Simulating Fish Motion through a Diagonal Reversible Turbine

Abstract

1. Introduction

2. Numerical Methods

2.1. Particle-Based Methods

| Equation | Formulation | |

| Momentum equation | (1) | |

| Drag force | (2) | |

| Pressure gradient force | (3) | |

| Virtual mass force | (4) |

2.2. Overset Meshes

2.3. Immersed Boundaries

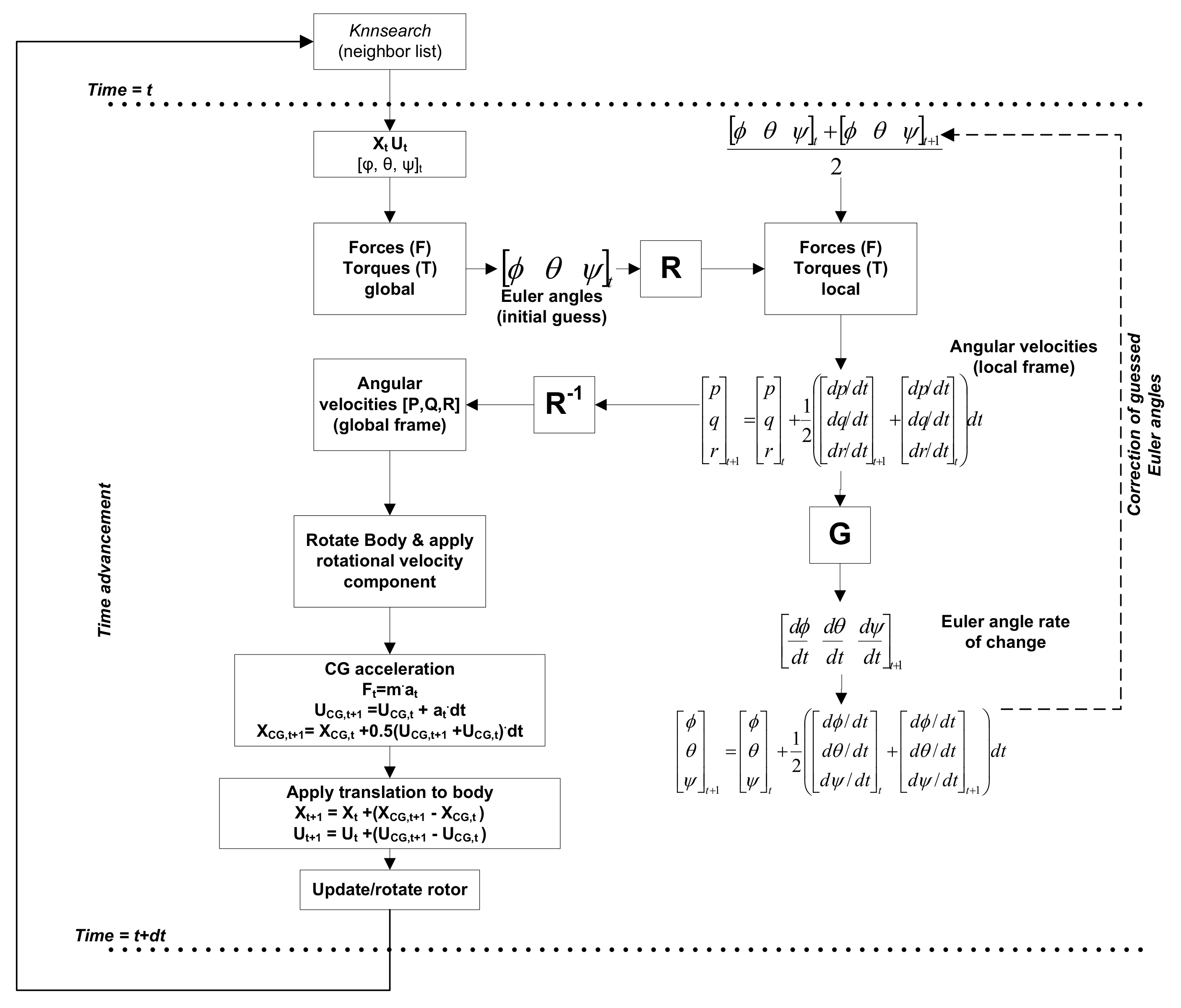

2.4. Uncoupled 6-DoF Tracking

2.4.1. Fluid Coupling and 6-DoF

2.4.2. Collision Detection

- −

- use knn-search to find the closest (i.e., min distance, dmin) wall boundary element (indicated with red highlight in Figure 3)

- −

- project the minimum distance vector at the local wall normal, n, to calculate dproj

- −

- if the projection is positive, do nothing (no penetration)

- −

- if the projection is negative, apply Equation (18).

3. Case Description

- −

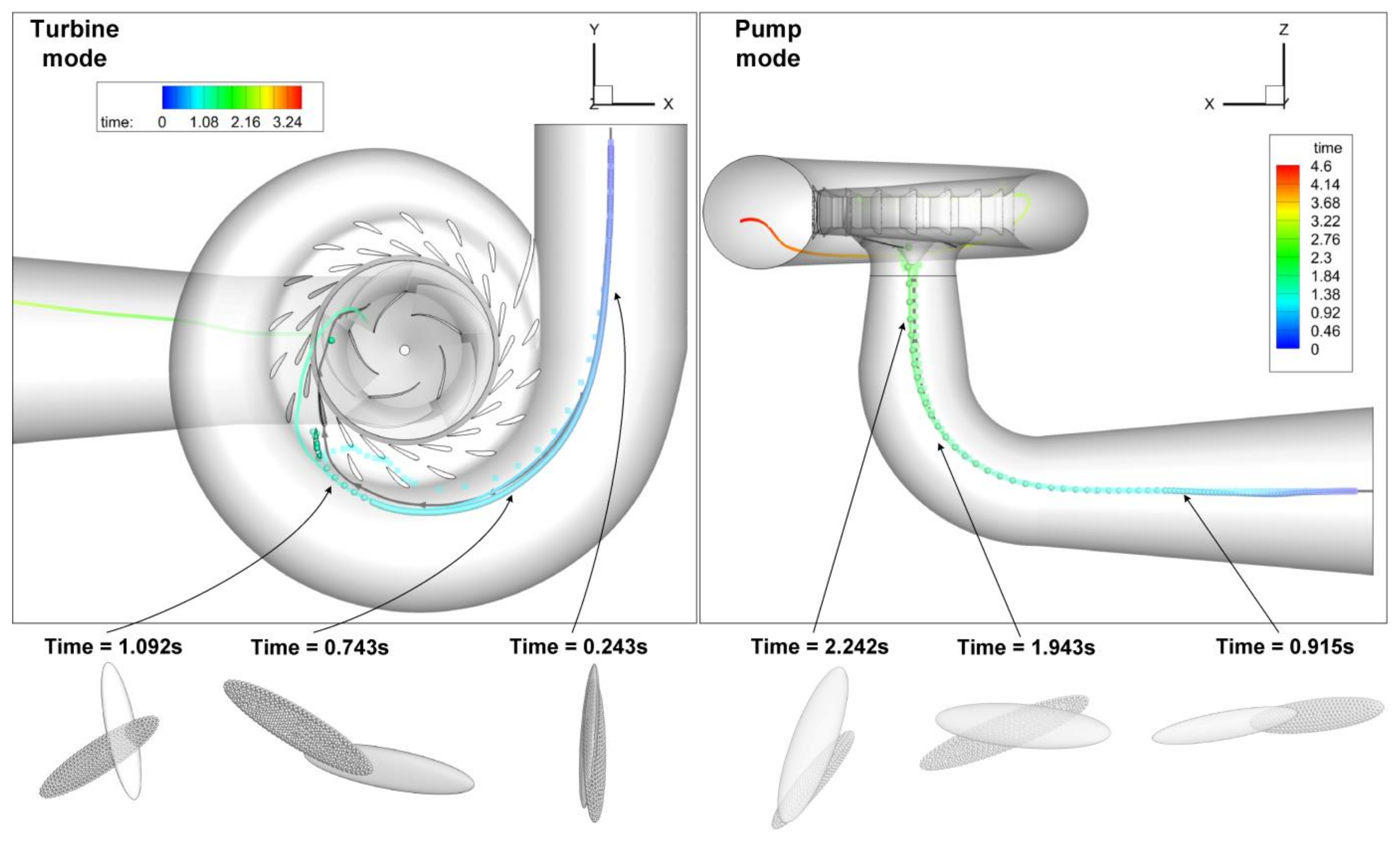

- Particle tracking or the uncoupled 6-DoF tracking are performed with sliding meshes. In this case, the rotor consists of a moving (rotating) mesh in the case of particle tracking, or rotating reference frame in the case of the uncoupled 6-DoF tracking. Particle tracking was done in a transient analysis in ANSYS Fluent v2021, whereas the uncoupled 6-DoF was performed using a steady state flow field, also from ANSYS Fluent v2021. In the frame of the present investigation, particles emulating the fish are approximated as equivalent spheres of radius 24.7 mm, considering drag, lift, added mass force and rotation. Non-spherical effects are taken into account using a non-spherical factor of 0.66 corresponding to the surface area ratio of the fish model and a sphere of the same equivalent volume.

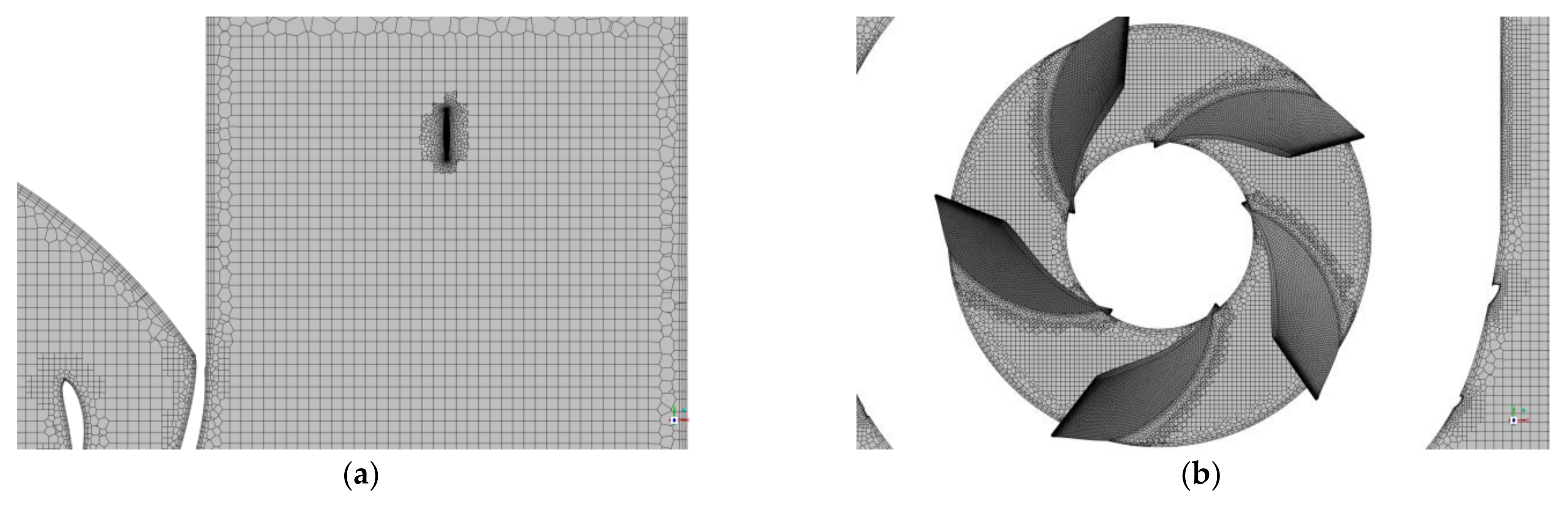

- −

- Overset mesh body tracking was performed using similar meshing methods and resolution as the sliding mesh approach, but with a different structure to accommodate for overset domains; an indicative view of the mesh structure, showing overlapping regions, is in Figure 7. The set-up can be summarized as follows: a rotating mesh was used for the rotor, which was considered as component mesh with the lowest grid priority. The fish was introduced in another component mesh, enclosed within a sphere of diameter 0.74 m, or 4.35 fish lengths; it had intermediate grid priority. The fish domain 6-DoF properties (mass, moments of inertia) are the same as the uncoupled 6-DoF approach (see Section 2.4.1). Finally, the background mesh consisting of the complete flow path (including casing, stator blades and duct) had the highest grid priority. Overset simulation was performed using ANSYS Fluent v2021. The body was tracked with an implicit scheme, to maintain stability while using large time steps, in the order of 1 ms.

- −

- Immersed boundary was set up using CFX v2021, by introducing the flow passage through the turbine and modeling the rotor blades and the fish as immersed bodies. However, due to the large aspect ratio of the fish and blades (effectively very thin bodies) it was impossible to obtain a good representation for reasonable mesh resolutions and a tractable computational cost.

4. Validation

4.1. Influence of the Interpolation Method

4.2. Resolution of the Body

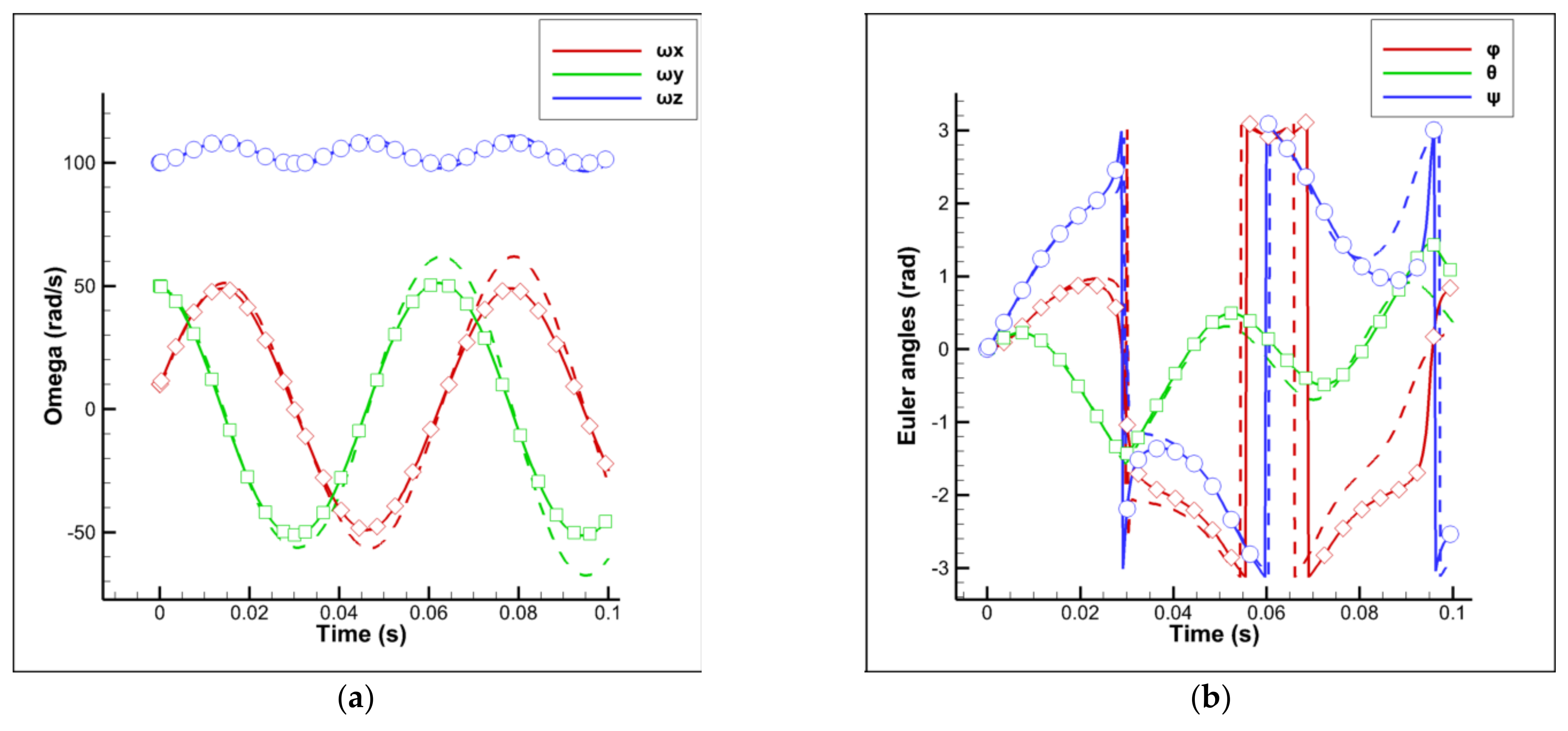

4.3. Prediction of Free Rotation of the Fish Model

4.4. Prediction of a Fish Track in the Diagonal Turbine Model/Comparison of Different Techniques

- −

- the uncoupled 6-DoF requires ~1–2 h for a single track using a single processor (indicatively Intel i7-3632), while limiting the body motion to 2.5–10% of the max. body dimension per time step for stability, depending on the location in the turbine (lower near the blades, or in vortices, e.g., draft tube in turbine mode).

- −

- the unsteady particle tracking requires 1–2 days on a 6-core machine (indicatively Intel i7-8850), depending on the time step used; higher time steps are faster but more prone to no-clipping.

- −

- the overset method has an immense computational cost, requiring 3–4 days to reach the runner on a 16-core machine (indicatively Intel Xeon Gold 6140). The simulation was not pursued further, due to lack of the boundary collision algorithm implemented in Fluent v2021, which caused the body to effectively pass through the stator blades and rotor wall, resulting in an unrealistic configuration.

- −

- the streamline is trivial to complete, requiring mere seconds; however, it does not consider body motion or rotor rotation.

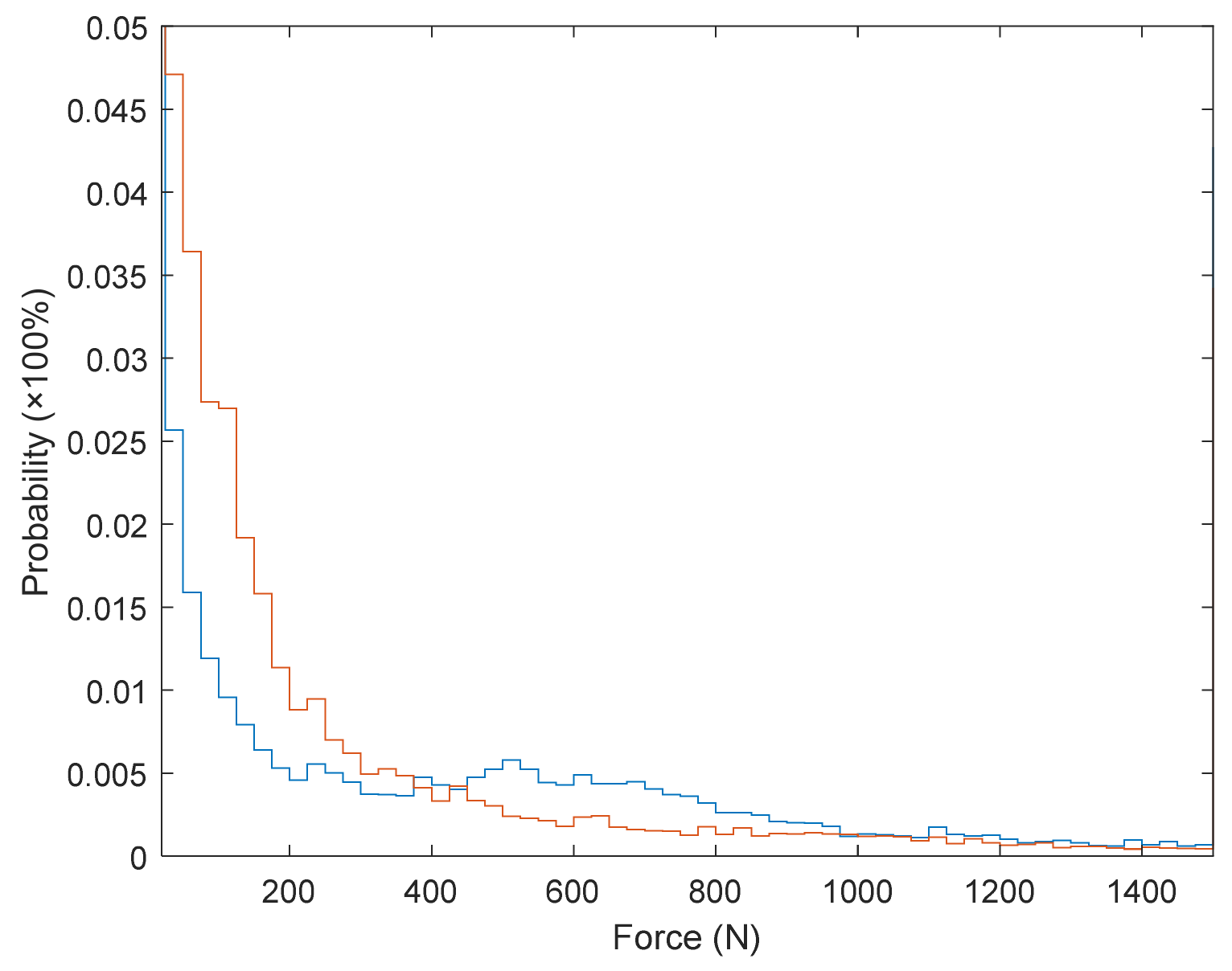

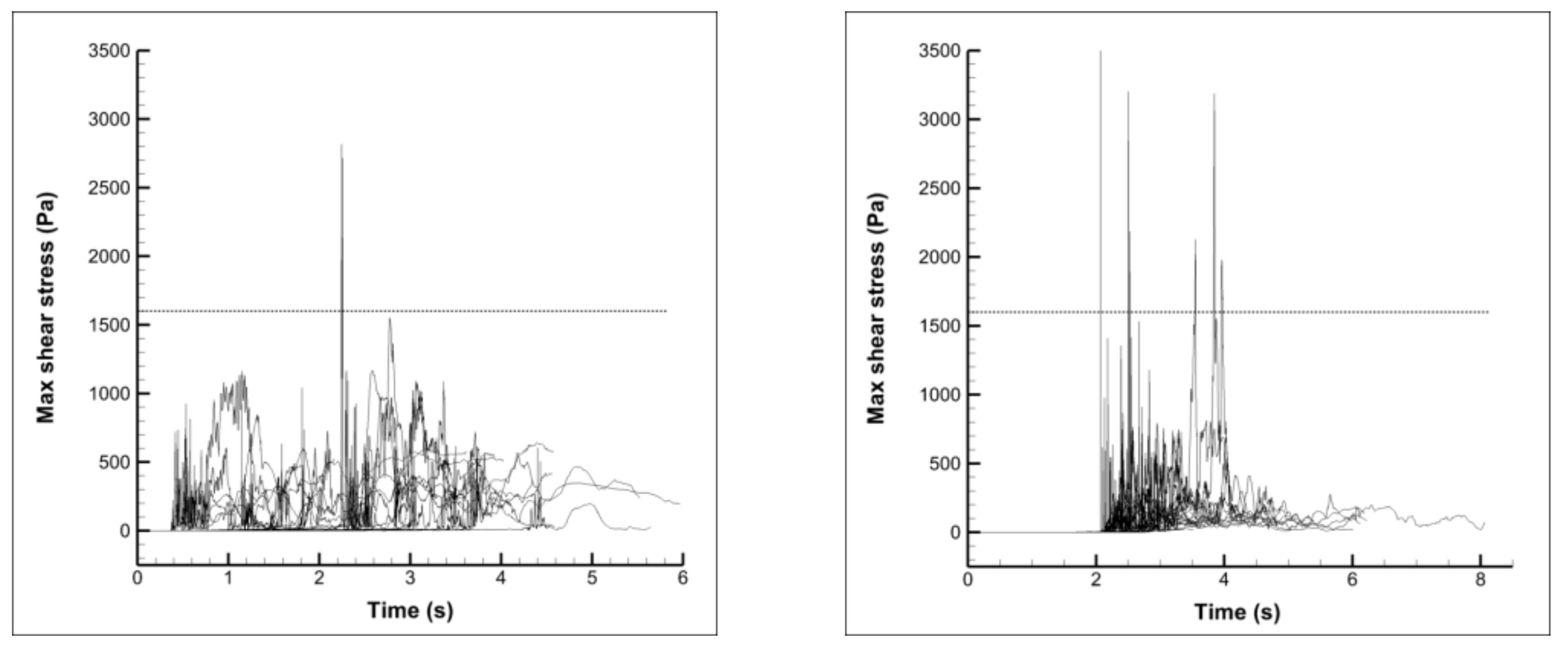

5. Statistics of Trajectories

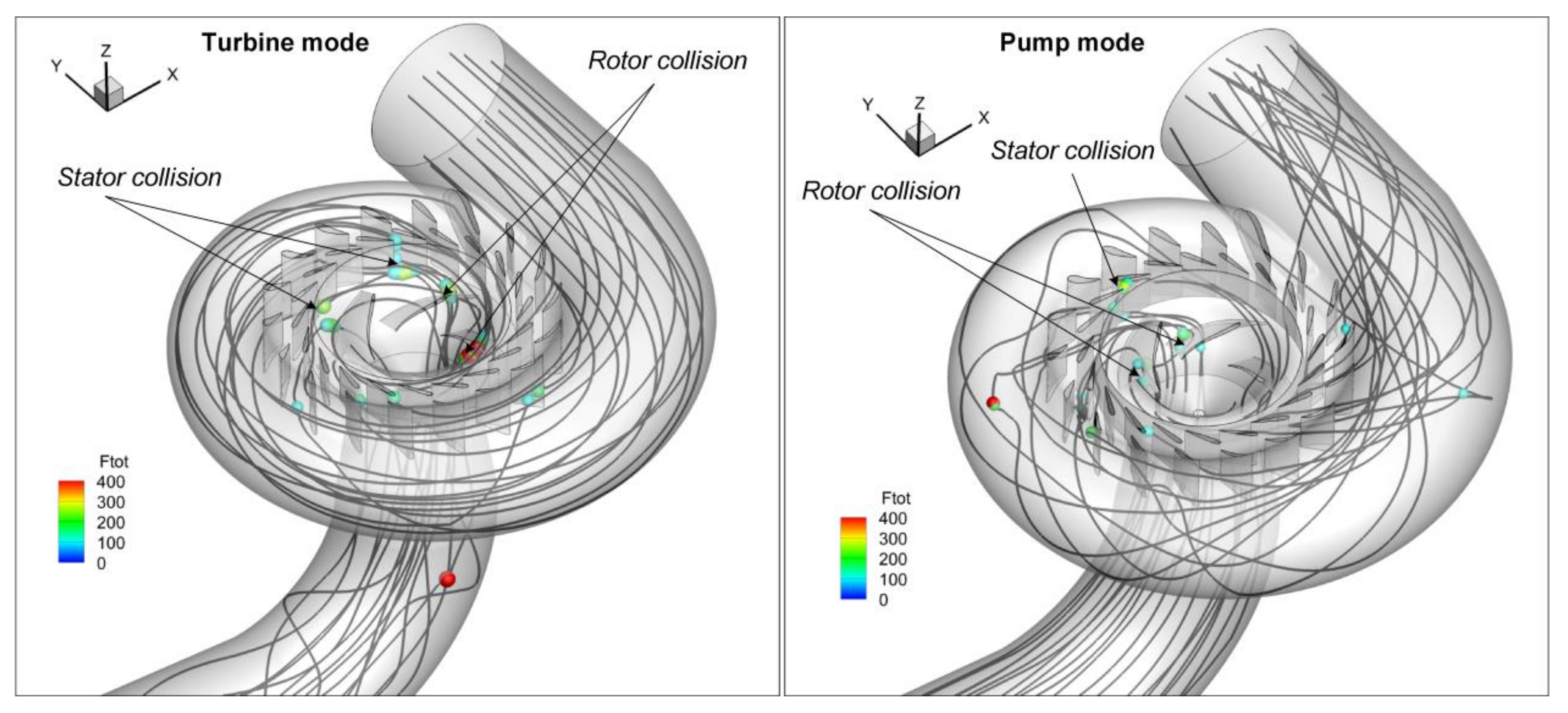

- −

- in turbine mode, 18.75% of tracked fish undergo a rotor blade impact and 43% undergo a stator blade impact, although this is much milder than the rotor impact. Indicatively, stator blade impact is in the order of 100 N, whereas rotor blade impact may be in excess of 400 N.

- −

- in pumping mode, 10% of tracked fish undergo a rotor blade impact and 40% a stator blade impact. Here however, the magnitude of impacts is rather comparable, in the order of 100 N, most likely due to the fact that at the inlet section of the runner at pump mode the circumferential velocity is smaller than the turbine mode. As a measure of comparison, the hydrodynamic forces are much smaller, in the order of 1–10 N, depending on the location (higher near/at the runner).

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| m | Mass [kg] |

| F | Force [N] |

| Cd | Drag coefficient [-] |

| ρ | Density [kg/m3] |

| A | Surface area [m2] |

| u | Velocity [m/s] |

| V | Volume [m3] |

| p | Pressure [Pa] |

| CVm | Virtual mass coefficient [-] |

| φ | Generic interpolated quantity (pressure or velocity here, [m/s] or [Pa]) |

| d, d | Distance [m] |

| w | Radial basis function/Linear regression weight (unit dependent on interpolated quantity) |

| x, r | Coordinate vector [m] |

| n | Normal vector [-] |

| T | Torque [N.m] |

| dS | Infinitesimal surface area [m2] |

| Acceleration [m/s2] | |

| R | Transformation tensor [-] |

| φ, θ, ψ | Euler angles [rad] |

| ω | Angular velocity [rad/s] |

| Angular acceleration [rad/s2] | |

| I | Moment of inertia tensor [kg.m2] |

| G | Euler angular velocity transformation tensor [-] |

| kspring | Spring constant [N/m] |

| τij | Shear stress [Pa] |

| μeff | Effective dynamic viscosity [Pa.s] |

References

- BP, p.l.c.bp Statistical Review of World Energy. 2022. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2022-full-report.pdf (accessed on 24 November 2022).

- IRENA. Renewable Energy Statistics 2022; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2022. [Google Scholar]

- Jager, H.I.; De Silva, T.; Uria-Martinez, R.; Pracheil, B.M.; Macknick, J. Shifts in hydropower operation to balance wind and solar will modify effects on aquatic biota. Water Biol. Secur. 2022, 1, 100060. [Google Scholar] [CrossRef]

- International Energy Agency. How Rapidly Will the Global Electricity Storage Market Grow by 2026? International Energy Agency: Paris, France, 2021. [Google Scholar]

- Killingtveit, Å. 15—Hydroelectric Power; Elsevier Ltd.: Amsterdam, The Netherlands, 2020; ISBN 9780081028865. [Google Scholar]

- International Energy Agency. Hydropower; International Energy Agency: Paris, France, 2021. [Google Scholar]

- Murdock, H.; Duncan, G.; Thomas, A. Renewables Global Status Report; International Atomic Energy Agency: Vienna, Austria, 2021. [Google Scholar]

- Schmutz, S.; Sendzimir, J. Riverine Ecosystem Management; Schmutz, S., Sendzimir, J., Eds.; Springer International Publishing: Cham, Switzerland, 2018; ISBN 978-3-319-73249-7. [Google Scholar]

- Gøtske, E.K.; Victoria, M. Future operation of hydropower in Europe under high renewable penetration and climate change. Iscience 2021, 24, 102999. [Google Scholar] [CrossRef] [PubMed]

- Sale, M.J.; Cada, G.F.; Carlson, T.J.; Dauble, D.D.; Hunt, R.T.; Sommers, G.L.; Rinehart, B.N.; Flynn, J.V.; Brookshier, P.A. DOE Hydropower Program Annual Report for FY 2001; Idaho National Lab.: Idaho Falls, ID, USA, 2002. [Google Scholar]

- Cada, G.F.; Coutant, C.C.; Whitney, R.R. Development of Biological Criteria for the Design of Advanced Hydropower Turbines; EERE Publication and Product Library: Washington, DC, USA, 1997. [Google Scholar]

- Brown, R.S.; Pflugrath, B.D.; Colotelo, A.H.; Brauner, C.J.; Carlson, T.J.; Deng, Z.D.; Seaburg, A.G. Pathways of barotrauma in juvenile salmonids exposed to simulated hydroturbine passage: Boyle’s law vs. Henry’s law. Fish. Res. 2012, 121–122, 43–50. [Google Scholar] [CrossRef]

- Garrison, L.A.; Fisher, J.R.K.; Sale, M.J.; Cada, G. Application of Biological Design Criteria and Computational Fluid Dynamics to Investigate Fish Survival in Kaplan Turbines. In Proceedings of the HydroVision 2002 Technical Papers, Portland, OR, USA, 29 July–2 August 2002; HCI Publications: Kansas City, MO, USA, 2002. [Google Scholar] [CrossRef]

- Fu, T.; Deng, Z.D.; Duncan, J.P.; Zhou, D.; Carlson, T.J.; Johnson, G.E.; Hou, H. Assessing hydraulic conditions through Francis turbines using an autonomous sensor device. Renew. Energy 2016, 99, 1244–1252. [Google Scholar] [CrossRef]

- Martinez, J.; Deng, Z.; Titzler, P.; Duncan, J.; Lu, J.; Mueller, R.; Tian, C.; Trumbo, B.; Ahmann, M.; Renholds, J. Hydraulic and biological characterization of a large Kaplan turbine. Renew. Energy 2018, 131, 240–249. [Google Scholar] [CrossRef]

- Van Esch, B.; Spierts, I. Validation of a model to predict fish passage mortality in pumping stations. Can. J. Fish. Aquat. Sci. 2014, 71, 1910–1923. [Google Scholar] [CrossRef]

- Romero-Gomez, P.; Lang, M.; Michelcic, J.; Weissenberger, S. Particle-based evaluations of fish-friendliness in Kaplan turbine operations. IOP Conf. Series Earth Environ. Sci. 2019, 240, 042016. [Google Scholar] [CrossRef]

- Richmond, M.; Romero-Gómez, P. Fish passage through hydropower turbines: Simulating blade strike using the discrete element method. IOP Conf. Series Earth Environ. Sci. 2014, 22, 062010. [Google Scholar] [CrossRef]

- Huang, Z.; Cheng, Y.; Wu, J.; Diao, W.; Huai, W. FSI simulation of dynamics of fish passing through a tubular turbine based on the immersed boundary-lattice Boltzmann coupling scheme. J. Hydrodyn. 2022, 34, 135–147. [Google Scholar] [CrossRef]

- Kassanos, I.; Alexopoulos, V.; Anagnostopoulos, J. Numerical design methodology for reversible Deriaz turbine with high energy performance and reduced fish impacts. In Proceedings of the IAHR 2022, 31st Symposium on Hydraulic Machinery and Systems, Trondheim, Norway, 26 June–1 July 2022. [Google Scholar] [CrossRef]

- ANSYS®. ANSYS Fluent v2021 User Manual, 12.2.1 Equations of Motion for Particles. ANSYS Inc. Available online: https://dl.cfdexperts.net/cfd_resources/Ansys_Documentation/Fluent/Ansys_Fluent_Theory_Guide.pdf (accessed on 24 November 2022).

- Sharma, A.; Ananthan, S.; Sitaraman, J.; Thomas, S.; Sprague, M.A. Overset meshes for incompressible flows: On preserving accuracy of underlying discretizations. J. Comput. Phys. 2020, 428, 109987. [Google Scholar] [CrossRef]

- Kim, W.; Choi, H. Immersed boundary methods for fluid-structure interaction: A review. Int. J. Heat Fluid Flow 2019, 75, 301–309. [Google Scholar] [CrossRef]

- Friedman, J.H.; Bentley, J.L.; Finkel, R.A. An Algorithm for Finding Best Matches in Logarithmic Expected Time. ACM Trans. Math. Softw. 1977, 3, 209–226. [Google Scholar] [CrossRef]

- Amidror, I. Scattered data interpolation methods for electronic imaging systems: A survey. J. Electron. Imaging 2002, 11, 157. [Google Scholar] [CrossRef]

- Etkin, B. Dynamics of Atmospheric Flight; Dover Publications: Mineola, NY, USA, 2005; ISBN 978-0486445229. [Google Scholar]

- Süli, E.; Mayers, D.F. An Introduction to Numerical Analysis; Cambridge University Press: Cambridge, UK, 2003; ISBN 9780521007948. [Google Scholar]

- Ozdemir, R. Fish Surface Loft. Available online: https://grabcad.com/library/fish-surface-loft (accessed on 18 March 2022).

- Aref, H.; Jones, S.W. Chaotic motion of a solid through ideal fluid. Phys. Fluids A Fluid Dyn. 1993, 5, 3026–3028. [Google Scholar] [CrossRef]

- Borisov, A.V.; Mamaev, I.S. On the motion of a heavy rigid body in an ideal fluid with circulation. Chaos Interdiscip. J. Nonlinear Sci. 2006, 16, 13118. [Google Scholar] [CrossRef] [PubMed]

- Aref, H. Chaotic advection of fluid particles. Philos. Trans. R. Soc. London. Ser. A Phys. Eng. Sci. 1990, 333, 273–288. [Google Scholar] [CrossRef]

- Essmann, E.; Shui, P.; Popinet, S.; Zaleski, S.; Valluri, P.; Govindarajan, R. Chaotic orbits of tumbling ellipsoids. J. Fluid Mech. 2020, 903, A10. [Google Scholar] [CrossRef]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics: The Finite Volume Method; Pearson Education Limited: London, UK, 2007; ISBN 978-0-13-127498-3. [Google Scholar]

| Interpolation Method | Formulation | |

|---|---|---|

| Nearest Neighbor (NN) | (5) | |

| Inverse Distance (ID) | (6) | |

| Radial Basis Functions (RBF) | and weights are: | (7) |

| Linear Regression (Least Squares) | where the weight vector is calculated as: | (8) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koukouvinis, P.; Anagnostopoulos, J. Simulating Fish Motion through a Diagonal Reversible Turbine. Energies 2023, 16, 810. https://doi.org/10.3390/en16020810

Koukouvinis P, Anagnostopoulos J. Simulating Fish Motion through a Diagonal Reversible Turbine. Energies. 2023; 16(2):810. https://doi.org/10.3390/en16020810

Chicago/Turabian StyleKoukouvinis, Phoevos (Foivos), and John Anagnostopoulos. 2023. "Simulating Fish Motion through a Diagonal Reversible Turbine" Energies 16, no. 2: 810. https://doi.org/10.3390/en16020810

APA StyleKoukouvinis, P., & Anagnostopoulos, J. (2023). Simulating Fish Motion through a Diagonal Reversible Turbine. Energies, 16(2), 810. https://doi.org/10.3390/en16020810