Cosimulation of Integrated Organic Photovoltaic Glazing Systems Based on Functional Mock-Up Unit

Abstract

1. Introduction

2. Materials and Methods

2.1. Simulation Software Tools

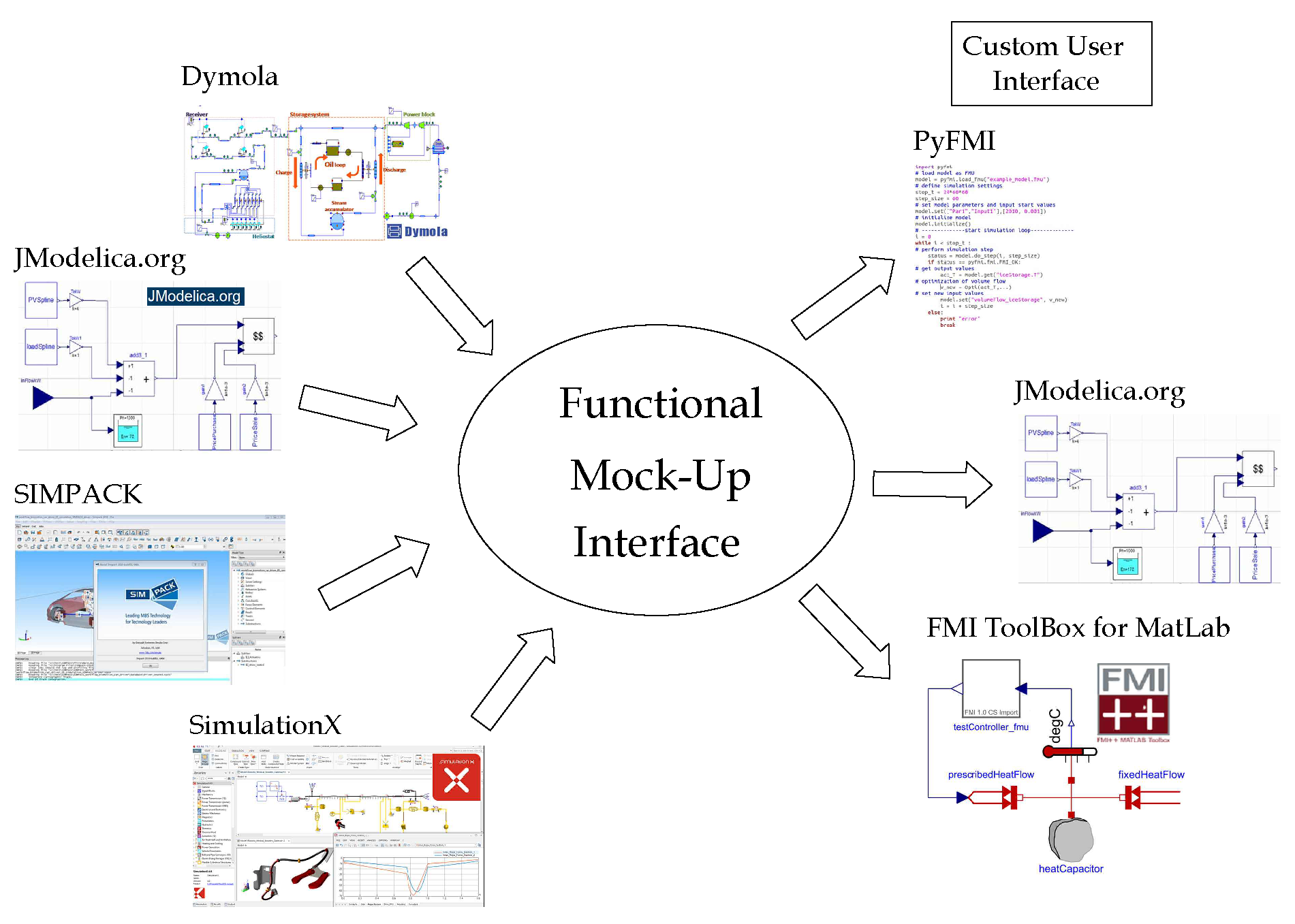

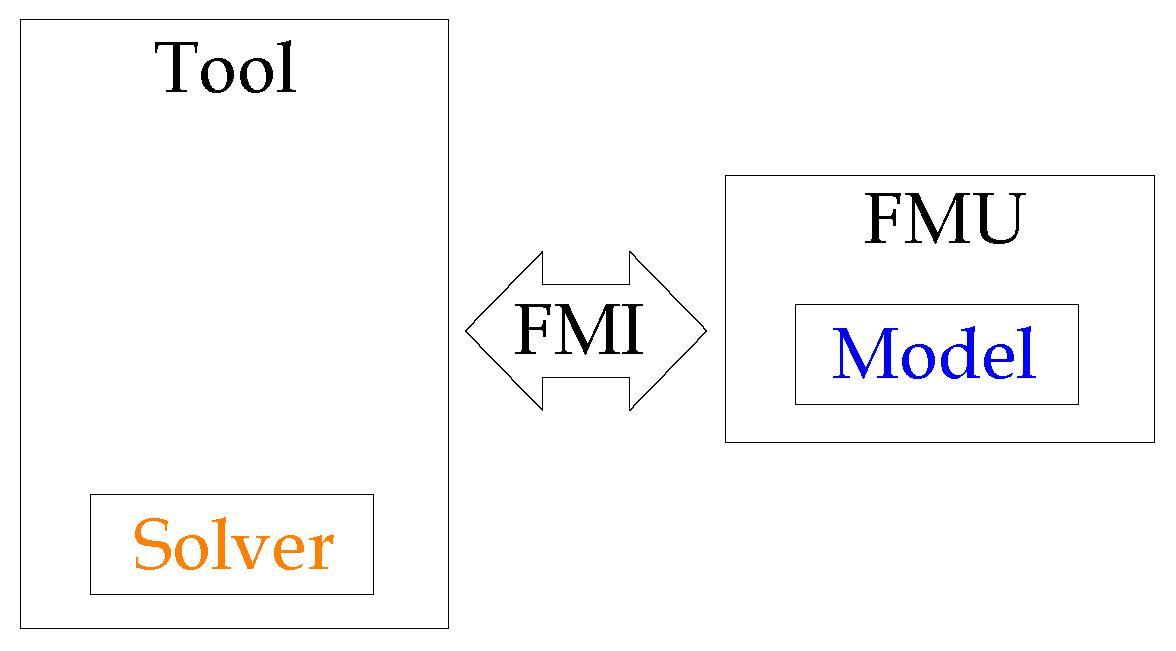

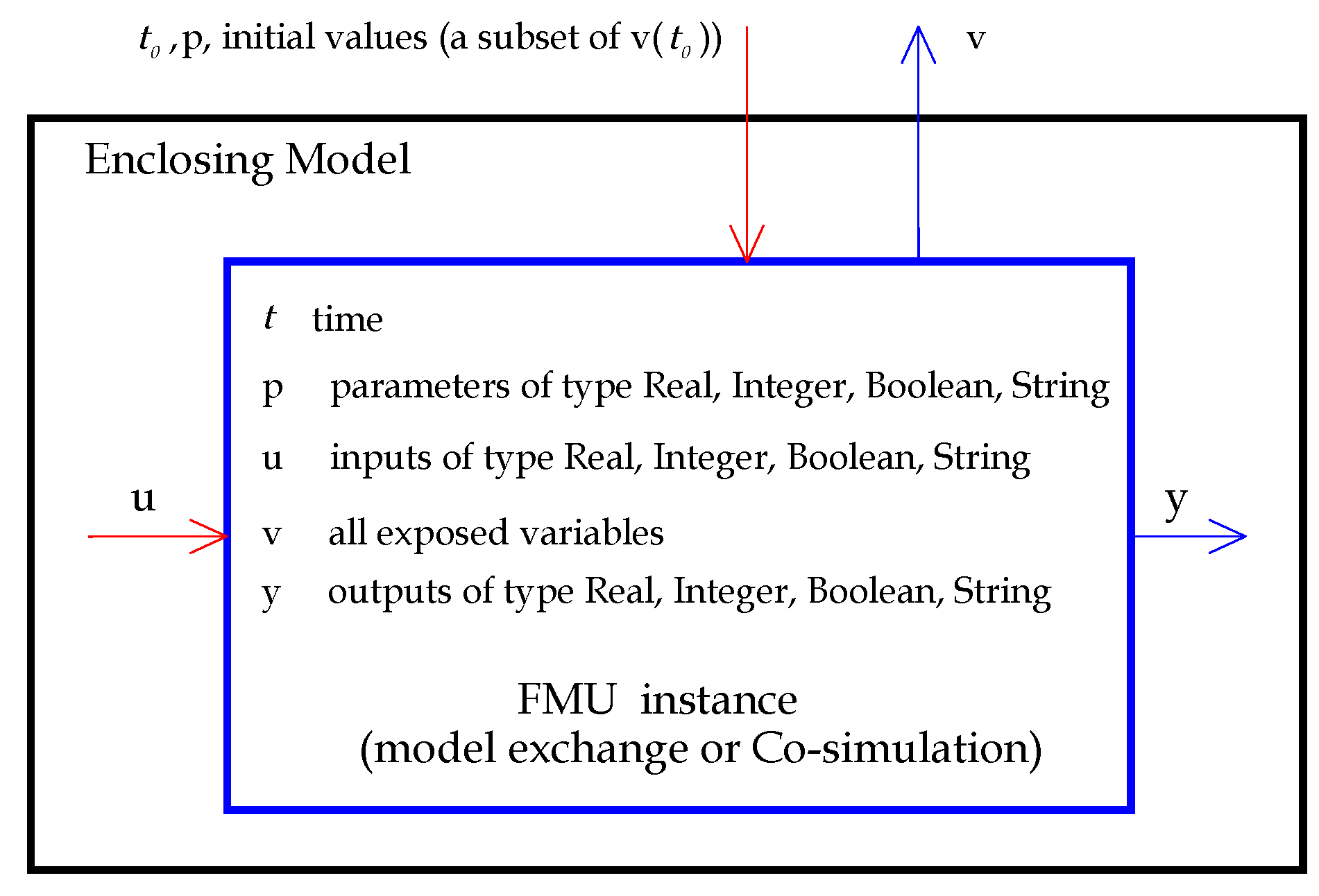

2.2. Functional Mock-Up Interface

2.3. Cosimulation

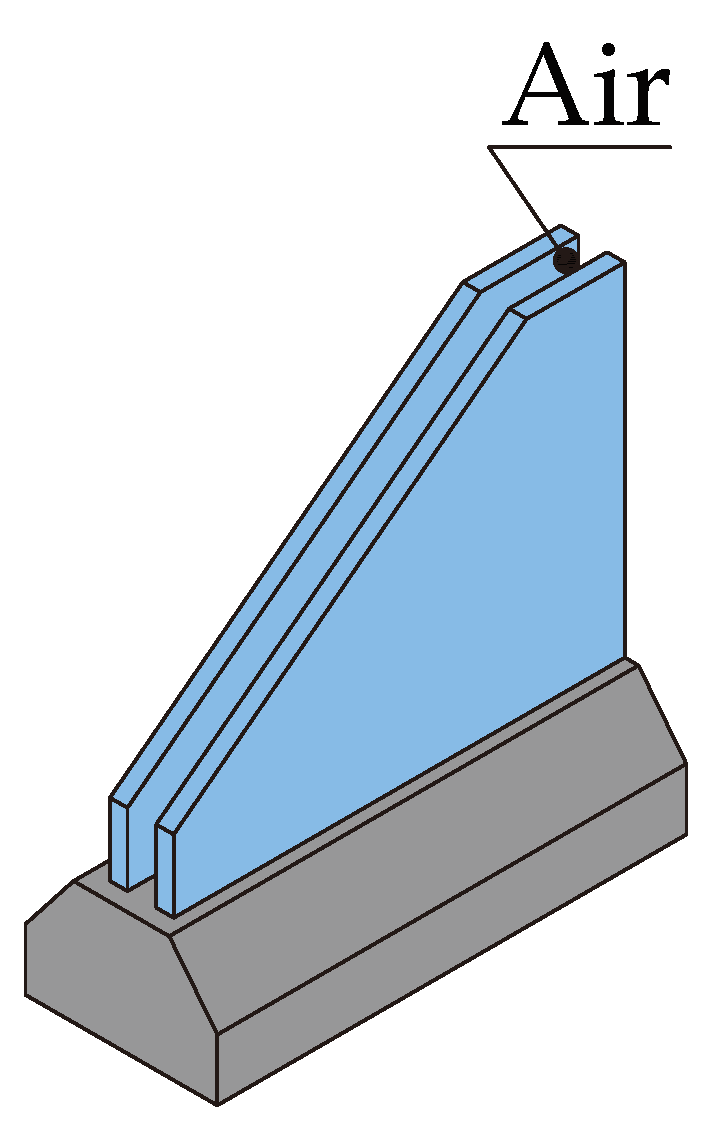

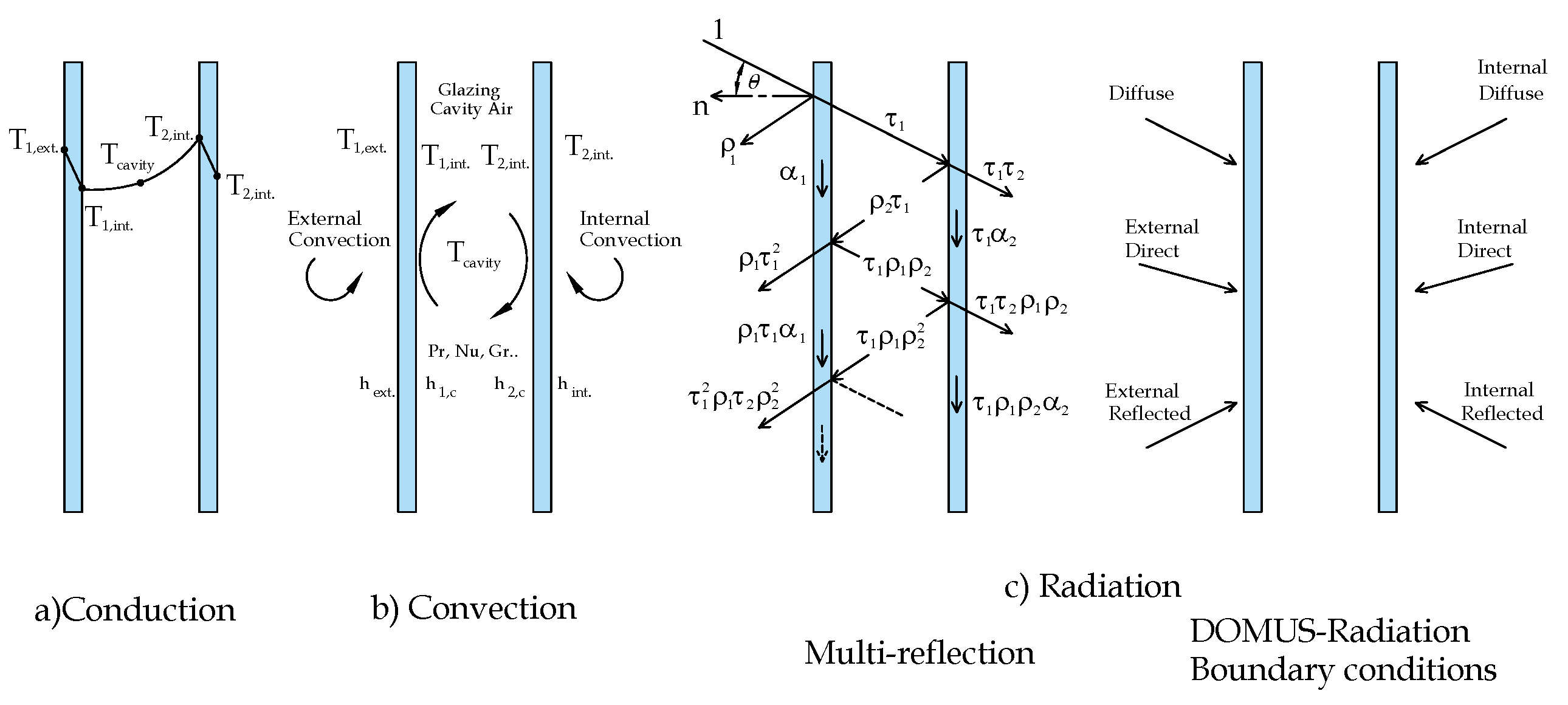

2.4. Integration of Glazing and Films

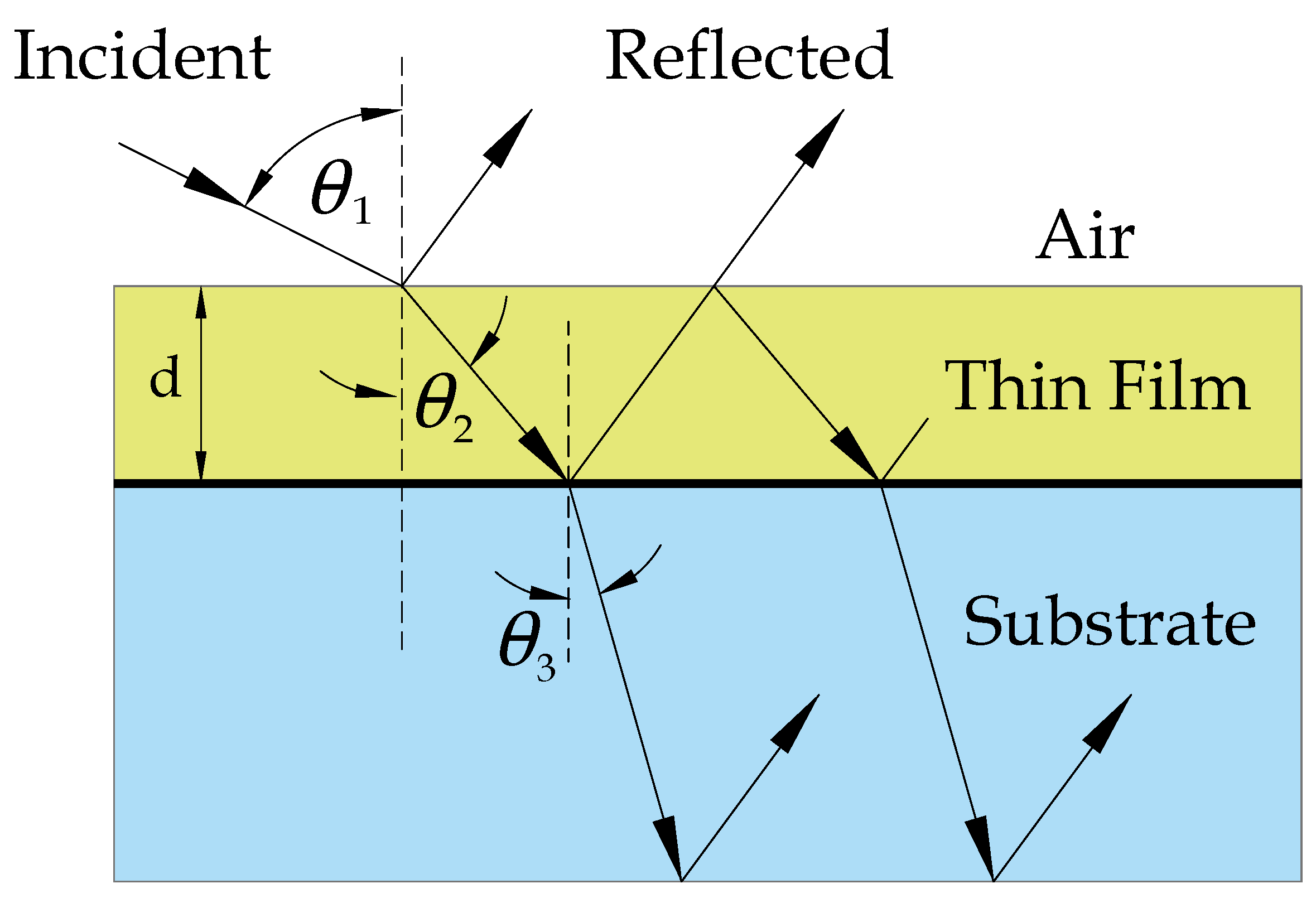

2.5. Modelling of Thin Films

2.6. Integration of Photovoltaic Glazing in Buildings Based on Thin Films

2.7. Organic Photovoltaic Application

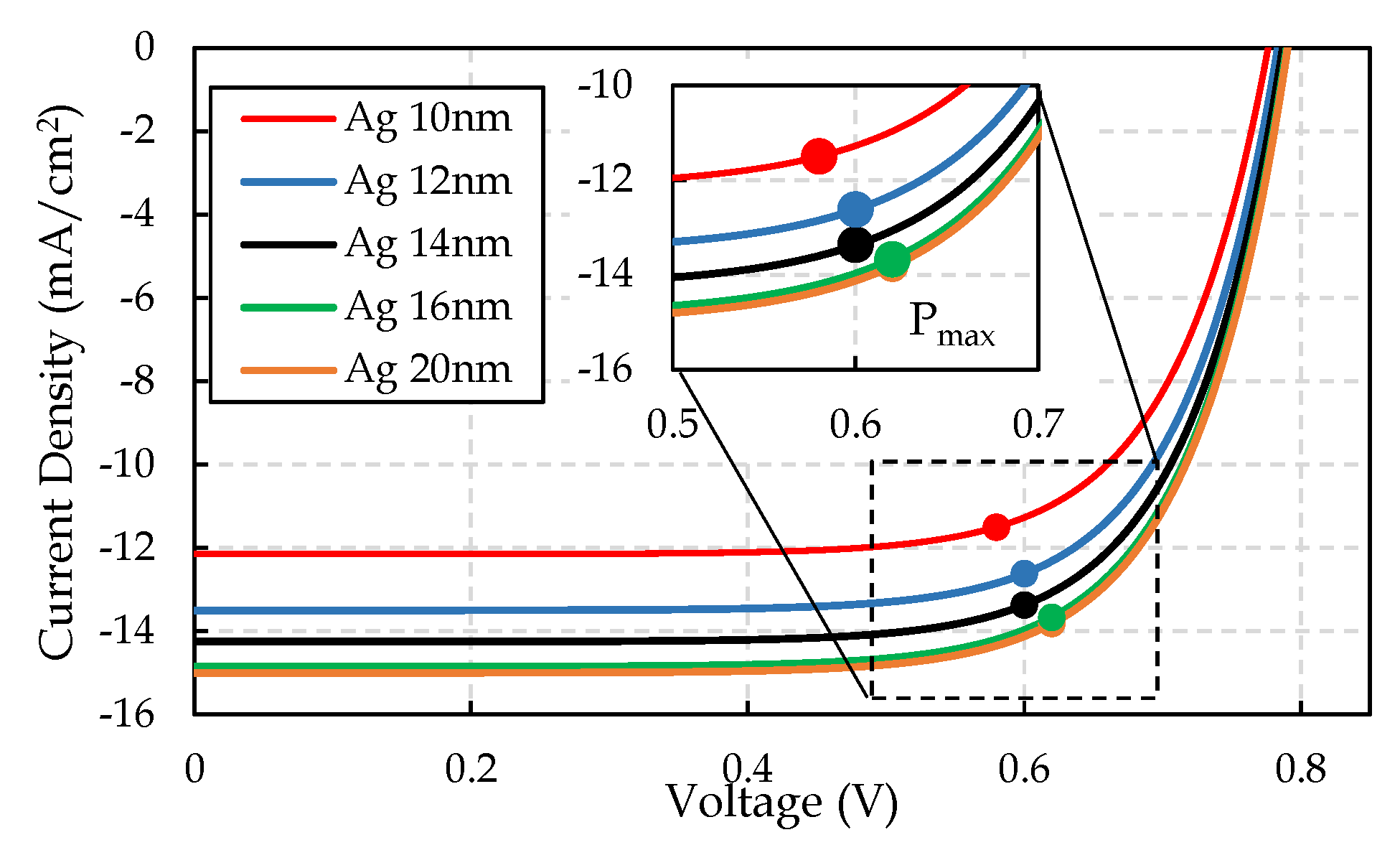

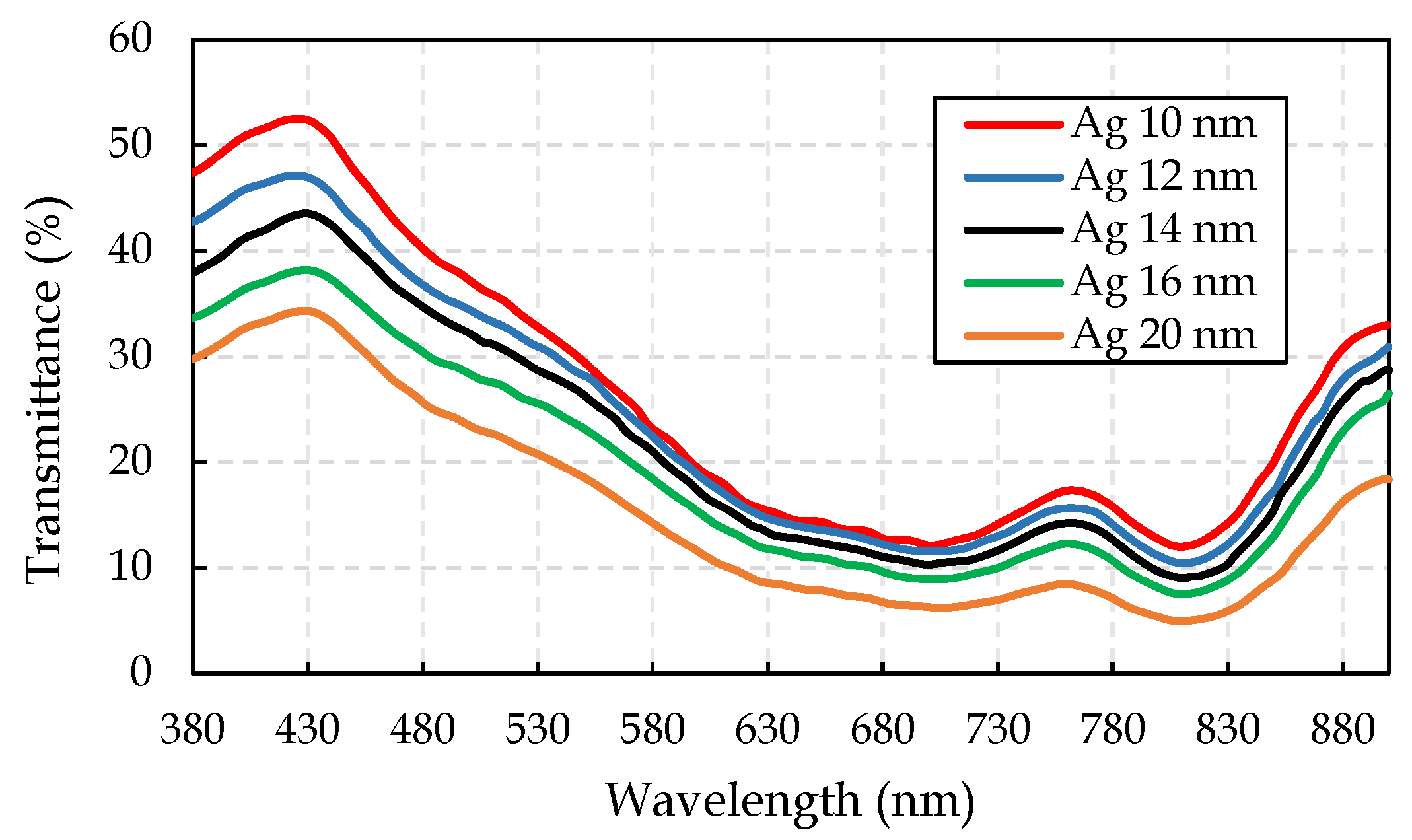

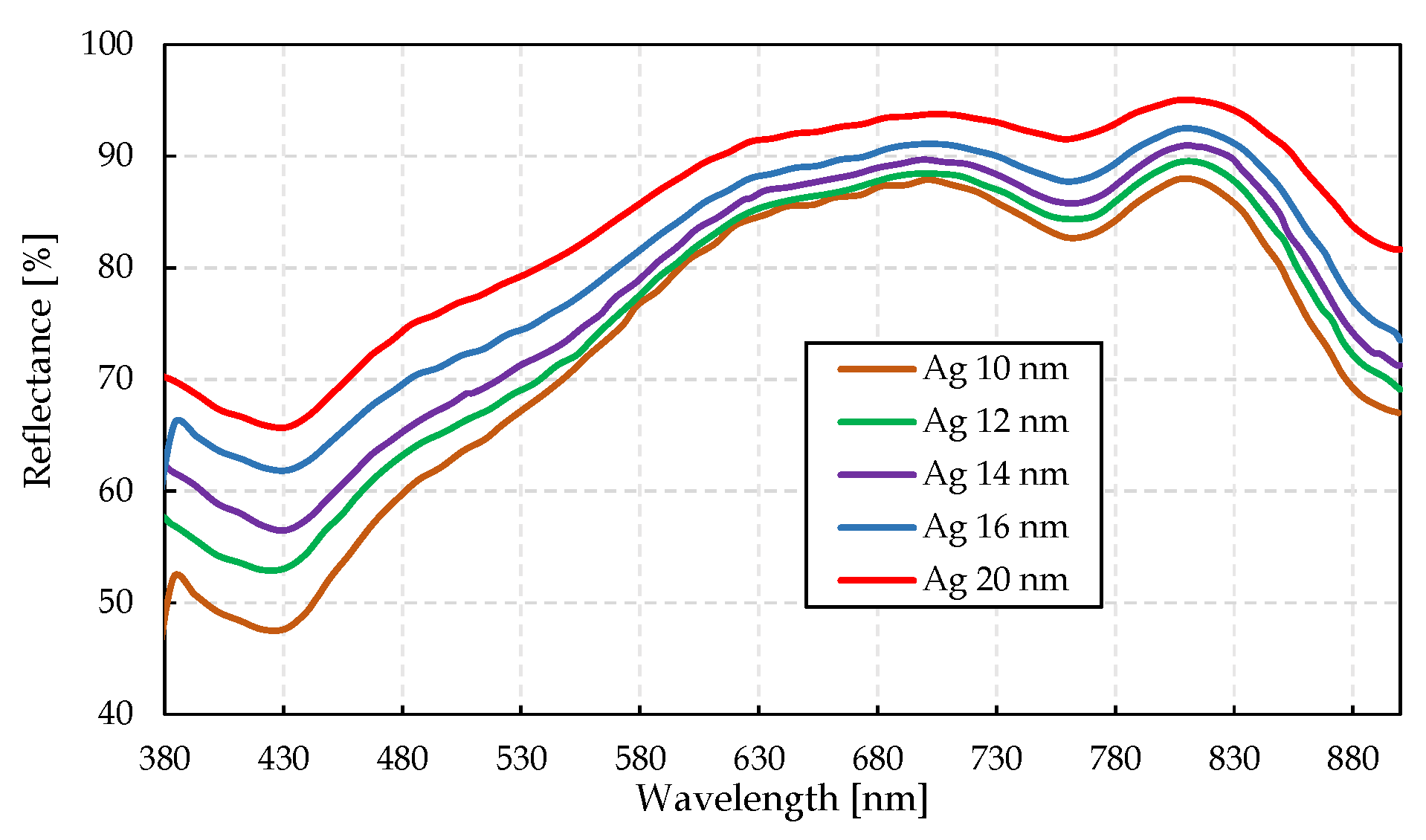

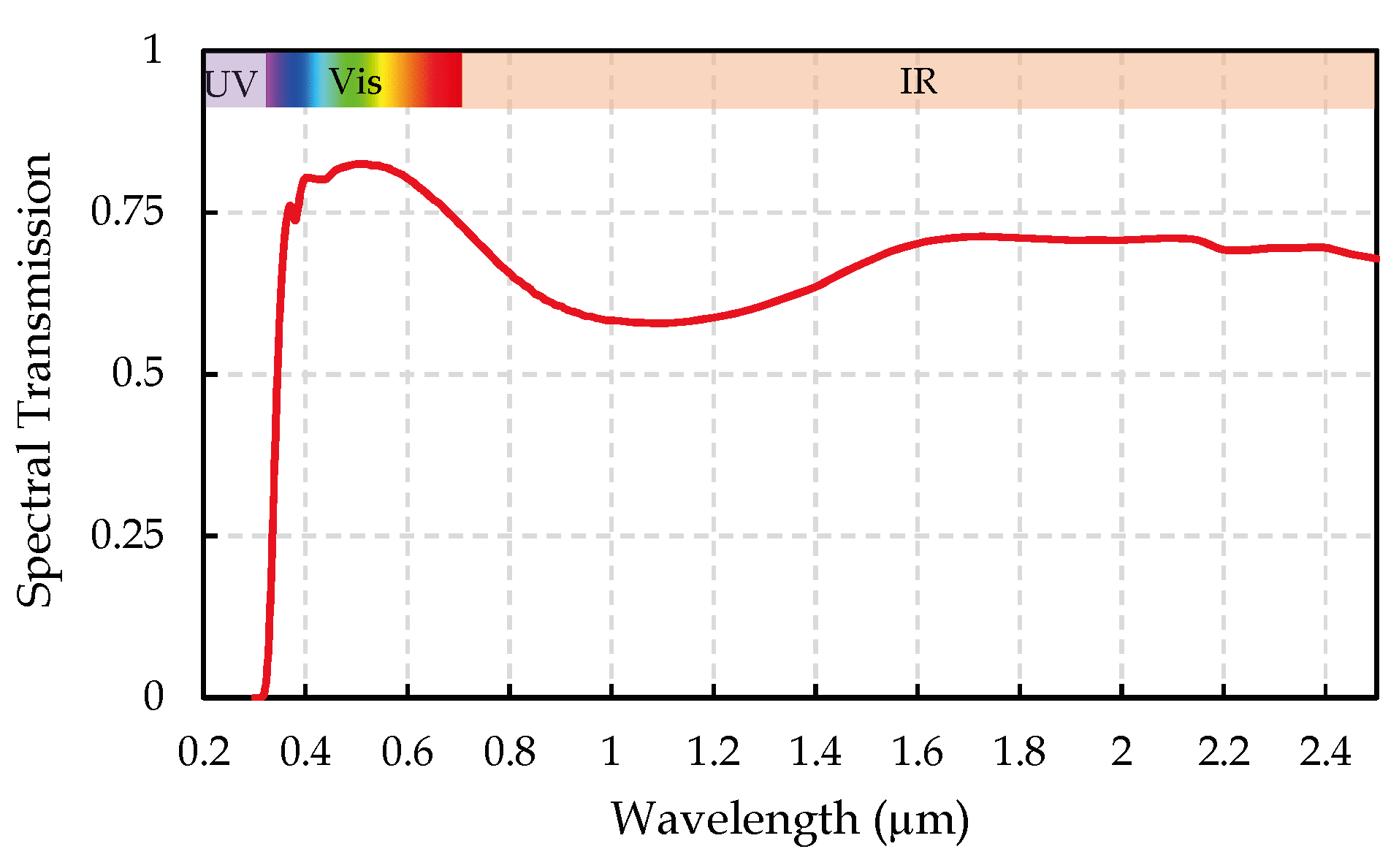

Characterization of ST-OPV

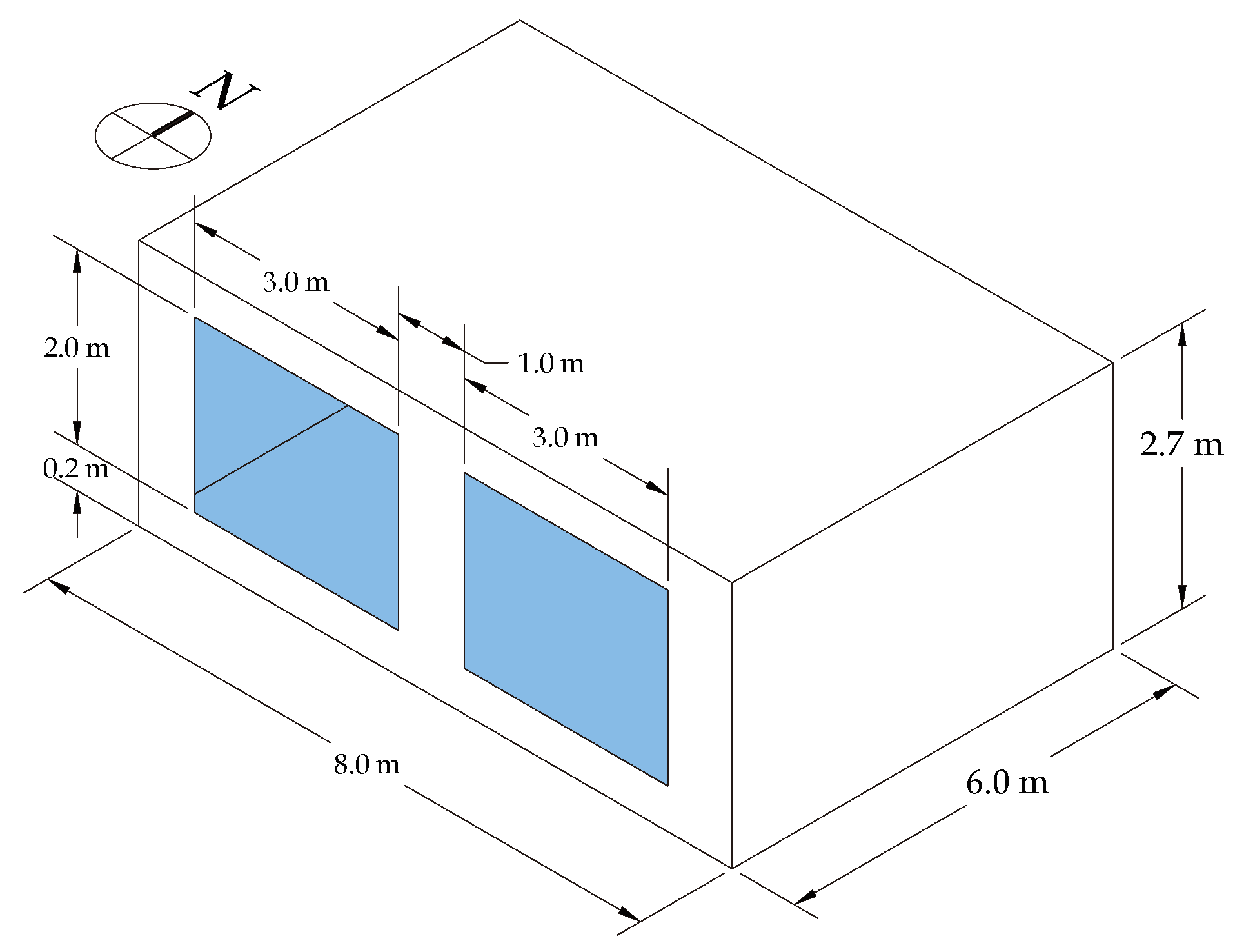

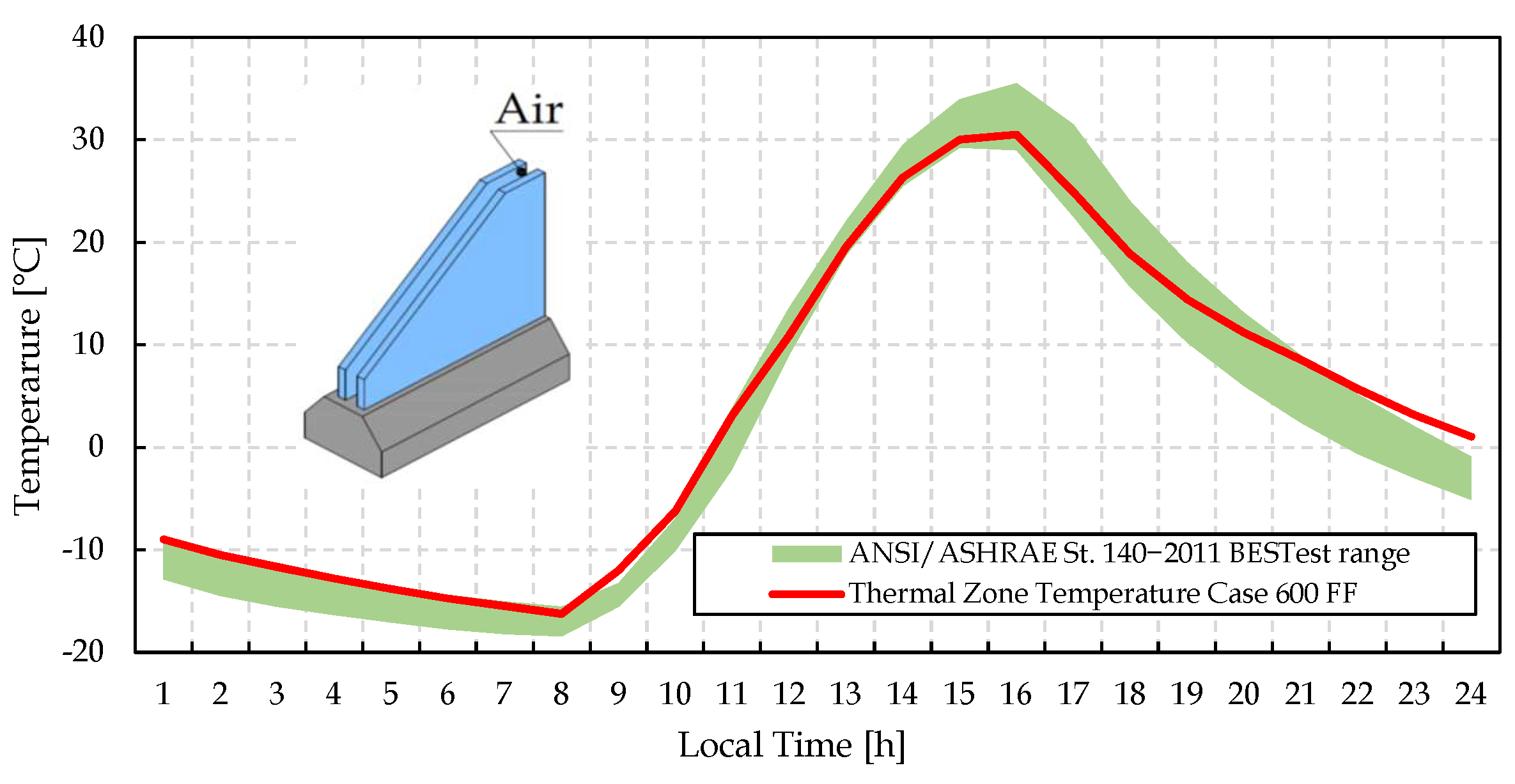

2.8. ANSI/ASHRAE Standard 140-2011

2.9. Development of a Cosimulation Tool

2.9.1. Whole-Building Hygrothermal Simulation Program DOMUS: Implementation

2.9.2. Scheme for Glazing Model

3. Verification

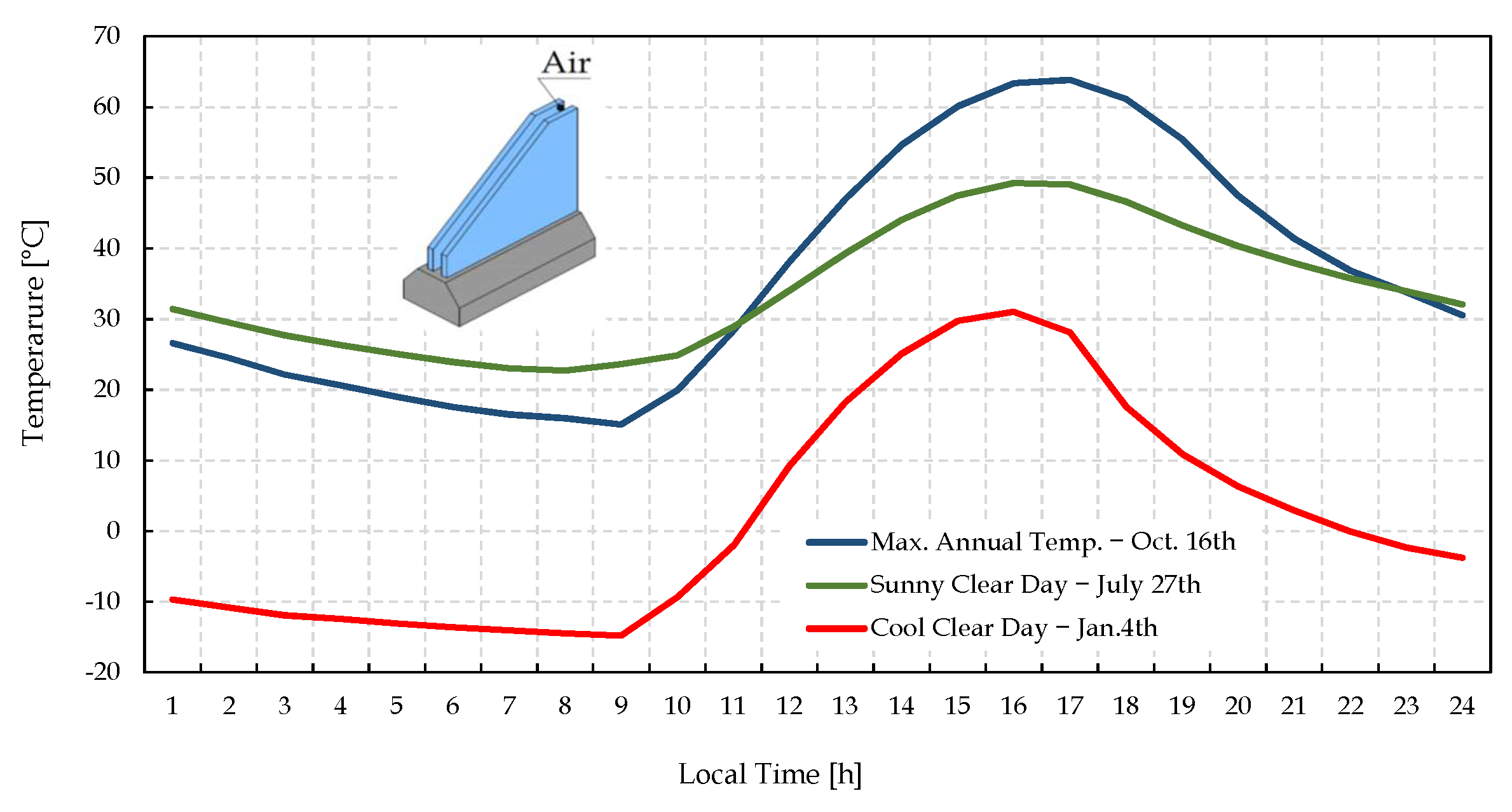

Domus Results for BESTest 600 FF

4. Results and Discussion

4.1. Approach of Integration Model for Estimating Photovoltaic Energy on a Glazing Facade

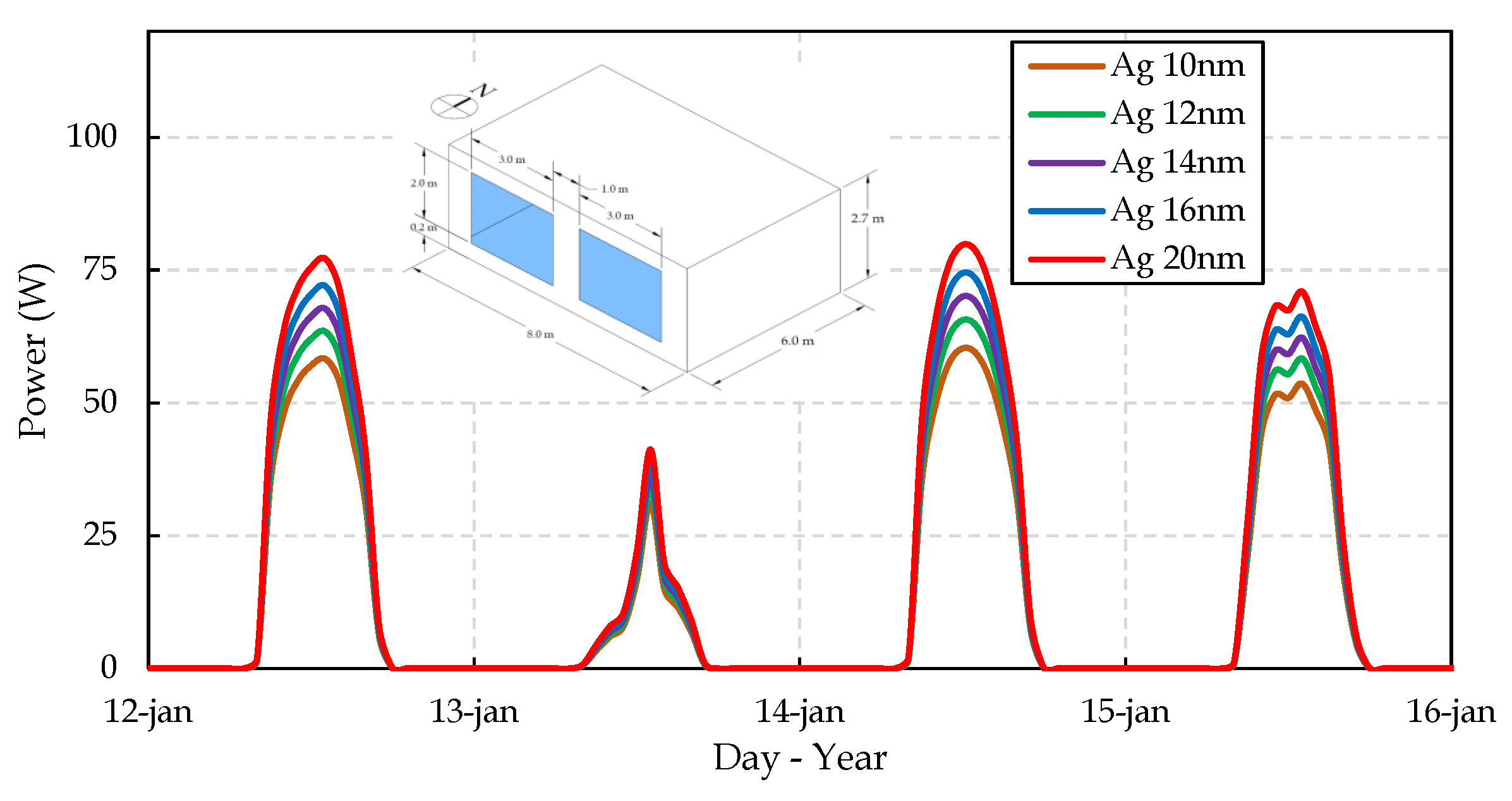

4.2. Photovoltaic Modelling Results

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schweiger, G.; Eckerstorfer, L.; Hafner, I.; Fleischhacker, A.; Radl, J.; Glock, B.; Wastian, M.; Rößler, M.; Lettner, G.; Popper, N.; et al. Active consumer participation in smart energy systems. Energy Build. 2020, 227, 110359. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook 2020. Available online: https://www.iea.org/reports/world-energy-outlook-2020 (accessed on 17 February 2022).

- Radulovic, J.; Skerlic, J.; Vaskovic, M.; Bojic, L. Building integrated photovoltaics. In Proceedings of the 13th International Quality Conference, Nicosia, Cyprus, 26–29 December 2019. [Google Scholar]

- Heinstein, P.; Ballif, C.; Perret-Aebi, L.-E. Building Integrated Photovoltaics (BIPV): Review, Potentials, Barriers and Myths. Green 2013, 3, 125–156. [Google Scholar] [CrossRef]

- Ordenes, M.; Marinoski, D.L.; Braun, P.; Rüther, R. The impact of building-integrated photovoltaics on the energy demand of multi-family dwellings in Brazil. Energy Build. 2007, 39, 629–642. [Google Scholar] [CrossRef]

- Joseph, B.; Pogrebnaya, T.; Kichonge, B. Semitransparent Building-Integrated Photovoltaic: Review on Energy Performance, Challenges, and Future Potential. Int. J. Photoenergy 2019, 2019, 5214150. [Google Scholar] [CrossRef]

- Shukla, A.K.; Sudhakar, K.; Baredar, P. Exergetic analysis of building integrated semitransparent photovoltaic module in clear sky condition at Bhopal India. Case Stud. Therm. Eng. 2016, 8, 142–151. [Google Scholar] [CrossRef]

- Stoichkov, V.; Sweet, T.K.; Jenkins, N.; Kettle, J. Studying the outdoor performance of organic building-integrated photovoltaics laminated to the cladding of a building prototype. Sol. Energy Mater. Sol. Cells 2019, 191, 356–364. [Google Scholar] [CrossRef]

- Cui, Y.; Yao, H.; Zhang, J.; Xian, K.; Zhang, T.; Hong, L.; Wang, Y.; Xu, Y.; Ma, K.; An, C.; et al. Single-Junction Organic Photovoltaic Cells with Approaching 18% Efficiency. Adv. Mater. 2020, 32, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Schopp, N.; Brus, V.V. A Review on the Materials Science and Device Physics of Semitransparent Organic Photovoltaics. Energies 2022, 15, 4639. [Google Scholar] [CrossRef]

- Fritzson, P.; Aronsson, P.; Lundvall, H.; Nyström, K.; Pop, A.; Saldamli, L.; Broman, D. The OpenModelica Modeling, Simulation, and Development Environment. In Proceedings of the 46th Conference on Simulation and Modelling of the Scandinavian Simulation Society (SIMS2005), Trondheim, Norway, 13–14 October 2005; pp. 83–90. [Google Scholar]

- Wetter, M. Co-simulation of building energy and control systems with the Building Controls Virtual Test Bed. J. Build. Perform. Simul. 2011, 4, 185–203. [Google Scholar] [CrossRef]

- Wetter, M.; van Treeck, C. IEA EBC Annex 60: New Generation Computing Tools for Building and Community Energy Systems. Available online: https://www.iea-annex60.org/ (accessed on 18 September 2022).

- Crawley, D.B.; Pedersen, C.O.; Lawrie, L.K.; Winkelmann, F.C. Energyplus: Energy simulation program. ASHRAE J. 2000, 42, 49–56. [Google Scholar]

- MATLAB. Version 9.9.0 (R2020b); The MathWorks Inc.: Natick, MA, USA, 2020. [Google Scholar]

- Simulink. Simulation and Model-Based Design. Available online: https://www.mathworks.com/products/simulink.html (accessed on 18 September 2022).

- Modelica. The Modelica Association. Available online: https://modelica.org/ (accessed on 18 September 2022).

- Dymola. DYMOLA Systems Engineering. Multi-Engineering Modeling and Simulation based on Modelica and FMI. Available online: https://www.3ds.com/products-services/catia/products/dymola/key-advantages/ (accessed on 18 September 2022).

- Nouidui, T.; Wetter, M.; Zuo, W. Functional mock-up unit for co-simulation import in EnergyPlus. J. Build. Perform. Simul. 2014, 7, 192–202. [Google Scholar] [CrossRef]

- Python Software Foundation. Python. Available online: https://www.python.org/psf-landing/ (accessed on 18 September 2022).

- Mendes, N.; Oliveira, R.; Santos, G. DOMUS 2.0: A Whole-Building Hygrothermal Simulation Program. In Proceedings of the 8th IBPSA International Conference, Eindhoven, The Netherlands, 11–14 August 2003; pp. 863–870. [Google Scholar]

- Laouadi, A. Thermal performance modelling of complex fenestration systems. J. Build. Perform. Simul. 2009, 2, 189–207. [Google Scholar] [CrossRef]

- Eaton, J.W.; Bateman, D.; Hauberg, S.; Wehbring, R. GNU Octave Version 3.8.1 Manual: A High-Level Interactive Language for Numerical Computations; CreateSpace Independent Publishing Platform: Scotts Valley, CA, USA, 2014; ISBN 1441413006. Available online: http://www.gnu.org/software/octave/doc/interpreter/ (accessed on 18 September 2022).

- FMI Standard. Available online: https://fmi-standard.org/ (accessed on 18 September 2022).

- Modelisar Project. Available online: Http//www.modelisar.com (accessed on 17 February 2022).

- Simpack, 3ds. Available online: https://www.3ds.com/products-services/simulia/products/simpack/ (accessed on 17 February 2022).

- Available online: https://jmodelica.org/ (accessed on 17 February 2022).

- Riquelme, S.; Mendes, N.; Moura, L.M. An algorithm to determine radiative properties of glazing systems using simple window performance indicators. In Proceedings of the 24th ABCM International Congress of Mechanical Engineering, Curitiba, Brazil, 3–8 December 2017; pp. 1–12. [Google Scholar]

- Heavens, O. Optical Properties of Thin Solid Films; Dover Books on Physics Series; Dover Publications: Mineola, NY, USA, 1991. [Google Scholar]

- Schuster, C.S. Diffractive Optics for Thin-Film Silicon Solar Cells; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Walton, G. Thermal analysis research program reference manual. National Bureau of Standards, United States; Department of Energy, Building Energy Sciences Branch, U.S. Department of Commerce, National Bureau of Standards: Washington, DC, USA, 1983; Volume 1, p. 296. [Google Scholar]

- Born, M.; Wolf, E. Principles of Optics: Electromagnetic Theory of Propagation, Interference and Diffraction of Light, 7th ed.; Cambridge University Press: Cambridge, UK, 1999. [Google Scholar]

- Gao, Q.; Wu, X.; Xia, Z.; Fan, Y. Coating mechanism and near-infrared reflectance property of hollow fly ash bead/TiO2 composite pigment. Powder Technol. 2017, 305, 433–439. [Google Scholar] [CrossRef]

- Rubin, M. Optical properties of soda lime silica glasses. Sol. Energy Mater. 1985, 12, 275–288. [Google Scholar] [CrossRef]

- Riquelme, S.; Mendes, N.; Moura, L. Determination of spectral optical constants of glazings by numerical integration from FTIR spectrometer measurements. In Proceedings of the 25th ABCM International Congress of Mechanical Engineering, Uberlândia, Brazil, 20–25 October 2019. [Google Scholar]

- Clarke, J. Energy Simulation in Building Design; Routledge: London, UK, 2007. [Google Scholar]

- Buresch, M. Photovoltaic Energy Systems: Design and Installation; McGraw-Hill: New York, NY, USA, 1983. [Google Scholar]

- Sun, C.; Xia, R.; Shi, H.; Yao, H.; Liu, X.; Hou, J.; Huang, F.; Yip, H.-L.; Cao, Y. Heat-Insulating Multifunctional Semitransparent Polymer Solar Cells. Joule 2018, 2, 1816–1826. [Google Scholar] [CrossRef]

- Bellia, H.; Youcef, R.; Fatima, M. A detailed modeling of photovoltaic module using MATLAB. NRIAG J. Astron. Geophys. 2014, 3, 53–61. [Google Scholar] [CrossRef]

- Bayrakci, M.; Choi, Y.; Brownson, J.R. Temperature Dependent Power Modeling of Photovoltaics. Energy Procedia 2014, 57, 745–754. [Google Scholar] [CrossRef]

- Altas, I.H.; Sharaf, A.M. A photovoltaic array simulation model for matlab-simulink GUI environment. In Proceedings of the 2007 International Conference on Clean Electrical Power, ICCEP ’07, Capri, Italy, 21–23 May 2007; pp. 341–345. [Google Scholar]

- Duffie, J.; Beckman, W. Solar Engineering of Thermal Processes; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar]

- Judkoff, R.; Neymark, J. International Energy Agency Building Energy Simulation Test (BESTest) and Diagnostic Method; National Renewable Energy Lab. (NREL): Golden, CO, USA, 1995. [Google Scholar] [CrossRef]

- Jorissen, F.; Reynders, G.; Baetens, R.; Picard, D.; Saelens, D.; Helsen, L. Implementation and verification of the IDEAS building energy simulation library. J. Build. Perform. Simul. 2018, 11, 669–688. [Google Scholar] [CrossRef]

- Riquelme, S.; Mendes, N.; Moura, L.M. Validation and Application of a Numerical Code for Estimate Energy Performance of Complex Glazing Systems Based on Semi-transparent Organic Photovoltaics Elements. In Proceedings of the 16th IBPSA International Conference & Exhibition Building Simulation, Rome, Italy, 2–4 September 2019; pp. 4617–4624. [Google Scholar]

- Blochwitz, T.; Otter, M.; Akesson, J.; Arnold, M.; Clauss, C.; Elmqvist, H.; Friedrich, M.; Junghanns, A.; Mauss, J.; Neumerkel, D.; et al. Functional Mockup Interface 2.0: The Standard for Tool independent Exchange of Simulation Models. In Proceedings of the 9th International MODELICA Conference, Munich, Germany, 3–5 September 2012; pp. 173–184, ISBN 978-91-7519-826-2. [Google Scholar] [CrossRef]

- de Almeida Rocha, A.P.; Oliveira, R.C.L.F.; Mendes, N. Experimental validation and comparison of direct solar shading calculations within building energy simulation tools: Polygon clipping and pixel counting techniques. Sol. Energy 2017, 158, 462–473. [Google Scholar] [CrossRef]

- de Almeida Rocha, A.P.; Rodler, A.; Oliveira, R.C.L.F.; Virgone, J.; Mendes, N. A pixel counting technique for sun patch assessment within building enclosures. Sol. Energy 2019, 184, 173–186. [Google Scholar] [CrossRef]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; CRC Press: Boca Raton, FL, USA, 1980. [Google Scholar]

- Freire, R.Z.; Mazuroski, W.; Abadie, M.O.; Mendes, N. Capacitive effect on the heat transfer through building glazing systems. Appl. Energy 2011, 88, 4310–4319. [Google Scholar] [CrossRef]

- Rubin, M.; von Rotay, K.; Powels, R. Windows optics. Sol. Energy 1998, 62, 149–161. [Google Scholar] [CrossRef]

- ISO 9050; Glass in Building-Determination of Light Transmittance, Solar Direct Transmittance, Total Solar Energy Transmittance, Ultraviolet Transmittance and Related Glazing Factors. 2003. Available online: https://www.iso.org/obp/ui/#iso:std:iso:9050:ed-2:v1:en (accessed on 17 February 2022).

- Howell, J.; Menguc, M.; Siegel, R. Thermal Radiation Heat Transfer, 5th ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

| Class | Efficency | V | J | FF |

|---|---|---|---|---|

| % | V | mA/cm | % | |

| Ag 10 | 6.8 | 0.81 | 12.6 | 65 |

| Ag 12 | 7.4 | 0.81 | 13.5 | 66 |

| Ag 14 | 7.9 | 0.81 | 14.4 | 66 |

| Ag 16 | 8.4 | 0.81 | 15.4 | 66 |

| Ag 20 | 9.0 | 0.81 | 16.3 | 67 |

| Class | Visible | Total Spectrum |

|---|---|---|

| Ag 10 | 33.60 | 27.13 |

| Ag 12 | 30.53 | 24.62 |

| Ag 14 | 28.85 | 22.40 |

| Ag 16 | 23.67 | 19.69 |

| Ag 20 | 19.49 | 15.73 |

| Surfaces | Thickness | U-Value |

|---|---|---|

| (m) | (W/mK) | |

| Walls | 0.087 | 0.514 |

| Roof | 0.141 | 0.318 |

| Floor | 1.208 | 0.039 |

| Property | Value |

|---|---|

| Extinction coeff. | 0.0196 (1/mm) |

| Number of panes | 2 |

| Pane thickness | 3.175 (mm) |

| Air-gap thickness | 13 (mm) |

| Index of refraction | 1.526 |

| Transmittance one pane | 0.86156 |

| Thermal conduc. glass | 1.06 (W/mK) |

| Conductance glass pane | 333 (W/mK) |

| Exterior surf. coeff. | 21.00 (W/mK) |

| Interior surf. coeff. | 8.29 (W/mK) |

| Density of glass | 2500 (kg/m) |

| Specific heat of glass | 750 (J/kg K) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riquelme, S.; Gros, A.; Klemz, B.; Moura, L.M.; Mendes, N. Cosimulation of Integrated Organic Photovoltaic Glazing Systems Based on Functional Mock-Up Unit. Energies 2023, 16, 951. https://doi.org/10.3390/en16020951

Riquelme S, Gros A, Klemz B, Moura LM, Mendes N. Cosimulation of Integrated Organic Photovoltaic Glazing Systems Based on Functional Mock-Up Unit. Energies. 2023; 16(2):951. https://doi.org/10.3390/en16020951

Chicago/Turabian StyleRiquelme, Santiago, Adrien Gros, Bruno Klemz, Luís Mauro Moura, and Nathan Mendes. 2023. "Cosimulation of Integrated Organic Photovoltaic Glazing Systems Based on Functional Mock-Up Unit" Energies 16, no. 2: 951. https://doi.org/10.3390/en16020951

APA StyleRiquelme, S., Gros, A., Klemz, B., Moura, L. M., & Mendes, N. (2023). Cosimulation of Integrated Organic Photovoltaic Glazing Systems Based on Functional Mock-Up Unit. Energies, 16(2), 951. https://doi.org/10.3390/en16020951