Advances in Liquid Atomization via Flash Boiling—A Global Overview

Abstract

:1. Introduction

2. Flash-Boiling Atomization—Mechanisms, Theories, and Current Challenges

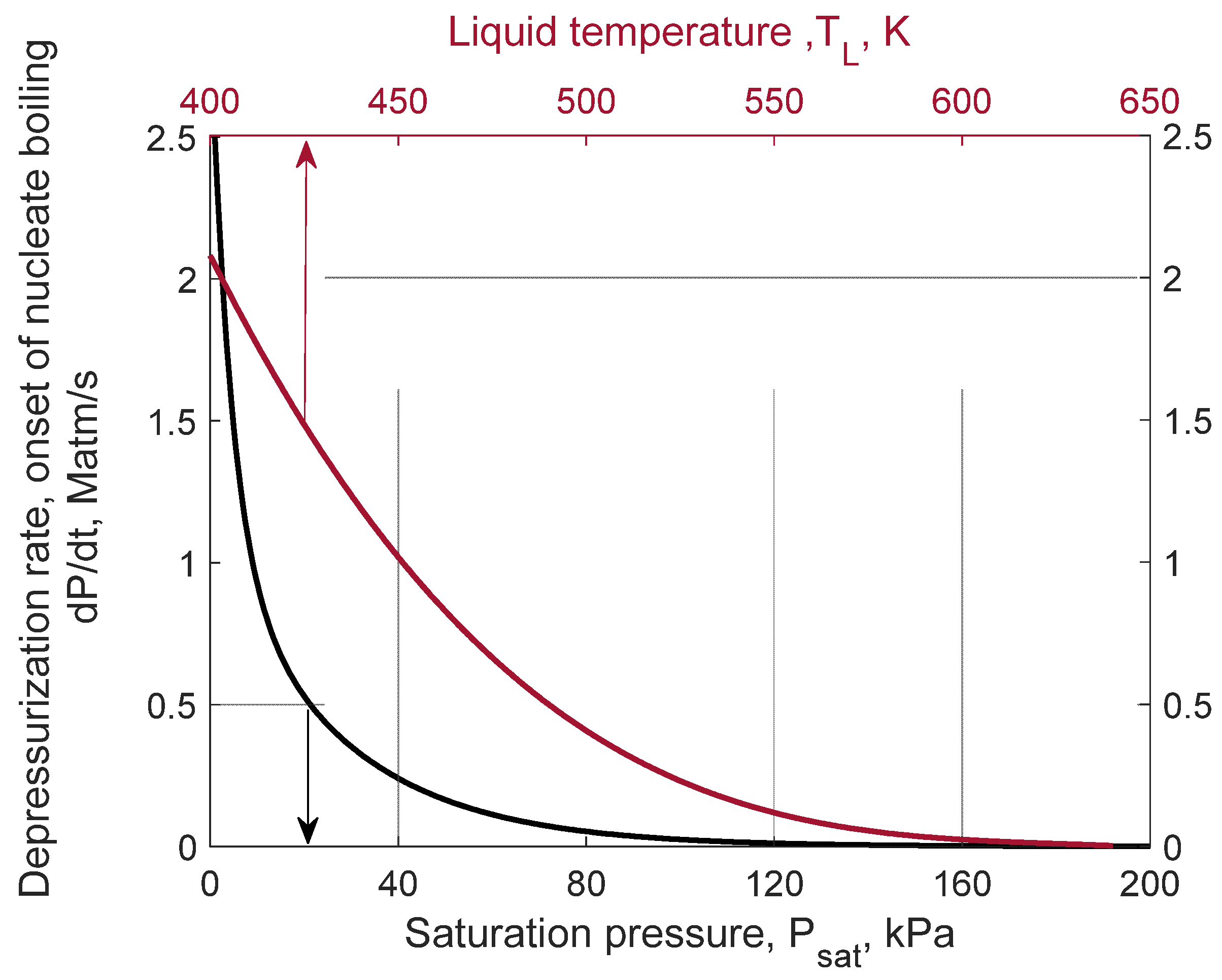

2.1. Flash Boiling

- Depressurization rate;

- Wettability;

- Nano-bubbles;

- Trans-critical conditions;

- Negative nucleation pressure.

2.2. Atomization Mechanisms Following Flash-Boiling

2.2.1. Bubble Growth

- Bubble growth in various depressurization rates;

- Varying pressure fields in micro-channels;

- Validated bubble growth rates for

- ○

- Micron-sized droplets in a highly convective environment; inertial regime;

- ○

- Various liquids.

2.2.2. Breakup

- Retracing liquid. This occurs at low Webber numbers. When the surface tension forces are dominant, the liquid momentum is not sufficient to complete the breakup, and the ligaments pull the liquid back into larger droplets.

- Ligament stretching. When thick ligaments are subjected to larger momentum forces, the ligaments are stretched until their breakup, resulting in one large droplet per interstitial volume. This is equivalent to the assumption suggested originally by Sher and Elata [42].

- Thin lamella. When the momentum forces are large enough to overcome the viscous and surface tension forces, they lead to highly deformed bubbles. Along with the continuous evaporation of the liquid lamella, the thin liquid lamellas continue to be stretched with the growing bubbles, until they are broken into small bubbles.

- Breakup patterns for various fluids in various conditions.

- Secondary breakup due to bubble formation within the larger droplets that continue to be superheated.

- Spray characteristics (droplet distributions, spreading angle, penetration length, etc.) as a function of the primary and secondary breakup processes.

2.3. Penetration Length and Spray Collapse

2.4. Fluids

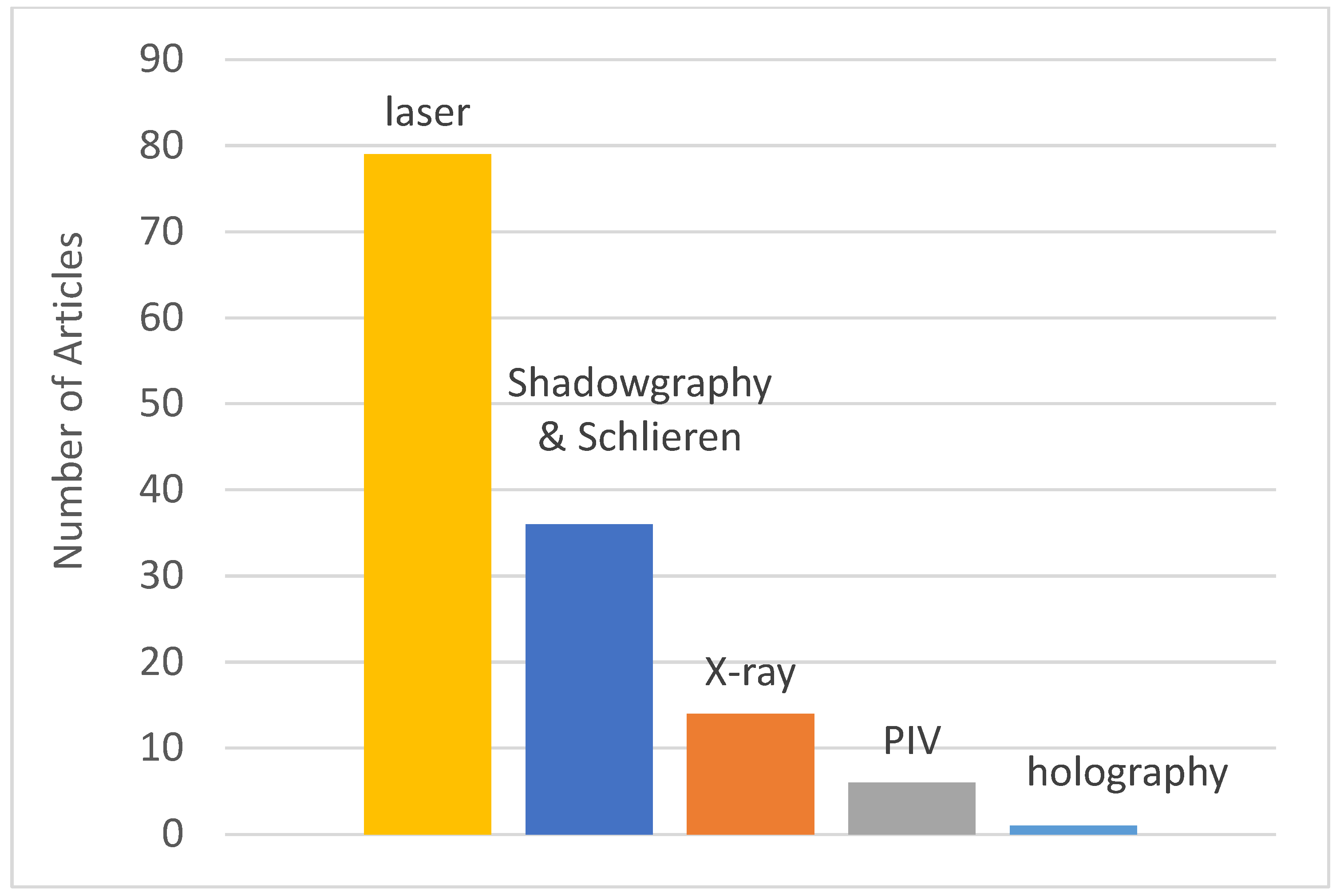

2.5. Diagnostics Aspects

3. Method of Analysis

4. Overview of the Development of the Research Methods

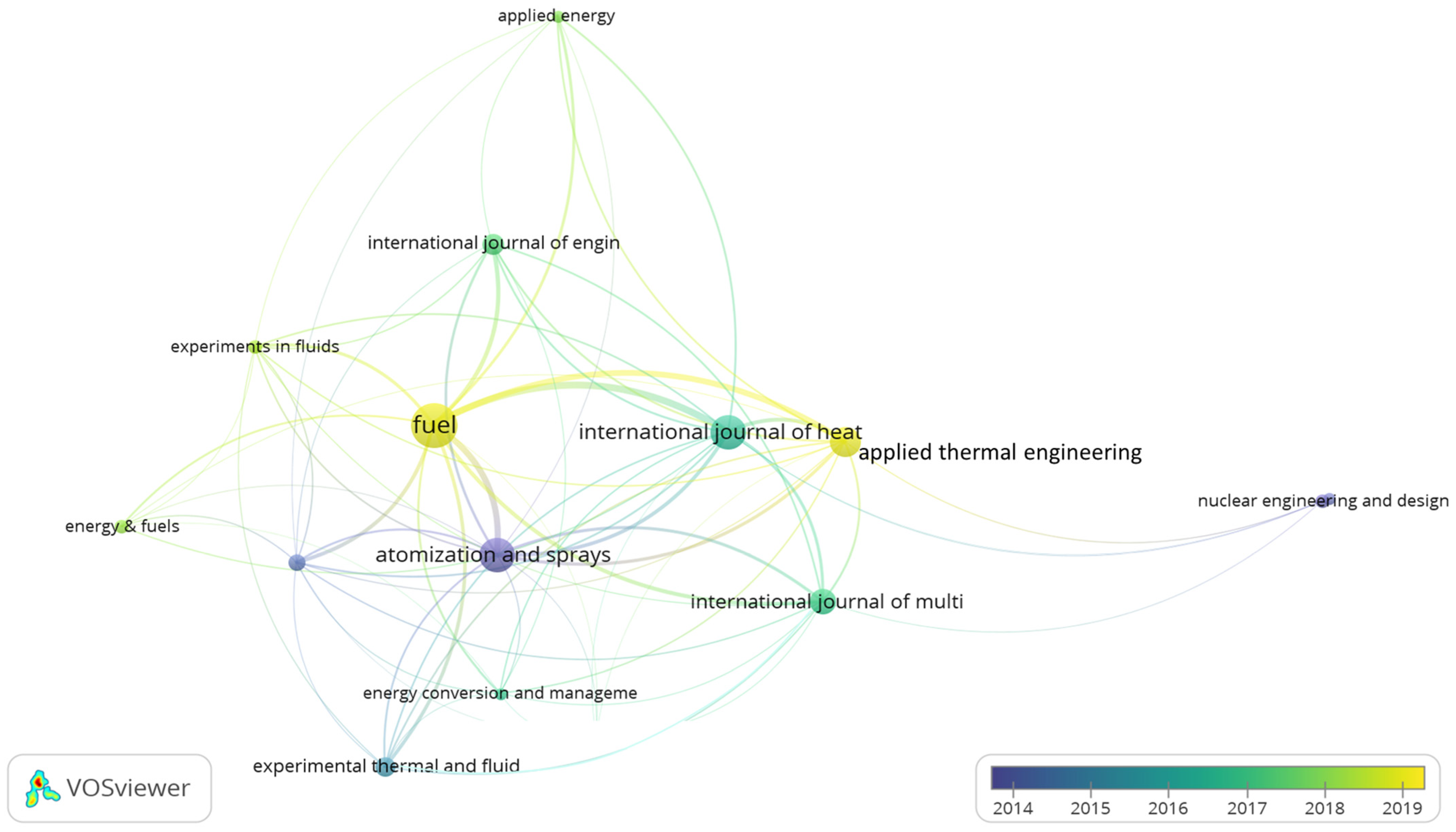

4.1. Science Mapping—Evolution of Flash-Boiling Research

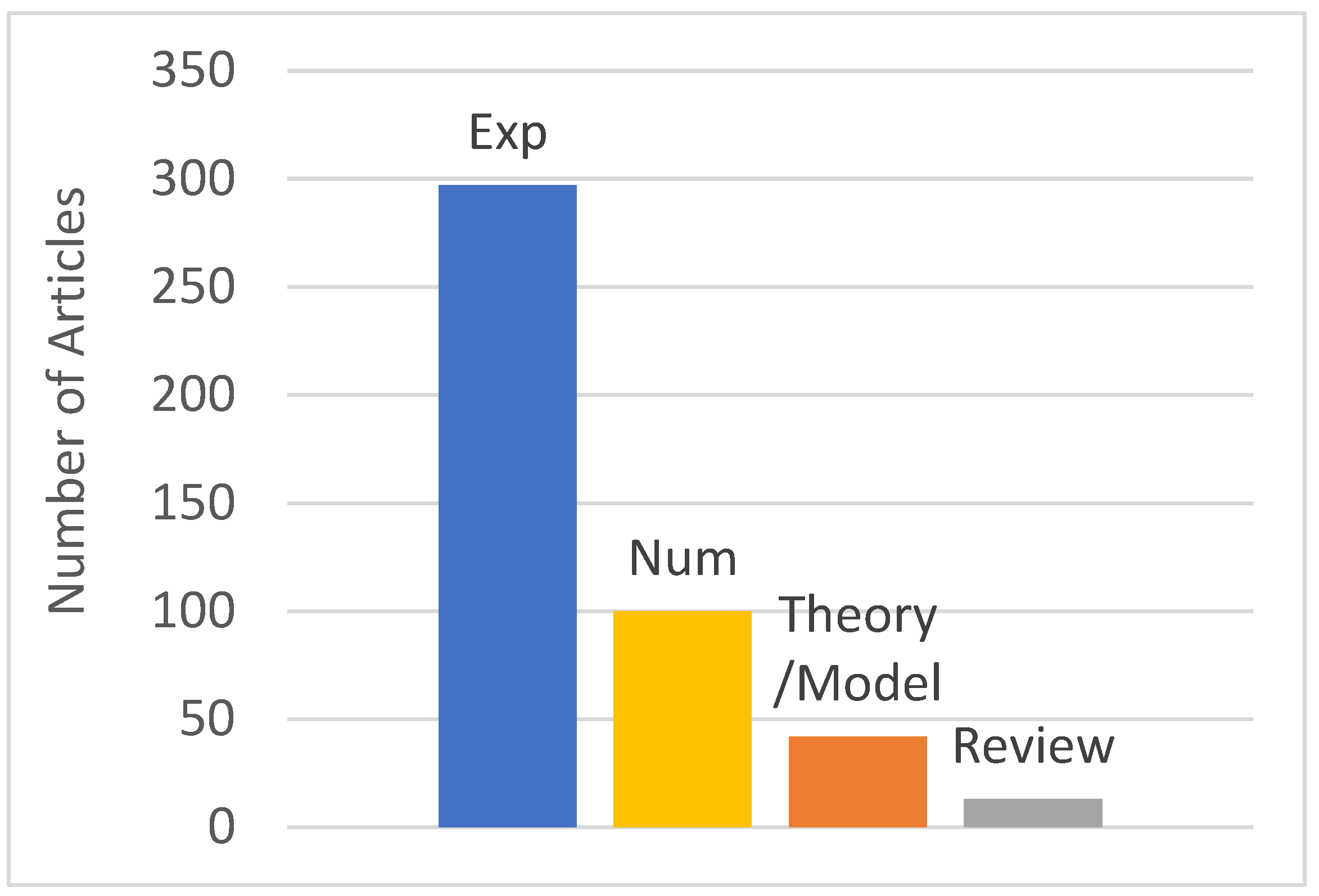

4.2. Categories and Applications

4.3. Emerging Technologies

5. Conclusions

- The engagement of the scientific community has grown dramatically over the last decades—more than 20 publications per year since 2017. In addition, the involvement of research centers worldwide in this field appears to have undergone a shift. Illustration of the co-authorship connections between countries in the realm of flash-boiling atomization shows that Japan and Israel pioneered the research, followed by a growing interest from the United States and Germany. Notably, over the last 5 years, there has been a substantial increase in publications originating from England and China.

- The majority of the articles revolve around experimental studies. These empirical investigations play a vital role in establishing the fundamental groundwork for subsequent theoretical and numerical modeling.

- The research contributions have been disseminated across a range of scientific journals, with Fuel being the most prominent among them, followed by Atomization and Sprays, and Int. J. Heat and Mass Transfer.

- The emerging interest in various fuel types is expressed by the number of papers that study ethanol and methanol. In addition, there is a notable interest in cryogenic fuels, primarily associated with space applications.

- Tremendous progress has been made over the last couple of decades in diagnostic tools, mainly in laser, including LDV, and Mie-scattering, followed by the well-established shadowgraph and Schlieren methods and X-ray technologies.

- Nucleation:

- Characterizing the nucleation pressure as a function of the depressurization rate.

- Identifying the effects of wettability, surface, and the reciprocal relations between surface roughness and the behavior of nano-bubbles, on nucleation flux.

- Improving the characterization of the nucleation process under special conditions, such as trans-critical conditions, and negative nucleation pressure.

- Bubble growth

- Identifying the effect of depressurization rates on bubble growth rates in both unconfined and confined liquid media (droplets, micro-channels, etc.).

- Validating bubble growth rates in the inertial regime that could be relevant to micron-sized droplets in a highly convective environment.

- Breakup

- Testing a variety of fluids (non/retrograde, cryogenic, etc.) exhibiting diverse breakup patterns under various conditions.

- Investigating the secondary breakup due to bubble formation within larger droplets, which remain superheated.

- Defining spray characteristics, such as droplet distributions, spreading angle, and penetration length, depending on both primary and secondary breakup mechanisms.

- Designing optimal multi-hole injectors considering the spray collapse.

- Testing flash-boiling atomization process in alternative fuels.

- Developing suitable fast and accurate diagnostics tools, including the use of X-rays. X-rays hold great promise for enabling real-time measurements in real operating conditions since it does not require visual transparency. It is expected that X-ray methods will continue to gain more significance in the near future.

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bar-Kohany, T.; Levy, M. State of the art review of flash-boiling atomization. At. Sprays 2016, 26, 1255–1305. [Google Scholar] [CrossRef]

- Sovani, S.D.; Sojka, P.E.; Lefebvre, A.H. Effervescent atomization. Prog. Energy Combust. Sci. 2001, 27, 483–521. [Google Scholar] [CrossRef]

- Zeigerson-Katz, M.; Sher, E. Spray formation by flashing of a binary mixture: A parametric study. At. Sprays 1998, 8, 255–266. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; McDonell, V.G. Atomization and Sprays; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2017. [Google Scholar]

- Ashgriz, N. Handbook of Atomization and Sprays: Theory and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Sher, E.; Zeigerson-Katz, M. Spray formation by flashing of a binary mixture: An energy balance approach. At. Sprays 1996, 6, 447–459. [Google Scholar] [CrossRef]

- Sazhin, S. Droplets and Sprays; Springer: London, UK, 2014. [Google Scholar]

- Sirignano, W.A. Fluid Dynamics and Transport of Droplets and Sprays; Cambridge University Press: Cambridge, UK, 2010. [Google Scholar]

- Solomon, A.S.P.; Chen, L.D.; Faeth, G.M. Investigation of Spray Characteristics for Flashing Injection of Fuels Containing Dissolved Air and Superheated Fuels; No. NAS 1.26; NASA: Washington, DC, USA, 1999; p. 3563. [Google Scholar]

- Skripov, V.P. Metastable Liquids; Wiley: New York, NY, USA, 1974. [Google Scholar]

- Carey, V.P. Liquid-Vapor Phase-Change Phenomena: An Introduction to the Thermophysics of Vaporization and Condensation Processes in Heat Transfer Equipment; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2018. [Google Scholar]

- Bar-Kohany, T. Minimal heating rate for isobaric nucleation at the spinodal in liquids. Int. J. Heat Mass Transf. 2021, 165, 120636. [Google Scholar] [CrossRef]

- Bar-Kohany, T.; Amsalem, Y. Nucleation temperature under various heating rates. Int. J. Heat Mass Transf. 2018, 126, 411–415. [Google Scholar] [CrossRef]

- Ching, E.J.; Avedisian, C.T.; Cavicchi, R.C.; Chung, D.H.; Rah, K.J.; Carrier, M.J. Rapid evaporation at the superheat limit of methanol, ethanol, butanol and n-heptane on platinum films supported by low-stress sin membranes. Int. J. Heat Mass Transf. 2016, 101, 707–718. [Google Scholar] [CrossRef]

- Glod, S.; Poulikakos, D.; Zhao, Z.; Yadigaroglu, G. An investigation of microscale explosive vaporization of water on an ultrathin pt wire. Int. J. Heat Mass Transf. 2002, 45, 367–379. [Google Scholar] [CrossRef]

- Shusser, M.; Weihs, D. Explosive boiling of a liquid droplet. Int. J. Multiphase. Flow. 1999, 25, 1561–1573. [Google Scholar] [CrossRef]

- Skripov, P.V.; Bar-Kohany, T.; Antonov, D.V.; Strizhak, P.A.; Sazhin, S.S. Approximations for the nucleation temperature of water. Int. J. Heat Mass Transf. 2023, 207, 123970. [Google Scholar] [CrossRef]

- Su, G.-Y.; Bucci, M.; McKrell, T.; Buongiorno, J. Transient boiling of water under exponentially escalating heat inputs. part i: Pool boiling. Int. J. Heat Mass Transf. 2016, 96, 667–684. [Google Scholar] [CrossRef]

- Avni, O.; Bar-Kohany, T.; Sher, E. Flash-boiling atomization triggered and driven by intensive radiation. Therm. Sci. Eng. Prog. 2022, 32, 101334. [Google Scholar] [CrossRef]

- Alamgir, M.; Lienhard, J.H. Correlation of Pressure Undershoot of Pressure During Hot Water Depressurization. J. Heat Trans. 1981, 103, 52–56. [Google Scholar] [CrossRef]

- Barták, J. Study of the Rapid Depressurization of Hot Water and the Dynamics of Vapour Bubble Generation in Superheated Liquid. Int. J. Multiph. Flow. 1990, 16, 789–798. [Google Scholar] [CrossRef]

- Elias, E.; Chambré, P.L. Flashing inception in water during rapid decompression. J. Heat Transf. 1993, 115, 231–238. [Google Scholar] [CrossRef]

- Moshkovich, Y.; Levy, Y.; Sher, E. Theoretical criteria for homogeneous flash-boiling atomization. Chem. Eng. Sci. 2019, 206, 471–475. [Google Scholar] [CrossRef]

- Sher, E.; Bar-Kohany, T.; Rashkovan, A. Flash-boiling atomization. Prog. Energy Combust Sci. 2008, 34, 417–439. [Google Scholar] [CrossRef]

- Avedisian, C.T.; Skyllingstad, K.; Cavicchi, R.C.; Lippe, C.; Carrier, M.J. Initiation of flash boiling of multicomponent miscible mixtures with application to transportation fuels and their surrogates. Energy Fuels 2018, 32, 9971–9981. [Google Scholar] [CrossRef]

- Prosperetti, A. Vapor bubbles. Annu. Rev. Fluid. Mech. 2017, 49, 221–248. [Google Scholar] [CrossRef]

- Mikic, B.B.; Rohsenow, W.M.; Griffith, P. On Bubble Growth Rates. Int. J. Heat Mass Trans. 1970, 13, 657–666. [Google Scholar] [CrossRef]

- Plesset, M.; Zwick, S.A. The growth of vapor bubbles in superheated liquids. J. Appl. Phys. 1954, 25, 493–500. [Google Scholar] [CrossRef]

- Mahmoud, M.M.; Karayiannis, T.G. Bubble growth on a smooth metallic surface at atmospheric and sub-atmospheric pressure. Int. J. Heat Mass Transf. 2023, 209, 124103. [Google Scholar] [CrossRef]

- Zanje, S.; Iyer, K.; Murallidharan, J.S.; Punekar, H.; Gupta, V.K. Development of generalized bubble growth model for cavitation and flash boiling. Phys. Fluids 2021, 33, 077116. [Google Scholar] [CrossRef]

- Jones, O.; Zuber, N. Bubble growth in variable pressure fields. J. Heat Transf. 1978, 100, 453–459. [Google Scholar] [CrossRef]

- Avedisian, C.T. Bubble growth in superheated liquid droplets. Encycl. Fluid Mech. 1985, 3, 130–190. [Google Scholar]

- Bar-Kohany, T.; Antonov, D.V.; Strizhak, P.A.; Sazhin, S.S. Nucleation and bubble growth during puffing and micro-explosions in composite droplets. Fuel 2023, 340, 126991. [Google Scholar] [CrossRef]

- Lightfoot, M. Fundamental classification of atomization processes. At. Sprays 2009, 19, 1065–1104. [Google Scholar] [CrossRef]

- Schulte, K.; Tropea, C.; Weigand, B. Droplet Dynamics under Extreme Ambient Conditions; Springer Nature: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Konstantinov, D.; Marsh, R.; Bowen, P.J.; Crayford, A. Effervescent Atomization for Industrial Energy–Technology Review. At. Sprays 2010, 20, 525–552. [Google Scholar] [CrossRef]

- Witlox, H.; Harper, M.; Bowen, P.; Cleary, V. Flashing liquid jets and two-phase droplet dispersion: II. Comparison and validation of droplet size and rainout formulations. J. Hazard Mater. 2007, 142, 797–809. [Google Scholar] [CrossRef]

- Kitamura, Y.; Morimitsu, H.; Takahashi, T. Critical superheat for flashing of superheated liquid jets. Ind. Eng. Chem. Fund. 1986, 25, 206–211. [Google Scholar] [CrossRef]

- Hutcherson, M.N.; Henry, R.; Wollersheim, D. Two-phase vessel blowdown of an initially saturated liquid—Part 2: Analytical. J. Heat Transf. 1983, 105, 694–699. [Google Scholar] [CrossRef]

- Lamanna, G.; Kamoun, H.; Weigand, B.; Steelant, J. Towards a unified treatment of fully flashing sprays. Int. J. Multiph. Flow. 2014, 58, 168–184. [Google Scholar] [CrossRef]

- Loureiro, D.D.; Reutzsch, J.; Kronenburg, A.; Weigand, B.; Vogiatzaki, K. Primary breakup regimes for cryogenic flash atomization. Int. J. Multiph. Flow. 2020, 132, 103405. [Google Scholar] [CrossRef]

- Sher, E.; Elata, C. Spray formation from pressure cans by flashing. Ind. Eng. Chem. Process Des. Dev. 1977, 16, 237–242. [Google Scholar] [CrossRef]

- Wu, S.; Yang, S.; Wooldridge, M.; Xu, M. Experimental study of the spray collapse process of multi-hole gasoline fuel injection at flash boiling conditions. Fuel 2019, 242, 109–123. [Google Scholar] [CrossRef]

- Kapusta, Ł.J. Understanding the collapse of flash-boiling sprays formed by multi-hole injectors operating at low injection pressures. Energy 2022, 247, 123388. [Google Scholar] [CrossRef]

- Li, Y.; Guo, H.; Fei, S.; Ma, X.; Zhang, Z.; Chen, L.; Feng, L.; Wang, Z. An exploration on collapse mechanism of multi-jet flash-boiling sprays. Appl. Therm. Eng. 2018, 134, 20–28. [Google Scholar] [CrossRef]

- Fan, Y.; Sun, Z.; Gu, Q.; Xu, Q.; Li, X.; Xu, M. Combustion improved by using flash boiling sprays in an ethanol-gasoline optical engine under cold operating conditions. Energy Fuels 2021, 35, 10134–101345. [Google Scholar] [CrossRef]

- Bae, C.; Kim, J. Alternative fuels for internal combustion engines. Proc. Combust. Inst. 2017, 36, 3389–3413. [Google Scholar] [CrossRef]

- Lamanna, G.; Kamoun, H.; Weigand, B.; Manfletti, C.; Rees, A.; Sender, J.; Oschwald, M.; Steelant, J. Flashing behavior of rocket engine propellants. At. Sprays 2015, 25, 837–856. [Google Scholar] [CrossRef]

- Sun, Z.; Yang, S.; Nour, M.; Li, X.; Hung, D.; Xu, M. Significant impact of flash boiling spray on in-cylinder soot formation and oxidation process. Energy Fuels 2020, 34, 10030–10038. [Google Scholar] [CrossRef]

- Qiu, S.; Wang, S.; Zhang, Y.; Li, X.; Hung, D.; Xu, M. Dense-field spray droplet size quantification of flashing boiling atomization using structured laser illumination planar imaging technique. Fuel 2023, 335, 127085. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, Z.; Chen, B.; Yang, T.; Zhang, L.; Romeos, A.; Giannadakis, A.; Panidis, T. Flow visualization of the transient effect of the internal two-phase flow on the external iso-pentane flashing spray under different injection pressure. Fuel 2023, 333, 126151. [Google Scholar] [CrossRef]

- Wang, S.; Qiu, S.; Zhang, Y.; Cui, M.; Li, X.; Xu, M. In-nozzle multi-phase flow patterns in flash-boiling atomization and their impacts on external sprays. Exp. Fluids 2023, 64, 48. [Google Scholar] [CrossRef]

- Wu, S.; Xu, M.; Hung, D.L.; Li, T.; Pan, H. Near-nozzle spray and spray collapse characteristics of spark-ignition direct-injection fuel injectors under sub-cooled and superheated conditions. Fuel 2016, 183, 322–334. [Google Scholar] [CrossRef]

- Yang, S.; Ma, Z.; Li, X.; Hung, D.L.; Xu, M. A review on the experimental non-intrusive investigation of fuel injector phase changing flow. Fuel 2020, 259, 116188. [Google Scholar] [CrossRef]

- Minniti, M.; Dunn-Rankin, D.; Chien, Y.C. Long-range microscopy of optically dense spray structures using ultra-short pulse off-axis digital holography. At. Sprays 2021, 31, 47–59. [Google Scholar] [CrossRef]

- Cavicchi, A.; Postrioti, L.; Sorbini, G.; Brizi, G. Local momentum flux measurement: An effective way for GDI spray targeting in flash-boiling conditions. Fuel 2022, 317, 123454. [Google Scholar] [CrossRef]

- Butcher, A.J.; Aleiferis, P.G.; Richardson, D. Development of a real-size optical injector nozzle for studies of cavitation, spray formation and flash-boiling at conditions relevant to direct-injection spark-ignition engines. Int. J. Engine Res. 2013, 14, 557–577. [Google Scholar] [CrossRef]

- Aleiferis, P.G.; Hardalupas, Y.; Kolokotronis, D.; Taylor, A.M.K.P.; Kimura, T. Investigation of the Internal Flow Field of a Diesel Model Injector Using Particle Image Velocimetry and cfd (No. 2007-01-1897); SAE Technical Article; SAE International: Warrendale, PA, USA, 2007. [Google Scholar]

- Singh, V.K.; Singh, P.; Karmakar, M.; Leta, J.; Mayr, P. The journal coverage of Web of Science, Scopus and Dimensions: A comparative analysis. Scientometrics 2021, 126, 5113–5142. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. VOSviewer Manual. 24 January 2022. Available online: https://www.vosviewer.com/documentation/Manual_VOSviewer_1.6.18.pdf (accessed on 5 May 2023).

| Dimensionless Number | Equation | Meaning |

|---|---|---|

| Reynolds | Ratio of inertial to viscous forces | |

| Weber | Ratio of inertial to surface tension forces | |

| Ohnesorge | Ratio of viscous to inertial and surface tension forces | |

| Jakob | Ratio of sensible to latent heat |

| Category | Logic | Terms |

|---|---|---|

| Topic | “flashing flow” or “flash boiling” or “flashing spray” | |

| Title | Or | flash* AND “atomization” |

| Title | Or | flash* AND “spray” |

| Title | Or | “spray formation by flashing” OR “flashing jets” OR “flashing in nozzles” |

| Document type | And | Article |

| Language | And | English |

| Author keywords | And | Spray, flash, cryogenic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bar-Kohany, T.; Arogeti, M.; Malka, A.; Sher, E. Advances in Liquid Atomization via Flash Boiling—A Global Overview. Energies 2023, 16, 6763. https://doi.org/10.3390/en16196763

Bar-Kohany T, Arogeti M, Malka A, Sher E. Advances in Liquid Atomization via Flash Boiling—A Global Overview. Energies. 2023; 16(19):6763. https://doi.org/10.3390/en16196763

Chicago/Turabian StyleBar-Kohany, Tali, Merav Arogeti, Avihai Malka, and Eran Sher. 2023. "Advances in Liquid Atomization via Flash Boiling—A Global Overview" Energies 16, no. 19: 6763. https://doi.org/10.3390/en16196763