Working with Different Building Energy Performance Tools: From Input Data to Energy and Indoor Temperature Predictions

Abstract

:1. Introduction

1.1. State of Art

1.2. Objectives

2. Materials and Methods

2.1. Location and Meteorological Data

- Pw—is the wind pressure, Pa;

- Cw—is the pressure coefficient, 1;

- ρ—is the air density, kg m−3;

- v—is the wind speed at roof height of building, m s−1.

2.2. Geometric Model and Building Components

- -

- wind speed: 5.5 m s−1;

- -

- indoor air temperature: 21 °C;

- -

- outdoor air temperature: −18 °C.

2.3. Boundary System Conditions

2.3.1. Heat Pumps

2.3.2. Ventilation System

- qtot—is the total ventilation rate for the breathing zone, L s−1;

- a—is the design value for the number of persons in the room, 1;

- qp —is the ventilation rate for occupancy per person, L s−1 person−1;

- AR —is the floor area, m2;

- qB —is the ventilation rate for emissions from building, L s−1 m−2.

2.3.3. Auxiliary Devices

2.4. Internal Heat Gains, Lighting, and Air Velocity

- Return Air Fraction—is the fraction of the heat from lights that is transported out of the room and into the zone return air, 1;

- Fraction Radiant—is the fraction of heat from light that goes into the zone as long-wave radiation, 1;

2.5. Output Comparisons

2.5.1. Temperatures

Relative Differences

- CPH1winter—is the overall number of hours for Copenhagen with to ≥ 20 °C, 1;

- CPH1summer—is the overall number of hours for Copenhagen with to ≤ 26 °C, 1.

Absolute Differences

- Δθ%—is the fraction of the time that the temperature difference values fall into a specific range, %;

- n—is the number of hours that the temperature difference values fall into a specific range, 1.

2.5.2. Energy

Relative Differences

- ΔEF—is the difference in energy flows for each component, %;

- CPH1—are energy flows for Copenhagen in scenario 1 (small window), kWh;

- CPH2—are energy flows for Copenhagen in scenario 2 (large window), kWh.

- ΔC—is the cooling difference between the two scenarios, %;

- ΔH—is the heating difference between the two scenarios, %;

- CPH1—is Copenhagen in scenario 1 (small window), kWh m−2;

- CPH2—is Copenhagen in scenario 2 (large window), kWh m−2.

Absolute Differences

- ΔEF—are the differences in energy flows for each component, %;

- CPH1IDA—is Copenhagen in scenario 1 for IDA ICE, kWh;

- CPH1DB—is Copenhagen in scenario 1 for Design Builder, kWh.

- ΔC—is the cooling difference between IDA ICE and Design Builder, %;

- ΔH—is the heating difference between IDA ICE and Design Builder, %;

- CPH1IDA—is Copenhagen in scenario 1 for IDA ICE, kWh m−2;

- CPH1DB—is Copenhagen in scenario 1 for Design Builder, kWh m−2.

3. Results and Discussion

3.1. U-Value of Building Components

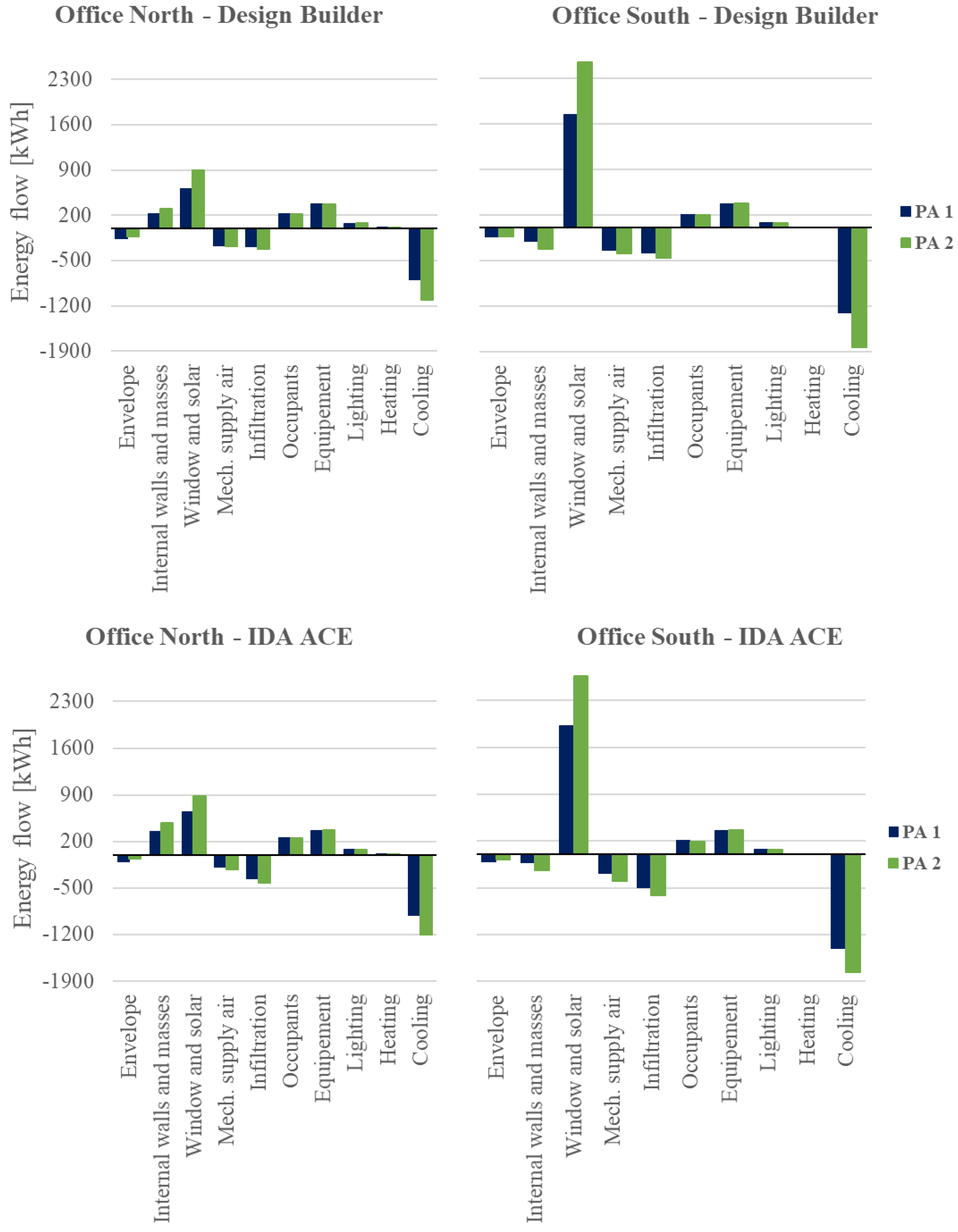

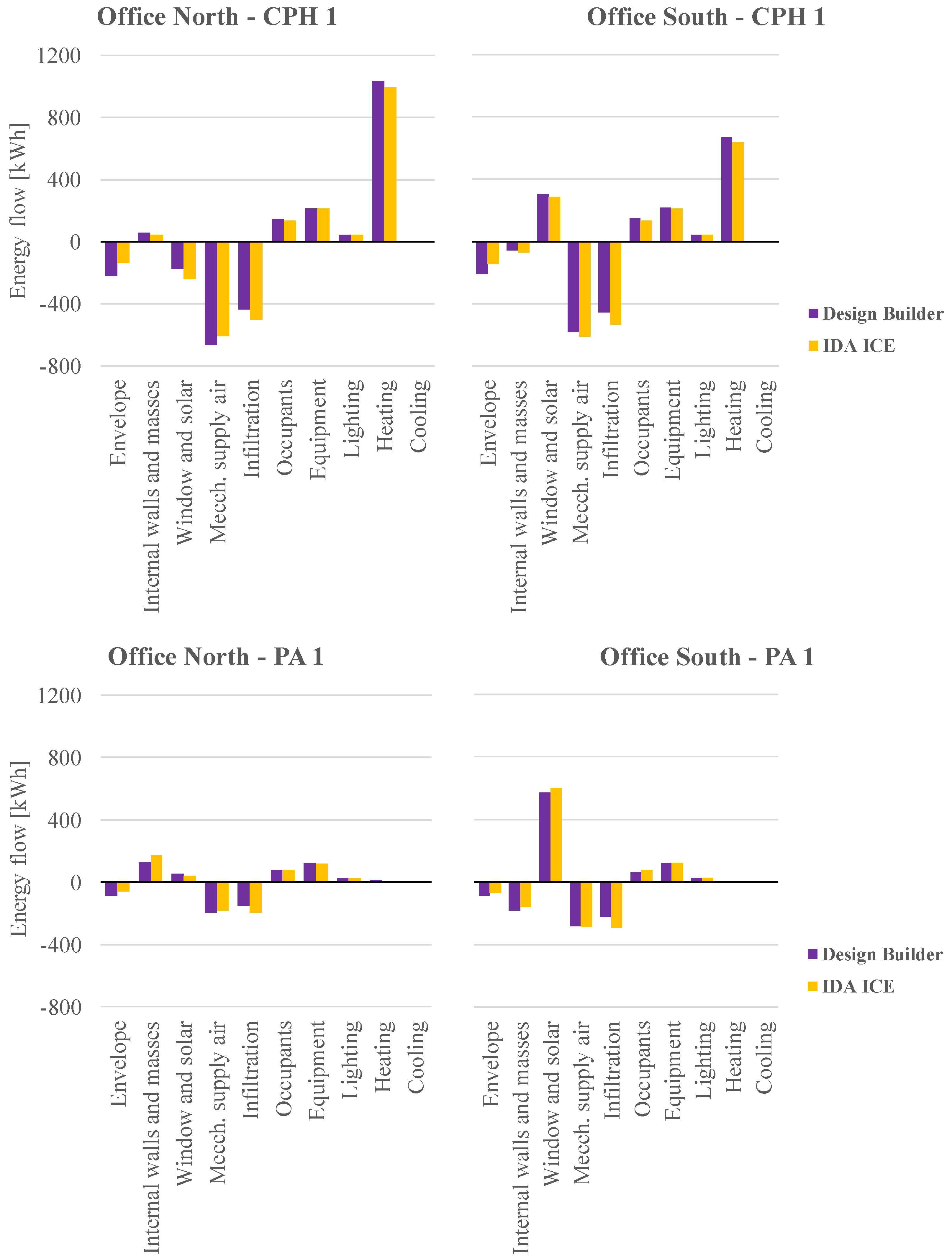

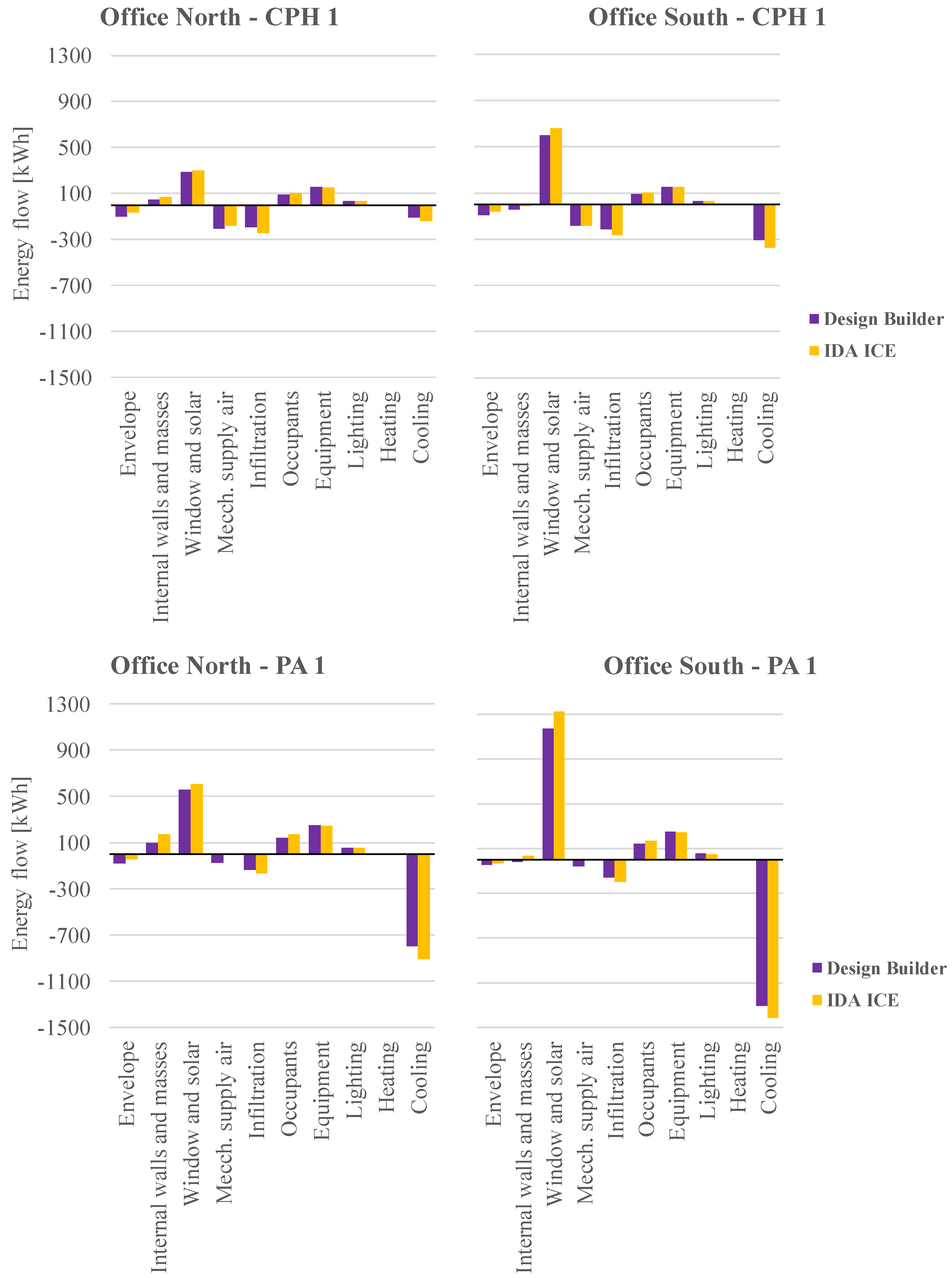

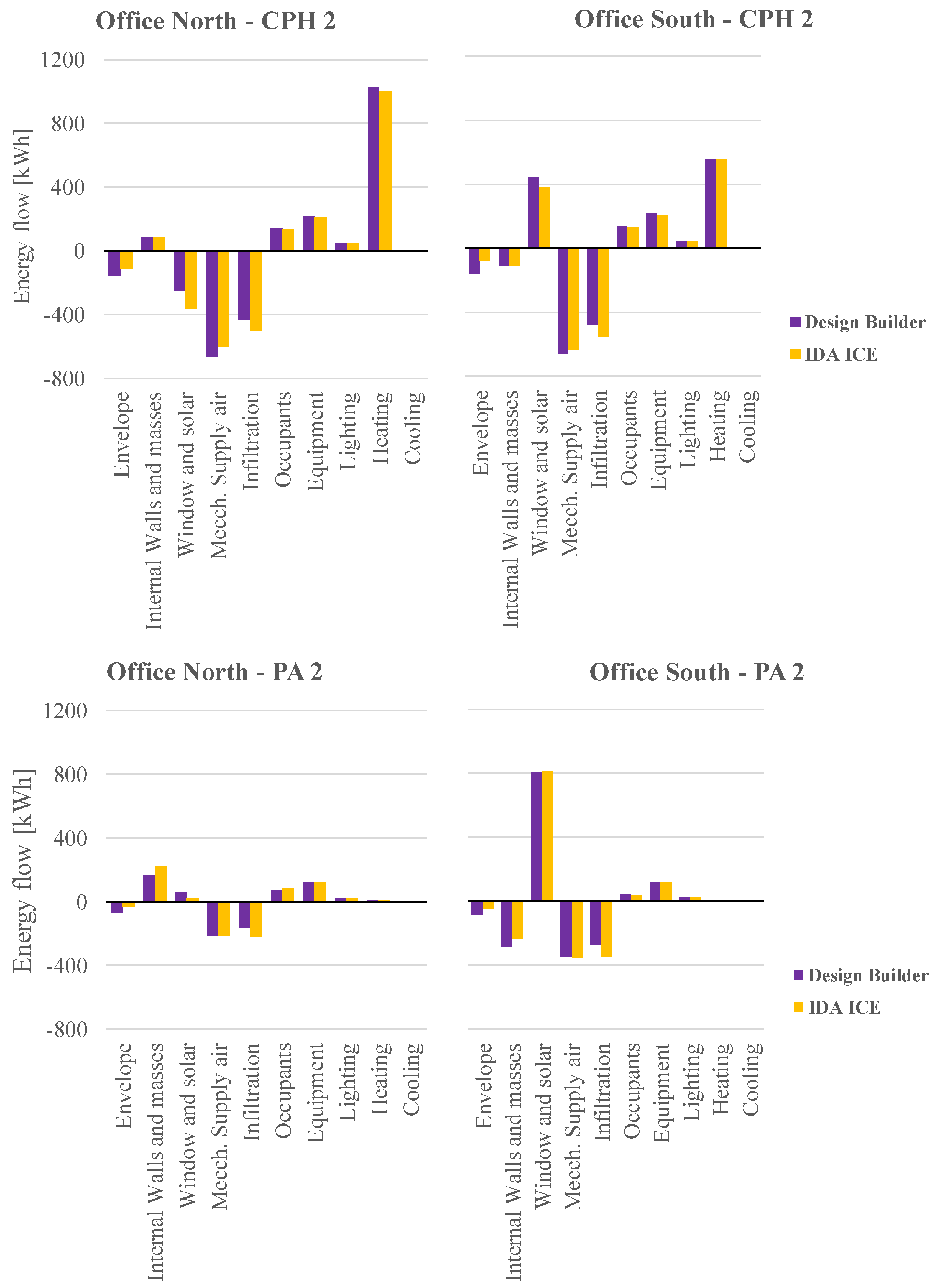

3.2. First Scenario vs. Second Scenario

3.2.1. Operative Temperature

3.2.2. Energy Flows

3.2.3. Delivered Energy

3.3. First Scenario (Small Window) Design Builder vs. IDA ICE

3.3.1. Temperatures

3.3.2. Energy Flows

3.3.3. Delivered Energy

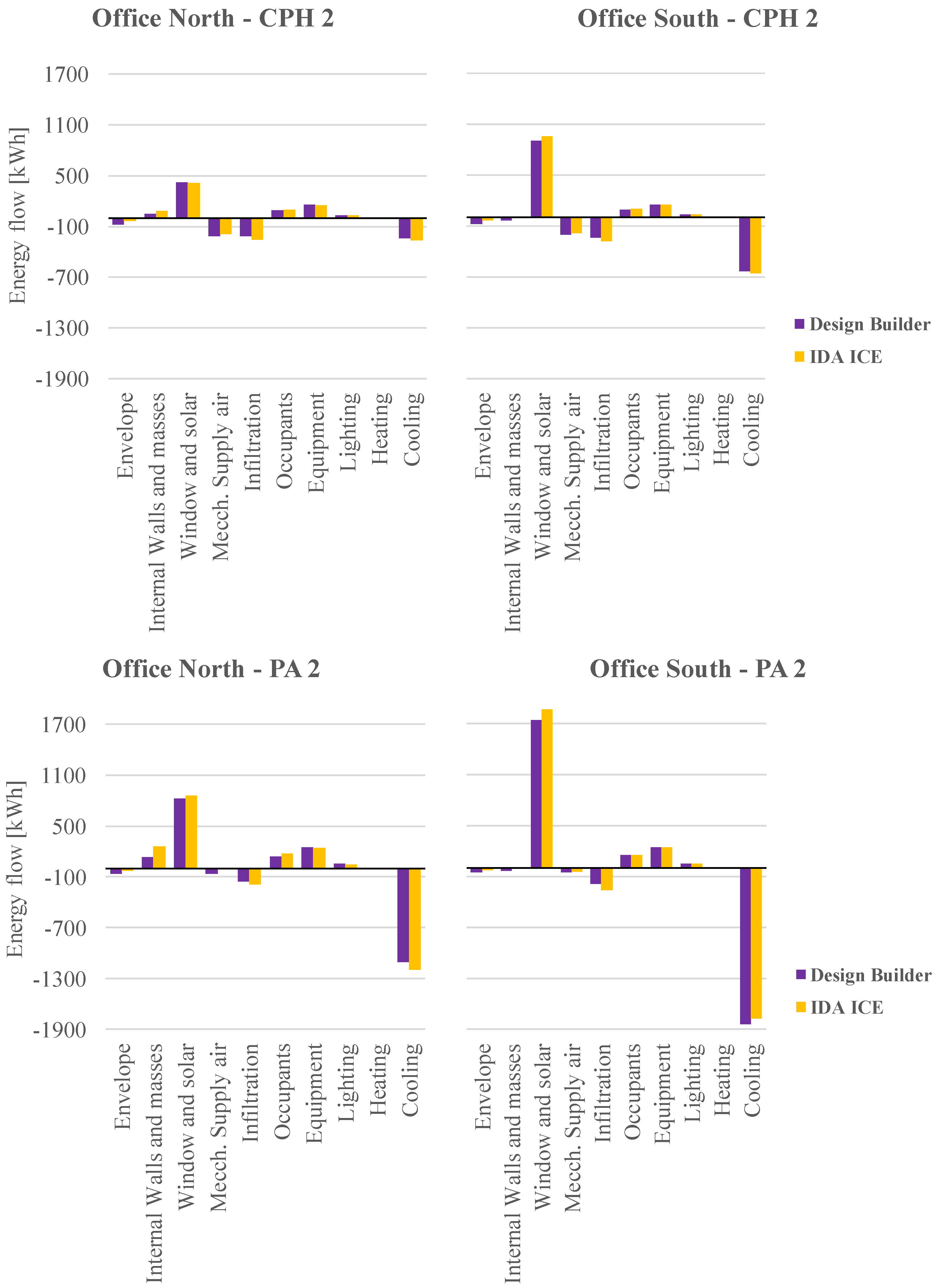

3.4. Second Scenario (Large Windows) Design Builder vs. IDA ICE

3.4.1. Temperatures

3.4.2. Energy Flows

3.4.3. Delivered Energy

4. Conclusions

- Creating the same building model using different tools requires significant effort to define input data. Most notably, we have shown that using the same input data set is not always possible. Consequently, it is impossible to evaluate how any slight variation of the input data can affect the output for the same building model. For instance, the U-values obtained by the two tools can differ above 12% for the same building typology (e.g., used materials, thicknesses values).

- In agreement with previous investigations that focused on the energy use predicted by different simulation tools, Design Builder and IDA ICE do not exhibit significant differences (<4%) in the yearly energy use of the building. Some differences (>10%) occur for the energy flows related to specific components (e.g., internal walls and masses, windows, and solar components during summer). A plausible explanation could be the different ways to calculate the U-value and consider the solar radiation absorbed by the glazing walls.

- The most significant differences when using the two tools are related to the operative temperatures rather than the energy delivered for the identical building model.

- IDA ICE exhibits a more noticeable temperature variation that affects the overall energy used for cooling. Consequently, cooling is sometimes required in winter to have better thermal comfort conditions. The effects are most significant for a warmer climate (Palermo) and in the presence of wide glazing walls. In this case, the operative temperature differences obtained by the two tools exceed 2.0 °C one-third of the time. A plausible explanation could be the different ways of evaluating the U-values and the solar radiation through the windows. However, the differences in evaluating thermal comfort conditions through the PMV require further investigation.

- Using a simple HVAC system in Design Builder does not allow the user to define a range of thermal comfort, but it only gives the option to define the set point temperature for the heating and cooling system. Given this, the HVAC system provides heating/cooling when the operative temperature is below/above the desired temperature set point. When this does not happen, the reason could be an insufficient capacity/control of the system plant or a free-running condition, as occurred in simulations for Palermo. The differences in the results could be relevant in terms of design choices or a tender offer.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Symbols and Abbreviations

| a | design value for the number of persons in the room, 1 |

| AR | floor area, m2 |

| c | specific heat, W h kg−1 K−1 |

| Cw | pressure coefficient, 1 |

| CPH 1 | Copenhagen in the scenario 1 (small window) |

| CPH 2 | Copenhagen in the scenario 2 (large window) |

| CPH1IDA | Copenhagen in the scenario 1 for IDA ICE |

| CPH1DB | Copenhagen in the scenario 1 for Design Builder |

| CPH1winter | overall number of hours with to ≥ 20 °C, 1 |

| CPH1summer | overall number of hours with to ≤ 26 °C, 1 |

| PA 1 | Palermo in the scenario 1 (small window) |

| PA 2 | Palermo in the scenario 2 (large window) |

| HVAC | Heating, Ventilation & Air Conditioning |

| Icl | basic clothing thermal insulation, m2 K W−1 (or clo) |

| IGDG | Italian Climatic data collection Gianni De Giorgio |

| IWEC | International Weather for Energy Calculations |

| NFRC | National Fenestration Rating Council |

| M | Metabolic rate, W m−2 (or met) |

| n | number of hours that the temperature difference values fall into a specific range, 1 |

| Pw | wind pressure, Pa |

| qB | ventilation rate for emissions from building, L s−1 m−2 |

| qp | ventilation rate for occupancy per person, L s−1 person−1 |

| qtot | total ventilation rate for breathing zone, L s−1 |

| Rse | external resistance, m2 K W−1 |

| Rsi | internal resistance, m2 K W−1 |

| s | thickness, mm |

| SFP | Specific Fan Power, kW s m−3 |

| SHCG | Solar Heat Gain Coefficient |

| Timeto ≥ 20 °C | percentage of the time with operative temperature values consistent with minimum (winter) thermal comfort criteria, % |

| Timeto ≤ 26 °C | percentage of the time with operative temperature values consistent with maximum (summer) thermal comfort criteria, % |

| S | summer |

| t | temperature, °C |

| to | operative temperature, °C |

| U-value | transmittance, W m−2 K−1 |

| v | wind speed, at roof height of building, m s−1 |

| va | air velocity, m s−1 |

| w | wind speed, m s−1 |

| W | winter |

| wx | component of wind vector on the x-axis, m s−1 |

| wy | component of wind vector on the y-axis, m s−1 |

| Greek letters | |

| ΔC | cooling difference between two scenarios/software, % |

| ΔEF | differences in terms of energy flows for each component, % |

| ΔH | heating difference between two scenarios/software, % |

| ΔP | pressure rise, Pa |

| ΔS | summer difference between two scenarios, % |

| Δt | difference of temperature, °C |

| ΔW | winter difference between two scenarios, % |

| Δθ% | fraction of the time that the temperature difference values fall into a specific range, % |

| ε | emissivity, 1 |

| λ | thermal conductivity, W m−1 K−1 |

| ρ | density, kg m−3 |

References

- Vijayavenkataraman, S.; Iniyan, S.; Goic, R. A review of climate change, mitigation and adaptation. Renew. Sustain. Energy Rev. 2012, 16, 878–897. [Google Scholar] [CrossRef]

- Buildings—Tracking Report September 2022; International Energy Agency: Paris, France, 2022; Available online: https://www.iea.org/reports/buildings (accessed on 27 December 2022).

- European Parliament. Directive (EU) 2018/844 of the European Parliament and of the Council of 30 May 2018 amending Directive 2010/31/EU on the energy performance of buildings and Directive 2012/27/EU on energy efficiency. Off. J. Eur. Union 2018, 156, 75–91. [Google Scholar]

- Artola, I.; Rademaekers, K.; Williams, R.; Yearwood, J. Boosting Building Renovation: What Potential and Value for Europe; Study for the iTRE Committee, Commissioned by DG for Internal Policies Policy Department A; European Parliament: Brussels, Belgium, 2016; Volume 72. [Google Scholar]

- D’Agostino, D.; Mazzarella, L. What is a Nearly zero energy building? Overview, implementation and comparison of definitions. J. Build. Eng. 2019, 21, 200–212. [Google Scholar] [CrossRef]

- Hong, T.; Langevin, J.; Sun, K. Building simulation: Ten challenges. Build. Simul. 2018, 11, 871–898. [Google Scholar] [CrossRef] [Green Version]

- EN 16798-2; Energy Performance of Buildings—Ventilation for Buildings—Part 2: Interpretation of the Requirements in EN 16798-1—Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics—Module M1-6. European Committee for Standardization: Brussels, Belgium, 2019.

- EN 16798-1; Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics-Module M1-6. European Committee for Standardization: Brussels, Belgium, 2019.

- Santos-Herrero, J.M.; Lopez-Guede, J.M.; Flores-Abascal, I. Modeling, simulation and control tools for nZEB: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 142, 110851. [Google Scholar] [CrossRef]

- Baglivo, C.; Congedo, P.; Di Cataldo, M.; Coluccia, L.; D’Agostino, D. Envelope design optimization by thermal modelling of a building in a warm climate. Energies 2017, 10, 1808. [Google Scholar] [CrossRef] [Green Version]

- Hoyt, T.; Arens, E.; Zhang, H. Extending air temperature setpoints: Simulated energy savings and design considerations for new and retrofit buildings. Build. Environ. 2015, 88, 89–96. [Google Scholar] [CrossRef] [Green Version]

- Hong, T.; Chena, Y.; Luo, X.; Luo, N.; Lee, S.H. Ten questions on urban building energy modelling. Build. Environ. 2020, 168, 106508. [Google Scholar] [CrossRef] [Green Version]

- Wang, C.; Ferrando, M.; Causone, F.; Jin, X.; Zhou, X.; Shi, X. Data acquisition for urban building energy modeling: A review. Build. Environ. 2022, 217, 109056. [Google Scholar] [CrossRef]

- EnergyPlus Building Energy Simulation Program of U.S. Department of Energy’s (DOE) Building Technologies Office (BTO) and Managed by the National Renewable Energy Laboratory (NREL). Available online: https://energyplus.net/ (accessed on 10 December 2022).

- DesignBuilder Software Ltd. Stroud House Russell Street Stroud, Gloucs GL5 3AN, UK. Available online: https://designbuilder.co.uk/ (accessed on 4 January 2023).

- IDA Indoor Climate and Energy. EQUA Simulation AB Råsundavägen 100, 169 57 Solna, Sweden. Available online: https://www.equa.se/en/ida-ice/ (accessed on 10 December 2022).

- ASHRAE 140; Standard Method of Test for the Evaluation of Building Energy Analysis Computer Programs. American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2014.

- EN 15255; Energy Performance of Buildings—Sensible Room Cooling Load Calculation—General Criteria and Validation Procedures. European Committee for Standardization: Brussels, Belgium, 2007.

- EN 15265; Energy Performance of Buildings—Calculation of Energy Needs for Space Heating and Cooling Using Dynamic Methods—General Criteria and Validation Procedures. European Committee for Standardization: Brussels, Belgium, 2007.

- EN 13791; Thermal Performance of Buildings—Calculation of Internal Temperatures of a Room in Summer without Mechanical Cooling—General Criteria and Validation Procedures. European Committee for Standardization: Brussels, Belgium, 2012.

- Lolli, N.; Brozovsky, J.; Nocente, A.; Grynning, S. Temperature and thermal comfort in office spaces: Measurements vs. simulations. In Proceedings of the 16th IBPSA Conference, Rome, Italy, 2–4 September 2019; pp. 1849–1858. [Google Scholar] [CrossRef]

- Yu, J.; Chang, W.-S.; Dong, Y. Building Energy Prediction Models and Related Uncertainties: A Review. Buildings 2022, 12, 1284. [Google Scholar] [CrossRef]

- van Dronkelaar, C.; Dowson, M.; Spataru, C.; Mumovic, D. A Review of the Regulatory Energy Performance Gap and Its Underlying Causes in Non-domestic Buildings. Front. Mech. Eng. 2016, 1, 17. [Google Scholar] [CrossRef] [Green Version]

- van den Brom, P.; Meijer, A.; Visscher, H. Performance gaps in energy consumption: Household groups and building characteristics. Build. Res. Inf. 2018, 46, 54–70. [Google Scholar] [CrossRef] [Green Version]

- Laskari, M.; de Masi, R.-F.; Karatasou, S.; Santamouris, M.; Assimakopoulos, M.-N. On the impact of user behaviour on heating energy consumption and indoor temperature in residential buildings. Energy Build. 2022, 255, 111657. [Google Scholar] [CrossRef]

- Huerto-Cardenas, H.E.; Leonforte, F.; Aste, N.; Del Pero, C.; Evola, G.; Costanzo, V.; Lucchi, E. Validation of dynamic hygrothermal simulation models for historical buildings: State of the art, research challenges and recommendations. Energy Build. 2020, 180, 107081. [Google Scholar] [CrossRef]

- Crawley, D.B.; Hand, J.W.; Kummert, M.; Griffith, B.T. Contrasting the capabilities of building energy performance simulation programs. Build. Environ. 2008, 43, 661–673. [Google Scholar] [CrossRef] [Green Version]

- Sousa, J. Energy simulation software for buildings: Review and comparison. Inf. Technol. Energy Appl. 2012, 6–7. Available online: https://ceur-ws.org/Vol-923/paper08.pdf (accessed on 4 January 2023).

- Mazzeo, D.; Matera, N.; Cornaro, C.; Oliveti, G.; Romagnoni, P.; De Santoli, L. EnergyPlus, IDA ICE and TRNSYS predictive simulation accuracy for building thermal behaviour evaluation by using an experimental campaign in solar test boxes with and without a PCM module. Energy Build. 2020, 212, 109812. [Google Scholar] [CrossRef]

- Vadiee, A.; Dodoo, A.; Gustavsson, L. A Comparison Between Four Dynamic Energy Modeling Tools for Simulation of Space Heating Demand of Buildings. In CCC 2018: Cold Climate HVAC 2018; Springer Proceedings in Energy; Johansson, D., Bagge, H., Wahlström, Å., Eds.; Springer: Cham, Switzerland. [CrossRef]

- Johari, F.; Nilsson, A.; Åberg, M.; Widén, J. Towards Urban Building Energy Modelling: A Comparison of Available Tools. In Proceedings of the ECEEE 2019 Summer Study on Energy Efficiency: Is Efficient Sufficient? Hyères, France, 3–8 June 2019; pp. 1515–1524. [Google Scholar]

- Mirsadeghi, M.; Costola, D.; Blocken, B.; Hensen, J.L. Review of external convective heat transfer coefficient models in building energy simulation programs: Implementation and uncertainty. Appl. Therm. Eng. 2013, 56, 134–151. [Google Scholar] [CrossRef]

- Gelesz, A.; Lucchino, E.C.; Goia, F.; Serra, V.; Reith, A. Characteristics that matter in a climate façade: A sensitivity analysis with building energy simulation tools. Energy Build. 2020, 229, 110467. [Google Scholar] [CrossRef]

- Zhu, D.; Hong, T.; Yan, D.; Wang, C.A. A detailed loads comparison of three building energy modeling programs: EnergyPlus, DeST and DOE-2.1 E. Build. Simul. 2013, 6, 323–335. [Google Scholar] [CrossRef]

- Kottek, M.; Grieser, J.; Beck, C.; Rudolf, B.; Rubel, F. World Map of the Köppen-Geiger climate classification updated. Meteorol. Z. 2006, 15, 259–263. [Google Scholar] [CrossRef]

- Weather Data Available in EnergyPlus. Available online: https://energyplus.net/weather/ (accessed on 4 January 2023).

- Big Ladder Software LLC. Elements for Windows (Ver. 1.06). Available online: https://download.bigladdersoftware.com/?ref=elements-latest-win (accessed on 4 January 2023).

- Olesen, B.W.; Dossi, F.C. Operation and control of activated slab heating and cooling systems. In Proceedings of the CIB World Building Congress 2004: Building for the Future, Toronto, ON, Canada, 2–7 May 2004. [Google Scholar]

- WINDOW Computer Program Developed at Lawrence Berkeley National Laboratory (LBNL). Available online: https://windows.lbl.gov/sites/default/files/software/WINDOW/WINDOW7UserManual.pdf (accessed on 4 January 2023).

- Kolarik, J.; Toftum, J.; Olesen, B.W.; Jensen, K.L. Simulation of energy use, human thermal comfort and office work performance in buildings with moderately drifting operative temperatures. Energy Build. 2011, 43, 2988–2997. [Google Scholar] [CrossRef] [Green Version]

- Decree by The President of the Republic 16 Aprile 2013 n. 74, Regolamento Recante Norme per la Progettazione, L’installazione, L’esercizio e la Manutenzione degli Impianti Termici Degli Edifici ai Fini del Contenimento dei Consumi di Energia, in Attuazione dell’art. 4, Comma 4, Della Legge 9 Gennaio 1991 n. 10. Gazzetta Ufficiale n. del 149 del 27 giugno 2013; Presidenza della Repubblica Italiana, Rome, Italy 2013. Available online: https://www.gazzettaufficiale.it/eli/id/2013/06/27/13G00114/sg (accessed on 7 January 2023).

- Standalone DesignBuilder Results Viewer. Available online: https://designbuilder.co.uk/helpv5.5/#ResultsProcessor.htm?Highlight=results (accessed on 10 December 2022).

- Auxiliary Energy data in DesignBuilder. Available online: https://designbuilder.co.uk/helpv5.5/#Auxiliary_Energy.htm?Highlight=Auxiliary%20Energy (accessed on 10 December 2022).

- ISO 8996; Ergonomics of the Thermal Environment—Determination of Metabolic Rate. International Standardization Organization: Geneva, Switzerland, 2022.

- Du Bois, D.; Dubois, E. A formula to estimate the approximate surface area if height and weight be known. Arch. Intern. Med. 1916, 17, 863–871. [Google Scholar] [CrossRef] [Green Version]

- ISO 7730; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. European Standardization Organization: Brussels, Belgium, 2005.

- General Lighting in DesignBuilder. Available online: https://designbuilder.co.uk/helpv5.5/#_General_lighting.htm?Highlight=radiant%20fraction (accessed on 10 December 2022).

- ISO 6946; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Method. International Standardization Organization: Geneva, Switzerland, 2018.

- EQUA Simulation AB, Energy Modeling in IDA ICE according to ASHRAE 90.1-2010. Available online: http://www.equaonline.com/iceuser/pdf/ASHRAE_90.1_Extension_v2010.pdf (accessed on 10 December 2022).

- ASHRAE 90.1; Energy Standard for Buildings Except Low-Rise Residential Buildings. American Society of Heating, Refrigerating, and Air-Conditioning Engineers, Inc.: Atlanta, GA, USA, 2019.

- ISO 7726; Ergonomics of the Thermal Environment—Instruments for Measuring Physical Quantities. International Standardization Organization: Geneva, Switzerland, 2002.

- Dell’Isola, M.; Frattolillo, A.; Palella, B.I.; Riccio, G. Influence of Measurement Uncertainties on the Thermal Environment Assessment. Int. J. Thermophys. 2012, 33, 1616–1632. [Google Scholar] [CrossRef]

- d’Ambrosio Alfano, F.R.; Palella, B.I.; Riccio, G. The Role of Measurement Accuracy on the Thermal Environment Assessment by means of PMV Index. Build. Environ. 2011, 46, 1361–1369. [Google Scholar] [CrossRef]

- Palella, B.I.; Quaranta, F.; Riccio, G. On the management and prevention of heat stress for crews onboard ships. Ocean Eng. 2016, 112, 277–286. [Google Scholar] [CrossRef]

- d’Ambrosio Alfano, F.R.; Olesen, B.W.; Pepe, D.; Palella, B.I.; Riccio, G. Fifty Years of PMV Model: Reliability, Implementation and Design of Software for Its Calculation. Atmosphere 2020, 11, 49. [Google Scholar] [CrossRef] [Green Version]

- d’Ambrosio Alfano, F.R.; Ficco, G.; Frattolillo, A.; Palella, B.I.; Riccio, G. Mean Radiant Temperature Measurements through Small Black Globes under Forced Convection Conditions. Atmosphere 2021, 12, 621. [Google Scholar] [CrossRef]

| Wall | Design Builder | IDA ICE | Δ (%) | ||||

|---|---|---|---|---|---|---|---|

| Rsi | Rse | U-Value | Rsi | Rse | U-Value | ||

| (m2 K W−1) | (m2 K W−1) | (W m2 K−1) | (m2 K W−1) | (m2 K W−1) | (W m2 K−1) | ||

| Ceiling roof | 0.11 | 0.08 | 1.7 | 0.13 | 0.04 | 1.8 | 6 |

| Floor | 0.16 | 0.08 | 1.6 | 0.13 | 0.04 | 1.8 | 12 |

| Outside wall | 0.12 | 0.03 | 0.4 | 0.13 | 0.04 | 0.4 | 0 |

| Internal wall | 0.12 | 0.03 | 2.1 | 0.13 | 0.04 | 2.0 | −5 |

| Software | Comparison | Office | Month | Δto |

|---|---|---|---|---|

| Design Builder | CPH1 vs. CPH2 | North | May | 1.9 |

| South | April | 3.5 | ||

| PA1 vs. PA2 | North | March | 2.1 | |

| South | February | 4.3 | ||

| IDA ICE | CPH1 vs. CPH2 | North | April/May | 3.3 |

| South | April | 5.2 | ||

| PA1 vs. PA2 | North | Aug | 3.0 | |

| South | Oct | 5.2 |

| Software | Simulation | Office | W (%) | S (%) | ΔW (%) | ΔS (%) |

|---|---|---|---|---|---|---|

| Design Builder | CPH 1 | North | 100 | 100 | 0 | 0 |

| South | 100 | 100 | 0 | −3 | ||

| CPH 2 | North | 100 | 100 | |||

| South | 100 | 97 | ||||

| PA 1 | North | 100 | 99 | 0 | −6 | |

| South | 100 | 85 | 0 | −24 | ||

| PA 2 | North | 100 | 93 | |||

| South | 100 | 61 | ||||

| IDA ICE | CPH 1 | North | 100 | 100 | 0 | 0 |

| South | 100 | 98 | 0 | −8 | ||

| CPH 2 | North | 100 | 100 | |||

| South | 100 | 90 | ||||

| PA 1 | North | 100 | 96 | 0 | −20 | |

| South | 100 | 74 | 0 | −25 | ||

| PA 2 | North | 100 | 76 | |||

| South | 100 | 49 |

| Software | Simulation | Office | Winter | Summer | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Avg | σ | Min | Max | Avg | σ | |||

| Design Builder | CPH 1 | North | 22.5 | 17.4 | 20.4 | 0.4 | 26.0 | 20.4 | 24.2 | 1.4 |

| South | 26.9 | 18.1 | 20.9 | 1.1 | 26.4 | 22.0 | 25.2 | 0.7 | ||

| CPH 2 | North | 25.6 | 17.2 | 20.6 | 0.8 | 26.1 | 22.1 | 25.2 | 0.6 | |

| South | 31.9 | 18.3 | 21.8 | 2.3 | 29.1 | 23.5 | 25.6 | 0.6 | ||

| PA 1 | North | 26.7 | 20.4 | 23.3 | 1.3 | 27.2 | 23.3 | 25.5 | 0.4 | |

| South | 32.1 | 23.5 | 28.5 | 1.6 | 29.6 | 24.9 | 26.0 | 0.9 | ||

| PA 2 | North | 28.8 | 20.9 | 24.7 | 1.6 | 29.7 | 23.7 | 26.0 | 1.0 | |

| South | 35.9 | 25.4 | 31.5 | 1.9 | 33.5 | 25.3 | 27.4 | 2.3 | ||

| IDA ICE | CPH 1 | North | 22.2 | 19.3 | 20.6 | 0.3 | 25.5 | 20.7 | 24.5 | 1.2 |

| South | 25.6 | 19.7 | 20.9 | 1.0 | 25.5 | 22.8 | 25.3 | 0.5 | ||

| CPH 2 | North | 23.4 | 18.9 | 20.6 | 0.5 | 25.5 | 22.0 | 25.1 | 0.8 | |

| South | 29.1 | 19.5 | 21.5 | 1.7 | 27.5 | 24.1 | 25.5 | 0.3 | ||

| PA 1 | North | 25.0 | 20.5 | 22.2 | 1.1 | 26.4 | 23.0 | 25.4 | 0.4 | |

| South | 29.7 | 21.3 | 26.7 | 1.6 | 27.1 | 25.3 | 25.7 | 0.3 | ||

| PA 2 | North | 27.0 | 20.5 | 23.4 | 1.5 | 26.8 | 23.3 | 25.6 | 0.4 | |

| South | 33.8 | 22.6 | 29.8 | 2.1 | 30.0 | 25.5 | 26.0 | 0.8 | ||

| Software | Simulation | Comparison | |||

|---|---|---|---|---|---|

| Scenario 1 vs. Scenario 2 | Design Builder vs. IDA ICE | ||||

| ΔC (%) | ΔH (%) | ΔW (%) | ΔS (%) | ||

| Design Builder | CPH 1 | 8 | −6 | 0 | −4 |

| CPH 2 | 0 | 0 | |||

| PA 1 | 22 | 0 | 0 | 0 | |

| PA 2 | −4 | 0 | |||

| IDA ICE | CPH 1 | 8 | −4 | ||

| CPH 2 | |||||

| PA 1 | 19 | 0 | |||

| PA 2 | |||||

| Condition | Scenario | North Office | South Office | Scenario | North Office | South Office |

|---|---|---|---|---|---|---|

| CPH 1 | Operative temperature | PA 1 | Operative temperature | |||

| Δt ≤ 0.5 | 82 | 83 | 67 | 53 | ||

| 0.5 < Δt ≤ 1.0 | 11 | 11 | 12 | 10 | ||

| 1.0 < Δt ≤ 2.0 | 7 | 6 | 19 | 21 | ||

| Δt > 2.0 | 0 | 0 | 2 | 16 | ||

| Mean radiant temperature | Mean radiant temperature | |||||

| Δt ≤ 0.5 | 34 | 50 | 66 | 47 | ||

| 0.5 < Δt ≤ 1.0 | 36 | 32 | 10 | 22 | ||

| 1.0 < Δt ≤ 2.0 | 30 | 18 | 21 | 19 | ||

| Δt > 2.0 | 0 | 0 | 3 | 12 | ||

| Air temperature | Air temperature | |||||

| Δt ≤ 0.5 | 32 | 47 | 59 | 39 | ||

| 0.5 < Δt ≤ 1.0 | 28 | 29 | 20 | 18 | ||

| 1.0 < Δt ≤ 2.0 | 38 | 23 | 19 | 23 | ||

| Δt > 2.0 | 2 | 1 | 2 | 20 | ||

| CPH 2 | Operative temperature | PA 2 | Operative temperature | |||

| Δt ≤ 0.5 | 91 | 78 | 53 | 38 | ||

| 0.5 < Δt ≤ 1.0 | 4 | 10 | 11 | 10 | ||

| 1.0 < Δt ≤ 2.0 | 4 | 9 | 29 | 18 | ||

| Δt > 2.0 | 1 | 3 | 7 | 34 | ||

| Mean radiant temperature | Mean radiant temperature | |||||

| Δt ≤ 0.5 | 47 | 47 | 51 | 31 | ||

| 0.5 < Δt ≤ 1.0 | 22 | 33 | 18 | 21 | ||

| 1.0 < Δt ≤ 2.0 | 30 | 17 | 26 | 23 | ||

| Δt > 2.0 | 1 | 3 | 5 | 25 | ||

| Air temperature | Air temperature | |||||

| Δt ≤ 0.5 | 43 | 42 | 45 | 22 | ||

| 0.5 < Δt ≤ 1.0 | 19 | 28 | 17 | 16 | ||

| 1.0 < Δt ≤ 2.0 | 35 | 25 | 26 | 21 | ||

| Δt > 2.0 | 3 | 5 | 12 | 41 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

d’Ambrosio Alfano, F.R.; Olesen, B.W.; Pepe, D.; Palella, B.I. Working with Different Building Energy Performance Tools: From Input Data to Energy and Indoor Temperature Predictions. Energies 2023, 16, 743. https://doi.org/10.3390/en16020743

d’Ambrosio Alfano FR, Olesen BW, Pepe D, Palella BI. Working with Different Building Energy Performance Tools: From Input Data to Energy and Indoor Temperature Predictions. Energies. 2023; 16(2):743. https://doi.org/10.3390/en16020743

Chicago/Turabian Styled’Ambrosio Alfano, Francesca Romana, Bjarne Wilkens Olesen, Daniela Pepe, and Boris Igor Palella. 2023. "Working with Different Building Energy Performance Tools: From Input Data to Energy and Indoor Temperature Predictions" Energies 16, no. 2: 743. https://doi.org/10.3390/en16020743