the pharmaceutical bioprocess optimization. Eur. J. Pharm. Biopharm. 2021, 166, 144–154. [Google Scholar] [CrossRef]

- Acheson, C.; Mackle, D.; Murphy, A.; Butterfield, J.; Higgins, P.; Collins, R.; Higgins, C.; Darlington, J.; Tame, R. Using Design of Experiments to Define Factory Simulations for Manufacturing Investment Decisions. In Proceedings of the 34th International Manufacturing Conference, Sligo, Ireland, 30–31 August 2017. [Google Scholar]

- Dejaegher, B.; Vander Heyden, Y. Experimental designs and their recent advances in set-up, data interpretation, and analyti829 cal applications. J. Pharm. Biomed. Anal. 2011, 56, 141–158. [Google Scholar]

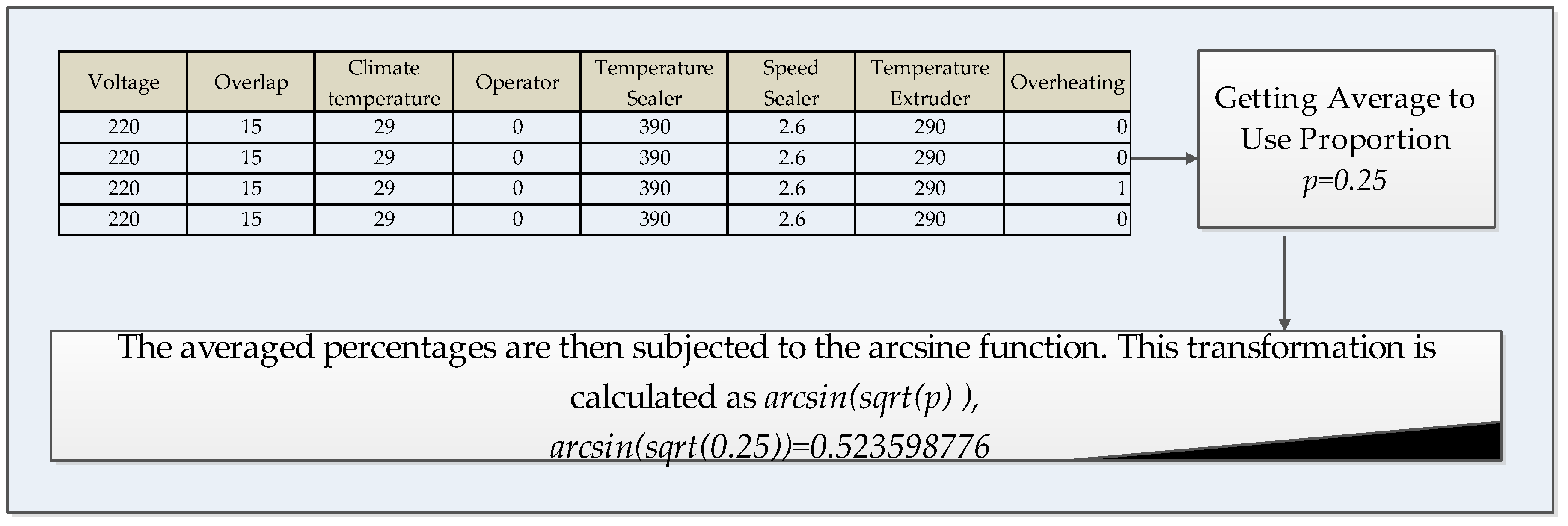

- Laurencelle, L.; Cousineau, D. Analysis of proportions using arcsine transform with any experimental design. Front. Psychol. 2023, 13, 1045436. [Google Scholar] [CrossRef]

- Román-Ramírez, L.; Marco, J. Design of experiments applied to lithium-ion batteries: A literature review. Appl. Energy 2022, 320, 119305. [Google Scholar] [CrossRef]

- Farrahi, G.H.; Kashyzadeh, K.R.; Minaei, M.; Sharifpour, A.; Riazi, S. Analysis of Resistance Spot Welding Process Parameters Effect on the Weld Quality of Three-steel Sheets Used in Automotive Industry: Experimental and Finite Element Simulation. Int. J. Eng. 2020, 33, 148–157. [Google Scholar]

- Eshraghi, M.; Tschopp, M.A.; Zaeem, M.A.; Felicelli, S.D. A parametric study of resistance spot welding of a dual-phase steel using finite element analysis. In Proceedings of the 8th International Congress on Advanced Materials and Processing, Waikoloa, HI, USA, 4–9 August 2013; Springer: Berlin/Heidelberg, Germany, 2013; Volume 33, pp. 3073–3080. [Google Scholar]

- Shrivas, S.P.; Vaidya, S.K.; Khandelwal, A.K.; Vishvakarma, A.K. Investigation of TIG welding parameters to improve strength. Mater. Today Proc. 2020, 26, 1897–1902. [Google Scholar] [CrossRef]

- Madrid, J.; Lorin, S.; Söderberg, R.; Hammersberg, P.; Wärmefjord, K.; Lööf, J. A Virtual Design of Experiments Method to Evaluate the Effect of Design and Welding Parameters on Weld Quality in Aerospace Applications. Aerospace 2019, 6, 74. [Google Scholar] [CrossRef]

- Raveendra, J.; Parmar, R.S. Mathematical models to predict weld bead geometry for flux cored arc welding. J. Met. Constr. 1987, 19, 31R–35R. [Google Scholar]

- Gupta, V.K.; Parmar, R.S. Parmar, Fractional factorial technique to predict dimensions of the weld bead in automatic submerged arc welding. J. Inst. Eng. 1989, 70, 67–75. [Google Scholar]

- Kim, I.; Son, K.; Yang, Y.; Yaragada, P. Sensitivity analysis for process parameters in GMA welding processes using a factorial design method. Int. J. Mach. Tools Manuf. 2003, 43, 763–769. [Google Scholar]

- Gunaraj, V.; Murugan, N. Application of response surface methodology for predicting weld bead quality in submerged arc welding of pipes. J. Mater. Process. Technol. 1999, 88, 266–275. [Google Scholar] [CrossRef]

- Murugan, N.; Gunaraj, V. Prediction and control of weld bead geometry and shape relationships in submerged arc welding of pipes. J. Mater. Process. Technol. 2005, 168, 478–487. [Google Scholar] [CrossRef]

- Pahkamaa, A.; Wärmefjord, K.; Karlsson, L.; Söderberg, R.; Goldak, J. Combining variation simulation with welding simulation for prediction of deformation and variation of a final assembly. J. Comput. Inf. Sci. Eng. 2012, 12, 021002. [Google Scholar]

- Benyounis, K.; Olabi, A.-G. Optimization of different welding processes using statistical and numerical approaches—A reference guide. Adv. Eng. Softw. 2008, 39, 483–496. [Google Scholar] [CrossRef]

- Manonmani, K.; Murugan, N.; Buvanasekaran, G. Effects of process parameters on the bead geometry of laser beam butt welded stainless steel sheets. Int. J. Adv. Manuf. Technol. 2007, 32, 1125–1133. [Google Scholar] [CrossRef]

- Siddaiah, A.; Singh, B.; Mastanaiah, P. Prediction and optimization of weld bead geometry for electron beam welding of AISI 304 stainless steel. Int. J. Adv. Manuf. Technol. 2017, 89, 27–43. [Google Scholar] [CrossRef]

- Benyounis, K.Y.; Olabi, A.G.; Hashmi, M.S.J. Optimizing the laser-welded butt joints of medium carbon steel using RSM. J. Mater. Process. Technol. 2005, 164, 986–989. [Google Scholar] [CrossRef]

- Vicente, G.; Coteron, A.; Martinez, M.; Aracil, J. Application of the factorial design of experiments and response surface methodology to optimize biodiesel production. Ind. Crop. Prod. 1998, 8, 29–35. [Google Scholar] [CrossRef]

- Koudache, F.; Yala, A.A. A Contribution to the Optimisation of Biogas Digesters with the Design of Experiments Method. J. Inter. Environ. Appl. Sci. 2008, 3, 195–200. [Google Scholar]

- Bose, A.; O’Shea, R.; Lin, R.; Murphy, J.D. A comparative evaluation of design factors on bubble column operation in photosynthetic biogas upgrading. Biofuel Res. J. 2021, 8, 1351–1373. [Google Scholar] [CrossRef]

- Bharadwaz, Y.D.; Rao, B.G.; Rao, V.D.; Anusha, C. Improvement of biodiesel methanol blends performance in a variable compression ratio engine using response surface methodology. Alex. Eng. J. 2016, 55, 1201–1209. [Google Scholar] [CrossRef]

- Clean, J. Evaluation of biogas upgrading technologies using a response surface methodology for process simulation. J. Clean. Prod. 2017, 141, 978–988. [Google Scholar]

- Oo, Y.M.; Legwiriyakul, A.; Thawornprasert, J.; Somnuk, K. Production of diesel–biodiesel–water fuel nanoemulsions using three-dimensional printed rotor–stator hydrodynamic cavitation. Fuel 2022, 317, 123445. [Google Scholar] [CrossRef]

- Chuquiruna, E.J.L.; Chuquiruna, N.A.L. Cut and Tear Resistance in HDPE Geomembrane. Bachelor’s Thesis, Northern Private University, Trujillo, Peru, 2019. [Google Scholar]

- Mendoza Pumacahua, D.O. Fusion Welding Parameters in the HDPE Geomembrane Reservoir in the Community of San Pedro, District of San José de Ticllas, Huamanga-Ayacucho-2023; Universidad Nacional de San Cristóbal de Huamanga: Ayacucho, Peru, 2023. [Google Scholar]

- Chong, B.W.; Othman, R.; Putra Jaya, R.; Mohd Hasan, M.R.; Sandu, A.V.; Nabiałek, M.; Jeż, B.; Pietrusiewicz, P.; Kwiatkowski, D.; Postawa, P.; et al. Design of Experiment on Concrete Mechanical Properties Prediction: A Critical Re883 view. Materials 2021, 14, 1866. [Google Scholar] [CrossRef]

- Wang, H.; Chen, K.; Lin, B.; Kou, J.; Li, L.; Wu, S.; Liao, S.; Sun, G.; Pu, J.; Yang, H.; et al. Process Development and Optimization of Linagliptin Aided by the Design of Experiments (DoE). Org. Process. Res. Dev. 2022, 26, 3254–3264. [Google Scholar] [CrossRef]

- Idris, M.; Abiola, O. Performance evaluation of three different-shaped bio-digesters for biogas production and optimization by artificial neural network integrated with genetic algorithm. Sustain. Energy Technol. Assess. 2018, 26, 116–124. [Google Scholar]

| Specification Levels | Properties | Specifications |

|---|---|---|

| 0 | Operator | Untrained |

| 1 | Trained | |

| 390 °C | Wedge sealer temperature | Measured in °C |

| 450 °C | ||

| 2.6 | Speed sealer | Measured in meters per minute (m/min) |

| 3.6 | ||

| 270 | Extruder temperature | Measured in °C. |

| 290 |

| Properties | Specifications |

|---|---|

| Type of geomembrane | HDPE type Gm13 with 1.5 mm thickness |

| Weather temperature, | 29 °C and 9 °C |

| Voltage | 220 Volts |

| Geomembrane overlap | 15 cm |

| Voltage | Overlap | Weather | Operator | Wedge Sealer Temperature | Speed Sealer | Extruder Temperature | Overheating | Resistance | Gas Leak Tests |

|---|---|---|---|---|---|---|---|---|---|

| 220 | 15 | 29 | 0 | 390 | 2.6 | 290 | 0 | 0.6349 | 1.0000 |

| 220 | 15 | 29 | 0 | 390 | 2.6 | 290 | 0 | 0.5238 | 0.8333 |

| 220 | 15 | 29 | 0 | 390 | 2.6 | 290 | 1 | 0.7619 | 0.1667 |

| 220 | 15 | 29 | 0 | 390 | 2.6 | 290 | 0 | 0.8810 | 0.3333 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 290 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 290 | 1 | 0.6349 | 0.3333 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 290 | 1 | 0.4365 | 0.1667 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 290 | 1 | 0.4286 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 260 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 260 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 260 | 1 | 0.4444 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 260 | 0 | 0.3492 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 260 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 260 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 260 | 1 | 0.6032 | 0.1667 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 260 | 1 | 0.6825 | 0.0000 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 260 | 1 | 0.6111 | 1.0000 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 260 | 0 | 0.5952 | 0.6667 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 260 | 1 | 0.6111 | 1.0000 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 260 | 0 | 0.6111 | 0.8333 |

| 220 | 15 | 29 | 0 | 390 | 2.6 | 260 | 0 | 0.6349 | 0.8333 |

| 220 | 15 | 29 | 0 | 390 | 2.6 | 260 | 1 | 0.6111 | 0.8333 |

| 220 | 15 | 29 | 0 | 390 | 2.6 | 260 | 1 | 0.5952 | 0.6667 |

| 220 | 15 | 29 | 0 | 390 | 2.6 | 260 | 0 | 0.5714 | 0.1667 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 290 | 1 | 0.6349 | 0.3333 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 290 | 1 | 0.6032 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 290 | 1 | 0.5238 | 0.0000 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 290 | 1 | 0.6508 | 0.0000 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 290 | 0 | 0.5317 | 0.0000 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 290 | 0 | 0.5238 | 0.0000 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 290 | 0 | 0.5317 | 0.8333 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 290 | 0 | 0.5635 | 0.1667 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 290 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 290 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 290 | 1 | 0.5635 | 0.1667 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 290 | 1 | 0.7857 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 260 | 0 | 0.6349 | 0.3333 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 260 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 260 | 0 | 0.8889 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 260 | 1 | 0.7222 | 0.1667 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 260 | 1 | 0.4365 | 0.0000 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 260 | 1 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 260 | 1 | 0.4444 | 0.5000 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 260 | 1 | 0.9762 | 0.1667 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 260 | 0 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 260 | 0 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 260 | 0 | 0.8254 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 260 | 0 | 0.7778 | 0.3333 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 260 | 1 | 0.9841 | 0.1667 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 260 | 1 | 0.8810 | 0.1667 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 260 | 0 | 0.8889 | 0.0000 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 260 | 0 | 0.8413 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 290 | 0 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 290 | 0 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 290 | 0 | 0.7778 | 0.1667 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 290 | 0 | 0.7698 | 0.1667 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 290 | 1 | 0.9921 | 0.0000 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 290 | 0 | 1.0000 | 0.0000 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 290 | 1 | 0.9286 | 0.1667 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 290 | 0 | 0.9524 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 290 | 0 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 290 | 0 | 0.6349 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 290 | 0 | 0.5794 | 0.0000 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 290 | 0 | 0.6508 | 0.0000 |

| Voltage | Overlap | Weather | Operator | Wedge Sealer Temperature | Speed Sealer | Extruder Temperature | Overheating | Resistance | Gas Leak Tests |

|---|---|---|---|---|---|---|---|---|---|

| 220 | 15 | 9 | 0 | 390 | 2.6 | 290 | 0 | 0.6032 | 0.8333 |

| 220 | 15 | 9 | 0 | 390 | 2.6 | 290 | 0 | 0.6190 | 0.3333 |

| 220 | 15 | 9 | 0 | 450 | 3.6 | 290 | 0 | 0.6905 | 0.1667 |

| 220 | 15 | 9 | 0 | 450 | 3.6 | 290 | 0 | 0.5238 | 0.5000 |

| 220 | 15 | 9 | 0 | 450 | 3.6 | 260 | 0 | 0.6270 | 0.3333 |

| 220 | 15 | 9 | 0 | 450 | 3.6 | 260 | 0 | 0.6984 | 0.3333 |

| 220 | 15 | 9 | 0 | 450 | 2.6 | 260 | 1 | 0.7857 | 0.1667 |

| 220 | 15 | 9 | 0 | 450 | 2.6 | 260 | 1 | 0.6270 | 0.6667 |

| 220 | 15 | 9 | 0 | 390 | 3.6 | 260 | 0 | 0.4286 | 0.1667 |

| 220 | 15 | 9 | 0 | 390 | 3.6 | 260 | 0 | 0.5079 | 1.0000 |

| 220 | 15 | 9 | 0 | 390 | 2.6 | 260 | 0 | 0.5794 | 0.0000 |

| 220 | 15 | 9 | 0 | 390 | 2.6 | 260 | 0 | 0.5238 | 0.1667 |

| 220 | 15 | 9 | 0 | 450 | 2.6 | 290 | 1 | 0.8889 | 0.1667 |

| 220 | 15 | 9 | 0 | 450 | 2.6 | 290 | 0 | 0.9841 | 0.1667 |

| 220 | 15 | 9 | 0 | 390 | 3.6 | 290 | 0 | 0.4841 | 0.0000 |

| 220 | 15 | 9 | 0 | 390 | 3.6 | 290 | 0 | 0.4762 | 1.0000 |

| 220 | 15 | 9 | 1 | 450 | 2.6 | 290 | 0 | 1.0000 | 0.0000 |

| 220 | 15 | 9 | 1 | 450 | 2.6 | 290 | 0 | 0.9683 | 0.0000 |

| 220 | 15 | 9 | 1 | 390 | 2.6 | 260 | 0 | 0.6111 | 0.1667 |

| 220 | 15 | 9 | 1 | 390 | 2.6 | 260 | 0 | 0.5476 | 0.0000 |

| 220 | 15 | 9 | 1 | 450 | 2.6 | 260 | 0 | 0.9683 | 0.0000 |

| 220 | 15 | 9 | 1 | 450 | 2.6 | 260 | 0 | 0.9762 | 0.0000 |

| 220 | 15 | 9 | 1 | 390 | 3.6 | 260 | 0 | 0.6984 | 0.0000 |

| 220 | 15 | 9 | 1 | 390 | 3.6 | 260 | 0 | 0.7540 | 0.0000 |

| 220 | 15 | 9 | 1 | 450 | 3.6 | 260 | 0 | 0.8254 | 0.3333 |

| 220 | 15 | 9 | 1 | 450 | 3.6 | 260 | 0 | 0.8413 | 0.1667 |

| 220 | 15 | 9 | 1 | 390 | 2.6 | 290 | 0 | 0.5556 | 0.1667 |

| 220 | 15 | 9 | 1 | 390 | 2.6 | 290 | 0 | 0.6429 | 0.0000 |

| 220 | 15 | 9 | 1 | 450 | 3.6 | 290 | 0 | 0.6746 | 0.0000 |

| 220 | 15 | 9 | 1 | 450 | 3.6 | 290 | 0 | 0.8810 | 0.0000 |

| 220 | 15 | 9 | 1 | 390 | 3.6 | 290 | 0 | 0.6429 | 0.0000 |

| 220 | 15 | 9 | 1 | 390 | 3.6 | 290 | 0 | 0.6349 | 0.0000 |

| Voltage | Overlap | Weather | Operator | Wedge Sealer Temperature | Speed Sealer | Extruder Temperature | Overheating | Resistance | Gas Leak Tests |

|---|---|---|---|---|---|---|---|---|---|

| 220 | 15 | 29 | 0 | 390 | 2.6 | 290 | 0.5235 | 0.9915 | 0.8691 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 290 | 1.5707 | 0.8191 | 0.3613 |

| 220 | 15 | 29 | 0 | 450 | 3.6 | 260 | 1.0471 | 0.8012 | 0 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 260 | 1.5707 | 0.9261 | 0.2055 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 260 | 0.7853 | 0.8933 | 1.2094 |

| 220 | 15 | 29 | 0 | 390 | 2.6 | 260 | 0.7853 | 0.8893 | 0.9117 |

| 220 | 15 | 29 | 0 | 450 | 2.6 | 290 | 1.5707 | 0.8893 | 0.2928 |

| 220 | 15 | 29 | 0 | 390 | 3.6 | 290 | 0 | 0.8231 | 0.5235 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 290 | 1.570 | 0.9427 | 0.2055 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 260 | 0.7853 | 1.0134 | 0.3613 |

| 220 | 15 | 29 | 1 | 450 | 2.6 | 260 | 1.5707 | 0.9096 | 0.4205 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 260 | 0 | 1.0112 | 0.2928 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 260 | 0.7853 | 1.2470 | 0.2928 |

| 220 | 15 | 29 | 1 | 390 | 2.6 | 290 | 0 | 0.9959 | 0.2928 |

| 220 | 15 | 29 | 1 | 450 | 3.6 | 290 | 0.7853 | 1.3916 | 0.2055 |

| 220 | 15 | 29 | 1 | 390 | 3.6 | 290 | 0 | 0.9117 | 0 |

| Voltage | Overlap | Weather | Operator | Wedge Sealer Temperature | Speed Sealer | Extruder Temperature | Overheating | Resistance | Gas Leak Tests |

|---|---|---|---|---|---|---|---|---|---|

| 220 | 15 | 9 | 0 | 390 | 2.6 | 290 | 0 | 0.8974 | 0.8691 |

| 220 | 15 | 9 | 0 | 450 | 3.6 | 290 | 0 | 0.8933 | 0.6154 |

| 220 | 15 | 9 | 0 | 450 | 3.6 | 260 | 0 | 0.9511 | 0.6154 |

| 220 | 15 | 9 | 0 | 450 | 2.6 | 260 | 1.5707 | 0.9981 | 0.7016 |

| 220 | 15 | 9 | 0 | 390 | 3.6 | 260 | 0 | 0.7536 | 0.8691 |

| 220 | 15 | 9 | 0 | 390 | 2.6 | 260 | 0 | 0.8370 | 0.2928 |

| 220 | 15 | 9 | 0 | 450 | 2.6 | 290 | 0.7853 | 1.3160 | 0.4205 |

| 220 | 15 | 9 | 0 | 390 | 3.6 | 290 | 0 | 0.7655 | 0.7853 |

| 220 | 15 | 9 | 1 | 450 | 2.6 | 290 | 0 | 1.4444 | 0 |

| 220 | 15 | 9 | 1 | 390 | 2.6 | 260 | 0 | 0.8651 | 0.2928 |

| 220 | 15 | 9 | 1 | 450 | 2.6 | 260 | 0 | 1.4033 | 0 |

| 220 | 15 | 9 | 1 | 390 | 3.6 | 260 | 0 | 1.0201 | 0 |

| 220 | 15 | 9 | 1 | 450 | 3.6 | 260 | 0 | 1.1502 | 0.5235 |

| 220 | 15 | 9 | 1 | 390 | 2.6 | 290 | 0 | 0.8852 | 0.2928 |

| 220 | 15 | 9 | 1 | 450 | 3.6 | 290 | 0 | 1.0799 | 0 |

| 220 | 15 | 9 | 1 | 390 | 3.6 | 290 | 0 | 0.9261 | 0 |

| Response Variable | Operator | Wedge Sealing Temperature | Sealing Speed | Extruder Temperature |

|---|---|---|---|---|

| Overheating | 1 | 390 °C | 3.6 m/min | 290 °C |

| Resistance | 1 | 450 °C | 3.6 m/min | 290 °C |

| Air test | 1 | 450 °C | 3.6 m/min | 290 °C |

| Response Variable | Operator | Wedge Sealing Temperature | Sealing Speed | Extruder Temperature |

|---|---|---|---|---|

| Overheating | 1 | 450 °C | 3.6 m/min | 290 °C |

| Resistance | 1 | 450 °C | 2.6 m/min | 290 °C |

| Air test | 1 | 450 °C | 3.6 m/min | 290 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Camarena-Martinez, R.; Baeza-Serrato, R.; Lizarraga-Morales, R.A. Optimization of Welding Process of Geomembranes in Biodigesters Using Design of Factorial Experiments. Energies 2023, 16, 6583. https://doi.org/10.3390/en16186583

Camarena-Martinez R, Baeza-Serrato R, Lizarraga-Morales RA. Optimization of Welding Process of Geomembranes in Biodigesters Using Design of Factorial Experiments. Energies. 2023; 16(18):6583. https://doi.org/10.3390/en16186583

Chicago/Turabian StyleCamarena-Martinez, Rocio, Roberto Baeza-Serrato, and Rocio A. Lizarraga-Morales. 2023. "Optimization of Welding Process of Geomembranes in Biodigesters Using Design of Factorial Experiments" Energies 16, no. 18: 6583. https://doi.org/10.3390/en16186583

APA StyleCamarena-Martinez, R., Baeza-Serrato, R., & Lizarraga-Morales, R. A. (2023). Optimization of Welding Process of Geomembranes in Biodigesters Using Design of Factorial Experiments. Energies, 16(18), 6583. https://doi.org/10.3390/en16186583