Green Diesel Production via Deoxygenation Process: A Review

Abstract

1. Introduction

1.1. An Overview of Climate Change

1.2. Energy Crisis

1.3. Renewable Energy Sources: Biomass and Biofuel

2. Biodiesel and Green Diesel

3. Green Diesel Production: DO Process

3.1. Primary Reactions of the DO Process

3.2. Secondary Reactions of DO

3.3. Reaction Conditions

3.4. Mass Transfer Limitation

3.5. Feedstock for the DO Process

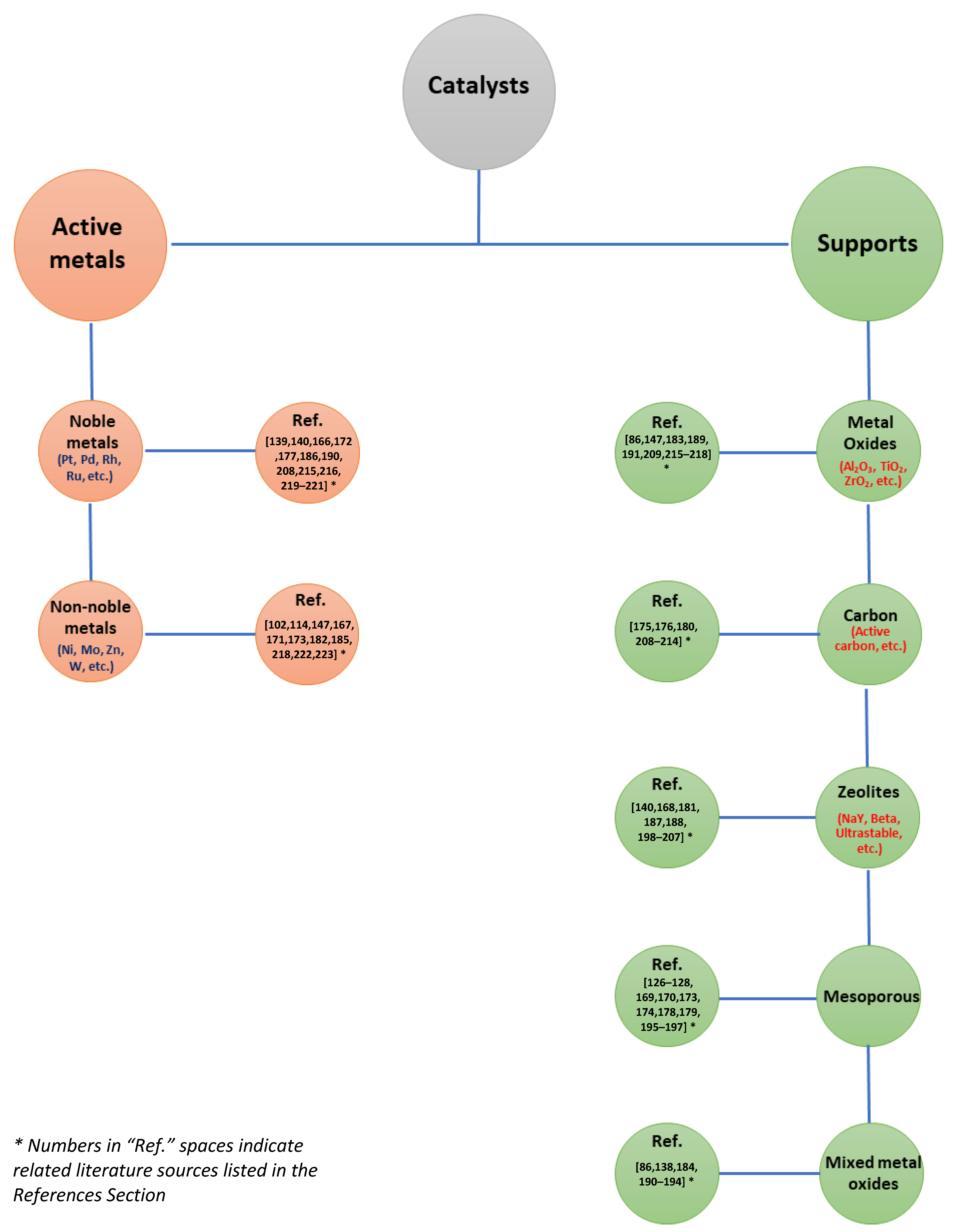

3.6. Catalysts for Green Diesel Production

3.6.1. Catalysts’ Active Phases for Heterogeneous Catalysis

3.6.2. Catalytic Supports

3.6.3. Catalyst Deactivation and Regeneration

4. Reactors for Catalytic DO and Performance Evaluation

| Catalyst | Support | Feedstock | Reactor Type | Reaction Conditions | Conversion (%) | Ref. | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| T (°C) | PH2 (bar) | Time/Residence Time | Solvent | Other Specifications | ||||||

| Ni | Palygorskite | WCO | Stirred batch | 310 | 40 | 4 h | Dodecane | - | 83.0 | [224] |

| Ni | Palygorskite | FAD | Stirred batch | 310 | 40 | 4 h | Dodecane | - | 68.0 | [224] |

| Ni | Palygorskite | CHO | Stirred batch | 310 | 40 | 4 h | Dodecane | - | 98.0 | [224] |

| Ni | Palygorskite | SCGO | Stirred batch | 310 | 40 | 4 h | Dodecane | - | 10.0 | [224] |

| Ni | Alumina | WCO | Falling basket batch | 310 | 40 | 9 h | - | - | 100 | [154] |

| Co | Commercial AC | Macauba Oil | Parr batch | 350 | 30 | 2 h | Dodecane | - | >97.0 | [253] |

| Mo | Al2O3 | Sunflower Oil | Falling basket batch | 310 | 40 | 9 h | - | - | 97.0 | [254] |

| Fe | HMS | Triolein | Stirred batch | 320–410 | - | 0.5–4 h | - | - | 27.0–80.0 (at 2 h) | [173] |

| Ni | HMS | Triolein | Stirred batch | 380 | - | 2 h | - | - | >75.2 | [174] |

| NiMo | Alumina | Karanja Oil | Stirred batch | 280–360 | 30 | 5 h | Dodecane | - | 10.0–100 | [127] |

| Ni | Alumina | Karanja Oil | Parr batch | 280–360 | 30 | 6 h | Dodecane | - | 45.0–100 | [128] |

| NiP | AC | Palmitic Acid | Packed bed | 350 | 10 | 2.5 h | - | - | >86.2 | [175] |

| Ni | ZrO2 | Palmitic Acid | Parr batch | 270 | 10 | 6 h | Dodecane | - | 98.3 | [255] |

| Ni | AC | Palmitic Acid | Parr batch | 270 | 10 | 6 h | Dodecane | - | 44.7 | [255] |

| Ni | HZSM-5 | Palmitic Acid | Parr batch | 270 | 10 | 6 h | Dodecane | - | 86.2 | [255] |

| Ni | AC | WCO | Stirred semi-batch | 350 | - | 3 h | - | - | 90.0 | [157] |

| Ni | Beta Zeolite | WCO | Stirred semi-batch | 350 | - | 3 h | - | - | 85.0 | [157] |

| Ni | Graphene oxides | WCO | Stirred semi-batch | 350 | - | 3 h | - | - | 78.0 | [157] |

| NiMo | γ-Al2O3 | WCO | Autoclave batch | 300 | 20 | 3 h | Dodecane | - | 80.0 | [153] |

| NiMo | HZSM-5 | WCO | Autoclave batch | 300 | 20 | 3 h | Dodecane | - | 71.8 | [153] |

| NiMo | β-zeolite | WCO | Autoclave batch | 300 | 20 | 3 h | Dodecane | - | 64.2 | [153] |

| NiMo | AC | WCO | Autoclave batch | 300 | 20 | 3 h | Dodecane | - | 50.7 | [153] |

| NiMo | Bentonite | WCO | Autoclave batch | 300 | 20 | 3 h | Dodecane | - | 71.7 | [153] |

| Ni | MgO–Al2O3 | Oleic Acid | Autoclave batch | 300 | 40 | 3 h | - | - | >80.0 | [256] |

| FeNi | C | Stearic Acid | Micro-batch | 300–350 | - | 3 h | - | - | 99.9 | [176] |

| Ni | Pd/Al2O3 | Tristearin | Stirred semi-batch | 260 | 40 | 3 h | Dodecane | - | 0–100 | [96] |

| Ni-Fe | ZrO2 | Sunflower Oil | Stirred batch | 240 | 20 | 3 h | Dodecane | - | 96.8 | [166] |

| Ni-Fe | ZrO2 | Microalgae Oil | Stirred batch | 240 | 20 | 3 h | Dodecane | - | 92.0 | [166] |

| Ni-Fe | ZrO2 | Oleic Acid | Stirred batch | 240 | 20 | 3 h | Dodecane | - | 98.7 | [166] |

| Ni-Fe | ZrO2 | Stearic Acid | Stirred batch | 240 | 20 | 3 h | Dodecane | - | 99.1 | [166] |

| Ni-Fe | ZrO2 | Octadecanol | Stirred batch | 240 | 20 | 3 h | Dodecane | - | 100 | [166] |

| NiZn | AC | WCO | Autoclave semi-batch | 350 | - | 1 h | - | - | >78.0 | [257] |

| ReNiMo | γ-Al2O3 | Oleic Acid | Batch | 330–400 | 40 | 1 h | - | - | 100 | [177] |

| Ni | MgO–Al2O3 | Oleic Acid | Autoclave batch | 300 | 20 | 3 h | - | - | 96.7 | [256] |

| Pd | C | Cashew Nut Shell Liquid | Parr batch | 180–300 | 10–40 | 5–10 h | - | - | >65.0 | [121] |

| Ni-Co | SBA-15 | WCO | Stirred semi-batch | 350 | - | 2 h | - | - | - | [178] |

| Ni-Fe | SBA-15 | WCO | Stirred semi-batch | 350 | - | 2 h | - | - | - | [178] |

| Co-Fe | SBA-15 | WCO | Stirred semi-batch | 350 | - | 2 h | - | - | - | [178] |

| W-Ni | Al2O3 | Sunflower Oil | Autoclave batch | 310 | 40 | 9 h | - | - | >70.0 | [150] |

| Al2O3-TiO2 | - | Triolein | Stirred semi-batch | 380 | - | 1 h | - | - | >48.0 | [169] |

| Ni | Al-MCM-41 | Reutealis Trisperma Oil | Stirred semi-batch | 350 | - | 4 h | - | - | >48.0 | [179] |

| Pd | AC | WCO | Autoclave batch | 300–350 | - | 0.5–3 h | - | - | >15.0 | [180] |

| Ni | ZSM-5 | Palmitic Acid | Parr batch | 300 | 35 | 8 h | Dodecane | - | >27.0 | [181] |

| NiMo | ZSM-5 | Palmitic Acid | Parr batch | 300 | 35 | 8 h | Dodecane | - | >67.0 | [181] |

| NiMo | γ-Al2O3 | Oleic Acid | Parr batch | 300–350 | - | 3 h | - | - | >43.0 | [182] |

| NiMo | γ-Al2O3 | Microalgae Oil | Continuous microreactor | 360 | 34.5 | 1 sec | - | H2/oil = 1 sL/mL | 98.7 | [129] |

| Pt-Sn | Al2O3 | Rapeseed Oil | Packed bed continuous | 400–480 | 50.7 | - | - | H2 space velocity = 100 mL/min | 100 at 480 °C | [139] |

| Ni2P | SiO2 | Methyl laurate | Packed bed continuous | 300–340 | 20 | - | - | WHSV = 10 h−1; H2/feed = 50 | >97.0 | [258] |

| Ni2P | MCM-41 | Methyl laurate | Packed bed continuous | 300–340 | 20 | - | - | WHSV = 10 h−1; H2/feed = 50 | >97.0 | [258] |

| Ni2P | SBA-15 | Methyl laurate | Packed bed continuous | 300–340 | 20 | - | - | WHSV = 10 h−1; H2/feed = 50 | >97.0 | [258] |

| Pd/P | γ-Al2O3 | Tricaprylin | Packed-bed microreactor | 300–350 | 21 | - | - | WHSV = 4 h−1; H2/feed = 20 | 100 | [183] |

| NiMo | Mn-Al2O3 | WSO | Continuous microreactor | 380–410 | 40 | - | - | H2/feed = 87.5 | 12.9–48.8 at 380 °C | [147] |

| NiMoS2 | γ-Al2O3 | Palm Oil | Packed bed continuous | 270–420 | 15–80 | - | - | LHSV = 0.25–5 h−1; H2/feed = 250–200 Ncm3/m3 | >97.0 | [259] |

| NiP | - | Palm Oil | Packed bed continuous | 300–400 | 50 | 3 h | - | H2/feed = 1–1000 NmL/mL | >90.0 | [136] |

| CuP | - | Palm Oil | Packed bed continuous | 300–400 | 50 | 3 h | - | H2/feed = 1–1000 NmL/mL | >80.0 | [136] |

| CoP | - | Palm Oil | Packed bed continuous | 300–400 | 50 | 3 h | - | H2/feed = 1–1000 NmL/mL | >35.0 | [136] |

| NiP | Na-Mordenite | Palm Oil | Continuous trickle bed | 300–450 | 1–50 | 3–9 h | - | H2/feed = 1000 LHSV = 1 h−1 WHSV = 0.9 h−1 | >75.0 | [138] |

| Ni | Al2O3 | Palm Oil | Continuous packed bed | 250–400 | 20–30 | 6–20 h | Dodecane | H2/feed = 250–2000 cm3/cm3 LHSV = 1.4–4.8 h−1 | 55.0–90.0 at 350 °C | [86] |

| Ni | ZrO2 | Palm Oil | Continuous packed bed | 250–400 | 20–30 | 6–20 h | Dodecane | H2/feed = 250–2000 cm3/cm3 LHSV = 1.4–4.8 h−1 | 65.0–90.0 at 350 °C | [86] |

| Ni | SiO2 | Palm Oil | Continuous packed bed | 250–400 | 20–30 | 6–20 h | Dodecane | H2/feed = 250–2000 cm3/cm3 LHSV = 1.4–4.8 h−1 | 50.0–80.0 at 350 °C | [86] |

| Ni | CaO-MgO-Al2O3 | Palm Oil | Continuous packed bed | 300–400 | 30 | 6–20 h | Dodecane | H2/feed = 1000 cm3/cm3 LHSV = 1.2–3.6 h−1 | >55.0 at 6 h varying T; | [184] |

| Ni | Al2O3 | Palm Oil | Continuous packed bed | 300–400 | 30 | 6–20 h | Dodecane | H2/feed = 1000 cm3/cm3 LHSV = 1.2–3.6 h−1 | 55.0 (300 °C)–100 (375 °C) | [243] |

| Ni | La2O3–Al2O3 | Palm Oil | Continuous packed bed | 300–400 | 30 | 6–20 h | Dodecane | H2/feed = 1000 cm3/cm3 LHSV = 1.2–3.6 h−1 | >85.0 | [243] |

| NiMo | Al2O3 | Castor Oil | Two continuous packed bed | 300–370 | 35 | 66–132 min | - | H2/feed = 35–105 | >57.2 | [260] |

| HZSM-5 | - | Coconut Oil | Autoclave batch | 350–400 | 20–40 | 1–3 h | - | - | 69.6 | [261] |

| Pd | C | Coconut Oil | Batch | 300 | 10 | 6 h | - | - | 100 | [262] |

| Pd | C | Macauba Oil | Parr batch | 300 | 10–19 | 5 h | Dodecane | - | 85.0 | [263] |

| CeZrO2 | - | Oleic Acid | Autoclave batch | 300 | 1 | 3 h | - | - | 45.7–69.6 | [264] |

| Mo-Zn | Al2O3 | Carinata Oil | Parr batch | 350 | 20 | 5 h | - | - | >90.0 | [265] |

| Ni | SAPO-11 | Stearic Acid | Autoclave semi-batch | 290 | 40 | 3 h | n-Heptane | - | 92.4 | [266] |

| Ni | Co-S | Stearic Acid | Autoclave semi-batch | 290 | 40 | 3 h | n-Heptane | - | 99.0 | [266] |

| NiCo | SAPO-11 | Stearic Acid | Autoclave semi-batch | 290 | 40 | 3 h | n-Heptane | - | 94.5 | [266] |

| Mesoporous Tantalum Phosphate | - | Palm Seed Oil | Autoclave batch | 300–400 | 10 | 2–4 h | - | - | >32.3 | [267] |

| Rh | HZSM-5 | Palm Oil | Continuous mini packed bed | 400–500 | 7–34 | - | - | H2/feed = 36.6–220.9 WHSV = 10–43.7 h−1 | >95 | [172] |

| Ni | Al2O3 | Chicken Fats | Continuous trickle bed | 330 | 50 | - | - | H2/feed = 1000 cm3/cm3 LHSV = 0.5–2.0 h−1 | 100 | [185] |

| Pd | C | Oleic Acid | Continuous | 380–450 | - | 1–4 h | - | H2 = 5.0–95.0 mL/min WHSV = 1.6–7.9 h−1 | >70 | [268] |

| Ni-Al LDH | - | Tristearin | Semi-batch | 260–360 | 40 | 6 h | - | - | 100 | [269] |

| Ni/CeO2 | Al2O3 | Methyl Oleate | Stirred batch | 300 | 25 | 6 h | - | - | 100 | [270] |

| Ni-Ca | SiO2-Al2O3 | Ceiba Pentandra Oil | Stirred semi-batch | 300–380 | - | 0.5–3 h | - | - | >25.0 | [271] |

| Ir-ReOx | SiO2 | Stearic Acid | Parr batch | 140–180 | 20 | 1–5 h | - | - | >38 | [272] |

| NiMoCe | γ-Al2O3 | Kemiri Sunan Oil | Autoclave batch | 400 | 35 | 5 h | - | - | <57.8 | [273] |

| Co | AC | Stearic Acid | Batch | 300 | 40 | 1 h | Decane | - | 100 | [274] |

| Pd | C | Phoenix Dactylifera Kernel Oil | Stirred batch | 300 | 10 | 5 h | Dodecane | - | 91.1 | [275] |

| Pd | SiW-SiO2 | Methyl Stearate | Autoclave batch | 200 | 15 | 5 h | Cyclohexane | - | <66.7 | [276] |

| Pt-WOx | SiO2-Al2O3 | Oleic Acid | Parr batch | 260 | 20 | 2.5 h | n-Heptane | - | >39.0 | [186] |

| Ni | Zeolite | Methyl Palmitate | Parr batch | 240 | 25 | 4 h | Heptane | - | >38.0 | [187] |

| Ni | CaO | Triolein | Stirred batch | 350 | - | 1 h | - | - | 50.0 | [277] |

| Zn | CaO | Triolein | Stirred batch | 350 | - | 1 h | - | - | 50.0 | [277] |

| Fe | CaO | Triolein | Stirred batch | 350 | - | 1 h | - | - | 45.0 | [277] |

| Co | CaO | Triolein | Stirred batch | 350 | - | 1 h | - | - | 55.0 | [277] |

| Ni | ZrO2 | Palmitic Acid | Micro-batch | 300 | 55 | 6 h | - | - | 100 | [278] |

| Hydrotalcite | - | Jatropha Curcas Oil | Parr batch | 400 | - | 3–6 h | - | - | >80.0 | [279] |

| γ-Al2O3 | - | Jatropha Curcas Oil | Parr batch | 400 | - | 3–6 h | - | - | >85.0 | [279] |

| Co | NP-NC | Oleic Acid | Stirred batch | 220 | 20 | 3 h | Dodecane | - | 99.6 | [280] |

| NiMo | Al2O3 | Rapeseed Oil | Packed bed batch | 260–280 | 35 | 6 h | - | - | >20.0 | [281] |

| Pd | C | Stearic Acid | Stirred batch | 300 | - | 0–5 h | Dodecane | - | >33.0 | [282] |

| Co3O4 | SiO2-Al2O3 | Methyl Stearate | Stirred batch | 250–300 | 2–30 | 6–8 h | n-Heptane | - | >88.0 | [283] |

| CoMo | - | Oleic Acid | Autoclave batch | 300 | - | 3 h | - | - | 85.0 | [284] |

5. Simulations of Green Diesel Production

6. Environmental Considerations, Life Cycle Assessment, and Costs of Green Diesel Production

7. Industrial Green Diesel Production

8. Final Remarks and Future Perspectives

Author Contributions

Funding

Conflicts of Interest

Appendix A. Catalyst Characterization

References

- Climate Change 2021: The Physical Science Basis. Available online: https://www.ipcc.ch/report/ar6/wg1/ (accessed on 14 December 2022).

- Conti, J.; Holtberg, P.; Diefenderfer, J.; LaRose, A.; Turnure, J.T.; Westfall, L. International Energy Outlook 2016 with Projections to 2040; DOE/EIA-0484(2016); USDOE Energy Information Administration (EIA): Washington, DC, USA, 2016.

- Sri Shalini, S.; Palanivelu, K.; Ramachandran, A.; Raghavan, V. Biochar from Biomass Waste as a Renewable Carbon Material for Climate Change Mitigation in Reducing Greenhouse Gas Emissions—A Review. Biomass Convers Biorefin 2021, 11, 2247–2267. [Google Scholar] [CrossRef]

- Global Warming of 1.5 °C. Available online: https://www.ipcc.ch/sr15/ (accessed on 15 September 2022).

- Kuramochi, T.; Nascimento, L.; Moisio, M.; den Elzen, M.; Forsell, N.; van Soest, H.; Tanguy, P.; Gonzales, S.; Hans, F.; Jeffery, M.L.; et al. Greenhouse Gas Emission Scenarios in Nine Key Non-G20 Countries: An Assessment of Progress toward 2030 Climate Targets. Env. Sci Policy 2021, 123, 67–81. [Google Scholar] [CrossRef]

- The Paris Agreement | UNFCCC. Available online: https://unfccc.int/process-and-meetings/the-paris-agreement/the-paris-agreement (accessed on 9 August 2022).

- Glasgow Climate Change Conference—October-November 2021|UNFCCC. Available online: https://unfccc.int/conference/glasgow-climate-change-conference-october-november-2021 (accessed on 9 August 2022).

- Ritchie, H.; Roser, M. CO₂ and Greenhouse Gas Emissions—Our World in Data. Available online: https://ourworldindata.org/co2-and-other-greenhouse-gas-emissions (accessed on 9 August 2022).

- Dolge, K.; Blumberga, D. Economic Growth in Contrast to GHG Emission Reduction Measures in Green Deal Context. Ecol. Indic. 2021, 130, 108153. [Google Scholar] [CrossRef]

- 2050 Long-Term Strategy. Available online: https://climate.ec.europa.eu/eu-action/climate-strategies-targets/2050-long-term-strategy_en (accessed on 14 December 2022).

- EU Responses to Climate Change | News | European Parliament. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20180703STO07129/eu-responses-to-climate-change (accessed on 9 August 2022).

- Feng, R.; Fang, X. China’s Pathways to Synchronize the Emission Reductions of Air Pollutants and Greenhouse Gases: Pros and Cons. Resour. Conserv. Recycl. 2022, 184, 106392. [Google Scholar] [CrossRef]

- Global Energy Review 2021—Analysis—IEA. Available online: https://www.iea.org/reports/global-energy-review-2021 (accessed on 14 December 2022).

- Baruch, J.J. Combating Global Warming While Enhancing the Future. Technol. Soc. 2008, 30, 111–121. [Google Scholar] [CrossRef]

- Xu, H.; Lee, U.; Wang, M. Life-Cycle Energy Use and Greenhouse Gas Emissions of Palm Fatty Acid Distillate Derived Renewable Diesel. Renew. Sustain. Energy Rev. 2020, 134, 110144. [Google Scholar] [CrossRef]

- di Vito Nolfi, G.; Gallucci, K.; Rossi, L. Green Diesel Production by Catalytic Hydrodeoxygenation of Vegetables Oils. Int. J. Environ. Res. Public Health 2021 2021, 18, 13041. [Google Scholar] [CrossRef]

- Hosseini, S.E. Fundamentals of Low Emission Flameless Combustion and Its Applications, 1st ed.; Hosseini, S., Ed.; Academic Press: Cambridge, MA, USA, 2022; Volume 1, ISBN 9780323852449. [Google Scholar]

- Nielsen, K.S.; Nicholas, K.A.; Creutzig, F.; Dietz, T.; Stern, P.C. The Role of High-Socioeconomic-Status People in Locking in or Rapidly Reducing Energy-Driven Greenhouse Gas Emissions. Nat. Energy 2021, 6, 1011–1016. [Google Scholar] [CrossRef]

- Renewable Energy Directive (RED II)—Europex. Available online: https://www.europex.org/eulegislation/renewable-energy-energy-directive/ (accessed on 10 August 2022).

- Jåstad, E.O.; Bolkesjø, T.F.; Trømborg, E.; Rørstad, P.K. The Role of Woody Biomass for Reduction of Fossil GHG Emissions in the Future North European Energy Sector. Appl. Energy 2020, 274, 115360. [Google Scholar] [CrossRef]

- Krug, M.; Nucci, M.R.d.; Caldera, M.; de Luca, E. Mainstreaming Community Energy: Is the Renewable Energy Directive a Driver for Renewable Energy Communities in Germany and Italy? Sustainability 2022, 14, 7181. [Google Scholar] [CrossRef]

- Bórawski, P.; Wyszomierski, R.; Bełdycka-Bórawska, A.; Mickiewicz, B.; Kalinowska, B.; Dunn, J.W.; Rokicki, T. Development of Renewable Energy Sources in the European Union in the Context of Sustainable Development Policy. Energies 2022, 15, 1545. [Google Scholar] [CrossRef]

- Zhou, B.; He, L.; Zhang, S.; Wang, R.; Zhang, L.; Li, M.; Liu, Y.; Zhang, S.; Wu, Y.; Hao, J. Variability of Fuel Consumption and CO2 Emissions of a Gasoline Passenger Car under Multiple In-Laboratory and on-Road Testing Conditions. J. Environ. Sci. 2023, 125, 266–276. [Google Scholar] [CrossRef]

- Andrés, L.; Alcántara, V.; Padilla, E. Transportation, Storage and GHG Emissions: A New Perspective of Input-Output Subsystem Analysis. Transp. Res. D Transp. Environ. 2021, 90, 102646. [Google Scholar] [CrossRef]

- Year-to-Year Change in Primary Energy Consumption from Fossil Fuels VS. Low-Carbon Energy, World. 2021. Available online: https://ourworldindata.org/grapher/annual-primary-energy-fossil-vs-low-carbon?time=latest&country=~OWID_WRL (accessed on 9 August 2022).

- Bull, S.R. Renewable Energy Today and Tomorrow. Proc. IEEE 2001, 89, 1216–1226. [Google Scholar] [CrossRef]

- di Giuliano, A.; Lucantonio, S.; Gallucci, K. Devolatilization of Residual Biomasses for Chemical Looping Gasification in Fluidized Beds Made Up of Oxygen-Carriers. Energies 2021, 14, 311. [Google Scholar] [CrossRef]

- Yana, S.; Nizar, M.; Irhamni; Mulyati, D. Biomass Waste as a Renewable Energy in Developing Bio-Based Economies in Indonesia: A Review. Renew. Sustain. Energy Rev. 2022, 160, 112268. [Google Scholar] [CrossRef]

- Ekpeni, L.E.N.; Benyounis, K.Y.; Nkem-Ekpeni, F.; Stokes, J.; Olabi, A.G. Energy Diversity through Renewable Energy Source (RES)—A Case Study of Biomass. Energy Procedia 2014, 61, 1740–1747. [Google Scholar] [CrossRef]

- Lim, J.S.; Abdul Manan, Z.; Wan Alwi, S.R.; Hashim, H. A Review on Utilisation of Biomass from Rice Industry as a Source of Renewable Energy. Renew. Sustain. Energy Rev. 2012, 16, 3084–3094. [Google Scholar] [CrossRef]

- CLARA—Chemical Looping Gasification for Sustainable Production of Biofuels. Available online: https://clara-h2020.eu/ (accessed on 14 December 2022).

- Rodríguez, J.L.; Álvarez, X.; Valero, E.; Ortiz, L.; de la Torre-Rodríguez, N.; Acuña-Alonso, C. Influence of Ashes in the Use of Forest Biomass as Source of Energy. Fuel 2021, 283, 119256. [Google Scholar] [CrossRef]

- Perea-Moreno, M.-A.; Samerón-Manzano, E.; Perea-Moreno, A.-J. Biomass as Renewable Energy: Worldwide Research Trends. Sustainability 2019, 11, 863. [Google Scholar] [CrossRef]

- Hazeena, S.H.; Sindhu, R.; Pandey, A.; Binod, P. Lignocellulosic Bio-Refinery Approach for Microbial 2,3-Butanediol Production. Bioresour. Technol. 2020, 302, 122873. [Google Scholar] [CrossRef] [PubMed]

- Ashokkumar, V.; Venkatkarthick, R.; Jayashree, S.; Chuetor, S.; Dharmaraj, S.; Kumar, G.; Chen, W.H.; Ngamcharussrivichai, C. Recent Advances in Lignocellulosic Biomass for Biofuels and Value-Added Bioproducts—A Critical Review. Bioresour. Technol. 2022, 344, 126195. [Google Scholar] [CrossRef] [PubMed]

- Rodionova, M.V.; Bozieva, A.M.; Zharmukhamedov, S.K.; Leong, Y.K.; Chi-Wei Lan, J.; Veziroglu, A.; Veziroglu, T.N.; Tomo, T.; Chang, J.S.; Allakhverdiev, S.I. A Comprehensive Review on Lignocellulosic Biomass Biorefinery for Sustainable Biofuel Production. Int. J. Hydrogen Energy 2022, 47, 1481–1498. [Google Scholar] [CrossRef]

- Saravanan, A.; Senthil Kumar, P.; Jeevanantham, S.; Karishma, S.; Vo, D.V.N. Recent Advances and Sustainable Development of Biofuels Production from Lignocellulosic Biomass. Bioresour. Technol. 2022, 344, 126203. [Google Scholar] [CrossRef]

- Glossary: Biofuels—Statistics Explained. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Glossary:Biofuels (accessed on 15 September 2022).

- Ayala-Ruíz, N.; Malagón-Romero, D.H.; Milquez-Sanabria, H.A. Exergoeconomic Evaluation of a Banana Waste Pyrolysis Plant for Biofuel Production. J. Clean. Prod. 2022, 359, 132108. [Google Scholar] [CrossRef]

- Alalwan, H.A.; Alminshid, A.H.; Aljaafari, H.A.S. Promising Evolution of Biofuel Generations. Subject Review. Renew. Energy Focus 2019, 28, 127–139. [Google Scholar] [CrossRef]

- An Introduction to Biogas and Biomethane—Outlook for Biogas and Biomethane: Prospects for Organic Growth—Analysis—IEA. Available online: https://www.iea.org/reports/outlook-for-biogas-and-biomethane-prospects-for-organic-growth/an-introduction-to-biogas-and-biomethane (accessed on 15 September 2022).

- Westensee, D.K.; Rumbold, K.; Harding, K.G.; Sheridan, C.M.; van Dyk, L.D.; Simate, G.S.; Postma, F. The Availability of Second Generation Feedstocks for the Treatment of Acid Mine Drainage and to Improve South Africa’s Bio-Based Economy. Sci. Total Environ. 2018, 637–638, 132–136. [Google Scholar] [CrossRef]

- Rocha-Meneses, L.; Raud, M.; Orupõld, K.; Kikas, T. Second-Generation Bioethanol Production: A Review of Strategies for Waste Valorisation. Agron. Res. 2017, 15, 830–847. [Google Scholar]

- Mahapatra, S.; Kumar, D.; Singh, B.; Sachan, P.K. Biofuels and Their Sources of Production: A Review on Cleaner Sustainable Alternative against Conventional Fuel, in the Framework of the Food and Energy Nexus. Energy Nexus 2021, 4, 100036. [Google Scholar] [CrossRef]

- Leong, W.H.; Lim, J.W.; Lam, M.K.; Uemura, Y.; Ho, Y.C. Third Generation Biofuels: A Nutritional Perspective in Enhancing Microbial Lipid Production. Renew. Sustain. Energy Rev. 2018, 91, 950–961. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T. Microalgae Biofuels: A Critical Review of Issues, Problems and the Way Forward. Biotechnol. Adv. 2012, 30, 673–690. [Google Scholar] [CrossRef]

- Jin, M.; Slininger, P.J.; Dien, B.S.; Waghmode, S.; Moser, B.R.; Orjuela, A.; da Costa Sousa, L.; Balan, V. Microbial Lipid-Based Lignocellulosic Biorefinery: Feasibility and Challenges. Trends Biotechnol. 2015, 33, 43–54. [Google Scholar] [CrossRef]

- Shah, S.H.; Raja, I.A.; Rizwan, M.; Rashid, N.; Mahmood, Q.; Shah, F.A.; Pervez, A. Potential of Microalgal Biodiesel Production and Its Sustainability Perspectives in Pakistan. Renew. Sustain. Energy Rev. 2018, 81, 76–92. [Google Scholar] [CrossRef]

- Daneshvar, E.; Santhosh, C.; Antikainen, E.; Bhatnagar, A. Microalgal Growth and Nitrate Removal Efficiency in Different Cultivation Conditions: Effect of Macro and Micronutrients and Salinity. J. Environ. Chem. Eng. 2018, 6, 1848–1854. [Google Scholar] [CrossRef]

- Zhou, W.; Chen, P.; Min, M.; Ma, X.; Wang, J.; Griffith, R.; Hussain, F.; Peng, P.; Xie, Q.; Li, Y.; et al. Environment-Enhancing Algal Biofuel Production Using Wastewaters. Renew. Sustain. Energy Rev. 2014, 36, 256–269. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. Composition, Properties and Challenges of Algae Biomass for Biofuel Application: An Overview. Fuel 2016, 181, 1–33. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in Biofuel Production from Gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Torkashvand, M.; Hasan-Zadeh, A.; Torkashvand, A. Mini Review on Importance, Application, Advantages and Disadvantages of Biofuels. J. Mater. Environ. Sci. 2022, 2022, 6. [Google Scholar]

- Berchmans, H.J.; Hirata, S. Biodiesel Production from Crude Jatropha curcas L. Seed Oil with a High Content of Free Fatty Acids. Bioresour. Technol. 2008, 99, 1716–1721. [Google Scholar] [CrossRef]

- Vicente, G.; Martínez, M.; Aracil, J. Integrated Biodiesel Production: A Comparison of Different Homogeneous Catalysts Systems. Bioresour. Technol. 2004, 92, 297–305. [Google Scholar] [CrossRef]

- Yusuf, N.N.A.N.; Kamarudin, S.K.; Yaakub, Z. Overview on the Current Trends in Biodiesel Production. Energy Convers. Manag. 2011, 52, 2741–2751. [Google Scholar] [CrossRef]

- Kalita, P.; Basumatary, B.; Saikia, P.; Das, B.; Basumatary, S. Biodiesel as Renewable Biofuel Produced via Enzyme-Based Catalyzed Transesterification. Energy Nexus 2022, 6, 100087. [Google Scholar] [CrossRef]

- Rawat, I.; Ranjith Kumar, R.; Mutanda, T.; Bux, F. Biodiesel from Microalgae: A Critical Evaluation from Laboratory to Large Scale Production. Appl. Energy 2013, 103, 444–467. [Google Scholar] [CrossRef]

- Pinzi, S.; Gandía, L.M.; Arzamendi, G.; Ruiz, J.J.; Dorado, M.P. Influence of Vegetable Oils Fatty Acid Composition on Reaction Temperature and Glycerides Conversion to Biodiesel during Transesterification. Bioresour. Technol. 2011, 102, 1044–1050. [Google Scholar] [CrossRef]

- Babadi, A.A.; Rahmati, S.; Fakhlaei, R.; Barati, B.; Wang, S.; Doherty, W.; Ostrikov, K. Emerging Technologies for Biodiesel Production: Processes, Challenges, and Opportunities. Biomass Bioenergy 2022, 163, 106521. [Google Scholar] [CrossRef]

- Akram, F.; Haq, I.U.; Raja, S.I.; Mir, A.S.; Qureshi, S.S.; Aqeel, A.; Shah, F.I. Current Trends in Biodiesel Production Technologies and Future Progressions: A Possible Displacement of the Petro-Diesel. J. Clean Prod. 2022, 370, 133479. [Google Scholar] [CrossRef]

- Basumatary, S.F.; Patir, K.; Das, B.; Saikia, P.; Brahma, S.; Basumatary, B.; Nath, B.; Basumatary, B.; Basumatary, S. Production of Renewable Biodiesel Using Metal Organic Frameworks Based Materials as Efficient Heterogeneous Catalysts. J. Clean Prod. 2022, 358, 131955. [Google Scholar] [CrossRef]

- Awogbemi, O.; Von Kallon, D.V.; Aigbodion, V.S. Trends in the Development and Utilization of Agricultural Wastes as Heterogeneous Catalyst for Biodiesel Production. J. Energy Inst. 2021, 98, 244–258. [Google Scholar] [CrossRef]

- Alternative Fuels Data Center: Biodiesel Blends. Available online: https://afdc.energy.gov/fuels/biodiesel_blends.html (accessed on 16 September 2022).

- Zhang, Y.; Duan, L.; Esmaeili, H. A Review on Biodiesel Production Using Various Heterogeneous Nanocatalysts: Operation Mechanisms and Performances. Biomass Bioenergy 2022, 158, 106356. [Google Scholar] [CrossRef]

- Moser, B.R. Biodiesel Production, Properties, and Feedstocks. In Biofuels: Global Impact on Renewable Energy, Production Agriculture, and Technological Advancements; Springer: New York, NY, USA, 2011; pp. 285–347. [Google Scholar] [CrossRef]

- Vonortas, A.; Papayannakos, N. Comparative Analysis of Biodiesel versus Green Diesel. WIREs Energy Environ. 2014, 3, 3–23. [Google Scholar] [CrossRef]

- Pimenta, J.L.C.W.; de Oliveira Camargo, M.; Belo Duarte, R.; dos Santos, O.A.A.; de Matos Jorge, L.M. Deoxygenation of Vegetable Oils for the Production of Renewable Diesel: Improved Aerogel Based Catalysts. Fuel 2021, 290, 119979. [Google Scholar] [CrossRef]

- Mahdi, H.I.; Bazargan, A.; McKay, G.; Azelee, N.I.W.; Meili, L. Catalytic Deoxygenation of Palm Oil and Its Residue in Green Diesel Production: A Current Technological Review. Chem. Eng. Res. Des. 2021, 174, 158–187. [Google Scholar] [CrossRef]

- Douvartzides, S.L.; Charisiou, N.D.; Papageridis, K.N.; Goula, M.A. Green Diesel: Biomass Feedstocks, Production Technologies, Catalytic Research, Fuel Properties and Performance in Compression Ignition Internal Combustion Engines. Energies 2019, 12, 809. [Google Scholar] [CrossRef]

- Yao, X.; Strathmann, T.J.; Li, Y.; Cronmiller, L.E.; Ma, H.; Zhang, J. Catalytic hydrothermal deoxygenation of lipids and fatty acids to diesel-like hydrocarbons: A review. Green Chem. 2021, 23, 1114–1129. [Google Scholar] [CrossRef]

- Yoon, J.J. What’s the Difference between Biodiesel and Renewable (Green) Diesel? Available online: https://advancedbiofuelsusa.info/whats-the-difference-between-biodiesel-and-renewable-green-diesel/ (accessed on 11 August 2022).

- Kalghatgi, G. Is It Really the End of Internal Combustion Engines and Petroleum in Transport? Appl. Energy 2018, 225, 965–974. [Google Scholar] [CrossRef]

- Abdul Razak, N.A.; Mijan, N.-A.; Taufiq-Yap, Y.H.; Derawi, D. Production of Green Diesel via Hydrogen-Free and Solventless Deoxygenation Reaction of Waste Cooking Oil. J. Clean Prod. 2022, 366, 132971. [Google Scholar] [CrossRef]

- Ameen, M.; Azizan, M.T.; Yusup, S.; Ramli, A.; Yasir, M. Catalytic Hydrodeoxygenation of Triglycerides: An Approach to Clean Diesel Fuel Production. Renew. Sustain. Energy Rev. 2017, 80, 1072–1088. [Google Scholar] [CrossRef]

- Zhou, Y.; Remón, J.; Jiang, Z.; Matharu, A.S.; Hu, C. Tuning the Selectivity of Natural Oils and Fatty Acids/Esters Deoxygenation to Biofuels and Fatty Alcohols: A Review. Green Energy Environ. 2022. [Google Scholar] [CrossRef]

- Gosselink, R.W.; Hollak, S.A.W.; Chang, S.W.; van Haveren, J.; de Jong, K.P.; Bitter, J.H.; van Es, D.S. Reaction Pathways for the Deoxygenation of Vegetable Oils and Related Model Compounds. ChemSusChem 2013, 6, 1576–1594. [Google Scholar] [CrossRef]

- Hongloi, N.; Prapainainar, P.; Prapainainar, C. Review of Green Diesel Production from Fatty Acid Deoxygenation over Ni-Based Catalysts. Mol. Catal. 2022, 523, 111696. [Google Scholar] [CrossRef]

- Li, X.; Luo, X.; Jin, Y.; Li, J.; Zhang, H.; Zhang, A.; Xie, J. Heterogeneous Sulfur-Free Hydrodeoxygenation Catalysts for Selectively Upgrading the Renewable Bio-Oils to Second Generation Biofuels. Renew. Sustain. Energy Rev. 2018, 82, 3762–3797. [Google Scholar] [CrossRef]

- Khan, S.; Kay Lup, A.N.; Qureshi, K.M.; Abnisa, F.; Wan Daud, W.M.A.; Patah, M.F.A. A Review on Deoxygenation of Triglycerides for Jet Fuel Range Hydrocarbons. J. Anal. Appl. Pyrolysis 2019, 140, 1–24. [Google Scholar] [CrossRef]

- Tabandeh, M.; Cheng, C.K.; Centi, G.; Show, P.L.; Chen, W.H.; Ling, T.C.; Ong, H.C.; Ng, E.P.; Juan, J.C.; Lam, S.S. Recent Advancement in Deoxygenation of Fatty Acids via Homogeneous Catalysis for Biofuel Production. Mol. Catal. 2022, 523, 111207. [Google Scholar] [CrossRef]

- Santillan-Jimenez, E.; Crocker, M. Catalytic Deoxygenation of Fatty Acids and Their Derivatives to Hydrocarbon Fuels via Decarboxylation/Decarbonylation. J. Chem. Technol. Biotechnol. 2012, 87, 1041–1050. [Google Scholar] [CrossRef]

- Srifa, A.; Faungnawakij, K.; Itthibenchapong, V.; Assabumrungrat, S. Roles of Monometallic Catalysts in Hydrodeoxygenation of Palm Oil to Green Diesel. Chem. Eng. J. 2015, 278, 249–258. [Google Scholar] [CrossRef]

- Valencia, D.; García-Cruz, I.; Uc, V.H.; Ramírez-Verduzco, L.F.; Amezcua-Allieri, M.A.; Aburto, J. Unravelling the Chemical Reactions of Fatty Acids and Triacylglycerides under Hydrodeoxygenation Conditions Based on a Comprehensive Thermodynamic Analysis. Biomass Bioenergy 2018, 112, 37–44. [Google Scholar] [CrossRef]

- Chen, L.; Zhu, Y.; Zheng, H.; Zhang, C.; Zhang, B.; Li, Y. Aqueous-Phase Hydrodeoxygenation of Carboxylic Acids to Alcohols or Alkanes over Supported Ru Catalysts. J. Mol. Catal. A Chem. 2011, 351, 217–227. [Google Scholar] [CrossRef]

- Papageridis, K.N.; Charisiou, N.D.; Douvartzides, S.L.; Sebastian, V.; Hinder, S.J.; Baker, M.A.; AlKhoori, S.; Polychronopoulou, K.; Goula, M.A. Effect of Operating Parameters on the Selective Catalytic Deoxygenation of Palm Oil to Produce Renewable Diesel over Ni Supported on Al2O3, ZrO2 and SiO2 Catalysts. Fuel Process. Technol. 2020, 209, 106547. [Google Scholar] [CrossRef]

- Kiméné, A.; Wojcieszak, R.; Paul, S.; Dumeignil, F. Catalytic Decarboxylation of Fatty Acids to Hydrocarbons over Non-Noble Metal Catalysts: The State of the Art. J. Chem. Technol. Biotechnol. 2019, 94, 658–669. [Google Scholar] [CrossRef]

- Lam, J.E.; Mohamed, A.R.; Kay Lup, A.N.; Koh, M.K. Palm Fatty Acid Distillate Derived Biofuels via Deoxygenation: Properties, Catalysts and Processes. Fuel Process. Technol. 2022, 236, 107394. [Google Scholar] [CrossRef]

- Long, F.; Liu, W.; Jiang, X.; Zhai, Q.; Cao, X.; Jiang, J.; Xu, J. State-of-the-Art Technologies for Biofuel Production from Triglycerides: A Review. Renew. Sustain. Energy Rev. 2021, 148, 111269. [Google Scholar] [CrossRef]

- Pattanaik, B.P.; Misra, R.D. Effect of Reaction Pathway and Operating Parameters on the Deoxygenation of Vegetable Oils to Produce Diesel Range Hydrocarbon Fuels: A Review. Renew. Sustain. Energy Rev. 2017, 73, 545–557. [Google Scholar] [CrossRef]

- Liu, Z.; Gao, X.; Liu, B.; Ma, Q.; Zhao, T.S.; Zhang, J. Recent Advances in Thermal Catalytic CO2 Methanation on Hydrotalcite-Derived Catalysts. Fuel 2022, 321, 124115. [Google Scholar] [CrossRef]

- Fan, W.K.; Tahir, M. Recent Trends in Developments of Active Metals and Heterogenous Materials for Catalytic CO2 Hydrogenation to Renewable Methane: A Review. J. Environ. Chem. Eng. 2021, 9, 105460. [Google Scholar] [CrossRef]

- Stangeland, K.; Kalai, D.; Li, H.; Yu, Z. CO2 Methanation: The Effect of Catalysts and Reaction Conditions. Energy Procedia 2017, 105, 2022–2027. [Google Scholar] [CrossRef]

- Donnis, B.; Gottschalck, R.; Ae, E.; Blom, P.; Kim, A.E.; Knudsen, G. Hydroprocessing of Bio-Oils and Oxygenates to Hydrocarbons. Understanding the Reaction Routes. Top. Catal. 2009, 55, 229–240. [Google Scholar] [CrossRef]

- Lahijani, P.; Zainal, Z.A.; Mohammadi, M.; Mohamed, A.R. Conversion of the Greenhouse Gas CO2 to the Fuel Gas CO via the Boudouard Reaction: A Review. Renew. Sustain. Energy Rev. 2015, 41, 615–632. [Google Scholar] [CrossRef]

- Wang, F.; Pace, R.; Ji, Y.; Jiang, J.; Jiang, X.; Krystianiak, A.; Heintz, O.; Caboche, G.; Santillan-Jimenez, E.; Crocker, M. Effect of Pd Promotion and Catalyst Support on the Ni-Catalyzed Deoxygenation of Tristearin to Fuel-like Hydrocarbons. Renew. Energy 2022, 195, 1468–1479. [Google Scholar] [CrossRef]

- Mäki-Arvela, P.; Khel, T.A.K.; Azkaar, M.; Engblom, S.; Murzin, D.Y. Catalytic Hydroisomerization of Long-Chain Hydrocarbons for the Production of Fuels. Catalysts 2018, 8, 534. [Google Scholar] [CrossRef]

- Martens, J.A.; Verboekend, D.; Thomas, K.; Vanbutsele, G.; Pérez-Ramírez, J.; Gilson, J.P. Hydroisomerization and Hydrocracking of Linear and Multibranched Long Model Alkanes on Hierarchical Pt/ZSM-22 Zeolite. Catal. Today 2013, 218–219, 135–142. [Google Scholar] [CrossRef]

- Knothe, G. Biodiesel and Renewable Diesel: A Comparison. Prog. Energy Combust. Sci. 2010, 36, 364–373. [Google Scholar] [CrossRef]

- Lin, J.K.; Lee, C.P.; Lin, H.P.; Halim, E.; Wang, W.C. The Production of Hydro-Processed Renewable Diesel over the Nonsulfide Catalyst. Int. J. Energy Res. 2021, 45, 19043–19061. [Google Scholar] [CrossRef]

- Chen, R.X.; Wang, W.C. The Production of Renewable Aviation Fuel from Waste Cooking Oil. Part I: Bio-Alkane Conversion through Hydro-Processing of Oil. Renew. Energy 2019, 135, 819–835. [Google Scholar] [CrossRef]

- Jȩczmionek, L.; Porzycka-Semczuk, K. Hydrodeoxygenation, Decarboxylation and Decarbonylation Reactions While Co-Processing Vegetable Oils over NiMo Hydrotreatment Catalyst. Part II: Thermal Effects—Experimental Results. Fuel 2014, 128, 296–301. [Google Scholar] [CrossRef]

- Santillan-Jimenez, E.; Morgan, T.; Lacny, J.; Mohapatra, S.; Crocker, M. Catalytic Deoxygenation of Triglycerides and Fatty Acids to Hydrocarbons over Carbon-Supported Nickel. Fuel 2013, 103, 1010–1017. [Google Scholar] [CrossRef]

- Mäki-Arvela, P.; Kubickova, I.; Snåre, M.; Eränen, K.; Murzin, D.Y. Catalytic Deoxygenation of Fatty Acids and Their Derivatives. Energy Fuels 2006, 21, 30–41. [Google Scholar] [CrossRef]

- Hongloi, N.; Prapainainar, P.; Muadmai, T.; Namboonlue, J.; Seubsai, A.; Prapainainar, C. Green Diesel Production from Oleic Acid Deoxygenation Using Subcritical Water under Hydrogen-Free Condition. Eng. J. 2021, 25, 115–122. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Lee, H.V.; Abdulkareem-Alsultan, G.; Afandi, A.; Taufiq-Yap, Y.H. Production of Green Diesel via Cleaner Catalytic Deoxygenation of Jatropha Curcas Oil. J. Clean Prod. 2017, 167, 1048–1059. [Google Scholar] [CrossRef]

- Hermida, L.; Abdullah, A.Z.; Mohamed, A.R. Deoxygenation of Fatty Acid to Produce Diesel-like Hydrocarbons: A Review of Process Conditions, Reaction Kinetics and Mechanism. Renew. Sustain. Energy Rev. 2015, 42, 1223–1233. [Google Scholar] [CrossRef]

- Han, J.; Sun, H.; Ding, Y.; Lou, H.; Zheng, X. Palladium-Catalyzed Decarboxylation of Higher Aliphatic Esters: Towards a New Protocol to the Second Generation Biodiesel Production. Green Chem. 2010, 12, 463–467. [Google Scholar] [CrossRef]

- Bezergianni, S.; Dimitriadis, A.; Kalogianni, A.; Knudsen, K.G. Toward Hydrotreating of Waste Cooking Oil for Biodiesel Production. Effect of Pressure, H2/Oil Ratio, and Liquid Hourly Space Velocity. Ind. Eng. Chem. Res. 2011, 50, 3874–3879. [Google Scholar] [CrossRef]

- Sonthalia, A.; Kumar, N. Hydroprocessed Vegetable Oil as a Fuel for Transportation Sector: A Review. J. Energy Inst. 2019, 92, 1–17. [Google Scholar] [CrossRef]

- Bouras, H.; Haroun, Y.; Philippe, R.; Augier, F.; Fongarland, P. CFD Modeling of Mass Transfer in Gas-Liquid-Solid Catalytic Reactors. Chem. Eng. Sci. 2021, 233, 116378. [Google Scholar] [CrossRef]

- Hachemi, I.; Jeništová, K.; Mäki-Arvela, P.; Kumar, N.; Eränen, K.; Hemming, J.; Murzin, D.Y. Comparative Study of Sulfur-Free Nickel and Palladium Catalysts in Hydrodeoxygenation of Different Fatty Acid Feedstocks for Production of Biofuels. Catal. Sci. Technol. 2016, 6, 1476–1487. [Google Scholar] [CrossRef]

- Bischoff, K.B. An Extension of the General Criterion for Importance of Pore Diffusion with Chemical Reactions. Chem. Eng. Sci. 1967, 22, 525–530. [Google Scholar] [CrossRef]

- Zhou, L.; Lawal, A. Kinetic Study of Hydrodeoxygenation of Palmitic Acid as a Model Compound for Microalgae Oil over Pt/γ-Al2O3. Appl. Catal. A Gen. 2017, 532, 40–49. [Google Scholar] [CrossRef]

- Arora, P.; Grennfelt, E.L.; Olsson, L.; Creaser, D. Kinetic Study of Hydrodeoxygenation of Stearic Acid as Model Compound for Renewable Oils. Chem. Eng. J. 2019, 364, 376–389. [Google Scholar] [CrossRef]

- Arun, N.; Sharma, R.V.; Dalai, A.K. Green Diesel Synthesis by Hydrodeoxygenation of Bio-Based Feedstocks: Strategies for Catalyst Design and Development. Renew. Sustain. Energy Rev. 2015, 48, 240–255. [Google Scholar] [CrossRef]

- Srivastava, A.; Prasad, R. Triglycerides-Based Diesel Fuels. Renew. Sustain. Energy Rev. 2000, 4, 111–133. [Google Scholar] [CrossRef]

- Riazi, B.; Mosby, J.M.; Millet, B.; Spatari, S. Renewable Diesel from Oils and Animal Fat Waste: Implications of Feedstock, Technology, Co-Products and ILUC on Life Cycle GWP. Resour. Conserv. Recycl. 2020, 161, 104944. [Google Scholar] [CrossRef]

- Hájek, M.; Vávra, A.; de Paz Carmona, H.; Kocík, J. The Catalysed Transformation of Vegetable Oils or Animal Fats to Biofuels and Bio-Lubricants: A Review. Catalysts 2021, 11, 1118. [Google Scholar] [CrossRef]

- Pocha, C.K.R.; Chia, S.R.; Chia, W.Y.; Koyande, A.K.; Nomanbhay, S.; Chew, K.W. Utilization of Agricultural Lignocellulosic Wastes for Biofuels and Green Diesel Production. Chemosphere 2022, 290, 133246. [Google Scholar] [CrossRef] [PubMed]

- Scaldaferri, C.A.; Pasa, V.M.D. Green Diesel Production from Upgrading of Cashew Nut Shell Liquid. Renew. Sustain. Energy Rev. 2019, 111, 303–313. [Google Scholar] [CrossRef]

- Pal, N.; Verma, V.; Khan, A.; Mishra, A.; Anand, M.; Venkata Pramod, C.; Akhtar Farooqui, S.; Kumar Sinha, A. Hydrotreating and Hydrodemetalation of Raw Jatropha Oil Using Mesoporous Ni-Mo/γ-Al2O3 Catalyst. Fuel 2022, 326, 125108. [Google Scholar] [CrossRef]

- Ramesh, A.; Palanichamy, K.; Tamizhdurai, P.; Umasankar, S.; Sureshkumar, K.; Shanthi, K. Sulphated Zr–Al2O3 Catalysts through Jatropha Oil to Green-Diesel Production. Mater. Lett. 2019, 238, 62–65. [Google Scholar] [CrossRef]

- Ruban, M.; Karikalan, L.; Chakraborty, S.K. Performances and Emissions Characteristics of Diesel Engine by Using Jatropha Oil. Mater. Today Proc. 2021, 37, 631–633. [Google Scholar] [CrossRef]

- Du, X.; Zhou, K.; Zhou, L.; Lei, X.; Yang, H.; Li, D.; Hu, C. Efficient Catalytic Conversion of Jatropha Oil to High Grade Biofuel on Ni-Mo2C/MCM-41 Catalysts with Tuned Surface Properties. J. Energy Chem. 2021, 61, 425–435. [Google Scholar] [CrossRef]

- Ramesh, A.; Tamizhdurai, P.; Shanthi, K. Catalytic Hydrodeoxygenation of Jojoba Oil to the Green-Fuel Application on Ni-MoS/Mesoporous Zirconia-Silica Catalysts. Renew. Energy 2019, 138, 161–173. [Google Scholar] [CrossRef]

- Yenumala, S.R.; Kumar, P.; Maity, S.K.; Shee, D. Production of Green Diesel from Karanja Oil (Pongamia Pinnata) Using Mesoporous NiMo-Alumina Composite Catalysts. Bioresour. Technol. Rep. 2019, 7, 100288. [Google Scholar] [CrossRef]

- Yenumala, S.R.; Kumar, P.; Maity, S.K.; Shee, D. Hydrodeoxygenation of Karanja Oil Using Ordered Mesoporous Nickel-Alumina Composite Catalysts. Catal. Today 2020, 348, 45–54. [Google Scholar] [CrossRef]

- Zhou, L.; Lawal, A. Evaluation of Presulfided NiMo/γ-Al 2 O 3 for Hydrodeoxygenation of Microalgae Oil to Produce Green Diesel. Energy Fuels 2015, 29, 262–272. [Google Scholar] [CrossRef]

- Choo, M.Y.; Oi, L.E.; Show, P.L.; Chang, J.S.; Ling, T.C.; Ng, E.P.; Phang, S.M.; Juan, J.C. Recent Progress in Catalytic Conversion of Microalgae Oil to Green Hydrocarbon: A Review. J. Taiwan Inst. Chem. Eng. 2017, 79, 116–124. [Google Scholar] [CrossRef]

- Pragya, N.; Pandey, K.K. Life Cycle Assessment of Green Diesel Production from Microalgae. Renew. Energy 2016, 86, 623–632. [Google Scholar] [CrossRef]

- Peng, B.; Yao, Y.; Zhao, C.; Lercher, J.A. Towards Quantitative Conversion of Microalgae Oil to Diesel-Range Alkanes with Bifunctional Catalysts. Angew. Chem. Int. Ed. 2012, 51, 2072–2075. [Google Scholar] [CrossRef]

- Song, W.; Zhao, C.; Lercher, J.A. Importance of Size and Distribution of Ni Nanoparticles for the Hydrodeoxygenation of Microalgae Oil. Chemistry 2013, 19, 9833–9842. [Google Scholar] [CrossRef]

- Kandel, K.; Anderegg, J.W.; Nelson, N.C.; Chaudhary, U.; Slowing, I.I. Supported Iron Nanoparticles for the Hydrodeoxygenation of Microalgal Oil to Green Diesel. J. Catal. 2014, 314, 142–148. [Google Scholar] [CrossRef]

- Yani, F.T.; Husin, H.; Darmadi; Muhammad, S.; Abnisa, F.; Nurhazanah; Nasution, F. Erdiwansyah Palm Oil Hydrodeoxygenation into Green Diesel over NiO/NbOPO4 Catalyst: A Novel Approach of Synthesizing NbOPO4 from NbCl5. J. Clean Prod. 2022, 354, 131704. [Google Scholar] [CrossRef]

- Ruangudomsakul, M.; Osakoo, N.; Wittayakun, J.; Keawkumay, C.; Butburee, T.; Youngjan, S.; Faungnawakij, K.; Poo-arporn, Y.; Kidkhunthod, P.; Khemthong, P. Hydrodeoxygenation of Palm Oil to Green Diesel Products on Mixed-Phase Nickel Phosphides. Mol. Catal. 2021, 523, 111422. [Google Scholar] [CrossRef]

- Srifa, A.; Kaewmeesri, R.; Fang, C.; Itthibenchapong, V.; Faungnawakij, K. NiAl2O4 Spinel-Type Catalysts for Deoxygenation of Palm Oil to Green Diesel. Chem. Eng. J. 2018, 345, 107–113. [Google Scholar] [CrossRef]

- Rakmae, S.; Osakoo, N.; Pimsuta, M.; Deekamwong, K.; Keawkumay, C.; Butburee, T.; Faungnawakij, K.; Geantet, C.; Prayoonpokarach, S.; Wittayakun, J.; et al. Defining Nickel Phosphides Supported on Sodium Mordenite for Hydrodeoxygenation of Palm Oil. Fuel Process. Technol. 2020, 198, 106236. [Google Scholar] [CrossRef]

- Zharova, P.A.; Chistyakov, A.V.; Shapovalov, S.S.; Pasynskii, A.A.; Tsodikov, M.V. Original Pt-Sn/Al2O3 Catalyst for Selective Hydrodeoxygenation of Vegetable Oils. Energy 2019, 172, 18–25. [Google Scholar] [CrossRef]

- Sotelo-Boyás, R.; Liu, Y.; Minowa, T. Renewable Diesel Production from the Hydrotreating of Rapeseed Oil with Pt/Zeolite and NiMo/Al2O3 Catalysts. Ind. Eng. Chem. Res. 2010, 50, 2791–2799. [Google Scholar] [CrossRef]

- Šimáček, P.; Kubička, D.; Šebor, G.; PospíŠil, M. Fuel Properties of Hydroprocessed Rapeseed Oil. Fuel 2010, 89, 611–615. [Google Scholar] [CrossRef]

- Ameen, M.; Azizan, M.T.; Yusup, S.; Ramli, A.; Shahbaz, M.; Aqsha, A.; Kaur, H.; Wai, C.K. Parametric Studies on Hydrodeoxygenation of Rubber Seed Oil for Diesel Range Hydrocarbon Production. Energy Fuels 2020, 34, 4603–4617. [Google Scholar] [CrossRef]

- Ameen, M.; Azizan, M.T.; Ramli, A.; Yusup, S.; Alnarabiji, M.S. Catalytic Hydrodeoxygenation of Rubber Seed Oil over Sonochemically Synthesized Ni-Mo/γ-Al2O3 Catalyst for Green Diesel Production. Ultrason. Sonochemistry 2019, 51, 90–102. [Google Scholar] [CrossRef]

- Cheah, K.W.; Yusup, S.; Gurdeep Singh, H.K.; Uemura, Y.; Lam, H.L. Process Simulation and Techno Economic Analysis of Renewable Diesel Production via Catalytic Decarboxylation of Rubber Seed Oil—A Case Study in Malaysia. J. Environ. Manag. 2017, 203, 950–996. [Google Scholar] [CrossRef]

- Cavalcanti, C.J.S.; Ravagnani, M.A.S.S.; Stragevitch, L.; Carvalho, F.R.; Pimentel, M.F. Simulation of the Soybean Oil Hydrotreating Process for Green Diesel Production. Clean. Chem. Eng. 2022, 1, 100004. [Google Scholar] [CrossRef]

- Kim, S.K.; Brand, S.; Lee, H.S.; Kim, Y.; Kim, J. Production of Renewable Diesel by Hydrotreatment of Soybean Oil: Effect of Reaction Parameters. Chem. Eng. J. 2013, 228, 114–123. [Google Scholar] [CrossRef]

- Vázquez-Garrido, I.; López-Benítez, A.; Guevara-Lara, A.; Berhault, G. Synthesis of NiMo Catalysts Supported on Mn-Al2O3 for Obtaining Green Diesel from Waste Soybean Oil. Catal. Today 2021, 365, 327–340. [Google Scholar] [CrossRef]

- Scaldaferri, C.A.; Pasa, V.M.D. Production of Jet Fuel and Green Diesel Range Biohydrocarbons by Hydroprocessing of Soybean Oil over Niobium Phosphate Catalyst. Fuel 2019, 245, 458–466. [Google Scholar] [CrossRef]

- Fattahi, B.; Haghighi, M.; Rahmanivahid, B.; Vardast, N. Green Fuel Production from Sunflower Oil Using Nanocatalysts Based on Metal Oxides (SrO, La2O3, CaO, MgO, Li2O) Supported over Combustion-synthesized Mg-Spinel. Chem. Eng. Res. Des. 2022, 183, 411–423. [Google Scholar] [CrossRef]

- Papadopoulos, C.; Kordouli, E.; Sygellou, L.; Bourikas, K.; Kordulis, C.; Lycourghiotis, A. W Promoted Ni-Al2O3 Co-Precipitated Catalysts for Green Diesel Production. Fuel Process. Technol. 2021, 217, 106820. [Google Scholar] [CrossRef]

- Gousi, M.; Kordouli, E.; Bourikas, K.; Simianakis, E.; Ladas, S.; Panagiotou, G.D.; Kordulis, C.; Lycourghiotis, A. Green Diesel Production over Nickel-Alumina Nanostructured Catalysts Promoted by Zinc. Catal. Today 2020, 355, 903–909. [Google Scholar] [CrossRef]

- Lycourghiotis, S.; Kordouli, E.; Sygellou, L.; Bourikas, K.; Kordulis, C. Nickel Catalysts Supported on Palygorskite for Transformation of Waste Cooking Oils into Green Diesel. Appl. Catal. B 2019, 259, 118059. [Google Scholar] [CrossRef]

- Ding, S.; Li, F.; Li, Z.; Yu, H.; Song, C.; Xiong, D.; Lin, H. Catalytic Hydrodeoxygenation of Waste Cooking Oil and Stearic Acid over Reduced Nickel-Basded Catalysts. Catal. Commun. 2021, 149, 106235. [Google Scholar] [CrossRef]

- Nikolopoulos, I.; Kogkos, G.; Kordouli, E.; Bourikas, K.; Kordulis, C.; Lycourghiotis, A. Waste Cooking Oil Transformation into Third Generation Green Diesel Catalyzed by Nickel—Alumina Catalysts. Mol. Catal. 2020, 482, 110697. [Google Scholar] [CrossRef]

- Hafriz, R.S.R.M.; Shafizah, I.N.; Arifin, N.A.; Salmiaton, A.; Yunus, R.; Yap, Y.H.T.; Shamsuddin, A.H. Effect of Ni/Malaysian Dolomite Catalyst Synthesis Technique on Deoxygenation Reaction Activity of Waste Cooking Oil. Renew. Energy 2021, 178, 128–143. [Google Scholar] [CrossRef]

- Mohammed, S.T.; Gheni, S.A.; Aqar, D.Y.; Hamad, K.I.; Ahmed, S.M.R.; Mahmood, M.A.; Abdullah, G.H.; Ali, M.K. Evaluation and Optimal Design of a High Stability Hydrothermal Deoxygenation Process for Production of Green Diesel Fuel via Deoxygenation of Waste Cooking Oil. Process Saf. Environ. Prot. 2022, 159, 489–499. [Google Scholar] [CrossRef]

- Khalit, W.N.A.W.; Asikin-Mijan, N.; Marliza, T.S.; Gamal, M.S.; Shamsuddin, M.R.; Saiman, M.I.; Taufiq-Yap, Y.H. Catalytic Deoxygenation of Waste Cooking Oil Utilizing Nickel Oxide Catalysts over Various Supports to Produce Renewable Diesel Fuel. Biomass Bioenergy 2021, 154, 106248. [Google Scholar] [CrossRef]

- Caballero, B.; Finglas, P.; Toldrà, F. Encyclopedia of Food and Health, 1st ed.; Academic Press: Cambridge, MA, USA, 2015; ISBN 9780123849472. [Google Scholar]

- Patel, R.L.; Sankhavara, C.D. Biodiesel Production from Karanja Oil and Its Use in Diesel Engine: A Review. Renew. Sustain. Energy Rev. 2017, 71, 464–474. [Google Scholar] [CrossRef]

- Becker, K.; Makkar, H.P.S. Jatropha Curcas: A Potential Source for Tomorrow’ s Oil and Biodiesel. Lipid Technol. 2008, 20, 104–107. [Google Scholar] [CrossRef]

- Morais, S.; Mata, T.M.; Martins, A.A.; Pinto, G.A.; Costa, C.A.V. Simulation and Life Cycle Assessment of Process Design Alternatives for Biodiesel Production from Waste Vegetable Oils. J. Clean Prod. 2010, 18, 1251–1259. [Google Scholar] [CrossRef]

- Esmaeili, H. A Critical Review on the Economic Aspects and Life Cycle Assessment of Biodiesel Production Using Heterogeneous Nanocatalysts. Fuel Process. Technol. 2022, 230, 107224. [Google Scholar] [CrossRef]

- Ooi, X.Y.; Gao, W.; Ong, H.C.; Lee, H.V.; Juan, J.C.; Chen, W.H.; Lee, K.T. Overview on Catalytic Deoxygenation for Biofuel Synthesis Using Metal Oxide Supported Catalysts. Renew. Sustain. Energy Rev. 2019, 112, 834–852. [Google Scholar] [CrossRef]

- Cheng, S.; Wei, L.; Julson, J.; Rabnawaz, M. Upgrading Pyrolysis Bio-Oil through Hydrodeoxygenation (HDO) Using Non-Sulfided Fe-Co/SiO2 Catalyst. Energy Convers. Manag. 2017, 150, 331–342. [Google Scholar] [CrossRef]

- Hafriz, R.S.R.M.; Nor Shafizah, I.; Arifin, N.A.; Maisarah, A.H.; Salmiaton, A.; Shamsuddin, A.H. Comparative, Reusability and Regeneration Study of Potassium Oxide-Based Catalyst in Deoxygenation Reaction of WCO. Energy Convers. Manag. X 2022, 13, 100173. [Google Scholar] [CrossRef]

- Wang, F.; Xu, H.; Yu, S.; Zhu, H.; Du, Y.; Zhang, Z.; You, C.; Jiang, X.; Jiang, J. Fe-Promoted Ni Catalyst with Extremely High Loading and Oxygen Vacancy for Lipid Deoxygenation into Green Diesel. Renew. Energy 2022, 197, 40–49. [Google Scholar] [CrossRef]

- Afshar Taromi, A.; Kaliaguine, S. Green Diesel Production via Continuous Hydrotreatment of Triglycerides over Mesostructured γ-Alumina Supported NiMo/CoMo Catalysts. Fuel Process. Technol. 2018, 171, 20–30. [Google Scholar] [CrossRef]

- Li, T.; Cheng, J.; Huang, R.; Zhou, J.; Cen, K. Conversion Pathways of Palm Oil into Jet Biofuel Catalyzed by Mesoporous Zeolites. RSC Adv. 2016, 6, 103965–103972. [Google Scholar] [CrossRef]

- Ooi, X.Y.; Oi, L.E.; Choo, M.Y.; Ong, H.C.; Lee, H.V.; Show, P.L.; Lin, Y.C.; Juan, J.C. Efficient Deoxygenation of Triglycerides to Hydrocarbon-Biofuel over Mesoporous Al2O3-TiO2 Catalyst. Fuel Process. Technol. 2019, 194, 106120. [Google Scholar] [CrossRef]

- Kamaruzaman, M.F.; Taufiq-Yap, Y.H.; Derawi, D. Green Diesel Production from Palm Fatty Acid Distillate over SBA-15-Supported Nickel, Cobalt, and Nickel/Cobalt Catalysts. Biomass Bioenergy 2020, 134, 105476. [Google Scholar] [CrossRef]

- Kim, S.K.; Han, J.Y.; Lee, H.S.; Yum, T.; Kim, Y.; Kim, J. Production of Renewable Diesel via Catalytic Deoxygenation of Natural Triglycerides: Comprehensive Understanding of Reaction Intermediates and Hydrocarbons. Appl. Energy 2014, 116, 199–205. [Google Scholar] [CrossRef]

- Kaewchada, A.; Akkarawatkhoosith, N.; Bunpim, D.; Bangjang, T.; Ngamcharussrivichai, C.; Jaree, A. Production of Bio-Hydrogenated Diesel from Palm Oil Using Rh/HZSM-5 in a Continuous Mini Fixed-Bed Reactor. Chem. Eng. Process. Process Intensif. 2021, 168, 108586. [Google Scholar] [CrossRef]

- Zulkepli, S.; Lee, H.V.; Rahman, N.A.; Chuan, L.T.; Show, P.L.; Chen, W.H.; Juan, J.C. Highly Active Iron-Promoted Hexagonal Mesoporous Silica (HMS) for Deoxygenation of Triglycerides to Green Hydrocarbon-like Biofuel. Fuel 2022, 308, 121860. [Google Scholar] [CrossRef]

- Zulkepli, S.; Juan, J.C.; Lee, H.V.; Rahman, N.S.A.; Show, P.L.; Ng, E.P. Modified Mesoporous HMS Supported Ni for Deoxygenation of Triolein into Hydrocarbon-Biofuel Production. Energy Convers. Manag. 2018, 165, 495–508. [Google Scholar] [CrossRef]

- Xin, H.; Guo, K.; Li, D.; Yang, H.; Hu, C. Production of High-Grade Diesel from Palmitic Acid over Activated Carbon-Supported Nickel Phosphide Catalysts. Appl. Catal. B 2016, 187, 375–385. [Google Scholar] [CrossRef]

- Zhong, J.; Deng, Q.; Cai, T.; Li, X.; Gao, R.; Wang, J.; Zeng, Z.; Dai, G.; Deng, S. Graphitic Carbon Embedded FeNi Nanoparticles for Efficient Deoxygenation of Stearic Acid without Using Hydrogen and Solvent. Fuel 2021, 292, 120248. [Google Scholar] [CrossRef]

- Thongkumkoon, S.; Kiatkittipong, W.; Hartley, U.W.; Laosiripojana, N.; Daorattanachai, P. Catalytic Activity of Trimetallic Sulfided Re-Ni-Mo/γ-Al2O3 toward Deoxygenation of Palm Feedstocks. Renew. Energy 2019, 140, 111–123. [Google Scholar] [CrossRef]

- Rashidi, N.A.; Mustapha, E.; Theng, Y.Y.; Razak, N.A.A.; Bar, N.A.; Baharudin, K.B.; Derawi, D. Advanced Biofuels from Waste Cooking Oil via Solventless and Hydrogen-Free Catalytic Deoxygenation over Mesostructured Ni-Co/SBA-15, Ni-Fe/SBA-15, and Co-Fe/SBA-15 Catalysts. Fuel 2022, 313, 122695. [Google Scholar] [CrossRef]

- Nugraha, R.E.; Prasetyoko, D.; Bahruji, H.; Suprapto, S.; Asikin-Mijan, N.; Oetami, T.P.; Jalil, A.A.; Vo, D.V.N.; Taufiq-Yap, Y.H. Lewis Acid Ni/Al-MCM-41 Catalysts for H 2 -Free Deoxygenation of Reutealis Trisperma Oil to Biofuels. RSC Adv. 2021, 11, 21885–21896. [Google Scholar] [CrossRef]

- Mohammed, S.T.; Hamad, K.I.; Gheni, S.A.; Aqar, D.Y.; Ahmed, S.M.R.; Mahmood, M.A.; Ceylan, S.; Abdullah, G.H. Enhancement of Stability of Pd/AC Deoxygenation Catalyst for Hydrothermal Production of Green Diesel Fuel from Waste Cooking Oil. Chem. Eng. Sci. 2022, 251, 117489. [Google Scholar] [CrossRef]

- Lee, C.W.; Lin, P.Y.; Chen, B.H.; Kukushkin, R.G.; Yakovlev, V.A. Hydrodeoxygenation of Palmitic Acid over Zeolite-Supported Nickel Catalysts. Catal. Today 2021, 379, 124–131. [Google Scholar] [CrossRef]

- Krobkrong, N.; Itthibenchapong, V.; Khongpracha, P.; Faungnawakij, K. Deoxygenation of Oleic Acid under an Inert Atmosphere Using Molybdenum Oxide-Based Catalysts. Energy Convers. Manag. 2018, 167, 1–8. [Google Scholar] [CrossRef]

- Vikár, A.; Solt, H.E.; Novodárszki, G.; Mihályi, M.R.; Barthos, R.; Domján, A.; Hancsók, J.; Valyon, J.; Lónyi, F. A Study of the Mechanism of Triglyceride Hydrodeoxygenation over Alumina-Supported and Phosphatized-Alumina-Supported Pd Catalysts. J. Catal. 2021, 404, 67–79. [Google Scholar] [CrossRef]

- Papageridis, K.N.; Charisiou, N.D.; Douvartzides, S.; Sebastian, V.; Hinder, S.J.; Baker, M.A.; AlKhoori, S.; Polychronopoulou, K.; Goula, M.A. Promoting Effect of CaO-MgO Mixed Oxide on Ni/γ-Al2O3 Catalyst for Selective Catalytic Deoxygenation of Palm Oil. Renew. Energy 2020, 162, 1793–1810. [Google Scholar] [CrossRef]

- Kaewmeesri, R.; Srifa, A.; Itthibenchapong, V.; Faungnawakij, K. Deoxygenation of Waste Chicken Fats to Green Diesel over Ni/Al2O3: Effect of Water and Free Fatty Acid Content. Energy Fuels 2015, 29, 833–840. [Google Scholar] [CrossRef]

- Janampelli, S.; Darbha, S. Effect of Support on the Catalytic Activity of WOx Promoted Pt in Green Diesel Production. Mol. Catal. 2018, 451, 125–134. [Google Scholar] [CrossRef]

- Papanikolaou, G.; Lanzafame, P.; Giorgianni, G.; Abate, S.; Perathoner, S.; Centi, G. Highly Selective Bifunctional Ni Zeo-Type Catalysts for Hydroprocessing of Methyl Palmitate to Green Diesel. Catal. Today 2020, 345, 14–21. [Google Scholar] [CrossRef]

- Herskowitz, M.; Landau, M.V.; Reizner, Y.; Berger, D. A Commercially-Viable, One-Step Process for Production of Green Diesel from Soybean Oil on Pt/SAPO-11. Fuel 2013, 111, 157–164. [Google Scholar] [CrossRef]

- Kordouli, E.; Sygellou, L.; Kordulis, C.; Bourikas, K.; Lycourghiotis, A. Probing the Synergistic Ratio of the NiMo/γ-Al2O3 Reduced Catalysts for the Transformation of Natural Triglycerides into Green Diesel. Appl. Catal. B 2017, 209, 12–22. [Google Scholar] [CrossRef]

- Malins, K. Synthesis of Renewable Hydrocarbons from Vegetable Oil Feedstock by Hydrotreatment over Selective Sulfur-Free SiO2-Al2O3 Supported Monometallic Pd, Pt, Ru, Ni, Mo and Bimetallic NiMo Catalysts. Fuel 2021, 285, 119129. [Google Scholar] [CrossRef]

- Liu, Y.; Sotelo-Boyás, R.; Murata, K.; Minowa, T.; Sakanishi, K. Hydrotreatment of Jatropha Oil to Produce Green Diesel over Trifunctional Ni–Mo/SiO2–Al2O3 Catalyst. Chem. Lett. 2009, 38, 552–553. [Google Scholar] [CrossRef]

- Yurpalov, V.L.; Neponiashchii, A.A.; Drozdov, V.A.; Antonicheva, N.V.; Buluchevskiy, E.A.; Lavrenov, A.V. The Deactivation of Acidic Sites of NiMo/B2O3–Al2O3 Catalysts during Vegetable Oil Hydrodeoxygenation Studied by EPR Spectroscopy. Magn. Reson. Chem. 2021, 59, 600–607. [Google Scholar] [CrossRef]

- Toba, M.; Abe, Y.; Kuramochi, H.; Osako, M.; Mochizuki, T.; Yoshimura, Y. Hydrodeoxygenation of Waste Vegetable Oil over Sulfide Catalysts. Catal. Today 2011, 164, 533–537. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Lee, H.V.; Juan, J.C.; Noorsaadah, A.R.; Ong, H.C.; Razali, S.M.; Taufiq-Yap, Y.H. Promoting Deoxygenation of Triglycerides via Co-Ca Loaded SiO2-Al2O3 Catalyst. Appl. Catal. A Gen. 2018, 552, 38–48. [Google Scholar] [CrossRef]

- Baharudin, K.B.; Taufiq-Yap, Y.H.; Hunns, J.; Isaacs, M.; Wilson, K.; Derawi, D. Mesoporous NiO/Al-SBA-15 Catalysts for Solvent-Free Deoxygenation of Palm Fatty Acid Distillate. Microporous Mesoporous Mater. 2019, 276, 13–22. [Google Scholar] [CrossRef]

- Jiraroj, D.; Jirarattanapochai, O.; Anutrasakda, W.; Samec, J.S.M.; Tungasmita, D.N. Selective Decarboxylation of Biobased Fatty Acids Using a Ni-FSM-16 Catalyst. Appl. Catal. B 2021, 291, 120050. [Google Scholar] [CrossRef]

- Lestari, S.; Päivi, M.A.; Bernas, H.; Simakova, O.; Sjöholm, R.; Beltramini, J.; Max Lu, G.Q.; Myllyoja, J.; Simakova, I.; Murzin, D.Y. Catalytic Deoxygenation of Stearic Acid in a Continuous Reactor over a Mesoporous Carbon-Supported Pd Catalyst. Energy Fuels 2009, 23, 3842–3845. [Google Scholar] [CrossRef]

- Sousa, F.P.; Silva, L.N.; de Rezende, D.B.; de Oliveira, L.C.A.; Pasa, V.M.D. Simultaneous Deoxygenation, Cracking and Isomerization of Palm Kernel Oil and Palm Olein over Beta Zeolite to Produce Biogasoline, Green Diesel and Biojet-Fuel. Fuel 2018, 223, 149–156. [Google Scholar] [CrossRef]

- Ameen, M.; Azizan, M.T.; Yusup, S.; Ramli, A.; Yasir, M.; Kaur, H.; Wai, C.K. H-Y Zeolite as Hydrodeoxygenation Catalyst for Diesel Range Hydrocarbon Production from Rubber Seed Oil. Mater. Today Proc. 2019, 16, 1742–1749. [Google Scholar] [CrossRef]

- Azreena, I.N.; Lau, H.; Asikin-Mijan, N.; Hassan, M.; Izham, S.M.; Kennedy, E.; Stockenhuber, M.; Mastuli, M.; Alharthi, F.A.; Alghamdi, A.A.; et al. A Promoter Effect on Hydrodeoxygenation Reactions of Oleic Acid by Zeolite Beta Catalysts. J. Anal. Appl. Pyrolysis 2021, 155, 105044. [Google Scholar] [CrossRef]

- Susanto, B.H.; Nasikin, M.; Sukirno; Wiyo, A. Synthesis of Renewable Diesel through Hydrodeoxygenation Using Pd/Zeolite Catalysts. Procedia Chem. 2014, 9, 139–150. [Google Scholar] [CrossRef]

- Choo, M.Y.; Oi, L.E.; Daou, T.J.; Ling, T.C.; Lin, Y.C.; Centi, G.; Ng, E.P.; Juan, J.C. Deposition of NiO Nanoparticles on Nanosized Zeolite NaY for Production of Biofuel via Hydrogen-Free Deoxygenation. Materials 2020, 13, 3104. [Google Scholar] [CrossRef] [PubMed]

- Crawford, J.M.; Smoljan, C.S.; Lucero, J.; Carreon, M.A. Deoxygenation of Stearic Acid over Cobalt-Based NaX Zeolite Catalysts. Catalysts 2019, 9, 42. [Google Scholar] [CrossRef]

- Choo, M.Y.; Juan, J.C.; Oi, L.E.; Ling, T.C.; Ng, E.P.; Rahman Noorsaadah, A.; Centi, G.; Lee, K.T. The Role of Nanosized Zeolite Y in the H2-Free Catalytic Deoxygenation of Triolein. Catal. Sci. Technol. 2019, 9, 772–782. [Google Scholar] [CrossRef]

- Putra, R.; Lestari, W.W.; Wibowo, R.; Susanto, B.H. Fe/Indonesian Natural Zeolite as Hydrodeoxygenation Catalyst in Green Diesel Production from Palm Oil. Bull. Chem. React. Eng. Catal. 2018, 13, 245–255. [Google Scholar] [CrossRef]

- Hidalgo, J.M.; Tišler, Z.; Vráblík, A.; Velvarská, R.; Lederer, J. Acid-Modified Phonolite and Foamed Zeolite as Supports for NiW Catalysts for Deoxygenation of Waste Rendering Fat. React. Kinet. Mech. Catal. 2019, 126, 773–793. [Google Scholar] [CrossRef]

- de Oliveira Camargo, M.; Castagnari Willimann Pimenta, J.L.; de Oliveira Camargo, M.; Arroyo, P.A. Green Diesel Production by Solvent-Free Deoxygenation of Oleic Acid over Nickel Phosphide Bifunctional Catalysts: Effect of the Support. Fuel 2020, 281, 118719. [Google Scholar] [CrossRef]

- Konwar, L.J.; Mikkola, J.P. Carbon Support Effects on Metal (Pd, Pt and Ru) Catalyzed Hydrothermal Decarboxylation/Deoxygenation of Triglycerides. Appl. Catal. A Gen. 2022, 638, 118611. [Google Scholar] [CrossRef]

- Kim, S.K.; Yoon, D.; Lee, S.C.; Kim, J. Mo2C/Graphene Nanocomposite as a Hydrodeoxygenation Catalyst for the Production of Diesel Range Hydrocarbons. ACS Catal. 2015, 5, 3292–3303. [Google Scholar] [CrossRef]

- Han, J.; Duan, J.; Chen, P.; Lou, H.; Zheng, X. Molybdenum Carbide-Catalyzed Conversion of Renewable Oils into Diesel-like Hydrocarbons. Adv. Synth. Catal. 2011, 353, 2577–2583. [Google Scholar] [CrossRef]

- Qin, Y.; Chen, P.; Duan, J.; Han, J.; Lou, H.; Zheng, X.; Hong, H. Carbon Nanofibers Supported Molybdenum Carbide Catalysts for Hydrodeoxygenation of Vegetable Oils. RSC Adv. 2013, 3, 17485–17491. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Rosman, N.A.; AbdulKareem-Alsultan, G.; Mastuli, M.S.; Lee, H.V.; Nabihah-Fauzi, N.; Lokman, I.M.; Alharthi, F.A.; Alghamdi, A.A.; Aisyahi, A.A.; et al. Production of Renewable Diesel from Jatropha Curcas Oil via Pyrolytic-Deoxygenation over Various Multi-Wall Carbon Nanotube-Based Catalysts. Process Saf. Environ. Prot. 2020, 142, 336–349. [Google Scholar] [CrossRef]

- Li, X.F.; Luo, X.G. Preparation of Mesoporous Activated Carbon Supported Ni Catalyst for Deoxygenation of Stearic Acid into Hydrocarbons. Environ. Prog. Sustain. Energy 2015, 34, 607–612. [Google Scholar] [CrossRef]

- Safa-Gamal, M.; Asikin-Mijan, N.; Arumugam, M.; Khalit, W.N.A.W.; Nur Azreena, I.; Hafez, F.S.; Taufiq-Yap, Y.H. Catalytic Deoxygenation by H2-Free Single-Step Conversion of Free Fatty Acid Feedstock over a Co-Ag Carbon-Based Catalyst for Green Diesel Production. J. Anal. Appl. Pyrolysis 2021, 160, 105334. [Google Scholar] [CrossRef]

- Janampelli, S.; Darbha, S. Selective and Reusable Pt-WOx/Al2O3 Catalyst for Deoxygenation of Fatty Acids and Their Esters to Diesel-Range Hydrocarbons. Catal. Today 2018, 309, 219–226. [Google Scholar] [CrossRef]

- Janampelli, S.; Darbha, S. Highly Efficient Pt-MoOx/ZrO2 Catalyst for Green Diesel Production. Catal. Commun. 2019, 125, 70–76. [Google Scholar] [CrossRef]

- Jing, Z.; Zhang, T.; Shang, J.; Zhai, M.; Yang, H.; Qiao, C.; Ma, X. Influence of Cu and Mo Components of γ-Al2O3 Supported Nickel Catalysts on Hydrodeoxygenation of Fatty Acid Methyl Esters to Fuel-like Hydrocarbons. J. Fuel Chem. Technol. 2018, 46, 427–440. [Google Scholar] [CrossRef]

- Hanafi, S.A.; Mamdouh; Elmelawy, S.; Ahmed, H.A. Solvent-Free Deoxygenation of Low-Cost Fat to Produce Diesel-like Hydrocarbons over Ni–MoS2/Al2O3–TiO2 Heterogenized Catalyst. Int. J. Energy Water Resour. 2021, 6, 1–13. [Google Scholar] [CrossRef]

- Oh, M.; Jin, M.; Lee, K.; Kim, J.C.; Ryoo, R.; Choi, M. Importance of Pore Size and Lewis Acidity of Pt/Al2O3 for Mitigating Mass Transfer Limitation and Catalyst Fouling in Triglyceride Deoxygenation. Chem. Eng. J. 2022, 439, 135530. [Google Scholar] [CrossRef]

- Di, L.; Yao, S.; Song, S.; Wu, G.; Dai, W.; Guan, N.; Li, L. Robust Ruthenium Catalysts for the Selective Conversion of Stearic Acid to Diesel-Range Alkanes. Appl. Catal. B 2017, 201, 137–149. [Google Scholar] [CrossRef]

- Hengsawad, T.; Jindarat, T.; Resasco, D.E.; Jongpatiwut, S. Synergistic Effect of Oxygen Vacancies and Highly Dispersed Pd Nanoparticles over Pd-Loaded TiO2 Prepared by a Single-Step Sol–Gel Process for Deoxygenation of Triglycerides. Appl. Catal. A Gen. 2018, 566, 74–86. [Google Scholar] [CrossRef]

- Loe, R.; Santillan-Jimenez, E.; Morgan, T.; Sewell, L.; Ji, Y.; Jones, S.; Isaacs, M.A.; Lee, A.F.; Crocker, M. Effect of Cu and Sn Promotion on the Catalytic Deoxygenation of Model and Algal Lipids to Fuel-like Hydrocarbons over Supported Ni Catalysts. Appl. Catal. B 2016, 191, 147–156. [Google Scholar] [CrossRef]

- Kaewmeesri, R.; Nonkumwong, J.; Kiatkittipong, W.; Laosiripojana, N.; Faungnawakij, K. Deoxygenations of Palm Oil-Derived Methyl Esters over Mono- and Bimetallic NiCo Catalysts. J. Environ. Chem. Eng. 2021, 9, 105128. [Google Scholar] [CrossRef]

- Lycourghiotis, S.; Kordouli, E.; Kordulis, C.; Bourikas, K. Transformation of Residual Fatty Raw Materials into Third Generation Green Diesel over a Nickel Catalyst Supported on Mineral Palygorskite. Renew. Energy 2021, 180, 773–786. [Google Scholar] [CrossRef]

- Metals Quotation—Legor. Available online: https://www.legor.com/en-us/metals-quotation (accessed on 20 September 2022).

- Lee, J.; Jung, J.M.; Park, C.; Jeon, B.H.; Wang, C.H.; Lee, S.R.; Kwon, E.E. Rapid Conversion of Fat, Oil and Grease (FOG) into Biodiesel without Pre-Treatment of FOG. J. Clean Prod. 2017, 168, 1211–1216. [Google Scholar] [CrossRef]

- Hachemi, I.; Kumar, N.; Mäki-Arvela, P.; Roine, J.; Peurla, M.; Hemming, J.; Salonen, J.; Murzin, D.Y. Sulfur-Free Ni Catalyst for Production of Green Diesel by Hydrodeoxygenation. J. Catal. 2017, 347, 205–221. [Google Scholar] [CrossRef]

- Cao, X.; Long, F.; Wang, F.; Zhao, J.; Xu, J.; Jiang, J. Chemoselective Decarboxylation of Higher Aliphatic Esters to Diesel-Range Alkanes over the NiCu/Al2O3 Bifunctional Catalyst under Mild Reaction Conditions. Renew. Energy 2021, 180, 1–13. [Google Scholar] [CrossRef]

- Cherstiouk, O.V.; Simonov, P.A.; Oshchepkov, A.G.; Zaikovskii, V.I.; Kardash, T.Y.; Bonnefont, A.; Parmon, V.N.; Savinova, E.R. Electrocatalysis of the Hydrogen Oxidation Reaction on Carbon-Supported Bimetallic NiCu Particles Prepared by an Improved Wet Chemical Synthesis. J. Electroanal. Chem. 2016, 783, 146–151. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Lee, H.V.; Marliza, T.S.; Taufiq-Yap, Y.H. Pyrolytic-Deoxygenation of Triglycerides Model Compound and Non-Edible Oil to Hydrocarbons over SiO2-Al2O3 Supported NiO-CaO Catalysts. J. Anal. Appl. Pyrolysis 2018, 129, 221–230. [Google Scholar] [CrossRef]

- Chen, S.; Zhou, G.; Miao, C. Green and Renewable Bio-Diesel Produce from Oil Hydrodeoxygenation: Strategies for Catalyst Development and Mechanism. Renew. Sustain. Energy Rev. 2019, 101, 568–589. [Google Scholar] [CrossRef]

- Lei, X.; Xin, H.; Du, X.; Yang, H.; Zeng, Y.; Zhou, L.; Juan, C.; Zhang, H.; Li, D.; Hu, C. Efficiency Conversion of Jatropha Oil into High-Quality Biofuel over the Innovative Ni-Mo2N Based Catalyst. Fuel 2022, 324, 124548. [Google Scholar] [CrossRef]

- Si, Z.; Zhang, X.; Wang, C.; Ma, L.; Dong, R. An Overview on Catalytic Hydrodeoxygenation of Pyrolysis Oil and Its Model Compounds. Catalysts 2017, 7, 169. [Google Scholar] [CrossRef]

- Kordulis, C.; Bourikas, K.; Gousi, M.; Kordouli, E.; Lycourghiotis, A. Development of Nickel Based Catalysts for the Transformation of Natural Triglycerides and Related Compounds into Green Diesel: A Critical Review. Appl. Catal. B 2016, 181, 156–196. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, F.; Li, G.; Li, X. Effect of Zn/Al Ratio of Ni/ZnO-Al2O3 Catalysts on the Catalytic Deoxygenation of Oleic Acid into Alkane. Appl. Catal. A Gen. 2017, 529, 175–184. [Google Scholar] [CrossRef]

- Gamal, M.S.; Asikin-Mijan, N.; Khalit, W.N.A.W.; Arumugam, M.; Izham, S.M.; Taufiq-Yap, Y.H. Effective Catalytic Deoxygenation of Palm Fatty Acid Distillate for Green Diesel Production under Hydrogen-Free Atmosphere over Bimetallic Catalyst CoMo Supported on Activated Carbon. Fuel Process. Technol. 2020, 208, 106519. [Google Scholar] [CrossRef]

- Nikolopoulos, I.; Kogkos, G.; Andriopoulou, C.; Kordouli, E.; Dracopoulos, V.; Bourikas, K.; Kordulis, C.; Lycourghiotis, A. Cobalt−Alumina Coprecipitated Catalysts for Green Diesel Production. Ind. Eng. Chem. Res. 2021, 60, 18672–18683. [Google Scholar] [CrossRef]

- Nazemi, M.K.; Sheibani, S.; Rashchi, F.; Gonzalez-Delacruz, V.M.; Caballero, A. Preparation of Nanostructured Nickel Aluminate Spinel Powder from Spent NiO/Al2O3 Catalyst by Mechano-Chemical Synthesis. Adv. Powder Technol. 2012, 23, 833–838. [Google Scholar] [CrossRef]

- Rogers, K.A.; Zheng, Y. Selective Deoxygenation of Biomass-Derived Bio-Oils within Hydrogen-Modest Environments: A Review and New Insights. ChemSusChem 2016, 9, 1750–1772. [Google Scholar] [CrossRef]

- Cheah, K.W.; Yusup, S.; Loy, A.C.M.; How, B.S.; Skoulou, V.; Taylor, M.J. Recent Advances in the Catalytic Deoxygenation of Plant Oils and Prototypical Fatty Acid Models Compounds: Catalysis, Process, and Kinetics. Mol. Catal. 2021, 523, 111469. [Google Scholar] [CrossRef]

- Jeon, K.W.; Na, H.S.; Lee, Y.L.; Ahn, S.Y.; Kim, K.J.; Shim, J.O.; Jang, W.J.; Jeong, D.W.; Nah, I.W.; Roh, H.S. Catalytic Deoxygenation of Oleic Acid over a Ni-CeZrO2 Catalyst. Fuel 2019, 258, 116179. [Google Scholar] [CrossRef]

- Peng, B.; Zhao, C.; Kasakov, S.; Foraita, S.; Lercher, J.A. Manipulating Catalytic Pathways: Deoxygenation of Palmitic Acid on Multifunctional Catalysts. Chem. A Eur. J. 2013, 19, 4732–4741. [Google Scholar] [CrossRef] [PubMed]

- Papageridis, K.N.; Charisiou, N.D.; Douvartzides, S.; Sebastian, V.; Hinder, S.J.; Baker, M.A.; AlKhoori, A.A.; AlKhoori, S.I.; Polychronopoulou, K.; Goula, M.A. Continuous Selective Deoxygenation of Palm Oil for Renewable Diesel Production over Ni Catalysts Supported on Al2O3 and La2O3–Al2O3. RSC Adv. 2021, 11, 8569–8584. [Google Scholar] [CrossRef] [PubMed]

- Charisiou, N.D.; Tzounis, L.; Sebastian, V.; Hinder, S.J.; Baker, M.A.; Polychronopoulou, K.; Goula, M.A. Investigating the Correlation between Deactivation and the Carbon Deposited on the Surface of Ni/Al2O3 and Ni/La2O3-Al2O3 Catalysts during the Biogas Reforming Reaction. Appl. Surf. Sci. 2019, 474, 42–56. [Google Scholar] [CrossRef]

- Kay Lup, A.N.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. A Review on Reaction Mechanisms of Metal-Catalyzed Deoxygenation Process in Bio-Oil Model Compounds. Appl. Catal. A. Gen. 2017, 541, 87–106. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, M.F.; Chu, Y.; Chen, J.X. Influence of CS2 on Performance of Ni2P/SiO2 for Deoxygenation of Methyl Laurate as a Model Compound to Hydrocarbons: Simultaneous Investigation on Catalyst Deactivation. Fuel Process. Technol. 2015, 134, 259–269. [Google Scholar] [CrossRef]

- Kay Lup, A.N.; Abnisa, F.; Wan Daud, W.M.A.; Aroua, M.K. A Review on Reactivity and Stability of Heterogeneous Metal Catalysts for Deoxygenation of Bio-Oil Model Compounds. J. Ind. Eng. Chem. 2017, 56, 1–34. [Google Scholar] [CrossRef]

- Alsultan, G.A.; Asikin-Mijan, N.; Lee, H.V.; Albazzaz, A.S.; Taufiq-Yap, Y.H. Deoxygenation of Waste Cooking to Renewable Diesel over Walnut Shell-Derived Nanorode Activated Carbon Supported CaO-La2O3 Catalyst. Energy Convers. Manag. 2017, 151, 311–323. [Google Scholar] [CrossRef]

- Satyanarayana, C.V.; Srikant, D.; Gurav, H.R. Catalyst Deactivation and Regeneration. In Industrial Catalytic Processes for Fine and Specialty Chemicals; Elsevier: Amsterdam, The Netherlands, 2016; pp. 187–219. [Google Scholar] [CrossRef]

- To, A.T.; Resasco, D.E. Role of a Phenolic Pool in the Conversion of M-Cresol to Aromatics over HY and HZSM-5 Zeolites. Appl. Catal. A Gen. 2014, 487, 62–71. [Google Scholar] [CrossRef]

- Tran, N.T.T.; Uemura, Y.; Ramli, A. Hydrodeoxygenation of Guaiacol over Al-MCM-41 Supported Metal Catalysts: A Comparative Study of Co and Ni. Procedia Eng. 2016, 148, 1252–1258. [Google Scholar] [CrossRef]

- Ferella, F.; Innocenzi, V.; Maggiore, F. Oil Refining Spent Catalysts: A Review of Possible Recycling Technologies. Resour. Conserv. Recycl. 2016, 108, 10–20. [Google Scholar] [CrossRef]

- de Barros Dias Moreira, J.; Bastos de Rezende, D.; Márcia Duarte Pasa, V. Deoxygenation of Macauba Acid Oil over Co-Based Catalyst Supported on Activated Biochar from Macauba Endocarp: A Potential and Sustainable Route for Green Diesel and Biokerosene Production. Fuel 2020, 269, 117253. [Google Scholar] [CrossRef]

- Kordouli, E.; Pawelec, B.; Bourikas, K.; Kordulis, C.; Fierro, J.L.G.; Lycourghiotis, A. Mo Promoted Ni-Al2O3 Co-Precipitated Catalysts for Green Diesel Production. Appl. Catal. B 2018, 229, 139–154. [Google Scholar] [CrossRef]

- Hongloi, N.; Prapainainar, P.; Seubsai, A.; Sudsakorn, K.; Prapainainar, C. Nickel Catalyst with Different Supports for Green Diesel Production. Energy 2019, 182, 306–320. [Google Scholar] [CrossRef]

- Jeon, K.W.; Park, H.R.; Lee, Y.L.; Kim, J.E.; Jang, W.J.; Shim, J.O.; Roh, H.S. Deoxygenation of Non-Edible Fatty Acid for Green Diesel Production: Effect of Metal Loading Amount over Ni/MgO–Al2O3 on the Catalytic Performance and Reaction Pathway. Fuel 2022, 311, 122488. [Google Scholar] [CrossRef]

- Wan Khalit, W.N.A.; Asikin-Mijan, N.; Marliza, T.S.; Safa-Gamal, M.; Shamsuddin, M.R.; Azreena, I.N.; Saiman, M.I.; Taufiq-Yap, Y.H. One-Pot Decarboxylation and Decarbonylation Reaction of Waste Cooking Oil over Activated Carbon Supported Nickel-Zinc Catalyst into Diesel-like Fuels. J. Anal. Appl. Pyrolysis 2022, 164, 105505. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, J.; Shi, H. Deoxygenation of Methyl Laurate as a Model Compound to Hydrocarbons on Ni2P/SiO2, Ni2P/MCM-41, and Ni 2P/SBA-15 Catalysts with Different Dispersions. Energy Fuels 2013, 27, 3400–3409. [Google Scholar] [CrossRef]

- Srifa, A.; Faungnawakij, K.; Itthibenchapong, V.; Viriya-empikul, N.; Charinpanitkul, T.; Assabumrungrat, S. Production of Bio-Hydrogenated Diesel by Catalytic Hydrotreating of Palm Oil over NiMoS2/γ-Al2O3 Catalyst. Bioresour. Technol. 2014, 158, 81–90. [Google Scholar] [CrossRef]

- Orozco, L.M.; Echeverri, D.A.; Sánchez, L.; Rios, L.A. Second-Generation Green Diesel from Castor Oil: Development of a New and Efficient Continuous-Production Process. Chem. Eng. J. 2017, 322, 149–156. [Google Scholar] [CrossRef]

- Yotsomnuk, P.; Skolpap, W. Effect of Process Parameters on Yield of Biofuel Production from Waste Virgin Coconut Oil. Eng. J. 2018, 22, 21–35. [Google Scholar] [CrossRef]

- Sugami, Y.; Minami, E.; Saka, S. Hydrocarbon Production from Coconut Oil by Hydrolysis Coupled with Hydrogenation and Subsequent Decarboxylation. Fuel 2017, 197, 272–276. [Google Scholar] [CrossRef]

- Silva, L.N.; Fortes, I.C.P.; de Sousa, F.P.; Pasa, V.M.D. Biokerosene and Green Diesel from Macauba Oils via Catalytic Deoxygenation over Pd/C. Fuel 2016, 164, 329–338. [Google Scholar] [CrossRef]

- Shim, J.O.; Jeong, D.W.; Jang, W.J.; Jeon, K.W.; Jeon, B.H.; Cho, S.Y.; Roh, H.S.; Na, J.G.; Ko, C.H.; Oh, Y.K.; et al. Deoxygenation of Oleic Acid over Ce(1-x)Zr(x)O2 Catalysts in Hydrogen Environment. Renew. Energy 2014, 65, 36–40. [Google Scholar] [CrossRef]

- Zhao, X.; Wei, L.; Cheng, S.; Kadis, E.; Cao, Y.; Boakye, E.; Gu, Z.; Julson, J. Hydroprocessing of Carinata Oil for Hydrocarbon Biofuel over Mo-Zn/Al2O3. Appl. Catal. B 2016, 196, 41–49. [Google Scholar] [CrossRef]

- Zheng, D.; Guo, D.; Wang, Z.; Wang, X.; Shan, Y.; Liu, X.; Yan, Z.; Yu, S.; Liu, Y. Synergistic Effect of CoOx and Ni-Co Alloy in Ni-Co/SAPO-11 Catalysts for the Deoxygenation of Stearic Acids. Chem. Eng. J. 2022, 451, 138929. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Sivarajasekar, N.; Velu, S.; Sudha, P.N.; Wongsakulphasatch, S.; Banat, F. Sustainable Production of Bio-Jet Fuel and Green Gasoline from Date Palm Seed Oil via Hydroprocessing over Tantalum Phosphate. Fuel 2023, 331, 125688. [Google Scholar] [CrossRef]

- Arend, M.; Nonnen, T.; Hoelderich, W.F.; Fischer, J.; Groos, J. Catalytic Deoxygenation of Oleic Acid in Continuous Gas Flow for the Production of Diesel-like Hydrocarbons. Appl. Catal. A Gen. 2011, 399, 198–204. [Google Scholar] [CrossRef]

- Santillan-Jimenez, E.; Morgan, T.; Loe, R.; Crocker, M. Continuous Catalytic Deoxygenation of Model and Algal Lipids to Fuel-like Hydrocarbons over Ni–Al Layered Double Hydroxide. Catal. Today 2015, 258, 284–293. [Google Scholar] [CrossRef]

- Fu, L.; Li, Y.; Cui, H.; Ba, W.; Liu, Y. Highly Stable and Selective Catalytic Deoxygenation of Renewable Bio-Lipids over Ni/CeO2-Al2O3 for N-Alkanes. Appl. Catal. A Gen. 2021, 623, 118258. [Google Scholar] [CrossRef]

- Abdullah, N.H.B.; Mijan, N.A.; Taufiq-Yap, Y.H.; Ong, H.C.; Lee, H.V. Environment-Friendly Deoxygenation of Non-Edible Ceiba Oil to Liquid Hydrocarbon Biofuel: Process Parameters and Optimization Study. Environ. Sci. Pollut. Res. 2022, 29, 51143–51152. [Google Scholar] [CrossRef]

- Liu, S.; Simonetti, T.; Zheng, W.; Saha, B. Selective Hydrodeoxygenation of Vegetable Oils and Waste Cooking Oils to Green Diesel Using a Silica-Supported Ir–ReOx Bimetallic Catalyst. ChemSusChem 2018, 11, 1446–1454. [Google Scholar] [CrossRef]

- Yulia, D.; Zulys, A. Hydroprocessing of Kemiri Sunan Oil (Reutealis Trisperma (Blanco) Airy Shaw) over NiMoCe/γ-Al2O3 Catalyst to Produce Green Diesel. IOP Conf. Series: Mater. Sci. Eng. 2020, 763, 012038. [Google Scholar] [CrossRef]

- Simanjuntak, F.S.H.; Wijaya, G.H.A.; Saldi, Z.S.; Dwiatmoko, A.A. Cobalt Supported on Activated Biochar as Catalyst for Green Diesel Production. IOP Conf. Series: Earth Environ. Sci. 2021, 927, 012036. [Google Scholar] [CrossRef]

- Jamil, F.; Al-Muhtaseb, A.H.; Al-Haj, L.; Al-Hinai, M.A.; Baawain, M. Phoenix Dactylifera Kernel Oil Used As Potential Source for Synthesizing Jet Fuel and Green Diesel. Energy Procedia 2017, 118, 35–39. [Google Scholar] [CrossRef]

- Liu, H.; Han, J.; Huang, Q.; Shen, H.; Lei, L.; Huang, Z.; Zhang, Z.; Zhao, Z.K.; Wang, F. Catalytic Hydrodeoxygenation of Methyl Stearate and Microbial Lipids to Diesel-Range Alkanes over Pd/HPA-SiO2Catalysts. Ind. Eng. Chem. Res. 2020, 59, 17440–17450. [Google Scholar] [CrossRef]

- Asikin-Mijan, N.; Lee, H.V.; Juan, J.C.; Noorsaadah, A.R.; Taufiq-Yap, Y.H. Catalytic Deoxygenation of Triglycerides to Green Diesel over Modified CaO-Based Catalysts. RSC Adv. 2017, 7, 46445–46460. [Google Scholar] [CrossRef]

- Miao, C.; Marin-Flores, O.; Davidson, S.D.; Li, T.; Dong, T.; Gao, D.; Wang, Y.; Garcia-Pérez, M.; Chen, S. Hydrothermal Catalytic Deoxygenation of Palmitic Acid over Nickel Catalyst. Fuel 2016, 166, 302–308. [Google Scholar] [CrossRef]

- Romero, M.; Pizzi, A.; Toscano, G.; Casazza, A.A.; Busca, G.; Bosio, B.; Arato, E. Preliminary Experimental Study on Biofuel Production by Deoxygenation of Jatropha Oil. Fuel Process. Technol. 2015, 137, 31–37. [Google Scholar] [CrossRef]