Fundamental Study for Applying a Propane Gas Injection System in a Small-Ship Engine

Abstract

:1. Introduction

1.1. Background

1.2. Previous Studies

1.3. Research Purpose

2. Experimental Setup

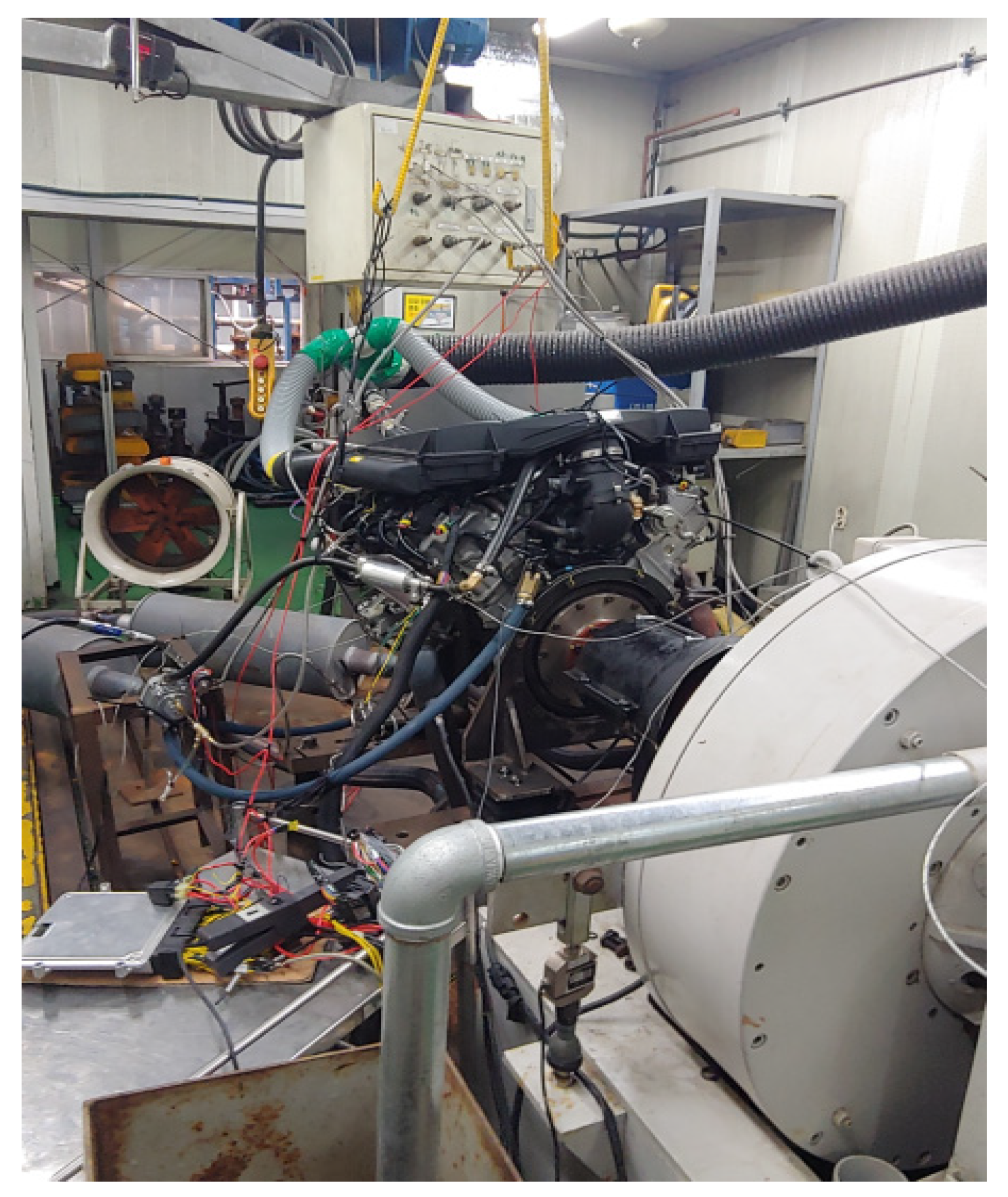

2.1. Engine Experiments

2.2. Fuel System

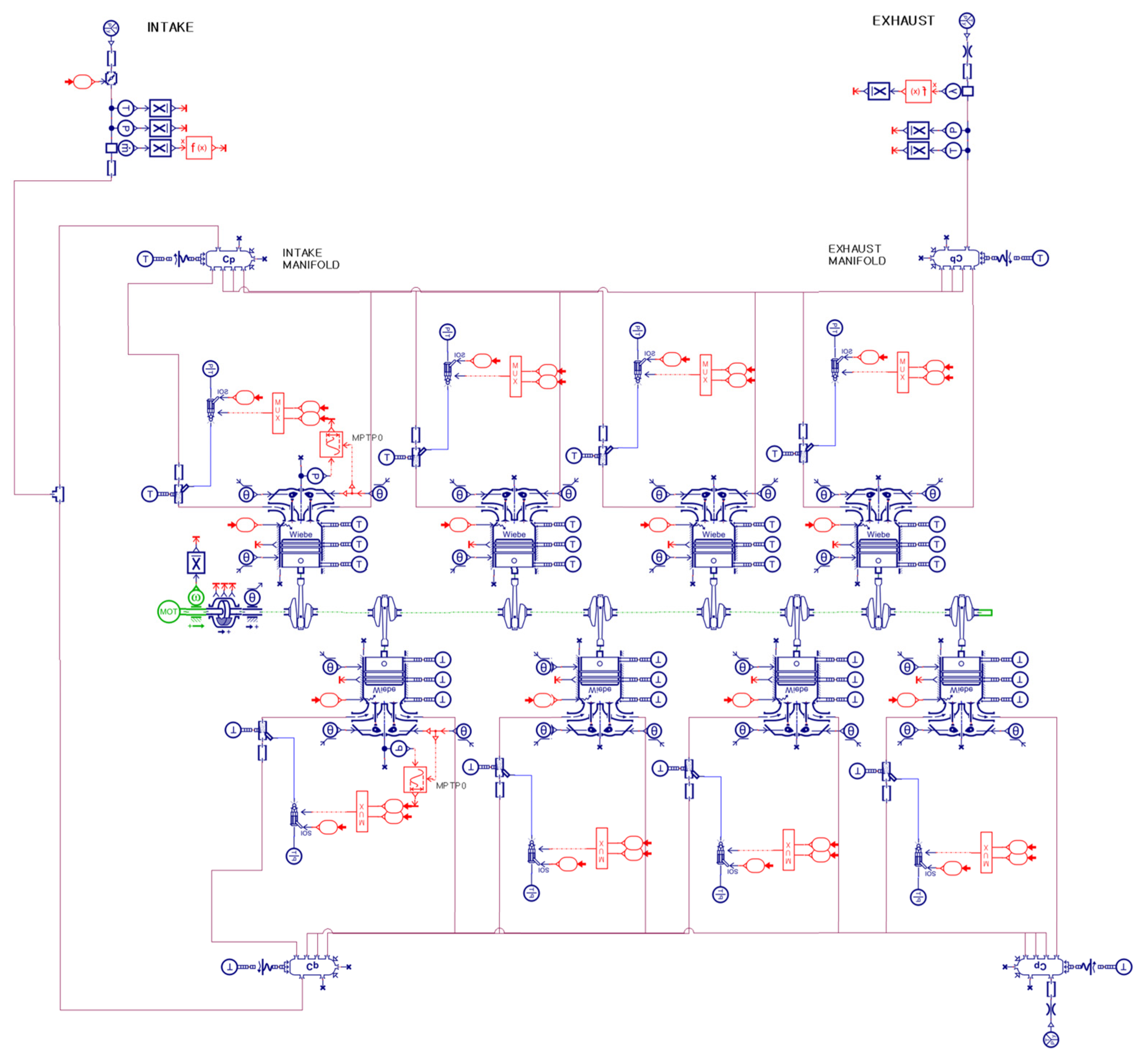

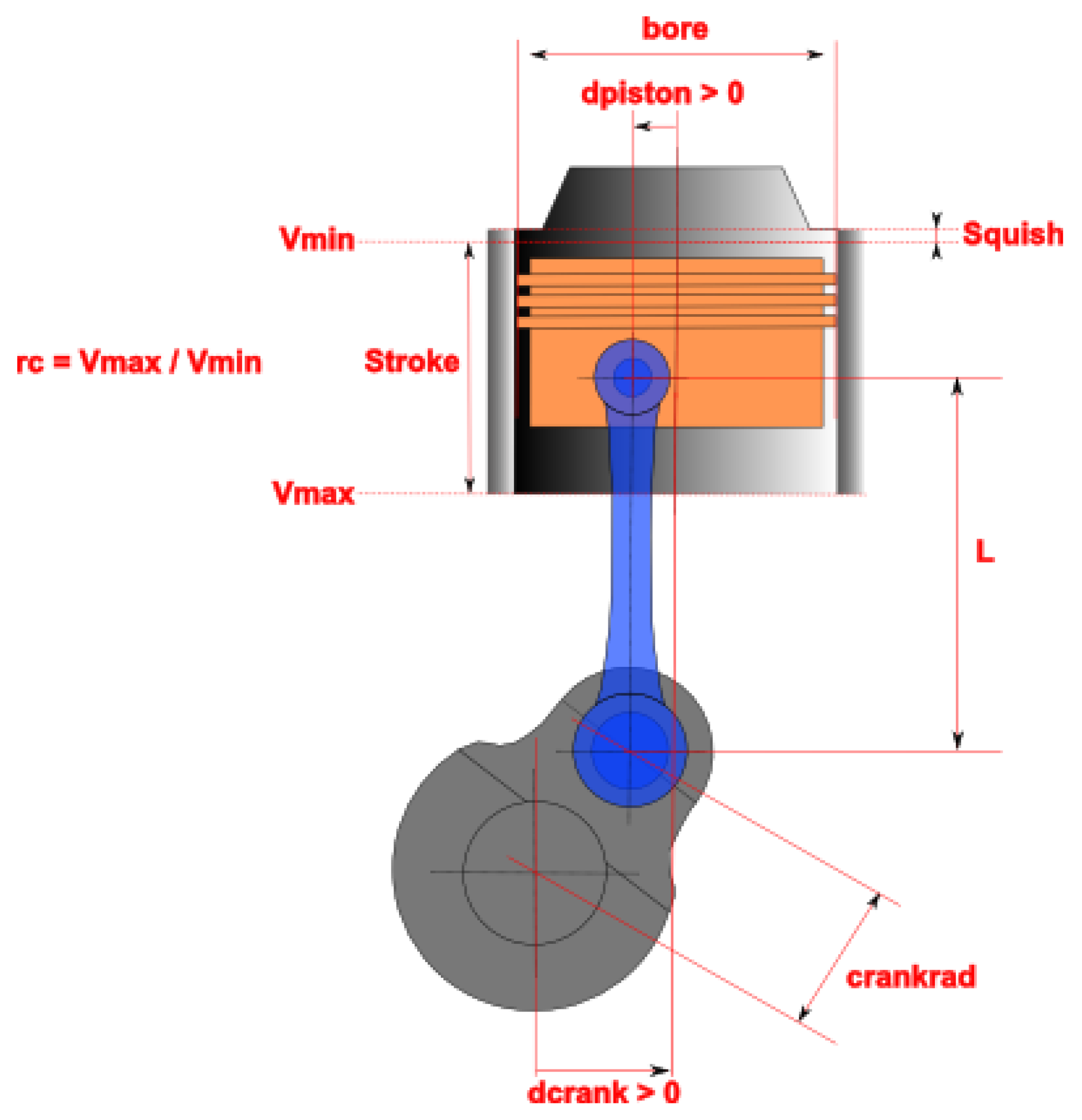

2.3. Simulation Model

3. Results and Discussion

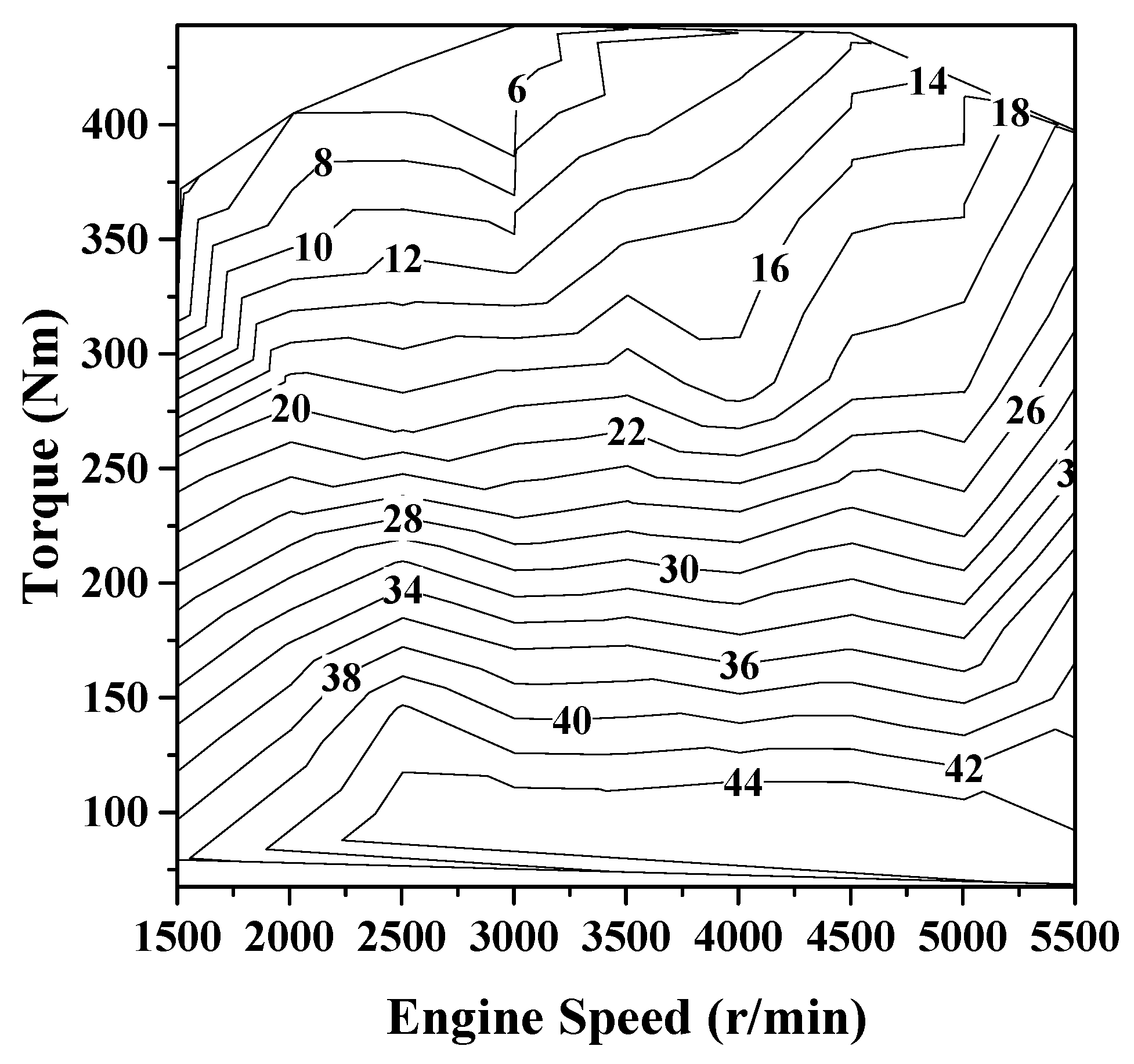

3.1. Simulation Model Validation and Results

3.2. Engine Experiment Results

3.2.1. Ignition Timing Optimization

3.2.2. Comparison of Engine Performance

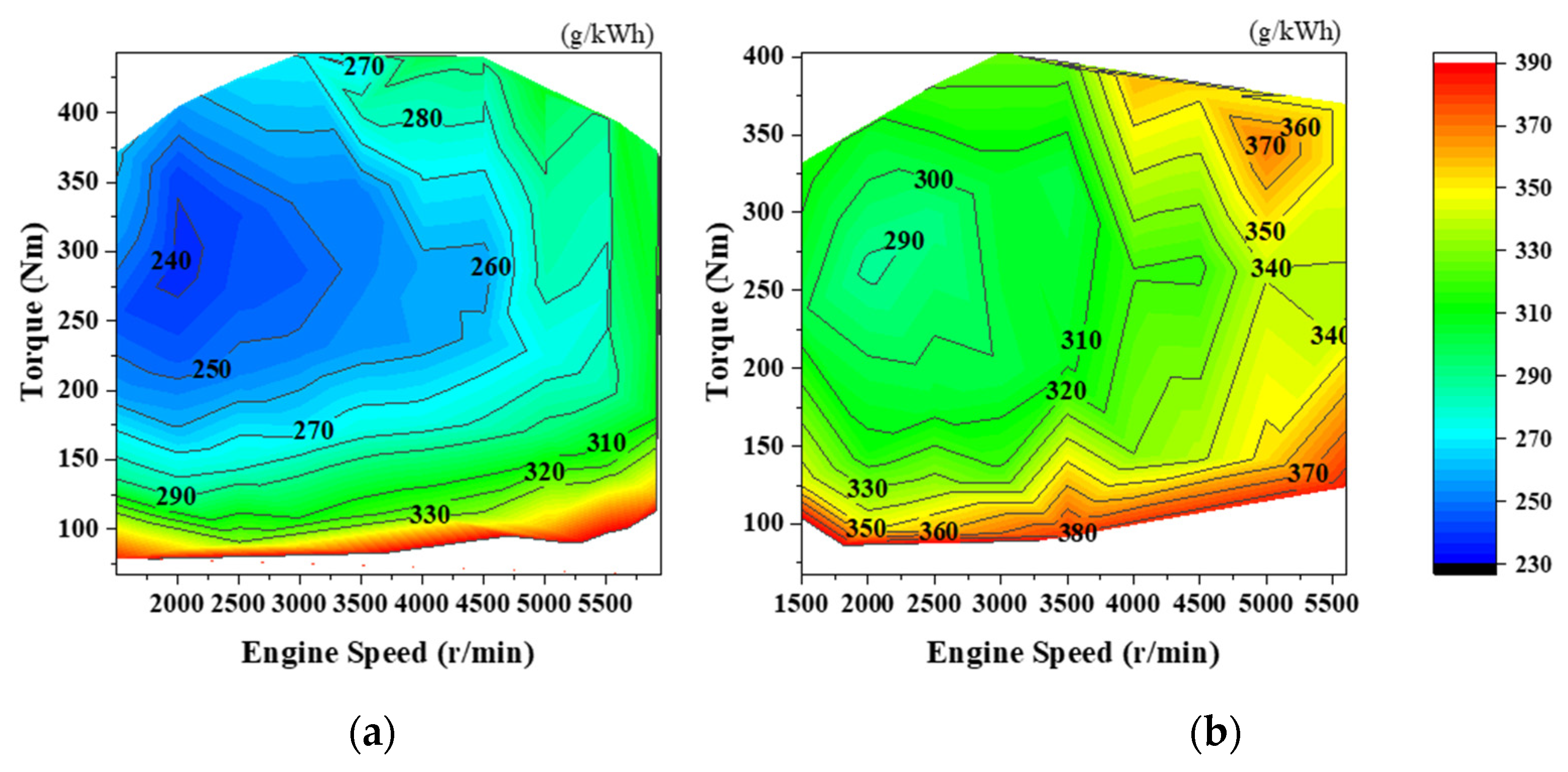

3.2.3. Fuel Consumption Study

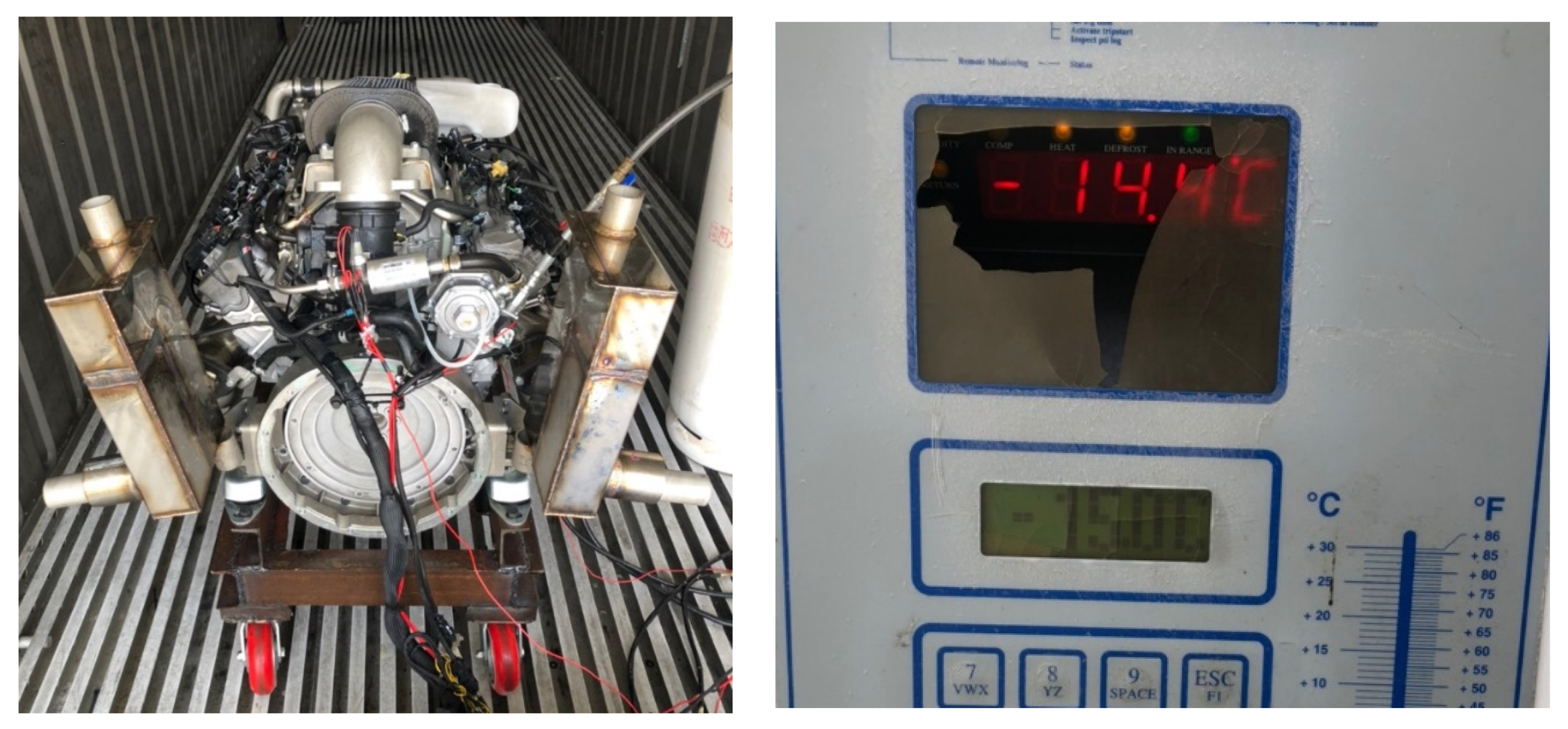

3.2.4. Cold-Start Performance

4. Conclusions

- In order to develop an environmentally friendly and economically viable propane engine, a 5.0 L gasoline base engine was converted to a propane engine. Research was conducted on the gas injection fuel system, ignition timing, and combustion optimization.

- Through 1D simulation modeling of the target propane engine and subsequent validation based on experimental results, it was determined that the error in engine torque was within 0.4%, BSFC within 1.17%, BMEP within 0.89, and ignition timing within 1.01%. Therefore, the reliability of the 1D simulation model was confirmed.

- As a result of the optimal ignition timing MBT investigation using 1D simulation, the development period was shortened, and an ignition timing map was configured for up to 44° BTDC with a 6° delay according to the operating conditions. Because propane has a higher octane number (112) than gasoline, the knocking resistance was exceptional, and the ignition timing was advanced compared to that of the gasoline-based engine. Therefore, it was possible to improve the thermal efficiency of the propane engine.

- The heating value of propane was approximately 27.8% lower than that of gasoline; hence, the BSFC result of the propane engine was higher than that of gasoline. However, due to gas injection, a well-formed mixture of intake air was achieved compared to liquid gasoline injection, allowing for faster combustion. Additionally, the higher octane number of propane (112) compared to gasoline (89) improved resistance to knocking, enabling advanced ignition timing and thereby increasing efficiency. For these reasons, the propane gas injection engine achieved a maximum power that was 95% of the gasoline-based engine and a maximum torque that was 97%.

- To test its cold-start performance, the propane engine was started after soaking in a cold chamber at −15 °C for 12 h. In the cold-start performance test, the engine speed reached 1660 RPM after 1.2 s from cranking, thereby confirming that the engine started well even under low-temperature conditions.

- This study involved the fabrication of a fuel system and the optimization of ignition timing for the development of a propane marine engine, as well as fundamental research on its performance. As part of our future work, research and development for a small-ship propane engine through IMO-regulated mode tests and onboard ship operation experiments will be conducted.

Author Contributions

Funding

Conflicts of Interest

References

- Fletcher, S.E.M.; Schaefer, H. Rising methane: A new climate challenge. Science 2019, 364, 932–933. [Google Scholar] [CrossRef]

- Anderson, T.R.; Hawkins, E.; Jones, P.D. CO2, the greenhouse effect and global warming: From the pioneering work of Arrhenius and Callendar to today’s Earth System Models. Endeavour 2016, 40, 178–187. [Google Scholar] [CrossRef] [PubMed]

- Ryu, J.; Lyu, Y.; Eom, M.; Jeon, M.; Kim, D.; Jung, S.; Kim, D. A Study on the Greenhouse Gas Control Strategies for Motor Vehicles. Natl. Inst. Environ. Res. 2005, 81–89. [Google Scholar]

- Oberthür, S.; Ott, H.E. The Kyoto Protocol: International Climate Policy for the 21st Century; Springer Science & Business Media: Berlin, Germany, 1999. [Google Scholar]

- Agreement, P. Paris Agreement; Report of the Conference of the Parties to the United Nations Framework Convention on Climate Change (21st Session, 2015: Paris); HeinOnline: Buffalo, NY, USA, 2015; p. 2017. [Google Scholar]

- IMO. Initial IMO Strategy on Reduction of GHG Emissions from Ships, Resolution MEPC. 304; Adopted on 13 April 2018; International Maritime Organization: London, UK, 2018. [Google Scholar]

- Joung, T.-H.; Kang, S.-G.; Lee, J.-K.; Ahn, J. The IMO initial strategy for reducing Greenhouse Gas (GHG) emissions, and its follow-up actions towards 2050. J. Int. Marit. Saf. Environ. Aff. Shipp. 2020, 4, 1–7. [Google Scholar] [CrossRef]

- Dieselnet IMO Marine Engine Regulations. Available online: https://dieselnet.com/standards/inter/imo.php (accessed on 7 October 2023).

- Emission Control Areas (ECAs) Designated under MARPOL Annex VI. Available online: https://www.imo.org/en/OurWork/Environment/Pages/Emission-Control-Areas-(ECAs)-designated-under-regulation-13-of-MARPOL-Annex-VI-(NOx-emission-control).aspx (accessed on 7 October 2023).

- Myśków, J.; Borkowski, T.; Bludszuweit, M.; Frohlingsdorf, W. Marine engine exhaust gas emission aftertreatment system concept. J. KONES 2011, 18, 307–315. [Google Scholar]

- Zhou, J.; Wang, H. Study on efficient removal of SOx and NOx from marine exhaust gas by wet scrubbing method using urea peroxide solution. Chem. Eng. J. 2020, 390, 124567. [Google Scholar] [CrossRef]

- Feng, S.; Xu, S.; Yuan, P.; Xing, Y.; Shen, B.; Li, Z.; Zhang, C.; Wang, X.; Wang, Z.; Ma, J.; et al. The Impact of Alternative Fuels on Ship Engine Emissions and Aftertreatment Systems: A Review. Catalysts 2022, 12, 138. [Google Scholar] [CrossRef]

- Zorzoană, I.-A. The Activity of Transposing Directive 2014/94/EU of the European Parliament and Council of 22 October 2014 on the Deployment of Alternative Fuels Infrastructure. the Post-Transposing Attributions of the Romanian Energy Regulatory Authority. Chall. Knowl. Soc. 2019, 855–861. [Google Scholar]

- Li, J.; Wu, B.; Mao, G. Research on the performance and emission characteristics of the LNG-diesel marine engine. J. Nat. Gas Sci. Eng. 2015, 27, 945–954. [Google Scholar] [CrossRef]

- Park, T.; So, S.; Jeong, B.; Zhou, P.; Lee, J.-U. Life cycle assessment for enhanced Re-liquefaction systems applied to LNG carriers; effectiveness of partial Re-liquefaction system. J. Clean. Prod. 2021, 285, 124832. [Google Scholar] [CrossRef]

- Yeo, S.-J.; Kim, J.; Lee, W.-J. Potential economic and environmental advantages of liquid petroleum gas as a marine fuel through analysis of registered ships in South Korea. J. Clean. Prod. 2022, 330, 129955. [Google Scholar] [CrossRef]

- Mahmud, S.; Ahmed, S.A. Prospect of LPG for Marine Engines in Bangladesh. Syed Aurongzeb, Prospect of LPG for Marine Engines in Bangladesh. In Proceedings of the International Conference on Marine Technology, BUET, Dhaka, Bangladesh, 21–22 December 2022. [Google Scholar]

- Wang, Y.; Cao, Q.; Liu, L.; Wu, Y.; Liu, H.; Gu, Z.; Zhu, C. A review of low and zero carbon fuel technologies: Achieving ship carbon reduction targets. Sustain. Energy Technol. Assess. 2022, 54, 102762. [Google Scholar] [CrossRef]

- IMO. Guidelines on Alternative Design and Arrangements for Fire Safety; International Maritime Organisation: London, UK, 2001. [Google Scholar]

- Erkuş, B.; Karamangil, M.İ.; Sürmen, A. Enhancing the heavy load performance of a gasoline engine converted for LPG use by modifying the ignition timings. Appl. Therm. Eng. 2015, 85, 188–194. [Google Scholar] [CrossRef]

- Okamoto, K.; Ichikawa, T.; Saitoh, K.; Oyama, K.; Hiraya, K.; Urushihara, T. Study of Antiknock Performance Under Various Octane Numbers and Compression Ratios in a DISI Engine. SAE Trans. 2003, 112, 1079–1087. [Google Scholar]

- Garin, F. Mechanism of NOx decomposition. Appl. Catal. A Gen. 2001, 222, 183–219. [Google Scholar] [CrossRef]

- Masi, M.; Gobbato, P. Measure of the volumetric efficiency and evaporator device performance for a liquefied petroleum gas spark ignition engine. Energy Convers. Manag. 2012, 60, 18–27. [Google Scholar] [CrossRef]

- Choi, G.; Cho, U. A Study on Reduction of Exhaust Gas Temperature in Retrofitted LPG Fueled Engine Based Mdium-Duty Diesel Engine. Trans. Korean Soc. Automot. Eng. 2003, 11, 63–68. [Google Scholar]

- Irimescu, A. Study of volumetric efficiency for spark ignition engines using alternative fuels. Analele Univ. Eftimie Murgu 2010, 2, 149–154. [Google Scholar]

- Gumus, M. Effects of volumetric efficiency on the performance and emissions characteristics of a dual fueled (gasoline and LPG) spark ignition engine. Fuel Process. Technol. 2011, 92, 1862–1867. [Google Scholar] [CrossRef]

| Engine Specification | |

|---|---|

| engine type | V-Type, 90°, 4 cycle |

| maximum output (kW/rpm) | 213/5600 |

| maximum torque (Nm) | 420 |

| displacement (cc) | 4966 |

| bore × stroke (mm) | 97 × 84 |

| compression ratio | 10:1 |

| firing order | 1-5-4-2-6-3-7-8 |

| valve lash adjust | hydraulic lash adjuster |

| Characteristic | Propane | Gasoline |

|---|---|---|

| chemical formula | C3H8 | CHy (y: 1.85~2.3) |

| molecular weight (kg/kmol) | 44.097 | 114.15 |

| specific gravity of liquid @ 25 °C | 0.495 | 0.71–0.77 |

| octane number (RON) | 112 | 86–94 |

| gaseous density @ 15 °C (kg/m3) | 1.898 | ─ |

| gaseous expansion | 1 L (liquid) = 270 L (gas) | ─ |

| auto-ignition temperature (°C) | 470 | 257 |

| lower heating value (MJ/L) | 23.1 | 32 |

| boiling point (°C) | −42 | 35 |

| air–fuel ratio | 15.67:1 | 14.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.; Park, B.Y.; Woo, S.; Jeong, J.W.; Park, S.; Lee, K. Fundamental Study for Applying a Propane Gas Injection System in a Small-Ship Engine. Energies 2023, 16, 7036. https://doi.org/10.3390/en16207036

Kim Y, Park BY, Woo S, Jeong JW, Park S, Lee K. Fundamental Study for Applying a Propane Gas Injection System in a Small-Ship Engine. Energies. 2023; 16(20):7036. https://doi.org/10.3390/en16207036

Chicago/Turabian StyleKim, Youngkun, Bum Youl Park, Seungchul Woo, Jun Woo Jeong, Sihyun Park, and Kihyung Lee. 2023. "Fundamental Study for Applying a Propane Gas Injection System in a Small-Ship Engine" Energies 16, no. 20: 7036. https://doi.org/10.3390/en16207036

APA StyleKim, Y., Park, B. Y., Woo, S., Jeong, J. W., Park, S., & Lee, K. (2023). Fundamental Study for Applying a Propane Gas Injection System in a Small-Ship Engine. Energies, 16(20), 7036. https://doi.org/10.3390/en16207036