Abstract

The global push towards sustainable energy solutions has intensified research into alternative fuels, such as biodiesel. This study investigates the performance and emission characteristics of biodiesel derived from waste swine oil in comparison to traditional diesel fuel. Using an engine running at 75% load across a range of speeds (1200 rpm to 1800 rpm), various metrics such as Brake-Specific Fuel Consumption (BSFC), Brake Thermal Efficiency (BTE), and emissions including Carbon Monoxide (CO), Hydrocarbon (HC), Carbon Dioxide (CO2), Nitrogen Oxide (NOx), and smoke opacity were measured. The biodiesel demonstrated a higher BSFC (270 g/kWh) compared to diesel (245 g/kWh) but showed reduced Brake Thermal Efficiency (28.5% vs. 29.8%) compared to diesel. In terms of emissions, biodiesel blends recorded lower levels of CO, HC, and smoke opacity, but elevated levels of CO2 and NOx. The results indicate that while biodiesel from waste swine oil presents some environmental benefits, such as reduced CO, HC, and smoke emissions, challenges remain in terms of higher NOx emissions and less efficient fuel consumption.

1. Introduction

1.1. Background: Importance of Alternative Fuels

The global dependence on fossil fuels coupled with the alarming increase in greenhouse gas emissions has compelled the scientific community to consider sustainable energy solutions. With depleting reserves of fossil fuels and the stark impacts of climate change, alternative fuels have emerged at the forefront of discussions around sustainable and eco-friendly energy resources [1]. This urgency has spurred significant advancements in research aimed at identifying and optimizing alternative fuel sources.

Biodiesel refers to a group of esters produced from the transesterification of organic oils, both vegetable and animal-sourced, with an alcohol, typically methanol [2]. It serves as a direct replacement for conventional diesel and is renowned for its cleaner combustion properties. The importance of biodiesel extends beyond its eco-friendly combustion characteristics; its production and utilization can aid in reducing the carbon footprint, decrease dependence on foreign oil, and stimulate economic growth within local agricultural sectors [3]. According to experts, oil, as a primary source of raw materials for the creation of a wide range of products, will be depleted over the next 100 years, resulting in a severe decrease in production. A systematic shift to renewable energy sources can help to avoid an economic downturn and mitigate the effects of declining oil supplies [4].

Waste swine oil, a byproduct of the pork industry, has traditionally been discarded or used in low-value applications. Recently, however, its potential as a feedstock for biodiesel production has been explored [5]. Owing to its abundant availability and relatively low processing costs, waste swine oil presents an attractive option. Preliminary studies have showcased that biodiesel derived from waste swine oil exhibits comparable performance to that of traditional biodiesel sources, making it a viable and sustainable feedstock [6,7].

Engine performance under varying load conditions provides vital insight into the feasibility and efficiency of different fuels. The 75% load condition, in particular, represents a typical high-demand scenario often encountered in transportation and industrial applications [8,9,10]. By examining engine behavior at this load, researchers can gather realistic data about fuel efficiency, emissions, and overall performance, allowing for more informed decision making regarding fuel choices.

1.2. Objectives of the Current Study

This study seeks to:

- Investigate the properties of biodiesel derived from waste swine oil.

- Assess the performance characteristics of a single-cylinder engine when fueled with this biodiesel at a 75% load condition.

- Analyze the emissions profile and compare it to traditional biodiesel and diesel fuels under similar conditions.

- Provide insight and recommendations for the wider adoption of waste swine oil as a biodiesel feedstock.

2. Literature Review

2.1. Previous Studies on Biodiesel and Its Feedstocks

The transformation from non-renewable fossil fuels to more sustainable options has emerged as a dominant theme in recent energy research. Biodiesel, as a bio-based alternative, has been the subject of intensive studies given its multiple benefits, such as decreased greenhouse gas emissions and potential for local production [11]. Okolie et al. undertook a broad review of biodiesel, emphasizing its environmental advantages and the importance of identifying suitable feedstocks [12]. Zhang et al. expanded this conversation by exploring a range of feedstocks, including vegetable oils and animal fats, underlining the significance of the source in determining biodiesel properties and performance [13].

The interaction of biodiesel with engine performance has been a focal area of research, primarily due to the distinct physical and chemical properties of biodiesel compared to conventional diesel [2]. A study by Imdadul et al. (2015) highlighted that biodiesel’s increased viscosity could influence its combustion properties and overall engine behavior [14]. However, with necessary engine calibrations, it is feasible to achieve optimized performance. Moreover, Kamil et al. (2023) discussed the adaptability of engines when fueled with biodiesel derived from desert palm date seeds, emphasizing the need for specific engine modifications to ensure efficiency and longevity [15].

While the general properties and benefits of biodiesel have been extensively researched, the specific exploration of waste swine oil as a feedstock for biodiesel production has been less prominent. Waste swine oil, a byproduct of the meat processing industry, presents an unconventional yet promising feedstock for biodiesel production [16]. Bhatia et al. (2021) delved into biodiesel production from waste swine oil and noted that the resultant fuel adhered to standard quality parameters when subjected to appropriate transesterification [17]. Further research by Madhu et al. (2023) demonstrated that engines fueled with waste swine oil biodiesel emitted fewer particulate matter and NOx compared to some other biodiesel sources [18].

Studies have evaluated the performance and emissions of internal combustion engines using waste-derived biofuels as additives, demonstrating the potential for their utilization in such engines [19]. Furthermore, the introduction of biodiesel or other biofuels in engine operation is considered to reduce greenhouse gas emissions [20]. However, it is essential to note that the performance of internal combustion engines can be affected when renewable biofuels are used instead of fossil fuels in unmodified engines [21]. Additionally, the combustion of biofuels, including waste swine biofuel, has been associated with carbonaceous aerosol emissions, which contribute to environmental concerns [22]. Moreover, the combustion of biofuels has been linked to particulate matter emissions, emphasizing the importance of understanding the interactions between biofuels and fuel components to mitigate such emissions [23]. Therefore, while waste swine biofuel shows promise as a potential alternative fuel for internal combustion engines, its impact on emissions and engine performance necessitates further investigation.

Despite these advances, the literature still lacks a comprehensive understanding of how waste swine oil biodiesel performs under various engine loads and speeds. Most existing studies have either focused on the production process or limited their scope to specific emission types without considering the full spectrum of operational conditions.

This gap in research is particularly pertinent given the increasing interest in sustainable biofuels and the need to find cost-effective and environmentally friendly alternatives to traditional diesel. The unique characteristics of waste swine oil, such as its fatty acid composition and viscosity, may influence engine performance and emissions in ways that have not been fully explored in existing studies.

2.2. Impact of Engine Load on Performance and Emissions

One crucial operational condition is the engine load. It signifies the demand placed on an engine, reflecting its operational intensity. Operating an engine at 75% load is particularly relevant, as it represents a high yet not extreme operational scenario. This ensures the findings are both realistic and practical, resonating with everyday scenarios [8,9,10].

Assessing engine performance under varied load conditions is crucial to understanding the real-world applicability of biodiesel fuels. This research seeks to bridge the knowledge gap by presenting an experimental investigation on the performance of a single-cylinder engine fueled by biodiesel derived from waste swine oil, particularly at a 75% load condition. Through this study, we aim to shed light on the intricate interplay between the fuel’s properties and the engine’s operational conditions, setting the stage for potential large-scale applications of such biodiesels in the future.

3. Materials and Methods

3.1. Production of Biofuel and Its Blends

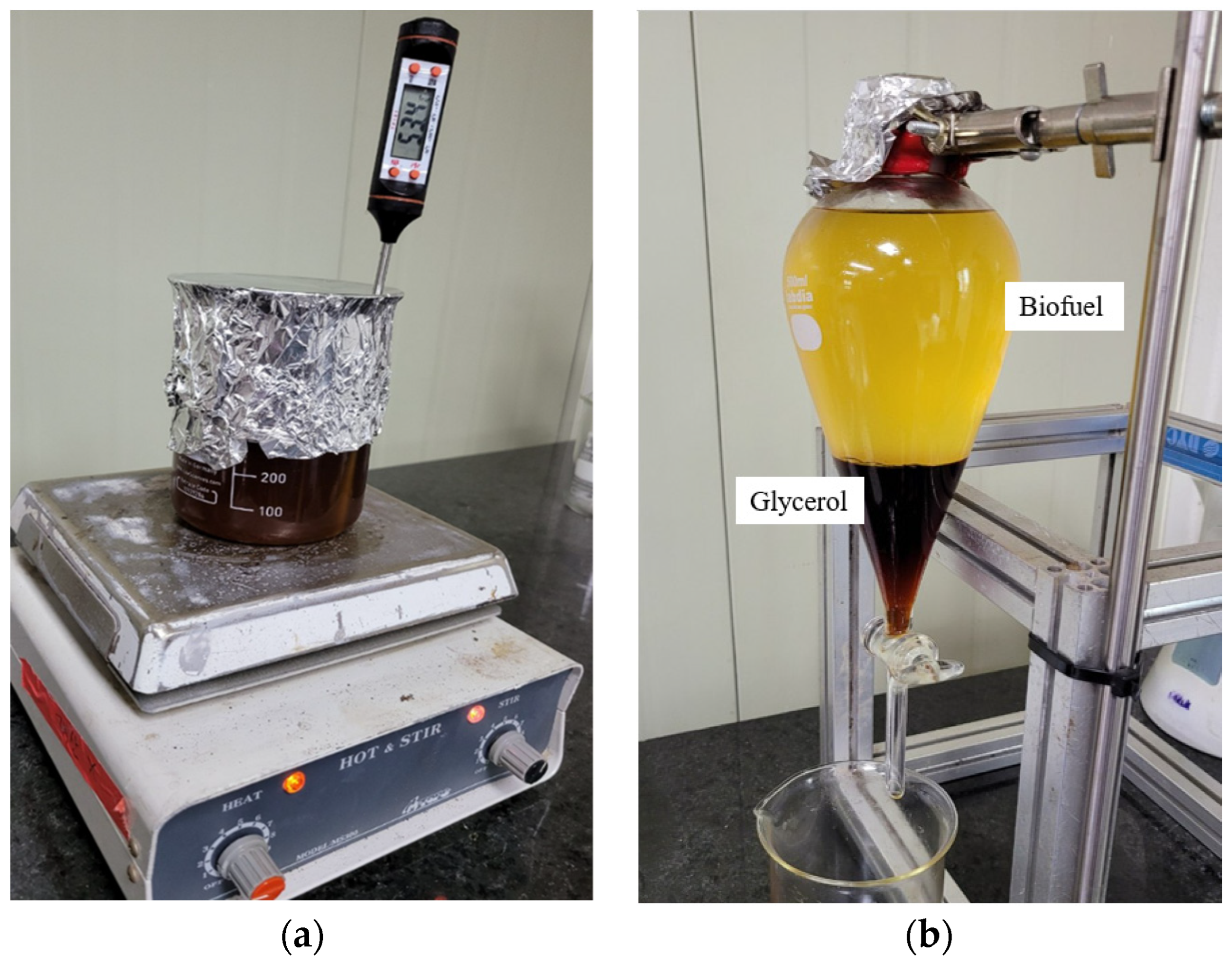

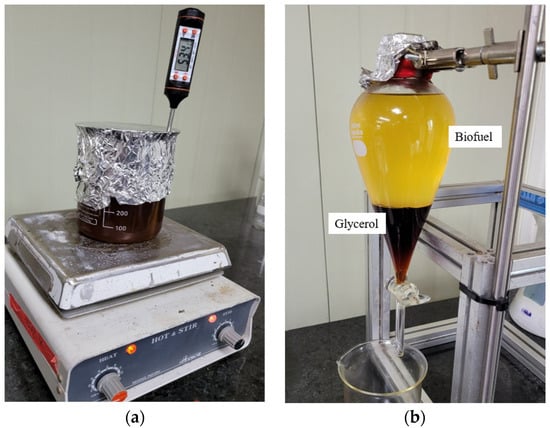

In a comprehensive transesterification process, waste swine oil—sourced from a Barbecue (BBQ) restaurant—was reacted with methanol, under the facilitation of a potassium hydroxide (KOH) catalyst to form biodiesel and glycerol [24]. The swine oil, amounting to 500 mL, was initially heated to 55 °C on a magnetic stirrer, with parallel preparation of a methanol (purity ≥ 99.9%) and KOH catalyst (reagent grade 90%) mixture, ensuring the complete dissolution of KOH pellets. For this 500 mL of oil, 135 mL of methanol and 2.5 gm of KOH were utilized. All of the requisite chemicals for the process were acquired from Sigma-Aldrich (Republic of Korea).

Following the preparation, this methanol–KOH mixture was integrated with the preheated oil and maintained under heat and stirring for 2 h, as shown in Figure 1a. This step was crucial for ensuring the thorough conversion of triglycerides into methyl esters [25]. Post-reaction, the resultant concoction was transferred to a separating funnel and left to cool for 24 h, facilitating the separation of biodiesel from glycerol, with glycerol forming the heavier bottom layer, as illustrated in Figure 1b.

Figure 1.

(a) Heating and stirring process, (b) Separation of glycerol from biofuel.

Nevertheless, the initially obtained biodiesel was marked by impurities. Hence, a subsequent purification process was employed to refine the biodiesel of impurities and excessive methanol. The separated biodiesel layer underwent washing with warm distilled water to eliminate the remaining catalyst and any soap formations, followed by a vacuum drying process aimed at reducing the glycerol content to below 0.02% [26]. This meticulous and multistep approach ensured the effective transformation and extraction of purified biodiesel from waste swine oil.

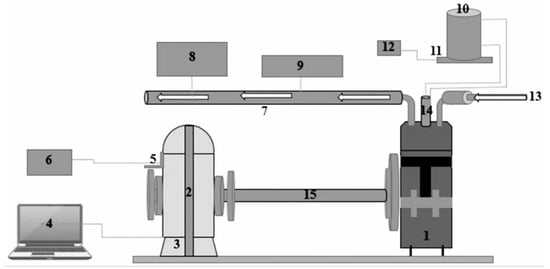

3.2. Engine Specifications and Setup

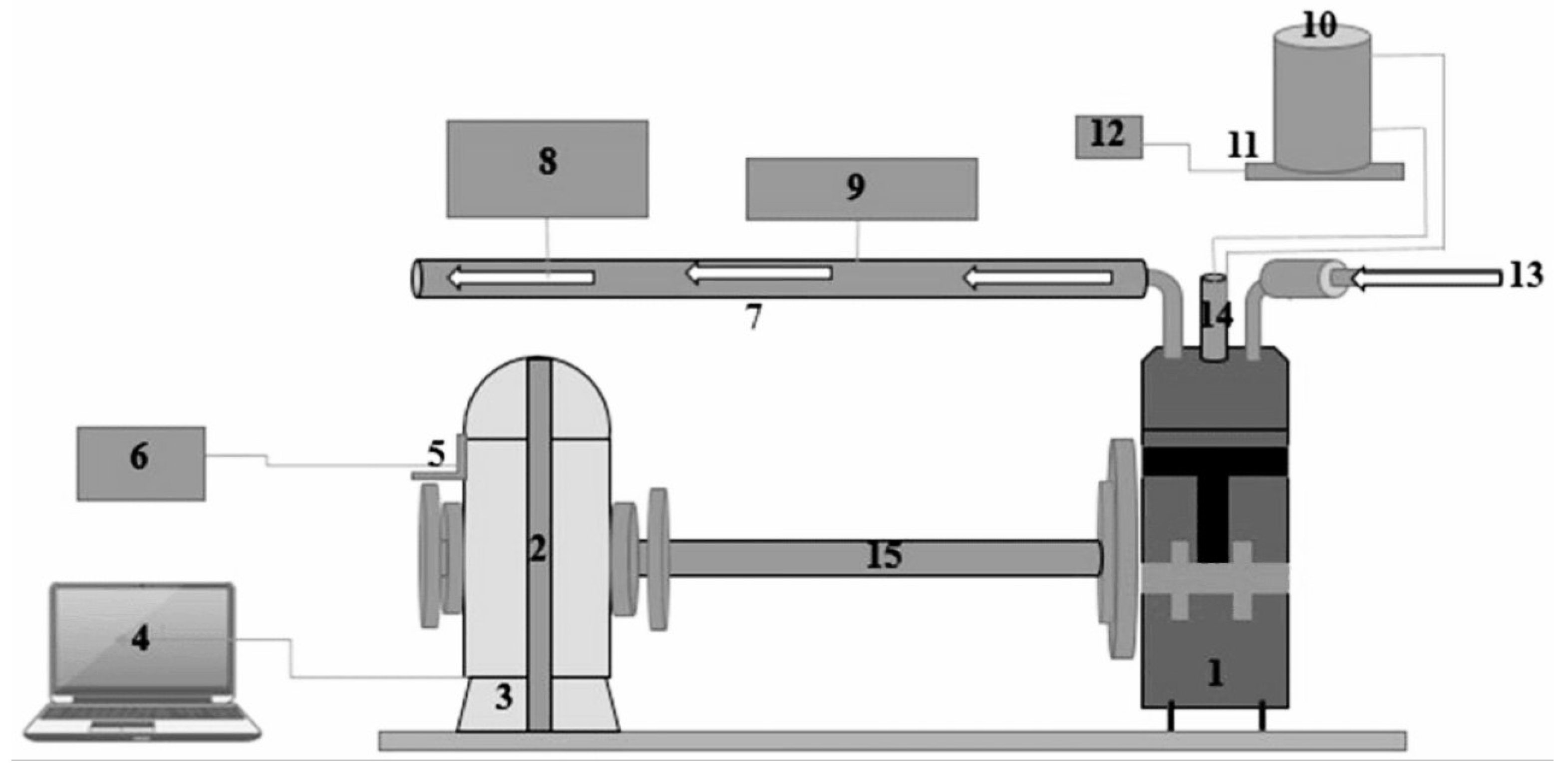

Figure 2 illustrates the experimental arrangement for a single-cylinder, water-cooled agricultural diesel engine that has a rated power output of 7.4 kW, provided by Daedong Korea Ltd. (Daegu Gwangyeoksi, Republic of Korea) with indirect injection. The engine was coupled to an eddy current dynamometer to control and measure the load conditions. Various sensors and equipment were installed to record parameters like fuel consumption rate, exhaust temperature, and engine speed. Various engine specifications and data points are enumerated in Table 1.

Figure 2.

Experimental setup: (1) single-cylinder engine indirect ignition, (2) eddy current dynamometer, (3) load cell for torque, (4) torque measurement, (5) RPM sensor, (6) RPM display, (7) exhaust pipe, (8) gas emission analyzer, (9) smoke analyzer, (10) fuel tank, (11) load cell for fuel weight, (12) fuel weight display, (13) air intake, (14) injector, (15) propeller shaft.

Table 1.

Engine specifications and data points.

This study was conducted using an unmodified internal combustion engine to ensure the results authentically represent the performance and emissions of typical engines in real-world conditions. This method allows for a realistic assessment of various biodiesel blends and standard diesel in standard engine configurations. By refraining from any engine modifications, the study preserves the engine’s original design characteristics, making the findings highly relevant and applicable to the majority of existing engines in use.

3.3. Test Procedures

The engine was initially operated using pure diesel to establish the baseline performance. Once stable operations were achieved, the engine was switched to biodiesel derived from waste swine oil. The tests were conducted at varying speeds, including 1200, 1400, 1600, and 1800 rpm, focusing on the 75% load condition. Parameters like brake-specific fuel consumption (BSFC), brake thermal efficiency (BTE), and exhaust emissions (CO, CO2 NOx, HC, and PM) were recorded for both fuel types.

3.4. Error Analysis and Uncertainty

Throughout the experiments, the temperature of the lubricating oil was sustained between 85 and 90 °C. The engine operated for a span of 15 min, during which time observations and recordings were meticulously conducted. To minimize the likelihood of errors in the data, the uncertainty was meticulously assessed. Ensuring the calibration of the equipment is crucial for garnering accurate results in the experimentation phase. To affirm precision, measurements were recorded at least 4 times throughout the experiment, and the arithmetic mean of the readings was subsequently calculated.

In the statistical analysis of the experimental data, the arithmetic mean was employed to determine the average value from the 4 conducted trials. This method, widely recognized for its reliability in representing central tendencies, involves summing all of the obtained values and dividing by the number of trials. Specifically, for this experiment, the formula used was:

where V1, V2, V3, and V4 represent the individual outcomes of each trial. This approach is particularly effective in normalizing the effects of any random variability across the trials, providing a consolidated view of the experimental results. The use of the arithmetic mean, therefore, serves as a robust and straightforward statistical tool for synthesizing the data into a singular, representative value, facilitating a clearer understanding and interpretation of the experimental findings. The error and uncertainty analysis of the smoke meter and gas analyzer are detailed in Table 2.

Table 2.

Measuring Range and Precision of Smoke Meter and Gas Analyzer.

The fluctuations in engine performance attributes were gauged using BTE and BSFC. A gas analyzer (CGA-4500), originating from the Republic of Korea, was deployed to scrutinize the engine emission parameters. This analyzer leverages non-dispersive infrared (NDIR) technology to assess carbon monoxide (CO) concentrations within a scope of 0.00 to 10.00%. Additionally, it employs NDIR to evaluate carbon dioxide (CO2) concentrations, spanning 0.0 to 20.0%. The hydrocarbon (HC) measurement proficiency of the analyzer ranges from 0 to 10,000 ppm. Conversely, oxygen (O2) concentrations were ascertained utilizing an electrochemical sensor within a spectrum of 0.00 to 25.00%. Nitric oxide (NO) concentrations, ranging from 0 to 5000 ppm, were quantified utilizing another electrochemical sensor.

To accumulate digital emission data, a probe was integrated into the exhaust pipe. The smoke produced by the engine was gauged using a smoke meter, and a k-type thermocouple was designated to record the exhaust gas temperature.

4. Results and Discussion

4.1. Biodiesel Characterization

Biodiesel’s viability as a potential substitute for diesel is primarily dependent on its physicochemical properties. These properties influence the fuel’s ignition quality, combustion behavior, and overall engine performance.

4.1.1. Fuel Properties

Table 3 displays the fuel properties and their ASTM standards for both the waste swine oil biodiesel and the diesel that were utilized in the experiment. B20, B40, B60, and B80 refer to different biodiesel blends, signifying the percentage of biodiesel relative to conventional diesel fuel. Specifically:

Table 3.

Fuel properties of waste swine oil biofuel and ASTM standards.

- B20: This blend contained 20% biofuel and 80% conventional diesel.

- B40: This blend consisted of 40% biofuel and 60% conventional diesel.

- B60: This blend included 60% biofuel and 40% conventional diesel.

- B80: This blend comprised 80% biofuel and 20% conventional diesel.

These designations are vital for understanding the varying biodiesel content in the blends and how it affected engine performance and emissions in the study.

The biodiesel derived from waste swine oil exhibited distinct properties after the transesterification and purification phases. The cetane number, a critical metric that represents the ignition quality of diesel fuel, was found to be 63 for the biodiesel. This value is a strong indicator of the fuel’s capability to ensure efficient and smooth combustion.

Furthermore, the biodiesel displayed a density of 893 kg/m3 at 15 °C, considerably higher than that of typical diesel fuels, which suggests that the biodiesel had a weighty mass per unit volume. In terms of viscosity, a crucial factor for ensuring adequate fuel atomization and injection, the biodiesel marked a kinematic viscosity of 5.91 mm2/s at 40 °C.

4.1.2. Comparison with Standard Diesel

In comparison with standard diesel, both fuels aligned relatively well in terms of density, falling within the 800–880 kg/m3 standard range. However, lard biodiesel had a higher viscosity (5.91 cSt) at 40 °C compared to diesel (2.87 cSt), implying the thicker, more viscous nature of the biodiesel. The flashpoint of lard biodiesel was also considerably higher (114 °C) than that of diesel (58 °C), suggesting it is less volatile and potentially safer in terms of ignition risk. Moreover, lard biodiesel excelled with a high cetane number (65), demonstrating superior ignition quality compared to diesel’s 48.7. Lastly, in terms of calorific value, diesel exhibited an advantage with 45.51 MJ/kg, presenting higher energy content compared to lard biodiesel’s 40.21 MJ/kg, potentially translating to better fuel efficiency.

4.2. Engine Performance at 75% Load

Analyzing engine performance under specific load conditions, such as 75% load, is pivotal to ascertaining biodiesel’s capability under real-world scenarios.

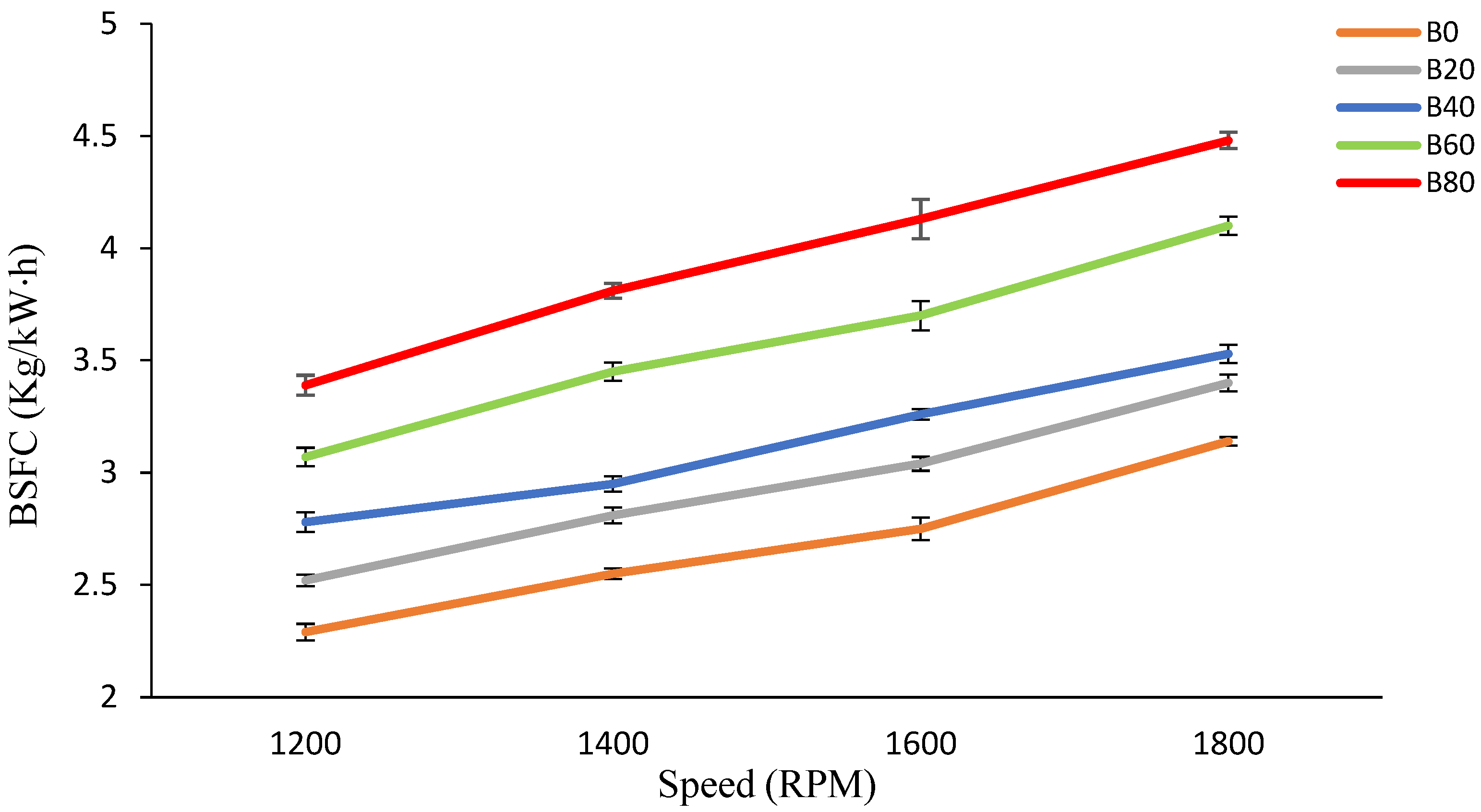

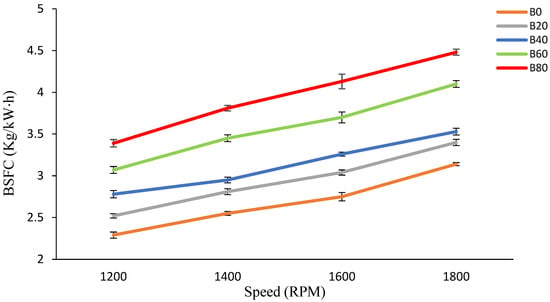

4.2.1. Brake-Specific Fuel Consumption (BSFC)

The Brake-Specific Fuel Consumption (BSFC) characteristic measures the effectiveness of an engine that burns gasoline and produces rotational power. The fuel flow rate to output brake power ratio is referred to as BSFC [27]. Figure 3 depicts the change in Brake-Specific Fuel Consumption (BSFC) between biodiesel, processed from waste swine oil (BBQ oil), and standard diesel, revealing discernible disparities in fuel efficiency at 75% engine load. The observed BSFC value for biodiesel was 270 g/kWh, which was notably higher than the 245 g/kWh recorded for standard diesel. This increment in BSFC underscores biodiesel’s diminished fuel efficiency under the specified load condition, likely attributable to its inherent lower energy density, augmented viscosity, and distinct combustion dynamics compared to standard diesel. This implies a necessity for a greater volume of biodiesel to yield the same power output as its diesel counterpart, reflecting the inherent variations in energy density between these fuels [25,28].

Figure 3.

Variation in BSFC with engine speed at 75% load.

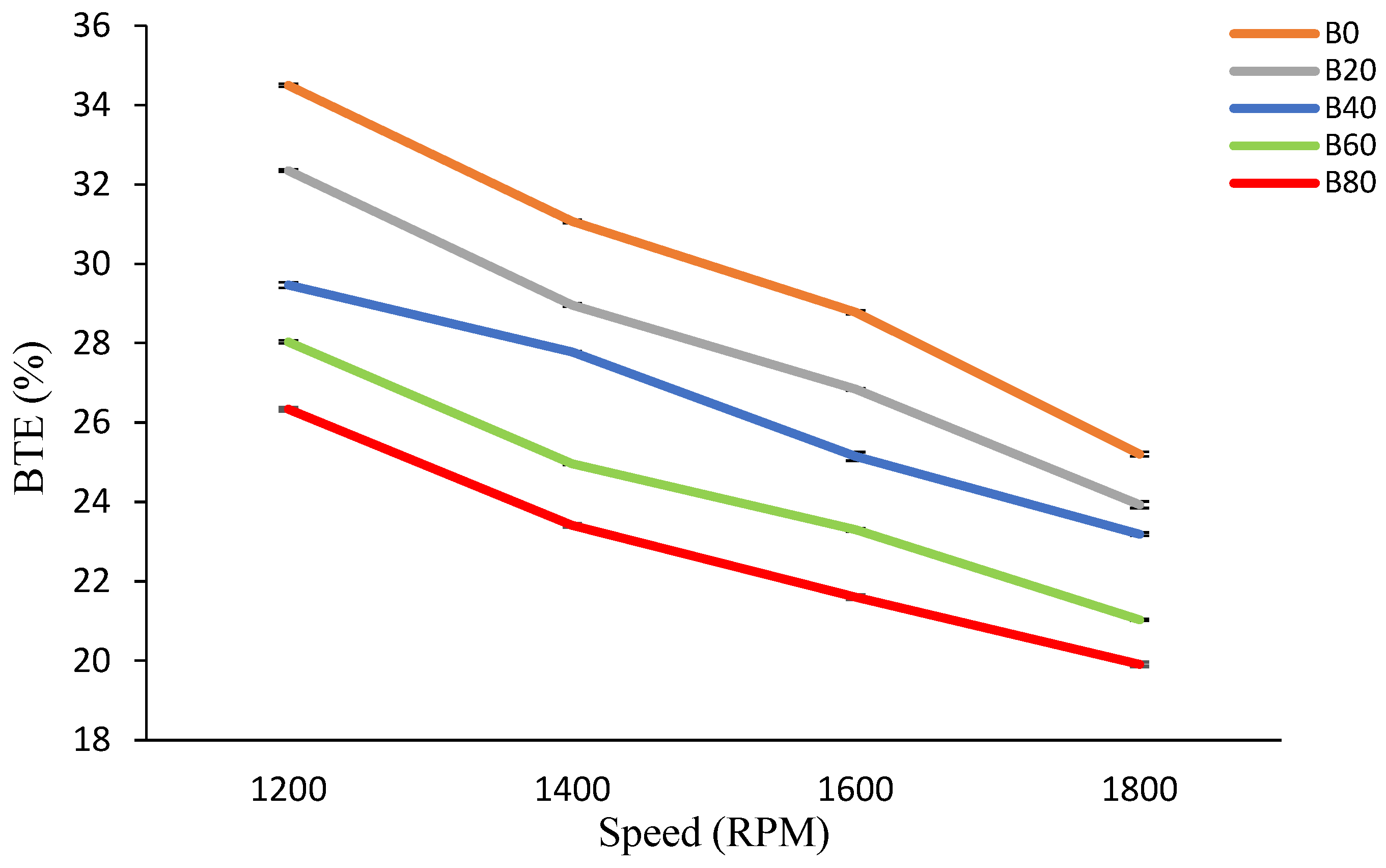

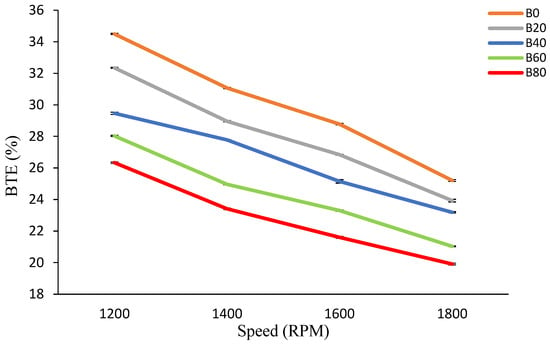

4.2.2. Brake Thermal Efficiency (BTE)

Efficiency in converting fuel’s energy to mechanical power is represented by BTE [29]. Figure 4 illustrates a direct proportional relationship between Brake Thermal Efficiency (BTE) and engine speed at 75% engine load across varying diesel–biodiesel blends. Pure diesel fuel consistently exhibited the highest BTE, delineating values of 34.5%, 31.07%, 28.78%, and 25.21% at engine speeds of 1200 rpm, 1400 rpm, 1600 rpm, and 1800 rpm, respectively.

Figure 4.

Variation in BTE with engine speed at 75% load.

In comparison, B20 mixtures demonstrated a descending BTE ranging from 32.35% to 23.93% within the same engine speed range. More substantial biodiesel concentrations in the fuel blends, namely B40 and B60, marked a further decrease in BTE, recorded between 29.47% to 23.19% and 28.03% to 21.03% at 1200 rpm to 1800 rpm, respectively. The B80 mixture manifested the lowest BTE values, spanning from 26.34% to 19.91% within the given engine speed range.

The data suggest that although biodiesel blends may result in a lower BTE than standard diesel, they still exhibit a similar trend in terms of the relationship between BTE and engine speed. However, the drop in BTE was more significant at higher biodiesel ratios, implying a potential compromise in engine efficiency with increased use of biodiesel.

4.3. Emission Characteristics

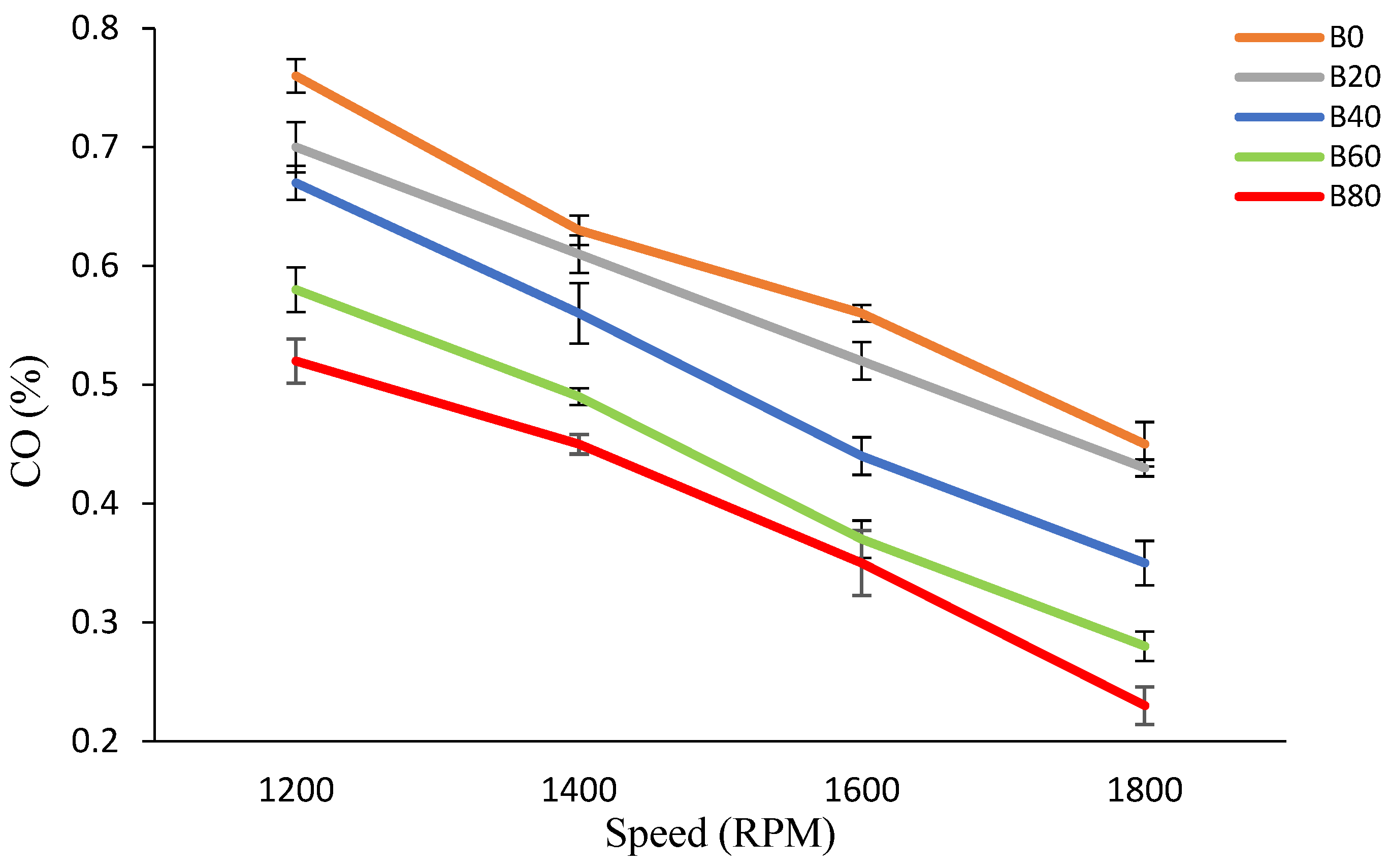

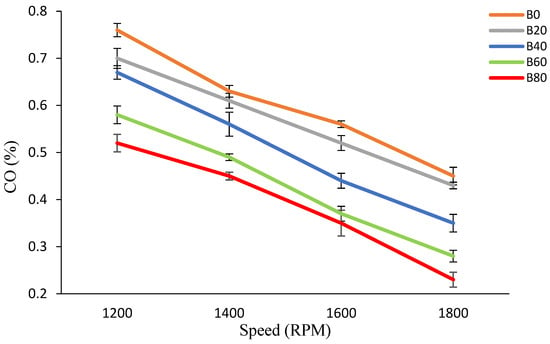

4.3.1. Variation in Carbon Monoxide (CO) with Engine Speed

Figure 5 depicts the CO emission levels for various biodiesel blends (B20, B40, B60, and B80) as well as standard diesel (B0) at 75% engine load. Interestingly, diesel fuel exhibited the highest levels of CO emissions, measuring 0.76%, 0.63%, 0.56%, and 0.45% at 1200 rpm, 1400 rpm, 1600 rpm, and 1800 rpm, respectively.

Figure 5.

Variation in CO with engine speed at 75% load.

In contrast, the CO emissions at 1800 rpm decreased with increasing biodiesel content: 0.45% for B0, 0.43% for B20, 0.35% for B40, 0.28% for B60, and 0.23% for B80. This reduced emission profile for biodiesel blends can be attributed to biodiesel’s increased oxygen content, which promotes more complete combustion [30].

While biodiesel may require some compromise in terms of engine efficiency metrics like BSFC and BTE, it offers a clear advantage in reducing harmful CO emissions, thereby making it a more environmentally friendly alternative to standard diesel.

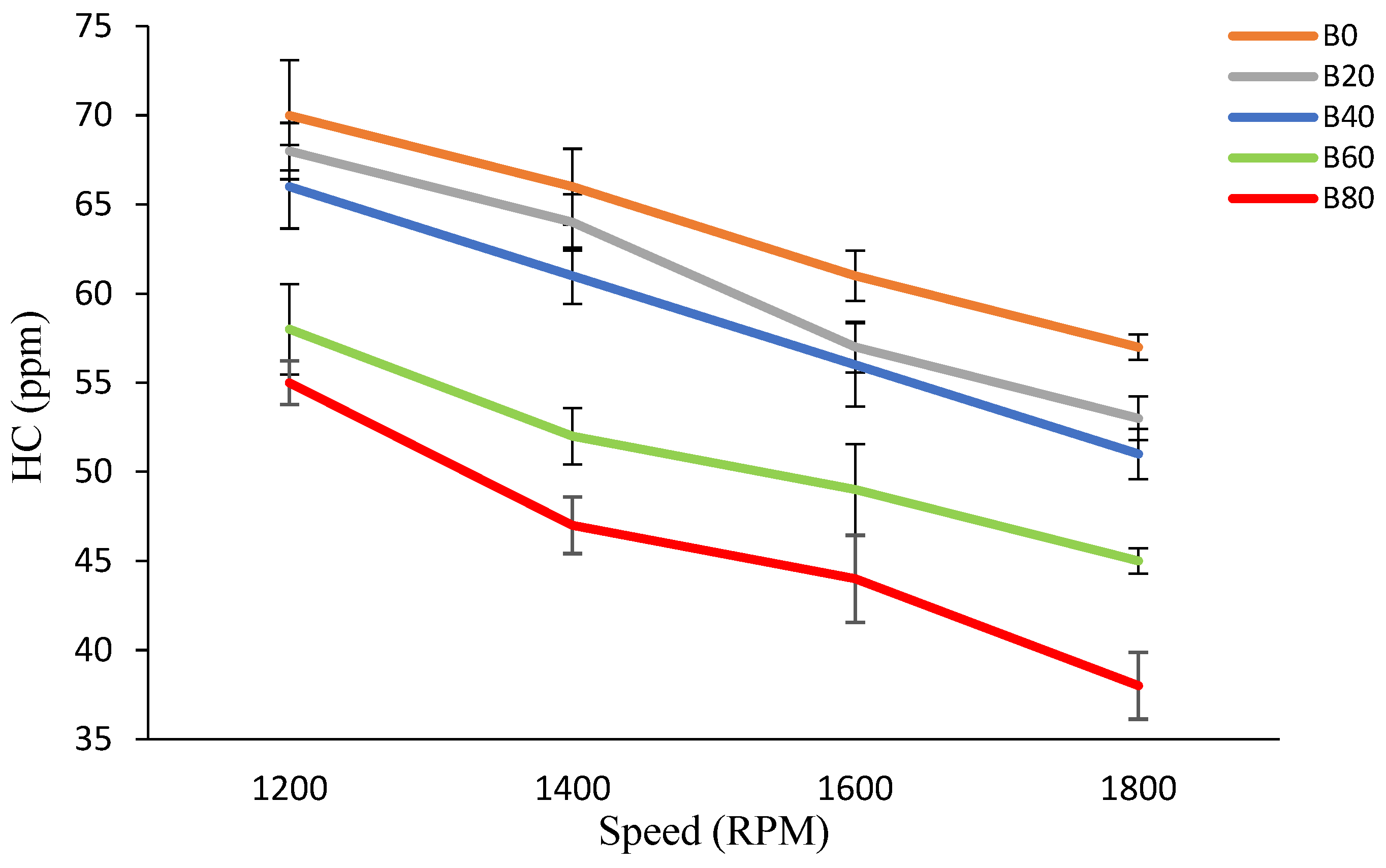

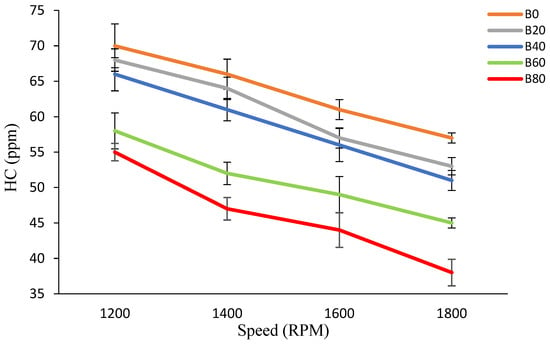

4.3.2. Variation in HC with Engine Speed

Partial combustion of fuel inside the combustion chamber leads to hydrocarbon emissions, which are another critical environmental concern. Figure 6 reveals that for the B20 fuel blend, HC emissions were lower than those from baseline diesel fuel at engine speeds of 1600 rpm and 1800 rpm. This may be associated with biodiesel’s higher cetane number leading to a shorter ignition delay, as indicated in the study by Labeckas et al. [31].

Figure 6.

Variation in HC with engine speed at 75% load.

For standard diesel fuel at 75% load, the HC emissions were measured at 70 ppm, 66 ppm, 61 ppm, and 57 ppm at 1200 rpm, 1400 rpm, 1600 rpm, and 1800 rpm, respectively. These were notably higher than those observed with biodiesel blends. These results are supported by the findings from a study by Sayin et al. [32], which also reported reduced HC emissions as the biodiesel blend ratio increased. However, our data indicated a sharper decline in HC emissions at higher RPMs, a point not emphasized in the study by Sayin et al. The reduction in HC emissions seen in biodiesel blends, especially at higher RPMs, further establishes biodiesel as an environmentally advantageous alternative to standard diesel. This, coupled with the reduction in CO emissions previously discussed, makes biodiesel a compelling choice from an emissions perspective, despite some trade-offs in engine efficiency metrics like BSFC and BTE.

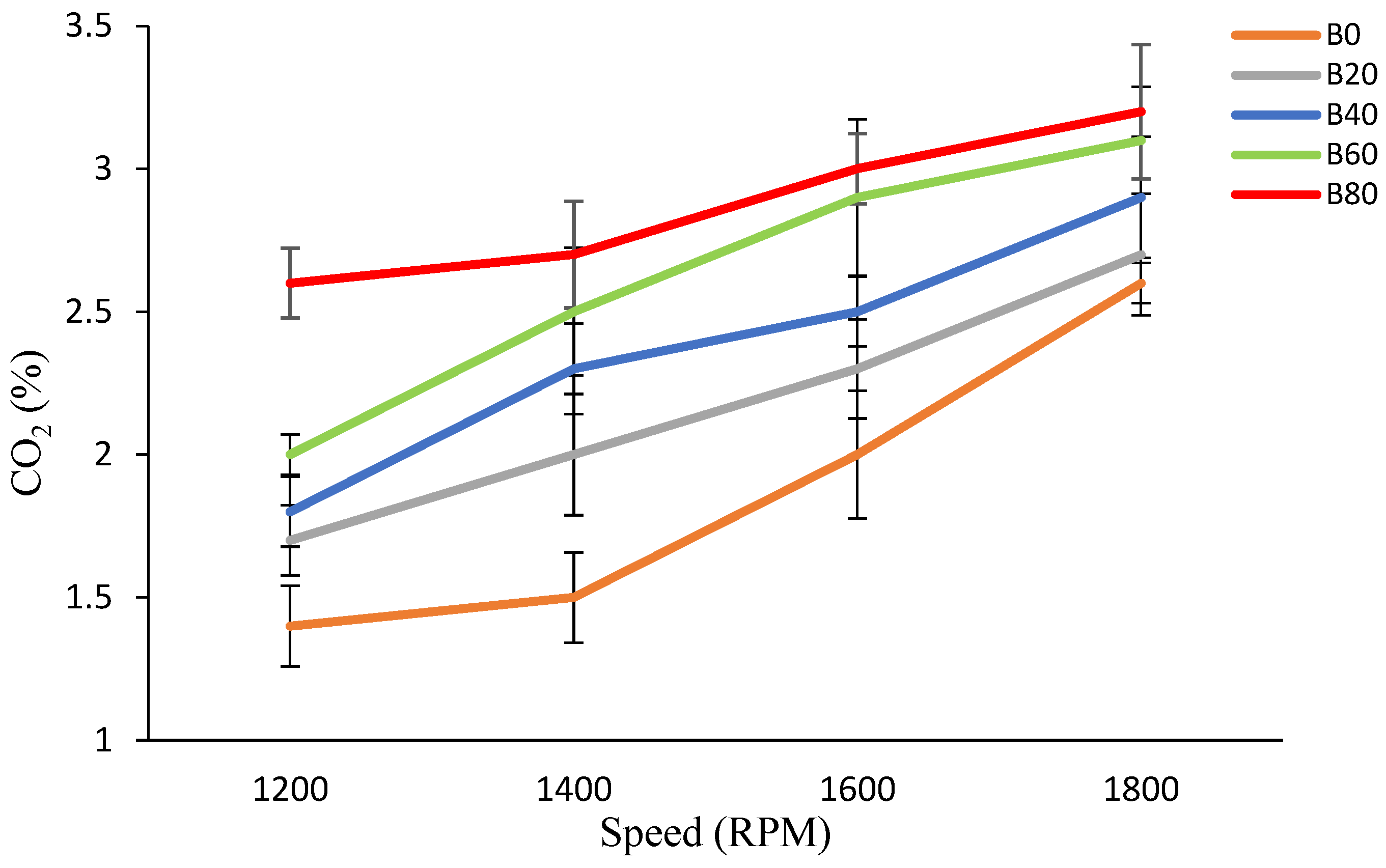

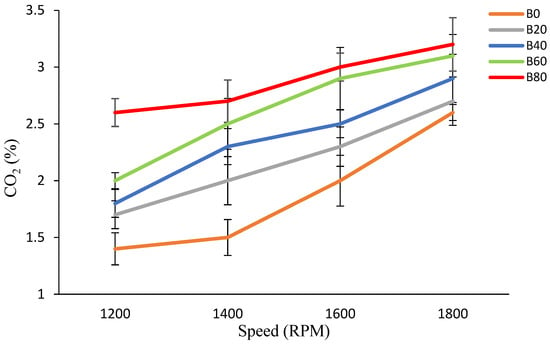

4.3.3. Variation of CO2 with Engine Speed

Figure 7 illustrates how CO2 emissions varied with engine speed (rpm) for B20, B40, B60, and B80 biodiesel blends at 75% engine load. It is noteworthy that diesel fuel emitted the least amount of CO2 among the tested fuels. Specifically, the CO2 emissions from diesel were measured at 1.4 %vol. at 1200 rpm, 1.5 %vol. at 1400 rpm, 2 %vol. at 1600 rpm, and 2.7 %vol. at 1800 rpm. The elevated levels of CO2 emissions in biodiesel blends can be primarily attributed to the fuel’s higher oxygen content. During combustion, this extra oxygen combines with unburned carbon atoms, leading to increased CO2 formation [33]. While biodiesel offers advantages in reducing CO and HC emissions, it poses a challenge in terms of elevated CO2 emissions. This highlights the complexity of choosing an alternative fuel; although biodiesel shows promise in some environmental metrics, it may necessitate compromise in others, such as global warming potential due to increased CO2 emissions.

Figure 7.

Variation in CO2 with engine speed at 75% load.

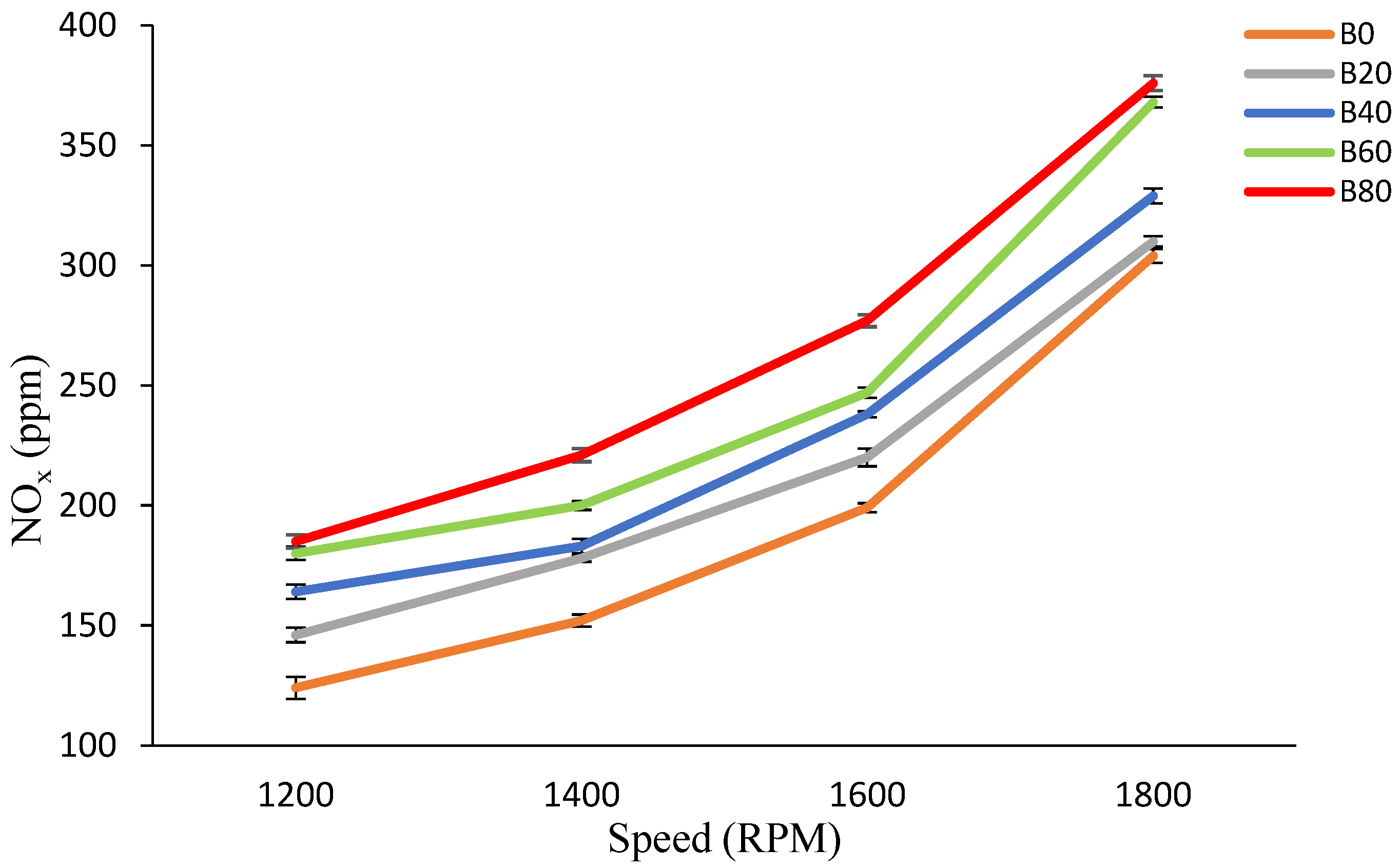

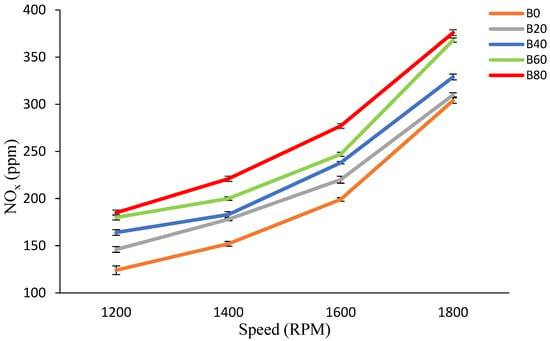

4.3.4. Variation in NOX with Engine Speed

Nitrogen oxides are generated through high-temperature reactions between oxygen and nitrogen particles in the air [1]. Figure 8 shows the NOx emission levels for biodiesel blends compared to standard diesel fuel. Notably, biodiesel blends exhibited higher NOx emissions, a phenomenon that can be attributed to biodiesel’s higher combustion temperature and greater degree of unsaturation [34]. Cheng et al. conducted a study on the impact of biodiesel (specifically soy-based biofuel) on NOx emissions in diesel engines. Their findings revealed that biodiesel use leads to an increase in NOx emissions. This increase is attributed to earlier combustion onset and a larger premixed burning fraction [35]. Similarly, Mueller et al. found that NOx emissions rose under all conditions when using biodiesel. This increase was due to higher local and average in-cylinder temperatures, more advanced combustion, and reduced radiative heat loss [36].

Figure 8.

Variation in NOX with engine speed at 75% load.

For instance, at 1200 rpm and 75% engine load, NOx emissions for diesel, B20, B40, B60, and B80 were recorded as 124 ppm, 146 ppm, 164 ppm, 180 ppm, and 185 ppm, respectively. Similarly, at 1800 rpm, the NOx emissions for the respective blends were 304 ppm, 310 ppm, 329 ppm, 368 ppm, and 376 ppm.

While biodiesel offers promising reductions in CO and HC emissions, its elevated NOx levels complicate its role as an environmentally friendly alternative. This highlights the necessity for optimizing biodiesel blends and combustion parameters to achieve an overall reduction in emissions, including NOx.

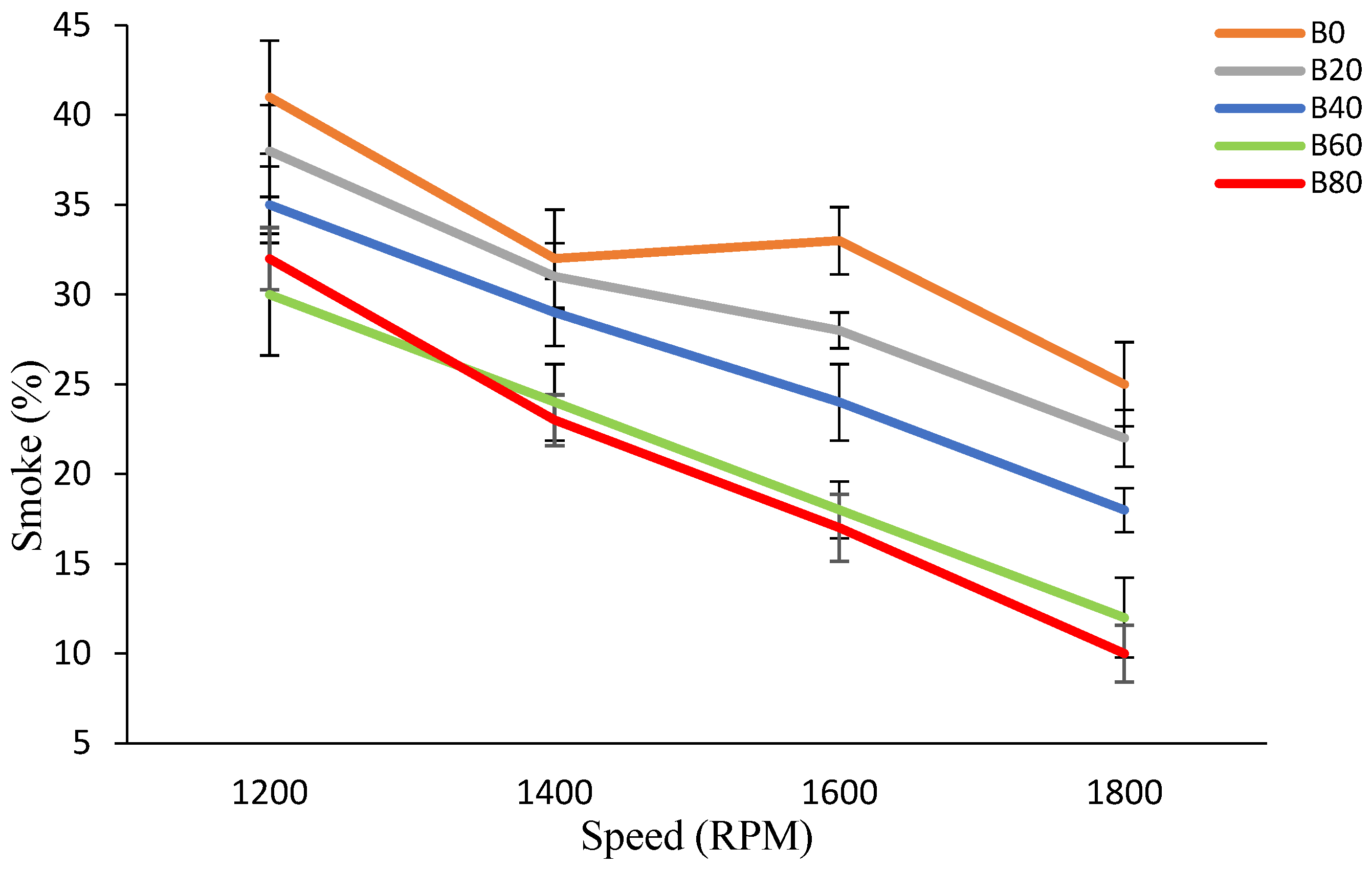

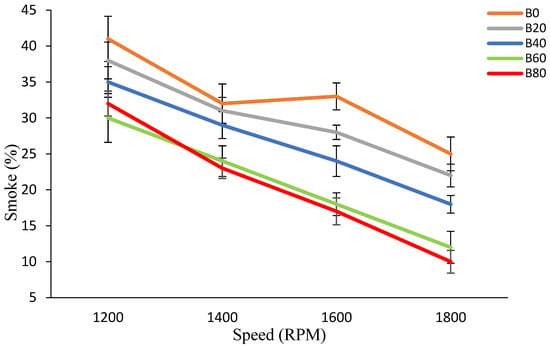

4.3.5. Variation in Smoke Opacity with Engine Speed

One of the prominent benefits of using biodiesel blends appears to be a reduction in smoke emissions, as illustrated in Figure 9. The elevated oxygen content in biodiesel aids in better combustion, thereby reducing the levels of emitted smoke [37].

Figure 9.

Variation in smoke opacity with engine speed at 75% load.

At 75% engine load, diesel fuel showed smoke opacities of 41%, 32%, 33%, and 25% at 1200 rpm, 1400 rpm, 1600 rpm, and 1800 rpm, respectively. In contrast, the opacity of smoke emissions decreased as the proportion of biodiesel in the fuel blend increased. For example, at 1200 rpm, B20 showed a smoke opacity of 38%, whereas B60 displayed a significantly lower opacity of 30%. This trend continued at 1800 rpm, where B20 had the highest smoke opacity of 22%, while B80 had the lowest at 10%. As stated above, biodiesel blends have lower smoke opacity than diesel because of the presence of oxygen molecules in biodiesel, which improves the combustion process and reduces smoke emissions [38].

4.4. Implications for Real-World Applications

The real-world applications of biodiesel from waste swine oil present a mixed bag of benefits and challenges. On the one hand, biodiesel is effective in reducing CO and HC emissions, which have immediate implications for air quality in urban environments. Lower smoke emissions also make it attractive from a public health standpoint.

On the other hand, elevated NOx emissions pose a significant challenge, requiring additional after treatment or engine modifications to bring them within acceptable levels. Similarly, the increased BSFC implies that for the same distance traveled, a vehicle would require more biodiesel than traditional diesel, making it less economical without further refinements in engine technology.

4.5. Advantages and Challenges of Using Biodiesel from Waste Swine Oil

Advantages:

- Waste Utilization: Using waste swine oil for biodiesel production offers an excellent waste management solution [39].

- Reduced CO and HC Emissions: Lower carbon monoxide and hydrocarbon emissions make it environmentally advantageous in some aspects [40].

- Lower Smoke Emissions: The significant reduction in smoke opacity is both an environmental and public health benefit [41].

Challenges:

- Elevated NOx Emissions: The rise in NOx emissions is a critical drawback that could limit the use of biodiesel in certain applications [42].

- Increased BSFC: Higher fuel consumption for the same energy output makes it less efficient.

- CO2 Emissions: Contrary to the trends in other emissions, biodiesel produces higher CO2 levels, posing challenges for its overall environmental footprint [33].

5. Conclusions

Our study aimed to assess the performance and emission characteristics of biodiesel derived from waste swine oil in comparison with traditional diesel fuel. The analysis was conducted at 75% engine load across a range of engine speeds from 1200 rpm to 1800 rpm. The investigation yielded several important insights:

Brake-Specific Fuel Consumption (BSFC): Biodiesel demonstrated a higher BSFC compared to traditional diesel, implying lower fuel efficiency. This is in line with the existing literature, which attributes this to the lower energy density of biodiesel.

Brake Thermal Efficiency (BTE): A marginal decrease in BTE was observed for biodiesel, substantiating earlier research that pointed to inherent differences in calorific values and combustion characteristics as possible explanations.

Emission Characteristics:

- CO Emissions: Biodiesel blends showed reduced carbon monoxide emissions, which is an environmental benefit.

- HC Emissions: Hydrocarbon emissions were also generally lower for biodiesel blends at higher engine speeds.

- CO2 Emissions: An increase in CO2 emissions due to complete combustion of biodiesel in the engine was observed for biodiesel blends, calling attention to its environmental drawbacks.

- NOx Emissions: An increase in nitrogen oxides was noted for biodiesel, which aligns with the literature and is attributed to biodiesel’s higher combustion temperature.

- Smoke Opacity: Biodiesel blends resulted in significantly lower smoke emissions, offering both environmental and public health advantages.

The biodiesel blends, particularly B20, demonstrated a propensity for lower hydrocarbon (HC) and smoke emissions, with the latter being indicative of more efficient combustion due to biodiesel’s elevated oxygen content, as reflected in the reduced smoke opacity readings from 38% at 1200 rpm to 10% at 1800 rpm for B80. Concurrently, CO2 emissions were observed to be higher for biodiesel, which, while indicative of more complete combustion, also suggests higher overall carbon output. This aligns with biodiesel’s higher cetane number, which facilitates a more complete burn by reducing ignition delay times. However, this increase in CO2 was accompanied by a rise in Brake-Specific Fuel Consumption (BSFC)—biodiesel recorded a BSFC value of 270 g/kWh at 75% engine load, compared to diesel’s 245 g/kWh—implying that while biodiesel burns cleaner in terms of HC and smoke, it requires more fuel to do the same amount of work. This trade-off highlights the complexity of optimizing engine performance while also reducing the environmental impact.

In conclusion, biodiesel derived from waste swine oil presents a promising but complex alternative to conventional diesel. Its benefits in terms of reduced CO, HC, and smoke emissions are noteworthy. However, challenges like increased NOx and CO2 emissions and lower thermal efficiency need to be overcome for it to be a fully viable alternative. Further research is required to optimize engine parameters for biodiesel use and to develop after-treatment solutions for controlling NOx emissions.

Author Contributions

Conceptualization, R.K.; methodology, R.K.; software, R.K.; validation, R.K., H.M.C. and M.I.M.; formal analysis, R.K.; investigation, R.K.; resources, H.M.C.; data curation, R.K.; writing—original draft preparation, R.K.; writing—review and editing, R.K., H.M.C. and M.I.M.; visualization, R.K.; supervision, H.M.C.; project administration, H.M.C. and M.I.M.; funding acquisition, H.M.C. and M.I.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by a National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (NRF-2022H1A7A2A02000033)/(NRF-2019R1A2C1010557).

Data Availability Statement

Data are contained within the article. The data presented in this study were collected during the experimental investigation by the first author.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| PPM | Parts Per Million |

| RPM | Revolutions Per Minute |

| BP | Brake Power |

| KOH | Potassium Hydroxide |

| BSFC | Brake-Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| EGR | Exhaust Gas Recirculation |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| HC | Hydrocarbon |

| NOX | Nitrogen Oxide |

References

- Zheng, F.; Cho, H. Combustion and Emission of Castor Biofuel Blends in a Single-Cylinder Diesel Engine. Energies 2023, 16, 5427. [Google Scholar] [CrossRef]

- Knothe, G.; Razon, L.F. Biodiesel fuels. Prog. Energy Combust. Sci. 2017, 58, 36–59. [Google Scholar] [CrossRef]

- Ashok, B.; Nanthagopal, K. Eco friendly biofuels for CI engine applications. In Advances in Eco-Fuels for a Sustainable Environment; Woodhead Publishing: Sawston, UK, 2019; pp. 407–440. [Google Scholar]

- Eremeeva, A.M.; Ilyushin, Y.V. Automation of the control system for drying grain crops of the technological process for obtaining biodiesel fuels. Sci. Rep. 2023, 13, 14956. [Google Scholar] [CrossRef] [PubMed]

- Baldino, C.; Searle, S.; Zhou, Y. Alternative Uses and Substitutes for Wastes, Residues, and Byproducts Used in Fuel Production in the United States. Working Paper 2020-25. 2020. Available online: https://theicct.org/wp-content/uploads/2021/06/Alternative-wastes-biofuels-oct2020.pdf (accessed on 26 August 2023).

- Ravikumar, R.; Kiran, K.; Gurumoorthy, S.H. Experimental analysis of biofuel produced from fat derivatives of bird and animal as an additive fuel in CI engine. Int. J. Renew. Energy Res. 2020, 10, 1226–1233. [Google Scholar]

- Veljković, V.B.; Banković-Ilić, I.B.; Stamenković, O.S.; Hung, Y.T. Waste Vegetable oils, fats, and cooking oils in biodiesel production. Integr. Nat. Resour. Res. 2021, 22, 147–263. [Google Scholar]

- Mariadhas, A.; Kumar, B.S.; Kabilan, K.; Jayaraman, J.; Alagu, K.; Joy, N.; Nirmala, N. Technical insights of microalgae derived bio-diesel on its performance and emission characteristics, techno-economics and practicability huddles. Fuel 2023, 349, 128744. [Google Scholar] [CrossRef]

- An, H.; Yang, W.M.; Chou, S.K.; Chua, K.J. Combustion and emissions characteristics of diesel engine fueled by biodiesel at partial load conditions. Appl. Energy 2012, 99, 363–371. [Google Scholar] [CrossRef]

- Nguyen, T.; Pham, M.; Le Anh, T. Spray, combustion, performance and emission characteristics of a common rail diesel engine fueled by fish-oil biodiesel blends. Fuel 2020, 269, 117108. [Google Scholar] [CrossRef]

- Yana, S.; Nizar, M.; Mulyati, D. Biomass waste as a renewable energy in developing bio-based economies in Indonesia: A review. Renewable and Sustainable Energy Rev. 2022, 160, 112268. [Google Scholar] [CrossRef]

- Okolie, J.A.; Epelle, E.I.; Tabat, M.E.; Orivri, U.; Amenaghawon, A.N.; Okoye, P.U.; Gunes, B. Waste biomass valorization for the production of biofuels and value-added products: A comprehensive review of thermochemical, biological and integrated processes. Process Saf. Environ. Prot. 2022, 159, 323–344. [Google Scholar] [CrossRef]

- Zhang, C.; Hui, X.; Lin, Y.; Sung, C.J. Recent development in studies of alternative jet fuel combustion: Progress, challenges, and opportunities. Renew. Sustain. Energy Rev. 2016, 54, 120–138. [Google Scholar] [CrossRef]

- Imdadul, H.K.; Masjuki, H.H.; Kalam, M.A.; Zulkifli NW, M.; Rashed, M.M.; Rashedul, H.K.; Monirul, I.M.; Mosarof, M.H. A comprehensive review on the assessment of fuel additive effects on combustion behavior in CI engine fuelled with diesel biodiesel blends. RSC Adv. 2015, 5, 67541–67567. [Google Scholar] [CrossRef]

- Kamil, M.; Almarashda, F.M. Economic Viability and Engine Performance Evaluation of Biodiesel Derived from Desert Palm Date Seeds. Energies 2023, 16, 1513. [Google Scholar] [CrossRef]

- Suresh, T.; Sivarajasekar, N.; Balasubramani, K.J.R.E. Enhanced ultrasonic assisted biodiesel production from meat industry waste (pig tallow) using green copper oxide nanocatalyst: Comparison of response surface and neural network modelling. Renew. Energy 2021, 164, 897–907. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Bhatia, R.K.; Jeon, J.M.; Pugazhendhi, A.; Awasthi, M.K.; Kumar, D.; Yang, Y.H. An overview on advancements in biobased transesterification methods for biodiesel production: Oil resources, extraction, biocatalysts, and process intensification technologies. Fuel 2021, 285, 119117. [Google Scholar] [CrossRef]

- Madhu, S.; Leo, G.L.; Prathap, P.; Devarajan, Y.; Jayabal, R. Effective utilization of waste pork fat as a potential alternate fuel in CRDI research diesel engine–Waste reduction and consumption technique. Process Saf. Environ. Prot. 2023, 172, 815–824. [Google Scholar] [CrossRef]

- Costa, J.; Martins, J.; Arantes, T.; Gonçalves, M.; Durão, L.; Brito, F. Experimental assessment of the performance and emissions of a spark-ignition engine using waste-derived biofuels as additives. Energies 2021, 14, 5209. [Google Scholar] [CrossRef]

- Orihuela, M.; Haralampous, O.; Chacartegui, R.; García, M.; Martinez-Fernandez, J. Numerical simulation of a wall-flow particulate filter made of biomorphic silicon carbide able to fit different fuel/biofuel inputs. Processes 2019, 7, 945. [Google Scholar] [CrossRef]

- Masera, K.; Hossain, A. Biofuels and thermal barrier: A review on compression ignition engine performance, combustion and exhaust gas emission. J. Energy Inst. 2019, 92, 783–801. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Duan, L.; Hao, J.; Nie, Y. Carbonaceous aerosol emissions from household biofuel combustion in china. Environ. Sci. Technol. 2009, 43, 6076–6081. [Google Scholar] [CrossRef]

- Feng, C.; Zhang, M.; Wu, H. Combustion of fuel mixtures containing crude glycerol (cg): Important role of interactions between cg and fuel components in particulate matter emission. Ind. Eng. Chem. Res. 2018, 57, 4132–4138. [Google Scholar] [CrossRef]

- Alajmi, F.S.; Hairuddin, A.A.; Adam, N.M.; Abdullah, L.C. Recent trends in biodiesel production from commonly used animal fats. Int. J. Energy Res. 2018, 42, 885–902. [Google Scholar] [CrossRef]

- Mandal, A.; Cha, D.; Cho, H. Impact of Waste Fry Biofuel on Diesel Engine Performance and Emissions. Energies 2023, 16, 3711. [Google Scholar] [CrossRef]

- Jariah, N.F.; Hassan, M.A.; Taufiq-Yap, Y.H.; Roslan, A.M. Technological advancement for efficiency enhancement of biodiesel and residual glycerol refining: A mini review. Processes 2021, 9, 1198. [Google Scholar] [CrossRef]

- Baweja, S.; Trehan, A.; Kumar, R. Combustion, performance, and emission analysis of a CI engine fueled with mustard oil biodiesel blended in diesel fuel. Fuel 2021, 292, 120346. [Google Scholar] [CrossRef]

- Reddy, S.R.; Murali, G.; Shaik, A.A.; Raju, V.D.; Reddy, M.S. Experimental evaluation of diesel engine powered with waste mango seed biodiesel at different injection timings and EGR rates. Fuel 2021, 285, 119047. [Google Scholar] [CrossRef]

- Elkelawy, M.; Bastawissi, H.A.E.; Esmaeil, K.K.; Radwan, A.M.; Panchal, H.; Sadasivuni, K.K.; Suresh, M.; Israr, M. Maximization of biodiesel production from sunflower and soybean oils and prediction of diesel engine performance and emission characteristics through response surface methodology. Fuel 2020, 266, 117072. [Google Scholar] [CrossRef]

- Devarajan, Y.; Munuswamy, D.B.; Nalla, B.T.; Choubey, G.; Mishra, R.; Vellaiyan, S. Experimental analysis of Sterculia foetida biodiesel and butanol blends as a renewable and eco-friendly fuel. Ind. Crops Prod. 2022, 178, 114612. [Google Scholar] [CrossRef]

- Labeckas, G.; Slavinskas, S.; Kanapkienė, I. The individual effects of cetane number, oxygen content or fuel properties on the ignition delay, combustion characteristics, and cyclic variation of a turbocharged CRDI diesel engine–Part 1. Energy Convers. Manag. 2017, 148, 1003–1027. [Google Scholar] [CrossRef]

- Sayin, C.; Gumus, M. Impact of compression ratio and injection parameters on the performance and emissions of a DI diesel engine fueled with biodiesel-blended diesel fuel. Appl. Therm. Eng. 2011, 31, 3182–3188. [Google Scholar] [CrossRef]

- Venu, H.; Madhavan, V. Influence of diethyl ether (DEE) addition in ethanol-biodiesel-diesel (EBD) and methanol-biodiesel-diesel (MBD) blends in a diesel engine. Fuel 2017, 189, 377–390. [Google Scholar] [CrossRef]

- Chiong, M.C.; Chong, C.T.; Ng, J.H.; Tran, M.V.; Lam, S.S.; Valera-Medina, A.; Jaafar, M.N.M. Combustion and emission performances of coconut, palm and soybean methyl esters under reacting spray flame conditions. J. Energy Inst. 2019, 92, 1034–1044. [Google Scholar] [CrossRef]

- Cheng, A.S.; Upatnieks, A.; Mueller, C.J. Investigation of the impact of biodiesel fuelling on NO x emissions using an optical direct injection diesel engine. Int. J. Engine Res. 2006, 7, 297–318. [Google Scholar] [CrossRef]

- Mueller, C.J.; Boehman, A.L.; Martin, G.C. An experimental investigation of the origin of increased NOx emissions when fueling a heavy-duty compression-ignition engine with soy biodiesel. SAE Int. J. Fuels Lubr. 2009, 2, 789–816. [Google Scholar] [CrossRef]

- Panithasan, M.S.; Gopalakichenin, D.; Venkadesan, G.; Veeraraagavan, S. Impact of rice husk nanoparticle on the performance and emission aspects of a diesel engine running on blends of pine oil-diesel. Environ. Sci. Pollut. Res. 2019, 26, 282–291. [Google Scholar] [CrossRef] [PubMed]

- Mohite, S.; Kumar, S.; Maji, S. Performance characteristics of mix oil biodiesel blends with smoke emissions. Int. J. Renew. Energy Dev. 2016, 5, 163–170. [Google Scholar] [CrossRef]

- Hafid, H.S.; Omar, F.N.; Abdul Rahman, N.A.; Wakisaka, M. Innovative conversion of food waste into biofuel in integrated waste management system. Crit. Rev. Environ. Sci. Technol. 2022, 52, 3453–3492. [Google Scholar] [CrossRef]

- Bhuiya, M.M.K.; Rasul, M.G.; Khan, M.M.K.; Ashwath, N.; Azad, A.K.; Hazrat, M.A. Prospects of 2nd generation biodiesel as a sustainable fuel–Part 2: Properties, performance and emission characteristics. Renew. Sustain. Energy Rev. 2016, 55, 1129–1146. [Google Scholar] [CrossRef]

- Mofijur, M.; Rasul, M.G.; Hyde, J.J.P.E. Recent developments on internal combustion engine performance and emissions fuelled with biodiesel-diesel-ethanol blends. Procedia Eng. 2015, 105, 658–664. [Google Scholar] [CrossRef]

- Gharehghani, A.; Pourrahmani, H. Performance evaluation of diesel engines (PEDE) for a diesel-biodiesel fueled CI engine using nano-particles additive. Energy Convers. Manag. 2019, 198, 111921. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).