Thermoelectric-Based Radiant Cooling Systems: An Experimental and Numerical Investigation of Thermal Comfort

Abstract

:1. Introduction

2. System Description

3. Numerical Model

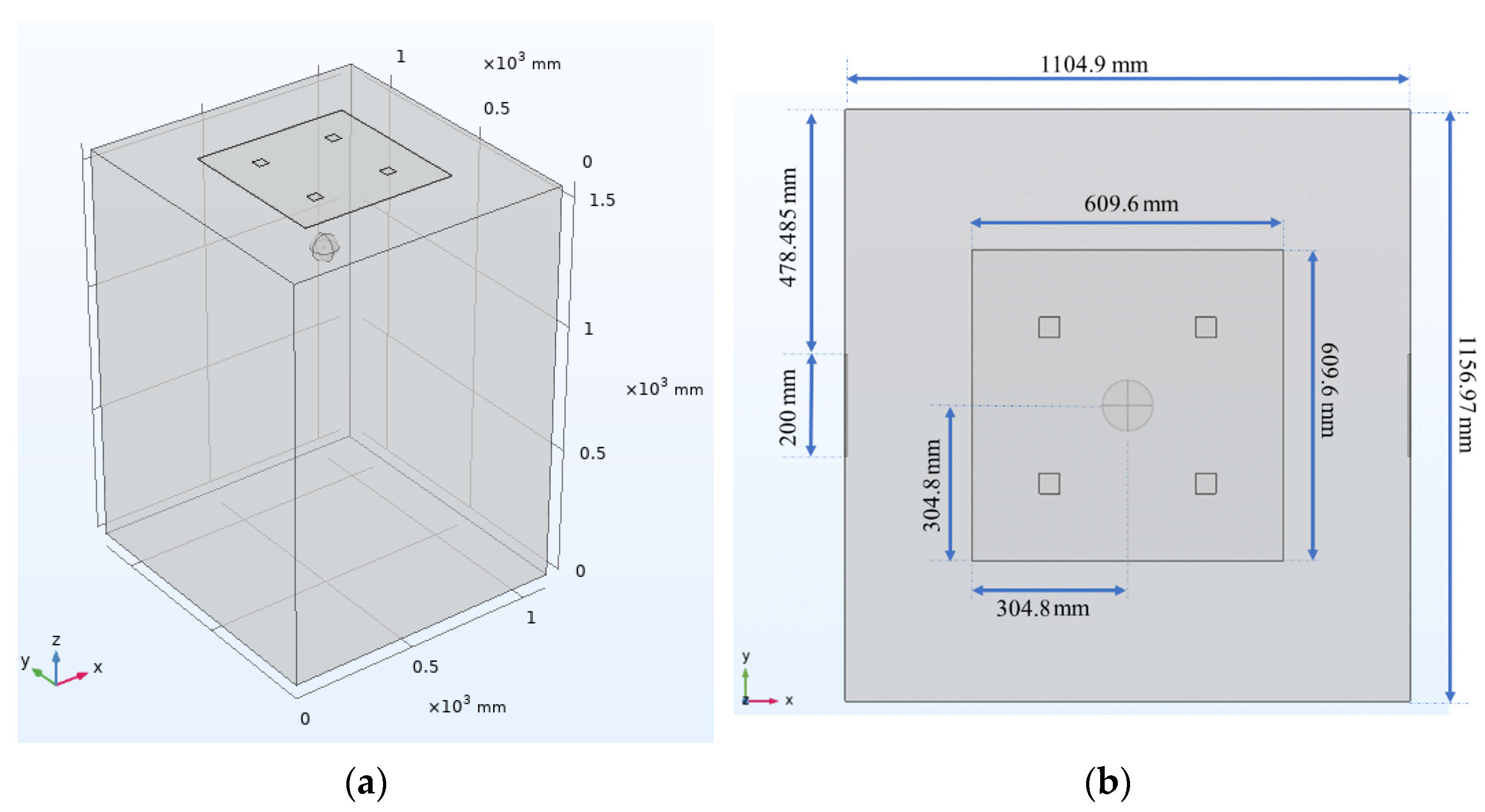

3.1. COMSOL Simulation Model

3.2. Assumptions and Initial and Boundary Conditions

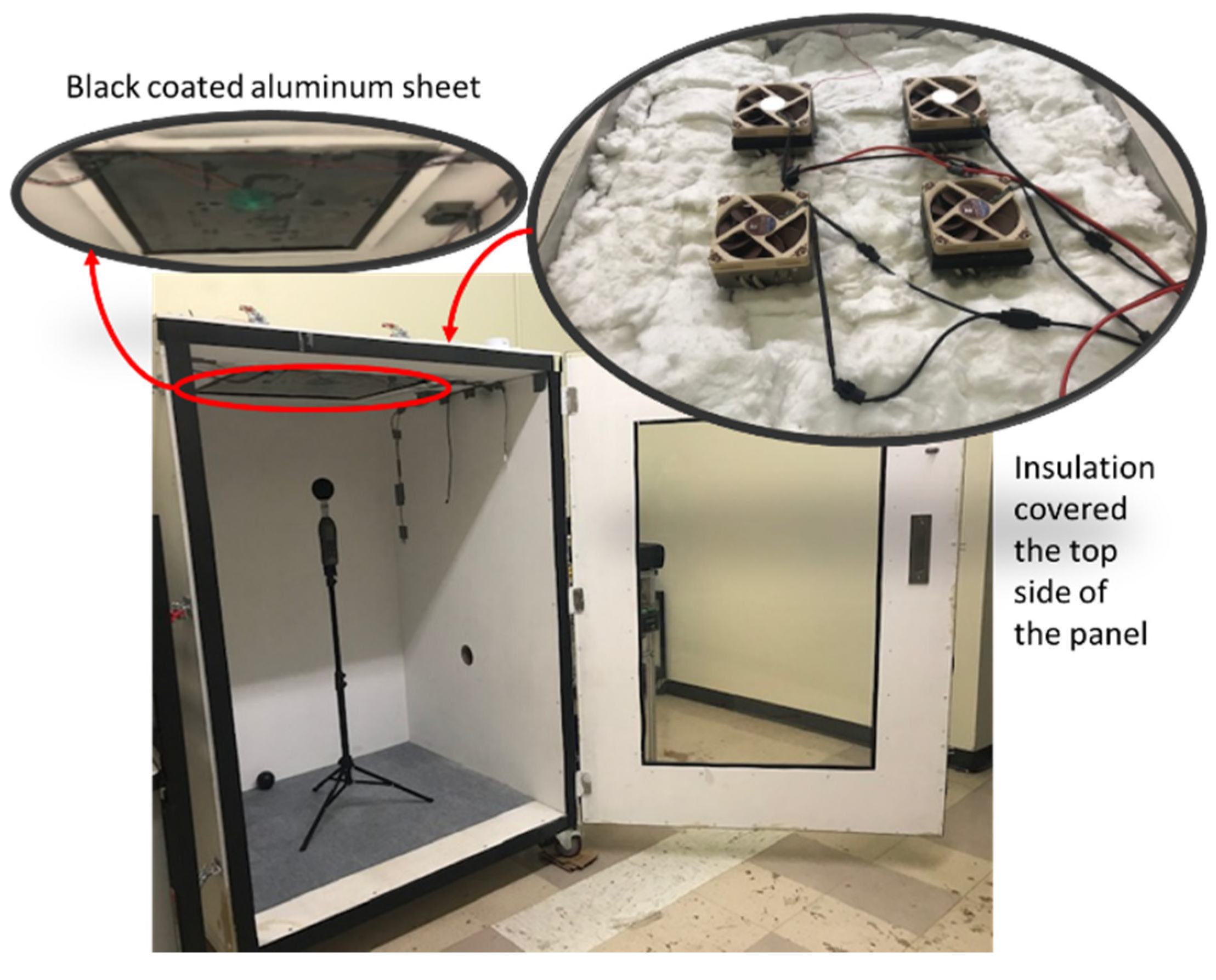

4. Experimental Setup

4.1. COMSOL Simulation Model

4.2. Experimental Setup and Test Procedure

5. Results and Discussion

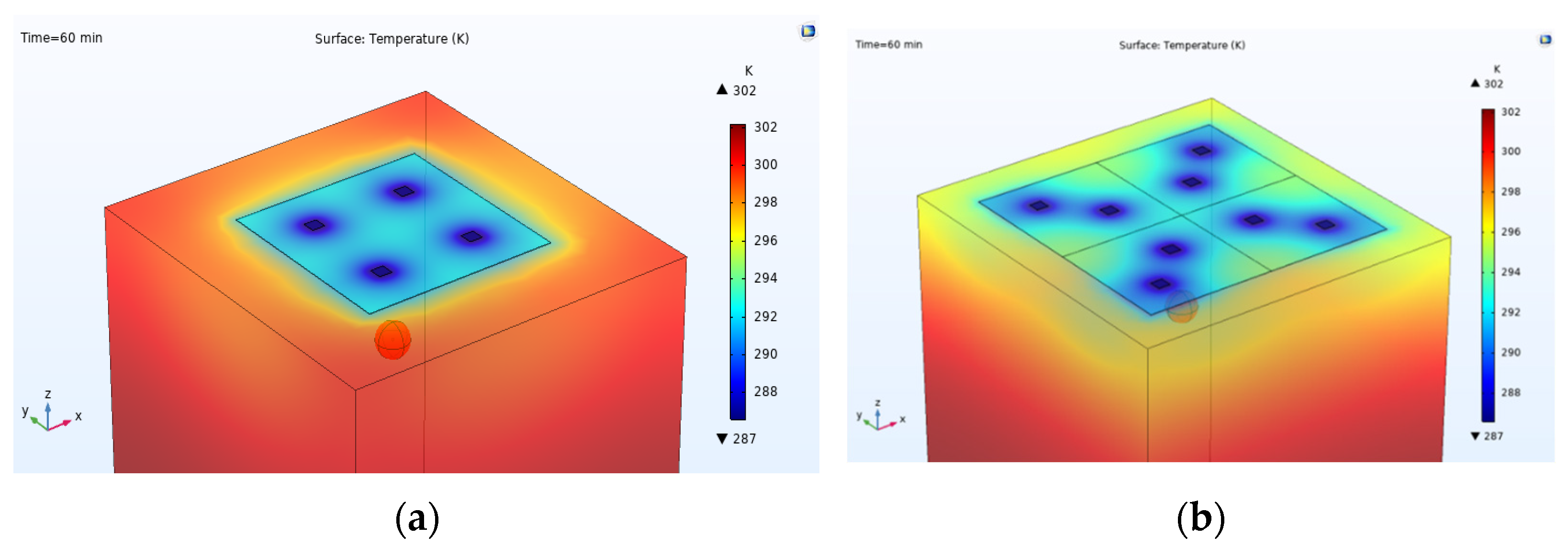

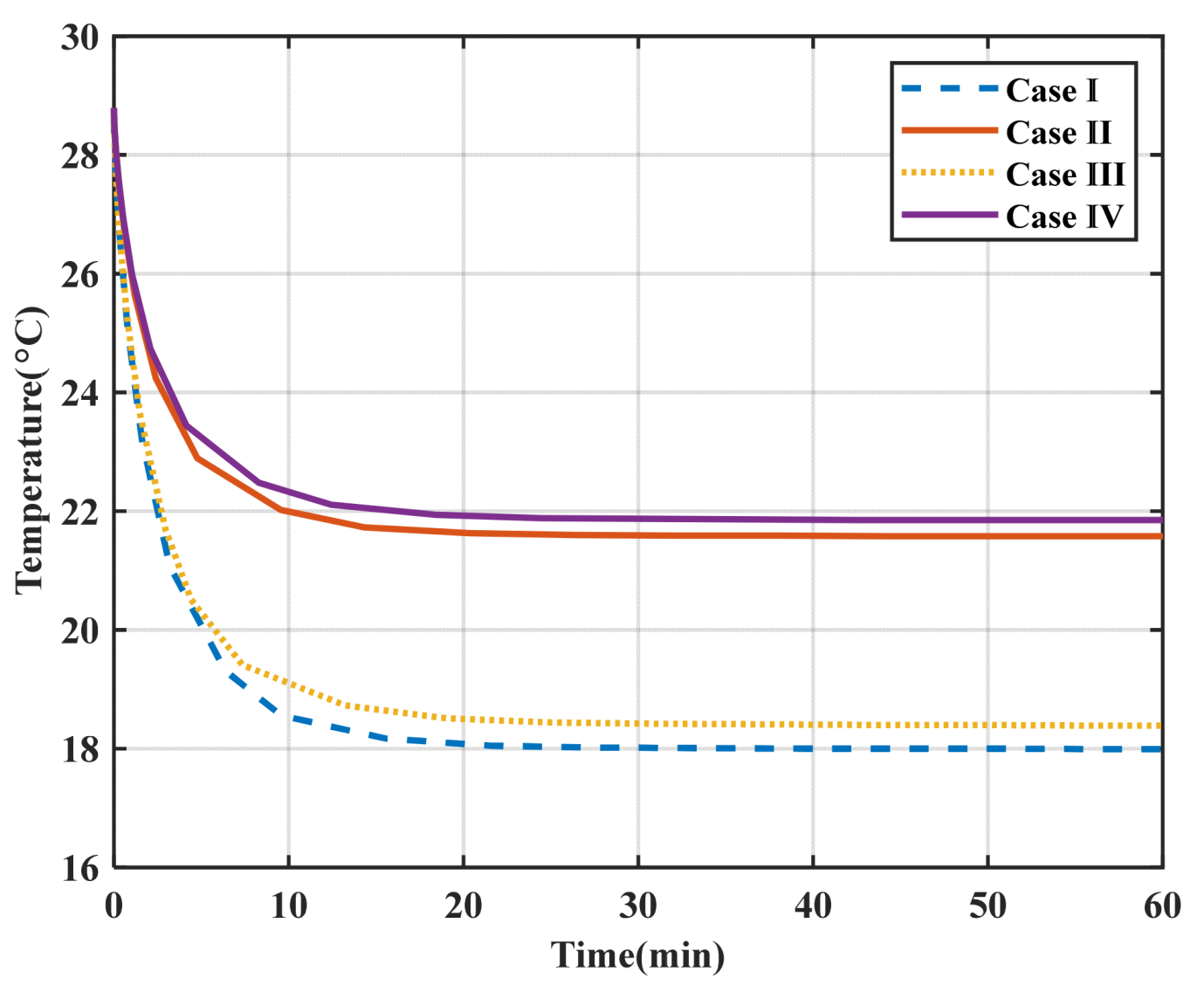

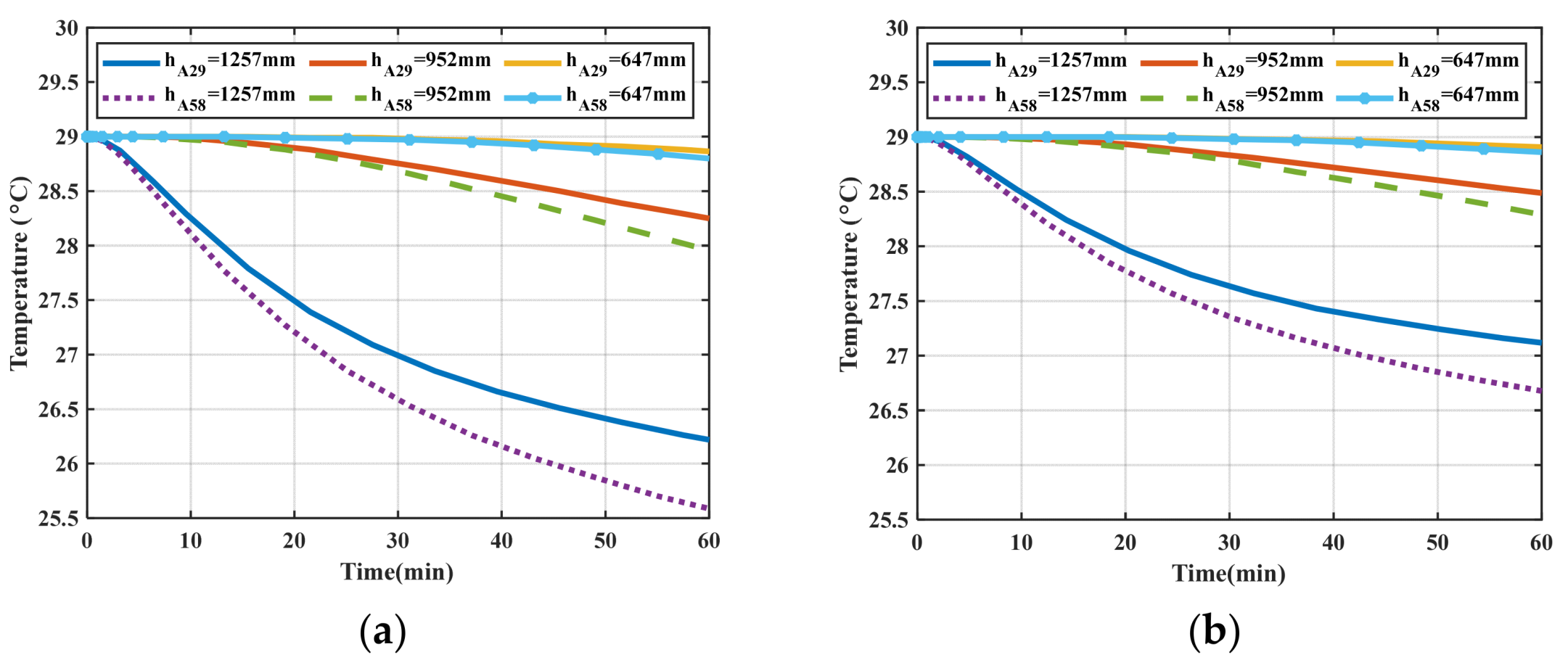

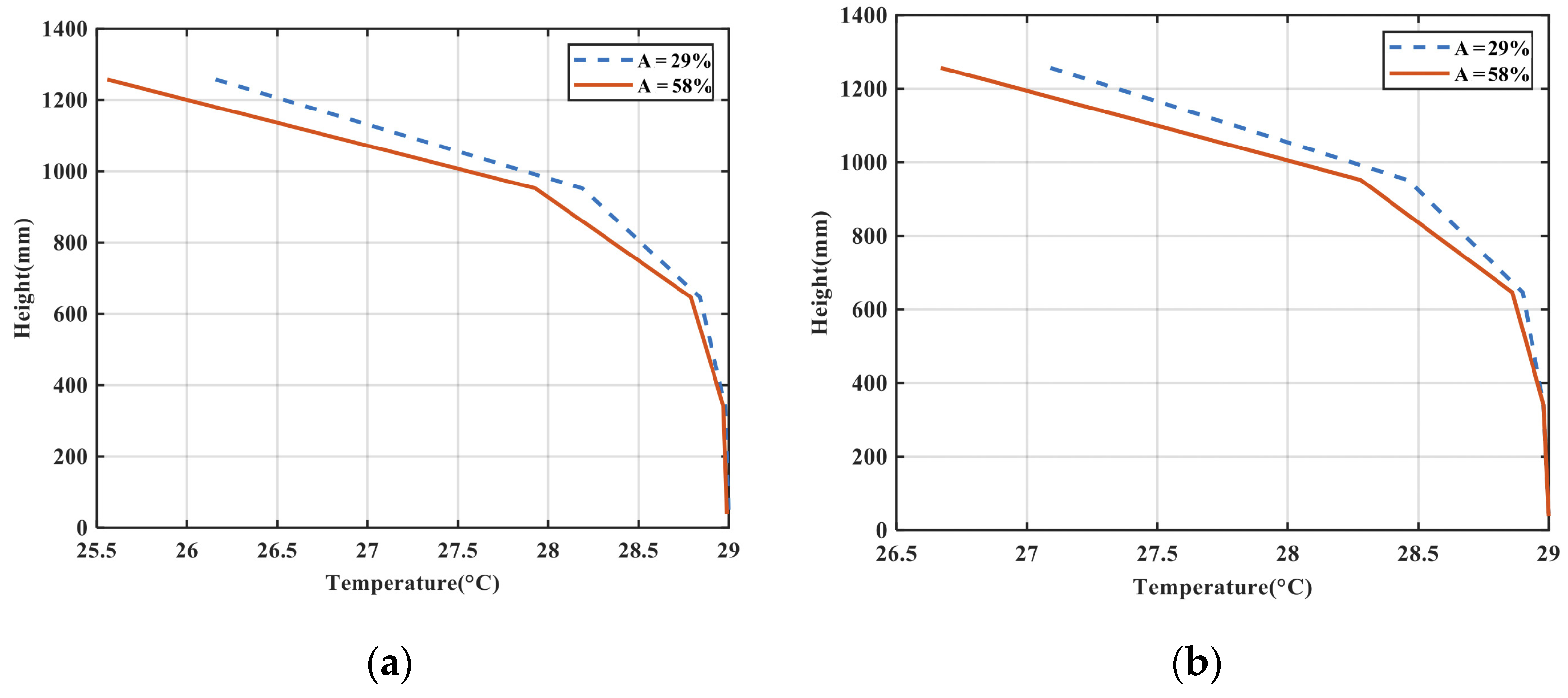

5.1. Parametric Study: Surface Temperature of the Ceiling Panel

5.2. Parametric Study: Surace Area of the Ceiling Panel

5.3. Thermal Comfort Assessment

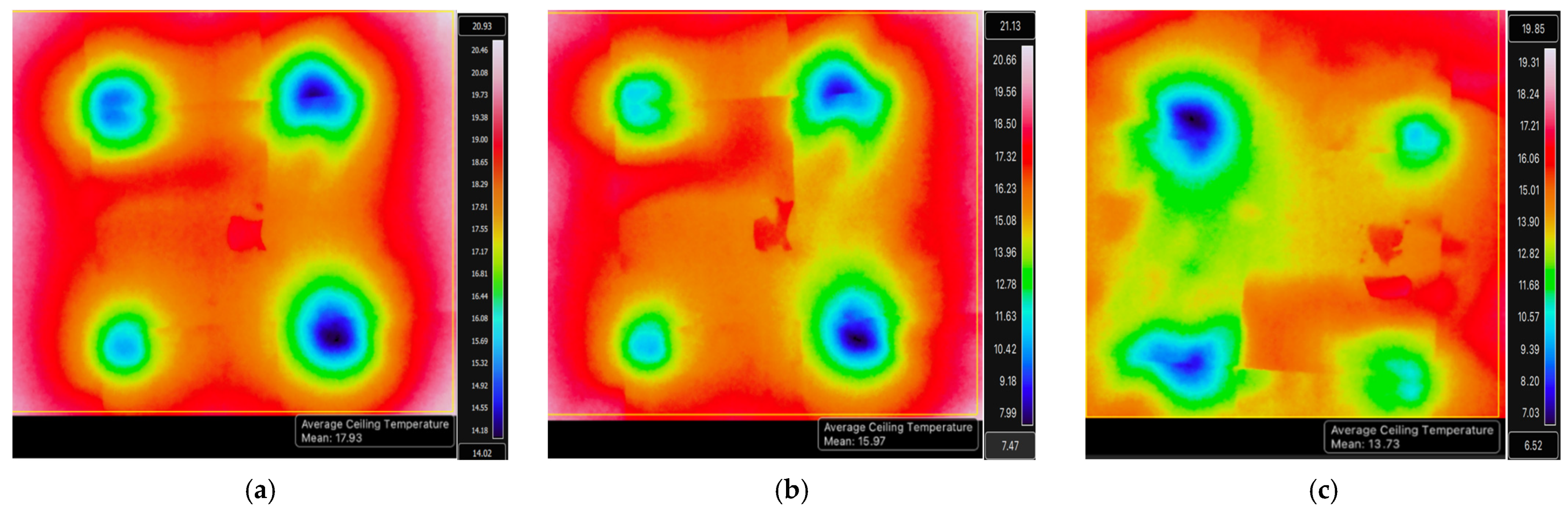

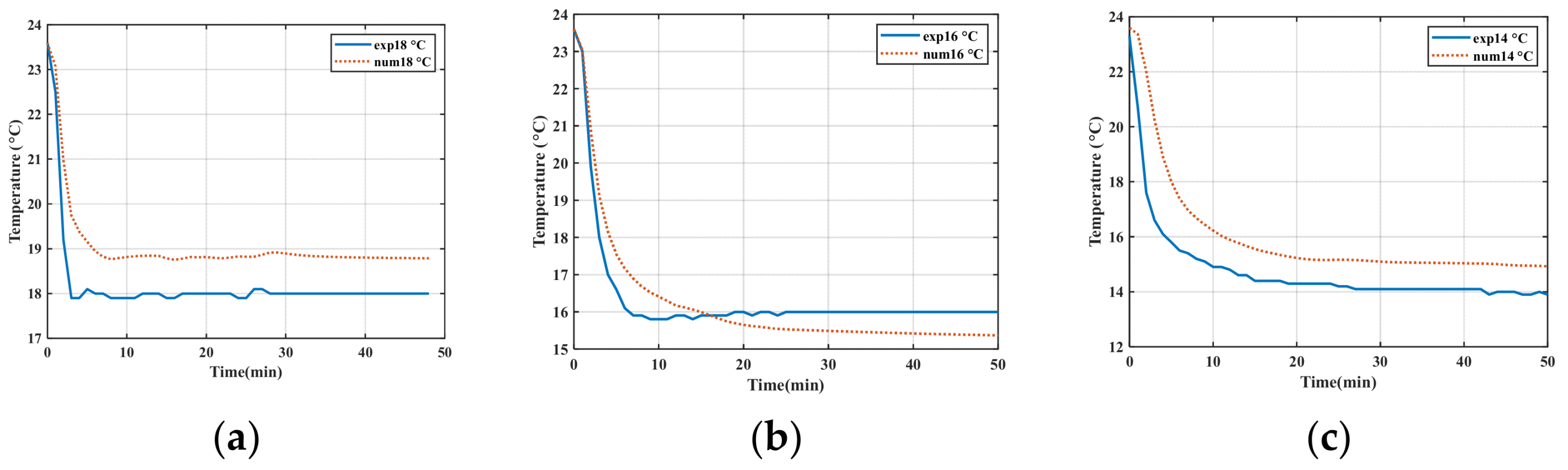

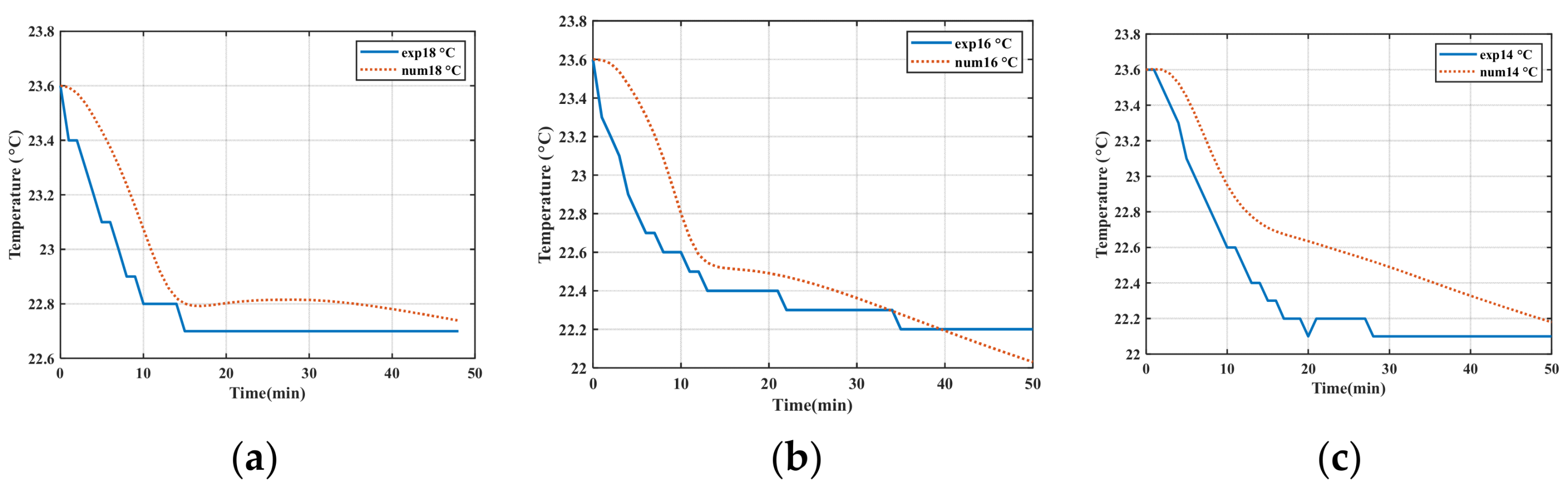

6. Model Validation

7. Conclusions

- Reducing the cold-side temperature of the thermoelectric modules from 18.5 °C to 13.5 °C resulted in a 4 °C decline in the average temperature of the ceiling panel. Additionally, this change is followed by a reduction in air temperature inside the test chamber at positions close to the ceiling;

- For a larger-sized ceiling panel (covering 58% of the ceiling area), a temperature reduction of 0.5 °C is accomplished at positions close to the ceiling, irrespective of TC value. This temperature difference is smaller for positions at higher distances from the ceiling;

- In the absence of any external forces and input/output airflow (free convection), the average air temperature in the room cannot reach the thermal comfort condition. Further study is needed to consider the airflow exchange in the conditioned space and how it may impact the system’s performance for achieving thermal comfort;

- The local thermal comfort was achieved at 1257 mm when the cold-side TE temperature was set at 13.5 °C and the large-size ceiling panel was in use, covering 58% of the ceiling. It was demonstrated that although case III is the optimum condition, it is possible to approach the comfort condition for case I with a PMV of 0.5 and a PDD of 10%;

- The experiments could successfully verify the numerical model by lowering the ceiling and room temperature to about 2 degrees at a height of 1257 mm;

- The test results are also a basis for future studies on thermoelectric-based cooling systems as alternatives to traditional cooling technologies.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| S2S | Surface to surface |

| A | Area (m2) |

| A29 | Radiant ceiling with 29% area coverage |

| A58 | Radiant ceiling with 58% area coverage |

| BC | Boundary Condition |

| Cp | Specific heat capacity (J/kg.k) |

| I | Input current (a) |

| e | Emissive power (W) |

| F | Volume force vector (N) |

| G | Irradiation (W/m2) |

| GT | Globe thermometer |

| g | Gravitational acceleration (m/s2) |

| J | Radiosity (W) |

| k | Thermal conductivity (W/m.K) |

| N | Number of TE modules |

| P | Pressure (Pa) |

| Q | Heat transfer (W) |

| R | Thermal resistance (K/W) |

| T | Temperature (K) |

| TCP | Thermocouple |

| u | Velocity (m/s) |

| V | Voltage (v) |

| Subscript | |

| amb | Ambient |

| ad | Additional |

| b | Black body |

| c | Cold side |

| cond | Conduction |

| d | Diffuse surfaces |

| ext | External |

| h | Hot side |

| m | Mutual radiant exchange |

| mrt | Mean radiant temperature (K) |

| opr | Operative temperature (°C) |

| P | Pressure |

| rad | Radiation |

| rcc | Radiant cooling ceiling |

| trans | Translational motion |

| TE | Thermoelectric |

| ted | Thermoelastic |

| Greek | |

| ɛ | Emissivity |

| ∆ | Gradient |

| σ | Stephan Boltzmann constant (5.6703 × 10−8 W/m2K4) |

| ρ | Density (Kg/M3) |

| τ | Viscous stress tensor |

References

- Fong, K.; Chow, T.; Lee, C.; Lin, Z.; Chan, L. Solar hybrid cooling system for high-tech offices in subtropical climate—Radiant cooling by absorption refrigeration and desiccant dehumidification. Energy Convers. Manag. 2011, 52, 2883–2894. [Google Scholar] [CrossRef]

- Pacheco, R.; Ordóñez, J.; Martínez, G. Energy efficient design of building: A review. Renew. Sustain. Energy Rev. 2012, 16, 3559–3573. [Google Scholar] [CrossRef]

- Doiphode, G.; Najafi, H.; Migliori, M. Energy Efficiency Improvement in K-12 Schools: A Case Study in Florida. ASME J. Eng. Sustain. Build. Cities 2021, 2, 011001. [Google Scholar] [CrossRef]

- Kwame, A.B.; Troy, N.V.; Hamidreza, N. A Multi-Facet Retrofit Approach to Improve Energy Efficiency of Existing Class of Single-Family Residential Buildings in Hot-Humid Climate Zones. Energies 2020, 13, 1178. [Google Scholar] [CrossRef]

- Rochelle, D.; Najafi, H. A review of the effect of biodiesel on gas turbine emissions and performance. Renew. Sustain. Energy Rev. 2019, 105, 129–137. [Google Scholar] [CrossRef]

- Najafi, H. Evaluation of Alternative Cooling Techniques for Photovoltaic Panels. Ph.D. Thesis, University of Alabama, Tuscaloosa, AL, USA, 2012. [Google Scholar]

- U.S. Energy Information Administration (EIA). Frequently Asked Questions (FAQs). Available online: https://www.eia.gov/tools/faqs/faq.php?id=87&t=1 (accessed on 22 September 2023).

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Seyednezhad, M.; Najafi, H. Energy and Economic Analysis of a Novel Hybrid Photovoltaic-Thermoelectric System for Building Cooling Applications. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition (IMECE), Salt Lake City, UT, USA, 11–14 November 2020; Volume 6. [Google Scholar] [CrossRef]

- Ma, X.; Zhao, H.; Zhao, X.; Li, G.; Shittu, S. Building Integrated Thermoelectric Air Conditioners—A Potentially Fully Environmentally Friendly Solution in Building Services. Future Cities Environ. 2019, 5, 12. [Google Scholar] [CrossRef]

- Zuazua-Ros, A.; Martín-Gómez, C.; Ibañez-Puy, E.; Vidaurre-Arbizu, M.; Gelbstein, Y. Investigation of the thermoelectric potential for heating, cooling and ventilation in buildings: Characterization options and applications. Renew. Energy 2019, 131, 229–239. [Google Scholar] [CrossRef]

- Le Pierrès, N.; Cosnier, M.; Luo, L.; Fraisse, G. Coupling of thermoelectric modules with a photovoltaic panel for air pre-heating and pre-cooling application; an annual simulation. Int. J. Energy Res. 2008, 32, 1316–1328. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Gong, G.; Han, T. Experimental evaluation of an active solar thermoelectric radiant wall system. Energy Convers. Manag. 2015, 94, 253–260. [Google Scholar] [CrossRef]

- Irshad, K.; Habib, K.; Basrawi, F.; Saha, B.B. Study of a thermoelectric air duct system assisted by photovoltaic wall for space cooling in tropical climate. Energy 2017, 119, 504–522. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Liu, Z.; Yu, J.; Xu, X.; Su, X. Towards net zero energy building: The application potential and adaptability of photovoltaic-thermoelectric-battery wall system. Appl. Energy 2020, 258, 114066. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Gong, G.; Luo, Y.; Meng, F. Evaluation of a prototype active solar thermoelectric radiant wall system in winter conditions. Appl. Therm. Eng. 2015, 89, 36–43. [Google Scholar] [CrossRef]

- Xu, X.; Van Dessel, S. Evaluation of a prototype active building envelope window-system. Energy Build. 2008, 40, 168–174. [Google Scholar] [CrossRef]

- Lertsatitthanakorn, C.; Tipsaenprom, W.; Srisuwan, W.; Atthajariyakul, S. Study on the Cooling Performance and Thermal Comfort of a Thermoelectric Ceiling Cooling Panel System. Indoor Built Environ. 2008, 17, 525–534. [Google Scholar] [CrossRef]

- He, W.; Zhou, J.; Hou, J.; Chen, C.; Ji, J. Theoretical and experimental investigation on a thermoelectric cooling and heating system driven by solar. Appl. Energy 2013, 107, 89–97. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, L.; Gong, G. Experimental evaluation of a solar thermoelectric cooled ceiling combined with displacement ventilation system. Energy Convers. Manag. 2014, 87, 559–565. [Google Scholar] [CrossRef]

- Chiang, W.-H.; Wang, C.-Y.; Huang, J.-S. Evaluation of cooling ceiling and mechanical ventilation systems on thermal comfort using CFD study in an office for subtropical region. Build. Environ. 2012, 48, 113–127. [Google Scholar] [CrossRef]

- Loveday, D.; Parsons, K.; Taki, A.; Hodder, S. Displacement ventilation environments with chilled ceilings: Thermal comfort design within the context of the BS EN ISO7730 versus adaptive debate. Energy Build. 2002, 34, 573–579. [Google Scholar] [CrossRef]

- Niu, J.L.; Zuo, H.G.; Burnett, J. Simulation Methodoly of Radiant Cooling with Elevated Air Movement. 2001. Available online: https://www.aivc.org/resource/simulation-methodoly-radiant-cooling-elevated-air-movement (accessed on 23 September 2023).

- Gan, G. Numerical investigation of local thermal discomfort in offices with displacement ventilation. Energy Build. 1995, 23, 73–81. [Google Scholar] [CrossRef]

- Zhang, L.; Niu, J. Indoor humidity behaviors associated with decoupled cooling in hot and humid climates. Build. Environ. 2003, 38, 99–107. [Google Scholar] [CrossRef]

- Lertsatitthanakorn, C.; Srisuwan, W.; Atthajariyakul, S. Experimental performance of a thermoelectric ceiling cooling panel. Int. J. Energy Res. 2008, 32, 950–957. [Google Scholar] [CrossRef]

- Lertsatitthanakorn, C.; Wiset, L.; Atthajariyakul, S. Evaluation of the Thermal Comfort of a Thermoelectric Ceiling Cooling Panel (TE-CCP) System. J. Electron. Mater. 2009, 38, 1472–1477. [Google Scholar] [CrossRef]

- Shen, L.; Xiao, F.; Chen, H.; Wang, S. Investigation of a novel thermoelectric radiant air-conditioning system. Energy Build. 2013, 59, 123–132. [Google Scholar] [CrossRef]

- Lim, H.; Kang, Y.-K.; Jeong, J.-W. Application of a phase change material to a thermoelectric ceiling radiant cooling panel as a heat storage layer. J. Build. Eng. 2020, 32, 101787. [Google Scholar] [CrossRef]

- Bhargava, A.; Najafi, H. Photovoltaic-Thermoelectric Systems for Building Cooling Applications: A Preliminary Study. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 11–17 November 2016; Volume 6b, p. V06BT08A011. [Google Scholar] [CrossRef]

- Lim, H.; Kang, Y.-K.; Jeong, J.-W. Development of empirical models to predict cooling performance of a thermoelectric radiant panel. Energy Build. 2019, 202, 109387. [Google Scholar] [CrossRef]

- Practical Applications of Radiant Heating and Cooling to Maintain Comfort Conditions (Conference). OSTI.GOV. Available online: https://www.osti.gov/biblio/392494 (accessed on 22 September 2023).

- Khatri, R.; Khare, V.R.; Kumar, H. Spatial distribution of air temperature and air flow analysis in radiant cooling system using CFD technique. Energy Rep. 2020, 6, 268–275. [Google Scholar] [CrossRef]

- Imanari, T.; Omori, T.; Bogaki, K. Thermal comfort and energy consumption of the radiant ceiling panel system: Comparison with the conventional all-air system. Energy Build. 1999, 30, 167–175. [Google Scholar] [CrossRef]

- Catalina, T.; Virgone, J.; Martin, J.J. Evaluation of Performances, Thermal Comfort and Energy Consumption of a Reversible Radiant Ceiling by Capillary Mat: Application for the Prefabricated Buildings. 2006. Available online: https://www.aivc.org/resource/evaluation-performances-thermal-comfort-and-energy-consumption-reversible-radiant-ceiling (accessed on 22 September 2023).

- Catalina, T.; Virgone, J.; Kuznik, F. Evaluation of thermal comfort using combined CFD and experimentation study in a test room equipped with a cooling ceiling. Build. Environ. 2009, 44, 1740–1750. [Google Scholar] [CrossRef]

- ISO 7730:1984; Moderate Thermal Environments—Determination of the PMV and PPD Indices and Specification of the Conditions for Thermal Comfort. International Organization for Standardization: Geneva, Switzerland, 1984. Available online: https://www.iso.org/standard/14566.html (accessed on 22 September 2023).

- Nagano, K.; Mochida, T. Experiments on thermal environmental design of ceiling radiant cooling for supine human subjects. Build. Environ. 2004, 39, 267–275. [Google Scholar] [CrossRef]

- Hodder, S.; Loveday, D.; Parsons, K.; Taki, A. Thermal comfort in chilled ceiling and displacement ventilation environments: Vertical radiant temperature asymmetry effects. Energy Build. 1998, 27, 167–173. [Google Scholar] [CrossRef]

- Kitagawa, K.; Komoda, N.; Hayano, H.; Tanabe, S.-I. Effect of humidity and small air movement on thermal comfort under a radiant cooling ceiling by subjective experiments. Energy Build. 1999, 30, 185–193. [Google Scholar] [CrossRef]

- Carlucci, S.; Pagliano, L. A review of indices for the long-term evaluation of the general thermal comfort conditions in buildings. Energy Build. 2012, 53, 194–205. [Google Scholar] [CrossRef]

- Bartzanas, T.; Kittas, C.; Sapounas, A.; Nikita-Martzopoulou, C. Analysis of airflow through experimental rural buildings: Sensitivity to turbulence models. Biosyst. Eng. 2007, 97, 229–239. [Google Scholar] [CrossRef]

- Stamou, A.I.; Katsiris, I.; Schaelin, A. Evaluation of thermal comfort in Galatsi Arena of the Olympics “Athens 2004” using a CFD model. Appl. Therm. Eng. 2008, 28, 1206–1215. [Google Scholar] [CrossRef]

- Tye-Gingras, M.; Gosselin, L. Comfort and energy consumption of hydronic heating radiant ceilings and walls based on CFD analysis. Build. Environ. 2012, 54, 1–13. [Google Scholar] [CrossRef]

- Hussain, S.; Oosthuizen, P.H.; Kalendar, A. Evaluation of various turbulence models for the prediction of the airflow and temperature distributions in atria. Energy Build. 2012, 48, 18–28. [Google Scholar] [CrossRef]

- Corgnati, S.; Perino, M.; Fracastoro, G.; Nielsen, P. Experimental and numerical analysis of air and radiant cooling systems in offices. Build. Environ. 2009, 44, 801–806. [Google Scholar] [CrossRef]

- ASHRAE 55 Standard; Thermal Environmental Conditions for Human Occupancy. American Society of Heating, Refrigerating, and Air-Conditioning Engineers: Peachtree Corners, GA, USA, 2020.

- Teitelbaum, E.; Chen, K.W.; Meggers, F.; Guo, H.; Houchois, N.; Pantelic, J.; Rysanek, A. Globe thermometer free convection error potentials. Sci. Rep. 2020, 10, 2652. [Google Scholar] [CrossRef]

- Osterman, E.; Tyagi, V.; Butala, V.; Rahim, N.; Stritih, U. Review of PCM based cooling technologies for buildings. Energy Build. 2012, 49, 37–49. [Google Scholar] [CrossRef]

- Uyanna, O.; Najafi, H.; Rajendra, B. An inverse method for real-time estimation of aerothermal heating for thermal protection systems of space vehicles. Int. J. Heat Mass Transf. 2021, 177, 121482. [Google Scholar] [CrossRef]

- Introduction to COMSOL Multiphysics; COMSOL: Burlington, MA, USA, 2019.

- Seyednezhad, M.; Najafi, H.; Kubwimana, B. Numerical and Experimental Investigation of a Thermoelectric-Based Radiant Ceiling Panel with Phase Change Material for Building Cooling Applications. Sustainability 2021, 13, 11936. [Google Scholar] [CrossRef]

- Sadineni, S.B.; Madala, S.; Boehm, R.F. Passive building energy savings: A review of building envelope components. Renew. Sustain. Energy Rev. 2011, 15, 3617–3631. [Google Scholar] [CrossRef]

- Tartarini, F.; Schiavon, S.; Cheung, T.; Hoyt, T. CBE Thermal Comfort Tool: Online tool for thermal comfort calculations and visualizations. SoftwareX 2020, 12, 100563. [Google Scholar] [CrossRef]

- Seyednezhad, M.; Najafi, H. Solar-Powered Thermoelectric-Based Cooling and Heating System for Building Applications: A Parametric Study. Energies 2021, 14, 5573. [Google Scholar] [CrossRef]

| Case Number | Percentage of Area Coverage | Tc |

|---|---|---|

| I | 29% | 13.5 °C |

| II | 29% | 18.5 °C |

| III | 58% | 13.5 °C |

| IV | 58% | 18.5 °C |

| Dimension (mm) | 40 × 40 × 3 |

|---|---|

| VTE,max | 16.1 V |

| ITE,max | 8 A |

| ΔTTE,max | 71 K |

| Qmax | 80 W |

| Ceiling Panel (Aluminum) | Globe Thermometer: Shell (Copper) | Globe Thermometer: TCP (Copper) | Air | Globe Thermometer Shell (Brass *) | |

|---|---|---|---|---|---|

| Dimension (mm) | L = 600, W = 600, H = 2 | Ri = 50 Ro = 49.6 | Rt = 5 | L = 1156.97, W = 1104.9, H = 1562.1 | Ri = 50 Ro = 49.6 |

| Density (kg/m3) | 2700 | 8960 | 8960 | varying with temp. | 8530 |

| Specific Heat, Cp (J/kg.K) | 904 | 385 | 385 | varying with temp. | 375 |

| Thermal Conductivity, k (W/m.K) | 237 | 400 | 400 | varying with temp. | 109.0 |

| Emissivity, ε | 0.95 | 0.95 | 0.95 | 0.95 | 0.90 |

| Components | Initial & Boundary Conditons |

|---|---|

| TE modules | IC: T = 29 °C BC1: Constant temperature: Tc = 13.5 °C, and 18.5 °C |

| Aluminum sheet top side | IC: T = 29 °C BC2: insulation (adiabatic) |

| Aluminum sheet backside | IC: T = 29 °C BC3: S2S radiation-diffuse surface, ε = 0.95 |

| Ceiling (areas not covered by TE-radiant panel) | IC: T = 29 °C BC2: insulation (adiabatic) |

| Air in the room | IC: T = 29 °C, |

| Walls & floor | IC: T = 29 °C BC2: insulation (adiabatic) |

| GT & TCP | IC: T = 29 °C BC3: S2S radiation-diffus surface, ε = 0.9 |

| Category | Accuracy or Range |

|---|---|

| NTC Thermistor: MP-2996 MP-3193 | 15K ohms at 25 °C Range: −20 °C to +100 °C |

| Temperature controller: TC-48-20 | Voltmax = 50 V Imax = 20 A |

| Wet bulb globe thermometer (WBGT) data logger (87786 AZ) | Accuracy: ±0.6 °C Range: 0~50 °C |

| HOBO data logger | Accuracy: ±0.21 °C from 0° to 50 °C Range: −20° to 70 °C |

| Thermal camera, FLIR A70 | Thermal sensitivity/NETD < 35 mK Accuracy: ±2 °C or ±2% of reading, for ambient temperature 15–35 °C and object temperature above 0 °C (32 °F) |

| Validation Case | Trcc (°C) | Tc,avg (°C) |

|---|---|---|

| Experimental cases | ||

| E1 | 18 | 17.93 |

| E2 | 16 | 15.97 |

| E3 | 14 | 13.73 |

| Numerical cases | ||

| N1 | 18 | 18.85 |

| N2 | 16 | 15.49 |

| N3 | 14 | 14.93 |

| Validation Case # | Trcc | I (A) | Volt (V) | P (W) |

|---|---|---|---|---|

| E1 | 18 °C | 17 | 24 | 408.3 |

| E2 | 16 °C | 23.5 | 24 | 564 |

| E3 | 14 °C | 29.7 | 24 | 712.8 |

| Components | Initial and Boundary Conditions | Components | Initial and Boundary Conditions |

|---|---|---|---|

| Room temperature (Tamb) | Tinit = 23.6 °C | Air in the room | IC: Tinit = 23.6 °C, |

| RH% | Trcc = 18 °C; RH = ~47.9% Trcc = 16 °C; RH = ~46.6% Trcc = 14 °C; RH = ~47.9% | Aluminum sheet bottom surface | IC: Tinit = 23.6 °C BC3: S2S radiation—diffuse surface, ε = 0.95 BC4: free convection (hal = 4 W/m2K, Tamb = 23.6 °C) BC1: constant temperature: Tc = 14 °C, 16 °C, and 18 °C |

| TE modules | IC: Tinit = 23.6 °C BC3: S2S radiation—diffuse surface, ε = 0.9 BC4: forced convection (hte = 20 W/m2K, Tamb = 23.6 °C) | Ceiling panel (areas not covered by the TE radiant panel) | IC: Tinit = 23.6 °C BC2: insulation (adiabatic) |

| Aluminum sheet top side | IC: Tinit = 23.6 °C BC2: insulation (adiabatic) | GT | IC: Tinit = 23.6 °C BC3: S2S radiation—diffuse surface, ε = 0.99 |

| Walls and floor | IC: Tinit = 23.6 °C BC2: insulation (adiabatic) | TCP | IC: Tinit = 23.6 °C BC3: S2S radiation—diffuse surface, ε = 0.99 |

| Case # | Ceiling Area Coverage | Tc (°C) | Trcc (°C) | Average Indoor Air Temperature (˚C) |

|---|---|---|---|---|

| I | 29% | 13.5 | 18 | 27.8 |

| II | 29% | 18.5 | 21.6 | 28.2 |

| III | 58% | 13.5 | 18.4 | 27.23 |

| IV | 58% | 18.5 | 21.85 | 27.81 |

| Case Number | A (%) | Tc (°C) | H (mm) | PMV | PPD |

|---|---|---|---|---|---|

| I | 29 | 13.5 | 1257 | 0.5 | 10% |

| 952 | 1.04 | 28% | |||

| 647 | 1.22 | 36% | |||

| II | 29 | 18.5 | 1257 | 0.79 | 18% |

| 952 | 1.15 | 33% | |||

| 647 | 1.25 | 38% | |||

| III | 58 | 13.5 | 1257 | 0.32 | 7% |

| 952 | 0.93 | 23% | |||

| 647 | 1.15 | 33% | |||

| IV | 58 | 18.5 | 1257 | 0.65 | 14% |

| 952 | 1.04 | 28% | |||

| 647 | 1.22 | 36% |

| Validation Case | Trcc (°C) | Tc,avg (°C) | Tg,avg (°C) |

|---|---|---|---|

| Experimental Tests | |||

| E1 | 18 | 23.1 | 22.81 |

| E2 | 16 | 23.2 | 22.42 |

| E3 | 14 | 22.7 | 22.67 |

| Numerical Tests | |||

| N1 | 18 | 21.24 | 22.94 |

| N2 | 16 | 19.13 | 22.55 |

| N3 | 14 | 19.34 | 22.38 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kubwimana, B.; Seyednezhad, M.; Najafi, H. Thermoelectric-Based Radiant Cooling Systems: An Experimental and Numerical Investigation of Thermal Comfort. Energies 2023, 16, 6981. https://doi.org/10.3390/en16196981

Kubwimana B, Seyednezhad M, Najafi H. Thermoelectric-Based Radiant Cooling Systems: An Experimental and Numerical Investigation of Thermal Comfort. Energies. 2023; 16(19):6981. https://doi.org/10.3390/en16196981

Chicago/Turabian StyleKubwimana, Benjamin, Mohadeseh Seyednezhad, and Hamidreza Najafi. 2023. "Thermoelectric-Based Radiant Cooling Systems: An Experimental and Numerical Investigation of Thermal Comfort" Energies 16, no. 19: 6981. https://doi.org/10.3390/en16196981

APA StyleKubwimana, B., Seyednezhad, M., & Najafi, H. (2023). Thermoelectric-Based Radiant Cooling Systems: An Experimental and Numerical Investigation of Thermal Comfort. Energies, 16(19), 6981. https://doi.org/10.3390/en16196981