A Fault Diagnosis Method of the Shearer Hydraulic Heightening System Based on a Rough Set and RBF Neural Network

Abstract

1. Introduction

2. Models and Methods

2.1. RS Model

2.2. RBFNN Model

2.3. RS-RBFNN Fault Diagnosis Model

- The model of the hydraulic heightening system was established, and the typical faults in the system were taken as the research object. Pressure, flow, displacement, and speed sensors were used to collect the fault data.

- RS theory was used to construct the original fault decision table. The fault symptoms that occurred many times in the system were taken as the condition attributes, and the fault type was taken as the decision attribute to generate the original fault decision table. The data of the original fault decision table was discretized at an equal distance. Then, using the attribute reduction based on genetic algorithm, the redundant conditional attributes were deleted under the condition of retaining the key input information, and the minimum set of conditional attributes was obtained.

- The minimum attribute reduction set was used as the input of the RBFNN. The mapping relationship between the fault symptoms and categories of the RBF neural network was used for learning and training. Finally, the fault diagnosis classification results of the shearer hydraulic heightening system were obtained.

3. Simulation

3.1. Research Object

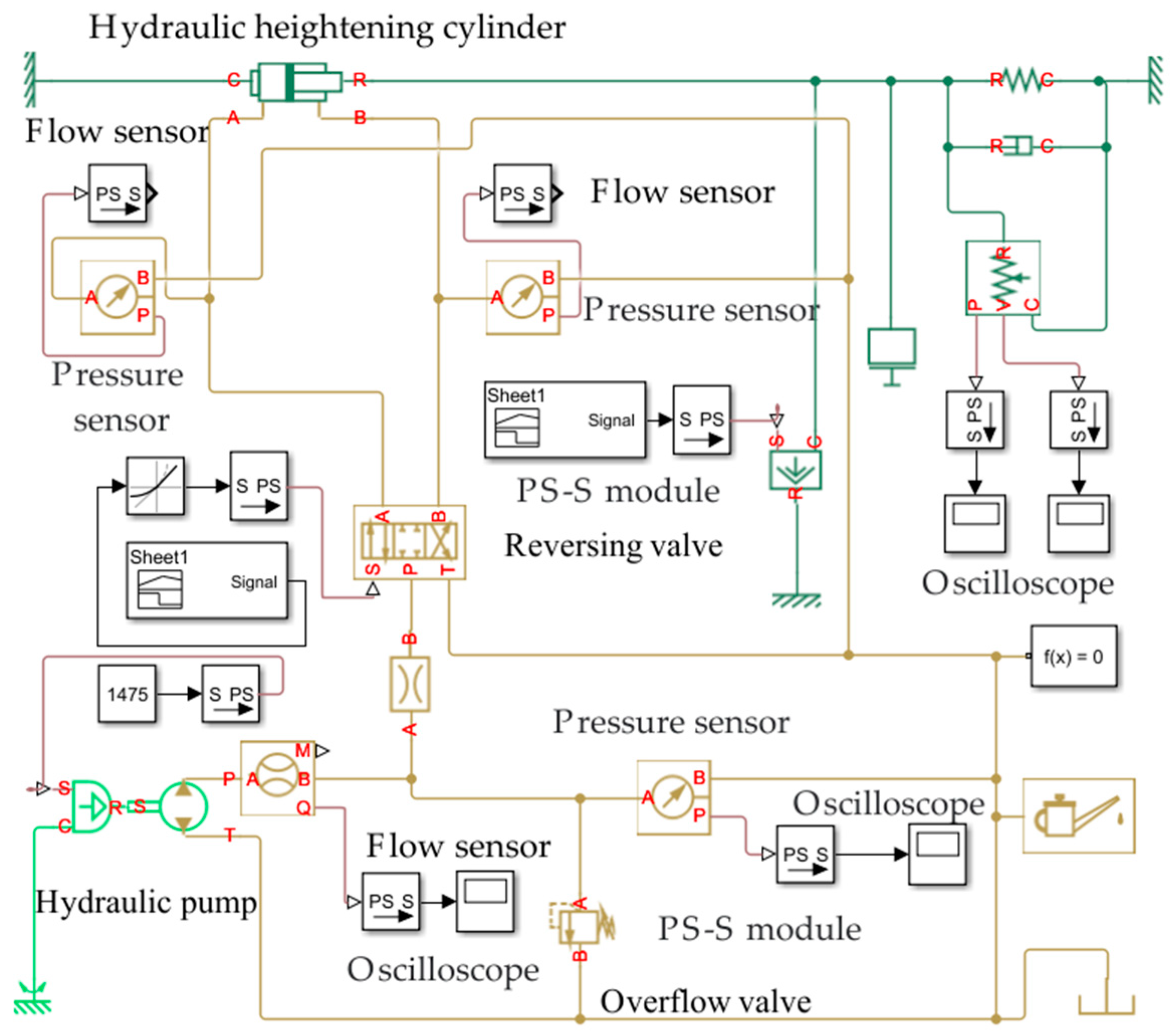

3.2. Simulation Model

4. Results of Fault Diagnosis

4.1. RS Preprocessing

4.2. RBFNN Diagnosis

5. Simulation Comparison

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, X.; Wang, G. Fault Monitoring System of Shearer Based on DSP. Appl. Mech. Mater. 2014, 9, 973–976. [Google Scholar]

- Zhang, X.; Yao, G.; Zhang, Y. Nonlinear multi body dynamic modeling and vibration analysis of a double drum coal shearer. J. Cent. South Univ. 2021, 28, 2120–2130. [Google Scholar] [CrossRef]

- Li, X.; Tang, R.; Sha, Y.; Bai, S.; Zhang, J. Fault Diagnosis Expert System of Continuous Miner Hydraulic System. Adv. Mat. Res. 2012, 619, 463–466. [Google Scholar]

- Bołoz, Ł.; Rak, Z.; Stasica, J. Comparative Analysis of the Failure Rates of Shearer and Plow Systems—A Case Study. Energies 2022, 15, 6170. [Google Scholar] [CrossRef]

- Gao, F.; Xiao, L.; Zhong, W.; Liu, W. Fault Diagnosis of Shearer Based on Fuzzy Inference. Appl. Mech. Mater. 2011, 1229, 1577–1580. [Google Scholar]

- Li, S.; Yang, Z.; Tian, H.; Chen, C.; Zhu, Y.; Deng, F.; Lu, S. Failure Analysis for Hydraulic System of Heavy-Duty Machine Tool with Incomplete Failure Data. Appl. Sci. 2021, 11, 1249. [Google Scholar] [CrossRef]

- Yang, J. Research on Fault Diagnosis of Shearer Hydraulic System Based on Information Fusion Technology. Master’s Thesis, North University of China, Taiyuan, China, 2021. [Google Scholar]

- Zhang, Y.; Wang, S.; Shi, J.; Yang, X.; Zhang, J.; Wang, X. SAR performance-based fault diagnosis for electrohydraulic control system: A novel FDI framework for closed-loop system. Chin. J. Aeronaut. 2022, 35, 381–392. [Google Scholar] [CrossRef]

- Dong, Z.; Zhang, X. Modified D-S evidential theory in hydraulic system fault diagnosis. Procedia Environ. Sci. 2011, 11, 98–102. [Google Scholar]

- He, X. Fault diagnosis approach of hydraulic system using FARX model. Procedia Eng. 2011, 15, 949–953. [Google Scholar] [CrossRef]

- Liu, H.; Wang, S.; Ouyang, P. Fault Diagnosis in a Hydraulic Position Servo System Using RBF Neural Network. Chin. J. Aeronaut. 2006, 19, 346–353. [Google Scholar] [CrossRef]

- Song, D.; Lu, C.; Ma, J.; Cheng, Y. Health Assessment for Hydraulic System based on GRNN and Metric Learning. IFAC PapersOnline 2020, 53, 37–42. [Google Scholar] [CrossRef]

- Kong, X.; Cai, B.; Liu, Y.; Zhu, H.; Liu, Y.; Shao, H.; Yang, C.; Li, H.; Mo, T. Optimal sensor placement methodology of hydraulic control system for fault diagnosis. Mech. Syst. Sig. Process. 2022, 174, 109069. [Google Scholar] [CrossRef]

- Wang, R.; Sun, W. Fault diagnosis of electrical automatic control system of hydraulic support based on particle swarm optimization algorithm. J. Ambient Intell. Hum. Comput. 2022, 4, 22–29. [Google Scholar] [CrossRef]

- Fu, X.; Liu, B.; Zhang, Y.; Lian, L. Fault diagnosis of hydraulic system in large forging hydraulic press. Measurement 2014, 49, 390–396. [Google Scholar] [CrossRef]

- Jegadeeshwaran, R.; Sugumaran, V. Comparative study of decision tree classififier and best fifirst tree classififier for fault diagnosis of automobile hydraulic brake system using statistical features. Measurement 2013, 46, 3247–3260. [Google Scholar] [CrossRef]

- Lan, Y.; Li, Z.; Liu, S.; Huang, J.; Niu, L.; Xiong, X.; Niu, C.; Wu, B.; Zhou, X.; Yan, J.; et al. Experimental investigation on cavitation and cavitation detection of axial piston pump based on MLP-Mixer. Measurement 2022, 200, 111582. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, G.; Wang, R.; Tang, S.; Su, H.; Cao, K. Intelligent fault diagnosis of hydraulic piston pump combining improved LeNet-5 and PSO hyperparameter optimization. Appl. Acoust. 2021, 183, 108336. [Google Scholar] [CrossRef]

- Ji, X.; Ren, Y.; Tang, H.; Xiang, J. DSmT-based three-layer method using multi-classififier to detect faults in hydraulic systems. Mech. Syst. Sig. Process. 2021, 153, 107513. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, S.; Zhou, C.; Hu, Z.; Li, R.; Jiang, J. Experimental study of hydraulic cylinder leakage and fault feature extraction based on wavelet packet analysis. Comput. Fluids. 2015, 106, 33–40. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhi, G.; Chen, W.; Qian, Q.; He, D.; Sun, B.; Sun, W. A new tool wear condition monitoring method based on deep learning under small samples. Measurement 2022, 189, 110622. [Google Scholar] [CrossRef]

- Zhou, Y.; Kumar, A.; Parkash, C.; Vashishtha, G.; Tang, H.; Xiang, J. A novel entropy-based sparsity measure for prognosis of bearing defects and development of a sparsogram to select sensitive filtering band of an axial piston pump. Measurement 2022, 203, 111997. [Google Scholar] [CrossRef]

- Guo, X.; Tian, M.; Li, Q.; KiAhn, C.; Yang, Y. Multiple-fault diagnosis for spacecraft attitude control systems using RBFNN-based observers. Aerosp. Sci. Technol. 2020, 106, 106195. [Google Scholar] [CrossRef]

- Wen, X.; Xu, Z. Wind turbine fault diagnosis based on ReliefF-PCA and DNN. Expert Syst. Appl. 2021, 178, 115016. [Google Scholar] [CrossRef]

- Gregov, G. Modeling and predictive analysis of the hydraulic GEROLER motor based on artificial neural network. Eng. Rev. 2022, 42, 91–100. [Google Scholar] [CrossRef]

- Qiu, Z.; Min, R.; Wang, D.; Fan, S. Energy features fusion based hydraulic cylinder seal wear and internal leakage fault diagnosis method. Measurement 2022, 195, 111042. [Google Scholar] [CrossRef]

- Zhang, D.; Zhu, P. Variable radius neighborhood rough sets and attribute reduction. Int. J. Approx. Reason. 2022, 150, 98–121. [Google Scholar] [CrossRef]

- Yakovyna, V.; Shakhovska, N. Software failure time series prediction with RBF, GRNN, and LSTM neural networks. Procedia Comput. Sci. 2022, 207, 837–847. [Google Scholar] [CrossRef]

- Yuan, Z.; Chen, H.; Li, T.; Yu, Z.; Sang, B.; Luo, C. Unsupervised attribute reduction for mixed data based on fuzzy rough sets. Inf. Sci. 2021, 572, 67–87. [Google Scholar] [CrossRef]

- Xiang, B.; Mu, Q. Gimbal control of inertially stabilized platform for airborne remote sensing system based on adaptive RBFNN feedback model. IFAC J. Syst. Control. 2021, 16, 100148. [Google Scholar] [CrossRef]

- Zeng, X.; Zhen, Z.; He, J.; Han, L. A feature selection approach based on sensitivity of RBFNNs. Neurocomputing 2018, 275, 2200–2208. [Google Scholar] [CrossRef]

- Li, J.; Yao, X.; Wang, X.; Yu, Q.; Zhang, Y. Multiscale local features learning based on BP neural network for rolling bearing intelligent fault diagnosis. Measurement 2020, 153, 107419. [Google Scholar] [CrossRef]

- Wang, C.; Kang, Y.; Shen, P.; Chang, Y.; Chung, Y. Applications of fault diagnosis in rotating machinery by using time series analysis with neural network. Expert Syst. Appl. 2010, 37, 1696–1702. [Google Scholar] [CrossRef]

| Category | Parameter |

|---|---|

| Hydraulic pump pressure | 21 MPa |

| Hydraulic pump speed | 188 rad/s |

| Hydraulic pump displacement | 3.675 × 10−6 m3/rad |

| Valve core opening amount | 5 × 10−3 m |

| Leakage area | 1 × 10−12 m2 |

| Cylinder piston rod displacement | 490 mm |

| Hydraulic cylinder rodless cavity area | 4.15 × 10−2 m2 |

| Hydraulic cylinder rod cavity area | 2.82 × 10−2 m2 |

| Sample | Condition Attribute | Decision Attribute D | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 (mm/s) | C3 (mm) | C4 (L/min) | C5 (L/min) | C6(kPa) | … | C10 (kPa) | C11 (kPa) | ||

| 1 | 0 | 0.00 | 0.00 | 34.17 | 34.17 | 21,003.89 | … | 10,501.95 | 10,501.95 | 0 |

| 2 | 0 | 0.00 | 0.00 | 34.17 | 34.17 | 21,003.89 | … | 8203.76 | 12,071.76 | 1 |

| … | … | … | … | … | … | … | … | … | … | … |

| 260 | 1 | 11.99 | 65.61 | 29.88 | 29.88 | 8307.38 | … | 5975.21 | 796.04 | 2 |

| 261 | 2 | 11.94 | 71.59 | 29.76 | 29.76 | 8786.80 | … | 6473.89 | 789.43 | 3 |

| … | … | … | … | … | … | … | … | … | … | … |

| 510 | 1 | 13.08 | 4.40 | 34.17 | 34.17 | 4106.27 | … | 1052.44 | 949.01 | 4 |

| Sample | Condition Attribute | Decision Attribute D | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C1 | C2 | C3 | C4 | C6 | C8 | C10 | C11 | ||

| 1 | 0 | 1 | 1 | 4 | 4 | 1 | 2 | 4 | 0 |

| 2 | 1 | 4 | 1 | 4 | 1 | 4 | 1 | 2 | 0 |

| … | … | … | … | … | … | … | … | … | … |

| 260 | 0 | 1 | 1 | 4 | 4 | 1 | 2 | 4 | 2 |

| 261 | 1 | 4 | 1 | 4 | 2 | 4 | 1 | 3 | 2 |

| … | … | … | … | … | … | … | … | … | … |

| 510 | 2 | 1 | 4 | 4 | 4 | 1 | 4 | 1 | 4 |

| Training Sample | x1 | x2 | x3 | x4 | x5 | x6 | x7 | x8 | y |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.50 | 1.00 | 0.02 | 1.00 | 0.06 | 1.00 | 0.05 | 0.09 | 0 |

| 2 | 0.50 | 1.00 | 0.04 | 1.00 | 0.08 | 1.00 | 0.08 | 0.09 | 0 |

| 3 | 1.00 | 0.73 | 0.77 | 0.44 | 1.00 | 0.73 | 0.92 | 0.05 | 1 |

| … | … | … | … | … | … | … | … | … | … |

| 447 | 0.50 | 0.86 | 0.01 | 0.61 | 0.00 | 0.86 | 0.04 | 0.06 | 2 |

| 448 | 1.00 | 0.44 | 0.82 | 1.00 | 1.00 | 0.44 | 0.94 | 0.05 | 3 |

| 449 | 0.50 | 0.61 | 0.75 | 1.00 | 1.00 | 0.81 | 0.91 | 0.03 | 4 |

| 450 | 1.00 | 0.00 | 1.00 | 1.00 | 1.00 | 0.21 | 0.99 | 0.00 | 4 |

| Test Sample | x1 | x2 | x3 | x4 | x5 | x6 | x7 | x8 |

|---|---|---|---|---|---|---|---|---|

| 1 | 1.0 | 0.68 | 0.97 | 1.00 | 1.00 | 0.68 | 0.93 | 0.04 |

| 2 | 1.0 | 0.73 | 0.85 | 0.44 | 1.00 | 0.73 | 0.92 | 0.05 |

| 3 | 1.0 | 0.00 | 1.00 | 0.00 | 1.00 | 0.00 | 1.00 | 0.00 |

| 4 | 1.0 | 0.44 | 0.87 | 1.00 | 1.00 | 0.44 | 0.94 | 0.05 |

| … | … | … | … | … | … | … | … | … |

| 60 | 0.5 | 0.95 | 0.02 | 1.00 | 0.05 | 1.00 | 0.05 | 0.08 |

| Parameter | BPNN | RBFNN | RS-RBFNN |

|---|---|---|---|

| Fault data sample | 510 | 510 | 510 |

| Number of iterations | 5000 | 5000 | 5000 |

| Learning rate | 0.1 | 0.1 | 0.1 |

| Error target value | 0.001 | 0.001 | 0.001 |

| Output layer | Sigmoid | Gaussian | Gaussian |

| Network structure | 11-14-5 | 11-14-5 | 8-11-5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Liu, Z.; Cui, J.; Kong, Y. A Fault Diagnosis Method of the Shearer Hydraulic Heightening System Based on a Rough Set and RBF Neural Network. Energies 2023, 16, 956. https://doi.org/10.3390/en16020956

Liu M, Liu Z, Cui J, Kong Y. A Fault Diagnosis Method of the Shearer Hydraulic Heightening System Based on a Rough Set and RBF Neural Network. Energies. 2023; 16(2):956. https://doi.org/10.3390/en16020956

Chicago/Turabian StyleLiu, Min, Zhiqi Liu, Jinyuan Cui, and Yigang Kong. 2023. "A Fault Diagnosis Method of the Shearer Hydraulic Heightening System Based on a Rough Set and RBF Neural Network" Energies 16, no. 2: 956. https://doi.org/10.3390/en16020956

APA StyleLiu, M., Liu, Z., Cui, J., & Kong, Y. (2023). A Fault Diagnosis Method of the Shearer Hydraulic Heightening System Based on a Rough Set and RBF Neural Network. Energies, 16(2), 956. https://doi.org/10.3390/en16020956