Abstract

The application of rapeseed oil (RO) blends with diesel fuel and/or alcohols and/or ethers is known to significantly affect the combustion process. Aiming to further investigate the effects of rapeseed oil in a blend with diethyl ether (DEE) on this process, the coefficient of variation of the mean indicated pressure (COVMIP) of a 2.5l direct injection diesel engine was calculated. The analysis of the experimental results revealed the repeatability of the combustion process variability of diesel fuel (DF), rapeseed oil (RO), and DEE/RO blends containing up to 20% DEE. In these cases, the COVMIP does not exceed 4%. Additionally, it became obvious that for a higher content of DEE in blend with RO, the cyclic repeatability of the mean indicated pressure (MIP) was reduced. Thus, the values of COVMIP for fuels containing 30 and 40% of DEE by vol. in blend with RO were even three times higher than the values obtained for the reference fuel i.e., DF. The results indicate that the increased content of DEE in the mixture with RO is disadvantageous as it leads to excessive unevenness of the engine operation compared to its fueling with DF. The observed deterioration of the combustion process is caused by the vapor locks, which are formed due to the evaporation of volatile DEE in the fuel line, leading to the interrupted operation of the fuel injector.

1. Introduction

Currently, the world is going through an energy crisis, as a result of which fuel prices at filling stations are breaking new records. The unpredictable rise in fossil fuel prices is forcing consumers to change their daily habits by reducing their daily use of cars, commuting by public transport, or choosing to walk. The choice of electric cars also serves as an option for solving mobility problems, but the crisis in the field of electricity production has not gone unnoticed either, and a constant increase in prices can be observed here as well, sometimes reaching moments when a trip with a diesel car is cheaper than with an electric car. In the hope that the crisis will not be long-term, solutions are being sought that would be able to survive this relatively difficult transition period with as little investment as possible, so that afterward we can fully return to the course of “green” energy. Nor should we forget about the strict ecological regulations fulfillment of which can be realized by reducing the consumption of fossil fuels in transport. One of the solutions could be biofuels, the first and the faster application of which was started in very similar circumstances—in the 70s of the last century—during another energy crisis. These are fuels, the extraction of which does not require excessive material investments, and have also been well-known to consumers since the beginning of the 2000s. Compatibility with the existing refueling infrastructure and internal combustion engines, as well as the positive ecological impact, are the most important advantages of biofuels, which have not been fully evaluated.

“Conventional” or first-generation biofuels still account for 90% of all liquid biofuels and over 80 countries have liquid biofuel blending mandates in place [1]. One such example is biodiesel, which is already constantly used in the form of a 7% admixture in transport. The use of larger mixtures or even neat fuel is mainly limited by the effect of low ambient temperature which results in a reduction in viscosity, as also the possibility of damaging the engine and emitting unbearable nitrous oxides (NOx) emissions [2]. However, the transformation of vegetable oil into biodiesel is not always the best option for improving the properties of the oil for use in low ambient temperatures. Research shows that properties such as viscosity can be improved using different solutions: dilution (blending with hydrocarbon fuel), co-solvent blending (micro-emulsification), and cracking (pyrolysis) [3]. The simplest method accompanied by the least negative consequences is dilution usually realized with hydrocarbon fuels and alcohols, like ethanol or methanol. It cannot be denied that alcohol plays a key role in the decarbonization of the energy conversion chains [4], but the use of pure alcohol fuels have also some disadvantages. For example, methanol application in CI engines is limited due to a very low cetane number; therefore, the best option is the conversion of the base diesel engine to dual fuel operation with methanol in such a way reduces two main pollutants: NOx and PM [5], but is associated with additional costs. Viscosity reduction by microemulsions has long-term negative consequences such as carbon deposit formation and injector needle sticking [6], while pyrolysis has high infrastructure cost and the necessity for separate distillation equipment [7]. The formation of ethers made it possible to expand the range of additives that could be used to improve the physicochemical properties of both fossil and alternative fuels. In this regard, two promising fuels emerged—dimethyl ether (DME) and diethyl ether (DEE). DME, which is considered to be a promising alternative due to its soot-free combustion [8] is produced through the chemical conversion of various renewable substances or fossil fuels such as natural gas, coal, and biomass. Overall, it can be considered a good liquid organic hydrogen carrier with wide application in engines [9]. The absence of the C-C bond, higher oxygen content, and cetane number, sufficiently good auto-ignitability, better atomization characteristics, and non-toxic and less corrosive mark the main advantages of this fuel, although there are also disadvantages. Due to the low combustion enthalpy, a larger amount of fuel and a longer injection period is necessary, and due to the low viscosity value, it is necessary to use a lubricity enhancer in order not to damage the fuel injection system [8].

Compared to methanol-based ethers, ethanol ones have some more advantages. While DME is similar to DEE, the last one has a liquid aggregate state exactly in ambient conditions, which significantly facilitates its logistical possibilities. Additionally, to this, DEE is produced by the dehydration process from ethanol, which allows it to be called a renewable fuel. There are many different benefits of DEE, but the most important ones are: improved miscibility, higher cetane number, and oxygen content, as also prolonged flammability. Various studies [10,11,12,13,14] on DEE application in diesel engines confirm that it can be also used in different mixtures with diesel fuel, biodiesel, ethanol, biodiesel/diesel, ethanol/biodiesel/blends, etc. Similar studies [15] in this regard have been carried out with DEE, the addition of which in proportion up to 30% contributed to a significant decrease in viscosity of both rapeseed and linseed oil, as an also positive tendency in the case of NOx and HC emission reduction in comparison to rapeseed oil [16]. Overall, both of these fuels are promising alternatives to fossil fuels, but DEE accounts for more possible advantages than it was chosen for this research.

The combination of DEE or DME with other types of fuel also shows a very promising perspective. For example, ammonia (NH3), which is recognized as a carbon-free hydrogen-carrier fuel in the fuel blend with DEE could lower the overall carbon content of the fuel and possibly the fuel cost [17]. The positive effect of alcohol and ammonia fuels has also been seen by Ariemma [18], who confirmed that such mixtures ensure a stable oxidation process in a wide range of operational parameters, as also a significant reduction of NOx emissions. In addition to that, Cai and Zhao [19] also confirm that optimizing the NH3/air combustion by blending with DME is a potentially applicable technique.

Much previously mentioned research has been done concerning DEE and different fuel blends with a focus on averaged results in combustion not taking into account differences in cycle-to-cycle operation. Although cycle-to-cycle variations (CCVs) were first studied directly in spark-ignition engines, interest in the given field of research has also increased for diesel engines, especially since the two-stage injection strategies on the mixture formation [20]. Studies showed that conventional compression ignition engines are not so exposed to such remarkable CCVs due to non-premixed combustion, although some noteworthy cases exist, such as variations in the indicated mean effective pressure caused by variations in the injected mass [21], variations in rotary fuel pump caused by variations in the injection timing among the cycles [22], found from indicator diagram variations in ignition delay of each cycle caused by variations in in-cylinder pressure [23].

Overall, factors affecting cyclic combustion variations include the mixing process in the cylinder, circulation of intake air, components of mixtures, and characteristics of ignition [24]. Thus, in the research on the combustion process, many parameters have to be given significant importance, such as indicated maximum combustion pressure, mean effective pressure, and rate of heat release, etc. Variations in these parameters may not be periodically observed and may be affected by fuel amount, engine speed, intake air temperature, and also other operating conditions [25].

It must be noted that the determination of the optimal operating limiting range of different fuels plays an important role. Many biofuels have differences from conventional diesel oxygen content, cetane number, as also physicochemical properties, which may result in combustion variation problems [25]. For example, Bittle [26] have found that cycle-to-cycle variability with biodiesel is on the same order as that of petroleum diesel fuel and that the differences in fluid properties, and changes of their properties before combustion could be the primary source for differences in cycle-to-cycle variability. Attai [27] observed that biofuels with higher hydrogen content produce lower CCVs, as also burning rates due to a higher flame speed. Yang [28] observed that biodiesel addition can effectively reduce the CCVs of compression ignition engines at low engine loads, but at the same time he concludes that oxygen content in biodiesel in the combustion process is less pronounced. Turkcan [29], after tests with diesel engine with bioethanol-biodiesel-diesel ternary blends, concluded that values of the coefficient of variation (COV) for maximum pressure rise and maximum cylinder gas pressure increased with an increase in bioethanol content in ternary blends. Bekal [30] have found that COV for peak pressure is higher for part load for sunflower and pongamia oil methyl ester/diesel blends, which corresponds also to higher values of brake specific energy consumption. Cycle-to-cycle variations of the combustion process was also investigated by Longwic et al. During this research the mean indicated pressure (MIP) variation, obtained for the diesel engine fueled with ethanol-FAME blends and DF as reference fuel, was investigated using the wavelet transform. The authors found that the MIP variations for DF were similar to the Gaussian white noise [31]. A similar problem was investigated by Asok et al. In this case, the fluctuations of MIP were studied with the continuous wavelet transform. The performed tests confirmed that depending on the engine’s rotational speed, the pressure variations may have a strong periodic component and/or be intermittent [32]. Ali et al. [33] investigated CCVs in a diesel engine fueled with biodiesel–diesel mixture with a DEE additive. The research was carried out at 2500 rpm, and over 200 consecutive cycles were recorded. After that, the mean effective pressure has been calculated. The authors concluded that the coefficient of variation for biodiesel—diesel mixture (B30) was the lowest. They also found that this coefficient value increased for the adequately higher additive ratios.

Similar to the above-mentioned results were found in studies of gaseous fuels. During tests with a single-cylinder diesel-hydrogen dual-fuel engine it was observed [34] that cyclic variability increases with increase in hydrogen enrichment and this variability is reduced at higher engine loads. At the same time, Cheng [35] in research with a single-cylinder compression ignition (CI) engine observed that the addition of hydrogen (H2) reduces CCVs when the hydrogen mole fraction is smaller than 20%, but without any effect above this limit; he also concluded that increase of the charge air temperature may lead high CCVs. Selim [36] also observed that combustion noise and cycle variability are strongly dependent on the type of gaseous fuel and their concentration after tests on a single-cylinder Ricardo E6 engine working on dual fuel of diesel and LPG tests diesel–methane and pure diesel fuel. Jagadish and Gumtapure [37] studied CCVs of diesel-raw biogas operated in dual fuel mode at full load and constant speed conditions, where they found that COV of maximal pressure for BG20 and BG40 is lower than that of the diesel by about 2.30% and 11.98%, but the COV of indicated mean effective pressure for BG40 is found to be lesser than that of diesel by about 88.87%.

Studies concerning CCVs have been performed also in the case of DME. For example, Wang [38] reported that DME quantity should be optimized under different conditions to minimize the CCVs and concurrently extend the operating range of the diesel-DME premixed charge compression ignition engines. Shere [39] in the case of an HCCI engine with DME observed that the coefficient of variation, maximum combustion pressure, indicated mean effective pressure, and knocking intensity must be lower than the limiting value (less than 5%), but the maximum rate of pressure rise must be lower the standard limiting value.

COV fluctuations tend to be different, which is also confirmed by Attai [40], who found that for engine loads greater than 25%, the COV for indicated mean effective pressure for all blends of pyrolytic castor oil is less than 10 and the whole values of COV for maximal pressure is less than 2.5, in the same conclusion that COV of combustion parameters is a profound method of assessing combustion characteristics and engine performance. A similar conclusion was done by Kyrtatos [41] after experiments with heavy-duty single-cylinder research engines claiming that it is necessary to understand the source of the pressure fluctuations and the effect of these variations on single-cycle and average combustion and emissions.

In the case of DEE, the number of such studies is limited, especially in the mixture variants with vegetable oil. Therefore, the aim of this research is to assess the quality of the combustion process of DEE/RO blends by analysis of the COVMIP. In this way, we will extend the state of knowledge on the suitability of such mixtures for combustion in a diesel engine.

2. Materials and Methods

2.1. Engine Test Stand and Methodology

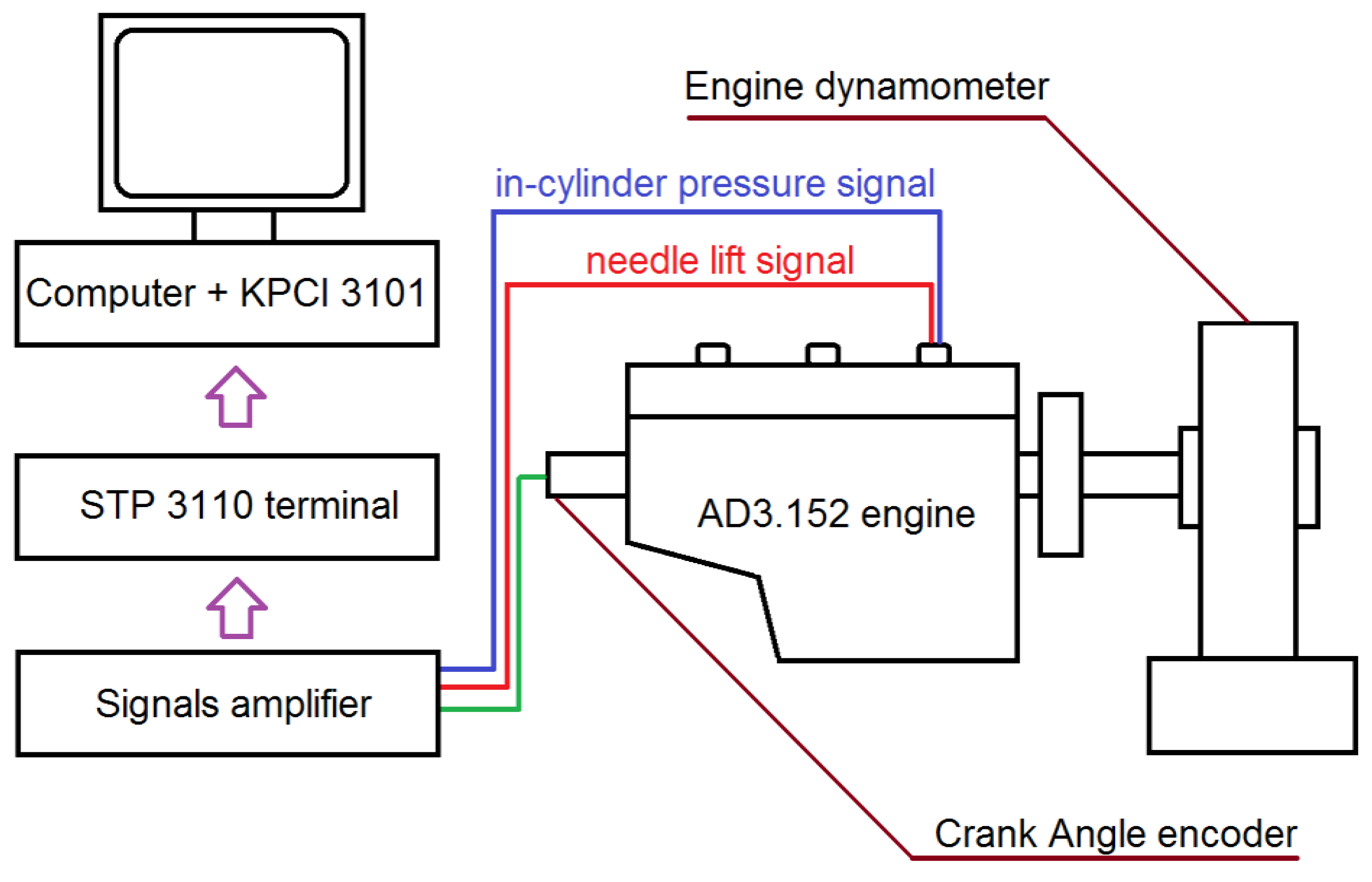

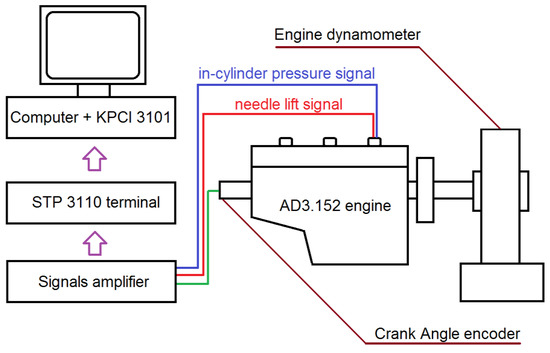

All necessary tests were carried out at the engine and chemical laboratory of the Kazimierz Pulaski University of Technology and Humanities in Radom. In detail, the view of the test stand configuration is shown in Figure 1.

Figure 1.

Test stand equipped with the AD3.152 engine.

The main object of this study is the AD3.152 diesel engine made in Poland on a Perkins license. It is well known, 3-cylinder engine equipped with a DPA fuel injection pump and a direct injection fuel system. The engine reaches a maximum torque of 145–165 Nm @ 1200–1400 rpm, depending on the fuel pump settings. The most fundamental technical details of this engine are shown in Table 1. The engine was coupled with the eddy current dynamometer (engine dynamometer) made by AUTOMEX. According to the manufacturer’s data, the dynamometer used can control the recorded engine torque with an accuracy of 1 Nm.

Table 1.

Selected data of the AD3.152 engine. Developed from [15,42,43].

In this study, a variability of the combustion process expressed by the coefficient of variation of the mean indicated pressure COVMIP has been performed for the AD3.152 engine fueled with diethyl ether (DEE)/rapeseed oil (RO) blends and with diesel fuel (DF) as reference. A necessary experiment was repeated for the constant conditions of the engine work, expressed by the following torque and the crankshaft rotational speed:

- 100 Nm at 1200 rpm;

- 140 Nm at 1200 rpm;

- 100 Nm at 1600 rpm;

- 140 Nm at 1600 rpm.

For all these constant conditions, 1024 consecutive cycles were recorded each time for the engine fueled with tested fuels.

These conditions represent the medium and high load of the AD3.152 engine. All measurements were carried out within a few hours of one day for the same atmospheric conditions. Thus, the effect of the variability of these conditions on the recorded in-cylinder pressure variations in the engine combustion chamber is negligible. Before the tests began, the engine was adjusted according to the manufacturer’s data. Tests were started after the engine had warmed up to its normal operating temperature. Then the operating parameters (speed and load) of the engine fueled with the tested fuel were set and its thermal stabilization was ensured. As mentioned, under these conditions, the in-cylinder pressure variations were recorded for 1024 consecutive cycles. This number was limited by the technical capabilities of the measurement system used, equipped with the KPCI 3110 measurement board made by Keithley Instruments, Inc. All necessary parameters were sampled in relationship to the angular position of the engine crankshaft every 0.7 degrees of crankshaft angle (CA). For this purpose, the angle optical encoder made by INTRON Company was used. The in-cylinder pressure was measured by the AVL QC34D water-cooled piezoelectric sensor connected to a charge amplifier and then to the measurement board. The most important technical data of this sensor are listed in Table 2.

Table 2.

Technical data of the AVL QC34D sensor. Developed from [44].

Noise occurring in the signal of the in-cylinder pressure was hardware filtered using a low-pass filter with a cut-off frequency of 1 kHz.

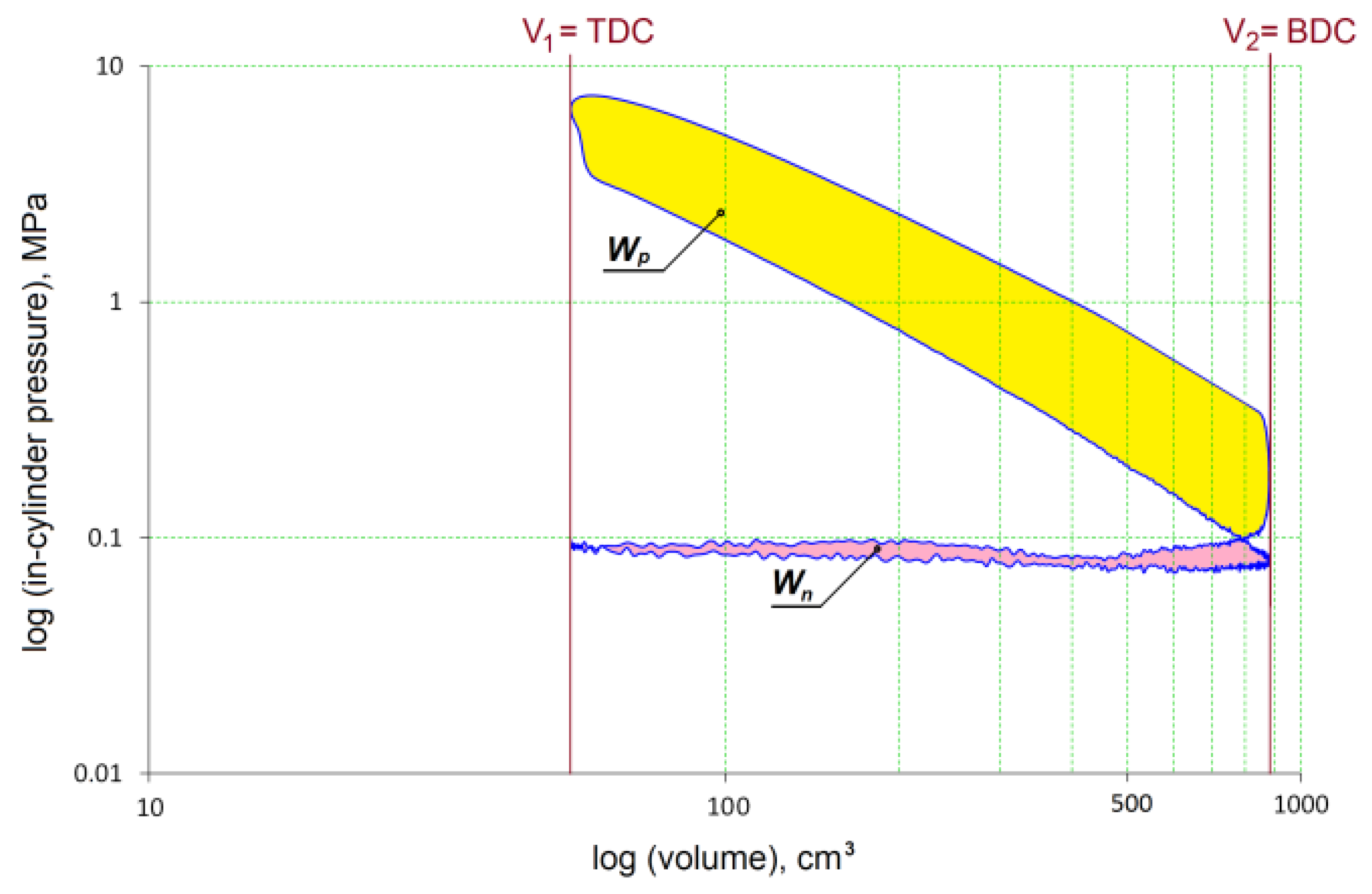

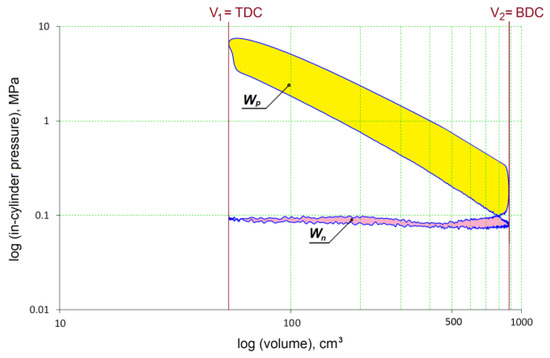

Recorded and denoised data were processed accordingly using MathCad ver. 14 software with the Wavelet Extension pack. In particular, the value of mean indicated pressure (MIP) has been calculated for all recorded cycles. The MIP is one of the most important parameters describing the combustion process. For this reason, it was selected to analyze the cycle-to-cycle variation of the combustion process in a diesel engine fueled with tested fuels. The MIP value is calculated by dividing the work per cycle by the cylinder volume displaced per cycle. As can be seen in the in-cylinder pressure vs. volume relationship (Figure 2), two distinct areas i.e., Wp and Wn are marked in yellow and pink color respectively. The upper Wp area has been formed between the compression and power strokes, whereas the lower Wn area represents the pumping work. The difference between the values of these areas corresponds to the indicated work Wi performed in the cylinder during one cycle of work.

Figure 2.

Variation of the in-cylinder pressure vs. volume of the AD3.152 engine (note: both axes are expressed in logarithmic scale for better visibility of Wp and Wn areas).

As mentioned above, the in-cylinder pressure variation can be expressed by the MIP value represented by the constant pressure acting on a piston within the one cycle of engine work. In simplicity the MIP can be calculated as follows:

where:

It is considered that in the case of a diesel engine operating in steady conditions, the variability of the fuel combustion process should be as low as possible. A commonly known measure of this cyclic variability is the coefficient of variation of mean indicated pressure COVMIP. The value of this coefficient can be calculated as follows:

where:

- SDMIP is standard deviation of MIP,

- MIPmean is the mean value of MIP.

It is expected that the value of the COVMIP should be as low as possible. For the stable fuel combustion process, the value of this parameter is usually less than 3%.

2.2. Tested Fuels

In this study, the DEE/RO fuel blends prepared in volumetric ratios 10:90, 20:80, 30:70 and 40:60 and a pure RO were examined. Moreover, a DF meeting the requirements of EN590 standard has been tested as reference fuel. RO tested in this research was made by KRUSZWICA Company. The reference DF was produced by PKN ORLEN and DEE with purity no less than 99.5% was made by POCH Company. Selected physicochemical properties of all test fuels were carried out at the Kazimierz Pulaski University of Technology and Humanities in Radom. Fundamental properties of these fuels i.e., DEE, RO, and DF are listed in Table 3.

Table 3.

Selected physicochemical properties of tested fuels. Developed from [15,42].

Diethyl ether (C4H10O) is considered an oxygenated fuel with an O2 content of 21.6% by mass. This ether can be easily blended with DF and plant oils, reducing their viscosity significantly. In this way, DEE/plant oils blends are more suitable as a fuel for diesel engines. An important advantage of DEE is its high derived cetane number (DCN). In studies carried out on an ignition quality tester (IQT), DCN even higher than 125 of DEE was obtained [45]. In the case of DF, the cetane number (CN) should be no less than 51 according to EN590 requirements. It should be pointed out that DCN and CN do not mean the same thing.

As mentioned, in this study DEE/RO blends were examined. The physicochemical properties of these blends were tested for volumetric ratios: 10:90, 20:80, 30:70, and 40:60. For these mixtures, selected physicochemical properties are listed in Table 4.

Table 4.

Physicochemical specification of tested blends.

Too high viscosity of plant oils is not favorable due to poor atomization of the fuel droplets injected into the combustion chamber. In addition a flow of a more viscous plant oil increases mechanical loses in the engine. As can be seen in Table 4, DEE reduces RO viscosity and surface tension significantly. These factors improve the fuel atomization affecting the quality of the combustion process. Moreover, the addition of DEE improves the low—temperature properties of RO, i.e., cold filter plugging point (CFPP) obtained for DEE30 and DEE40 allow us to consider these blends as a winter fuel. On the other hand, DEE has a lower heating value (LHV) compared with DF. For this reason, the engine fueled with DEE can reach a lower power and torque.

3. Results and Discussion

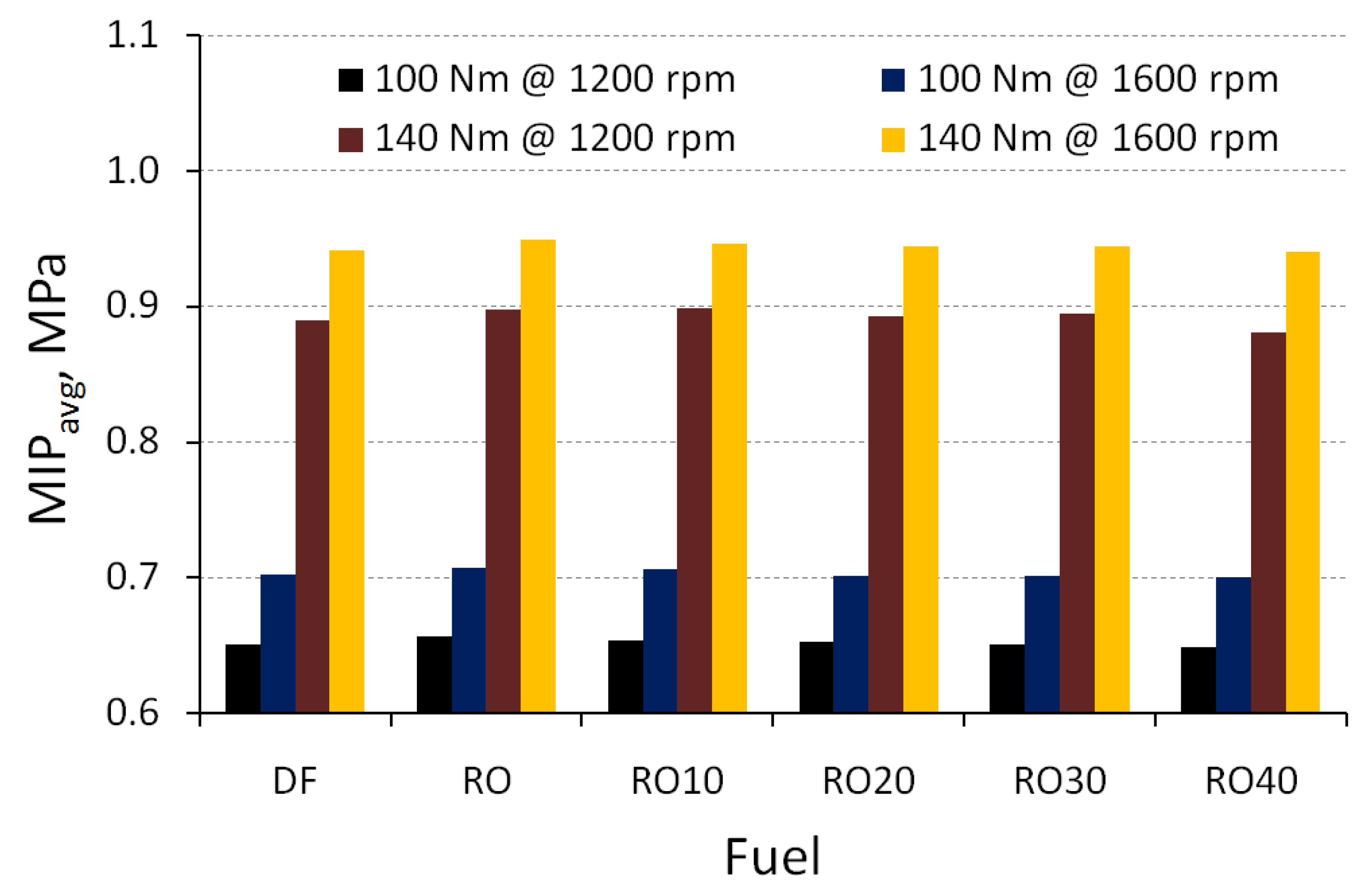

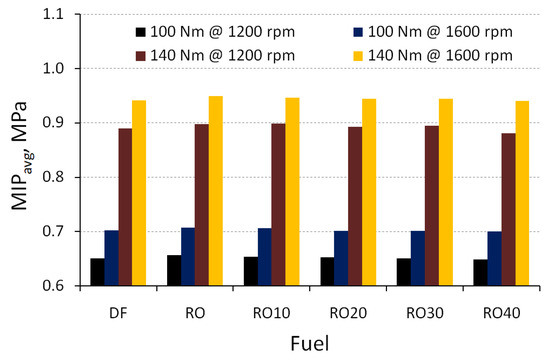

Figure 3 shows the average value of MIPavg calculated for 1024 consecutive cycles of the AD3.152 engine powered with tested fuels.

Figure 3.

The MIPavg calculated for the AD3.152 engine fueled with tested fuels.

As can be seen in Figure 3, the MIPavg calculated for the specified engine operating conditions is comparable for all tested fuels. In this case, the observed differences do not exceed 2% (for the same work conditions). However, it can be noted that the MIP values obtained for RO are slightly higher than for a DF. This is due to the higher viscosity of the plant fuel, which results in slightly higher pumping resistance. This requires a correspondingly larger dose of fuel injected into the combustion chamber, the combustion of which results in a noticeable increase in MIP value. It is noted, that increasing the rotational speed of the crankshaft increases the engine’s mechanical losses. For this reason, at the same output torque, it is necessary to adequately increase the dose of fuel burned, which results in an increase in the value of MIP. Taking into account Figure 3, it can be concluded that the tested engine can be powered with DEE/RO blends. Under the set load conditions, the engine powered by the tested fuels obtains comparable MIP values. However, further analysis of these fuels’ combustion process indicates that their combustion does not occur in the same repetitive way. This is visible in Figure 4, Figure 5, Figure 6 and Figure 7. These graphs show the MIP value calculated in each cycle of 1024 cycles recorded with the engine running on the test fuel.

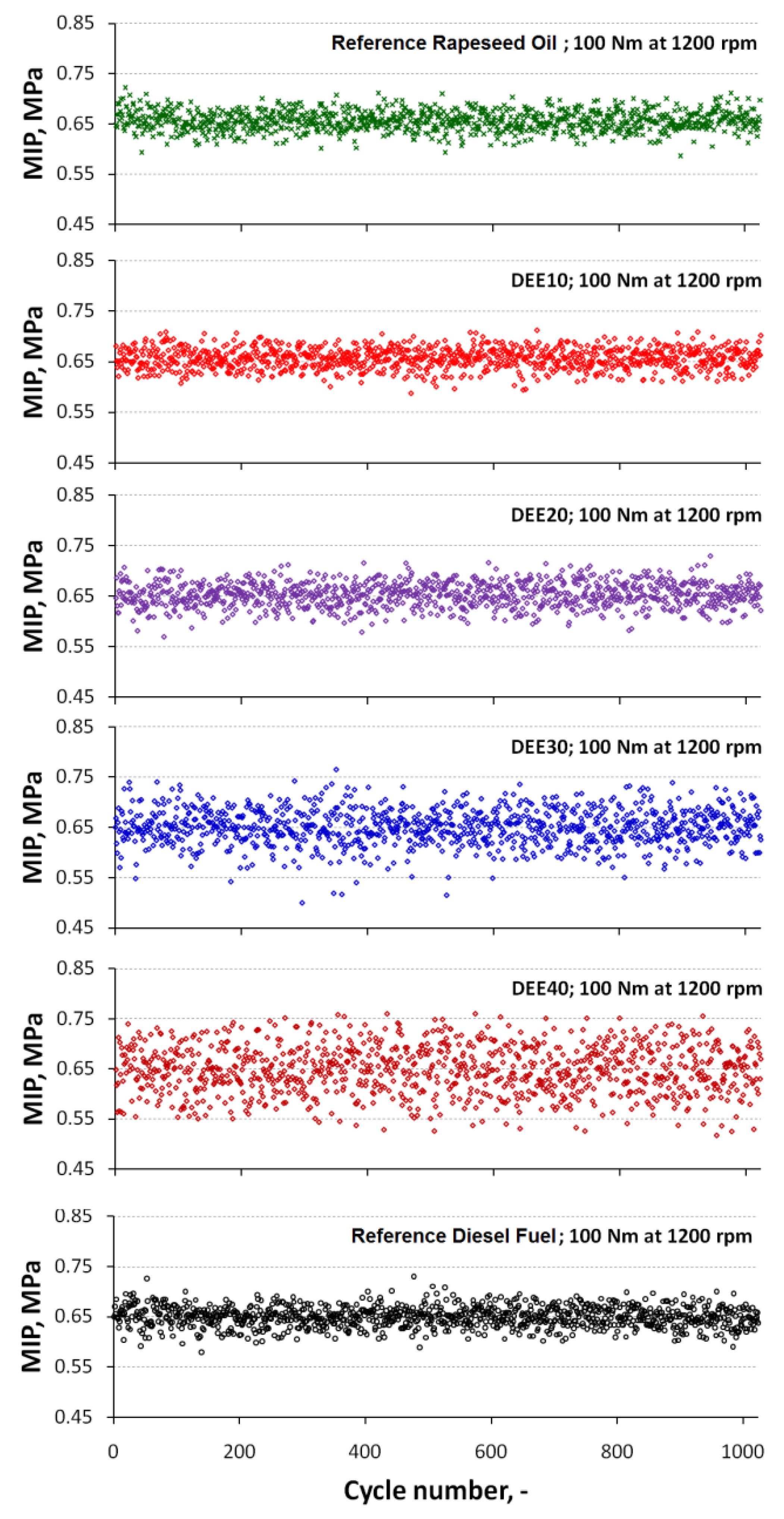

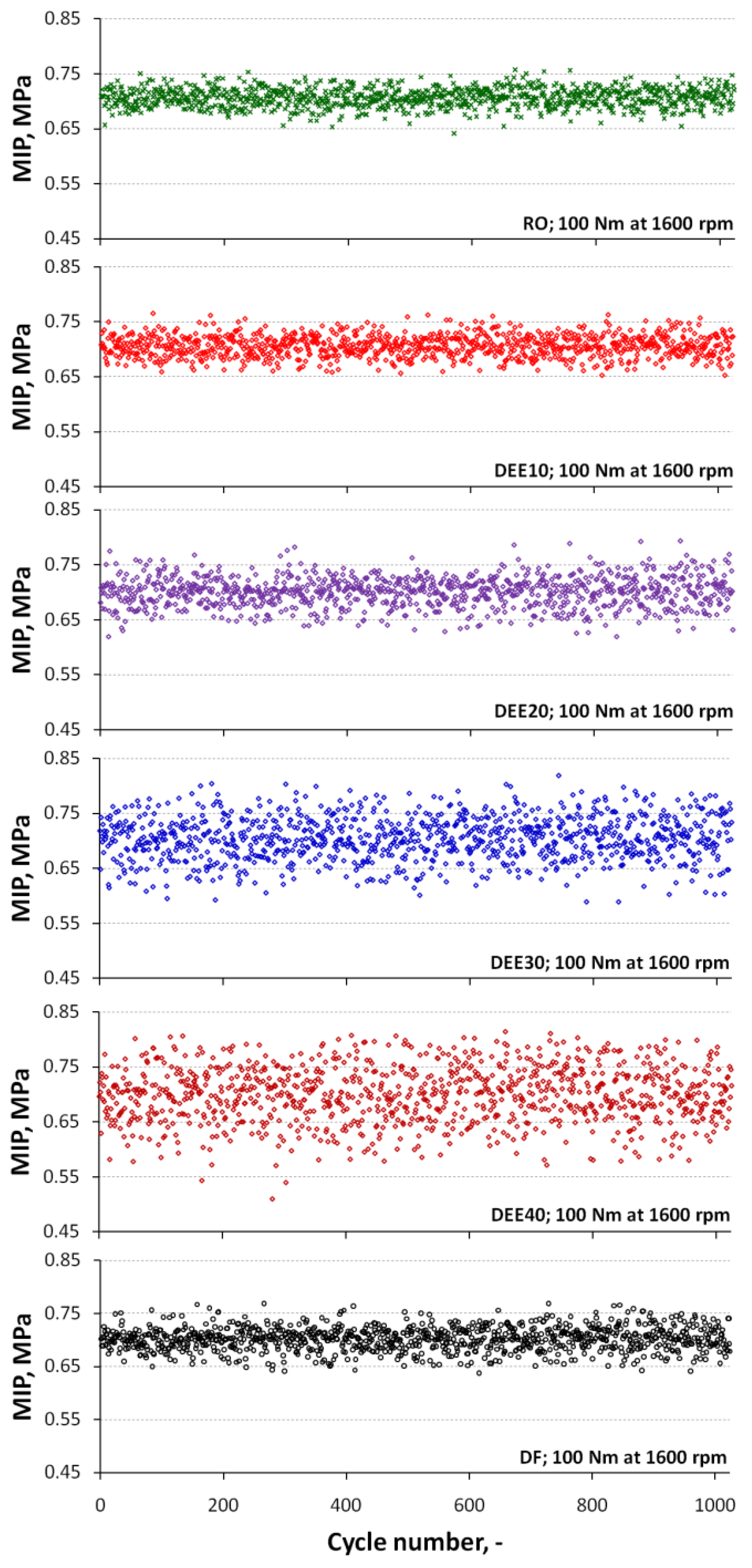

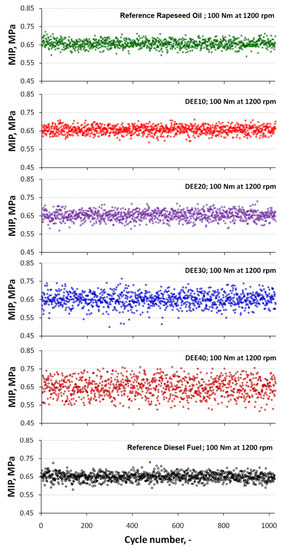

Figure 4.

MIP calculated for 1024 consecutive cycles recorded for the AD3.152 engine fueled with tested fuels, operated with 100 Nm at 1200 rpm.

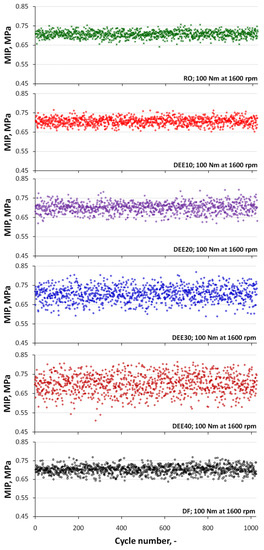

Figure 5.

MIP calculated for 1024 consecutive cycles recorded for the AD3.152 engine fueled with tested fuels, operated with 100 Nm at 1600 rpm.

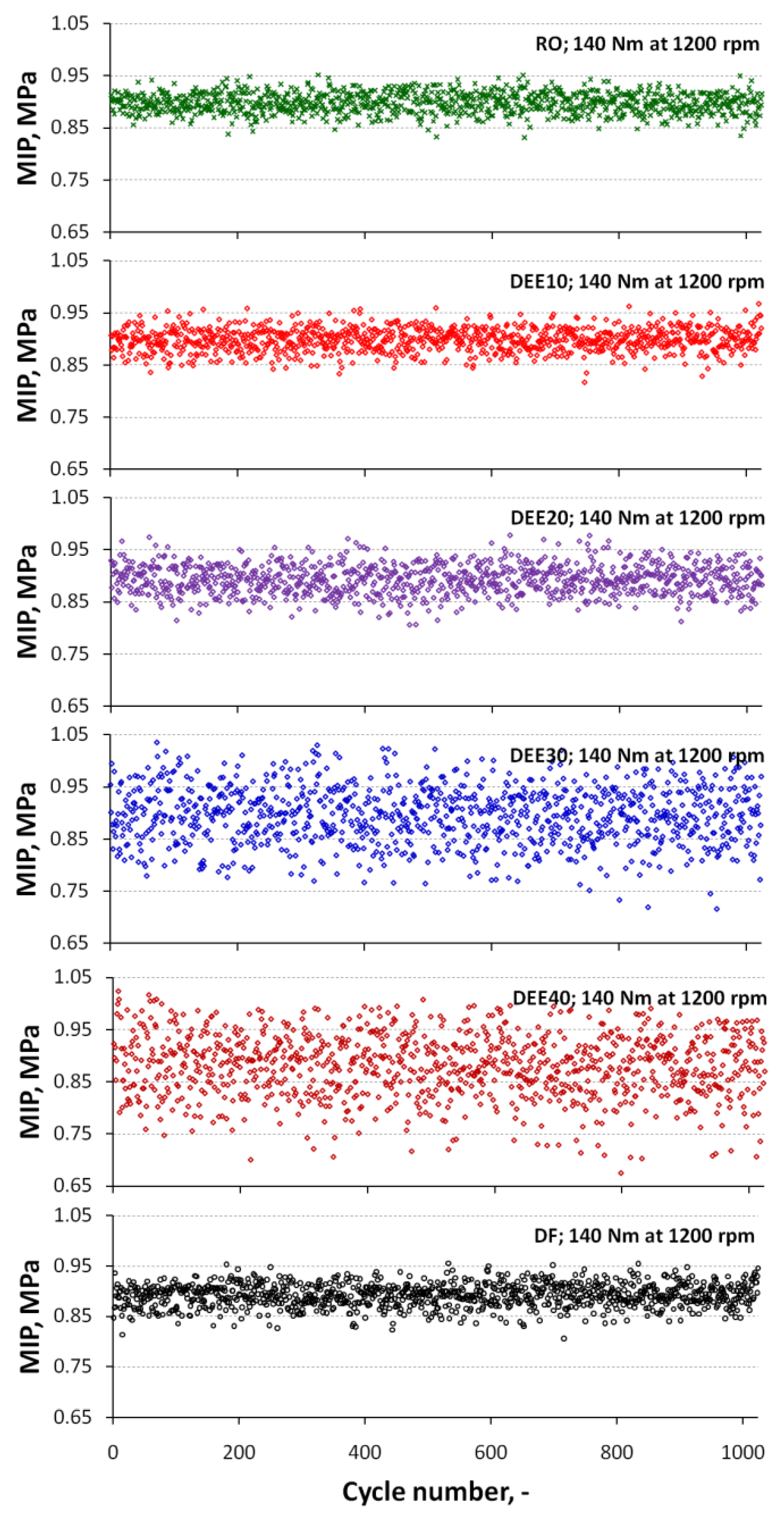

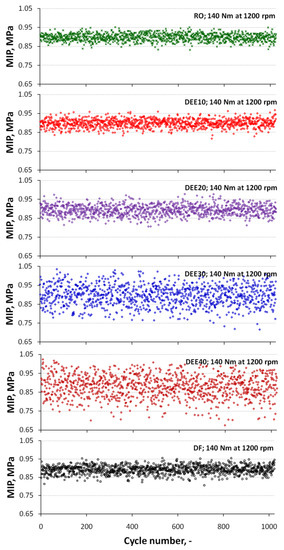

Figure 6.

MIP calculated for 1024 consecutive cycles recorded for the AD3.152 engine fueled with tested fuels, operated with 140 Nm at 1200 rpm.

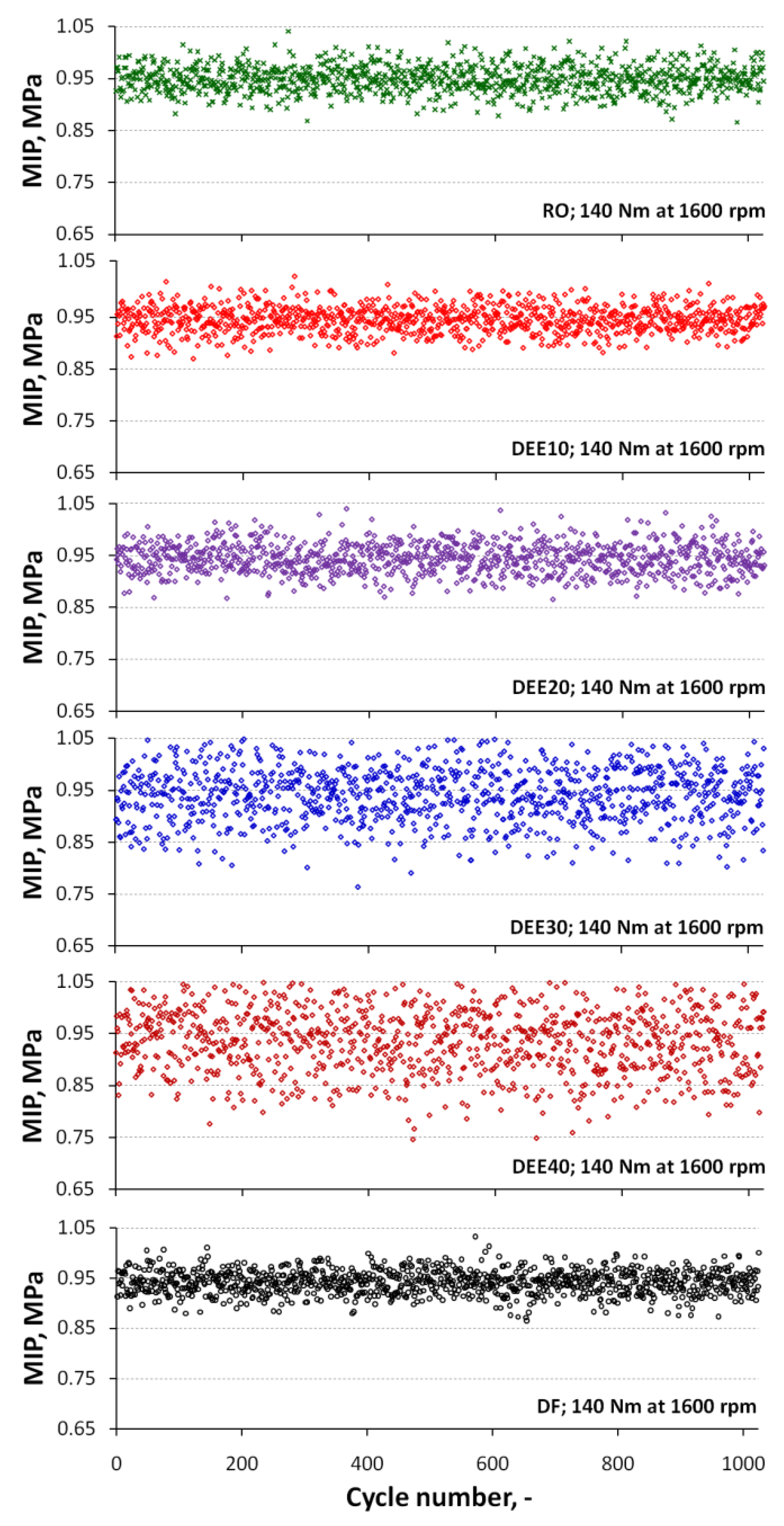

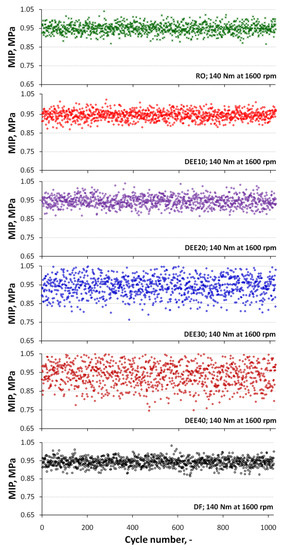

Figure 7.

MIP calculated for 1024 consecutive cycles recorded for the AD3.152 engine fueled with tested fuels, operated with 140 Nm at 1600 rpm.

Figure 4 represents data obtained for the AD3.152 engine worked with 100 Nm at 1200 rpm. In this case, the engine fueled with DF generates the average value of MIPavg = 0.65 MPa with the standard deviation σ = 0.021. A similar distribution of the measurement points is visible for the engine fueled with RO as well as with DEE10 and DEE20 i.e., fuels containing up to 20% by vol. of DEE in blend with RO. Further increase of DEE concentration in blend with RO causes an increase in the dispersion of the measurement points in relation to the average value. This is also visible for other engine operating conditions. Figure 5 represents the MIP value calculated for the engine operated with 100 Nm at 1600 rpm. In this case, the average MIP value calculated for DF is 0.702 MPa with SD = 0.022, whereas these parameters calculated for DEE40 equals 0.699 and 0.05, respectively.

Increasing the engine load from 100 to 140 Nm does not change the relationships observed so far. This is confirmed in Figure 6, which shows the MIP values obtained for the engine operating at a load of 140 Nm. In this case, the average MIP value varies between 0.881–0.899 MPa depending on the kind of fuel tested. Again, the greatest dispersion of the measurement points in relation to the average MIP value was observed for blends DEE30 and DEE40.

An increase in the crankshaft rotational speed at the same torque 140 Nm causes a further increase of the MIP average value. In detail, Figure 7 confirms that the standard deviation obtained for MIP in an engine fueled with DEE40 fuel is approx. 3 times higher compared with the AD3.152 engine fueled with DF.

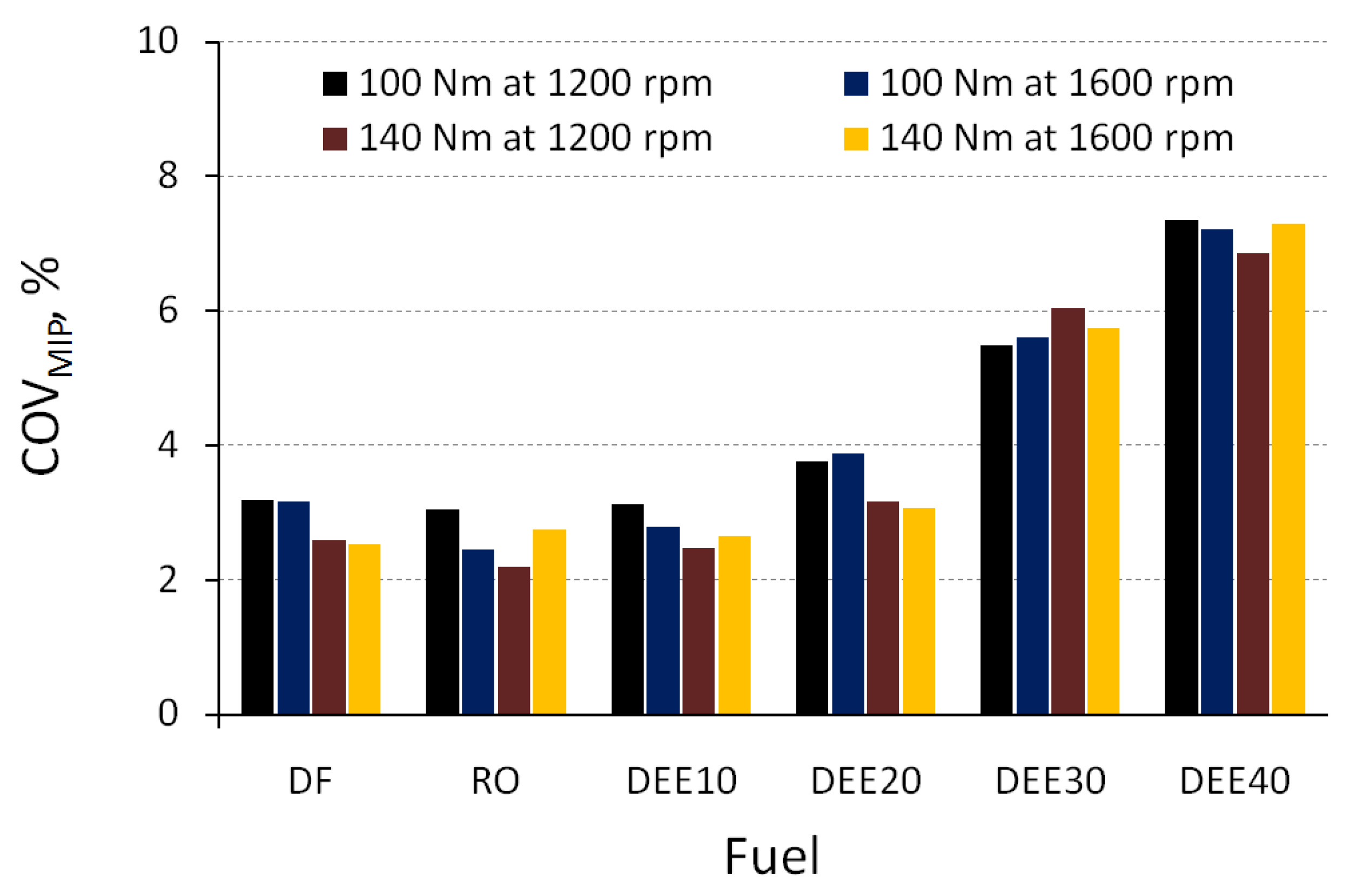

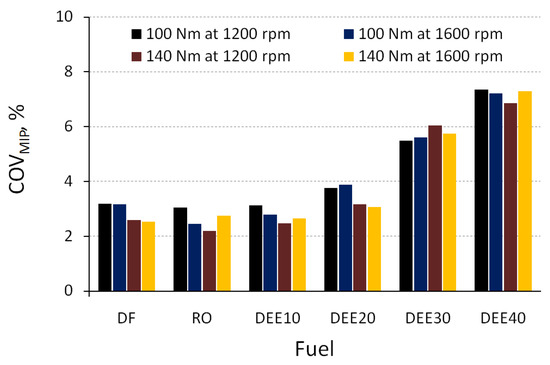

Figure 4, Figure 5, Figure 6 and Figure 7 show the dispersion of the measurement points obtained in the performed tests. While the summary of these results was quantified by the coefficient of variation of the mean indicated pressure COVMIP. Figure 8 confirms that for all measurement conditions, the COVMIP value is comparable for the engine fueled with DF, RO, and DEE/RO blends containing up to 20% by vol. of DEE in a mixture with RO. In the case of DEE30 and DEE40 the COVMIP value is approx. two or even three times higher than COVMIP calculated for other tested fuels, in particular for DF as reference.

Figure 8.

Impact of tested fuels on COVMIP calculated for the AD3.152 engine.

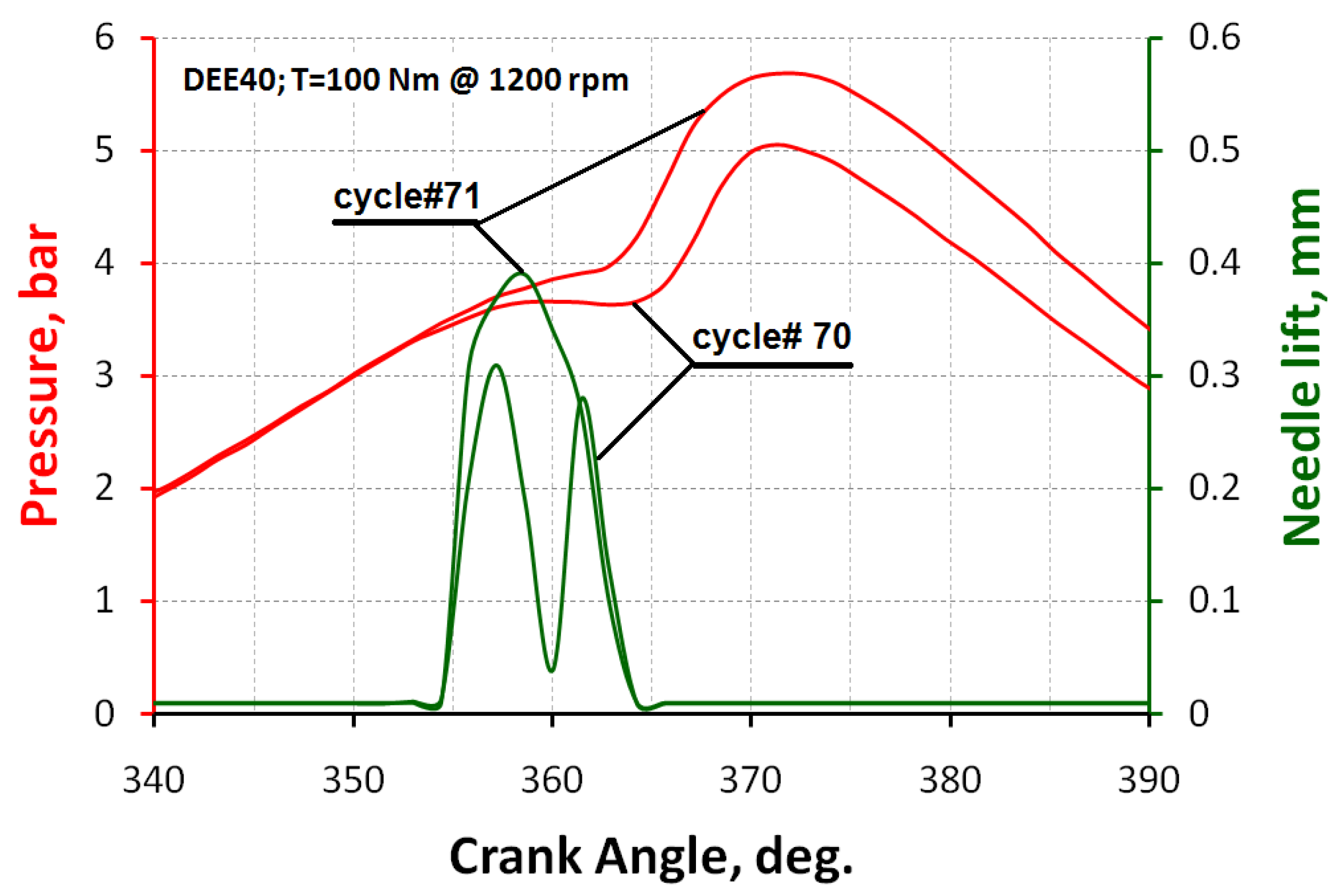

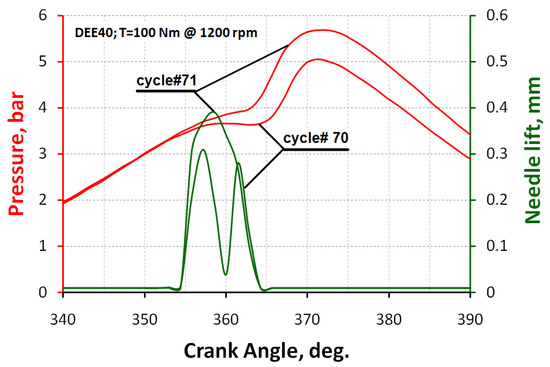

The obtained results showed that the combustion process of RO containing large amounts of DEE in the blend is more unstable. Such an engine obtains the appropriate torque, but its uniformity of operation is correspondingly worse than in the case of diesel fuel. The reason for the higher variability of the combustion process of DEE/RO blends is the disturbance of the fuel injection process, as shown in the example Figure 9. This figure shows two consecutive work cycles, i.e., no. 70 and 71 recorded in the AD3.152 engine, operated with 100 Nm at 1200 rpm and fueled with DEE40 blend.

Figure 9.

Variation of the in-cylinder pressure and the fuel injector needle lift vs. CA recorded at cycle no. 70 and 71 of the engine work.

The AD3.152 engine fueled with DEE40 blend and operated with 100 Nm at 1200 rpm generates the MIPavg = 0.648 bar. However, the exemplary two consecutive work cycles of this engine are significantly different. At cycle no. 70, the MIP = 0.576 bar, whereas in the next cycle no. 71 the MIP = 0.731 bar. The lower MIP in cycle no. 70 was caused by a disturbance in the fuel injection process. In particular, the fuel nozzle needle has lifted to a lower height and the fuel dose was divided. This caused the injection of a correspondingly smaller dose of fuel into the combustion chamber and a temporary reduction in the rotational speed of the crankshaft. In the next engine cycle, the control system increased the fuel dose so as to achieve the set torque value. For this reason, the MIP in cycle 71 increased to 0.731 bar. This time the fuel injection process was successful, the fuel nozzle needle has lifted to the full height, injecting the right dose of fuel into the combustion chamber. It can be assumed that the cause of malfunctions in the fuel injector work is vapor lock formed in the fuel system caused by the evaporation of volatile DEE. Our experience shows that it is also the reason for the difficult start-up of an engine fueled with vegetable oil with a large DEE content.

4. Conclusions

Plant-based oils can be used as a diesel fuel. However, due to their considerable viscosity, they should be suitably modified to resemble diesel fuel with their physicochemical properties. One such method is to blend plant oil with, for example, suitable alcohols or ethers. Literature reports indicate that such a valuable addition to plant oil can be DEE. This ether also has a positive effect on reducing emissions of some harmful components of exhaust gases. In contrast, the present study showed that the use of high concentrations of DEE in a mixture with RO causes greater disruption of the combustion process. Analysis of the COVMIP showed that the use of DEE in volumes above 20% in a mixture with RO is unfavorable, as it causes a significant increase in the COVMIP. In the case of the AD3.152 engine fueled with DEE30 and DEE40, the COVMIP was even 3 times higher than COVMIP obtained for the engine fueled with DF, RO, and DEE10 and DEE20. It means that from cycle to cycle the combustion process of DEE30 and DEE40 is more and more unstable. In this case, engine vibration and the temporary load of the crankshaft increase, which should be considered a disadvantageous feature of the engine powered by the DEE/RO fuel blend. The identified disturbances in the combustion of DEE/RO mixtures may be caused by the so-called vapor lock formed in the fuel system during the evaporation of volatile DEE. Limiting this phenomenon may require the use of an appropriate system to cool the fuel supplied to the injectors.

Author Contributions

Conceptualization, K.G., R.S. and D.T.; methodology, K.G. and R.S.; software, K.G.; validation, J.M. and D.T.; formal analysis, R.S., J.M.; investigation, K.G. and R.S.; resources, J.M. and D.T.; data curation, K.G., R.S. and J.M.; writing—original draft preparation, K.G., R.S. and D.T.; writing—review and editing, J.M.; visualization, K.G. and R.S.; supervision, K.G.; project administration, D.T.; and funding acquisition, D.T., R.S. and J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| ASTM | American Society for Testing and Materials |

| BDC | Bottom dead center |

| CA | Crank angle |

| CAV | Charles Anthony Vandervell |

| CCVs | Cycle-to-cycle variations |

| CFPP | Cold filter plugging point |

| CI | Compression ignition |

| CN | Cetane number |

| CP | Cloud point |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| COVMIP | Coefficient of variation of mean indicated pressure |

| DCN | Derived cetane number |

| DEE10 | 10% DEE by vol. in blend with 90% RO by vol. |

| DEE20 | 20% DEE by vol. in blend with 80% RO by vol. |

| DEE30 | 30% DEE by vol. in blend with 70% RO by vol. |

| DEE40 | 40% DEE by vol. in blend with 60% RO by vol. |

| DEE | Diethyl ether |

| DME | Dimethyl ether |

| DF | Diesel fuel |

| DI | Direct injection |

| DPA | Distributor pump assembly |

| EN | European norm |

| FAME | Fatty acids methyl esters |

| FP | Flash point |

| HC | Hydrocarbon |

| HCCI | Homogeneous charge compression ignition |

| IQT | Ignition quality tester |

| MIP | Mean indicated pressure |

| LHV | Lower heating value |

| NOX | Nitrogen oxides |

| PP | Pour point |

| RO | Rapeseed oil |

| rpm | Revolutions per minute |

| SD | Standard deviation |

| SVO | Straight vegetable oil |

| T | Torque |

| TDC | Top dead center |

| THC | Total hydrocarbons |

| V1 | Combustion chamber volume |

| V2 | Cylinder volume |

References

- World Energy Outlook 2022. IEA, October 2022. Available online: https://iea.blob.core.windows.net/assets/c282400e-00b0-4edf-9a8e-6f2ca6536ec8/WorldEnergyOutlook2022.pdf (accessed on 1 November 2022).

- Wu, G.; Wang, X.; Abubakar, S.; Li, Y. A skeletal mechanism for biodiesel-dimethyl ether combustion in engines. Fuel 2022, 325, 124834. [Google Scholar] [CrossRef]

- Srivastava, A.; Prasad, R. Triglycerides-based diesel fuels. Renew. Sustain. Energy Rev. 2000, 4, 111–133. [Google Scholar] [CrossRef]

- Ariemma, G.B.; Bozza, P.; de Joannon, M.; Sabia, P.; Sorrentino, G.; Ragucci, R. Alcohols as energy carriers in MILD combustion. Energy Fuels 2021, 35, 7253–7264. [Google Scholar] [CrossRef]

- Verhelst, S.; Turner, J.W.; Sileghem, L.; Vancoillie, J. Methanol as a fuel for internal combustion engines. Prog. Energy Combust. Sci. 2018, 70, 43–88. [Google Scholar] [CrossRef]

- Ramadhas, A.; Jayaraj, S.; Muraleedharan, C. Use of vegetable oils as I.C. engine fuels—A review. Renew. Energy 2004, 29, 727–742. [Google Scholar] [CrossRef]

- Sezer, I. Thermodynamic, performance and emission investigation of a diesel engine running on dimethyl ether and diethyl ether. Int. J. Therm. Sci. 2011, 50, 1594–1603. [Google Scholar] [CrossRef]

- Yoon, H.; Bae, C. Post injection in a compression ignition engine fueled with dimethyl-ether. Fuel 2013, 103, 1123–1131. [Google Scholar] [CrossRef]

- Catizzone, E.; Freda, C.; Braccio, G.; Frusteri, F.; Bonura, G. Dimethyl ether as circular hydrogen carrier: Catalytic aspects of hydrogenation/dehydrogenation steps. J. Energy Chem. 2021, 58, 55–77. [Google Scholar] [CrossRef]

- Ibrahim, A. Investigating the effect of using diethyl ether as a fuel additive on diesel engine performance and combustion. Appl. Therm. Eng. 2016, 107, 853–862. [Google Scholar] [CrossRef]

- Sezer, I. A review study on the using of diethyl ether in diesel engines: Effects on NOx emissions. Int. J. Automot. Eng. Technol. 2018, 7, 164–183. [Google Scholar] [CrossRef]

- Krishnamoorthi, M.; Malayalamurthi, R. A review on effect of diethyl ether additive on combustion, performance and emission characteristics of a diesel and biodiesel/vegetable oil fuelled engine. Adv. Nat. Appl. Sci. 2016, 10, 9–17. [Google Scholar]

- Aguado-Deblas, L.; Hidalgo-Carrillo, J.; Bautista, F.M.; Luna, D.; Luna, C.; Calero, J.; Posadillo, A.; Romero, A.A.; Estevez, R. Diethyl ether as an oxygenated additive for fossil diesel/vegetable oil blends: Evaluation of performance and emission quality of triple blends on a diesel engine. Energies 2020, 13, 1542. [Google Scholar] [CrossRef]

- Devaraj, J.; Robinson, Y.; Ganapathi, P. Experimental investigation of performance, emission and combustion characteristics of waste plastic pyrolysis oil blended with diethyl ether used as fuel for diesel engine. Energy 2015, 85, 304–309. [Google Scholar] [CrossRef]

- Górski, K.; Smigins, R.; Longwic, R. Research on physico-chemical properties of diethyl ether/linseed oil blends for the use as fuel in diesel engines. Energies 2020, 13, 6564. [Google Scholar] [CrossRef]

- Smigins, R.; Zakis, A. Impact of diethyl ether/rapeseed oil blends on performance and emissions of a light-duty diesel vehicle. Energies 2020, 13, 3788. [Google Scholar] [CrossRef]

- Issayev, G.; Giri, B.R.; Elbaz, A.M.; Shrestha, K.P.; Mauss, F.; Roberts, W.L.; Farooq, A. Combustion behavior of ammonia blended with diethyl ether. Proc. Combust. Inst. 2021, 38, 499–506. [Google Scholar] [CrossRef]

- Ariemma, G.B.; Sorrentino, G.; Sabia, P.; Ragucci, R.; de Joannon, M. MILD combustion of methanol, ethanol and 1-butanol binary blends with ammonia. Proc. Combust. Inst. 2022, in press. [Google Scholar] [CrossRef]

- Cai, T.; Zhao, D. Enhancing and assessing ammonia-air combustion performance by blending with dimethyl ether. Renew. Sustain. Energy Rev. 2022, 156, 112003. [Google Scholar] [CrossRef]

- Shi, J.; Wang, T.; Zhao, Z.; Wu, Z.; Zhang, Z. Cycle-to-cycle variation of a diesel engine fueled with fischer—Tropsch fuel synthesized from coal. Appl. Sci. 2019, 9, 2032. [Google Scholar] [CrossRef]

- Koizuml, I.; Gyakushi, N.; Takamoto, Y. Study on the cycle-by-cycle variation in diesel engines. Bull. JSME 1977, 20, 869–876. [Google Scholar] [CrossRef]

- Wing, R.D. The rotary fuel-injection pump as a source of cyclic variation in diesel engines, and its effect on nitric oxide emissions. Proc. Inst. Mech. Eng. 1975, 189, 497–505. [Google Scholar] [CrossRef]

- Sczomak, D.P.; Henein, N.A. Cycle-to-cycle variation with low ignition quality fuels in a cfr diesel engine. SAE Int. 1979, 790924. [Google Scholar] [CrossRef]

- Ozdor, N.; Dulger, M.; Sher, E. Cyclic variability in spark ignition engines a literature survey. SAE Tech. Pap. 1994, 940987. [Google Scholar] [CrossRef]

- Murayama, T.; Yamada, T.; Miyamoto, N.; Chikahisa, T. Nature and reduction of cycle-to-cycle combustion engine with ethanol-diesel fuel blends. J. Appl. Entomol. 1983, 135, 320–325. [Google Scholar] [CrossRef]

- Bittle, J.; Knight, B.M.; Jacobs, T.J. Biodiesel effects on cycle-to-cycle variability of combustion characteristics in a common-rail medium-duty diesel engine. SAE Int. 2010, 2010-01-0867. [Google Scholar] [CrossRef]

- Attai, Y.A.; El-Feky, S.M.; Radwan, M.S. Cyclic variations in SI engines fuelled by blends of jojoba biogasoline and petroleum gasoline. In Proceedings of the International Conference on Sustainable Energy and Environmental Protections (SEEP), Maribor, Slovenia, 20–23 August 2013; pp. 20–23. [Google Scholar]

- Yang, L.; Zare, A.; Bodisco, T.A.; Nabi, N.; Liu, Z.; Brown, R.J. Analysis of cycle-to-cycle variations in a common-rail compression ignition engine fuelled with diesel and biodiesel fuels. Fuel 2020, 290, 120010. [Google Scholar] [CrossRef]

- Turkcan, A. The effects of different types of biodiesels and biodiesel-bioethanol-diesel blends on the cyclic variations and correlation coefficient. Fuel 2020, 261, 116453. [Google Scholar] [CrossRef]

- Bekal, S.; Babu, T.P.A. An analysis of cycle-by-cycle fluctuation in combustion parameter in CI engine operation for various bio-fuels. Energy Sources Part A Recover. Util. Environ. Eff. 2011, 33, 1792–1801. [Google Scholar] [CrossRef]

- Longwic, R.; Sen, A.K.; Gorski, K.; Lotko, W.; Litak, G. Cycle-to-cycle variation of the combustion process in a diesel engine powered by different fuels. J. Vibroengineering 2011, 13, 120–127. [Google Scholar]

- Sen, A.K.; Longwic, R.; Litak, G.; Górski, K. Analysis of cycle-to-cycle pressure oscillations in a diesel engine. Mech. Syst. Signal Proc. 2008, 22, 362–373. [Google Scholar] [CrossRef]

- Ali, O.M.; Mamat, R.; Masjuki, H.; Abdullah, A.A. Analysis of blended fuel properties and cycle-to-cycle variation in a diesel engine with a diethyl ether additive. Energy Convers. Manag. 2016, 108, 511–519. [Google Scholar] [CrossRef]

- Santoso, W.B.; Bakar, R.A.; Ariyono, S.; Cholis, N. Study of cyclic variability in diesel hydrogen dual fuel engine combustion. Int. J. Mech. Mech. Eng. 2012, 12, 52–56. [Google Scholar]

- Cheng, Q.; Ahmad, Z.; Kaario, O.; Vuorinen, V.; Larmi, M. Experimental study on tri-fuel combustion using premixed methane-hydrogen mixtures ignited by a diesel pilot. Int. J. Hydrogen Energy 2021, 46, 21182–21197. [Google Scholar] [CrossRef]

- Selim, M.Y. Effect of engine parameters and gaseous fuel type on the cyclic variability of dual fuel engines. Fuel 2005, 84, 961–971. [Google Scholar] [CrossRef]

- Jagadish, C.; Gumtapure, V. Experimental studies on cyclic variations in a single cylinder diesel engine fuelled with raw biogas by dual mode of operation. Fuel 2020, 266, 117062. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, F.; Zhao, Y.; Li, D.; Lei, X. Study on cycle-by-cycle variations in a diesel engine with dimethyl ether as port premixing fuel. Appl. Energy 2015, 143, 58–70. [Google Scholar] [CrossRef]

- Shere, A.; Subramanian, K. Experimental investigation on effects of equivalence ratio on combustion with knock, performance, and emission characteristics of dimethyl ether fueled CRDI compression ignition engine under homogeneous charge compression ignition mode. Fuel 2022, 322, 124048. [Google Scholar] [CrossRef]

- Attai, Y.A.; Abu-Elyazeed, O.S.; Elbeshbeshy, R.; Gassour, H.; Gad, M.S. Experimental cyclic variations of diesel engine burning pyrolysis castor oil blends. Adv. Mech. Eng. 2020, 12, 1–10. [Google Scholar] [CrossRef]

- Kyrtatos, P.; Brückner, C.; Boulouchos, K. Cycle-to-cycle variations in diesel engines. Appl. Energy 2016, 171, 120–132. [Google Scholar] [CrossRef]

- Górski, K.; Smigins, R.; Matijošius, J.; Rimkus, A.; Longwic, R. Physicochemical properties of diethyl ether—Sunflower oil blends and their impact on diesel engine emissions. Energies 2022, 15, 4133. [Google Scholar] [CrossRef]

- Lotko, W.; Hernik, A.; Stobiecki, J.; Kosmanis, T.; Gorska, M. Smoke emission of AD3.152 engine fuelled with rapeseed oil/diethyl ether blends. Arch. Automot. Eng. Arch. Motoryz. 2018, 80, 65–76. [Google Scholar] [CrossRef]

- AVL. Pressure Sensors for Combustion Analysis. Available online: https://www.avl.com/documents/10138/885965/AVL+Pressure+Sensors+for+Combustion+Analysis/6c844a54-7a84-429d-8e57-4f34e948f95d (accessed on 2 November 2022).

- Bailey, B.; Eberhardt, J.; Goguen, S.; Erwin, J. Diethyl ether (DEE) as a renewable diesel fuel. SAE Trans. 1997, 106, 1578–1584. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).