Thermal Management Techniques for Lithium-Ion Batteries Based on Phase Change Materials: A Systematic Review and Prospective Recommendations

Abstract

:1. Introduction

2. Data and Methods

3. Results

3.1. Annual Publication Trends

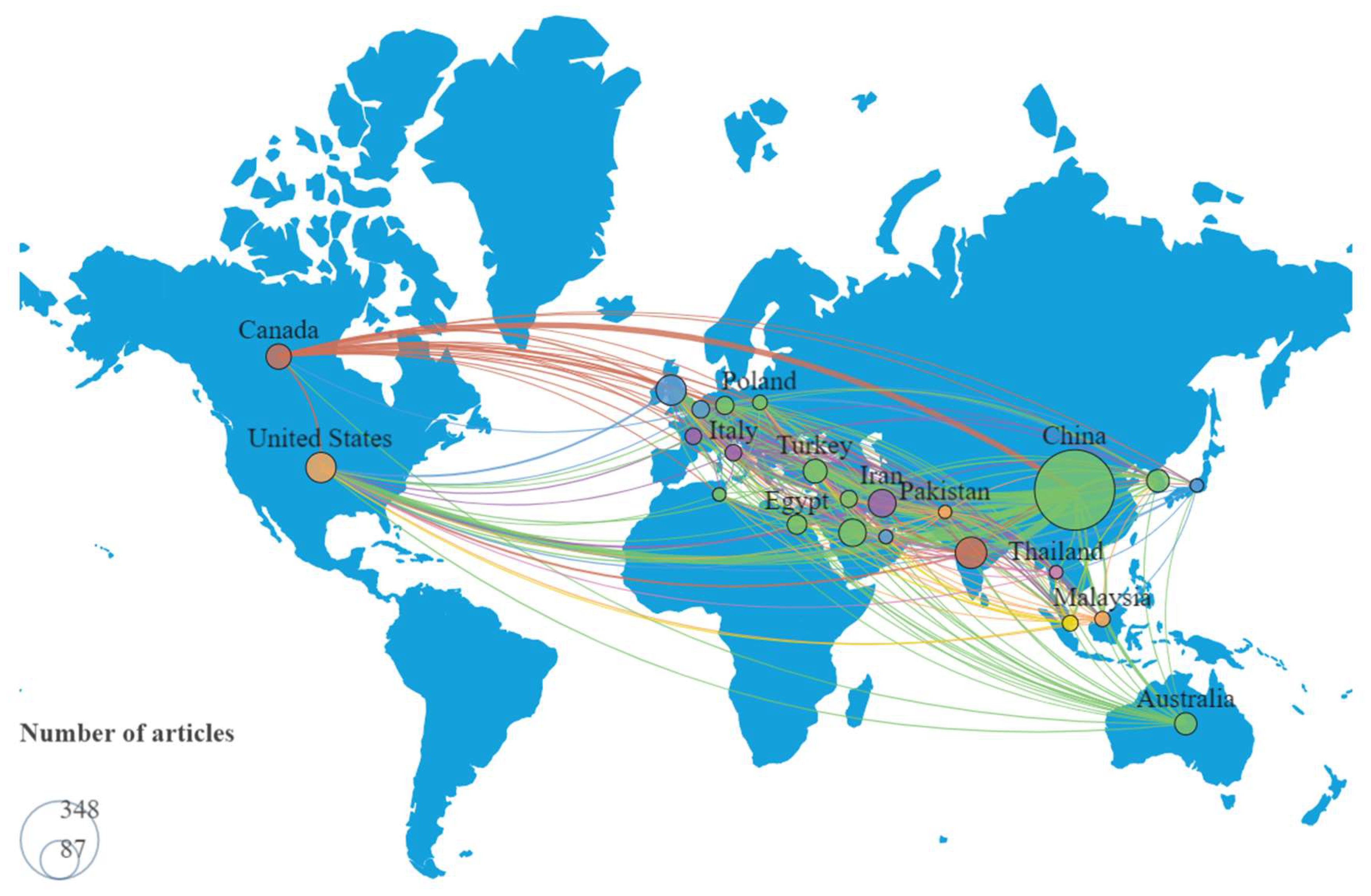

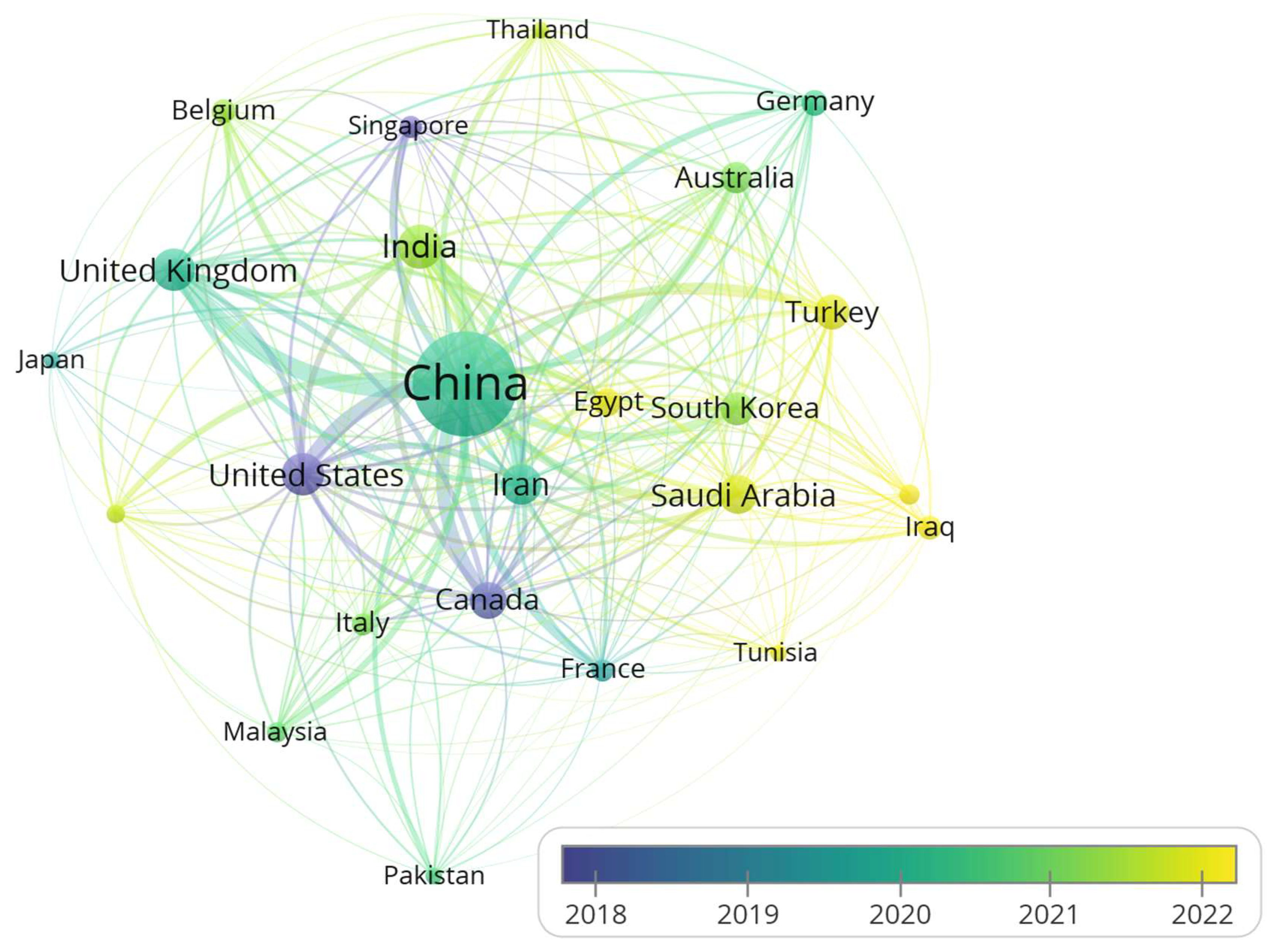

3.2. Geographical and Institutional Distribution

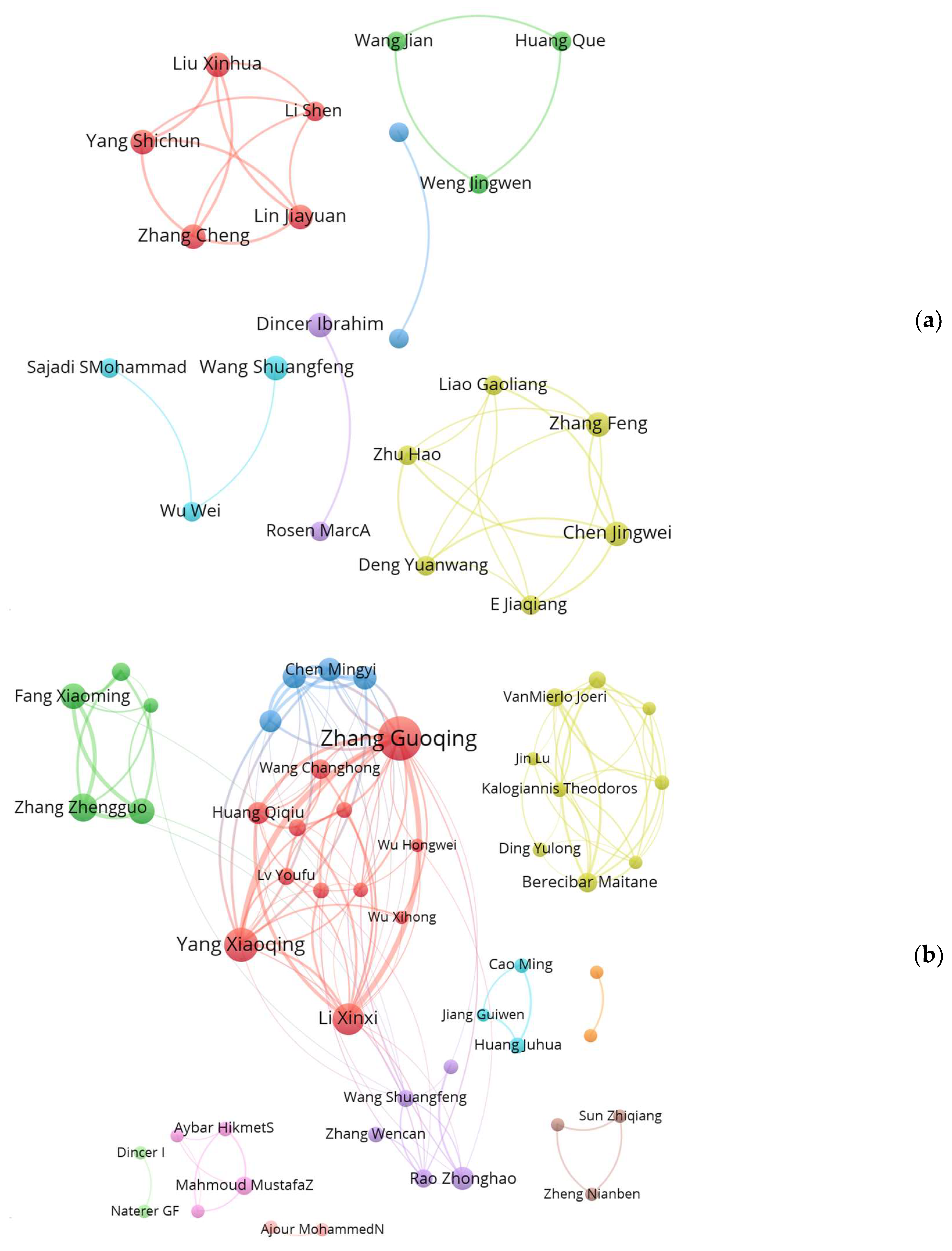

3.3. Authors and Their Cooperation Network

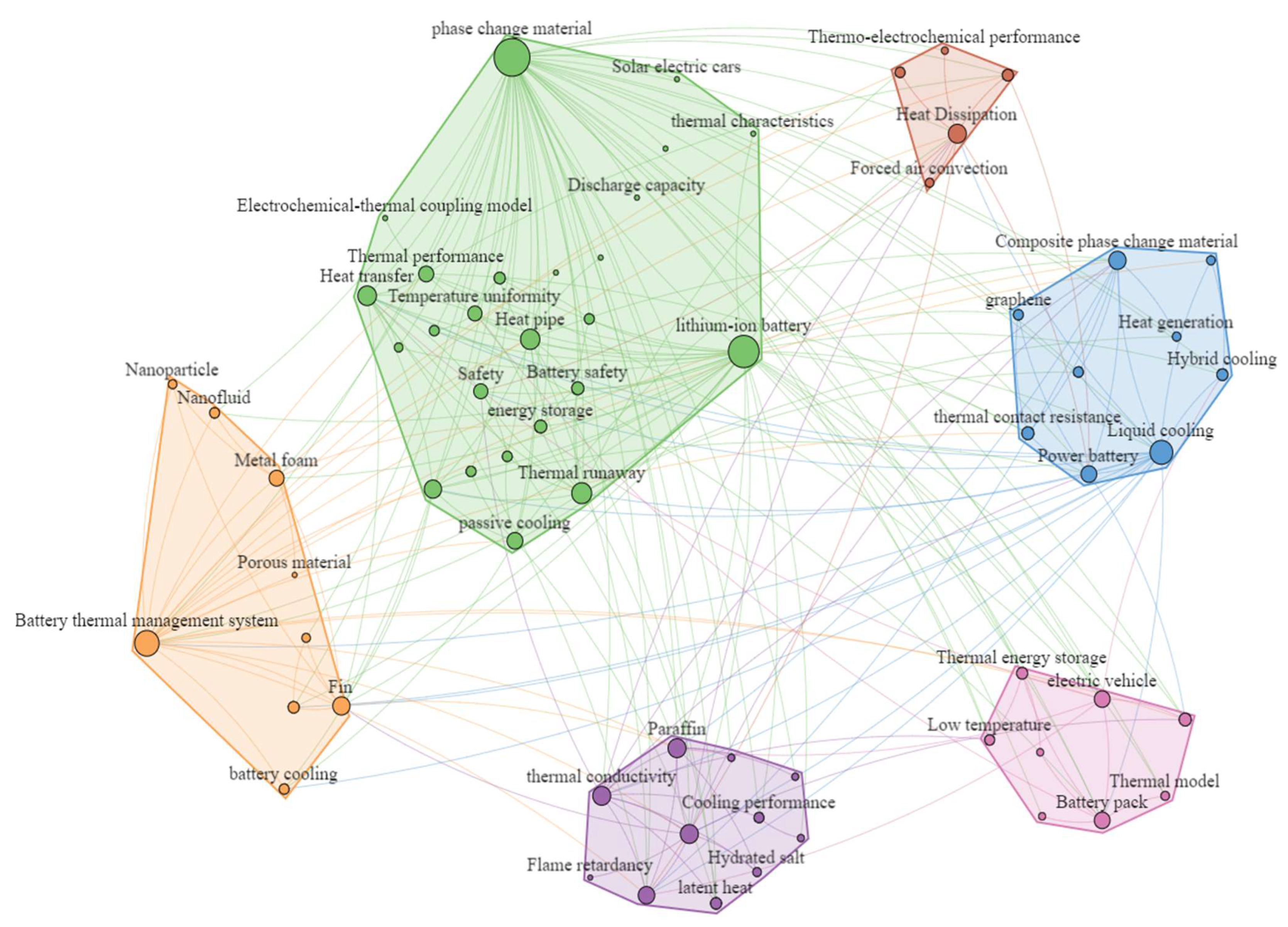

3.4. Research Hotsports Analysis

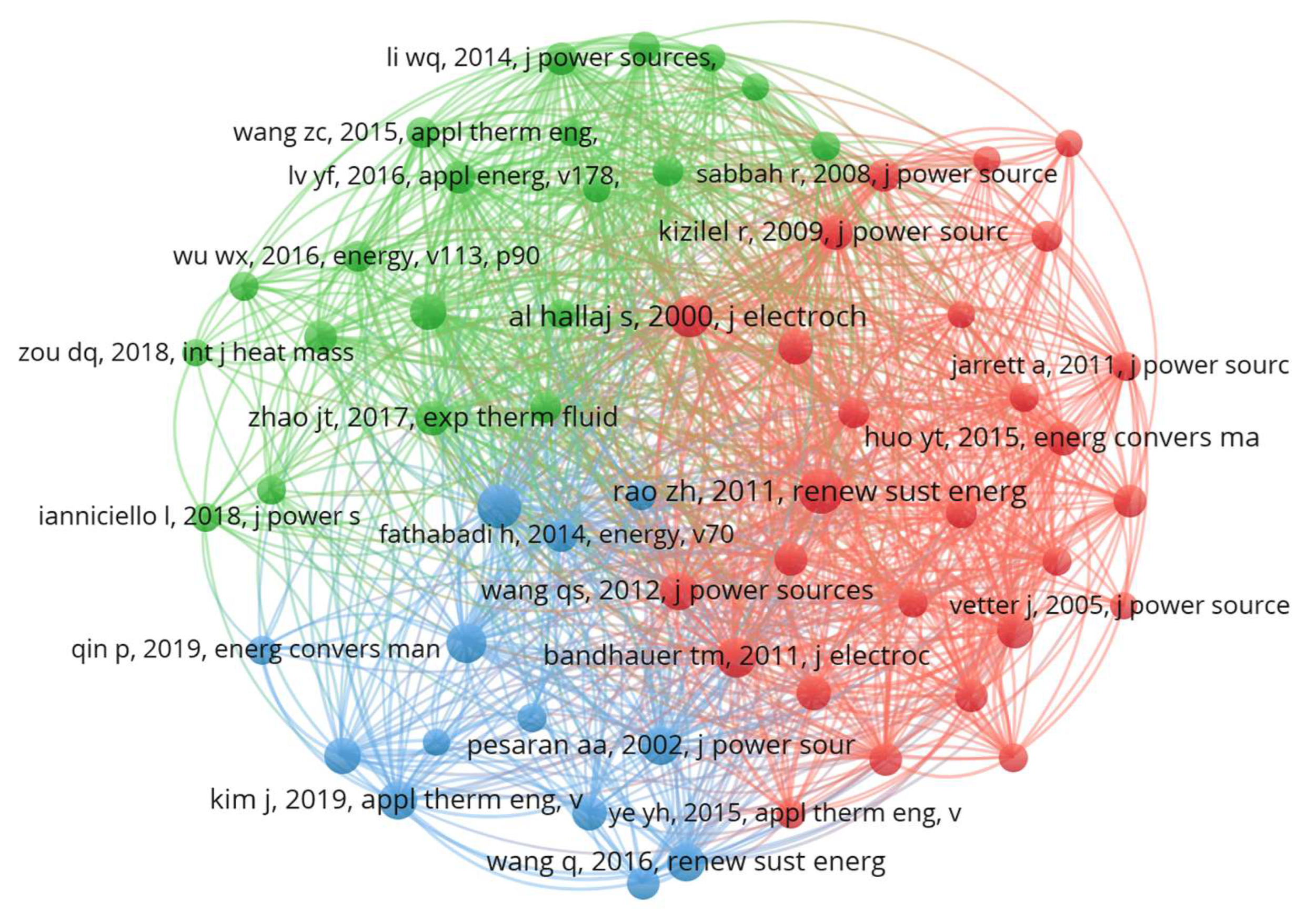

3.5. Reference Co-Citation Analysis

4. Discussion

4.1. Multilayer PCMs

4.2. CPCM

4.3. Structural Optimization

4.4. Lightweight Design

4.5. Low Temperature Heating

4.6. Thermal Runaway

4.7. Algorithm

4.8. Additional Technical Aspects

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hasib, S.A.; Islam, S.; Chakrabortty, R.K.; Ryan, M.J.; Saha, D.K.; Ahamed, M.H.; Moyeen, S.; Das, S.K.; Ali, M.F.; Islam, M.R.; et al. A Comprehensive Review of Available Battery Datasets, RUL Prediction Approaches, and Advanced Battery Management. IEEE Access 2021, 9, 86166. [Google Scholar] [CrossRef]

- Larcher, D.; Tarascon, J.M. Towards greener and more sustainable batteries for electrical energy storage. Nat. Chem. 2015, 7, 19–29. [Google Scholar] [CrossRef]

- Hannan, M.A.; Wali, S.B.; Ker, P.J.; Rahman, M.S.A.; Mansor, M.; Ramachandaramurthy, V.K.; Muttaqi, K.M.; Mahlia, T.M.I.; Dong, Z.Y. Battery energy-storage system: A review of technologies, optimization objectives, constraints, approaches, and outstanding issues. J. Energy Storage 2021, 42, 103023. [Google Scholar] [CrossRef]

- Li, M.; Lu, J.; Chen, Z.W.; Amine, K. 30 Years of Lithium-Ion Batteries. Adv. Mater. 2018, 30, 1800561. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Ping, P.; Zhao, X.J.; Chu, G.Q.; Sun, J.H.; Chen, C.H. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Sources 2012, 208, 210. [Google Scholar] [CrossRef]

- Li, B.; Parekh, M.H.; Pol, V.G.; Adams, T.E.; Fleetwood, J.; Jones, C.M.; Tomar, V. Operando Monitoring of Electrode Temperatures During Overcharge-Caused Thermal Runaway. Energy Technol. 2021, 9, 2100497. [Google Scholar] [CrossRef]

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1–R25. [Google Scholar] [CrossRef]

- Wang, Q.S.; Mao, B.B.; Stoliarov, S.I.; Sun, J.H. A review of lithium-ion battery failure mechanisms and fire prevention strategies. Prog. Energy Combust. Sci. 2019, 73, 95–131. [Google Scholar] [CrossRef]

- Whittingham, M.S. History, Evolution, and Future Status of Energy Storage. Proc. IEEE 2012, 100, 1518–1534. [Google Scholar] [CrossRef]

- Wang, Y.; Gao, Q.; Wang, G.H.; Lu, P.Y.; Zhao, M.D.; Bao, W.D. A review on research status and key technologies of battery thermal management and its enhanced safety. Int. J. Energy Res. 2018, 42, 4008–4033. [Google Scholar] [CrossRef]

- Rao, Z.H.; Wang, S.F. A review of power battery thermal energy management. Renew. Sustain. Energy Rev. 2011, 15, 4554–4571. [Google Scholar] [CrossRef]

- Yang, S.T.; Ling, C.; Fan, Y.Q.; Yang, Y.G.; Tan, X.J.; Dong, H.Y. A Review of Lithium-Ion Battery Thermal Management System Strategies and the Evaluate Criteria. Int. J. Electrochem. Sci. 2019, 14, 6077. [Google Scholar] [CrossRef]

- Mahamud, R.; Park, C. Reciprocating air flow for Li-ion battery thermal management to improve temperature uniformity. J. Power Sources 2011, 196, 5685. [Google Scholar] [CrossRef]

- Sabbah, R.; Kizilel, R.; Selman, J.R.; Al-Hallaj, S. Active (air-cooled) vs. passive (phase change material) thermal management of high power lithium-ion packs: Limitation of temperature rise and uniformity of temperature distribution. J. Power Sources 2008, 182, 630–638. [Google Scholar] [CrossRef]

- Zhu, X.L.; Shi, H.; Xu, W.B.; Zhang, T.; Wang, Y.S. An improved air supply scheme for battery energy storage systems. Bull. Pol. Acad. Sci. Tech. Sci. 2022, 70, e140692. [Google Scholar]

- Saw, L.H.; Ye, Y.H.; Tay, A.A.O.; Chong, W.T.; Kuan, S.H.; Yew, M.C. Computational fluid dynamic and thermal analysis of Lithium-ion battery pack with air cooling. Appl. Energy 2016, 177, 783–792. [Google Scholar] [CrossRef]

- Shi, H.; Liu, M.N.; Xu, W.B.; Zhu, X.L.; Zou, Y.T.; Yang, K.J. Optimization on Thermal Management of Lithium-Ion Batteries Using Computational Fluid Dynamics and Air-cooling Methods. Int. J. Electrochem. Sci. 2022, 17, 220550. [Google Scholar] [CrossRef]

- Rao, Z.H.; Qian, Z.; Kuang, Y.; Li, Y.M. Thermal performance of liquid cooling based thermal management system for cylindrical lithium-ion battery module with variable contact surface. Appl. Therm. Eng. 2017, 123, 1514–1522. [Google Scholar] [CrossRef]

- Wu, W.X.; Wang, S.F.; Wu, W.; Chen, K.; Hong, S.H.; Lai, Y.X. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281. [Google Scholar] [CrossRef]

- Wu, W.X.; Yang, X.Q.; Zhang, G.Q.; Chen, K.; Wang, S.F. Experimental investigation on the thermal performance of heat pipe-assisted phase change material based battery thermal management system. Energy Convers. Manag. 2017, 138, 486–492. [Google Scholar] [CrossRef]

- Hallaj, S.A.; Selman, J.R. A Novel Thermal Management System for Electric Vehicle Batteries Using Phase-Change Material. J. Electrochem. Soc. 2000, 147, 3231. [Google Scholar] [CrossRef]

- Sajawal, M.; Rehman, T.; Ali, H.M.; Sajjad, U.; Raza, A.; Bhatti, M.S. Experimental thermal performance analysis of finned tube-phase change material based double pass solar air heater. Case Stud. Therm. Eng. 2019, 15, 100543. [Google Scholar] [CrossRef]

- Malik, M.; Dincer, I.; Rosen, M.A. Review on use of phase change materials in battery thermal management for electric and hybrid electric vehicles: Review on use of PCM in battery thermal management for EV and HEV. Int. J. Energy Res. 2016, 40, 1011–1031. [Google Scholar] [CrossRef]

- Liu, H.Q.; Wei, Z.B.; He, W.D.; Zhao, J.Y. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: A review. Energy Convers. Manag. 2017, 150, 304–330. [Google Scholar] [CrossRef]

- Rodriguez, A.; Laio, A. Clustering by fast search and find of density peaks. Science 2014, 344, 1492–1496. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.M.; Ibekwe-SanJuan, F.; Hou, J.H. The structure and dynamics of cocitation clusters: A multiple-perspective cocitation analysis. J. Am. Soc. Inf. Sci. 2010, 61, 1386–1409. [Google Scholar] [CrossRef] [Green Version]

- Roldan-Valadez, E.; Salazar-Ruiz, S.Y.; Ibarra-Contreras, R.; Rios, C. Current concepts on bibliometrics: A brief review about impact factor, Eigenfactor score, CiteScore, SCImago Journal Rank, Source-Normalised Impact per Paper, H-index, and alternative metrics. Ir. J. Med. Sci. 2019, 188, 939–951. [Google Scholar] [CrossRef]

- Bornmann, L.; Mutz, R. Growth rates of modern science: A bibliometric analysis based on the number of publications and cited references: Growth Rates of Modern Science: A Bibliometric Analysis Based on the Number of Publications and Cited References. J. Assoc. Inf. Sci. Technol. 2015, 66, 2215–2222. [Google Scholar] [CrossRef] [Green Version]

- Moed, H.F. New developments in the use of citation analysis in research evaluation. Arch. Immunol. Ther. Exp. 2009, 57, 13–18. [Google Scholar] [CrossRef]

- Li, J.; Goerlandt, F.; Li, K.W. Slip and Fall Incidents at Work: A Visual Analytics Analysis of the Research Domain. Int. J. Environ. Res. Public Health 2019, 16, 4972. [Google Scholar] [CrossRef] [Green Version]

- Murugan, M.; Saravanan, A.; Elumalai, P.; Murali, G.; Dhineshbabu, N.R.; Kumar, P.; Afzal, A. Thermal Management System of Lithium-Ion Battery Packs for Electric Vehicles: An Insight Based on Bibliometric Study. J. Energy Storage 2022, 52, 104723. [Google Scholar] [CrossRef]

- Cabeza, L.F.; Frazzica, A.; Chafer, M.; Verez, D.; Palomba, V. Research Trends and Perspectives of Thermal Management of Electric Batteries: Bibliometric Analysis. J. Energy Storage 2020, 32, 101976. [Google Scholar] [CrossRef]

- Liu, J.H.; Li, J.; Wang, J.H. In-depth analysis on thermal hazards related research trends about lithium-ion batteries: A bibliometric study. J. Energy Storage 2021, 35, 102253. [Google Scholar] [CrossRef]

- Van Eck, N.J.; Waltman, L. Citation-based clustering of publications using CitNetExplorer and VOSviewer. Scientometrics 2017, 111, 1053–1070. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pizzi, S.; Caputo, A.; Corvino, A.; Venturelli, A. Management research and the UN sustainable development goals (SDGs): A bibliometric investigation and systematic review. J. Clean. Prod. 2020, 276, 124033. [Google Scholar] [CrossRef]

- Hu, Y.J.; Yang, L.; Duan, F.; Wang, H.; Li, C. A Scientometric Analysis and Review of the Emissions Trading System. Energies 2022, 15, 4423. [Google Scholar] [CrossRef]

- Yue, Q.L.; He, C.X.; Wu, M.C.; Zhao, T.S. Advances in thermal management systems for next-generation power batteries. Int. J. Heat Mass Transf. 2021, 181, 121853. [Google Scholar] [CrossRef]

- Qiu, Y.S.; Jiang, F.M. A review on passive and active strategies of enhancing the safety of lithium-ion batteries. Int. J. Heat Mass Transfer. 2022, 184, 122288. [Google Scholar] [CrossRef]

- Rao, Z.H.; Wang, S.F.; Zhang, G.Q. Simulation and Experiment of Thermal Energy Management with Phase Change Material for Ageing LiFePO4 Power Battery. Energy Convers. Manag. 2011, 52, 3408–3414. [Google Scholar] [CrossRef]

- Jaguemont, J.; Boulon, L.; Dube, Y. A Comprehensive Review of Lithium-Ion Batteries Used in Hybrid and Electric Vehicles at Cold Temperatures. Appl. Energy 2016, 164, 99–114. [Google Scholar] [CrossRef]

- Huang, Q.Q.; Li, X.X.; Zhang, G.Q.; Deng, J.; Wang, C.H. Thermal management of Lithium-ion battery pack through the application of flexible form-stable composite phase change materials. Appl. Therm. Eng. 2021, 183, 116151. [Google Scholar] [CrossRef]

- Xiao, C.R.; Zhang, G.Q.; Li, Z.H.; Yang, X.Q. Custom Design of Solid-Solid Phase Change Material with Ultra-High Thermal Stability for Battery Thermal Management. J. Mater. Chem. A 2020, 8, 14624–14633. [Google Scholar] [CrossRef]

- Zhang, J.Y.; Li, X.X.; Zhang, G.Q.; Wu, H.W.; Rao, Z.H.; Guo, J.W.; Zhou, D.Q. Experimental investigation of the flame retardant and form-stable composite phase change materials for a power battery thermal management system. J. Power Sources 2020, 480, 229116. [Google Scholar] [CrossRef]

- Ling, Z.Y.; Wen, X.Y.; Zhang, Z.G.; Fang, X.M.; Gao, X.N. Thermal management performance of phase change materials with different thermal conductivities for Li-ion battery packs operated at low temperatures. Energy 2018, 144, 977–983. [Google Scholar] [CrossRef]

- Ling, Z.Y.; Cao, J.H.; Zhang, W.B.; Zhang, Z.G.; Fang, X.M.; Gao, X.N. Compact liquid cooling strategy with phase change materials for Li-ion batteries optimized using response surface methodology. Appl. Energy 2018, 228, 777–788. [Google Scholar] [CrossRef]

- Cao, J.H.; He, Y.J.; Feng, J.X.; Lin, S.; Ling, Z.Y.; Zhang, Z.G.; Fang, X.M. Mini-Channel Cold Plate with Nano Phase Change Material Emulsion for Li-Ion Battery under High-Rate Discharge. Appl. Energy 2020, 279, 115808. [Google Scholar] [CrossRef]

- Rao, Z.H.; Wang, Q.C.; Huang, C.L. Investigation of the thermal performance of phase change material/mini-channel coupled battery thermal management system. Appl. Energy 2016, 164, 659–669. [Google Scholar] [CrossRef]

- Wang, Q.C.; Rao, Z.H.; Huo, Y.T.; Wang, S.F. Thermal performance of phase change material/oscillating heat pipe-based battery thermal management system. Int. J. Therm. Sci. 2016, 102, 9–16. [Google Scholar] [CrossRef]

- Huo, Y.T.; Guo, Y.Q.; Rao, Z.H. Investigation on the Thermal Performance of Phase Change Material/Porous Medium-Based Battery Thermal Management in Pore Scale. Int. J. Energy Res. 2019, 43, 767–778. [Google Scholar] [CrossRef]

- Weng, J.W.; Yang, X.Q.; Zhang, G.Q.; Ouyang, D.X.; Chen, M.Y.; Wang, J. Optimization of the Detailed Factors in a Phase-Change-Material Module for Battery Thermal Management. Int. J. Heat Mass Transf. 2019, 138, 126–134. [Google Scholar] [CrossRef]

- Weng, J.W.; He, Y.P.; Ouyang, D.X.; Yang, X.Q.; Chen, M.Y.; Cui, S.T.; Zhang, G.Q.; Yuen, R.K.K.; Wang, J. Honeycomb-inspired design of a thermal management module and its mitigation effect on thermal runaway propagation. J. Appl. Therm. Eng. 2021, 195, 117147. [Google Scholar] [CrossRef]

- Weng, J.W.; Ouyang, D.X.; Yang, X.Q.; Chen, M.Y.; Zhang, G.Q.; Wang, J. Alleviation of Thermal Runaway Propagation in Thermal Management Modules Using Aerogel Felt Coupled with Flame-Retarded Phase Change Material. Energy Convers. Manag. 2019, 200, 112071. [Google Scholar] [CrossRef]

- Mills, A.; Farid, M.; Selman, J.R.; Al-Hallaj, S. Thermal Conductivity Enhancement of Phase Change Materials Using a Graphite Matrix. Appl. Therm. Eng. 2006, 26, 1652–1661. [Google Scholar] [CrossRef]

- Goli, P.; Legedza, S.; Dhar, A.; Salgado, R.; Renteria, J.; Balandin, A.A. Graphene-Enhanced Hybrid Phase Change Materials for Thermal Management of Li-Ion Batteries. J. Power Sources 2014, 248, 37–43. [Google Scholar] [CrossRef] [Green Version]

- Chen, L.J.; Zou, R.Q.; Xia, W.; Liu, Z.P.; Shang, Y.Y.; Zhu, J.L.; Wang, Y.X.; Lin, J.H.; Xia, D.G.; Cao, A.Y. Electro- and Photodriven Phase Change Composites Based on Wax-Infiltrated Carbon Nanotube Sponges. Acs Nano 2012, 6, 10884–10892. [Google Scholar] [CrossRef] [PubMed]

- Li, W.Q.; Qu, Z.G.; He, Y.L.; Tao, Y.B. Experimental Study of a Passive Thermal Management System for High-Powered Lithium-ion Batteries Using Porous Metal Foam Saturated with Phase Change Materials. J. Power Sources 2014, 255, 9–15. [Google Scholar] [CrossRef]

- Heyhat, M.M.; Mousavi, S.; Siavashi, M. Battery Thermal Management with Thermal Energy Storage Composites of PCM, Metal Foam, Fin and Nanoparticle. J. Energy Storage 2020, 28, 101235. [Google Scholar] [CrossRef]

- Wilke, S.; Schweitzer, B.; Khateeb, S.; Al-Hallaj, S. Preventing Thermal Runaway Propagation in Lithium-ion Battery Packs Using a Phase Change Composite Material: An Experimental Study. J. Power Sources 2017, 340, 51–59. [Google Scholar] [CrossRef]

- Kizilel, R.; Sabbah, R.; Selman, J.R.; Al-Hallaj, S. An Alternative Cooling System to Enhance the Safety of Li-Ion Battery Packs. J. Power Sources 2009, 194, 1105–1112. [Google Scholar] [CrossRef]

- Kizilel, R.; Lateef, A.; Sabbah, R.; Farid, M.M.; Selman, J.R.; Al-Hallaj, S. Passive Control of Temperature Excursion and Uniformity in High-Energy Li-Ion Battery Packs at High Current and Ambient Temperature. J. Power Sources 2008, 183, 370–375. [Google Scholar] [CrossRef]

- Samimi, F.; Babapoor, A.; Azizi, M.; Karimi, G. Thermal management analysis of a Li-ion battery cell using phase change material loaded with carbon fibers. Energy 2016, 96, 355–371. [Google Scholar] [CrossRef]

- Babapoor, A.; Azizi, M.; Karimi, G. Thermal Management of a Li-Ion Battery Using Carbon Fiber-PCM Composites. Appl. Therm. Eng. 2015, 82, 281–290. [Google Scholar] [CrossRef]

- Perianes-Rodriguez, A.; Waltman, L.; van Eck, N.J. Constructing bibliometric networks: A comparison between full and fractional counting. J. Informetr. 2016, 10, 1178–1195. [Google Scholar] [CrossRef] [Green Version]

- Trujillo, C.M.; Long, T.M. Document co-citation analysis to enhance transdisciplinary research. Sci. Adv. 2018, 4, e1701130. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, J.H.; Yang, X.C.; Chen, C.M. Emerging trends and new developments in information science: A document co-citation analysis (2009–2016). Scientometrics 2018, 115, 869–892. [Google Scholar] [CrossRef]

- Meng, E.L.; Yu, H.; Zhan, G.Y.; He, Y. Experimental and numerical study of the thermal performance of a new type of phase change material room. Energy Convers. Manag. 2013, 74, 386–394. [Google Scholar] [CrossRef]

- Jin, X.; Zhang, X.S. Thermal analysis of a double layer phase change material floor. Appl. Therm. Eng. 2011, 31, 1576–1581. [Google Scholar] [CrossRef]

- Pasupathy, A.; Velraj, R. Effect of double layer phase change material in building roof for year round thermal management. Energy Build. 2008, 40, 193–203. [Google Scholar] [CrossRef]

- Zhu, N.; Liu, P.P.; Hu, P.F.; Liu, F.L.; Jiang, Z.N. Modeling and simulation on the performance of a novel double shape-stabilized phase change materials wallboard. Energy Build. 2015, 107, 181–190. [Google Scholar] [CrossRef]

- Diaconu, B.M.; Cruceru, M. Novel concept of composite phase change material wall system for year-round thermal energy savings. Energy Build. 2010, 42, 1759–1772. [Google Scholar] [CrossRef]

- Galazutdinova, Y.; Ushak, S.; Farid, M.; Al-Hallaj, S.; Grageda, M. Development of the Inorganic Composite Phase Change Materials for Passive Thermal Management of Li-Ion Batteries: Application. J. Power Sources 2021, 491, 229624. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Zhang, K.H.; Zhang, B.; Tong, Z.M.; Mao, S.L.; Bai, H.; Lu, Y.Y. Ultrafast Battery Heat Dissipation Enabled by Highly Ordered and Interconnected Hexagonal Boron Nitride Thermal Conductive Composites. Green Energy Environ. 2022, 7, 1401–1410. [Google Scholar] [CrossRef]

- Xu, T.; Li, Y.T.; Chen, J.Y.; Wu, H.J.; Zhou, X.Q.; Zhang, Z.G. Improving thermal management of electronic apparatus with paraffin (PA)/ expanded graphite (EG)/graphene (GN) composite material. Appl. Therm. Eng. 2018, 140, 13–22. [Google Scholar] [CrossRef]

- Huang, Q.Q.; Li, X.X.; Zhang, G.Q.; Kan, Y.C.; Li, C.B.; Deng, J.; Wang, C.H. Flexible Composite Phase Change Material with Anti-Leakage and Anti-Vibration Properties for Battery Thermal Management. Appl. Energy 2022, 309, 118434. [Google Scholar] [CrossRef]

- Bais, A.R.; Subhedar, D.G.; Panchal, S. Critical Thickness of Nano-Enhanced RT-42 Paraffin Based Battery Thermal Management System for Electric Vehicles: A Numerical Study. J. Energy Storage 2022, 52, 104757. [Google Scholar] [CrossRef]

- Zhou, Z.Z.; Wang, D.; Peng, Y.; Li, M.Y.; Wang, B.X.; Cao, B.; Yang, L.Z. Experimental Study on the Thermal Management Performance of Phase Change Material Module for the Large Format Prismatic Lithium-Ion Battery. Energy 2022, 238, 122081. [Google Scholar] [CrossRef]

- Jilte, R.; Afzal, A.; Panchal, S. A Novel Battery Thermal Management System Using Nano-Enhanced Phase Change Materials. Energy 2021, 219, 119564. [Google Scholar] [CrossRef]

- Sun, Z.Q.; Fan, R.J.; Zheng, N.B. Thermal Management of a Simulated Battery with the Compound Use of Phase Change Material and Fins: Experimental and Numerical Investigations. Int. J. Therm. Sci. 2021, 165, 106945. [Google Scholar] [CrossRef]

- Chen, H.J.; Abidi, A.; Hussein, A.K.; Younis, O.; Degani, M.; Heidarshenas, B. Investigation of the Use of Extended Surfaces in Paraffin Wax Phase Change Material in Thermal Management of a Cylindrical Lithium-Ion Battery: Applicable in the Aerospace Industry. J. Energy Storage 2022, 45, 103685. [Google Scholar] [CrossRef]

- Choudhari, V.G.; Dhoble, A.S.; Panchal, S.; Fowler, M.; Fraser, R. Numerical Investigation on Thermal Behaviour of 5 × 5 Cell Configured Battery Pack Using Phase Change Material and Fin Structure Layout. J. Energy Storage 2021, 43, 103234. [Google Scholar] [CrossRef]

- Liu, H.Q.; Ahmad, S.; Shi, Y.; Zhao, J.Y. A Parametric Study of a Hybrid Battery Thermal Management System That Couples PCM/Copper Foam Composite with Helical Liquid Channel Cooling. Energy 2021, 231, 120869. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, F.; Yang, W.; Gui, Y.; Zhang, Y. A Hybrid Thermal Management System with Liquid Cooling and Composite Phase Change Materials Containing Various Expanded Graphite Contents for Cylindrical Lithium-Ion Batteries. Appl. Therm. Eng. 2022, 200, 117702. [Google Scholar] [CrossRef]

- Luo, J.; Gu, H.; Wang, S.; Wang, H.; Zou, D.Q. A Coupled Power Battery Cooling System Based on Phase Change Material and Its Influencing Factors. Appl. Energy 2022, 326, 119917. [Google Scholar] [CrossRef]

- Youssef, R.; Hosen, M.S.; He, J.C.; AL-Saadi, M.; Van Mierlo, J.; Berecibar, M. Novel design optimization for passive cooling PCM assisted battery thermal management system in electric vehicles. Case Stud. Therm. Eng. 2022, 32, 101896. [Google Scholar] [CrossRef]

- Guo, S.S.; Xiong, R.; Shen, W.X.; Sun, F.C. Aging investigation of an echelon internal heating method on a three-electrode lithium ion cell at low temperatures. J. Energy Storage 2019, 25, 100878. [Google Scholar] [CrossRef]

- Wang, Y.J.; Zhang, X.C.; Chen, Z.H. Low Temperature Preheating Techniques for Lithium-Ion Batteries: Recent Advances and Future Challenges. Appl. Energy 2022, 313, 118832. [Google Scholar] [CrossRef]

- He, F.Q.; Li, X.X.; Zhang, G.Q.; Zhong, G.J.; He, J.S. Experimental investigation of thermal management system for lithium ion batteries module with coupling effect by heat sheets and phase change materials. Int. J. Energy Res. 2018, 42, 3279–3289. [Google Scholar] [CrossRef]

- Chen, Y.Q.; Kang, Y.Q.; Zhao, Y.; Wang, L.; Liu, J.L.; Li, Y.X.; Liang, Z.; He, X.M.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Lyu, P.Z.; Liu, X.J.; Qu, J.; Zhao, J.T.; Huo, Y.T.; Qu, Z.G.; Rao, Z.H. Recent advances of thermal safety of lithium ion battery for energy storage. Energy Storage Mater. 2020, 31, 195–220. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y.Y. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128. [Google Scholar] [CrossRef]

- Niu, J.Y.; Deng, S.Y.; Gao, X.N.; Niu, H.C.; Fang, Y.T.; Zhang, Z.G. Experimental study on low thermal conductive and flame retardant phase change composite material for mitigating battery thermal runaway propagation. J. Energy Storage 2022, 47, 103557. [Google Scholar] [CrossRef]

- Weng, J.W.; Xiao, C.R.; Ouyang, D.X.; Yang, X.Q.; Chen, M.Y.; Zhang, G.Q.; Yuen, R.K.K.; Wang, J. Mitigation Effects on Thermal Runaway Propagation of Structure-Enhanced Phase Change Material Modules with Flame Retardant Additives. Energy 2022, 239, 122087. [Google Scholar] [CrossRef]

- Zhang, W.C.; Liang, Z.C.; Yin, X.X.; Ling, G.Z. Avoiding thermal runaway propagation of lithium-ion battery modules by using hybrid phase change material and liquid cooling. Appl. Therm. Eng. 2021, 184, 116380. [Google Scholar] [CrossRef]

- Fayaz, H.; Afzal, A.; Samee, A.D.M.; Soudagar, M.E.M.; Akram, N.; Mujtaba, M.A.; Jilte, R.D.; Islam, M.T.; Agbulut, U.; Saleel, C.A. Optimization of Thermal and Structural Design in Lithium-Ion Batteries to Obtain Energy Efficient Battery Thermal Management System (BTMS): A Critical Review. Arch. Comput. Methods Eng. 2022, 29, 129–194. [Google Scholar] [CrossRef] [PubMed]

- Mesgarpour, M.; Mir, M.; Alizadeh, R.; Abad, J.M.N.; Borj, E.P. An evaluation of the thermal behaviour of a lithium-ion battery pack with a combination of pattern-based artificial neural networks (PBANN) and numerical simulation. J. Energy Storage 2022, 47, 103920. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, X.; Liu, L.; Yang, M. Optimization Investigation on Air Phase Change Material Based Battery Thermal Management System. Energy Technol. 2021, 9, 2100060. [Google Scholar] [CrossRef]

- Kolodziejczyk, F.; Mortazavi, B.; Rabczuk, T.; Zhuang, X.Y. Machine learning assisted multiscale modeling of composite phase change materials for Li-ion batteries’ thermal management. Int. J. Heat Mass Transf. 2021, 172, 121199. [Google Scholar] [CrossRef]

- Bao, N.S.; Wei, L.; Ma, C.; Fan, Y.C.; Li, T.Y. Multi-Objective Optimization of Structural Parameters of Air-Cooled System for Lithium Battery Pack Based on Surrogate Model. J. Electrochem. Energy Convers. Storage 2021, 18, 040902. [Google Scholar] [CrossRef]

- Zhu, W.H.; Lei, F.; Zhong, H.; Jiang, X.W. Thermal performance revival of composite PCM for hybrid BTMSs by architecture and formula integrated optimization. Appl. Therm. Eng. 2022, 210, 118320. [Google Scholar] [CrossRef]

- Cao, J.H.; Ling, Z.Y.; Fang, X.M.; Zhang, Z.G. Delayed Liquid Cooling Strategy with Phase Change Material to Achieve High Temperature Uniformity of Li-Ion Battery under High-Rate Discharge. J. Power Sources 2020, 450, 227673. [Google Scholar] [CrossRef]

- Joshy, N.; Hajiyan, M.; Siddique, A.R.M.; Tasnim, S.; Simha, H.; Mahmud, S. Experimental Investigation of the Effect of Vibration on Phase Change Material (PCM) Based Battery Thermal Management System. J. Power Sources 2020, 450, 227717. [Google Scholar] [CrossRef]

- Zhang, W.C.; Li, X.Y.; Wu, W.X.; Huang, J.F. Influence of Mechanical Vibration on Composite Phase Change Material Based Thermal Management System for Lithium-Ion Battery. J. Energy Storage 2022, 54, 105237. [Google Scholar] [CrossRef]

| Thermal Management Method | Advantages | Disadvantages | |

|---|---|---|---|

| Active cooling | Air cooling | Simple structure, light weight, low cost | Poor thermal conductivity, poor thermal management effect |

| Liquid cooling | Good thermal management effect, good temperature uniformity of batteries | Complex structure, large weight, leakage | |

| Passive cooling | Heat pipe cooling | Small size, light weight, high cooling efficiency | Combined with other thermal management methods |

| Phase change material cooling | High latent heat, no additional energy consumption | Uneven melting, low thermal conductivity, low utilization efficiency | |

| Composite cooling | PCM cooling+ Air cooling | Enhance heat storage capacity, environmental applicability, and heat dissipation performance of phase change materials | Large size and weight increase the complexity of the system and increase energy consumption |

| PCM cooling+ Liquid cooling | |||

| Sr. No | Review | Research Article | ||||

|---|---|---|---|---|---|---|

| Country | Articles | Citations | Country | Articles | Citations | |

| 1 | China | 47 | 3911 | China | 301 | 11,082 |

| 2 | India | 17 | 362 | USA | 40 | 3372 |

| 3 | UK | 14 | 350 | Iran | 37 | 1632 |

| 4 | Canada | 8 | 1091 | India | 33 | 764 |

| 5 | USA | 6 | 1350 | Saudi Arabia | 33 | 365 |

| Sr. No | Review | Research Article | ||||

|---|---|---|---|---|---|---|

| Organization | Articles | AC * | Organization | Articles | AC | |

| 1 | Chinese Academy of Sciences | 6 | 37.2 | Guangdong University of Technology | 58 | 40.0 |

| 2 | National Institute of Technology | 5 | 22.8 | Chinese Academy of Sciences | 37 | 31.0 |

| 3 | South China University of Technology | 5 | 260.8 | South China University of Technology | 33 | 67.0 |

| 4 | Imperial College London | 4 | 22.3 | University of Science & Technology of China, CAS | 28 | 38.3 |

| 5 | Hunan University | 3 | 119 | Prince Sattam Bin Abdulaziz University | 22 | 4.5 |

| 6 | Ontario Tech University | 3 | 85.7 | Jiangsu University | 21 | 16.3 |

| 7 | University of Science & Technology of China, CAS | 3 | 69.3 | China University of Mining & Technology | 15 | 73.6 |

| 8 | Beihang University | 3 | 24.6 | Xi’an Jiaotong University | 15 | 57.8 |

| 9 | Xi’an Jiaotong University | 3 | 24.3 | Egyptian Knowledge Bank (EKB) | 14 | 6.1 |

| 10 | Vellore Institute of Technology | 3 | 5.7 | City University of Hong Kong | 11 | 41.1 |

| Sr. No | Organization | Citations | Articles | AC |

|---|---|---|---|---|

| 1 | Los Alamos National Laboratory | 301 | 1 | 301.0 |

| 2 | Illinois Institute of Technology | 1479 | 6 | 246.5 |

| 3 | University of Auckland | 663 | 3 | 221.0 |

| 4 | Kharazmi University | 157 | 1 | 157.0 |

| 5 | University of California Riverside | 311 | 2 | 155.5 |

| 6 | University of California System | 311 | 2 | 155.5 |

| 7 | Tarbiat Modares University | 294 | 2 | 147.0 |

| 8 | Beijing Jiaotong University | 272 | 2 | 136.0 |

| 9 | United States Department of Energy | 388 | 3 | 129.3 |

| 10 | Jordan University of Science & Technology | 126 | 1 | 126.0 |

| Sr. No | Author | Articles | Citations | AC | Institution | Country | Reference |

|---|---|---|---|---|---|---|---|

| 1 | Mills, A. | 1 | 438 | 438.0 | University of Auckland | New Zealand | [53] |

| 2 | Sabbah, R. | 1 | 400 | 400.0 | Illinois Institute of Technology | USA | [14] |

| 3 | Goli, P. | 1 | 309 | 309.0 | University of California System | USA | [54] |

| 4 | Chen, L.J. | 1 | 301 | 301.0 | Peking university | China | [55] |

| 5 | Li, W.Q. | 1 | 247 | 247.0 | Xi An Jiao Tong university | China | [56] |

| 6 | Wilke, S. | 1 | 225 | 225.0 | California Institute of Technology | USA | [58] |

| 7 | Kizilel, R. | 2 | 412 | 206.0 | Illinois Institute of Technology | USA | [59,60] |

| 8 | Samimi, F. | 1 | 204 | 204.0 | Islamic Azad University | Iran | [61] |

| 9 | Babapoor, A. | 1 | 188 | 188.0 | Shiraz University | Iran | [62] |

| 10 | Heyhat, M.M. | 1 | 173 | 173.0 | Tarbiat Modares University | Iran | [57] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, H.; Cheng, M.; Feng, Y.; Qiu, C.; Song, C.; Yuan, N.; Kang, C.; Yang, K.; Yuan, J.; Li, Y. Thermal Management Techniques for Lithium-Ion Batteries Based on Phase Change Materials: A Systematic Review and Prospective Recommendations. Energies 2023, 16, 876. https://doi.org/10.3390/en16020876

Shi H, Cheng M, Feng Y, Qiu C, Song C, Yuan N, Kang C, Yang K, Yuan J, Li Y. Thermal Management Techniques for Lithium-Ion Batteries Based on Phase Change Materials: A Systematic Review and Prospective Recommendations. Energies. 2023; 16(2):876. https://doi.org/10.3390/en16020876

Chicago/Turabian StyleShi, Hong, Mengmeng Cheng, Yi Feng, Chenghui Qiu, Caiyue Song, Nenglin Yuan, Chuanzhi Kang, Kaijie Yang, Jie Yuan, and Yonghao Li. 2023. "Thermal Management Techniques for Lithium-Ion Batteries Based on Phase Change Materials: A Systematic Review and Prospective Recommendations" Energies 16, no. 2: 876. https://doi.org/10.3390/en16020876