Prognosis of Lithium-Ion Batteries’ Remaining Useful Life Based on a Sequence-to-Sequence Model with Variational Mode Decomposition

Abstract

1. Introduction

- (1)

- A hybrid deep learning model named VMD-BiLSTM-Attention is proposed to predict the battery lifetime at an early stage. Only the first 12% of discharging capacity are required to evaluate battery remaining useful life. In other words, the proposed model is capable of accurately predicting the lifetime of one battery before it deteriorates obviously.

- (2)

- The applied deep learning technique automates hyperparameters selection, avoiding the human-labor-based selection and the risk of missing the best model. The hyperparameters learned by deep learning have a stronger stability to give accurate predictions for new inputs that have never been seen during the training stage.

- (3)

- In the VMD-BiLSTM-Attention model, the cycle-to-cycle evolution of the discharging process is selected as the input. The VMD and BiLSTM are utilized to eliminate capacity noise and capture temporal information, respectively. The model architecture and implementation setups are demonstrated in detail.

2. Methods

2.1. VMD

2.2. Bi-LSTM

2.3. Seq-to-Seq NN Based on VMD-BiLSTM-Attention

| Algorithm 1. Outline of seq-to-seq RUL prediction model for lithium batteries. | |

| 1: | Input: The training set Ltrain |

| 2: | Output: Trained sequence-to-sequence model parameters |

| 3: | Initialize parameters |

| 4: | Repeat |

| 5: | Forward Propagation: |

| 6: | do |

| 7: | Step1: Conduct VMD operation with the capacity data in Equations (1)–(6). |

| 8: | Step2: Use BiLSTM Equations (7)–(15) to predict RUL using the SOH result from VMD. |

| 9: | Step3: Use dropout to prevent overfitting |

| 10: | Step4: Use temporal attention mechanism to focus sequence key in formation |

| 11: | Step5: Use time-distributed fully connected dense layer to handle time dimension of sequence. |

| 12: | Step6: Calculate the MAE introduced in Equation (18) between the prediction and targets. |

| 13: | end |

| 14: | Backward Propagation: |

| 15: | Compute the gradient using Adam and update network parameters |

| 16: | until A predefined small loss |

3. Results

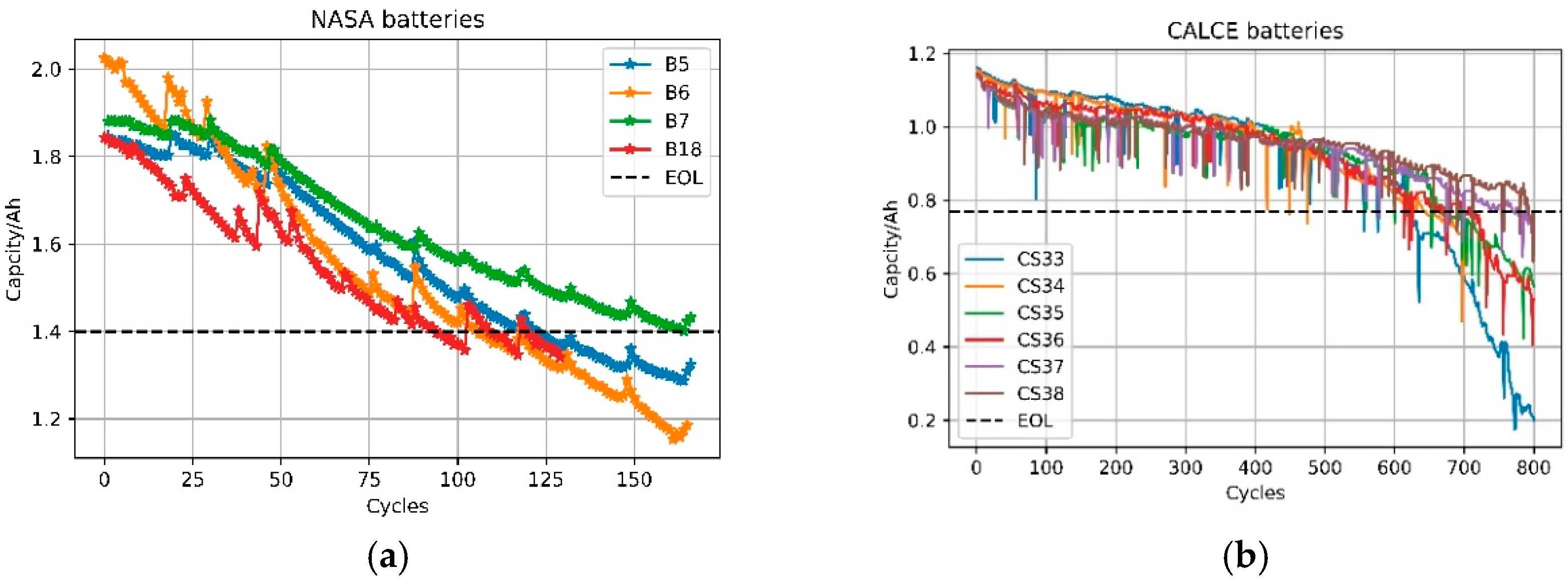

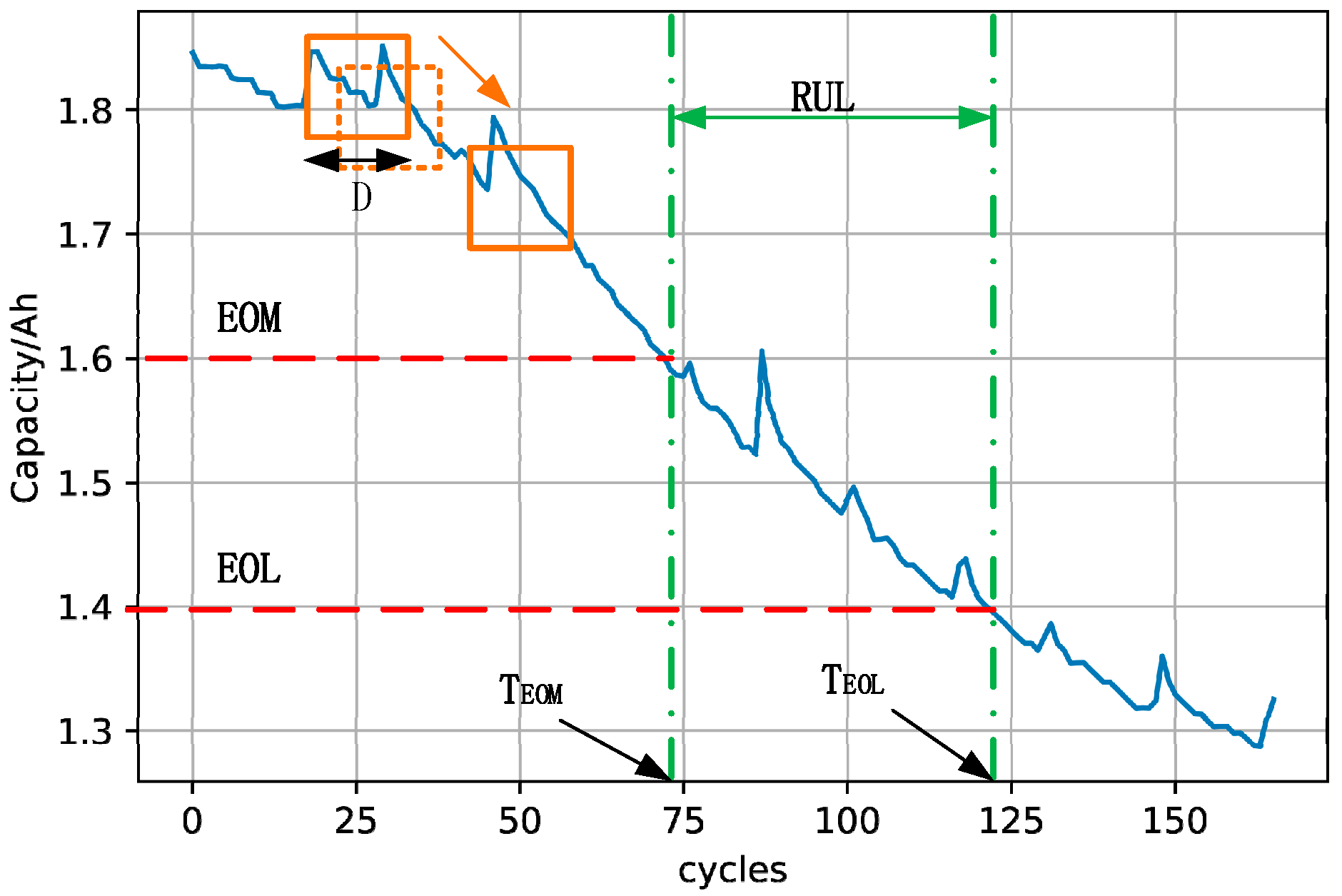

3.1. Data Sets Description

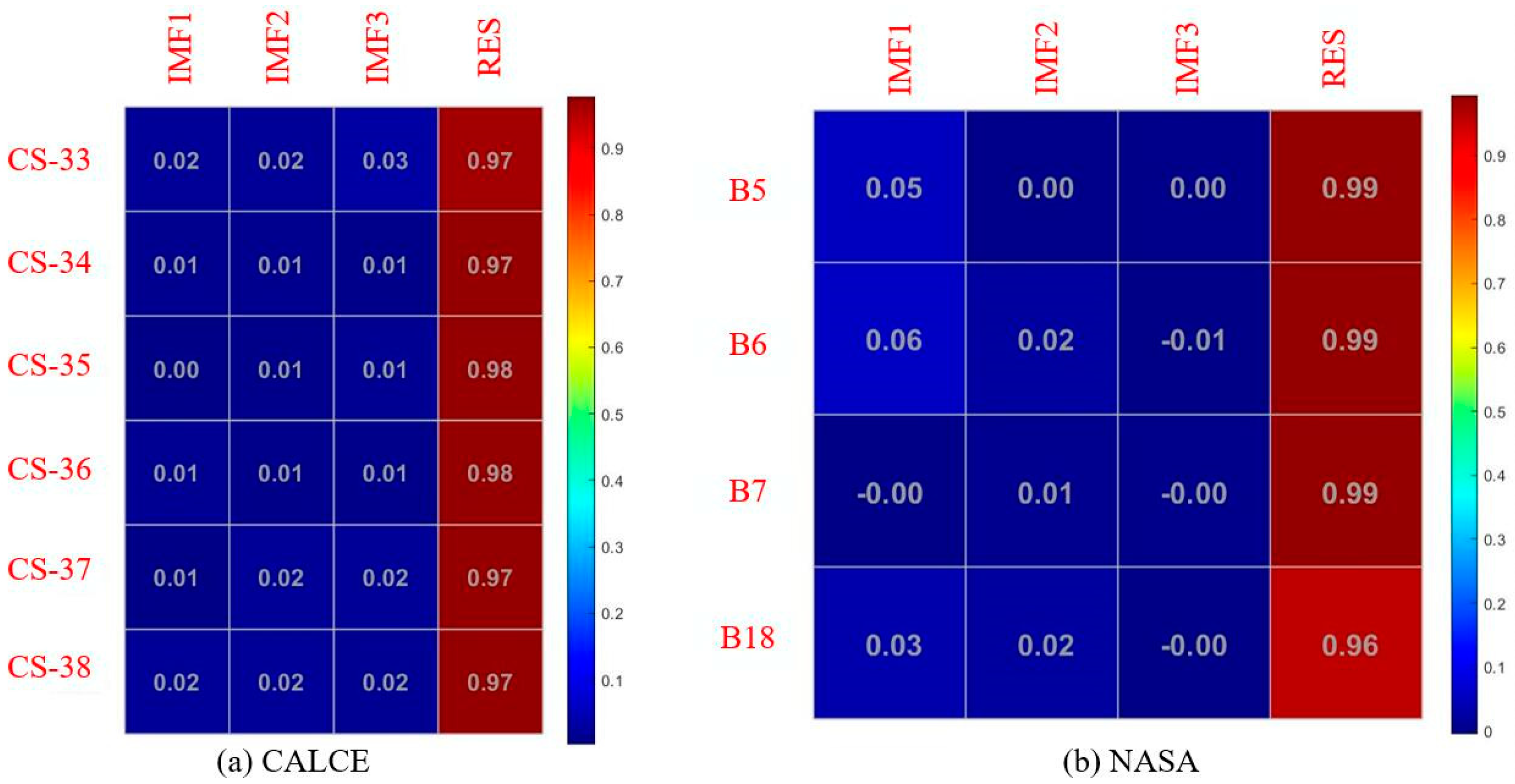

3.2. VMD Results

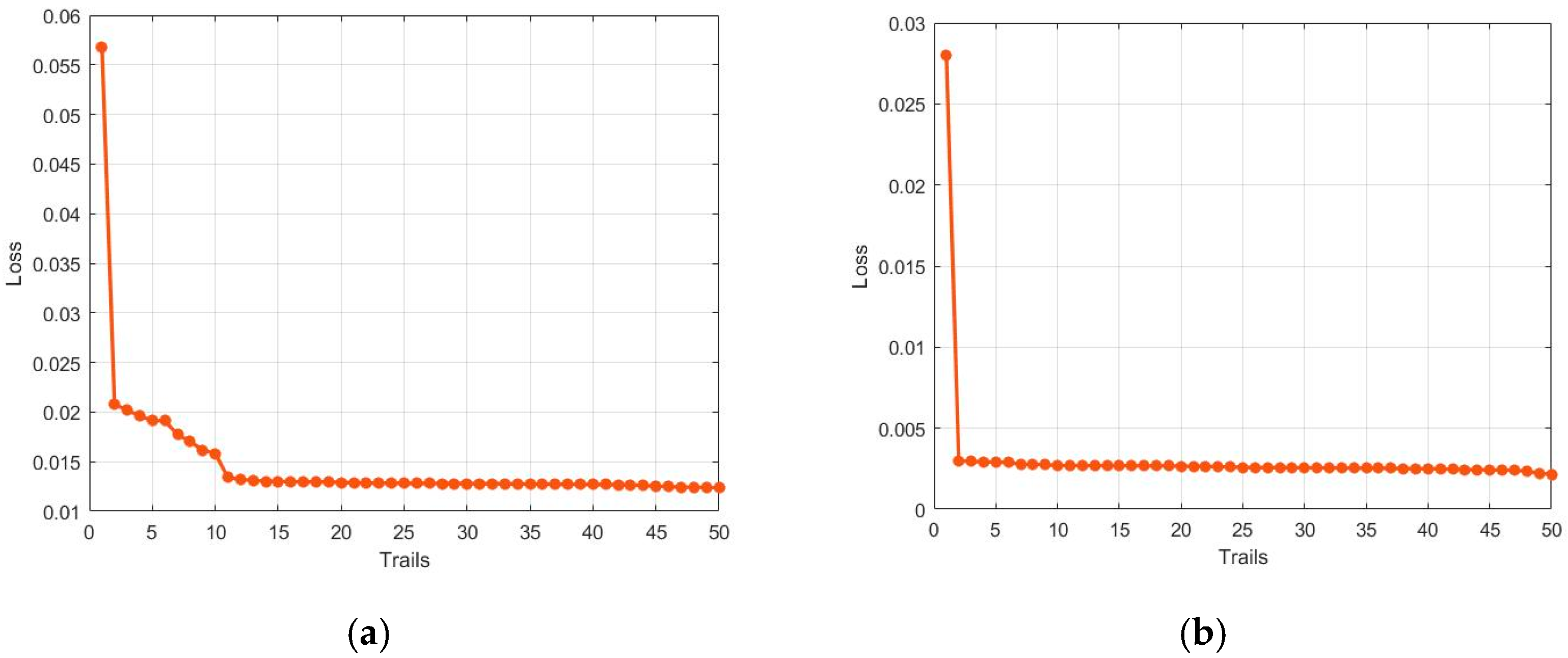

3.3. Training Detail

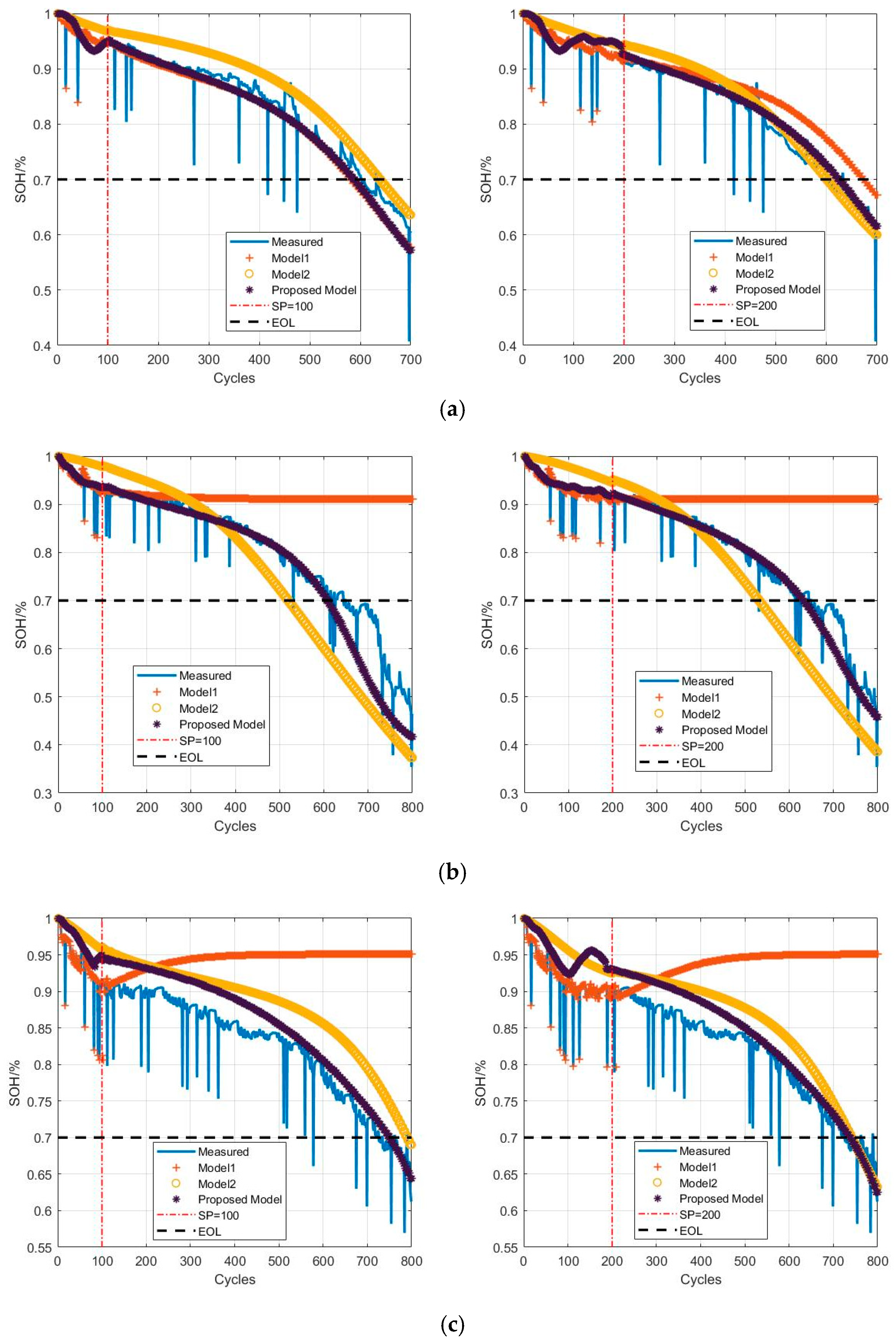

3.4. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Ge, M.F.; Liu, Y.; Jiang, X.; Liu, J. A review on state of health estimations and remaining useful life prognostics of lithium-ion batteries. Measurement 2021, 174, 109057. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Liu, K.; Wei, Z.; Yang, Z.; Li, K. Mass load prediction for lithium-ion battery electrode clean production: A machine learning approach. J. Clean. Prod. 2021, 289, 125159. [Google Scholar] [CrossRef]

- Liu, K.; Ashwin, T.R.; Hu, X.; Lucu, M.; Widanage, W.D. An evaluation study of different modelling techniques for calendar ageing prediction of lithium-ion batteries. Renew. Sustain. Energy Rev. 2020, 131, 110017. [Google Scholar] [CrossRef]

- Takagishi, Y.; Yamaue, T. Prediction of Li-ion Battery Module Performance under Running Condition Based on “Multifactorial Degradation Model”. Int. J. Automot. Eng. 2017, 8, 143–148. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.; Wei, Z.; Zhang, C.; Shang, Y.; Teodorescu, R.; Han, Q.-L. Towards long lifetime battery: AI-based manufacturing and management. IEEE/CAA J. Autom. Sin. 2022, 9, 1139–1165. [Google Scholar] [CrossRef]

- Liu, K.; Gao, Y.; Zhu, C.; Li, K.; Fei, M.; Peng, C.; Zhang, X.; Han, Q.-L. Electrochemical modeling and parameterization towards control-oriented management of lithium-ion batteries. Control Eng. Pract. 2022, 124, 105176. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Wei, J.; Dong, G.; Chen, Z. Remaining useful life prediction and state of health diagnosis for lithium-ion batteries using particle filter and support vector regression. IEEE Trans. Ind. Electron. 2017, 65, 5634–5643. [Google Scholar] [CrossRef]

- Yang, J.; Fang, W.; Chen, J.; Yao, B. A lithium-ion battery remaining useful life prediction method based on unscented particle filter and optimal combination strategy. J. Energy Storage 2022, 55, 105648. [Google Scholar] [CrossRef]

- Thelen, A.; Li, M.; Hu, C.; Bekyarova, E.; Kalinin, S.; Sanghadasa, M. Augmented model-based framework for battery remaining useful life prediction. Appl. Energy 2022, 324, 119624. [Google Scholar] [CrossRef]

- Saxena, S.; Hendricks, C.; Pecht, M. Cycle life testing and modeling of graphite/LiCoO2 cells under different state of charge ranges. J. Power Sources 2016, 327, 394–400. [Google Scholar] [CrossRef]

- Sarasketa-Zabala, E.; Martinez-Laserna, E.; Berecibar, M.; Gandiaga, I.; Rodriguez-Martinez, L.; Villarreal, I. Realistic lifetime prediction approach for Li-ion batteries. Appl. Energy 2016, 162, 839–852. [Google Scholar] [CrossRef]

- Wang, D.; Yang, F.; Zhao, Y.; Tsui, K.-L. Battery remaining useful life prediction at different discharge rates. Microelectron. Reliab. 2017, 78, 212–219. [Google Scholar] [CrossRef]

- He, W.; Williard, N.; Osterman, M.; Pecht, M. Prognostics of lithium-ion batteries based on dempster-shafer theory and the bayesian monte carlo method. J Power Sources 2011, 196, 10314–10321. [Google Scholar] [CrossRef]

- Guha, A.; Patra, A. State of health estimation of Lithium-ion batteries using capacity fade and internal resistance growth models. IEEE Trans. Transp. Electrif. 2018, 4, 135–146. [Google Scholar] [CrossRef]

- Li, H.; Pan, D.; Chen, C.L.P. Intelligent Prognostics for Battery Health Monitoring Using the Mean Entropy and Relevance Vector Machine. IEEE Trans. Syst. Man Cybern. Syst. 2014, 44, 851–862. [Google Scholar] [CrossRef]

- Yang, J.; Fang, W.; Chen, J.; Yao, B. State of health prediction for lithium-ion batteries using multiple-view feature fusion and support vector regression ensemble. Int. J. Mach. Learn. Cybern. 2019, 10, 2269–2282. [Google Scholar]

- Mansouri, S.S.; Karvelis, P.; Georgoulas, G.; Nikolakopoulos, G. Remaining useful battery life prediction for UAVs based on machine learning. IFAC-PapersOnLine 2017, 50, 4727–4732. [Google Scholar]

- Donato, T.H.R.; Quiles, M.G. Machine learning systems based on xgBoost and MLP neural network applied in satellite lithium-ion battery sets impedance estimation. Adv. Comput. Intell. Int. J. (ACII) 2018, 5, 1–20. [Google Scholar]

- Razavi-Far, R.; Chakrabarti, S.; Saif, M. Multi-step parallel-strategy for estimating the remaining useful life of batteries. In Proceedings of the 2017 IEEE 30th Canadian Conference on Electrical and Computer Engineering (CCECE), Windsor, ON, Canada, 30 April–3 May 2017; pp. 1–4. [Google Scholar]

- Patil, M.A.; Tagade, P.; Hariharan, K.S.; Kolake, S.M.; Song, T.; Yeo, T.; Doo, S. A novel multistage support vector machine based approach for Li ion battery remaining useful life estimation. Appl. Energy 2015, 159, 285–297. [Google Scholar] [CrossRef]

- Richardson, R.; Osborne, M.A.; Howey, A. Gaussian process regression for forecasting battery state of health. J. Power Sources 2017, 357, 209–219. [Google Scholar] [CrossRef]

- You, G.; Park, S.; Oh, D. Real-time state-of-health estimation for electric vehicle batteries: A data-driven approach. Appl. Energy 2016, 176, 92–103. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. Long short-term memory recurrent neural network for remaining useful life prediction of lithium-ion batteries. IEEE Trans. Veh. Technol. 2018, 67, 5695–5705. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Y.; Xiong, R.; He, H.; Pecht, M.G. State-of-health estimation and remaining useful life prediction for the lithium-ion battery based on a variant long short term memory neural network. J. Power Sources 2020, 459, 228069. [Google Scholar] [CrossRef]

- Kim, S.; Choi, Y.Y.; Kim, K.J.; Choi, J.I. Forecasting state-of-health of lithium-ion batteries using variational long short-term memory with transfer learning. J. Energy Storage 2021, 41, 102893. [Google Scholar] [CrossRef]

- Ding, P.; Liu, X.; Li, H.; Huang, Z.; Zhang, K.; Shao, L.; Abedinia, O. Useful life prediction based on wavelet packet decomposition and two-dimensional convolutional neural network for lithium-ion batteries. Renew. Sustain. Energy Rev. 2021, 148, 111287. [Google Scholar] [CrossRef]

- Hong, J.; Lee, D.; Jeong, E.-R.; Yi, Y. Towards the swift prediction of the remaining useful life of lithium-ion batteries with end-to-end deep learning. Appl. Energy 2020, 278, 115646. [Google Scholar] [CrossRef]

- Kim, S.W.; Oh, K.Y.; Lee, S. Novel informed deep learning-based prognostics framework for on-board health monitoring of lithium-ion batteries. Appl. Energy 2022, 315, 119011. [Google Scholar] [CrossRef]

- Tang, Y.; Yang, K.; Zheng, H.; Zhang, S.; Zhang, Z. Early prediction of lithium-ion battery lifetime via a hybrid deep learning model. Measurement 2022, 199, 111530. [Google Scholar] [CrossRef]

- Chen, D.; Zhang, W.; Zhang, C.; Sun, B.; Cong, X.; Wei, S.; Jiang, J. A novel deep learning-based life prediction method for lithium-ion batteries with strong generalization capability under multiple cycle profiles. Appl. Energy 2022, 327, 120114. [Google Scholar] [CrossRef]

- Pang, X.; Zhao, Z.; Wen, J.; Jia, J.; Shi, Y.; Zeng, J.; Dong, Y. An interval prediction approach based on fuzzy information granulation and linguistic description for remaining useful life of lithium-ion batteries. J. Power Sources 2022, 542, 231750. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, C.; Wang, Y. Lithium-ion battery capacity and remaining useful life prediction using board learning system and long short-term memory neural network. J. Energy Storage 2022, 52, 104901. [Google Scholar] [CrossRef]

- Saha, B.; Goebel, K. NASA Ames Prognostics Data Repository; NASA Ames: Moffett Field, CA, USA, 2007.

- Cheng, G.; Wang, X.; He, Y. Remaining useful life and state of health prediction for lithium batteries based on empirical mode decomposition and a long and short memory neural network. Energy 2021, 232, 121022. [Google Scholar] [CrossRef]

| Battery ID | SP | RUL | PRUL | RE/% | RMSE | MAE |

|---|---|---|---|---|---|---|

| CS34 | 100 | 602 | 590 | 1.9 | 0.026 | 0.017 |

| 200 | 602 | 621 | 3.1 | 0.025 | 0.015 | |

| CS36 | 100 | 618 | 608 | 1.6 | 0.048 | 0.028 |

| 200 | 618 | 630 | 1.9 | 0.028 | 0.016 | |

| CS37 | 100 | 726 | 746 | 2.7 | 0.036 | 0.029 |

| 200 | 726 | 736 | 1.4 | 0.034 | 0.026 |

| Battery ID | SP | RUL | PRUL | RE | RMSE | MAE |

|---|---|---|---|---|---|---|

| B5 | 20 | 124 | 131 | 5.6 | 0.026 | 0.022 |

| 30 | 124 | 129 | 4.0 | 0.028 | 0.024 | |

| B6 | 20 | 109 | 100 | 8.2 | 0.036 | 0.030 |

| 30 | 109 | 104 | 4.5 | 0.034 | 0.026 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, C.; He, Z.; Bao, Z.; Sun, C.; Gao, M. Prognosis of Lithium-Ion Batteries’ Remaining Useful Life Based on a Sequence-to-Sequence Model with Variational Mode Decomposition. Energies 2023, 16, 803. https://doi.org/10.3390/en16020803

Zhu C, He Z, Bao Z, Sun C, Gao M. Prognosis of Lithium-Ion Batteries’ Remaining Useful Life Based on a Sequence-to-Sequence Model with Variational Mode Decomposition. Energies. 2023; 16(2):803. https://doi.org/10.3390/en16020803

Chicago/Turabian StyleZhu, Chunxiang, Zhiwei He, Zhengyi Bao, Changcheng Sun, and Mingyu Gao. 2023. "Prognosis of Lithium-Ion Batteries’ Remaining Useful Life Based on a Sequence-to-Sequence Model with Variational Mode Decomposition" Energies 16, no. 2: 803. https://doi.org/10.3390/en16020803

APA StyleZhu, C., He, Z., Bao, Z., Sun, C., & Gao, M. (2023). Prognosis of Lithium-Ion Batteries’ Remaining Useful Life Based on a Sequence-to-Sequence Model with Variational Mode Decomposition. Energies, 16(2), 803. https://doi.org/10.3390/en16020803