Energy Efficiency of Induction Motor Drives: State of the Art, Analysis and Recommendations

Abstract

:1. Introduction

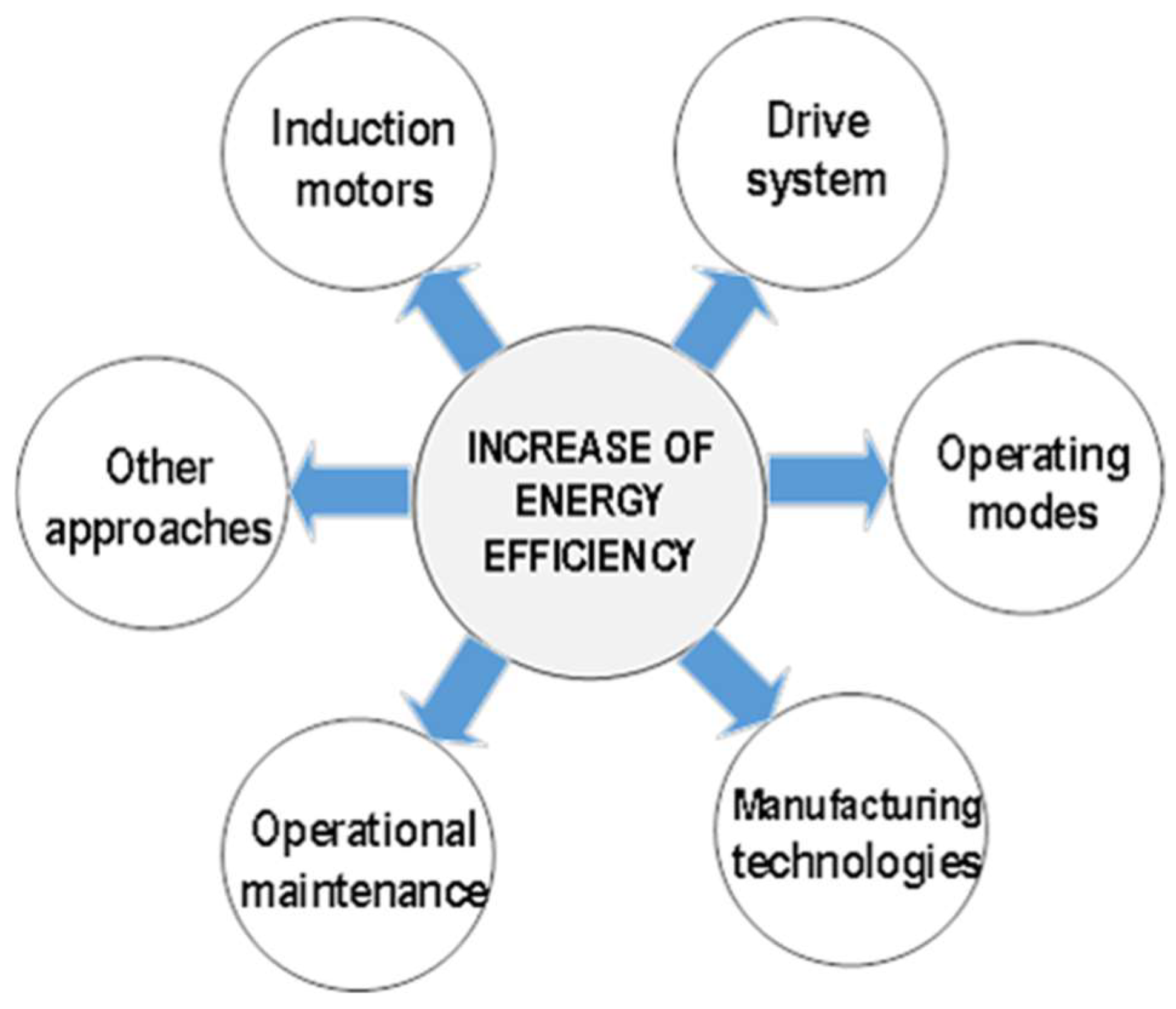

2. State of the Art

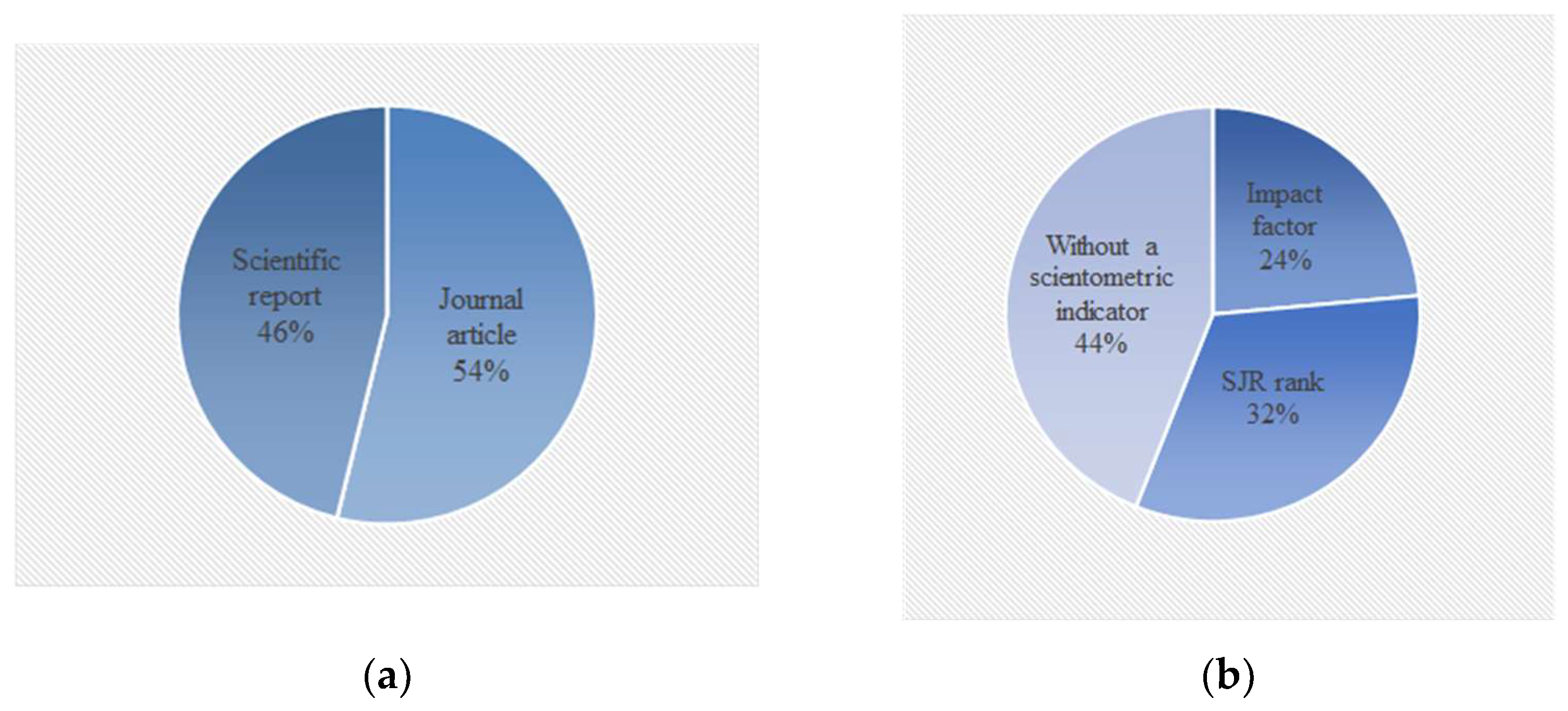

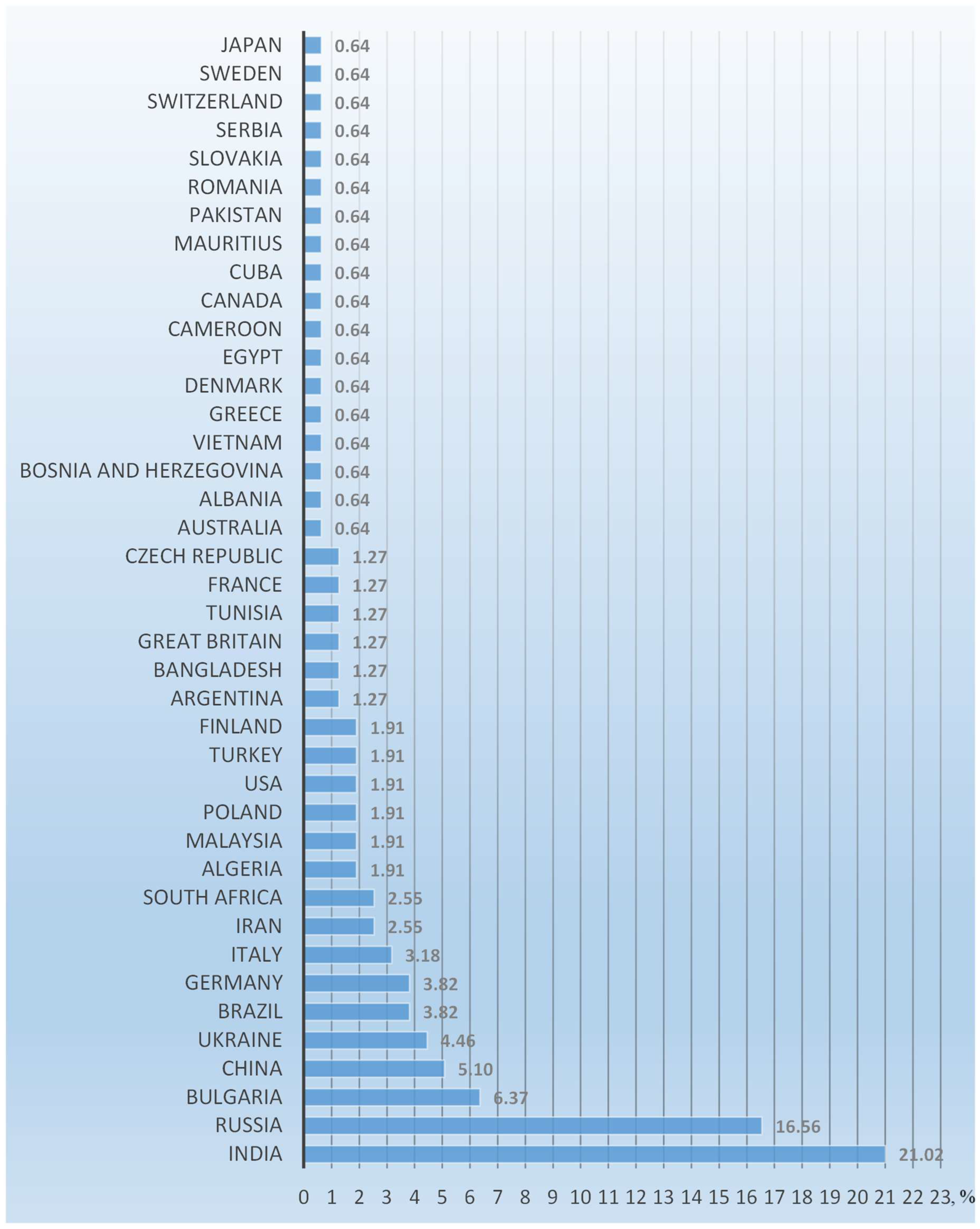

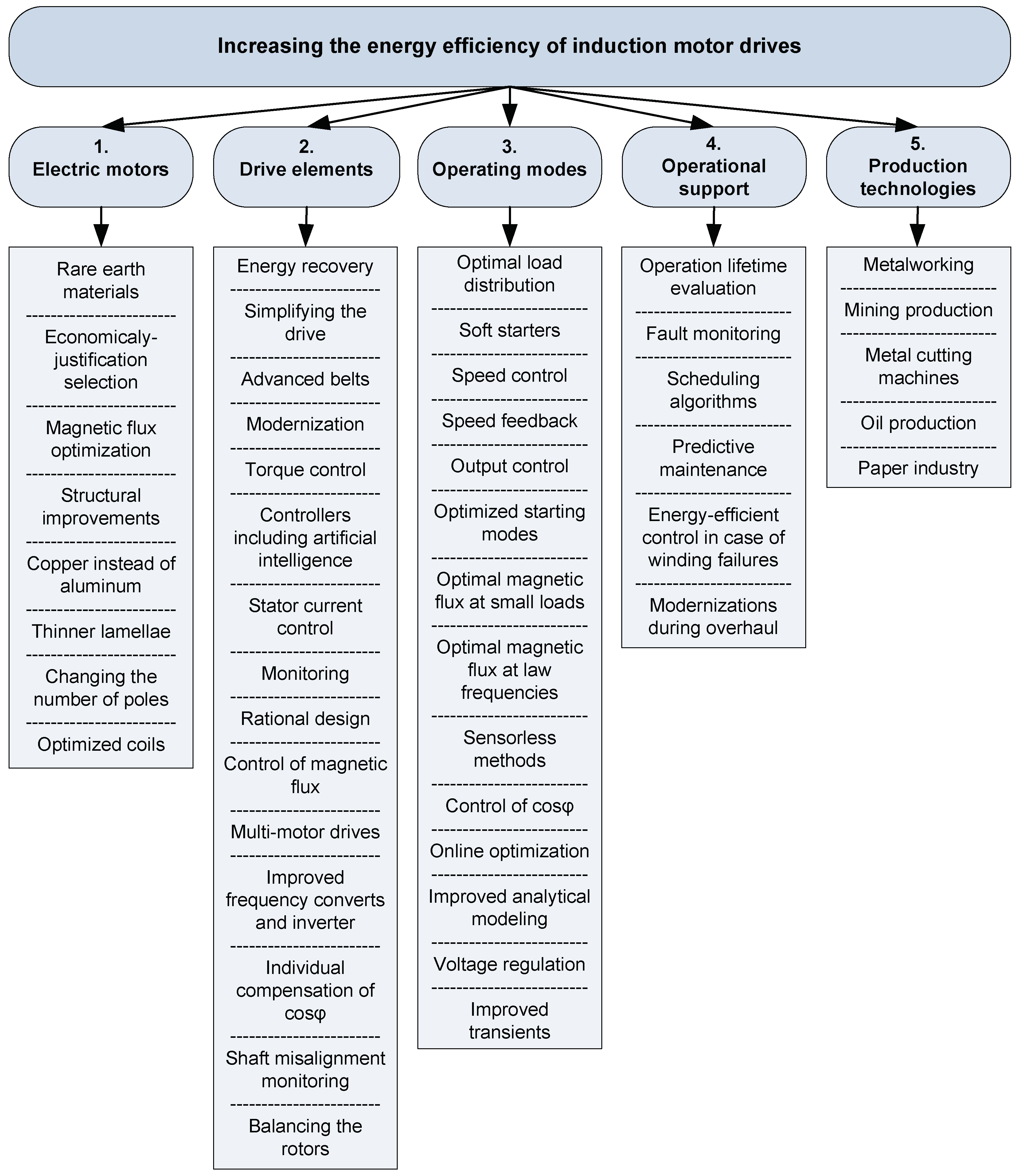

2.1. Systematization of Publications

- Increasing the energy efficiency of the main component of induction motor drives—the induction motor.

- Improving the components of induction motor drives, e.g., control systems, gears, etc.

- Achieving energy-efficient operating modes of the drives, especially at highly variable and/or low loads.

- Improved operational maintenance of electric drives.

- Achieving energy savings in the drives through improvements in the manufacturing technologies.

- Other research.

2.2. Increasing the Energy Efficiency of Induction Motor Drives

2.3. Improvement of Induction Motor Drives

2.4. Energy-Efficient Operating Modes of Drives

2.5. Improved Operational Maintenance

2.6. Improved Production Technologies

2.7. Other Research

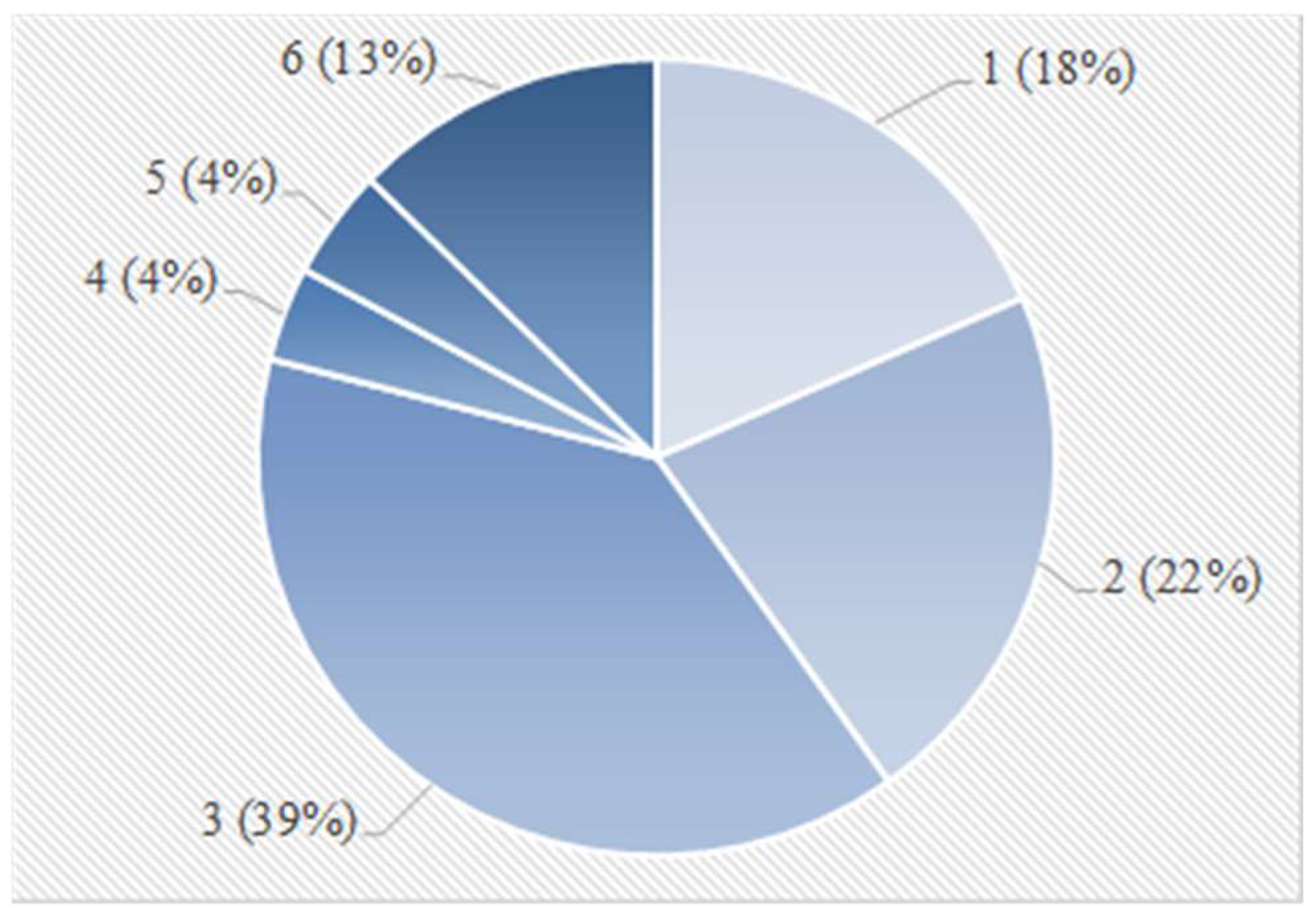

3. Summary Analysis

4. Conclusions and Recommendations

- An inverse correlation between the number of publications in scientific fields and the average number of citations has been identified. Based on this link, and with a view to increasing the research impact, future publications should focus on under-researched areas such as the improvement of operational maintenance and the improvement of manufacturing technologies.

- Owing to the numerous publications, the scientific sub-field dealing with the improvement of the operating modes of drives through magnetic flux- and rotational speed control systems proves to be sufficiently well-unfolded.

- Existing research has been performed under controlled laboratory conditions using precise and sophisticated instrumentation, with the results mainly being directed at the scientific community.

- Issues related to the adaptation of scientific results and the conditions for their effective and wide-ranging application in manufacturing environments are not discussed or investigated in the literature. Other researchers have also identified this conclusion.

- Due to the diversity and specificity of real-life facilities, science-based instruments should be sought to ensure the implementation of a range of options to improve energy efficiency.

- Research in the subject area should be expanded in terms of the adapted approaches that create prerequisites for the justified implementation of energy-efficiency improvement measures. This field is relatively under-represented in the literature.

- The process of adaptation of scientific results should take into account the possibilities of obtaining data, incl. measurement data, the competencies of energy managers and the type of information provided to them.

- The selection of parameters, the development of a mathematical description and the conducting of theoretical studies of the adapted model, taking into account the energy characteristics of the drive motors and the conditions for the algorithmization and automation of the experimental studies.

- Proposing a methodology and description of the facilities subject to study, which will allow one to study the practical applicability and operability of the developed models.

- Application of the proposed methodologies for typical industrial motor drives and operating modes, providing new data on the facilities under study and the possibility of interpretative analysis.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Energy Intensity. Eurostat. Available online: https://ec.europa.eu/eurostat/databrowser/view/nrg_ind_ei/default/table?lang=en (accessed on 3 December 2022).

- Ognyan, D.; Boryana, M.; Mihailov, L.; Andonov, K. Results from the application of a model for energy-efficiency investigation of mechanical handling machines and systems (Part 1). J. Eng. Stud. Res. 2013, 19, 64–70. [Google Scholar] [CrossRef]

- Dinolov, O.; Mihailov, L.; Ilieva, K.; Dinolova, P. Investigation of the Possibilities for Application of a Basis-Power Model in Analysing the Energy Efficiency of Type I Fluid Systems. In Proceedings of the 17th Conference on Electrical Machines, Drives and Power Systems, Sofia, Bulgaria, 1–4 July 2021; IEEE: New York, NY, USA, 2021; pp. 1–3. [Google Scholar]

- Tytiuk, V.; Modlo, Y.; Berdai, A.; Kikovka, S.; Busher, V.; Rozhnenko, Z. Exploring the MMF of a three-phase induction motor with twelve-zone stator windings. In Proceedings of the 20th IEEE International Conference on Modern Electrical and Energy Systems, Kremenchuk, Ukraine, 21–24 September 2021. [Google Scholar]

- Hristova, M.I.; Ruseva, V.S.; Krasteva, A.H. Constant losses in induction motors and possible solutions for their reduction. In Proceedings of the 8th International Conference on Energy Efficiency and Agricultural Engineering, Ruse, Bulgaria, 30 June–2 July 2022; pp. 1–4. [Google Scholar]

- Hristova, M.I.; Ruseva, V.S.; Krasteva, A.H. Possibilities for reduction of variable losses in induction motors. In Proceedings of the 8th International Conference on Energy Efficiency and Agricultural Engineering, Ruse, Bulgaria, 30 June–2 July 2022; pp. 1–5. [Google Scholar]

- Tamboli, P.D.; Kulkarni, S.S.; Thosar, A.G. Energy efficiency in manufacturing industry and analysis of industrial motors. In Proceedings of the 4th International Conference on Electronics, Communication and Aerospace Technology, Coimbatore, India, 5–7 November 2020; pp. 170–175. [Google Scholar]

- IEC 60034-30-1; Standard on Efficiency Classes For Low Voltage AC Motors—Technical Note. ABB: Cary, NC, USA, 2018.

- Gavrila, H.; Paltanea, V.M.; Paltanea, G.; Scutaru, G.; Peter, I. New Trends in Energy Efficient Electrical Machines. Procedia Eng. 2017, 181, 568–574. [Google Scholar] [CrossRef]

- Gómez, J.R.; Quispe, E.C.; Castrillón, R.d.P.; Viego, P.R. Identification of Technoeconomic Opportunities with the Use of Premium Efficiency Motors as Alternative for Developing Countries. Energies 2020, 13, 5411. [Google Scholar] [CrossRef]

- de Macedo, P.P.; Mota, C.M.d.M.; Sola, A.V.H. Meeting the Brazilian Energy Efficiency Law: A flexible and interactive multicriteria proposal to replace non-efficient motors. Sustain. Cities Soc. 2018, 41, 822–832. [Google Scholar] [CrossRef]

- Agrawal, S.K.; Noida, I.M.M.D.P.L. Energy Conservation and Efficiency by Energy Efficient Motor in India. Int. J. Eng. Adv. Technol. 2019, 9, 3917–3926. [Google Scholar] [CrossRef]

- Donolo, P.D.; Chiacchiera, E.; Pezzani, C.M.; Lifschitz, A.S.; De Angelo, C. Economic Barriers to the Application of Energy Efficient Motors in Industry. IEEE Lat. Am. Trans. 2020, 18, 1817–1825. [Google Scholar] [CrossRef]

- Tabora, J.M.; Tostes, M.E.D.L.; De Matos, E.O.; Soares, T.M.; Bezerra, U.H. Voltage Harmonic Impacts on Electric Motors: A Comparison between IE2, IE3 and IE4 Induction Motor Classes. Energies 2020, 13, 3333. [Google Scholar] [CrossRef]

- Khoury, G.; Ghosn, R.; Khatounian, F.; Fadel, M.; Tientcheu, M. Energy-efficient field-oriented control for induction motors taking into account core losses. In Proceedings of the 18th International Conference on Power Electronics and Motion Control, Budapest, Hungary, 26–30 August 2018; pp. 543–548. [Google Scholar]

- Yahya, Y.B.; Rahmat, M.K.; Salleh, S.F.; Abdullah, T.A.R.T. The effects of induction motor’s steel sheet thickness on efficiency, losses and electrical cost. Int. J. Integr. Eng. 2019, 11, 14–19. [Google Scholar] [CrossRef]

- Subramani, C.; Usha, S. An efficient induction motor design for performance intensification using magnet software. Int. Trans. Electr. Energy Syst. 2019, 30, e12306. [Google Scholar] [CrossRef]

- Dems, M.; Komeza, K. Designing an energy-saving induction motor operating in a wide frequency range. IEEE Trans. Ind. Electron. 2022, 69, 4387–4397. [Google Scholar] [CrossRef]

- Dominic, A.; Schullerus, G.; Winter, M. Rotor flux templates for energy efficient dynamic operation of induction machines. In Proceedings of the 2020 International Conference on Electrical Machines, Gothenburg, Sweden, 23–26 August 2020; pp. 312–318. [Google Scholar]

- Foti, S.; De Caro, S.; Testa, A.; Tornello, L.D.; Scelba, G.; Scarcella, G. Grid-connected open-end winding induction motor drives. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 24–26 June 2020; pp. 30–35. [Google Scholar]

- Goun, V.S.; Anikin, A.S.; Bakin, A.A. Experimental determination of suboptimal parameters for energy-efficient control of an induction motor. Int. J. Power Electron. Drive Syst. (IJPEDS) 2020, 11, 2173–2182. [Google Scholar] [CrossRef]

- Goun, V.S.; Bakin, A.A.; Anikin, A.S.; Sidorenko, N.Y. Determination of the parameters of an induction motor in transient modes to improve the quality of its operation. In Proceedings of the 2020 Global Smart Industry Conference, Chelyabinsk, Russia, 17–19 November 2020; pp. 223–228. [Google Scholar]

- Meshcheryakov, V.N.; Lastochkin, D.V.; Shakurova, Z.; Valtchev, S. Energy saving system of cascade variable frequency induction electric drive. E3S Web Conf. 2019, 124, 01037. [Google Scholar] [CrossRef]

- Iegorov, O.; Iegorova, O.; Kundenko, M.; Milenin, A. Single-phase induction motors winding parameters optimization with maximum efficiency. In Proceedings of the 25th IEEE International Conference on Problems of Automated Electric Drive, Theory and Practice, Kremenchuk, Ukraine, 21–25 September 2020. [Google Scholar]

- Aarniovuori, L.; Lindh, P.; Kärkkäinen, H.; Niemelä, M.; Pyrhönen, J.; Cao, W. Analytical evaluation of high-efficiency induction motor losses. In Proceedings of the IEEE International Electric Machines and Drives Conference, San Diego, CA, USA, 12–15 May 2019; pp. 1501–1507. [Google Scholar]

- Polnik, B.; Kaczmarczyk, K.; Niedworok, A.; Baltes, R.; Clausen, E. Energy Recuperation as One of the Factors Improving the Energy Efficiency of Mining Battery Locomotives. Manag. Syst. Prod. Eng. 2020, 28, 253–258. [Google Scholar] [CrossRef]

- Shukla, N.K.; Srivastava, R.; Mirjalili, S. A Hybrid Dragonfly Algorithm for Efficiency Optimization of Induction Motors. Sensors 2022, 22, 2594. [Google Scholar] [CrossRef]

- Susdorf, V.I.; Cherniy, S.P.; Buzikayeva, A.V. Synthesis of power-efficient series motor control. In Proceedings of the International Multi-Conference on Industrial Engineering and Modern Technologies, Vladivostok, Russia, 6–9 October 2020; p. 20256567. [Google Scholar]

- Sun, X.; Lei, T.; Zhao, R.; Liu, Z. Research on efficiency optimization for the induction motor by pole changing techniques. In Proceedings of the IEEE 5th International Electrical and Energy Conference, Nangjing, China, 27–29 May 2022; pp. 3672–3677. [Google Scholar]

- Mao, H.; Ye, R.; Liu, M. Dynamically reconfigurable motor technology for high density and high efficiency HEV drives without rare-earth materials. In Proceedings of the IEEE Transportation Electrification Conference and Expo, Anaheim, CA, USA, 15–17 June 2022; pp. 784–789. [Google Scholar]

- Iegorov, O.; Iegorova, O.; Shinkarenko, I.; Glebova, M. The single-phase induction motor windings parameters experimental optimization at a given capacity of the phase-shifting capacitor. In Proceedings of the 20th IEEE International Conference on Modern Electrical and Energy Systems, Kremenchuk, Ukraine, 21–24 September 2021. [Google Scholar]

- Mathaba, T.; Xia, X. Optimal and energy efficient operation of conveyor belt systems with downhill conveyors. Energy Effic. 2017, 10, 405–417. [Google Scholar] [CrossRef]

- Khoury, G.; Ghosn, R.; Khatounian, F.; Fadel, M.; Tientcheu, M. An energy-efficient scalar control taking core losses into account. Int. J. Comput. Math. Electr. Electron. Eng. 2018, 37, 849–867. [Google Scholar] [CrossRef]

- Usha, S.; Subramani, C.; Venkatesan, M.; Ragav, S.; Imraan, B. PLC based multi starter control using single control system for induction motor. Int. J. Recent Technol. Eng. 2019, 8, 2515–2521. [Google Scholar]

- Davydov, V.; Zhiligotov, R. Electrical drive efficiency improving using an adaptive neural network controller. IOP Conf. Ser. Mater. Sci. Eng. 2019, 643, 012110. [Google Scholar] [CrossRef]

- Shukla, N.; Shantanu, K.; Singh, K.; Srivastava, R. Energy saving of induction motor drive using artificial intelligence based controllers. Int. J. Control. Autom. 2020, 13, 652–664. [Google Scholar]

- Bruno, A.; Caruso, M.; Di Tommaso, A.O.; Miceli, R.; Nevoloso, C.; Viola, F. Simple and Flexible Power Loss Minimizer With Low-Cost MCU Implementation for High-Efficiency Three-Phase Induction Motor Drives. IEEE Trans. Ind. Appl. 2021, 57, 1472–1481. [Google Scholar] [CrossRef]

- Linenko, A.; Khalilov, B.; Kamalov, T.; Tuktarov, M.; Syrtlanov, D. Effective technical ways to improve the vibro-centrifugal separator electric drive for grain cleaning. J. Agric. Eng. 2021, 52, 1136. [Google Scholar] [CrossRef]

- Simakov, G.; Topovskiy, V. Energy-efficient control algorithm for induction motor drive of electromechanical unbalance vibration exciter. In Proceedings of the 14th International Scientific-Technical Conference on Actual Problems of Electronic Instrument Engineering, Novosibirsk, Russia, 2–6 October 2018; pp. 206–242. [Google Scholar]

- Mamizadeh, A.; Iskender, I. Designing of induction motor efficiency monitoring system without using torque meter and speed sensor. In Proceedings of the International Conference on Optimization of Electrical and Electronic Equipment, Brasov, Romania, 25–27 May 2017; pp. 330–335. [Google Scholar]

- Sever, F.; Mohammed, A.Q.; Ritchey, S.; Seryak, J. Deemed power savings of cogged V-belts versus smooth V-belts. Energy Eng. J. Assoc. Energy Eng. 2017, 114, 39–62. [Google Scholar] [CrossRef]

- Kopylov, K.; Kubrin, S.; Reshetnyak, S. The importance of improving energy efficiency and safety of coal mine extraction area. Ugol’ 2018, 10, 66–70. [Google Scholar] [CrossRef]

- Khan, M.; Sakib, M.; Tasneem, Z.; Uddin, M.; Salim, K. Statistical analysis of power consumption by the industrial sewing machines of Bangladesh and performance assessment of an energy-efficient solution by using single-phase variable frequency drive. In Proceedings of the IEEE Region 10 Symposium, Dhaka, Bangladesh, 5–7 June 2020; pp. 340–343. [Google Scholar]

- Spahiu, A.; Bizhga, D.; Dhamo, L. Reduction of electricity consumption and water cost in pump application. In Proceedings of the 3rd International Conference and Workshop in Obuda on Electrical and Power Engineering, Budapest, Hungary, 18–19 November 2020; IEEE: New York, NY, USA, 2020; pp. 137–142. [Google Scholar]

- Amerise, A.; Mengoni, M.; Zarri, L.; Tani, A.; Rubino, S.; Bojoi, R. Open-end windings induction motor drive with floating capacitor bridge at variable DC-link voltage. IEEE Trans. Ind. Appl. 2019, 55, 2741–2749. [Google Scholar] [CrossRef]

- Solodkiy, E.; Kazantsev, V.; Dadenkov, D. Improving the energy efficiency of the sucker-rod pump via its optimal counterbalancing. In Proceedings of the International Russian Automation Conference, Sochi, Russia, 8–14 September 2019. [Google Scholar]

- Baykov, D.V.; Gulyaev, I.V.; Inshakov, A.P.; Teplukhov, D.Y. Simulation Modeling of an Induction Motor Drive Controlled by an Array Frequency Converter. Russ. Electr. Eng. 2019, 90, 485–490. [Google Scholar] [CrossRef]

- Rozhkov, V.; Fedotov, V. Improving the properties and characteristics of avariable-frequency drive with an active rectifier. In Proceedings of the International Russian Automation Conference, Sochi, Russia, 6–12 September 2020; pp. 903–907. [Google Scholar]

- Patel, P.; Pandya, S. Energy regeneration during deceleration of direct torque control of induction motor drive for electric vehicles. In Proceedings of the 3rd IEEE International Conference on Electrical, Computer and Communication Technologies, Coimbatore, India, 20–22 February 2019. [Google Scholar]

- Jung, C.; Torrico, C.R.C.; Carati, E.G. Adaptive Loss Model Control for Robustness and Efficiency Improvement of Induction Motor Drives. IEEE Trans. Ind. Electron. 2022, 69, 10893–10903. [Google Scholar] [CrossRef]

- Voytenko, V.; Vodichev, V.; Kalinin, A. Comparative analysis of energy performance of induction single-motor and multi-motor traction electric drive. In Proceedings of the IEEE 2nd KhPI Week on Advanced Technology, Kharkiv, Ukraine, 13–17 September 2021; pp. 73–78. [Google Scholar]

- Mecke, R. High energy-efficient electrical drive with multilevel inverter and widebandgap power semiconductors. Renew. Energy Power Qual. J. 2021, 19, 91–96. [Google Scholar] [CrossRef]

- Parreiras, T.; Alves, M.; Bastos, R.; Pires, I.; Filho, B. The true unity power factor converter for BOF charging cranes. In Proceedings of the IEEE Industry Applications Society Annual Meeting, Detroit, MI, USA, 10–16 October 2020. [Google Scholar]

- Mugalimov, R.; Mugalimova, A.; Karandaev, A.; Zakirova, R.; Bokov, A. Increasing energy efficiency of asynchronous electric drives due to individual compensation of reactive power of motors. In Proceedings of the Russian Workshop on Power Engineering and Automation of Metallurgy Industry: Research and Practice, Magnitogorsk, Russia, 25–26 September 2020; pp. 62–66. [Google Scholar]

- Patel, P.; Pandya, S. Energy Regeneration in Direct Torque Control Drive of Induction Motor; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 604, pp. 179–189. [Google Scholar]

- Bhardwaj, S.R.; Rahi, O.P.; Sharma, V. Comparative Analysis of Induction Motor Drive with Chopper Controlled SPRS Employing Various Inverter Configurations. IETE J. Res. 2018, 65, 329–341. [Google Scholar] [CrossRef]

- Syed, W.; Thakur, R. Power factor improvement and harmonics reduction in PWM AC chopper fed three-phase induction motor drive using fuzzy logic controller. In Proceedings of the IEEE Delhi Section Conference, New Delhi, India, 11–13 February 2022. [Google Scholar]

- Haq, S.; Biswas, S.P.; Hosain, M.K. Performance investigation of different modulation schemes for an 11-level NPC inverter fed induction motor drive. In Proceedings of the International Conference on Automation, Control and Mechatronics for Industry 4.0, Rajshahi, Bangladesh, 8–9 July 2021. [Google Scholar]

- Dubey, M.; Sharma, S.; Saxena, R.; Singh, B. Sliding mode controlled solar power based induction motor drive. In Proceedings of the 9th IEEE International Conference on Power Electronics, Drives and Energy Systems, Jaipur, India, 16–19 December 2020. [Google Scholar]

- Patel, P.D.; Pandya, S.N. Regenerative energy fed to the grid by DC–AC converter during deceleration for direct torque control of induction motor drive. Int. J. Ambient. Energy 2020, 43, 1966–1973. [Google Scholar] [CrossRef]

- Verucchi, C.E.; Verucchi, C.J.; Giraldo, E.; Meira, M.; Ruschetti, C.R.; Bossio, J.M.; Bossio, G.R. Efficiency Assessment of Induction Motors Drives Operating Under Shaft Misalignment Conditions. Adv. Electr. Electron. Eng. 2020, 18, 142–152. [Google Scholar] [CrossRef]

- Mecke, R. Department of Automation and Computer Sciences Harz University of Applied Sciences Wernigerode. Germany Efficiency improvement with intelligent control of induction motor drives. Renew. Energy Power Qual. J. 2019, 17, 337–342. [Google Scholar] [CrossRef]

- Han, Z.; Wang, Z.; Wang, G. The impacts of variable frequency drives on drive system efficiency. ASHRAE Trans. 2019, 125, 90–92. [Google Scholar]

- Li, L.; Huang, H.; Zhao, F.; Sutherland, J.W.; Liu, Z. An Energy-Saving Method by Balancing the Load of Operations for Hydraulic Press. IEEE/ASME Trans. Mechatron. 2017, 22, 2673–2683. [Google Scholar] [CrossRef]

- Shi, Y.; Cai, M.; Xu, W.; Wang, Y. Methods to Evaluate and Measure Power of Pneumatic System and Their Applications. Chin. J. Mech. Eng. 2019, 32, 42. [Google Scholar] [CrossRef]

- Nel, A.; Arndt, D.; Vosloo, J.; Mathews, M. Achieving energy efficiency with medium voltage variable speed drives for ventilation-on-demand in South African mines. J. Clean. Prod. 2019, 232, 379–390. [Google Scholar] [CrossRef]

- Almani, M.N.; Hussain, G.A.; Zaher, A.A. An Improved Technique for Energy-Efficient Starting and Operating Control of Single Phase Induction Motors. IEEE Access 2021, 9, 12446–12462. [Google Scholar] [CrossRef]

- Hesar, H.M.; Khoshhava, M.A.; Zarchi, H.A. Model-based online efficiency control of induction motor drives based on nonlinear technique. IET Electr. Power Appl. 2022, 16, 1223–1231. [Google Scholar] [CrossRef]

- Dere, C.; Deniz, C. Load optimization of central cooling system pumps of a container ship for the slow steaming conditions to enhance the energy efficiency. J. Clean. Prod. 2019, 222, 206–217. [Google Scholar] [CrossRef]

- Rachev, S.; Dimitrov, L. Increasing the Energy Efficiency of a Ventilation System by Applying Frequency Control. In Proceedings of the 13th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 8–11 September 2021. [Google Scholar]

- Xiao, H.; Chuang, H.-C.; Yang, Z.-H.; Lee, C.-T. The efficiency improvement of induction motor with constant speed for belt drive mechanism. Energy Effic. 2021, 14, 87. [Google Scholar] [CrossRef]

- Choudhary, P.K.; Dubey, S.P. Energy efficient operation of induction motor drives: Economic and environmental analysis in cement manufacturing. Environ. Prog. Sustain. Energy 2019, 38, 672–679. [Google Scholar] [CrossRef]

- Frigerio, N.; Matta, A. Modelling the startup of machine tools for energy efficient multi-sleep control policies. J. Manuf. Syst. 2021, 60, 337–349. [Google Scholar] [CrossRef]

- Shvartsburg, L.; Gvozdkova, S. Study of Reactive Power Compensation Efficiency for Asynchronous Motors of Metal-Cutting Machine Electric Drives; Lecture Notes in Mechanical Engineering; Springer: Berlin/Heidelberg, Germany, 2021; pp. 122–129. [Google Scholar]

- Tolochko, O.; Kaluhin, D.; Burmelov, O. Speed vector control of induction motor with copper and iron losses minimization. In Proceedings of the 2nd Ukraine Conference on Electrical and Computer Engineering, Lviv, Ukraine, 2–6 July 2018; IEEE: New York, NY, USA, 2019; pp. 408–413. [Google Scholar]

- Krasteva, A.; Ivanova, D. Analysis of the meteorological factors affecting the efficient use of electricity in water supply systems. In Proceedings of the 8th International Conference on Energy Efficiency and Agricultural Engineering, Ruse, Bulgaria, 30 June–2 July 2022; pp. 1–5. [Google Scholar]

- Zarchi, H.; Hesar, H.; Khoshhava, M. Online maximum torque per power losses strategy for indirect rotor flux-oriented control-based induction motor drives. IET Electr. Power Appl. 2019, 13, 267–273. [Google Scholar]

- Ekong, U.U.; Inamori, M.; Morimoto, M. Field-Weakening Control for Torque and Efficiency Optimization of a Four-Switch Three-Phase Inverter-Fed Induction Motor Drive. IEEJ J. Ind. Appl. 2019, 8, 548–555. [Google Scholar] [CrossRef]

- Pal, A.; Das, S. Development of energy efficient scheme for speed sensorless induction motor drive. Int. Trans. Electr. Energy Syst. 2020, 30, e12448. [Google Scholar] [CrossRef]

- Ahmed, A.A.; Moharam, B.A.; Rashad, E.E. Improving energy efficiency and economics of motor-pump-system using electric variable-speed drives for automatic transition of working points. Comput. Electr. Eng. 2022, 97, 107607. [Google Scholar] [CrossRef]

- Djagarov, N.; Milushev, H.; Bonev, M.; Djagarova, J.; Grozdev, Z. Adaptive vector control of induction motor drive. In Proceedings of the 7th International Conference on Energy Efficiency and Agricultural Engineering, Ruse, Bulgaria, 12–14 November 2020. [Google Scholar]

- Sreejeth, M.; Singh, M.; Kumar, P. Efficiency enhancement for indirect vector-controlled induction motor drive. Int. J. Electron. 2019, 106, 1281–1294. [Google Scholar] [CrossRef]

- Urwashi, K.; Rani, A. Loss minimization in induction motor drive using grey wolf optimization. In Proceedings of the International Conference on Computing, Power and Communication Technologies, Greater Noida, India, 28–29 September 2018; pp. 770–774. [Google Scholar]

- Semenov, A. Practice of effective using variable-frequency drives in the mining industry process units. In Proceedings of the International Conference on Industrial Engineering, Applications and Manufacturing, Sochi, Russia, 25–29 March 2021; pp. 274–278. [Google Scholar]

- Biswal, A.; Satpathy, S. Vector control of 3-phase induction motor. In Proceedings of the 1st Odisha International Conference on Electrical Power Engineering, Communication and Computing Technology, Bhubaneswar, India, 8–9 January 2021. [Google Scholar]

- Ammar, A.; Ameid, T.; Azzoug, Y.; Kheldoun, A.; Metidji, B. Implementation of sliding mode based-direct flux and torque control for induction motor drive with efficiency optimization. In Proceedings of the International Conference on Advanced Electrical Engineering, Algiers, Algeria, 19–21 November 2019. [Google Scholar]

- Pugachev, A.; Kosmodamianskiy, A. Induction motor scalar control system with power losses minimization. In Proceedings of the International Conference on Industrial Engineering, Applications and Manufacturing, Sochi, Russia, 25–29 March 2019. [Google Scholar]

- Sequeira, M.; Alahakoon, S. Energy efficient variable speed drives empowered with torque estimation. Energy Procedia 2019, 160, 194–201. [Google Scholar] [CrossRef]

- Baranidharan, M.; Singh, R.R. AI Energy Optimal Strategy on Variable Speed Drives for Multi-Parallel Aqua Pumping System. Energies 2022, 15, 4343. [Google Scholar] [CrossRef]

- Graciola, C.L.; Goedtel, A.; Angélico, B.A.; Castoldi, M.F.; Costa, B.L.G. Energy Efficiency Optimization Strategy for Scalar Control of Three-Phase Induction Motors. J. Control. Autom. Electr. Syst. 2022, 33, 1032–1043. [Google Scholar] [CrossRef]

- Balasubramanian, G.; Chandrasekar, P.; Alexandar, S. Variable frequency drive operated air blower in air handling unit of heating, ventilation and air conditioning systems. In Proceedings of the IEEE Delhi Section Conference, New Delhi, India, 11–13 February 2022. [Google Scholar]

- Bizhani, H.; Muyeen, S.; Tatari, F.; Gao, F.; Geng, H. Comparative analysis of search algorithm based loss minimization techniques used in vector controlled induction motors. In Proceedings of the 2nd International Conference on Smart Power and Internet Energy Systems, Bangkok, Thailand, 15–18 September 2020; pp. 386–390. [Google Scholar]

- Eftekhari, S.; Davari, S.; Naderi, P.; Garcia, C.; Rodriguez, J. Reducing the parameter dependency of model-based loss minimization method for induction motor drives. In Proceedings of the IEEE International Conference on Industrial Technology, Buenos Aires, Argentina, 26–28 February 2020; pp. 1106–1111. [Google Scholar]

- Rai, K.; Seksena, S.; Thakur, A. A Comparative Assessment of Genetic and Golden Search Algorithm for Loss Minimization of Induction Motor Drive; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 659, pp. 119–131. [Google Scholar]

- Jeyashanthi, J.; Santhi, M. Improved efficiency of direct torque controlled induction motor drive by golden section method. Rev. Fac. De Ing. 2019, 91, 31–42. [Google Scholar]

- Seizovic, A.; Vojvodic, N.; Ristic, L.; Bebic, M. Energy efficient control of variable-speed induction motor drives based on particle swarm optimization. In Proceedings of the International Symposium on Industrial Electronics and Applications, Banja Luka, Bosnia and Herzegovina, 4–6 November 2020. [Google Scholar]

- Abdelati, R.; Mimouni, M.F. Loss Minimization of Induction Motors in a Transient Regime. Electr. Power Components Syst. 2020, 48, 969–988. [Google Scholar] [CrossRef]

- Nesri, M.; Nounou, K.; Marouani, K.; Houari, A.; Benkhoris, M.F. Efficiency improvement of a vector-controlled dual star induction machine drive system. Electr. Eng. 2020, 102, 939–952. [Google Scholar] [CrossRef]

- Tutaev, G.; Bobrov, M.; Artamonov, V.; Dubov, N. Evaluation strategy of energy efficiency doubly-fed induction motor drive control algorithms. J. Adv. Res. Dyn. Control. Syst. 2020, 12, 72–77. [Google Scholar]

- Jadeja, R.; Chaturvedi, H.; Polkowski, Z.; Verma, M.; Makwana, J. Flux Optimization of DTC Based Induction Motor Drive Using Recurrent Neural Network; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 605, pp. 330–338. [Google Scholar]

- Ho, S.; Brandstetter, P.; Dinh, C.; Tran, T.; Nguyen, M.; Dinh, B. On-Line Efficiency-Optimization Control of Induction Motor Drives Using Particle Swarm Optimization Algorithm; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 554, pp. 261–271. [Google Scholar]

- Latchoomun, L.; Gokhool, C.; King, R.A.; Busawon, K.; Barbot, J. Efficiency of VFD Coupled Induction Motors Operating in the Scalar Mode with Different Types of Loads; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2019; Volume 561, pp. 45–59. [Google Scholar]

- Houdji, E.T.; Tchaya, G.B.; Deli, K.; Kayem, G.J.; Kamta, M.; Djalo, H.; Djongyang, N. Improvement of the granularity of flour and energy saving by speed control of the induction motor of the grinder for a small-scale production of corn flour. Energy Effic. 2022, 15, 1–16. [Google Scholar]

- Lazek, T.; Pazdera, I.; Toman, M. Comparison and simulation of two loss minimization algorithms for field-oriented control of induction motor. In Proceedings of the IEEE 20th International Power Electronics and Motion Control Conference, Brasov, Romania, 25–28 September 2022; pp. 216–222. [Google Scholar]

- Devi, M.; Naik, R. Application of sensor less sliding mode observer in control of induction motor drive. In Proceedings of the IEEE 2nd International Conference on Sustainable Energy and Future Electric Transportation, Hyderabad, India, 4–6 August 2022. [Google Scholar]

- Zhang, J.; Li, H.; Li, Z.; Zhang, Z. Predictive power factor control of induction motor drives. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 22–24 June 2022; pp. 106–111. [Google Scholar]

- Pant, K.; Rajeevan, P. A speed range extension scheme for induction motor drive with open-end stator windings with maximum torque per ampere control. In Proceedings of the IEEE International Conference on Power Electronics, Smart Grid, and Renewable Energy, Trivandrum, India, 2–5 January 2022. [Google Scholar]

- Golsorkhi, M.S.; Binandeh, H.; Savaghebi, M. Online Efficiency Optimization and Speed Sensorless Control of Single-Phase Induction Motors. Appl. Sci. 2021, 11, 8863. [Google Scholar] [CrossRef]

- Inkov, Y.M.; Kosmodamianskiy, A.S.; Pugachev, A.A.; Morozov, S.V. Efficiency Increasing of Traction Electric Drives with Induction Motors and Vector Control System. Russ. Electr. Eng. 2021, 92, 476–480. [Google Scholar] [CrossRef]

- Iegorov, O.; Iegorova, O.; Potryvaieva, N.; Zaluzhna, H. The traction induction motor magnetic circuit saturation influence on the variable electric drive energy efficiency. In Proceedings of the 20th IEEE International Conference on Modern Electrical and Energy Systems, Kremenchuk, Ukraine, 21–24 September 2021. [Google Scholar]

- Behera, P.; Babu, N.; Senthilkumar, S. A New Energy-Saving Technique for Multiple-Induction Motor-Based Drive Heads at Mines under Light-Load Conditions; Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2021; Volume 700, pp. 1847–1857. [Google Scholar]

- Pal, A.; Das, S. Search controller-based online efficiency optimisation strategy for induction motor drives using modified adaptive quadratic interpolation. IET Power Electron. 2020, 13, 4282–4290. [Google Scholar] [CrossRef]

- Pavel, K.; Jiri, L.; Jan, B. Optimum flux search control on induction motor drive with predictive torque control. In Proceedings of the 21st International Scientific Conference on Electric Power Engineering, Prague, Czech Republic, 19–21 October 2020. [Google Scholar]

- Raptis, D.; Karlis, A.; Kladas, A. Optimized efficiency predictive controller for induction motor drives in electric ships. In Proceedings of the International Conference on Electrical Machines, Gothenburg, Sweden, 23–26 August 2020; pp. 2245–2250. [Google Scholar]

- Sharma, A.; Tiwari, S.; Singh, B. Intelligent speed estimation in induction motor drive control using feed—Forward neural network assisted model reference adaptive system. In Proceedings of the IEEE Students’ Conference on Engineering and Systems, Prayagraj, India, 10–12 July 2020. [Google Scholar]

- Caruso, M.; Di Tommaso, A.; Miceli, R.; Spataro, C.; Viola, F. Experimental investigation on high-efficiency control algorithms for three-phase induction motors. In Proceedings of the 24th IMEKO TC4 International Symposium and 22nd International Workshop on ADC and DAC Modelling and Testing, Palermo, Italy, 14–16 September 2020; pp. 479–484. [Google Scholar]

- Goh, W.; Idris, N.; Nordin, N.; Jidin, A. High-efficiency flux reference of direct torque controlled induction machine. In Proceedings of the IEEE Conference on Energy Conversion, Yogyakarta, Indonesia, 16–17 October 2019; pp. 126–131. [Google Scholar]

- Ammar, A.; Ameid, T.; Azzoug, Y.; Kheldoun, A.; Metidji, B. Efficiency improvement of robust-direct torque control for an induction motor drive. In Proceedings of the 4th International Conference on Power Electronics and their Applications, Elazig, Turkey, 25–27 September 2019. [Google Scholar]

- Gong, F.; Yu, H.; Liu, X. Active disturbance rejection speed control for induction motor drive with efficiency optimization. In Proceedings of the Chinese Automation Congress, Xi’an, China, 30 November–2 December 2018; pp. 2693–2698. [Google Scholar]

- Shukla, N.; Srivastava, R. Performance evaluation of three phase induction motor using flux search control and fuzzy controller. J. Adv. Res. Dyn. Control. Syst. 2019, 11, 1310–1318. [Google Scholar]

- Bobrov, M. Adjustable speed electric drive based on double-FEDinduction motor supplied by two power converters. J. Adv. Res. Dyn. Control. Syst. 2019, 11, 681–688. [Google Scholar]

- Rai, K.; Seksena, S.B.L.; Thakur, A. A Golden Section Search Algorithm Based Loss Minimization for Induction Motor Drive. Int. J. Electr. Eng. Inform. 2019, 11, 144–160. [Google Scholar] [CrossRef]

- Selcuk, S. Predictive maintenance, its implementation and latest trends. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2017, 231, 1670–1679. [Google Scholar] [CrossRef]

- Ayyappan, G.; Nikhil, N.; Raja, R.; Pandi, V.; Angel, T.; Babu, R. Electrical motor maintenance techniques and life cycle assessment—A review with case studies. In Proceedings of the 2019 2nd International Conference on Power and Embedded Drive Control, Chennai, India, 21–23 August 2019; pp. 167–172. [Google Scholar]

- Li, D.Z.; Wang, W.; Ismail, F. An Intelligent Harmonic Synthesis Technique for Air-Gap Eccentricity Fault Diagnosis in Induction Motors. Chin. J. Mech. Eng. 2017, 30, 1296–1304. [Google Scholar] [CrossRef]

- Singh, G.; Kumar, T.A.; Naikan, V. Efficiency monitoring as a strategy for cost effective maintenance of induction motors for minimizing carbon emission and energy consumption. Reliab. Eng. Syst. Saf. 2019, 184, 193–201. [Google Scholar] [CrossRef]

- Melnykov, V. The correction of the operation modes for frequency-controlled induction motor with scalar control under stator windings damage appearance. In Proceedings of the 20th IEEE International Conference on Modern Electrical and Energy Systems, Kremenchuk, Ukraine, 21–24 September 2021. [Google Scholar]

- Mugalimov, R.G.; Mugalimova, A.R.; Zakirova, R.A. Upgrading of induction motors with energy efficiency enhancement at the electrical repair shops and sites of the running industrial companies. IOP Conf. Ser. Mater. Sci. Eng. 2020, 966, 012099. [Google Scholar] [CrossRef]

- Karandaev, A.S.; Gasiyarov, V.R.; Radionov, A.A.; Loginov, B.M. Development of Digital Models of Interconnected Electrical Profiles for Rolling–Drawing Wire Mills. Machines 2021, 9, 54. [Google Scholar] [CrossRef]

- Svensson, A.; Paramonova, S. An analytical model for identifying and addressing energy efficiency improvement opportunities in industrial production systems—Model development and testing experiences from Sweden. J. Clean. Prod. 2017, 142, 2407–2422. [Google Scholar] [CrossRef]

- Golik, V.; North-Caucasian State Technological University; Komashchenko, V.; Morkun, V.; Morkun, N.; Hryshchenko, S. Gubkin Russian State University of Oil and Gas. Kryvyi Rih National University Energy Saving in Mining Production. Sci. Innov. 2018, 14, 29–39. [Google Scholar] [CrossRef]

- Wirtz, A.; Meißner, M.; Wiederkehr, P.; Biermann, D.; Myrzik, J. Evaluation of cutting processes using geometric physically-based process simulations in view of the electric power consumption of machine tools. Procedia CIRP 2019, 79, 602–607. [Google Scholar] [CrossRef]

- Babanova, I. Fundamental Approaches and requirements to assessing the effectiveness of adopting submersible electric plunger pumps for use on low-flowrate oil and gas wells. In Proceedings of the International Multi-Conference on Industrial Engineering and Modern Technologies, Vladivostok, Russia, 6–9 October 2020; p. 20256313. [Google Scholar]

- Uimonen, J. Energy savings in paper machine vacuum system—How to utilize modern vacuum and nip dewatering technology. Q. J. Indian Pulp Pap. Tech. Assoc. 2017, 29, 67–74. [Google Scholar]

- Sihag, N.; Sangwan, K.S.; Pundir, S. Development of a Structured Algorithm to Identify the Status of a Machine Tool to Improve Energy and Time Efficiencies. Procedia CIRP 2018, 69, 294–299. [Google Scholar] [CrossRef]

- Semenov, A.; Egorov, A.; Khubieva, V. Assessment of energy efficiency of electric drives of technological units at mining enterprises by mathematical modeling method. In Proceedings of the International Conference on Industrial Engineering, Applications and Manufacturing, Sochi, Russia, 25–29 March 2019; p. 18779341. [Google Scholar]

- Shang, Z.; Gao, D.; Jiang, Z.; Lu, Y. Towards less energy intensive heavy-duty machine tools: Power consumption characteristics and energy-saving strategies. Energy 2019, 178, 263–276. [Google Scholar] [CrossRef]

- Adenuga, O.T.; Mpofu, K.; Ramatsetse, B.I. Exploring energy efficiency prediction method for Industry 4.0: A reconfigurable vibrating screen case study. Procedia Manuf. 2020, 51, 243–250. [Google Scholar] [CrossRef]

- Denkena, B.; Abele, E.; Brecher, C.; Dittrich, M.-A.; Kara, S.; Mori, M. Energy efficient machine tools. CIRP Ann. 2020, 69, 646–667. [Google Scholar] [CrossRef]

- Bold, S.; Dolgirev, J.; Urschel, S. Resource and energy efficient synchronous reluctance machine for small power applications. In Proceedings of the 21st International Conference on Electrical Machines and Systems, Jeju, Republic of Korea, 7–10 October 2018; pp. 582–587. [Google Scholar]

- Lamb, J.; Godbole, N. Smart energy efficiency for a sustainable world. In Proceedings of the IEEE 10th Annual Ubiquitous Computing, Electronics and Mobile Communication Conference, New York, NY, USA, 10–12 October 2019; pp. 855–861. [Google Scholar]

- Manfren, M.; Nastasi, B.; Groppi, D.; Garcia, D.A. Open data and energy analytics—An analysis of essential information for energy system planning, design and operation. Energy 2020, 213, 118803. [Google Scholar] [CrossRef]

- Nagaveni, P.; Saravanakuma, V.; Amudha, D.; Prasanna, N.; Ramkumar, D.S.; Nivetha, M.; Emayavaramban, D. Power Quality Audit- An Experience in An Leading Engineering Industry. J. Adv. Res. Dyn. Control. Syst. 2019, 11, 1075–1085. [Google Scholar] [CrossRef]

- Uyulan, C.; Gokasan, M.; Bogosyan, S. Re-adhesion control strategy based on the optimal slip velocity seeking method. J. Mod. Transp. 2018, 26, 36–48. [Google Scholar] [CrossRef]

- Stopa, M.M.; Resende, M.R.; Luiz, A.-S.A.; Justino, J.C.G.; Rodrigues, G.G.; Filho, B.J.C. A Simple Torque Estimator for In-Service Efficiency Determination of Inverter-Fed Induction Motors. IEEE Trans. Ind. Appl. 2020, 56, 2087–2096. [Google Scholar] [CrossRef]

- Aarniovuori, L.; Kärkkäinen, H.; Niemelä, M.; Cai, K.; Pyrhönen, J.; Cao, W. Experimental investigation of the losses and efficiency of 75 kW induction motor drive system. In Proceedings of the IECON Proceedings, Lisbon, Portugal, 14–17 October 2019; pp. 1052–1058. [Google Scholar]

- Aazmi, M.A.; Fahmi, M.I.; Aihsan, M.Z.; Liew, H.F.; Saifizi, M. A review on VFD control and energy management system of induction motor for electric vehicle. In Proceedings of the 19th IEEE Student Conference on Research and Development: Sustainable Engineering and Technology towards Industry Revolution, Kota Kinabalu, Malaysia, 23–25 November 2021; pp. 36–41. [Google Scholar]

- Abdelati, R.; Mimouni, M.F. Loss minimization of induction machines during torque transients. J. Syst. Control. Eng. 2020, 234, 314–329. [Google Scholar] [CrossRef]

- Lozanov, Y.; Tzvetkova, S.; Petleshkov, A. Study of the effectiveness of a variable frequency drive of an induction motor. In Proceedings of the 11th Electrical Engineering Faculty Conference, Varna, Bulgaria, 11–14 September 2019. [Google Scholar]

- Popov, A.; Popova, V.; Gulyaev, I.; del Blanco, F.B. Power-efficient control of an induction motor: Methods of increasing its dynamics. Russ. Electr. Eng. 2019, 90, 479–484. [Google Scholar] [CrossRef]

- Kellner, J.; Prazenica, M. Research into the possibility of improving the efficiency and torque ripple of a drive with a five-phase induction motor by changing the control in a fault state. In Proceedings of the International Symposium on Power Electronics, Electrical Drives, Automation and Motion, Sorrento, Italy, 22–24 June 2022; pp. 663–670. [Google Scholar]

| No. | Lead Author | Country | Type | Scientometric Indicator | Citations |

|---|---|---|---|---|---|

| 1 | Gavrila H. | Romania | a | SJR 0.334 | 14 |

| 2 | de Macedo P. | Brazil | a | IF 10.696 | 12 |

| 3 | Tabora J. | Brazil | a | IF 3.252 | 8 |

| 4 | Gómez J. | Cuba | a | IF 3.252 | 7 |

| 5 | Meshcheryakov V. | Russia | r | SJR 0.237 | 6 |

| 6 | Iegorov O. | Ukraine | r | - | 5 |

| 7 | Aarniovuori L. | Finland | r | - | 5 |

| 8 | Foti S. | Italy | r | - | 4 |

| 9 | Dems M. | Poland | a | IF 8.162 | 4 |

| 10 | Donolo P. | Argentina | a | SJR 0.33 | 4 |

| 11 | Goun V. | Russia | a | SJR 0.346 | 4 |

| 12 | Yahya Y. | Malaysia | a | SJR 0.267 | 3 |

| 13 | Subramani C. | India | a | IF 2.639 | 3 |

| 14 | Khoury G. | France | r | - | 2 |

| 15 | Polnik B. | Poland | a | SJR 0.344 | 2 |

| 16 | Hristova M. | Bulgaria | r | - | 1 |

| 17 | Tamboli P. | India | r | - | 1 |

| 18 | Dominic A. | Germany | r | - | 1 |

| 19 | Shukla N. | India | a | SJR 0.803 | 1 |

| 20 | Tytyuk V. | Ukraine | r | - | 0 |

| 21 | Hristova M. | Bulgaria | r | - | 0 |

| 22 | Anonymous | Switzerland | b | - | 0 |

| 23 | Agrawal S. | United Kingdom | a | SJR 0.104 | 0 |

| 24 | Goun V. | Russia | r | - | 0 |

| 25 | Susdorf V. | Russia | r | - | 0 |

| 26 | Sun X. | China | r | - | 0 |

| 27 | Mao H. | USA | r | - | 0 |

| 28 | Iegorov O. | Ukraine | r | - | 0 |

| No. | Subject Area/Core Contribution |

|---|---|

| 1 | Trends in energy-efficient induction motors [9] |

| 2 | An approach for the replacement of inefficient induction motors [11] |

| 3 | Higher harmonics in induction motors [14] |

| 4 | A techno-economic evaluation of high-efficiency induction motors [10] |

| 5 | Connection diagram of the stator and rotor winding of a wound-rotor induction motor with variable rotational frequency of the rotor [23] |

| 6 | Improved stator winding to reduce the degree of field ellipticity in the air gap [24] |

| 7 | Analytical determination and separation of the losses of a four-pole cage-rotor induction motor in the IE3 energy class [25] |

| 8 | Application of “open end” windings in directly grid-connected constant- speed induction drives [20] |

| 9 | Design improvements of induction motors to increase efficiency when operating at reduced frequencies [18] |

| 10 | Difficulties in energy-efficient induction motors [13] |

| 11 | Optimization of the parameters of energy-efficient control parameters of an induction motor [21] |

| 12 | Influence of the lamination thickness [16] |

| 13 | Motor design improvements using software [17] |

| 14 | Energy-efficient control and losses in steel [15] |

| 15 | Energy recuperation at mining sites [26] |

| 16 | Constant losses in induction motors and reduction of these losses [5] |

| 17 | Analysis of induction motors in industry [7] |

| 18 | Improvement of the rotor magnetic flux of an induction machine [19] |

| 19 | A hybrid algorithm for increasing increase the efficiency of induction motors at loads below the rated ones [27] |

| 20 | Modeling the magnetomotive force of an induction motor with asymmetrical windings [4] |

| 21 | Variable losses in induction motors and reduction of those losses [6] |

| 22 | Standards for motor efficiency classes [8] |

| 23 | Energy-efficient motors [12] |

| 24 | Improvement in the parameters of an induction motor for transient modes [22] |

| 25 | Energy-efficient serial control of drives [28] |

| 26 | An optimized induction motor with variable number of active poles [29] |

| 27 | Dynamic number of poles for energy-efficient induction motors [30] |

| 28 | Optimization of winding parameters [31] |

| No. | Lead Author | Country | Type | Scientometric Indicator | Citations |

|---|---|---|---|---|---|

| 1 | Amerise A. | Italy | a | IF 4.079 | 25 |

| 2 | Mathaba T. | South Africa | a | IF 3.134 | 17 |

| 3 | Kopylov K. | Russia | a | SJR 0.415 | 16 |

| 4 | Bruno A. | Italy | a | IF 4.079 | 5 |

| 5 | Solodkiy E. | Russia | r | - | 5 |

| 6 | Baykov D. | Russia | a | SJR 0.343 | 5 |

| 7 | Khoury G. | France | a | IF 0.808 | 4 |

| 8 | Rozhkov V. | Russia | r | - | 4 |

| 9 | Linenko A. | Russia | a | SJR 0.296 | 3 |

| 10 | Mamizadeh A. | Turkey | r | - | 3 |

| 11 | Patel P. | India | r | - | 3 |

| 12 | Polnik B. | Poland | a | SJR 0.344 | 2 |

| 13 | Davydov V. | Russia | r | SJR 0.249 | 2 |

| 14 | Sever F. | USA | a | SJR 0.165 | 1 |

| 15 | Jung C. | Brazil | a | IF 8.162 | 1 |

| 16 | Voytenko V. | Ukraine | r | - | 1 |

| 17 | Mecke R. | Germany | a | SJR 0.148 | 1 |

| 18 | Parreiras T. | Brazil | r | - | 1 |

| 19 | Mugalimov G. | Russia | r | - | 1 |

| 20 | Patel P. | India | a | SJR 0.148 | 1 |

| 21 | Bhardwaj S. | India | a | IF 1.877 | 1 |

| 22 | Susdorf V. | Russia | r | - | 0 |

| 23 | Usha S. | India | a | SJR 0.107 | 0 |

| 24 | Shukla N. | India | a | SJR 0.102 | 0 |

| 25 | Simakov G. | Russia | r | - | 0 |

| 26 | Khan M. | Bangladesh | r | - | 0 |

| 27 | Spahiu A. | Albania | r | - | 0 |

| 28 | Syed W. | India | r | - | 0 |

| 29 | Haq S. | Bangladesh | r | - | 0 |

| 30 | Dubey M. | India | r | - | 0 |

| 31 | Patel P. | India | a | SJR 0.421 | 0 |

| 32 | Verucchi C. | Argentina | r | SJR 0.202 | 0 |

| 33 | Mecke R. | Germany | a | SJR 0.148 | 0 |

| 34 | Han Z. | China | r | SJR 0.161 | 0 |

| No. | Subject Area/Core Contribution |

|---|---|

| 1 | Reduction in losses in the auxiliary converter of open-end winding induction motors with dual power supply [45] |

| 2 | Efficient operating modes of descending belt conveyors [32] |

| 3 | Modernization and automation of drives in a mining plant [42] |

| 4 | An online algorithm for minimizing losses through the estimation of the optimum magnetization flux of an induction motor [37] |

| 5 | Optimum balancing of a pump unit based on rotational speed and torque [46] |

| 6 | Simulation modeling of a “matrix” frequency converter [47] |

| 7 | Scalar drive control and losses in steel [33] |

| 8 | Improving the energy efficiency of the induction motor drive of a crane via energy recuperation [48] |

| 9 | Ways to improve the energy efficiency of a separator [38] |

| 10 | An adapted induction motor monitoring system [40] |

| 11 | Energy recuperation under deceleration of a torque-controlled induction motor drive [49] |

| 12 | Energy recuperation in mining sites [26] |

| 13 | Improving the energy efficiency of a drive using a neural network-based controller [35] |

| 14 | Improved belt transmissions of drives [41] |

| 15 | Adaptive loss control of induction drives [50] |

| 16 | Comparative energy analysis of multi-motor induction motor drives [51] |

| 17 | Multistage inverters for energy-efficient induction motor drives [52] |

| 18 | Improved recuperative braking of induction motor drives in overhead cranes [53] |

| 19 | Individual instead of centralized power factor compensation [54] |

| 20 | Kinetic energy utilization during braking of industrial induction motor drives by means of two-way converters [55] |

| 21 | Improved transistors for reduction of the harmonic distortions of the inverter and improvement of the efficiency and power factor [56] |

| 22 | Energy-efficient serial control of drives [28] |

| 23 | Improved start-up mode by means of a programmable logic controller [34] |

| 24 | Artificial intelligence controllers for induction motor drives [36] |

| 25 | Vibration exciter control algorithm [39] |

| 26 | Frequency control for efficiency improvement [43] |

| 27 | Reduction of the electricity consumption of a pump unit [44] |

| 28 | Filtering of the harmonics and power factor improvement of an induction motor drive with a fuzzy logic controller [57] |

| 29 | Selection of an energy-efficient method for pulse-width modulation of a multistage inverter [58] |

| 30 | Avoiding DC-DC conversion in the control of an induction motor electric drive for microclimate conditioning via a photovoltaic power source [59] |

| 31 | Induction motor drive control unit with inverter recuperative braking capability [60] |

| 32 | Efficiency assessment of drives with shaft misalignment and optimum selection of flexible couplings [61] |

| 33 | Overview and analysis of frequency converters and energy savings during their use [62] |

| 34 | Study on the efficiency of frequency inverters and additional losses in the induction motor from harmonic distortions at nominal frequency of the supply voltage [63] |

| No. | Lead Author | Country | Type | Scientometric Indicator | Citations |

|---|---|---|---|---|---|

| 1 | Dere C. | Turkey | a | IF 11.072 | 33 |

| 2 | Li L. | China | a | SJR 2.095 | 29 |

| 3 | Zarchi H. | Iran | a | IF 1.737 | 17 |

| 4 | Nel A. | South Africa | a | IF 11.072 | 13 |

| 5 | Shi Y. | China | a | IF 2.964 | 10 |

| 6 | Almani M. | Pakistan | a | IF 3.476 | 8 |

| 7 | Ekong U. | Japan | a | SJR 0.589 | 8 |

| 8 | Pal A. | India | a | IF 2.639 | 7 |

| 9 | Ahmed A. | Egypt | a | IF 4.152 | 5 |

| 10 | Djagarov N. | Bulgaria | r | - | 5 |

| 11 | Sreejeth M. | India | a | IF 0.939 | 5 |

| 12 | Urwashi | India | r | - | 5 |

| 13 | Choudhary P. | India | a | SJR 0.489 | 4 |

| 14 | Semenov A. | Russia | r | - | 4 |

| 15 | Frigerio N. | Italy | a | IF 9.498 | 3 |

| 16 | Biswal A. | India | r | - | 3 |

| 17 | Ammar A. | Algeria | r | - | 3 |

| 18 | Pugachev A. | Russia | r | - | 3 |

| 19 | Sequeira M. | Australia | a | SJR 0.533 | 3 |

| 20 | Tolochko O. | Ukraine | r | - | 2 |

| 21 | Baranidharan M. | India | a | IF 3.252 | 2 |

| 22 | Graciola C. | Brazil | a | SJR 0.375 | 2 |

| 23 | Balasubramanian G. | India | r | - | 2 |

| 24 | Bizhani H. | Iran | r | - | 2 |

| 25 | Eftekhari S. | Iran | r | SJR 0.329 | 2 |

| 26 | Rai K. | India | a | SJR 0.148 | 2 |

| 27 | Jeyashanthi J. | India | a | SJR 0.206 | 2 |

| 28 | Xiao H. | China | a | IF 3.134 | 1 |

| 29 | Seizovic A. | Serbia | r | - | 1 |

| 30 | Abdelati R. | Tunisia | a | IF 1.276 | 1 |

| 31 | Nesri M. | Algeria | a | IF 1.630 | 1 |

| 32 | Tutaev G. | Russia | a | SJR 0.129 | 1 |

| 33 | Jadeja R. | India | a | SJR 0.148 | 1 |

| 34 | Ho S. | Vietnam | a | SJR 0.148 | 1 |

| 35 | Latchoomun L. | Mauritius | a | SJR 0.148 | 1 |

| 36 | Shvartsburg L. | Russia | a | SJR 0.190 | 0 |

| 37 | Goun V. | Russia | r | - | 0 |

| 38 | Mosaddegh H. | Iran | a | IF 1.737 | 0 |

| 39 | Rachev S. | Bulgaria | r | - | 0 |

| 40 | Krasteva A. | Bulgaria | r | - | 0 |

| 41 | Tchoffo E. | Cameroon | a | IF 3.134 | 0 |

| 42 | Lažek T. | Czech Republic | r | - | 0 |

| 43 | Devi M. | India | r | - | 0 |

| 44 | Zhang J. | China | r | - | 0 |

| 45 | Pant K. | India | r | - | 0 |

| 46 | Golsorkhi M. | Denmark | a | IF 2.838 | 0 |

| 47 | Inkov Y. | Russia | a | SJR 0.343 | 0 |

| 48 | Iegorov O. | Ukraine | r | - | 0 |

| 49 | Behera P. | India | a | SJR 0.148 | 0 |

| 50 | Pal A. | India | a | IF 2.112 | 0 |

| 51 | Karlovsky P. | Czech Republic | r | - | 0 |

| 52 | Raptis S. | Greece | r | - | 0 |

| 53 | Sharma A. | India | r | - | 0 |

| 54 | Caruso M. | Italy | r | - | 0 |

| 55 | Goh W. | Malaysia | r | - | 0 |

| 56 | Ammar A. | Algeria | r | - | 0 |

| 57 | Gong F. | China | r | - | 0 |

| 58 | Shukla N. | India | a | SJR 0.129 | 0 |

| 59 | Bobrov M. | Russia | a | SJR 0.129 | 0 |

| 60 | Rai K. | India | a | SJR 0.233 | 0 |

| No. | Subject Area/Core Contribution |

|---|---|

| 1 | Load optimization of pump units [69] |

| 2 | Energy saving through balancing the load on hydraulic presses [64] |

| 3 | Real-time indirect control method to ensure minimum losses per unit torque [77] |

| 4 | Speed control in ventilation systems of medium voltage [66] |

| 5 | Evaluation of electricity consumption of pneumatic systems [65] |

| 6 | Improved starting and operating modes of induction drives [67] |

| 7 | Improvement in the efficiency and mechanical response at high rotational speed of an inverter-controlled induction motor through magnetic field weakening [78] |

| 8 | Development of a strategy to increase the energy efficiency of an induction motor drive with sensorless speed control [79] |

| 9 | Frequency control for composite pump units [80] |

| 10 | A new method for adaptive vector control of an induction motor drive using a modal stabilizer [81] |

| 11 | Increasing the efficiency of an induction motor drive through optimization of the stator current and reduction in the rotor magnetic flux [82] |

| 12 | Loss minimization through Grey Wolf optimization of vector-controlled induction motor drive [83] |

| 13 | Energy-efficient modes of operation of induction motor drives in the cement industry [72] |

| 14 | Use of frequency converters in the mining industry [84] |

| 15 | Modeling the start-up process of metal-working machinery [73] |

| 16 | A developed model of an induction motor finding application in vector control of drives [85] |

| 17 | Implementation of a method to increase energy efficiency through slip control [86] |

| 18 | Scalar control of an induction motor with loss minimization and consideration of the skin effect and ferromagnetic saturation [87] |

| 19 | Variable-speed drive with the ability to measure angular velocity and maintain torque within a preset range [88] |

| 20 | Vector speed control and loss minimization in copper and steel [75] |

| 21 | Methodology for the rotational speed regulation of pump units in parallel [89] |

| 22 | Increasing energy efficiency through scalar control of an induction motor [90] |

| 23 | Ventilation system performance regulation via frequency converter [91] |

| 24 | Comparative analysis of loss minimization methodologies for vector-controlled induction motors [92] |

| 25 | Reducing the parameter correlation of a predictive model for control of the torque and magnetic flux of induction motor drives [93] |

| 26 | Comparative assessment of adaptive algorithms for stochastic optimization and loss minimization in steel [94] |

| 27 | Using the golden section method to optimize the magnetic flux level in the air gap [95] |

| 28 | Adjusting the phase of the supply voltage of a centrifugal fan with constant speed [71] |

| 29 | Energy-efficient control of induction motor drives through an iterative optimization algorithm [96] |

| 30 | Reducing transient losses of induction motors [97] |

| 31 | Minimizing the magnetization energy through a vector-control approach for a system of electric drives [98] |

| 32 | Methods for evaluation of control algorithms for inverter-fed induction motor drives [99] |

| 33 | Magnetic flux optimization through cyclic neural networks [100] |

| 34 | Operating mode control of induction motor drives through online energy efficiency optimization [101] |

| 35 | Study of the energy efficiency of induction motors with scalar frequency control following a change in the type of resistive torque [102] |

| 36 | Compensation of the reactive power of induction drives of machine tools via phase shifting [74] |

| 37 | Improved induction motor parameters for transients [22] |

| 38 | Methodology for online energy efficiency control [68] |

| 39 | Increasing the energy efficiency of a ventilation system through frequency control [70] |

| 40 | Weather factors and energy efficiency of water supply systems [76] |

| 41 | Speed regulation of a mill with induction motor electric drive [103] |

| 42 | Algorithms for the magnetic field optimization of an induction motor [104] |

| 43 | Sensorless slip monitoring of induction motors [105] |

| 44 | Predictive power factor control method [106] |

| 45 | Extending the frequency range of a dedicated induction motor drive controller [107] |

| 46 | Online energy efficiency optimization and sensorless control of induction motors [108] |

| 47 | Loss reduction via modeling the dependence of rotor magnetic flux on stator current [109] |

| 48 | Analysis of nonlinear magnetization characteristics of induction motors to improve their operating modes [110] |

| 49 | Energy savings and improved power factor (cos φ) through voltage regulators on multi-motor induction drives at low loads [111] |

| 50 | Online energy efficiency optimization via a speed controller and quadratic interpolation [112] |

| 51 | Optimum stator magnetic flux control [113] |

| 52 | Optimized-efficiency predictive controller for induction motor drives [114] |

| 53 | Speed control of an induction motor drive through an intelligent adaptive system and neural network [115] |

| 54 | Experimental investigation on the efficiency improvement of induction motor drives through real-time loss minimization algorithms [116] |

| 55 | Optimum stator magnetic flux for energy-efficient control at low torques [117] |

| 56 | Improving energy efficiency through an improved method for sustainable direct torque control [118] |

| 57 | Strategy for improved vector control by increasing stability at load drift and reducing the losses of an induction motor drive system [119] |

| 58 | Controllers with fuzzy logic and search algorithms to optimize energy efficiency through control of the magnetic flux in the air gap [120] |

| 59 | Rotor current frequency effect during control with two frequency converters of a wound-rotor induction motor [121] |

| 60 | Loss controller based on golden section search algorithms for optimizing the energy efficiency of induction drives [122] |

| No. | Lead Author | Country | Type | Scientometric Indicator | Citations |

|---|---|---|---|---|---|

| 1 | Selcuk S. | Bosnia and Herzegovina | a | SJR 0.737 | 160 |

| 2 | Singh G. | India | a | IF 7.247 | 18 |

| 3 | Li D. | Canada | a | IF 2.964 | 17 |

| 4 | Ayyappan G. | India | r | - | 7 |

| 5 | Melnykov V. | Ukraine | r | - | 2 |

| 6 | Mugalimov G. | Russia | r | SJR 0.249 | 0 |

| No. | Subject Area/Core Contribution |

|---|---|

| 1 | Current trends in the predictive maintenance of drives [123] |

| 2 | Reducing consumption through energy-efficiency maintenance and monitoring [126] |

| 3 | Improving the energy efficiency of induction motors by diagnosing air gap asymmetry [125] |

| 4 | Electrical motor maintenance and service life assessment [124] |

| 5 | Scalar control in the event of faults in the windings [127] |

| 6 | Improvement in the power factor (cos φ) by rewinding the windings with consideration of the ferroresonance phenomena and the current state of steel during overhaul of induction motors [128] |

| No. | Lead Author | Country | Type | Scientometric Indicator | Citations |

|---|---|---|---|---|---|

| 1 | Svensson A. | Sweden | a | IF 11.072 | 27 |

| 2 | Sihag N. | India | r | SJR 0.639 | 18 |

| 3 | Karandaev A. | Russia | a | IF 2.899 | 6 |

| 4 | Golik V. | Russia | a | SJR 0.211 | 6 |

| 5 | Wirtz A. | Germany | r | SJR 0.639 | 6 |

| 6 | Uimonen J. | Finland | a | SJR 0.110 | 1 |

| 7 | Babanova I. | Russia | r | - | 0 |

| No. | Subject Area/Core Contribution |

|---|---|

| 1 | An analytical model for increasing the energy efficiency of production systems [130] |

| 2 | A structured algorithm for identifying the state of a machine tool [135] |

| 3 | Digital models for changing machine tool settings [129] |

| 4 | Energy saving in the mining industry [131] |

| 5 | Evaluation of the electrical consumption of machine tools [132] |

| 6 | Modernization and energy savings of a vacuum machine [134] |

| 7 | The modernization of induction motor drive units by introducing submersible plunger pumps [133] |

| No. | Lead Author | Country | Type | Scientometric Indicator | Citations |

|---|---|---|---|---|---|

| 1 | Manfren M. | United Kingdom | a | IF 8.857 | 38 |

| 2 | Denkena B. | Germany | a | IF 4.482 | 30 |

| 3 | Shang Z. | China | a | IF 8.857 | 28 |

| 4 | Semenov A. | Russia | r | - | 15 |

| 5 | Nagaveni P. | India | a | SJR 0.129 | 13 |

| 6 | Stopa M. | Brazil | a | IF 4.079 | 10 |

| 7 | Adenuga O. | South Africa | a | - | 6 |

| 8 | Uyulan C. | Turkey | a | SJR 0.588 | 5 |

| 9 | Aarniovuori L. | Finland | r | SJR 0.252 | 3 |

| 10 | Aazmi M. | Malaysia | r | - | 2 |

| 11 | Abdelati R. | Tunisia | a | SJR 0.480 | 2 |

| 12 | Lozanov Y. | Bulgaria | r | - | 2 |

| 13 | Popov A. | Russia | a | SJR 0.343 | 2 |

| 14 | Tamboli P. | India | r | - | 1 |

| 15 | Bold S. | Germany | r | - | 0 |

| 16 | Lamb J. | USA | r | - | 0 |

| 17 | Kellner J. | Slovakia | r | - | 0 |

| No. | Subject Area/Core Contribution |

|---|---|

| 1 | Information assurance of energy systems [142] |

| 2 | Energy-efficient machine tools [139] |

| 3 | Energy-saving strategies for high-power machine tools [137] |

| 4 | Mathematical modeling and efficiency assessment of electric drives [136] |

| 5 | Electric power quality audit [143] |

| 6 | A tool for estimating the efficiency of adjustable drives under real operating conditions [145] |

| 7 | Predicting the energy efficiency of a vibrating screen [138] |

| 8 | Torque control and increased energy recuperation [144] |

| 9 | Laboratory determination of the losses of a 75 kW class IE3 induction motor fed by different serial frequency converters [146] |

| 10 | Comparative analysis of the frequency converters and energy management systems in induction motor drives [147] |

| 11 | Loss minimization algorithm for induction machines during transient torques [148] |

| 12 | Determination of the losses in an induction motor drive when changing angular velocity and torque [149] |

| 13 | Improved controllers for energy-efficient control of motors under dynamic loads [150] |

| 14 | Energy efficiency of electric motors in the manufacturing industry [7] |

| 15 | Replacement of induction motor machines [140] |

| 16 | Smart energy-efficiency solutions [141] |

| 17 | Adaptive control of induction motor drives in emergency modes of operation [151] |

| Scientific Field Number | 1 | 2 | 3 | 4 | 5 |

|---|---|---|---|---|---|

| Total number of citations in the field | 87 | 102 | 192 | 204 | 64 |

| Total number of publications in the field | 28 | 34 | 60 | 6 | 7 |

| Average number of citations per publication | 3.11 | 3.00 | 3.20 | 34.0 | 9.14 |

| Number of citations of the most cited publication | 14 | 25 | 33 | 160 | 27 |

| Sub-field of the most cited publication | Design improvements | Improved frequency converters and inverters | Optimum load distribution | Predictive maintenance | Metalworking |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dinolova, P.; Ruseva, V.; Dinolov, O. Energy Efficiency of Induction Motor Drives: State of the Art, Analysis and Recommendations. Energies 2023, 16, 7136. https://doi.org/10.3390/en16207136

Dinolova P, Ruseva V, Dinolov O. Energy Efficiency of Induction Motor Drives: State of the Art, Analysis and Recommendations. Energies. 2023; 16(20):7136. https://doi.org/10.3390/en16207136

Chicago/Turabian StyleDinolova, Plamena, Vyara Ruseva, and Ognyan Dinolov. 2023. "Energy Efficiency of Induction Motor Drives: State of the Art, Analysis and Recommendations" Energies 16, no. 20: 7136. https://doi.org/10.3390/en16207136

APA StyleDinolova, P., Ruseva, V., & Dinolov, O. (2023). Energy Efficiency of Induction Motor Drives: State of the Art, Analysis and Recommendations. Energies, 16(20), 7136. https://doi.org/10.3390/en16207136