The Design, Analysis, and Optimization of a New Pitch Mechanism for Small Wind Turbines

Abstract

:1. Introduction

2. Structural Design and Stress Analysis

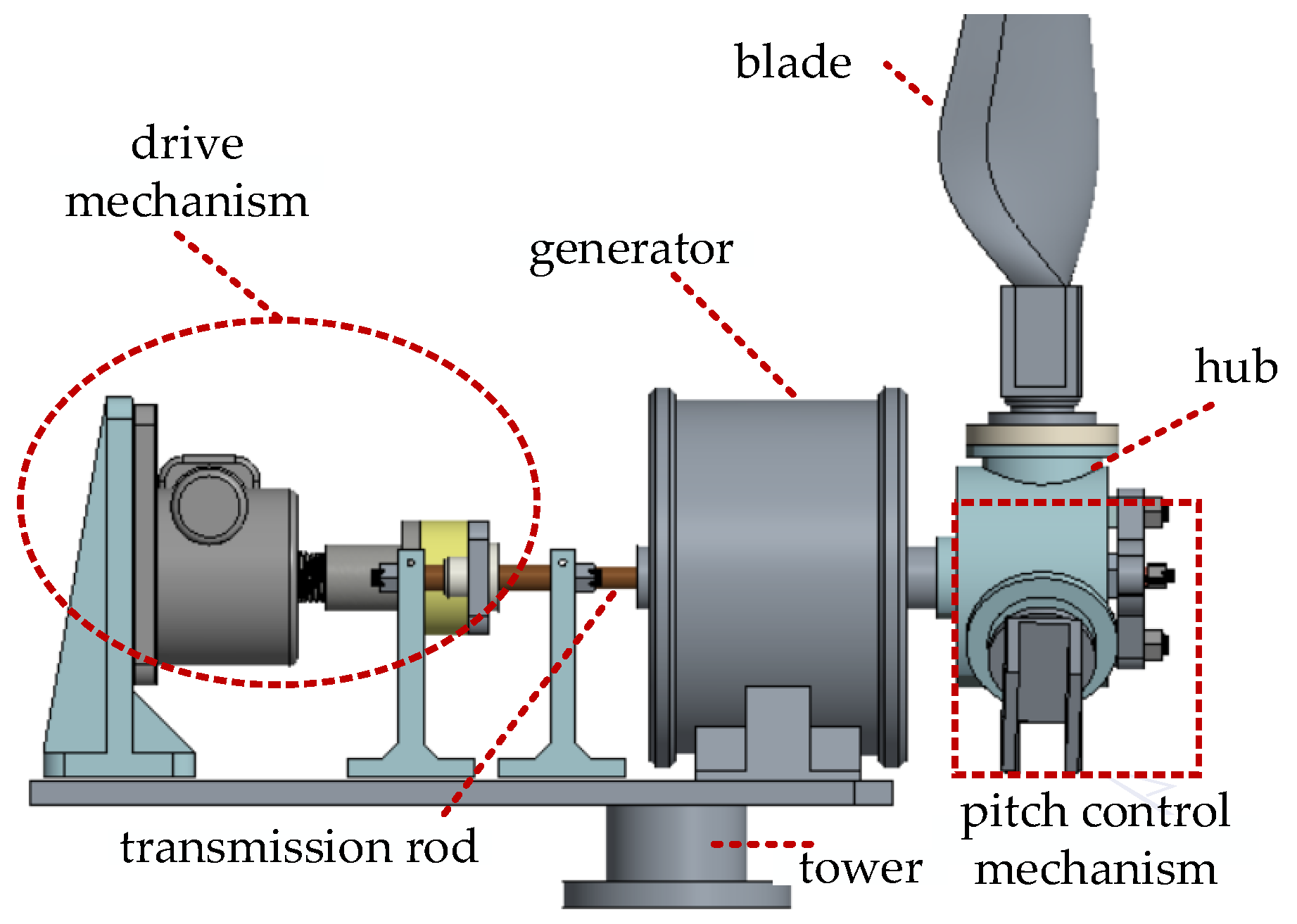

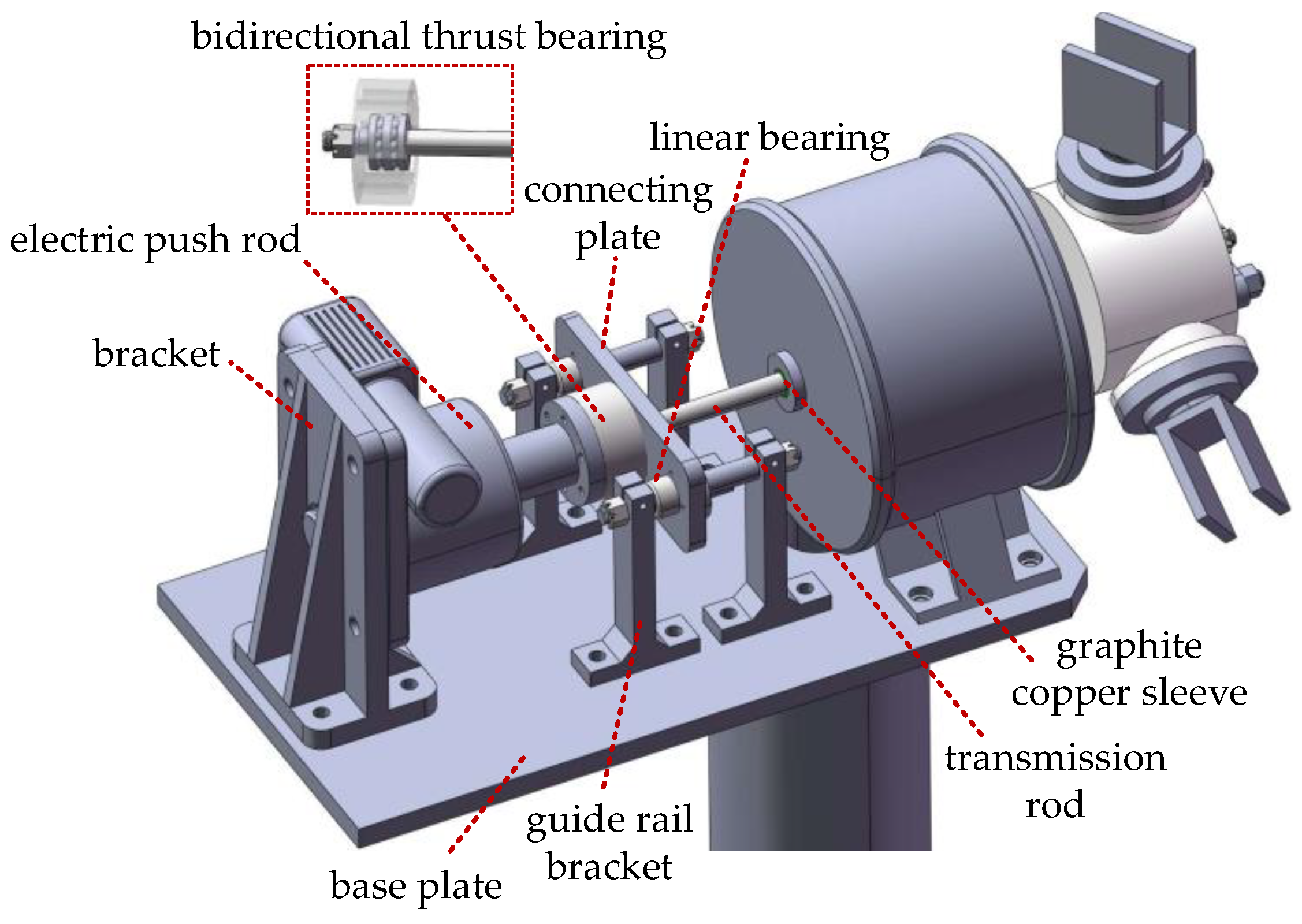

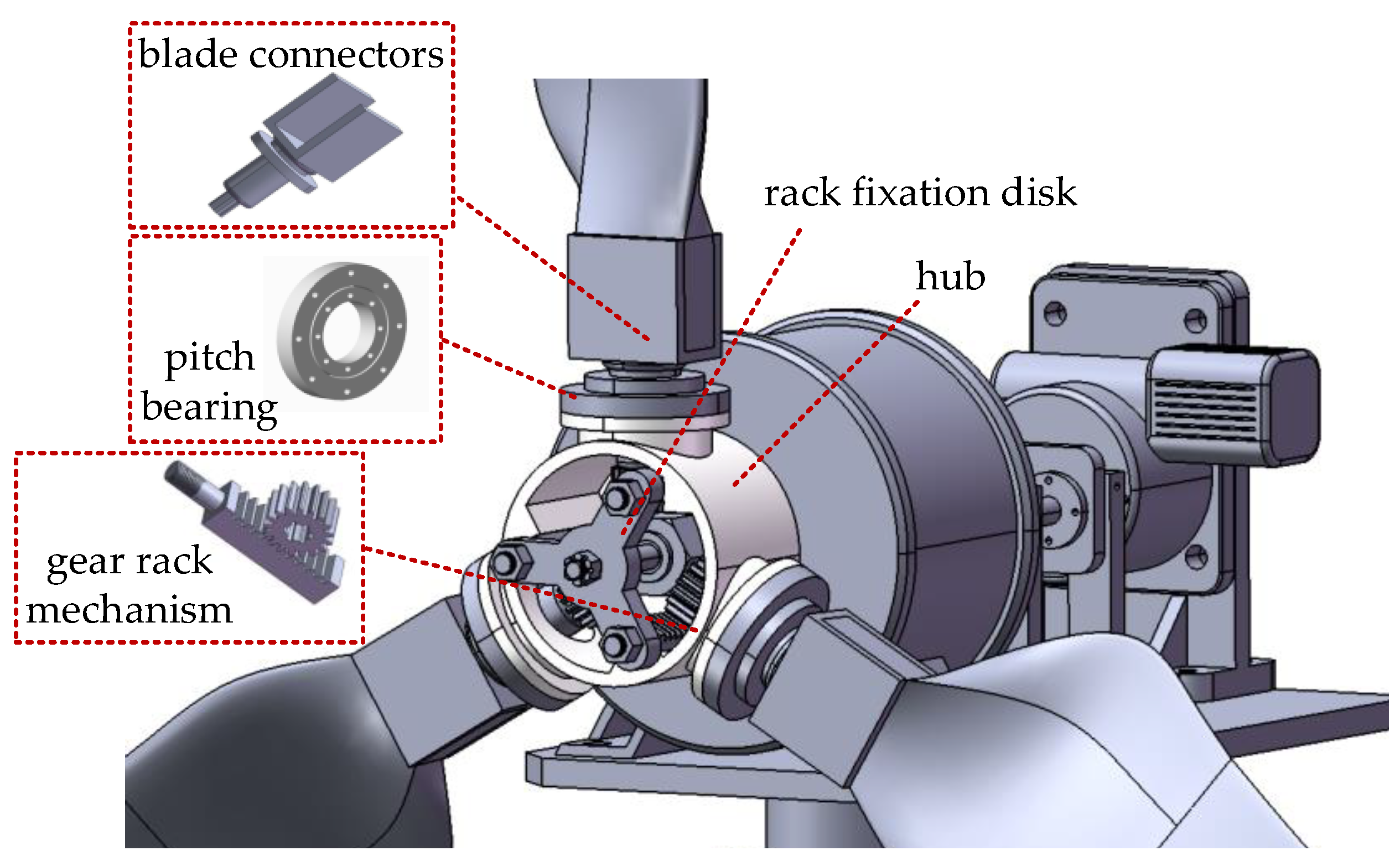

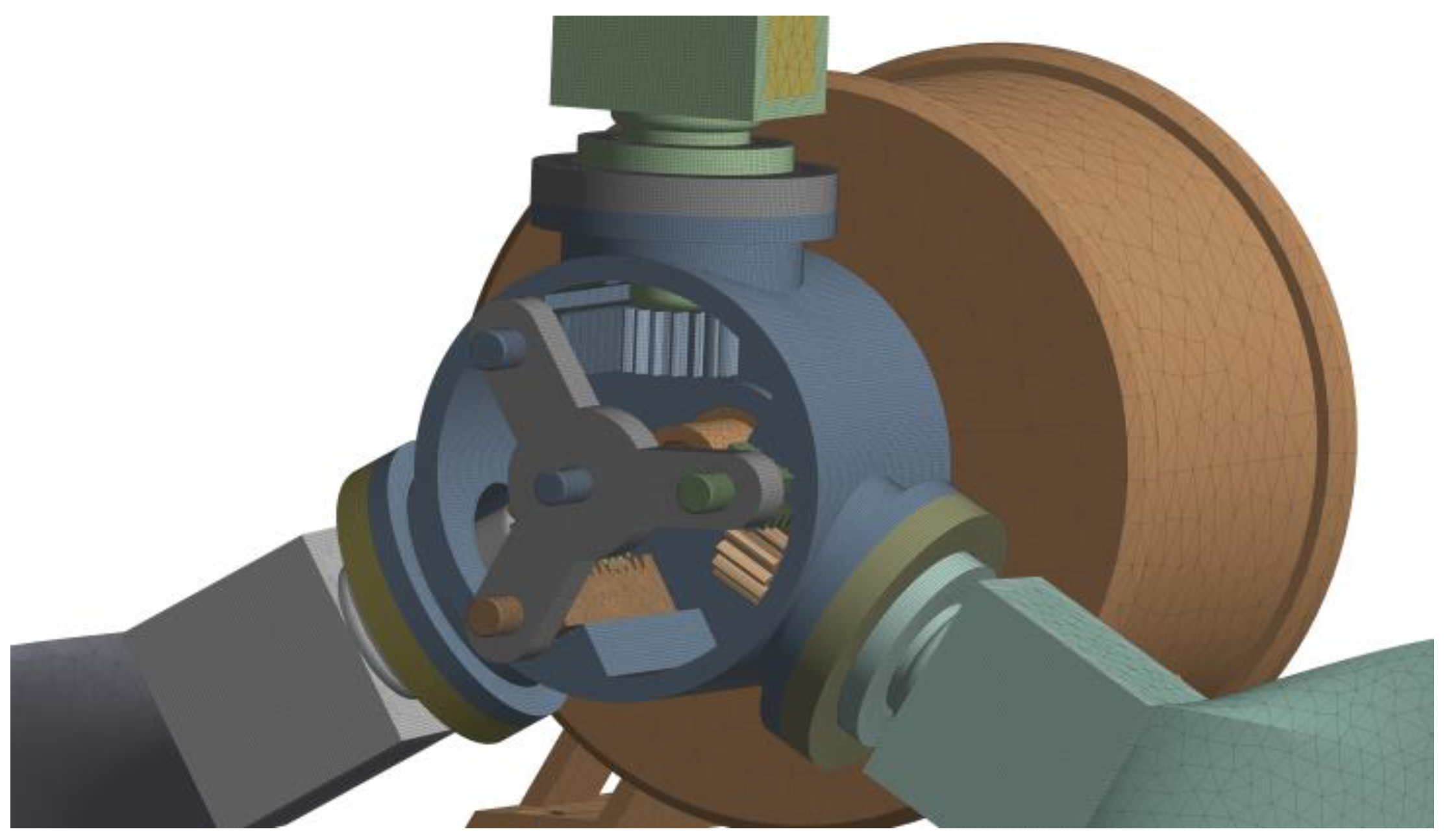

2.1. Basic Structure of the Novel Variable Pitch Wind Turbine

2.2. Working Principle of the Novel Variable Pitch Wind Turbine

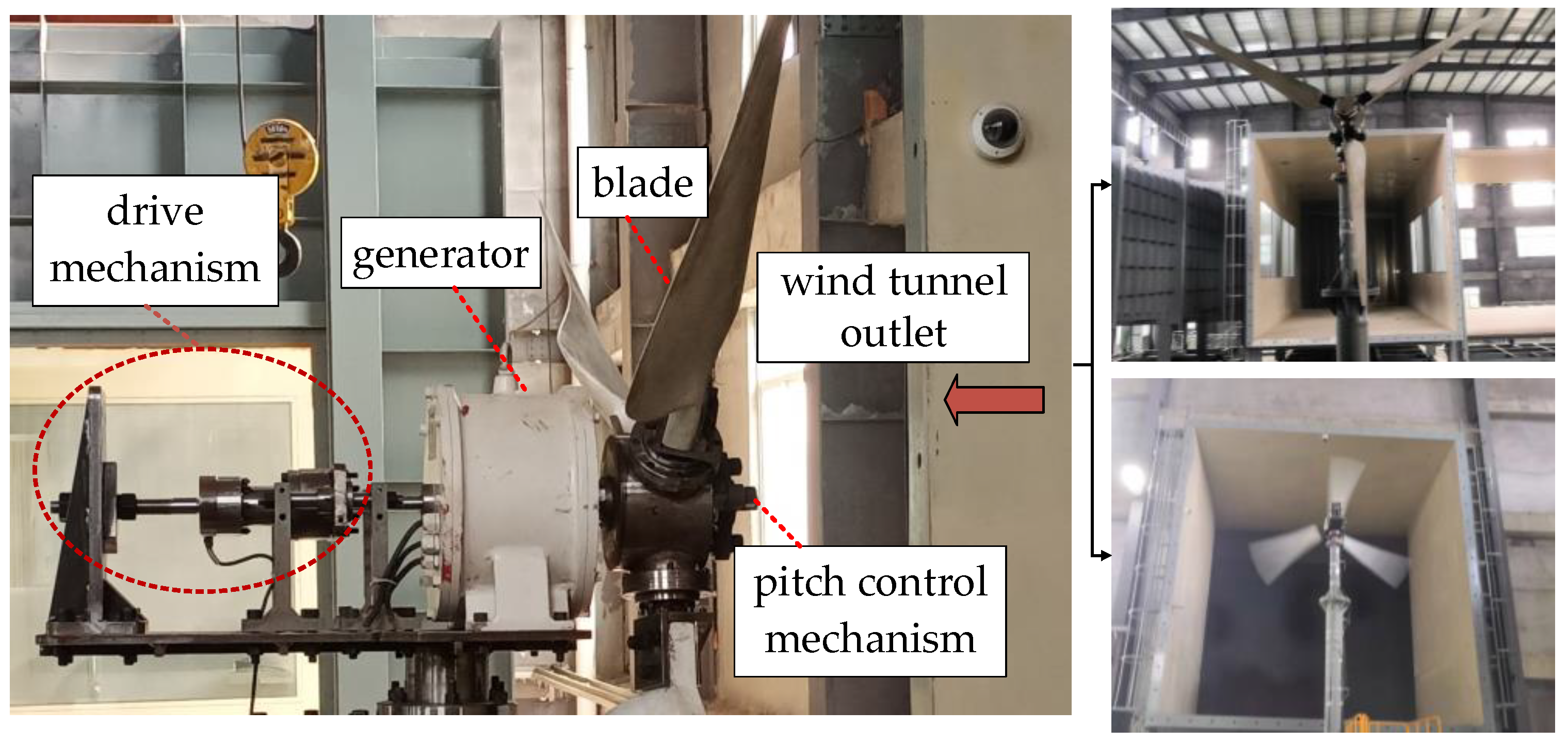

2.3. Small-Scale Model Test Verification

2.4. Experimental Study of a Prototype Test Hole for a New Variable Pitch Wind Turbine

2.5. Technical Advantages and Challenges of New Variable Pitch Wind Turbines

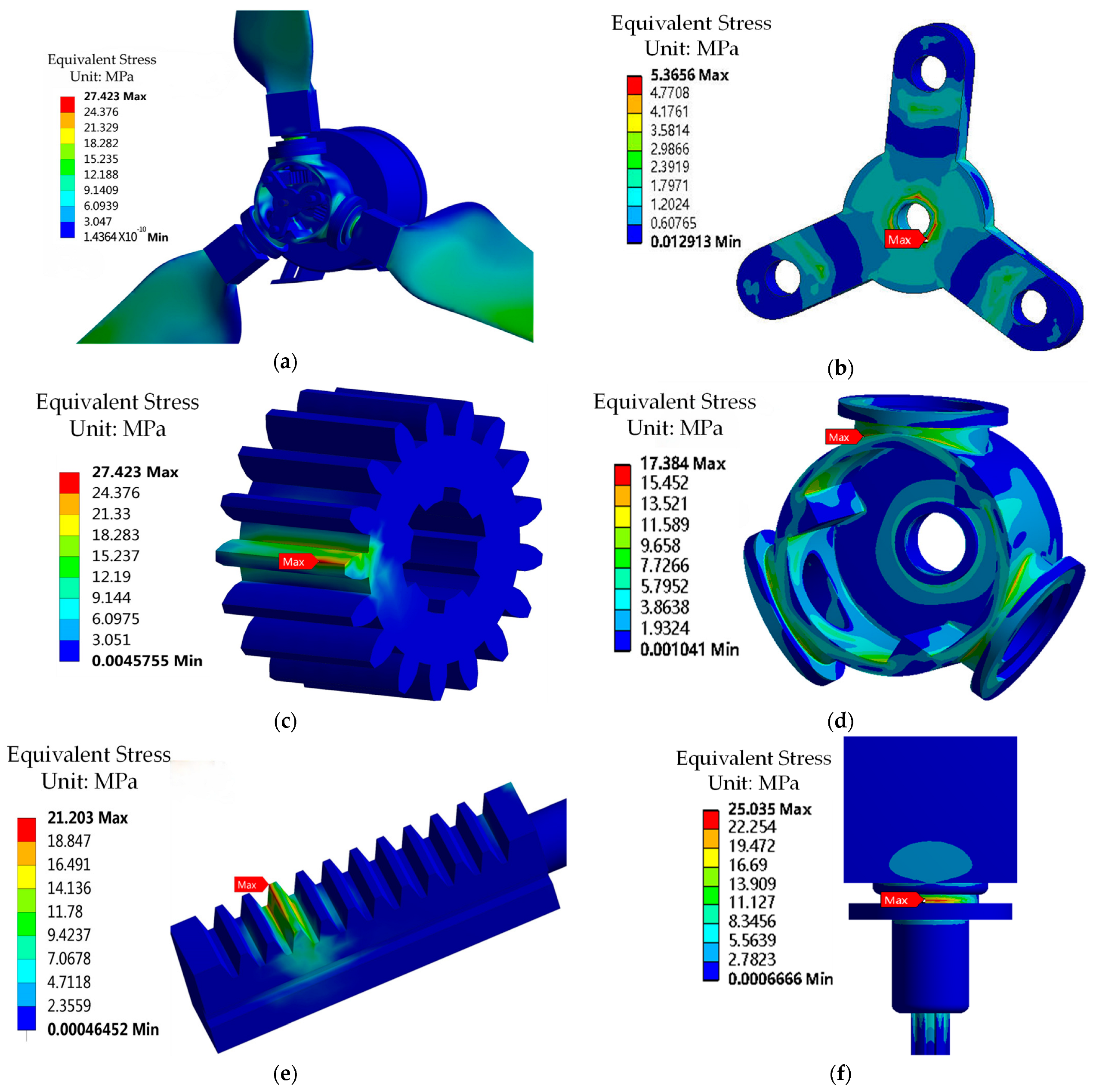

2.6. Stress Analysis of Variable Pitch Adjustment Mechanism Components

2.6.1. Model Parameters

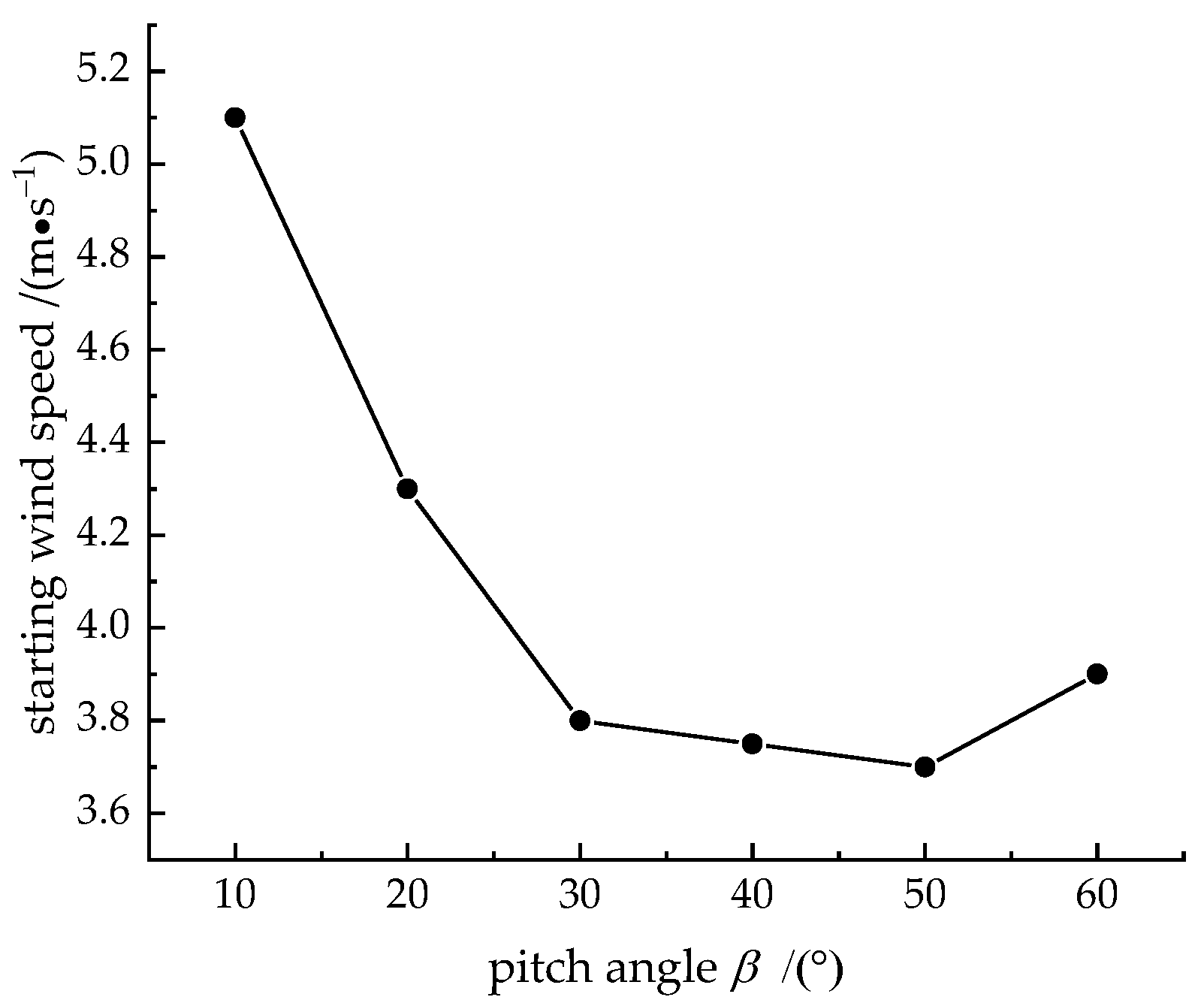

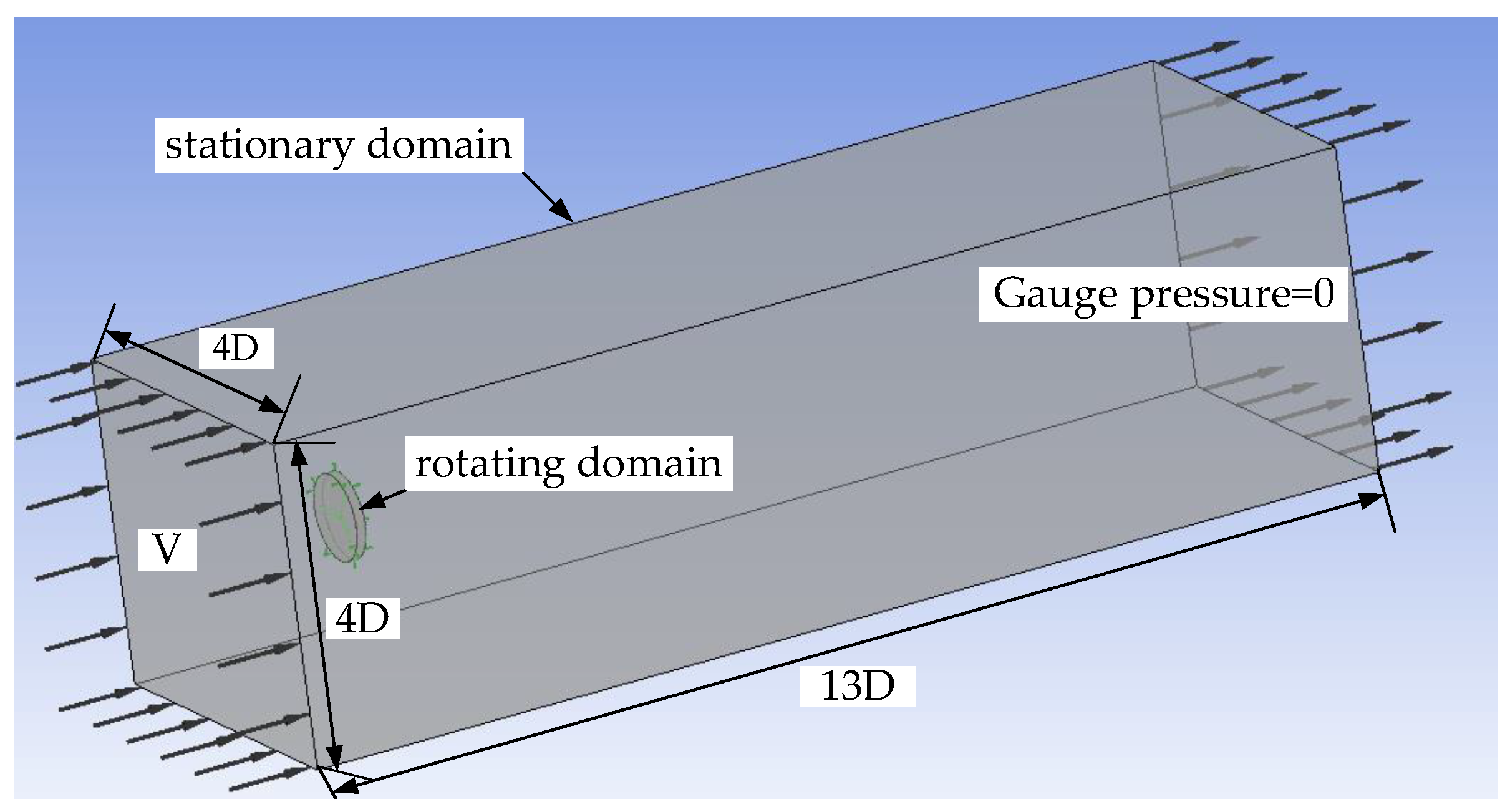

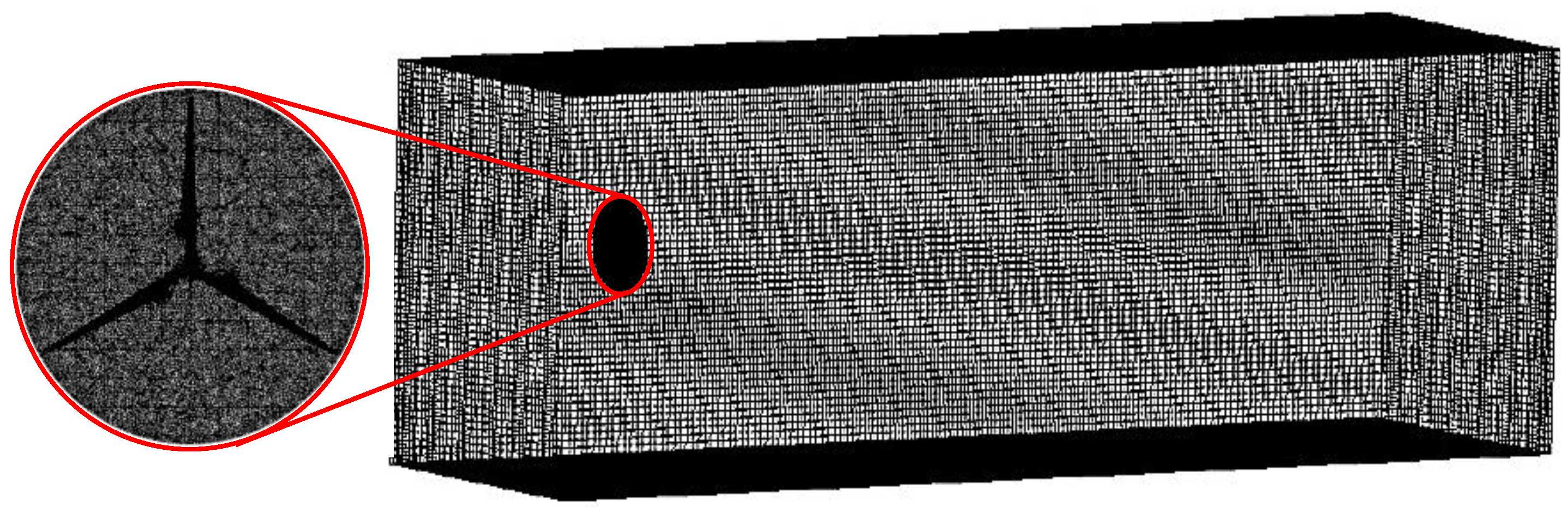

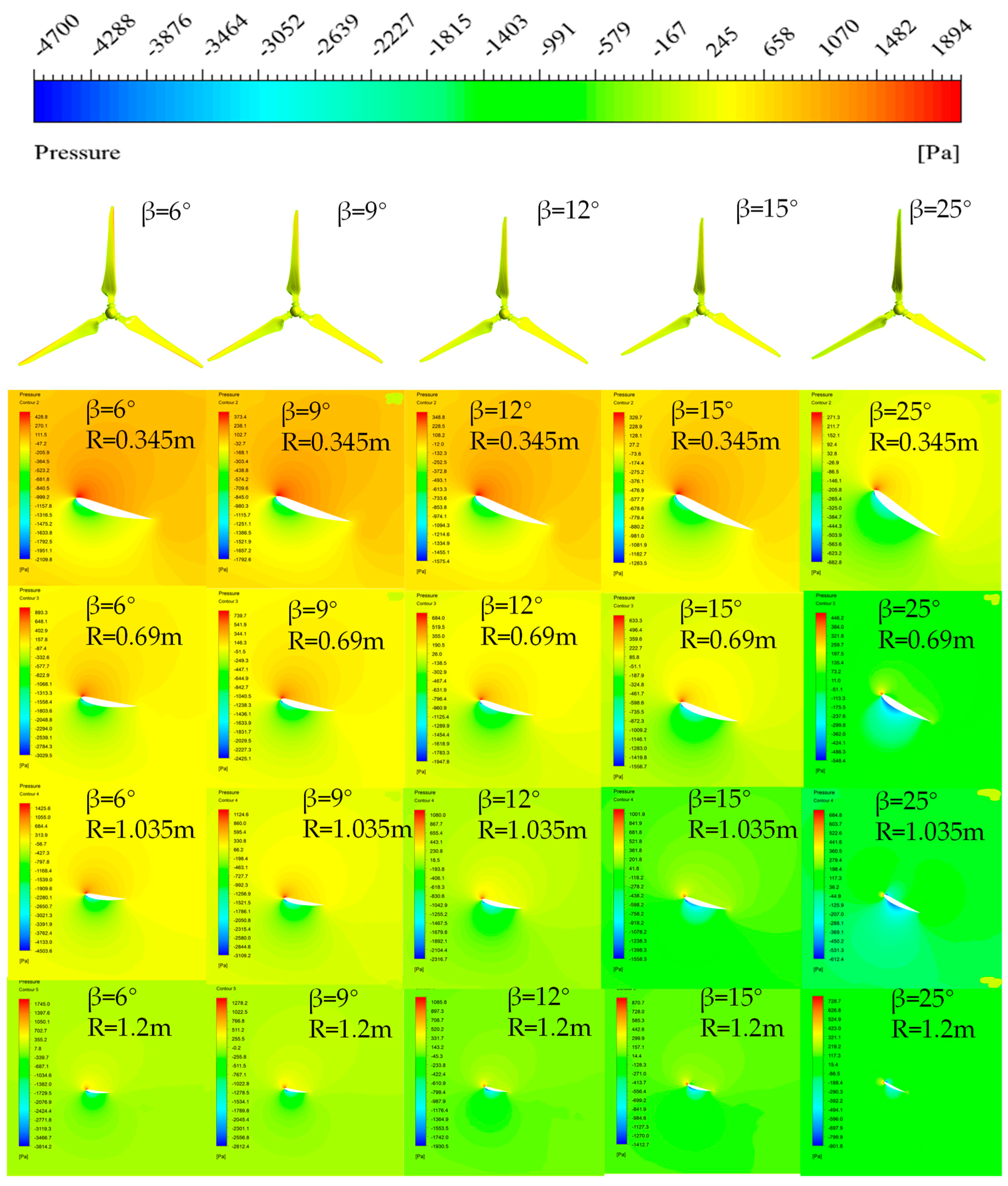

2.6.2. Boundary Condition Setting and Grid Validity Verification of Flow Field Analysis

2.6.3. Meshing and Boundary Condition Setting for Structural Field Analysis

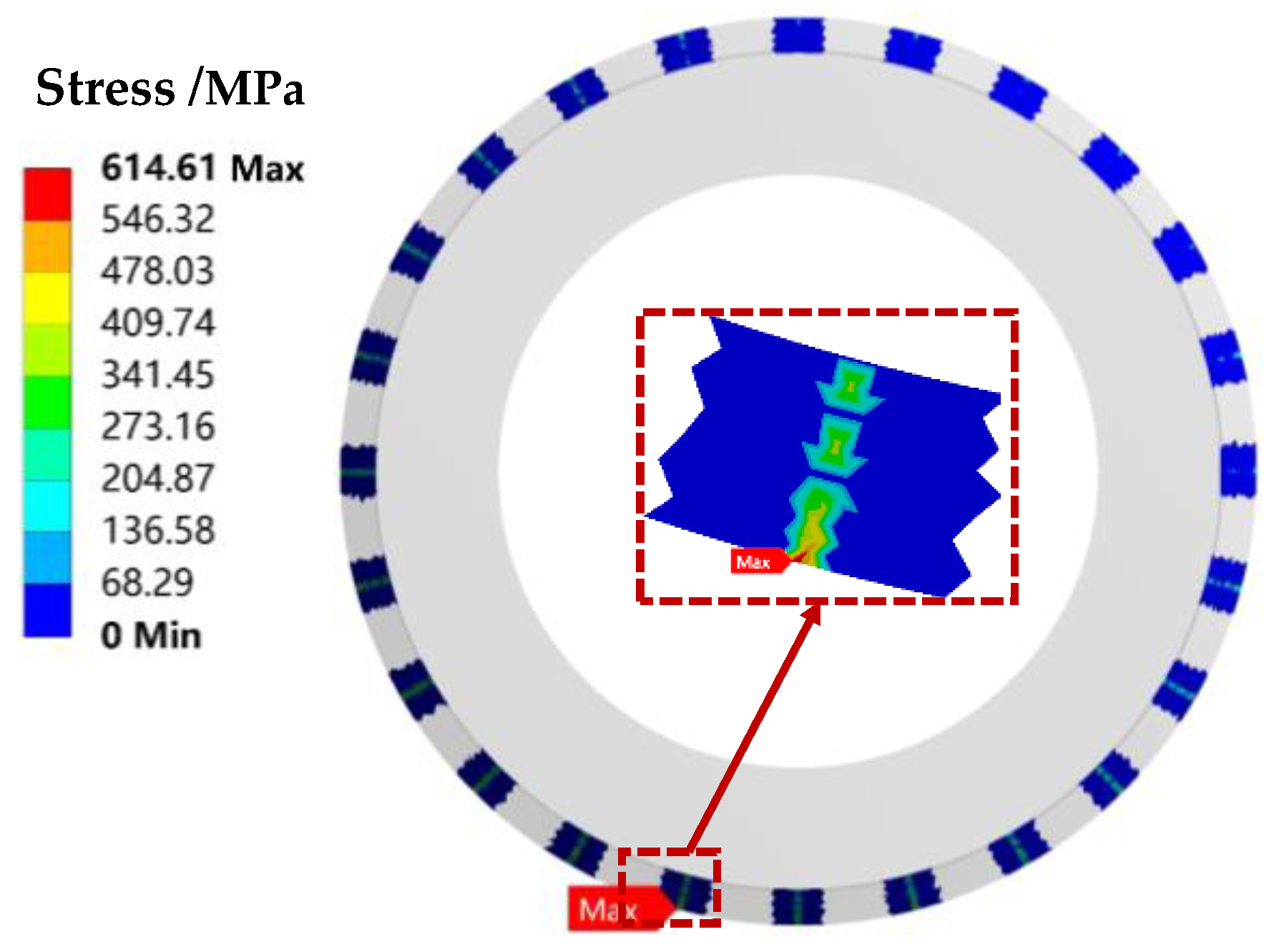

2.6.4. Results Analysis

3. Optimization of Components

3.1. Optimization Design of the Rack Synchronizer

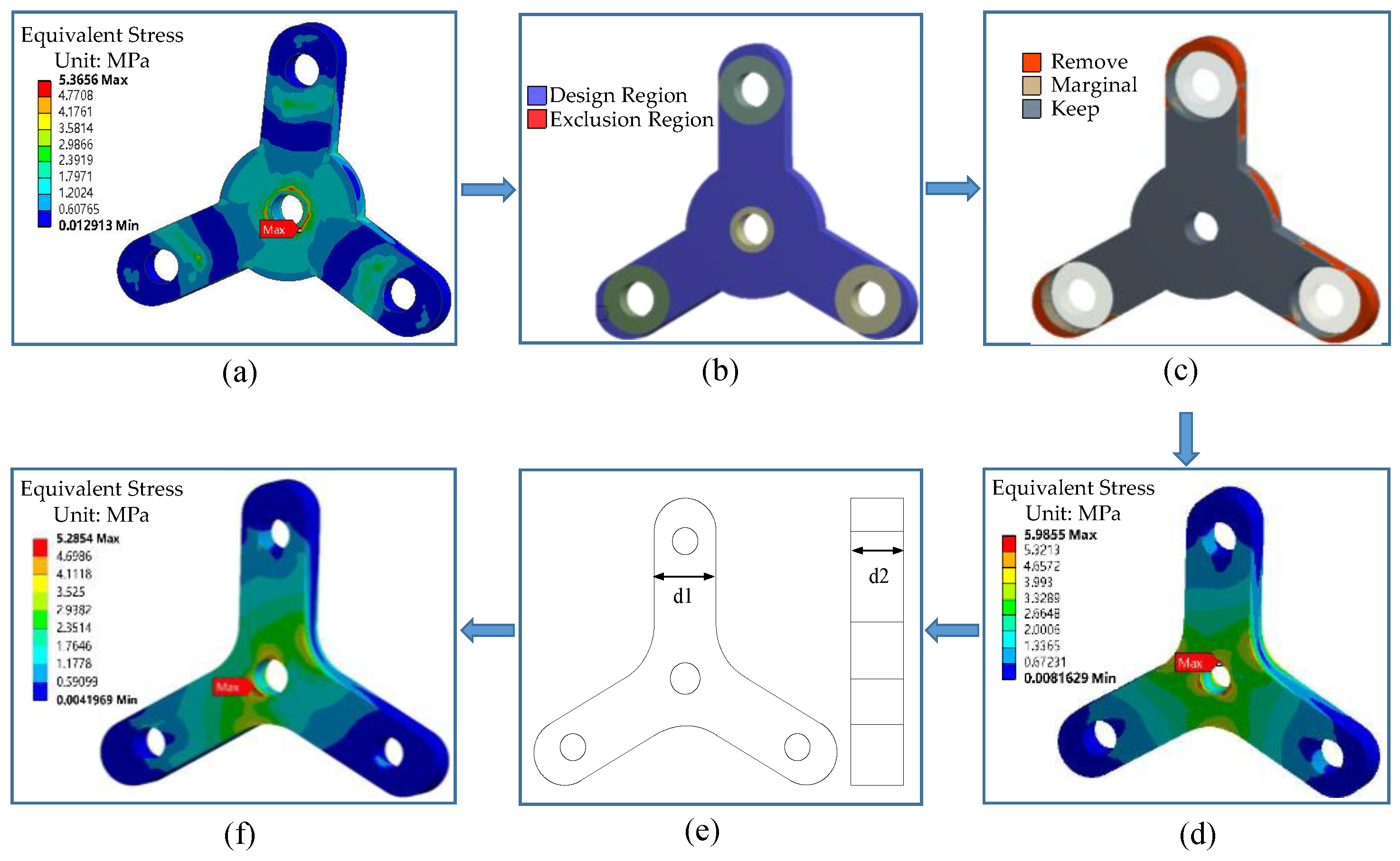

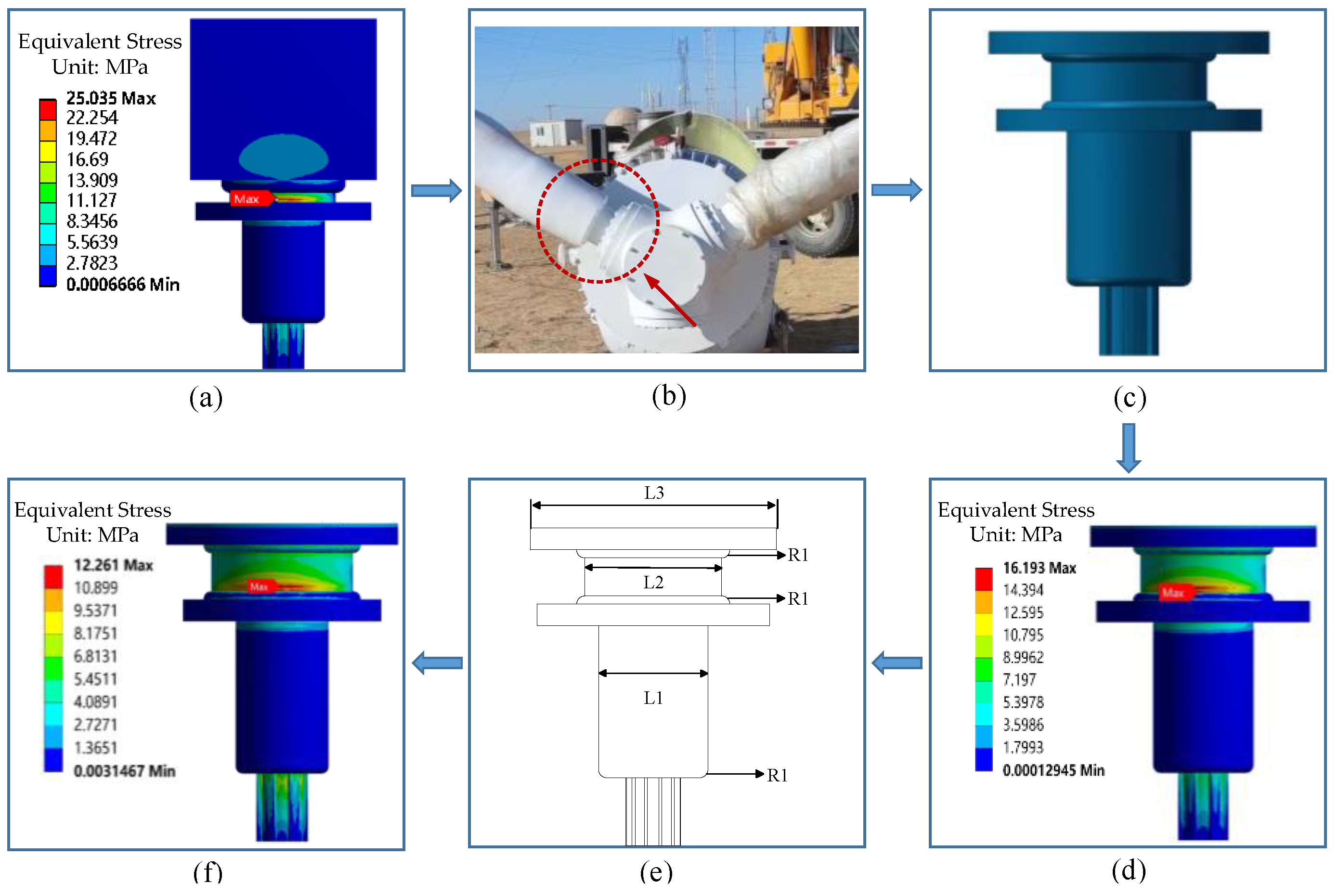

3.2. Optimization Design of the Blade Handle

3.3. Optimization Design of the Gear Rack Mechanism

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Number | Modulus (M) | Number of Teeth (Z) | Width (H)/mm | Bending Stress/MPa | Contact Stress/MPa | Mass /kg | Relative Closeness | Ranking |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.25 | 17 | 15 | 43.28 | 92.78 | 0.32 | 0.443 | 139 |

| 2 | 1.25 | 17 | 20 | 34.32 | 56.7 | 0.42 | 0.545 | 128 |

| 3 | 1.25 | 17 | 25 | 38.92 | 63.8 | 0.53 | 0.469 | 133 |

| 4 | 1.25 | 19 | 15 | 55.35 | 62.59 | 0.33 | 0.388 | 142 |

| 5 | 1.25 | 19 | 20 | 50.02 | 59.41 | 0.44 | 0.399 | 140 |

| 6 | 1.25 | 19 | 25 | 50.08 | 55.03 | 0.54 | 0.381 | 144 |

| 7 | 1.25 | 21 | 15 | 32.65 | 51.23 | 0.34 | 0.582 | 122 |

| 8 | 1.25 | 21 | 20 | 25.99 | 41.01 | 0.45 | 0.656 | 105 |

| 9 | 1.25 | 21 | 25 | 21.00 | 34.31 | 0.56 | 0.708 | 88 |

| 10 | 1.25 | 23 | 15 | 31.76 | 51.24 | 0.35 | 0.590 | 118 |

| 11 | 1.25 | 23 | 20 | 25.96 | 41.65 | 0.47 | 0.652 | 107 |

| 12 | 1.25 | 23 | 25 | 22.06 | 36.62 | 0.58 | 0.688 | 96 |

| 13 | 1.25 | 25 | 15 | 51.65 | 70.69 | 0.36 | 0.395 | 141 |

| 14 | 1.25 | 25 | 20 | 41.51 | 61.45 | 0.49 | 0.455 | 136 |

| 15 | 1.25 | 25 | 25 | 35.41 | 51.04 | 0.61 | 0.506 | 132 |

| 16 | 1.25 | 27 | 15 | 59.02 | 41.75 | 0.38 | 0.381 | 143 |

| 17 | 1.25 | 27 | 20 | 40.48 | 54.76 | 0.51 | 0.469 | 134 |

| 18 | 1.25 | 27 | 25 | 30.31 | 42.07 | 0.63 | 0.573 | 124 |

| 19 | 1.5 | 17 | 15 | 36.01 | 48.04 | 0.33 | 0.552 | 127 |

| 20 | 1.5 | 17 | 20 | 33.63 | 41.19 | 0.44 | 0.570 | 125 |

| 21 | 1.5 | 17 | 25 | 28.67 | 36.57 | 0.55 | 0.615 | 114 |

| 22 | 1.5 | 19 | 15 | 42.30 | 70.72 | 0.34 | 0.467 | 135 |

| 23 | 1.5 | 19 | 20 | 32.19 | 50.89 | 0.46 | 0.569 | 126 |

| 24 | 1.5 | 19 | 25 | 19.88 | 38.12 | 0.57 | 0.713 | 86 |

| 25 | 1.5 | 21 | 15 | 36.30 | 64.44 | 0.36 | 0.525 | 131 |

| 26 | 1.5 | 21 | 20 | 33.58 | 58.8 | 0.48 | 0.540 | 129 |

| 27 | 1.5 | 21 | 25 | 28.64 | 50.47 | 0.60 | 0.586 | 120 |

| 28 | 1.5 | 23 | 15 | 27.52 | 48.08 | 0.38 | 0.637 | 111 |

| 29 | 1.5 | 23 | 20 | 41.63 | 59.54 | 0.50 | 0.454 | 137 |

| 30 | 1.5 | 23 | 25 | 19.26 | 33.42 | 0.63 | 0.716 | 83 |

| 31 | 1.5 | 25 | 15 | 17.73 | 30.46 | 0.40 | 0.778 | 51 |

| 32 | 1.5 | 25 | 20 | 19.26 | 33.42 | 0.63 | 0.716 | 83 |

| 33 | 1.5 | 25 | 25 | 8.29 | 15.58 | 0.66 | 0.838 | 18 |

| 34 | 1.5 | 27 | 15 | 12.41 | 21.01 | 0.42 | 0.857 | 6 |

| 35 | 1.5 | 27 | 20 | 12.41 | 21.01 | 0.42 | 0.857 | 6 |

| 36 | 1.5 | 27 | 25 | 7.91 | 13.73 | 0.70 | 0.827 | 23 |

| 37 | 1.75 | 17 | 15 | 32.88 | 46.35 | 0.35 | 0.584 | 121 |

| 38 | 1.75 | 17 | 20 | 32.30 | 37.37 | 0.46 | 0.586 | 119 |

| 39 | 1.75 | 17 | 25 | 28.56 | 34.55 | 0.58 | 0.613 | 115 |

| 40 | 1.75 | 19 | 15 | 29.98 | 53.29 | 0.37 | 0.603 | 116 |

| 41 | 1.75 | 19 | 20 | 21.46 | 35.70 | 0.49 | 0.713 | 87 |

| 42 | 1.75 | 19 | 25 | 13.01 | 23.76 | 0.61 | 0.804 | 35 |

| 43 | 1.75 | 21 | 15 | 32.53 | 50.61 | 0.39 | 0.577 | 123 |

| 44 | 1.75 | 21 | 20 | 29.93 | 43.78 | 0.52 | 0.595 | 117 |

| 45 | 1.75 | 21 | 25 | 24.61 | 36.12 | 0.65 | 0.645 | 108 |

| 46 | 1.75 | 23 | 15 | 22.80 | 47.16 | 0.41 | 0.688 | 97 |

| 47 | 1.75 | 23 | 20 | 16.77 | 52.48 | 0.55 | 0.722 | 82 |

| 48 | 1.75 | 23 | 25 | 11.78 | 27.18 | 0.69 | 0.787 | 47 |

| 49 | 1.75 | 25 | 15 | 20.52 | 56.60 | 0.44 | 0.692 | 94 |

| 50 | 1.75 | 25 | 20 | 16.77 | 52.78 | 0.59 | 0.714 | 85 |

| 51 | 1.75 | 25 | 25 | 13.60 | 42.85 | 0.74 | 0.730 | 79 |

| 52 | 1.75 | 27 | 15 | 13.79 | 34.36 | 0.47 | 0.807 | 33 |

| 53 | 1.75 | 27 | 20 | 11.26 | 31.80 | 0.63 | 0.800 | 39 |

| 54 | 1.75 | 27 | 25 | 9.91 | 26.10 | 0.78 | 0.774 | 56 |

| 55 | 2 | 17 | 15 | 34.75 | 63.43 | 0.37 | 0.540 | 130 |

| 56 | 2 | 17 | 20 | 47.69 | 20.59 | 0.49 | 0.452 | 138 |

| 57 | 2 | 17 | 25 | 23.87 | 48.34 | 0.61 | 0.643 | 109 |

| 58 | 2 | 19 | 15 | 15.9 | 30.84 | 0.39 | 0.801 | 38 |

| 59 | 2 | 19 | 20 | 11.48 | 23.46 | 0.53 | 0.841 | 16 |

| 60 | 2 | 19 | 25 | 9.11 | 18.10 | 0.66 | 0.829 | 20 |

| 61 | 2 | 21 | 15 | 18.84 | 48.56 | 0.42 | 0.728 | 80 |

| 62 | 2 | 21 | 20 | 14.87 | 42.99 | 0.56 | 0.760 | 64 |

| 63 | 2 | 21 | 25 | 13.64 | 39.96 | 0.71 | 0.743 | 73 |

| 64 | 2 | 23 | 15 | 21.99 | 58.09 | 0.46 | 0.671 | 100 |

| 65 | 2 | 23 | 20 | 10.36 | 28.76 | 0.61 | 0.819 | 26 |

| 66 | 2 | 23 | 25 | 8.62 | 20.58 | 0.76 | 0.796 | 41 |

| 67 | 2 | 25 | 15 | 13.92 | 40.36 | 0.49 | 0.788 | 46 |

| 68 | 2 | 25 | 20 | 11.76 | 42.14 | 0.65 | 0.770 | 57 |

| 69 | 2 | 25 | 25 | 6.02 | 19.74 | 0.82 | 0.789 | 45 |

| 70 | 2 | 27 | 15 | 14.48 | 44.59 | 0.53 | 0.766 | 60 |

| 71 | 2 | 27 | 20 | 13.09 | 23.22 | 0.70 | 0.778 | 52 |

| 72 | 2 | 27 | 25 | 18.84 | 48.56 | 0.88 | 0.637 | 110 |

| 73 | 2.25 | 17 | 15 | 18.31 | 46.54 | 0.39 | 0.742 | 74 |

| 74 | 2.25 | 17 | 20 | 28.41 | 34.13 | 0.52 | 0.626 | 113 |

| 75 | 2.25 | 17 | 25 | 13.50 | 40.18 | 0.65 | 0.759 | 65 |

| 76 | 2.25 | 19 | 15 | 19.09 | 30.94 | 0.42 | 0.759 | 67 |

| 77 | 2.25 | 19 | 20 | 13.88 | 25.43 | 0.57 | 0.802 | 36 |

| 78 | 2.25 | 19 | 25 | 12.50 | 22.4 | 0.71 | 0.781 | 49 |

| 79 | 2.25 | 21 | 15 | 9.93 | 18.99 | 0.46 | 0.882 | 1 |

| 80 | 2.25 | 21 | 20 | 8.27 | 14.87 | 0.62 | 0.853 | 12 |

| 81 | 2.25 | 21 | 25 | 6.35 | 11.63 | 0.77 | 0.811 | 30 |

| 82 | 2.25 | 23 | 15 | 11.91 | 22.9 | 0.50 | 0.844 | 14 |

| 83 | 2.25 | 23 | 20 | 9.20 | 19.1 | 0.67 | 0.824 | 24 |

| 84 | 2.25 | 23 | 25 | 11.97 | 37.90 | 0.84 | 0.724 | 81 |

| 85 | 2.25 | 25 | 15 | 9.16 | 25.04 | 0.55 | 0.853 | 11 |

| 86 | 2.25 | 25 | 20 | 23.87 | 21.00 | 0.73 | 0.656 | 104 |

| 87 | 2.25 | 25 | 25 | 6.86 | 16.43 | 0.91 | 0.759 | 66 |

| 88 | 2.25 | 27 | 15 | 13.20 | 21.86 | 0.59 | 0.810 | 31 |

| 89 | 2.25 | 27 | 20 | 10.56 | 17.86 | 0.79 | 0.776 | 53 |

| 90 | 2.25 | 27 | 25 | 18.66 | 15.20 | 0.99 | 0.653 | 106 |

| 91 | 2.5 | 17 | 15 | 23.02 | 49.62 | 0.42 | 0.680 | 99 |

| 92 | 2.5 | 17 | 20 | 23.00 | 43.27 | 0.56 | 0.670 | 101 |

| 93 | 2.5 | 17 | 25 | 18.13 | 38.4 | 0.70 | 0.705 | 92 |

| 94 | 2.5 | 19 | 15 | 9.83 | 20.08 | 0.46 | 0.881 | 2 |

| 95 | 2.5 | 19 | 20 | 7.45 | 16.06 | 0.61 | 0.860 | 4 |

| 96 | 2.5 | 19 | 25 | 5.99 | 14.21 | 0.76 | 0.814 | 28 |

| 97 | 2.5 | 21 | 15 | 12.21 | 40.86 | 0.50 | 0.802 | 37 |

| 98 | 2.5 | 21 | 20 | 10.8 | 38.20 | 0.67 | 0.780 | 50 |

| 99 | 2.5 | 21 | 25 | 8.70 | 33.85 | 0.84 | 0.752 | 71 |

| 100 | 2.5 | 23 | 15 | 10.07 | 21.57 | 0.55 | 0.852 | 13 |

| 101 | 2.5 | 23 | 20 | 7.53 | 19.84 | 0.74 | 0.809 | 32 |

| 102 | 2.5 | 23 | 25 | 5.33 | 21.37 | 0.92 | 0.757 | 69 |

| 103 | 2.5 | 25 | 15 | 12.04 | 34.11 | 0.61 | 0.794 | 43 |

| 104 | 2.5 | 25 | 20 | 12.52 | 36.63 | 0.81 | 0.731 | 78 |

| 105 | 2.5 | 25 | 25 | 11.20 | 35.68 | 1.02 | 0.682 | 98 |

| 106 | 2.5 | 27 | 15 | 6.90 | 23.04 | 0.68 | 0.829 | 22 |

| 107 | 2.5 | 27 | 20 | 6.25 | 20.61 | 0.89 | 0.764 | 62 |

| 108 | 2.5 | 27 | 25 | 5.64 | 33.73 | 1.11 | 0.689 | 95 |

| 109 | 2.75 | 17 | 15 | 11.81 | 36.96 | 0.45 | 0.824 | 25 |

| 110 | 2.75 | 17 | 20 | 13.02 | 36.10 | 0.60 | 0.784 | 48 |

| 111 | 2.75 | 17 | 25 | 10.56 | 33.62 | 0.75 | 0.768 | 58 |

| 112 | 2.75 | 19 | 15 | 12.48 | 26.04 | 0.50 | 0.832 | 19 |

| 113 | 2.75 | 19 | 20 | 13.66 | 27.22 | 0.67 | 0.776 | 54 |

| 114 | 2.75 | 19 | 25 | 12.05 | 23.87 | 0.83 | 0.746 | 72 |

| 115 | 2.75 | 21 | 15 | 7.90 | 27.40 | 0.56 | 0.854 | 10 |

| 116 | 2.75 | 21 | 20 | 13.70 | 21.25 | 0.74 | 0.763 | 63 |

| 117 | 2.75 | 21 | 25 | 6.01 | 18.30 | 0.93 | 0.754 | 70 |

| 118 | 2.75 | 23 | 15 | 6.80 | 19.17 | 0.62 | 0.856 | 9 |

| 119 | 2.75 | 23 | 20 | 7.34 | 33.97 | 0.82 | 0.765 | 61 |

| 120 | 2.75 | 23 | 25 | 6.85 | 34.40 | 1.03 | 0.705 | 90 |

| 121 | 2.75 | 25 | 15 | 6.35 | 24.35 | 0.68 | 0.829 | 21 |

| 122 | 2.75 | 25 | 20 | 7.86 | 19.08 | 0.73 | 0.812 | 29 |

| 123 | 2.75 | 25 | 25 | 4.51 | 19.58 | 1.14 | 0.698 | 93 |

| 124 | 2.75 | 27 | 15 | 8.63 | 15.63 | 0.75 | 0.804 | 34 |

| 125 | 2.75 | 27 | 20 | 6.39 | 12.50 | 1.00 | 0.736 | 77 |

| 126 | 2.75 | 27 | 25 | 5.18 | 11.03 | 1.27 | 0.668 | 102 |

| 127 | 3 | 17 | 15 | 10.01 | 16.38 | 0.48 | 0.880 | 3 |

| 128 | 3 | 17 | 20 | 8.73 | 13.22 | 0.64 | 0.844 | 15 |

| 129 | 3 | 17 | 25 | 6.51 | 11.45 | 0.81 | 0.797 | 40 |

| 130 | 3 | 19 | 15 | 9.85 | 21.05 | 0.54 | 0.858 | 5 |

| 131 | 3 | 19 | 20 | 7.84 | 17.31 | 0.72 | 0.817 | 27 |

| 132 | 3 | 19 | 25 | 4.40 | 9.05 | 0.90 | 0.775 | 55 |

| 133 | 3 | 21 | 15 | 8.8 | 14.06 | 0.60 | 0.857 | 8 |

| 134 | 3 | 21 | 20 | 8.09 | 10.47 | 0.81 | 0.790 | 44 |

| 135 | 3 | 21 | 25 | 5.55 | 14.75 | 1.00 | 0.737 | 76 |

| 136 | 3 | 23 | 15 | 7.84 | 5.47 | 0.68 | 0.840 | 17 |

| 137 | 3 | 23 | 20 | 6.36 | 12.31 | 0.90 | 0.767 | 59 |

| 138 | 3 | 23 | 25 | 5.07 | 9.88 | 1.13 | 0.705 | 91 |

| 139 | 3 | 25 | 15 | 7.91 | 24.19 | 0.76 | 0.795 | 42 |

| 140 | 3 | 25 | 20 | 6.03 | 11.15 | 1.00 | 0.738 | 75 |

| 141 | 3 | 25 | 25 | 6.15 | 19.43 | 1.26 | 0.661 | 103 |

| 142 | 3 | 27 | 15 | 5.14 | 37.95 | 0.85 | 0.758 | 68 |

| 143 | 3 | 27 | 20 | 4.17 | 18.78 | 1.12 | 0.705 | 89 |

| 144 | 3 | 27 | 25 | 7.13 | 17.71 | 1.40 | 0.626 | 112 |

References

- Eras-Almeida, A.A.; Egido-Aguilera, M.A. Hybrid renewable mini-grids on non-interconnected small islands: Review of case studies. Renew. Sustain. Energy Rev. 2019, 116, 109417. [Google Scholar]

- Tummala, A.; Velamati, R.K.; Sinha, D.K.; Indraja, V.; Krishna, V.H. A review on small scale wind turbines. Renew. Sustain. Energy Rev. 2016, 56, 1351–1371. [Google Scholar]

- Chagas, C.C.M.; Pereira, M.G.; Rosa, L.P.; Da Silva, N.F.; Freitas, M.A.V.; Hunt, J.D. From Megawatts to Kilowatts: A Review of Small Wind Turbine Applications, Lessons from the US to Brazil. Sustainability 2020, 12, 2760. [Google Scholar] [CrossRef]

- Weir, T.; Kumar, M. Renewable energy can enhance resilience of small islands. Nat. Hazards 2020, 104, 2719–2725. [Google Scholar] [CrossRef]

- Ioannidis, A.; Chalvatzis, K.J.; Li, X.; Notton, G.; Stephanides, P. The case for islands’ energy vulnerability: Electricity supply diversity in 44 global islands. Renew. Energy 2019, 143, 440–452. [Google Scholar] [CrossRef]

- Orlando, N.A.; Liserre, M.; Mastromauro, R.A.; Dell’Aquila, A. A Survey of Control Issues in PMSG-Based Small Wind-Turbine Systems. IEEE Trans. Ind. Inform. 2013, 9, 1211–1221. [Google Scholar] [CrossRef]

- Battisti, L.; Ricci, M. MPPT with Current Control for a PMSG Small Wind Turbine in a Grid-Connected DC Microgrid. In Wind Energy Exploitation in Urban Environment; Battisti, L., Ricci, M., Eds.; Springer International Publishing AG: Cham, Switzerland, 2018; pp. 205–219. [Google Scholar]

- Calabrese, D.; Tricarico, G.; Brescia, E.; Cascella, G.L.; Monopoli, V.G.; Cupertino, F. Variable Structure Control of a Small Ducted Wind Turbine in the Whole Wind Speed Range Using a Luenberger Observer. Energies 2020, 13, 4647. [Google Scholar] [CrossRef]

- Çelik, E.; Kurt, E.; Öztürk, N. Wind turbine speed control of a contactless piezoelectric wind energy harvester. Int. J. Electron. 2020, 107, 226–238. [Google Scholar] [CrossRef]

- Mohammadi, E.; Fadaeinedjad, R.; Naji, H.R. Flicker emission, voltage fluctuations, and mechanical loads for small-scale stall- and yaw-controlled wind turbines. Energy Convers. Manag. 2018, 165, 567–577. [Google Scholar] [CrossRef]

- Meng, H.; Ma, Z.; Dou, B.; Zeng, P.; Lei, L. Investigation on the performance of a novel forward-folding rotor used in a downwind horizontal-axis turbine. Energy 2020, 190, 116384. [Google Scholar] [CrossRef]

- Akhter, M.Z.; Ali, A.R.; Jawahar, H.K.; Omar, F.K.; Elnajjar, E. Performance enhancement of small-scale wind turbine featuring morphing blades. Energy 2023, 278, 127772. [Google Scholar] [CrossRef]

- Cho, T.; Won, K.Y.; Jang, I.; Park, C.-w.; Kim, J. Experimental Study on the Aerodynamic Characteristics for the Side Furling Control System. J. Wind Energy 2017, 8, 39–44. [Google Scholar]

- Dong, Y.; Guo, J.; Zhang, X. Development and Performance Analysis of a Small Island Wind Turbine Generator System with High Reliability. J. Energy Eng. 2013, 139, 223–229. [Google Scholar] [CrossRef]

- Chirca, M.; Dranca, M.; Oprea, C.A.; Teodosescu, P.; Pacuraru, A.M.; Neamtu, C.; Breban, S. Electronically Controlled Actuators for a Micro Wind Turbine Furling Mechanism. Energies 2020, 13, 4207. [Google Scholar] [CrossRef]

- Chen, Y.; Shiah, Y. Experiments on the Performance of Small Horizontal Axis Wind Turbine with Passive Pitch Control by Disk Pulley. Energies 2016, 9, 353. [Google Scholar] [CrossRef]

- Staino, A.; Basu, B. Emerging trends in vibration control of wind turbines: A focus on a dual control strategy. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2015, 373, 20140069. [Google Scholar] [CrossRef]

- Sung, C.; Han, M. Design and performance evaluation of hinge type pitch control system in small-size wind turbine. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 335–341. [Google Scholar] [CrossRef]

- Porto, H.A.; Fortulan, C.A.; Porto, A.J.V. Power performance of starting-improved and multi-bladed horizontal-axis small wind turbines. Sustain. Energy Technol. 2022, 53, 102341. [Google Scholar]

- Evans, S.P.; Bradney, D.R.; Clausen, P.D. Development and experimental verification of a 5 kW small wind turbine aeroelastic model. J. Wind Eng. Ind. Aerodyn. 2018, 181, 104–111. [Google Scholar] [CrossRef]

- Zhang, R.Y.; Chen, C.H.; Tang, Y.G.; Huang, X.Y. Research Development and Key Technical on Floating Foundation for Offshore Wind Turbines. Adv. Mater. Res. 2012, 446–449, 1014–1019. [Google Scholar] [CrossRef]

- Sakagami, Y.; Radunz, W.C.; Santos, P.; Haas, R.; Passos, J.C.; Taves, F.F. Power curve performance of coastal turbines subject to low turbulence intensity offshore winds. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 24. [Google Scholar] [CrossRef]

- Evans, S.; Dana, S.; Clausen, P.; Wood, D. A simple method for modelling fatigue spectra of small wind turbine blades. Wind Energy 2021, 24, 549–557. [Google Scholar] [CrossRef]

- Taghinezhad, J.; Abdoli, S.; Silva, V.; Sheidaei, S.; Alimardani, R.; Mahmoodi, E. Computational fluid dynamic and response surface methodology coupling: A new method for optimization of the duct to be used in ducted wind turbines. Heliyon 2023, 9, e17057. [Google Scholar] [CrossRef]

- Wood, D. Small Wind Turbines; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- IEC 61400-2; Wind turbines. Part 2: Design Requirements for Small Wind Turbines. International Electro-Technical Commission: Geneva, Switzerland, 2006.

- BS ISO 6336-3; Calculation of Load Capacity of Spur and Helical Gears—Part 3 Calculation of Tooth Bending Strength. International Organization for Standardization: Geneva, Switzerland, 2006.

- BS ISO 6336-5; Calculation of Load Capacity of Spur and Helical Gears—Part 5 Strength and Quality of Materials. International Organization for Standardization: Geneva, Switzerland, 2006.

- Liu, H.; Zhang, B.; Zhu, C.; Wei, P. State of art of gear contact fatigue theories. Jixie Gongcheng Xuebao/J. Mech. Eng. 2022, 58, 95–120. [Google Scholar]

- Liu, H.; Liu, H.; Zhu, C.; Ge, Y. Influence of load spectrum on contact fatigue damage of a case carburized wind turbine gear. Eng. Fail. Anal. 2021, 119, 105005. [Google Scholar] [CrossRef]

- ISO 76-2006; Rolling Bearings-Static Load Ratings. International Organization for Standardization: Geneva Switzerland, 2006.

- Guideline for the Certification of Wind Turbines; Edition 2010; Germanischer Lloyd: Hamburg, Germany, 2010.

- Wang, Y.; Qin, D.; Wang, R.; Zhao, H. Dynamic Topology Optimization of Long-Span Continuum Structures. Shock. Vib. 2021, 2021, 4421298. [Google Scholar] [CrossRef]

- Park, H.J.; Oh, M.K.; Park, S.; Yoo, J. Structural design methodology for lightweight supporting structure of a multi-rotor wind turbine. Wind Struct. 2022, 34, 291–301. [Google Scholar]

- Lee, S. Reliability based design optimization using response surface augmented moment method. J. Mech. Sci. Technol. 2019, 33, 1751–1759. [Google Scholar] [CrossRef]

- Zhang, B.S.; Song, B.W.; Mao, Z.Y.; Tian, W.L.; Li, B.Y.; Li, B. A Novel Parametric Modeling Method and Optimal Design for Savonius Wind Turbines. Energies 2017, 10, 301. [Google Scholar] [CrossRef]

- BS ISO 54-1996; Cylindrical Gears for General Engineering and for Heavy Engineering. Modules. International Organization for Standardization: Geneva, Switzerland, 1996.

- Pereira, J.; Guedes, F.C.; Francisco, M.B.; Chiarello, A.G.; Gomes, G.F. Multi-objective design optimization of a high performance disk brake using lichtenberg algorithm. Mech. Based Des. Struct. Mach. 2023. [Google Scholar] [CrossRef]

- Khan, M.M.; Nisar, M.; Hajam, M.I. High-Stress Abrasive Wear Analysis of in Situ TiC-Reinforced Zinc-Aluminum Composites Using Integrated Taguchi-TOPSIS Method. Adv. Eng. Mater. 2023, 25, 2201862. [Google Scholar] [CrossRef]

- Huang, X.; Ji, W.T.; Ye, X.R.; Feng, Z.J. Configuration Planning of Expressway Self-Consistent Energy System Based on Multi-Objective Chance-Constrained Programming. Sustainability 2023, 15, 5605. [Google Scholar] [CrossRef]

| Material | Density/kg·m−3 | Elastic Modulus/GPa | Poisson’s Ratio |

|---|---|---|---|

| Wood composite | 900 | 15 | 0.3 |

| Carbon steel SAE 1045 | 7850 | 210 | 0.269 |

| Pitch Angle | |||||

|---|---|---|---|---|---|

| 6° | 9° | 12° | 15° | 25° | |

| Rotational speed/(r/min) | 375 | 332 | 313 | 301 | 238 |

| Name | σmax | σ0/1.1 | σ0/1.25 | Yield Strength/σ0 |

|---|---|---|---|---|

| hub | 17.38 MPa | 304.5 MPa | 268 MPa | 335 MPa |

| gear | 27.42 MPa | |||

| rack | 21.20 MPa | |||

| blade connector | 25.04 MPa | |||

| rack synchronizer | 5.36 MPa |

| Parameter Name | Value | Parameter Name | Value |

|---|---|---|---|

| Modulus (M) | 2.5 | Number of teeth (Z) | 17 |

| Gear width (H) | 25 mm | Pressure angle | 20° |

| Tip height coefficient (ha*) | 1 | Top clearance coefficient (C*) | 0.25 |

| Pitch circle diameter (d) | 42.5 mm | Base circle diameter (db) | 40 mm |

| Tip circle diameter (da) | 47.5 mm | Root circle diameter (df) | 39.5 mm |

| Parameter | Number of Rollers (Z) | Outer Diameter (D) | Inner Diameter (d) | Width (B) | Roller Diameter (R) |

|---|---|---|---|---|---|

| Value | 48 | 120 mm | 55 mm | 15 mm | 5 mm |

| Parameter | d1 | d2 | Mass | Maximum Stress |

|---|---|---|---|---|

| Before optimization | 30 mm | 20 mm | 1.10 kg | 5.37 MPa |

| After optimization | 25 mm | 21.5 mm | 0.87 kg | 5.29 MPa |

| Parameter | L1 | L2 | L3 | R1 | Mass | Maximum Stress |

|---|---|---|---|---|---|---|

| Before optimization | 40 mm | 50 mm | 85 mm | 3 mm | 3.70 kg | 25.04 MPa |

| After optimization | 36 mm | 55 mm | 77 mm | 2.6 mm | 2.15 kg | 12.61 MPa |

| Parameters | Initial Value | Range |

|---|---|---|

| Modulus (M) | 2.5 | [1.25,1.5,1.75,2,2.25,2.5,2.75,3] |

| Number of teeth (Z) | 17 | [17,19,21,23,25,27] |

| Gear width (H)/mm | 25 mm | [15,20,25] |

| Parameter Name | Mass | Contact Stress | Bending Stress |

|---|---|---|---|

| Information entropy | 0.954 | 0.924 | 0.966 |

| Weight coefficient | 0.294 | 0.488 | 0.218 |

| Mass Optimization | Gear Rack Component × 3 | Blade Handle × 3 | Rack Synchronizer | Pitch Bearing × 3 |

|---|---|---|---|---|

| Before | 2.10 kg | 11.10 kg | 1.10 kg | 7.80 kg |

| After | 1.38 kg | 4.59 kg | 0.87 kg | 7.80 kg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.; Bao, D.; Zhao, M.; Shi, Z.; Gao, F.; Han, F. The Design, Analysis, and Optimization of a New Pitch Mechanism for Small Wind Turbines. Energies 2023, 16, 6708. https://doi.org/10.3390/en16186708

Wang P, Bao D, Zhao M, Shi Z, Gao F, Han F. The Design, Analysis, and Optimization of a New Pitch Mechanism for Small Wind Turbines. Energies. 2023; 16(18):6708. https://doi.org/10.3390/en16186708

Chicago/Turabian StyleWang, Peng, Daorina Bao, Mingzhi Zhao, Zhongyu Shi, Fan Gao, and Feng Han. 2023. "The Design, Analysis, and Optimization of a New Pitch Mechanism for Small Wind Turbines" Energies 16, no. 18: 6708. https://doi.org/10.3390/en16186708