Advanced Power Converters and Learning in Diverse Robotic Innovation: A Review

Abstract

:1. Introduction

- The review discusses the integration of various machine-learning and AI methods, including reinforcement learning, supervised learning, unsupervised learning and Bayesian techniques, showcasing the diverse approaches being used to enhance robotic innovation.

- It explores the use of state-of-the-art energy-harvesting technologies, highlighting the latest developments in solar energy for robotic applications.

- The review discusses supercapacitors as a fast-charging alternative to batteries, emphasizing their structural flexibility and the potential for integrating them into robotic systems.

- The review mentions the potential use of polymer electrolyte membrane fuel cells for higher energy density in large robots like UAVs, presenting hydrogen fuel as a promising and economical option for renewable energy in robotics.

- Emerging synergy between advanced power management and learning integration in robotics.

- Emphasis on energy efficiency through advanced power converters.

- Learning integration enhancing robotic perception, decision-making and autonomy.

2. Advanced Power Converters in Robotics

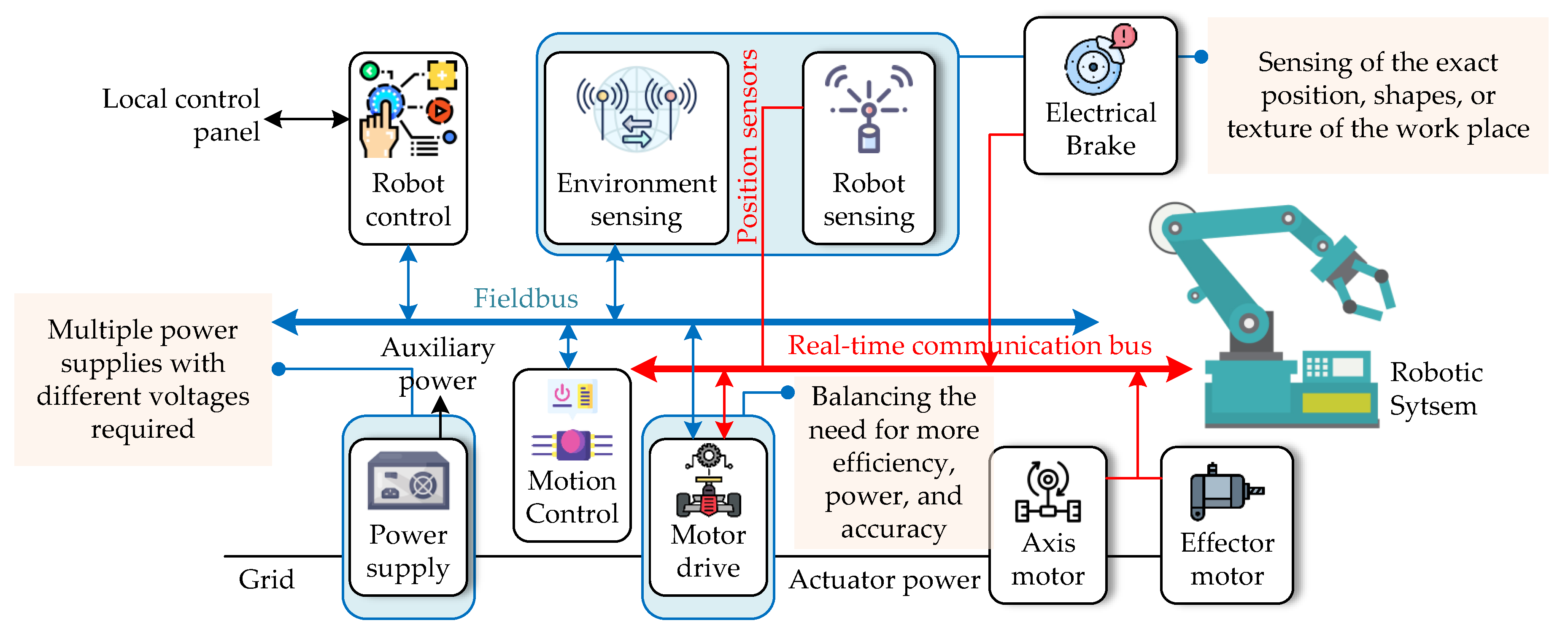

2.1. Role of Power Converters in Robotics

- Voltage Regulation: Robotic systems incorporate components with diverse voltage requirements. Power converters provide efficient voltage regulation, ensuring that sensors, microcontrollers and other components receive the appropriate voltage levels. This not only prevents potential damage due to overvoltage but also maximizes the efficiency of these components [40,42].

- Current Management: Motors and actuators, crucial for robotic motion and manipulation, often require varying current levels [43]. Power converters enable precise current control, allowing dynamic adjustment to match the specific demands of each task. This adaptability results in optimized motor performance and enhanced control accuracy [44].

- Waveform Shaping: Certain robotic components require specific waveform characteristics, such as sinusoidal signals for AC motors. Power converters facilitate waveform shaping, converting DC power to AC with the desired frequency and amplitude, thereby enabling precise control over motor behavior [45,46].

- Energy Efficiency: By minimizing energy losses during conversion and distribution, power converters contribute significantly to overall energy efficiency in robotic systems. Efficient power conversion reduces wasted energy as heat, leading to prolonged operational times and reduced battery replacements [21,40].

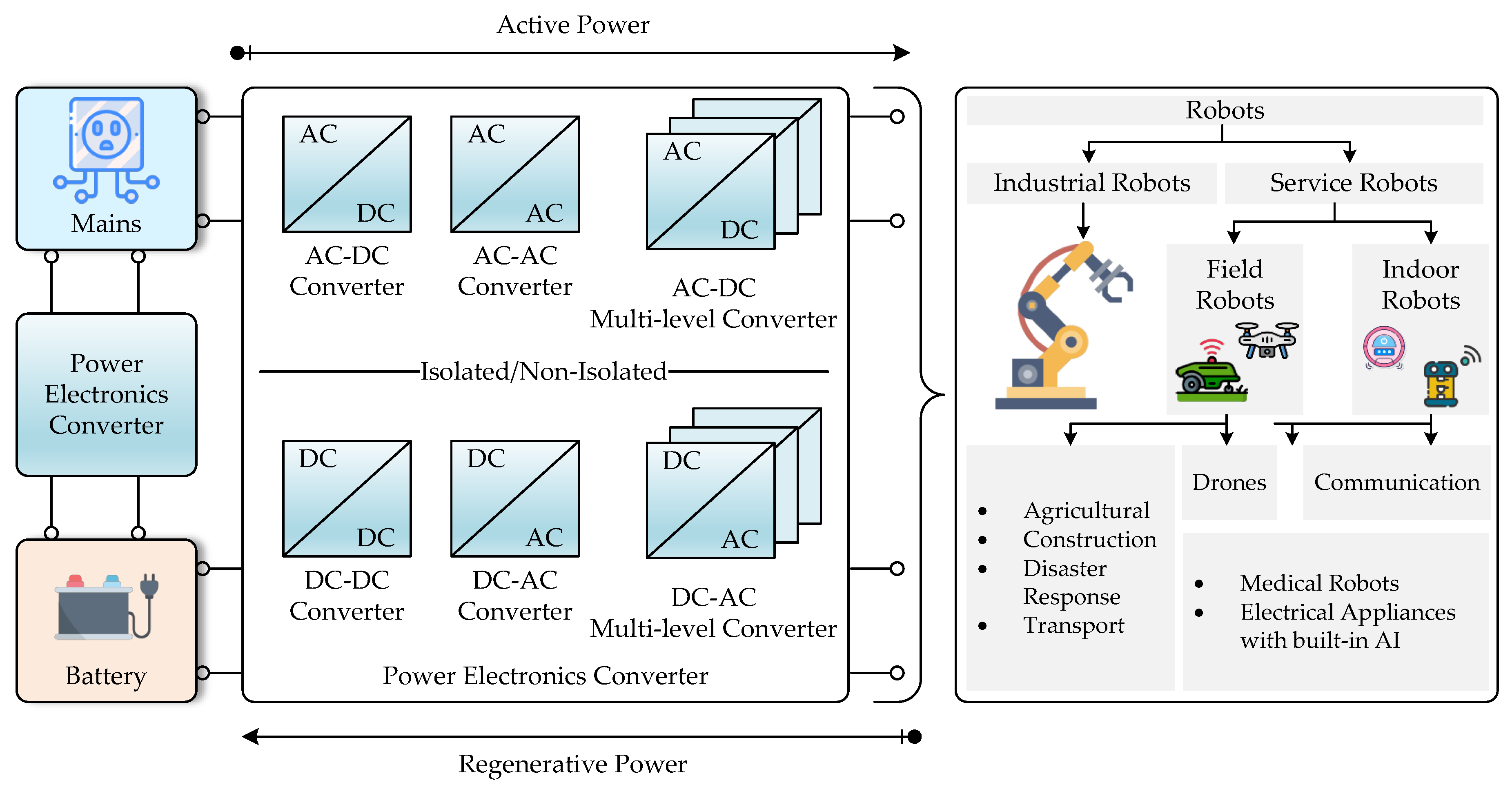

2.2. Types of Power Converters in Robotics

2.2.1. DC–DC Converters

2.2.2. DC–AC Converters

2.2.3. AC–DC Converters

2.2.4. Resonant Converters

2.2.5. Multi-Level Converters

2.2.6. Soft-Switching Converters

2.2.7. Matrix Converters

2.2.8. Dual Active Bridge Converters

2.3. Advancements in Power-Converter Technologies for Robotics

2.3.1. Integration of Wide-Bandgap Semiconductors

2.3.2. Enhanced High-Frequency Operation

| Advancement | Description | Benefits | Applications |

|---|---|---|---|

| GaN Transistors [71,72] | High-efficiency, fast-switching transistors enabling compact power converters. | Reduced power losses, smaller form factors, improved thermal management. | Industrial robots, drones, electric vehicles. |

| SiC Devices [73] | High-temperature, high-power devices for efficient and reliable converters. | Higher power handling, reduced cooling requirements, better performance in harsh environments. | Electric propulsion, extreme environment robotics. |

| Digital Power Management [74,75] | Real-time parameter adjustment for adaptable and efficient converters. | Improved adaptability, energy efficiency, remote monitoring. | Mobile robots, medical robots, automation. |

| Resonant Converter Topologies [76,77,78] | Reduced switching losses, high efficiency, low electromagnetic interference. | Improved efficiency, reduced heat, less EMI. | Renewable energy, wireless charging. |

| Hybrid and Multilevel Converters [79,80] | Combined topologies for efficiency and voltage control. | Enhanced efficiency, reduced distortion, improved voltage control. | Electric grids, robotic vehicles, renewables. |

| Advanced Cooling Techniques [81,82,83] | Innovative cooling for efficient operation in confined spaces. | Improved thermal management, higher power handling, compact designs. | High Performance Computing (HPC) clusters, motor drives, confined spaces. |

| Advanced Control Algorithms [84,85,86] | Precise regulation for changing conditions and loads. | Enhanced accuracy, better response, improved stability. | Prosthetics, haptics, precision control. |

| Wireless Power Transfer [71,87,88] | Wireless charging for convenience and seamless integration. | Convenience, reduced wear, seamless integration. | Mobile robotics, drones, underwater robots. |

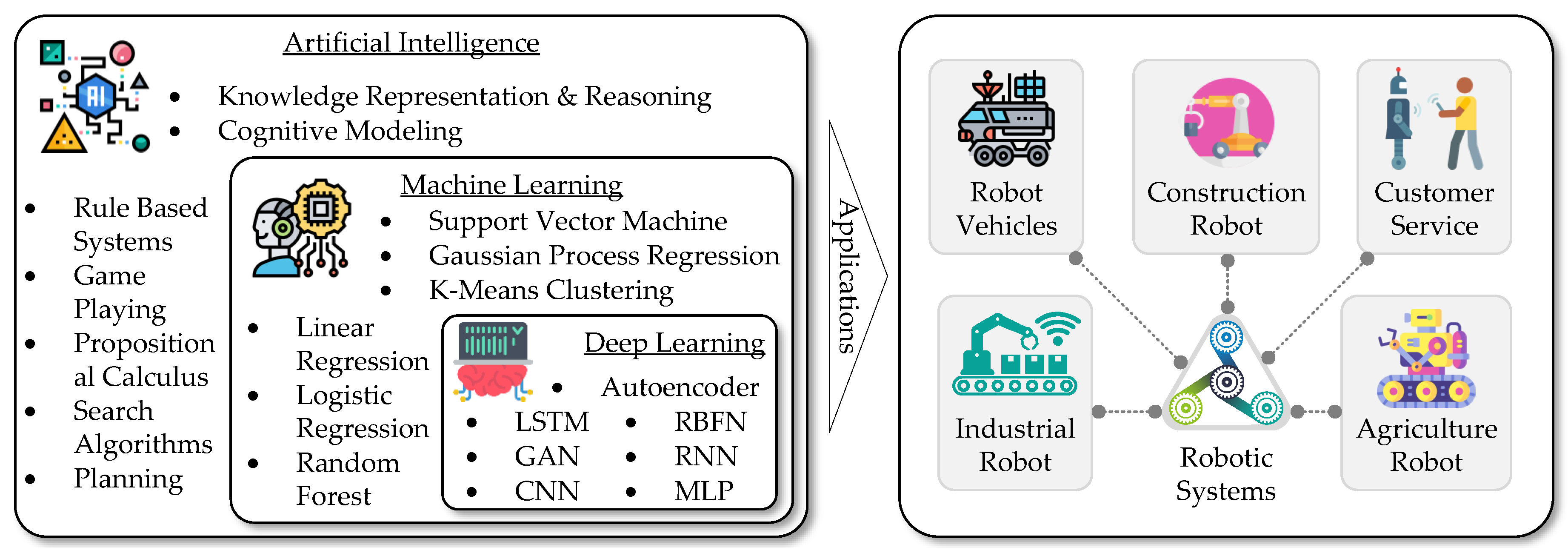

3. Learning Approaches for Robotic Innovation

3.1. Machine Learning and AI Fundamentals in Robotics

3.2. Enhancing Robotic Perception

3.2.1. Object Recognition and Detection

3.2.2. Semantic Segmentation and Scene Understanding

3.2.3. Sensor Fusion for Multi-Modal Perception

3.2.4. Anomaly Detection

3.3. Elevating Decision-Making Processes

4. Energy Harvesting for Robotic Application

4.1. Classification of Robots by Power Supply

4.1.1. Galvanic Contact-Powered Robots

4.1.2. Electromagnetic Wave-Powered Robots

4.1.3. Battery-Powered Robots

4.1.4. Hybrid Systems

4.1.5. Efficiency Considerations

- Energy Efficiency: Galvanic contact power supply is highly efficient, while electromagnetic wave power-transfer methods may have lower efficiency due to energy losses during wireless transmission.

- Mobility vs. Efficiency: Battery-powered robots offer mobility and autonomy but may have limited operational time between recharges or battery replacements. Electromagnetic wave-powered robots provide mobility but often at the expense of energy efficiency.

- Hybrid Approaches: Hybrid systems allow for a balance between mobility and energy efficiency by combining power-supply methods. For example, a drone with a primary battery source can use solar panels for energy harvesting during flight, extending its operational time.

- Application-Specific Considerations: The choice of power supply should align with the specific requirements of the robot’s intended application, considering factors such as mobility, energy demand and operational environment.

5. Technical Advancements Observed

5.1. Integration’s Influence on Robotic Applications

- Manufacturing and Automation: The integration of advanced power converters and learning approaches has revolutionized manufacturing processes [210]. Robots equipped with optimized power management systems can dynamically allocate resources, leading to significant energy savings and streamlined operations. Machine-learning algorithms, on the other hand, empower robots to learn from their interactions with the environment, enhancing their ability to handle intricate assembly tasks with precision and adapt to changing production demands [211,212].

- Healthcare and Medical Robotics: The integration has brought about remarkable advancements in medical robotics. Power converters designed for energy efficiency prolong the operation time of medical robots during critical procedures, while machine learning facilitates the development of robots capable of real-time diagnosis and personalized patient care [213,214]. These robots can learn to interpret medical data and collaborate with healthcare professionals, ultimately improving diagnostics, surgical procedures and patient outcomes.

- Agriculture and Environmental Monitoring: In agricultural and environmental settings, the synergy of advanced power converters and learning approaches has led to the creation of autonomous robots that can operate for extended periods in remote locations. These robots harness renewable energy sources through advanced converters, enabling prolonged missions for crop monitoring, soil analysis and wildlife observation [215,216,217]. In [218], the authors highlighted the role of geomatics in Agriculture 4.0, demonstrating the integration of diverse data sources such as satellite imagery, UAVs and autonomous vehicles through advanced data-fusion techniques. By optimizing vineyard management and production with methodologies like Normalized Difference Vegetation Index (NDVI) analysis and sensor-equipped autonomous vehicles, the research offered valuable insights for enhancing precision agriculture in the context of Agriculture 4.0. Further, ML algorithms can empower these robots to navigate challenging terrains, identify anomalies and make informed decisions, contributing to sustainable resource management.

- Search-and-Rescue Missions: The integration plays a pivotal role in enhancing robotic capabilities for search-and-rescue operations. By efficiently managing power resources, robots can operate in disaster-stricken areas for extended durations, maximizing their chances of locating and aiding survivors [219,220]. Learning approaches enable these robots to adapt their search patterns based on evolving conditions and past experiences, significantly increasing their effectiveness in locating and assisting individuals in distress [221,222].

5.2. Emerging Technologies

- Smart Factory Optimization: This case study showcases a manufacturing facility that has implemented advanced power converters to optimize energy consumption. By coupling this with machine-learning algorithms, robots within the factory have learned to predict production fluctuations and adapt their energy usage accordingly. The result is a significant reduction in operational costs and improved overall efficiency [223,224,225].

- Minimally Invasive Surgery Assistance: Here, we delve into a medical robotics scenario where power converters with rapid response capabilities enable precise movements of surgical instruments. Paired with learning algorithms, the robot learns to interpret real-time physiological data, adjusting its movements to ensure safe and accurate procedures [226,227]. This integration has led to shorter surgery times and improved patient safety.

- Autonomous Agricultural Monitoring: In the context of agriculture, this case study features autonomous robots powered by renewable energy sources. These robots navigate vast fields, collecting data on crop health and soil conditions. Machine-learning algorithms allow the robots to identify areas requiring special attention and customize their treatment strategies, resulting in higher yields and resource-efficient farming [23,228,229].

- Disaster Recovery with Aerial Robotics: This aspect focuses on the utilization of aerial drones equipped with advanced power systems and learning algorithms in disaster-stricken areas. These drones can fly longer missions, thanks to energy-efficient converters and employ machine learning to rapidly analyze vast amounts of visual and thermal data [230,231,232]. This integration has drastically reduced response times during disaster-recovery efforts.

6. Discussion and Future Trends in Robotics

6.1. Overall Trends

- Efficiency and Sustainability: Efficiency and sustainability are at the forefront of robotic system development. Power converters and energy-harvesting methods are being designed to minimize energy wastage and utilize renewable energy sources, contributing to more sustainable and eco-friendly robotics.

- Specialization: With robotics finding applications in a wide range of industries, specialized power converters and learning algorithms are on the rise. These specialized solutions cater to the unique demands of each application, whether it is in healthcare, manufacturing or autonomous vehicles.

- Increased Autonomy: Learning approaches, particularly reinforcement learning and AI, are empowering robots to become more autonomous and adaptable. This trend is particularly evident in fields like autonomous driving, where robots are learning to navigate complex environments with minimal human intervention.

- Integration of Efficient Energy: The integration of energy sources into robotic systems is a growing trend. Solar, thermoelectrical and supercapacitors are increasingly being used to power robots, reducing their reliance on traditional energy sources and contributing to longer operational times.

- Fuel Cell Technology: Fuel cell technology, such as polymer electrolyte membrane fuel cells, holds promise for larger robotic systems. They offer higher energy density, longer operational times and can be a game-changer for applications like UAVs.

6.2. Economic Aspects of Optimal Control in Robotic Applications

- Initial Costs: The choice of optimal control structures can have a substantial impact on initial costs. For instance, more complex control algorithms or hardware setups may require a larger upfront investment. However, it is essential to balance initial costs with long-term benefits, such as increased productivity, reduced labor costs and improved product quality.

- Operational Efficiency: Optimal control can enhance operational efficiency by improving accuracy, reducing cycle times and minimizing energy consumption. The economic benefit lies in increased productivity and reduced operating expenses over time. For example, in manufacturing, optimal control can lead to higher throughput, lower scrap rates and energy savings, all of which contribute to cost reduction.

- Maintenance: The choice of control structures can also impact maintenance costs. Complex control systems may require more frequent maintenance and specialized expertise, which can increase operating expenses. Simpler control systems with predictive maintenance capabilities can help reduce downtime and maintenance costs.

- Return on Investment (ROI): The economic feasibility of optimal control largely depends on the ROI it offers. While investing in advanced control structures may have a higher upfront cost, it is crucial to evaluate how quickly these investments will pay off through increased productivity and cost savings. Factors like the expected lifespan of the robotic system, industry-specific demands and potential market growth should be considered when calculating ROI.

- Customization: The optimal control structure should align with the specific needs of the application. Customizing the control system to the unique demands of the task can lead to more efficient and cost-effective solutions.

- Scalability: Consider control structures that can be scaled as needed. This allows for flexibility in adapting to changes in production volume or complexity, ensuring that the investment remains economically viable over time.

- Energy Efficiency: Opt for control structures that prioritize energy efficiency, as this not only reduces operational costs but also aligns with sustainability goals.

- Integration: Ensure that the chosen control structure integrates seamlessly with existing systems and processes. Compatibility can minimize disruptions and reduce integration costs.

- Predictive Maintenance: Implement predictive maintenance capabilities to proactively address issues before they lead to costly downtime. This can extend the lifespan of the robotic system and reduce maintenance expenses.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

List of Abbreviations and Acronyms

| AI | Artificial Intelligence | PCA | Principal Component Analysis |

| CCA | Canonical Correlation Analysis | PPO | Proximal Policy Optimization |

| CNNs | Convolutional Neural Networks | PID | Proportional-Integral-Derivative |

| DAB | Dual Active Bridge Converter | PSCs | Perovskite Solar Cells |

| DQN | Deep Q Networks | PWM | Pulse-Width Modulation |

| DRL | Deep Reinforcement Learning | R&D | Research and Development |

| EM | Energy Management | RL | Reinforcement Learning |

| EMI | Electromagnetic Interference | RNNs | Recurrent Neural Networks |

| EV | Electric Vehicle | SAC | Soft Actor-Critic |

| GaN | Gallium Nitride | SiC | Silicon Carbide |

| GANs | Generative Adversarial Networks | SPWM | Sinusoidal Pulse Width Modulation |

| GMM | Gaussian Mixture Models | SVMs | Support Vector Machines |

| HPC | High-Performance Computing | t-SNE | t-Distributed Stochastic Neighbor Embedding |

| HEV | Hybrid Electric Vehicle | TRPO | Trust Region Policy Optimization |

| ICA | Independent Component Analysis | UAV | Unmanned Aerial Vehicle |

| IoT | Internet of Things | UAVs | Unmanned Aerial Vehicles |

| K-means | K-means Clustering | VAEs | Variational Autoencoders |

| LSTM | Long Short-Term Memory | ZCS | Zero Current Switching |

| MCTS | Monte Carlo Tree Search | ZVS | Zero Voltage Switching |

| ML | Machine Learning | DSSCs | Dye-Sensitized Solar Cells |

| MPC | Model Predictive Control | CIGS | Copper Indium Gallium Diselenide |

| OSCs | Organic Solar Cells | ROI | Return on Investment |

| MAVs | Micro Air Vehicles | NDVI | Normalized Difference Vegetation Index |

References

- Bartoš, M.; Bulej, V.; Bohušík, M.; Stanček, J.; Ivanov, V.; Macek, P. An overview of robot applications in the automotive industry. Transp. Res. Procedia 2021, 55, 837–844. [Google Scholar] [CrossRef]

- Chodha, V.; Dubey, R.; Kumar, R.; Singh, S.; Kaur, S. Selection of industrial arc welding robot with TOPSIS and Entropy MCDM techniques. Mater. Today Proc. 2022, 50, 709–715. [Google Scholar] [CrossRef]

- Sherwani, F.; Asad, M.M.; Ibrahim, B.S.K.K. Collaborative Robots and Industrial Revolution 4.0 (IR 4.0). In Proceedings of the 2020 International Conference on Emerging Trends in Smart Technologies (ICETST), Karachi, Pakistan, 26–27 March 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Muhammad, K.; Ullah, A.; Lloret, J.; Del Ser, J.; de Albuquerque, V.H.C. Deep learning for safe autonomous driving: Current challenges and future directions. IEEE Trans. Intell. Transp. Syst. 2020, 22, 4316–4336. [Google Scholar] [CrossRef]

- Khayyam, H.; Javadi, B.; Jalili, M.; Jazar, R.N. Artificial intelligence and internet of things for autonomous vehicles. In Nonlinear Approaches in Engineering Applications: Automotive Applications of Engineering Problems; Springer: Berlin/Heidelberg, Germany, 2020; pp. 39–68. [Google Scholar]

- Vishnukumar, H.J.; Butting, B.; Müller, C.; Sax, E. Machine learning and deep neural network—Artificial intelligence core for lab and real-world test and validation for ADAS and autonomous vehicles: AI for efficient and quality test and validation. In Proceedings of the 2017 Intelligent Systems Conference (IntelliSys), London, UK, 7–8 September 2017; IEEE: Piscataway, NJ, USA, 2017. [Google Scholar]

- Lee, D.; Yoon, S.N. Application of artificial intelligence-based technologies in the healthcare industry: Opportunities and challenges. Int. J. Environ. Res. Public Health 2021, 18, 271. [Google Scholar] [CrossRef] [PubMed]

- Alugubelli, R. Exploratory study of artificial intelligence in healthcare. Int. J. Innov. Eng. Res. Technol. 2016, 3, 1–10. [Google Scholar]

- Denecke, K.; Claude R., B. A review of artificial intelligence and robotics in transformed health ecosystems. Front. Med. 2022, 9, 795957. [Google Scholar] [CrossRef]

- Castañé, G.; Dolgui, A.; Kousi, N.; Meyers, B.; Thevenin, S.; Vyhmeister, E.; Östberg, P.-O. The ASSISTANT project: AI for high level decisions in manufacturing. Int. J. Prod. Res. 2023, 61, 2288–2306. [Google Scholar] [CrossRef]

- Sjödin, D.R.; Parida, V.; Leksell, M.; Petrovic, A. Smart Factory Implementation and Process Innovation: A Preliminary Maturity Model for Leveraging Digitalization in Manufacturing. Moving to smart factories presents specific challenges that can be addressed through a structured approach focused on people, processes and technologies. Res. Technol. Manag. 2018, 61, 22–31. [Google Scholar]

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of artificial intelligence in agriculture for optimisation of irrigation and application of pesticides and herbicides. Artif. Intell. Agric. 2020, 4, 58–73. [Google Scholar] [CrossRef]

- Rejeb, A.; Abdollahi, A.; Rejeb, K.; Treiblmaier, H. Drones in agriculture: A review and bibliometric analysis. Comput. Electron. Agric. 2022, 198, 107017. [Google Scholar] [CrossRef]

- Cheng, C.; Fu, J.; Su, H.; Ren, L. Recent Advancements in Agriculture Robots: Benefits and Challenges. Machines 2023, 11, 48. [Google Scholar] [CrossRef]

- Balaska, V.; Adamidou, Z.; Vryzas, Z.; Gasteratos, A. Sustainable Crop Protection via Robotics and Artificial Intelligence Solutions. Machines 2023, 11, 774. [Google Scholar] [CrossRef]

- Park, K.-B.; Choi, S.H.; Lee, J.Y.; Ghasemi, Y.; Mohammed, M.; Jeong, H. Hands-free human–robot interaction using multimodal gestures and deep learning in wearable mixed reality. IEEE Access 2021, 9, 55448–55464. [Google Scholar] [CrossRef]

- Heydari, J.; Saha, O.; Ganapathy, V. Reinforcement learning-based coverage path planning with implicit cellular decomposition. arXiv 2021, arXiv:2110.09018. [Google Scholar]

- Pathmakumar, T.; Kalimuthu, M.; Elara, M.R.; Ramalingam, B. An autonomous robot-aided auditing scheme for floor cleaning. Sensors 2021, 21, 4332. [Google Scholar] [CrossRef] [PubMed]

- Alami, R.; Albu-Schaeffer, A.; Bicchi, A.; Bischoff, R.; Chatila, R.; De Luca, A.; De Santis, A.; Giralt, G.; Guiochet, J.; Hirzinger, G.; et al. Safe and Dependable Physical Human-Robot Interaction in Anthropic Domains: State of the Art and Challenges. In Proceedings of the 2006 IEEE/RSJ International Conference on Intelligent Robots and Systems, Beijing, China, 9–15 October 2006. [Google Scholar]

- Smith, C.; Karayiannidis, Y.; Nalpantidis, L.; Gratal, X.; Qi, P.; Dimarogonas, D.V.; Kragic, D. Dual Arm Manipulation—A Survey. Robot. Auton. Syst. 2012, 60, 1340–1353. [Google Scholar] [CrossRef]

- Carabin, G.; Wehrle, E.; Vidoni, R. A Review on Energy-Saving Optimization Methods for Robotic and Automatic Systems. Robotics 2017, 6, 39. [Google Scholar] [CrossRef]

- Mantha, B.R.K.; Jung, M.K.; García de Soto, B.; Menassa, C.C.; Kamat, V.R. Generalized task allocation and route planning for robots with multiple depots in indoor building environments. Autom. Constr. 2020, 119, 103359. [Google Scholar] [CrossRef]

- Ahmad, T.; Zhu, H.; Zhang, D.; Tariq, R.; Bassam, A.; Ullah, F.; AlGhamdi, A.S.; Alshamrani, S.S. Energetics Systems and artificial intelligence: Applications of industry 4.0. Energy Rep. 2022, 8, 334–361. [Google Scholar] [CrossRef]

- Mazumdar, A.; Spencer, S.J.; Hobart, C.; Salton, J.; Quigley, M.; Wu, T.; Bertrand, S.; Pratt, J.; Buerger, S.P. Parallel elastic elements improve energy efficiency on the STEPPR bipedal walking robot. IEEE/ASME Trans. Mechatronics 2016, 22, 898–908. [Google Scholar] [CrossRef]

- Fisk, W.J. Health and productivity gains from better indoor environments and their relationship with building energy efficiency. Annu. Rev. Energy Environ. 2000, 25, 537–566. [Google Scholar] [CrossRef]

- Xu, G.; Xu, K.; Zheng, C.; Zhang, X.; Zahid, T. Fully electrified regenerative braking control for deep energy recovery and maintaining safety of electric vehicles. IEEE Trans. Veh. Technol. 2015, 65, 1186–1198. [Google Scholar] [CrossRef]

- Prasanth, B.; Paul, R.; Kaliyaperumal, D.; Kannan, R.; Venkata Pavan Kumar, Y.; Kalyan Chakravarthi, M.; Venkatesan, N. Maximizing Regenerative Braking Energy Harnessing in Electric Vehicles Using Machine Learning Techniques. Electronics 2023, 12, 1119. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Optimization of Energy Consumption in Industrial Robots, A Review. Cogn. Robot. 2023, 3, 142–157. [Google Scholar] [CrossRef]

- Meireles, M.R.G.; Almeida, P.E.M.; Simões, M.G. A comprehensive review for industrial applicability of artificial neural networks. IEEE Trans. Ind. Electron. 2003, 50, 585–601. [Google Scholar] [CrossRef]

- Monmasson, E.; Cirstea, M.N. FPGA design methodology for industrial control systems—A review. IEEE Trans. Ind. Electron. 2007, 54, 1824–1842. [Google Scholar] [CrossRef]

- Lee, T.-S. Input-output linearization and zero-dynamics control of three-phase AC/DC voltage-source converters. IEEE Trans. Power Electron. 2003, 18, 11–22. [Google Scholar]

- Le, A.; Truong, L.; Quyen, T.; Nguyen, C.; Nguyen, M.; Truong, T.; Quyen, C.; Nguyen, M. Wireless power transfer near-field technologies for unmanned aerial vehicles (UAVs): A review. EAI Endorsed Trans. Ind. Netw. Intell. Syst. 2020, 7, e5. [Google Scholar] [CrossRef]

- Ucgun, H.; Ugur, Y.; Cuneyt, B. A review on applications of rotary-wing unmanned aerial vehicle charging stations. Int. J. Adv. Robot. Syst. 2021, 18, 17298814211015863. [Google Scholar] [CrossRef]

- Amjad, M.; Farooq-i-Azam, M.; Ni, Q.; Dong, M.; Ansari, E.A. Wireless charging systems for electric vehicles. Renew. Sustain. Energy Rev. 2022, 167, 112730. [Google Scholar] [CrossRef]

- Huo, Y.; Dong, X.; Lu, T.; Xu, W.; Yuen, M. Distributed and multilayer UAV networks for next-generation wireless communication and power transfer: A feasibility study. IEEE Internet Things J. 2019, 6, 7103–7115. [Google Scholar] [CrossRef]

- Nvss, S.; Esakki, B.; Yang, L.-J.; Udayagiri, C.; Vepa, K.S. Design and development of unibody quadcopter structure using optimization and additive manufacturing techniques. Designs 2022, 6, 8. [Google Scholar] [CrossRef]

- Arafat, M.Y.; Alam, M.M.; Moh, S. Vision-based navigation techniques for unmanned aerial vehicles: Review and challenges. Drones 2023, 7, 89. [Google Scholar] [CrossRef]

- Cao, X.; Liu, L.; Ge, J.; Yang, D. Conceptual design of long-endurance small solar-powered unmanned aerial vehicle with multiple tilts and hovers. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2023. [Google Scholar] [CrossRef]

- Mohan, V.; Jeyaraj, A.K.; Susan, L.-H. Systems Integration Framework for Hybrid-Electric Commuter and Regional Aircraft. Aerospace 2023, 10, 533. [Google Scholar] [CrossRef]

- Mikołajczyk, T.; Mikołajewski, D.; Kłodowski, A.; Łukaszewicz, A.; Mikołajewska, E.; Paczkowski, T.; Macko, M.; Skornia, M. Energy Sources of Mobile Robot Power Systems: A Systematic Review and Comparison of Efficiency. Appl. Sci. 2023, 13, 7547. [Google Scholar] [CrossRef]

- Paryanto; Brossog, M.; Bornschlegl, M.; Franke, J. Reducing the energy consumption of industrial robots in manufacturing systems. Int. J. Adv. Manuf. Technol. 2015, 78, 1315–1328. [Google Scholar] [CrossRef]

- Wang, J.; Chortos, A. Control Strategies for Soft Robot Systems. Adv. Intell. Syst. 2022, 4, 2100165. [Google Scholar] [CrossRef]

- Lewis, F.L.; Kreith, F. (Eds.) Robotics. In Mechanical Engineering Handbook; CRC Press LLC: Boca Raton, FL, USA, 1999. [Google Scholar]

- Afifa, R.; Ali, S.; Pervaiz, M.; Iqbal, J. Adaptive Backstepping Integral Sliding Mode Control of a MIMO Separately Excited DC Motor. Robotics 2023, 12, 105. [Google Scholar] [CrossRef]

- Lorenz, R.D.; Lipo, T.A.; Novotny, D.W. Motion Control with Induction Motors. Proc. IEEE 1994, 82, 1215–1240. [Google Scholar] [CrossRef]

- Dario, P.; Bergamasco, M. An advanced robot system for automated diagnostic tasks through palpation. IEEE Trans. Biomed. Eng. 1988, 35, 118–126. [Google Scholar] [CrossRef] [PubMed]

- Forouzesh, M.; Siwakoti, Y.P.; Gorji, S.A.; Blaabjerg, F.; Lehman, B. Step-Up DC–DC Converters: A Comprehensive Review of Voltage-Boosting Techniques, Topologies and Applications. IEEE Trans. Power Electron. 2017, 32, 9143–9178. [Google Scholar] [CrossRef]

- Musumeci, S.; Mandrile, F.; Barba, V.; Palma, M. Low-Voltage GaN FETs in Motor Control Application; Issues and Advantages: A Review. Energies 2021, 14, 6378. [Google Scholar] [CrossRef]

- Arrigo, D.; Adragna, C.; Marano, V.; Pozzi, R.; Pulicelli, F.; Pulvirenti, F. The Next “Automation Age”: How Semiconductor Technologies Are Changing Industrial Systems and Applications. In Proceedings of the ESSCIRC 2022-IEEE 48th European Solid State Circuits Conference (ESSCIRC), Milan, Italy, 19–22 September 2022; pp. 17–24. [Google Scholar] [CrossRef]

- Paul, S.; Lee, D.; Kim, K.; Chang, J. Nonlinear modeling and performance testing of high-power electromagnetic energy harvesting system for self-powering transmission line vibration deicing robot. Mech. Syst. Signal Process. 2021, 151, 107369. [Google Scholar] [CrossRef]

- Moradewicz, A.J.; Kazmierkowski, M.P. Contactless Energy Transfer System with FPGA-Controlled Resonant Converter. IEEE Trans. Ind. Electron. 2010, 57, 3181–3190. [Google Scholar] [CrossRef]

- Kikuchi, S.; Sakata, T.; Takahashi, E.; Kanno, H. Development of Wireless Power Transfer System for Robot Arm with Rotary and Linear Movement. In Proceedings of the 2016 IEEE International Conference on Advanced Intelligent Mechatronics (AIM), Banff, AB, Canada, 12–15 July 2016; pp. 1616–1621. [Google Scholar] [CrossRef]

- Barman, S.D.; Reza, A.W.; Kumar, N.; Karim, M.E.; Munir, A.B. Wireless powering by magnetic resonant coupling: Recent trends in wireless power transfer system and its applications. Renew. Sustain. Energy Rev. 2015, 51, 1525–1552. [Google Scholar] [CrossRef]

- Urrea, C.; Jara, D. Design, Analysis and Comparison of Control Strategies for an Industrial Robotic Arm Driven by a Multi-Level Inverter. Symmetry 2021, 13, 86. [Google Scholar] [CrossRef]

- Ghani, M.A.; Mallet, J. Switched capacitors multilevel converter design for robotics application employing arduino microcontroller. In Proceedings of the 2014 11th International Conference on Ubiquitous Robots and Ambient Intelligence (URAI), Kuala Lumpur, Malaysia, 12–15 November 2014; pp. 472–476. [Google Scholar] [CrossRef]

- Ivanovic, B.; Stojiljkovic, Z. A novel active soft switching snubber designed for boost converter. IEEE Trans. Power Electron. 2004, 19, 658–665. [Google Scholar] [CrossRef]

- Hasanpour, S.; Forouzesh, M.; Siwakoti, Y.P.; Blaabjerg, F. A Novel Full Soft-Switching High-Gain DC/DC Converter Based on Three-Winding Coupled-Inductor. IEEE Trans. Power Electron. 2021, 36, 12656–12669. [Google Scholar] [CrossRef]

- Rohouma, W.; Zanchetta, P.; Wheeler, P.W.; Empringham, L. A Four-Leg Matrix Converter Ground Power Unit with Repetitive Voltage Control. IEEE Trans. Ind. Electron. 2015, 62, 2032–2040. [Google Scholar] [CrossRef]

- Szczesniak, P.; Urbanski, K.; Fedyczak, Z.; Zawirski, K. Comparative study of drive systems using vector-controlled PMSM fed by a matrix converter and a conventional frequency converter. Turk. J. Electr. Eng. Comput. Sci. 2016, 24, 59. [Google Scholar] [CrossRef]

- Hao, K.; Lu, J. Modeling Research of Dual Active Bridge DC Converter Based on Double Phase Shift Control. In Proceedings of the 2019 3rd International Conference on Robotics and Automation Sciences (ICRAS), Wuhan, China, 1–3 June 2019; pp. 79–84. [Google Scholar]

- Wong, L.H.; Sivanesan, S.; Faisol, M.F.A.; Othman, W.A.F.W.; Wahab, A.A.A.; Alhady, S.S.N. Development of quadruped walking robot with passive compliance legs using XL4005 buck converter. J. Phys. Conf. Ser. 2021, 1969, 012003. [Google Scholar] [CrossRef]

- Abidin, Z.; Faridzi, M.A.; Siwindarto, P. Design of Solenoid Based Kicker with ZVS Boost Converter for Wheeled Soccer Robot. In Proceedings of the 2023 International Electronics Symposium (IES), Denpasar, Indonesia, 8–10 August 2023; pp. 150–154. [Google Scholar]

- Cruz-Lambert, J.; Benavidez, P.; Ortiz, J.; Richey, J.; Morris, S.; Gallardo, N.; Jamshidi, M. Converter design for solar powered outdoor mobile robot. In Proceedings of the 2016 World Automation Congress (WAC), Rio Grande, PR, USA, 3 July–4 August 2016; pp. 1–6. [Google Scholar] [CrossRef]

- Truong, T.-A.; Nguyen, T.K.; Huang, X.; Ashok, A.; Yadav, S.; Park, Y.; Thai, M.T.; Nguyen, N.-K.; Fallahi, H.; Peng, S.; et al. Engineering Route for Stretchable, 3D Microarchitectures of Wide Bandgap Semiconductors for Biomedical Applications. Adv. Funct. Mater. 2023, 33, 2211781. [Google Scholar] [CrossRef]

- Lee, W.; Li, S.; Han, D.; Sarlioglu, B.; Minav, T.A.; Pietola, M. A Review of Integrated Motor Drive and Wide-Bandgap Power Electronics for High-Performance Electro-Hydrostatic Actuators. IEEE Trans. Transp. Electrif. 2018, 4, 684–693. [Google Scholar] [CrossRef]

- Dorigo, M.; Theraulaz, G.; Trianni, V. Swarm Robotics: Past, Present and Future [Point of View]. Proc. IEEE 2021, 109, 1152–1165. [Google Scholar] [CrossRef]

- Lee, W.; Li, S.; Han, D.; Sarlioglu, B.; Minav, T.A.; Pietola, M. Achieving high-performance electrified actuation system with integrated motor drive and wide bandgap power electronics. In Proceedings of the 19th European Conference on Power Electronics and Applications (EPE’17 ECCE Europe), Warsaw, Poland, 11–14 September 2017; pp. P.1–P.10. [Google Scholar]

- Nguyen, K.T.; Kang, B.; Choi, E.; Park, J.O.; Kim, C.S. High-Frequency and High-Powered Electromagnetic Actuation System Utilizing Two-Stage Resonant Effects. IEEE/ASME Trans. Mechatron. 2020, 25, 2398–2408. [Google Scholar] [CrossRef]

- Hagn, U.; Nickl, M.; Jörg, S.; Passig, G.; Bahls, T.; Nothhelfer, A.; Hacker, F.; Le-Tien, L.; Albu-Schäffer, A.; Konietschke, R.; et al. The DLR MIRO: A Versatile Lightweight Robot for Surgical Applications. Ind. Robot. 2008, 35, 324–336. [Google Scholar] [CrossRef]

- Zhang, T.; Qian, F.; Li, C.; Masarati, P.; Hoover, A.M.; Birkmeyer, P.; Pullin, A.; Fearing, R.S.; Goldman, D.I. Ground fluidization promotes rapid running of a lightweight robot. Int. J. Robot. Res. 2013, 32, 859–869. [Google Scholar] [CrossRef]

- Makhdoom, R.; Maji, S.; Sinha, S.; Etta, D.; Afridi, K. Multi-MHz In-Motion Capacitive Wireless Power Transfer System for Mobile Robots. In Proceedings of the 2022 Wireless Power Week (WPW), Bordeaux, France, 5–8 July 2022; pp. 1–5. [Google Scholar]

- Lidow, A.; Glaser, J. GaN-based Solutions for Cost-effective Direct and Indirect Time-of-Flight Lidar Transmitters are Changing the Way We Live. In Proceedings of the 2022 International Power Electronics Conference (IPEC-Himeji 2022- ECCE Asia), Himeji, Japan, 15–19 May 2022; pp. 637–643. [Google Scholar] [CrossRef]

- Ino, K.; Miura, M.; Nakano, Y.; Aketa, M.; Kawamoto, N. SiC Power Device Evolution Opening a New Era in Power Electronics. In Proceedings of the 2019 IEEE International Conference on Electron Devices and Solid-State Circuits (EDSSC), Xi’an, China, 12–14 June 2019; pp. 1–3. [Google Scholar] [CrossRef]

- Carlson, S.J.; Arora, P.; Karakurt, T.; Moore, B.; Papachristos, C. Towards Multi-Day Field Deployment Autonomy: A Long-Term Self-Sustainable Micro Aerial Vehicle Robot. In Proceedings of the 2023 IEEE International Conference on Robotics and Automation (ICRA), London, UK, 29 May–2 June 2023; pp. 11396–11403. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R. Substantial Capabilities of Robotics in Enhancing Industry 4.0 Implementation. Cogn. Robot. 2021, 1, 58–75. [Google Scholar] [CrossRef]

- Chen, J.; Yang, C.; Zou, J. Robust Enhanced Voltage Range Control for Industrial Robot Chargers. IEEE Access 2022, 10, 132635–132643. [Google Scholar] [CrossRef]

- Natarajan, S.; Kannadasan, R.; Alsaif, F.; Alsharif, M.H. Design of Novel Modified Double-Ended Forward Converter for Stepper Motor Drive. Machines 2023, 11, 777. [Google Scholar] [CrossRef]

- Bodian, A.; Cardenas, A.; Ben Abdelghani, A.B. Double Outputs Resonant-based Wireless Charger for Electric Vehicle and Robotic Applications. In Proceedings of the 2022 5th International Conference on Advanced Systems and Emergent Technologies (IC_ASET), Hammamet, Tunisia, 22–24 March 2022; pp. 439–444. [Google Scholar]

- Silva, F.A. Advanced DC/AC Inverters: Applications in Renewable Energy (Luo, F.L. and Ye, H.; 2013) [Book News]. IEEE Ind. Electron. Mag. 2013, 7, 68–69. [Google Scholar] [CrossRef]

- Benmiloud, M.; Benalia, A. Finite-time stabilization of the limit cycle of two-cell DC/DC converter: Hybrid approach. Nonlinear Dyn. 2016, 83, 319–332. [Google Scholar] [CrossRef]

- Moreno, G.; Narumanchi, S.; Feng, X.; Anschel, P.; Myers, S.; Keller, P. Electric-Drive Vehicle Power Electronics Thermal Management: Current Status, Challenges and Future Directions. J. Electron. Packag. 2022, 144, 011004. [Google Scholar] [CrossRef]

- Omura, I. Power Electronics for a Future Sustainable Society. In Proceedings of the PCIM Europe 2022, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 10–12 May 2022; pp. 1–8. [Google Scholar] [CrossRef]

- Schellenberger, M.; Lorentz, V.; Eckardt, B. Cognitive Power Electronics—An Enabler for Smart Systems. In Proceedings of the PCIM Europe 2022; International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 10–12 May 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Dian, S.; Fang, H.; Zhao, T.; Wu, Q.; Hu, Y.; Guo, R.; Li, S. Modeling and Trajectory Tracking Control for Magnetic Wheeled Mobile Robots Based on Improved Dual-Heuristic Dynamic Programming. IEEE Trans. Ind. Inform. 2021, 17, 1470–1482. [Google Scholar] [CrossRef]

- Božek, P.; Nikitin, Y. The Development of an Optimally-Tuned PID Control for the Actuator of a Transport Robot. Actuators 2021, 10, 195. [Google Scholar] [CrossRef]

- Dini, P.; Saponara, S. Model-Based Design of an Improved Electric Drive Controller for High-Precision Applications Based on Feedback Linearization Technique. Electronics 2021, 10, 2954. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, B. Omnidirectional and Efficient Wireless Power Transfer System for Logistic Robots. IEEE Access 2020, 8, 13683–13693. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, J.; Zhang, Y.; Deng, F. A Wireless Power Transfer System With Dual Switch-Controlled Capacitors for Efficiency Optimization. IEEE Trans. Power Electron. 2020, 35, 6091–6101. [Google Scholar] [CrossRef]

- Borboni, A.; Reddy, K.V.V.; Elamvazuthi, I.; AL-Quraishi, M.S.; Natarajan, E.; Azhar Ali, S.S. The Expanding Role of Artificial Intelligence in Collaborative Robots for Industrial Applications: A Systematic Review of Recent Works. Machines 2023, 11, 111. [Google Scholar] [CrossRef]

- Mohsen, S.; Behrooz, A.; Roza, D. Artificial Intelligence, Machine Learning and Deep Learning in Advanced Robotics: A Review. Cogn. Robot. 2023, 3, 54–70. [Google Scholar] [CrossRef]

- Sarker, I.H. Machine Learning: Algorithms, Real-World Applications and Research Directions. SN Comput. Sci. 2021, 2, 160. [Google Scholar] [CrossRef] [PubMed]

- Han, D.; Mulyana, B.; Stankovic, V.; Cheng, S. A Survey on Deep Reinforcement Learning Algorithms for Robotic Manipulation. Sensors 2023, 23, 3762. [Google Scholar] [CrossRef]

- Liu, R.; Nageotte, F.; Zanne, P.; De Mathelin, M.; Dresp, B. Deep Reinforcement Learning for the Control of Robotic Manipulation: A Focused Mini-Review. Robotics 2021, 10, 22. [Google Scholar] [CrossRef]

- Shao, S.; Tsai, J.; Mysior, M.; Luk, W.; Chau, T.; Warren, A.; Jeppesen, B. Towards Hardware Accelerated Reinforcement Learning for Application-Specific Robotic Control. In Proceedings of the 2018 IEEE 29th International Conference on Application-specific Systems, Architectures and Processors (ASAP), Milan, Italy, 10–12 July 2018; pp. 1–8. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, X.; Xu, Y.; Guo, J. A Deep Q-network (DQN) Based Path Planning Method for Mobile Robots. In Proceedings of the 2018 IEEE International Conference on Information and Automation (ICIA), Wuyishan, China, 11–13 August 2018; pp. 366–371. [Google Scholar] [CrossRef]

- Schulman, J.; Wolski, F.; Dhariwal, P.; Radford, A.; Klimov, O. Proximal policy optimization algorithms. arXiv 2017, arXiv:1707.06347. [Google Scholar]

- Amarjyoti, S. Deep reinforcement learning for robotic manipulation-the state of the art. arXiv 2017, arXiv:1701.08878. [Google Scholar]

- Saeed, M.; Nagdi, M.; Rosman, B.; Ali, H.H. Deep Reinforcement Learning for Robotic Hand Manipulation. In Proceedings of the 2020 International Conference on Computer, Control, Electrical and Electronics Engineering (ICCCEEE), Khartoum, Sudan, 26 February–1 March 2021; pp. 1–5. [Google Scholar] [CrossRef]

- Ashraf, N.M.; Mostafa, R.R.; Sakr, R.H.; Rashad, M.Z. Optimizing hyperparameters of deep reinforcement learning for autonomous driving based on whale optimization algorithm. PLoS ONE 2021, 16, e0252754. [Google Scholar] [CrossRef]

- Mahony, N.O.; Campbell, S.; Carvalho, A.; Harapanahalli, S.; Velasco-Hernandez, G.; Krpalkova, L.; Riordan, D.; Walsh, J. Deep Learning vs. Traditional Computer Vision. In Advances in Computer Vision. CVC 2019. Advances in Intelligent Systems and Computing; Arai, K., Kapoor, S., Eds.; Spronger: Cham, Switzerland, 2020; Volume 943. [Google Scholar] [CrossRef]

- Wang, Z.; Majewicz Fey, A. Deep learning with convolutional neural network for objective skill evaluation in robot-assisted surgery. Int. J. CARS 2018, 13, 1959–1970. [Google Scholar] [CrossRef]

- Mayer, H.; Gomez, F.; Wierstra, D.; Nagy, I.; Knoll, A.; Schmidhuber, J. A System for Robotic Heart Surgery that Learns to Tie Knots Using Recurrent Neural Networks. Adv. Robot. 2008, 22, 1521–1537. [Google Scholar] [CrossRef]

- Zhang, M.; Chu, Z. Adaptive sliding mode control based on local recurrent neural networks for underwater robot. Ocean Eng. 2012, 45, 56–62. [Google Scholar] [CrossRef]

- Nair, R.S.; Supriya, P. Robotic Path Planning Using Recurrent Neural Networks. In Proceedings of the 2020 11th International Conference on Computing, Communication and Networking Technologies (ICCCNT), Kharagpur, India, 1–3 July 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Brown, C.Y.; Asada, H.H. Inter-finger coordination and postural synergies in robot hands via mechanical implementation of principal components analysis. In Proceedings of the 2007 IEEE/RSJ International Conference on Intelligent Robots and Systems, San Diego, CA, USA, 29 October–2 November 2007; pp. 2877–2882. [Google Scholar] [CrossRef]

- Kim, S.; Park, F.C. Fast Robot Motion Generation Using Principal Components: Framework and Algorithms. IEEE Trans. Ind. Electron. 2008, 55, 2506–2516. [Google Scholar] [CrossRef]

- Zhao, N.; Yang, G.; Cao, Y. Mining Technological Innovation Talents Based on Patent Index using t-SNE Algorithms: Take the Field of Intelligent Robot as an Example. In Proceedings of the 2020 IEEE International Conference on Artificial Intelligence and Computer Applications (ICAICA), Dalian, China, 27–29 June 2020; pp. 595–601. [Google Scholar] [CrossRef]

- AL-Furati, I.; Rashid, A.T.; Al-Ibadi, A. IR sensors array for robots localization using K means clustering algorithm. In Proceedings of the UKSim-AMSS 21st International Conference on Modelling & Simulation, Cambridge, UK, 27–29 March 2019. [Google Scholar] [CrossRef]

- Ravankar, A.A.; Hoshino, Y.; Emaru, T.; Kobayashi, Y. Robot Mapping Using k-means Clustering Of Laser Range Sensor Data. Bull. Netw. Comput. Syst. Softw. 2012, 1, 9–12. [Google Scholar]

- Elango, M.; Nachiappan, S.; Tiwari, M. KBalancing task allocation in multi-robot systems using K-means clustering and auction based mechanisms. Expert Syst. Appl. 2011, 38, 6486–6491. [Google Scholar] [CrossRef]

- Upcroft, B.; Kumar, S.; Ridley, M.; Ong, L.L.; Durrant-Whyte, H. Fast re-parameterisation of Gaussian mixture models for robotics applications. In Proceedings of the Australasian Conference on Robotics and Automation, Canberra, Australia, 6–8 December 2004. [Google Scholar]

- Jasim, I.F.; Plapper, P.W. Contact-state Modeling of Robotic Assembly Tasks Using Gaussian Mixture Models. Procedia CIRP 2014, 23, 229–234. [Google Scholar] [CrossRef]

- Park, D.; Hoshi, Y.; Kemp, C. CA Multimodal Anomaly Detector for Robot-Assisted Feeding Using an LSTM-Based Variational Autoencoder. IEEE Robot. Autom. Lett. 2018, 3, 1544–1551. [Google Scholar] [CrossRef]

- Chen, T.; Liu, X.; Xia, B.; Wang, W.; Lai, Y. Unsupervised Anomaly Detection of Industrial Robots Using Sliding-Window Convolutional Variational Autoencoder. IEEE Access 2020, 8, 47072–47081. [Google Scholar] [CrossRef]

- Ren, H.; Ben-Tzvi, P. Learning inverse kinematics and dynamics of a robotic manipulator using generative adversarial networks. Robot. Auton. Syst. 2020, 124, 103386. [Google Scholar] [CrossRef]

- Lembono, T.S.; Pignat, E.; Jankowski, J.; Calinon, S. Learning Constrained Distributions of Robot Configurations With Generative Adversarial Network. IEEE Robot. Autom. Lett. 2021, 6, 4233–4240. [Google Scholar] [CrossRef]

- Fayyad, J.; Jaradat, M.A.; Gruyer, D.; Najjaran, H. Deep Learning Sensor Fusion for Autonomous Vehicle Perception and Localization: A Review. Sensors 2020, 20, 4220. [Google Scholar] [CrossRef]

- Sadeghi Esfahlani, S.; Sanaei, A.; Ghorabian, M.; Shirvani, H. The Deep Convolutional Neural Network Role in the Autonomous Navigation of Mobile Robots (SROBO). Remote Sens. 2022, 14, 3324. [Google Scholar] [CrossRef]

- Premebida, C.; Ambrus, R.; Marton, Z.C. Intelligent robotic perception systems. In Applications of Mobile Robots; Books on Demand: Pasig, Philippines, 2018; pp. 111–127. [Google Scholar]

- Rajendran, S.V.; Debnath, B.; Mghames, S.; Mandil, W.; Parsa, S.; Parsons, S.; Ghalamzan-E, A. Towards autonomous selective harvesting: A review of robot perception, robot design, motion planning and control. J. Field Robot. 2023, 1–33. [Google Scholar] [CrossRef]

- Falco, P.; Lu, S.; Natale, C.; Pirozzi, S.; Lee, D.A. Transfer Learning Approach to Cross-Modal Object Recognition: From Visual Observation to Robotic Haptic Exploration. IEEE Trans. Robot. 2019, 35, 987–998. [Google Scholar] [CrossRef]

- Saha, O.; Dasgupta, P.; Woosley, B. Real-time robot path planning from simple to complex obstacle patterns via transfer learning of options. Auton. Robot. 2019, 43, 2071–2093. [Google Scholar] [CrossRef]

- Tsitos, A.C.; Dagioglou, M. Enhancing team performance with transfer-learning during real-world human–robot collaboration. arXiv 2022, arXiv:2211.13070. [Google Scholar]

- Song, D.; Tian, G.-M.; Liu, J. Real-time localization measure and perception detection using multi-sensor fusion for Automated Guided Vehicles. In Proceedings of the 40th Chinese Control Conference (CCC), Shanghai, China, 26–28 July 2021; IEEE: Piscataway, NJ, USA, 2021. [Google Scholar]

- Chebotar, Y.; Hausman, K.; Lu, Y.; Xiao, T.; Kalashnikov, D.; Varley, J.; Irpan, A.; Eysenbach, B.; Julian, R.; Finn, C.; et al. Actionable models: Unsupervised offline reinforcement learning of robotic skills. arXiv 2021, arXiv:2104.07749. [Google Scholar]

- Ohnishi, N.; Imiya, A. Independent component analysis of optical flow for robot navigation. Neurocomputing 2008, 71, 2140–2163. [Google Scholar] [CrossRef]

- Hudson, R.E.; Newman, W.S. Independent Component Analysis and Bayes’ Theorem for robotics and automation. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; IEEE: Piscataway, NJ, USA, 2010. [Google Scholar]

- Roberts, S.; Everson, R. (Eds.) Independent Component Analysis: Principles and Practice; Cambridge University Press: Cambridge, UK, 2001. [Google Scholar]

- Chen, L.; Wang, K.; Li, M.; Wu, M.; Pedrycz, W.; Hirota, K. K-means clustering-based kernel canonical correlation analysis for multimodal emotion recognition in human–robot interaction. IEEE Trans. Ind. Electron. 2022, 70, 1016–1024. [Google Scholar] [CrossRef]

- Richer, N.; Downey, R.J.; Hairston, W.D.; Ferris, D.P.; Nordin, A.D. Motion and muscle artifact removal validation using an electrical head phantom, robotic motion platform and dual layer mobile EEG. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 28, 1825–1835. [Google Scholar] [CrossRef]

- Pierson, H.A.; Michael, S.G. Deep learning in robotics: A review of recent research. Adv. Robot. 2017, 31, 821–835. [Google Scholar] [CrossRef]

- CChungath, T.T.; Nambiar, A.M.; Mittal, A. Transfer Learning and Few-Shot Learning Based Deep Neural Network Models for Underwater Sonar Image Classification with a Few Samples. IEEE J. Ocean. Eng. 2023. [Google Scholar] [CrossRef]

- Károly, A.I.; Tirczka, S.; Gao, H.; Rudas, I.J.; Galambos, P. Increasing the Robustness of Deep Learning Models for Object Segmentation: A Framework for Blending Automatically Annotated Real and Synthetic Data. IEEE Trans. Cybern. 2023, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Magalhães, S.A.; Castro, L.; Moreira, G.; dos Santos, F.N.; Cunha, M.; Dias, J.; Moreira, A.P. Evaluating the single-shot multibox detector and YOLO deep learning models for the detection of tomatoes in a greenhouse. Sensors 2021, 21, 3569. [Google Scholar] [CrossRef] [PubMed]

- Rogelio, J.; Dadios, E.; Bandala, A.; Vicerra, R.R.; Sybingco, E. Alignment control using visual servoing and mobilenet single-shot multi-box detection (SSD): A review. Int. J. Adv. Intell. Inform. 2022, 8, 97–114. [Google Scholar] [CrossRef]

- Kipkosgei, P.; Njiri, J.G.; Kimotho, J.K. Real-time object detection using single-shot multibox detector network for autonomous robotic arm. J. Sustain. Res. Eng. 2020, 6, 11–23. [Google Scholar]

- Luo, R.C.; Yu, Z.-L. AI enhanced visual inspection of post-polished workpieces using you only look once vision system for intelligent robotics applications. In Proceedings of the 2022 International Conference on Advanced Robotics and Intelligent Systems (ARIS), Taipei, Taiwan, 24–27 August 2021; IEEE: Piscataway, NJ, USA, 2022. [Google Scholar]

- Li, X.; Tian, M.; Kong, S.; Wu, L.; Yu, J. A modified YOLOv3 detection method for vision-based water surface garbage capture robot. Int. J. Adv. Robot. Syst. 2020, 17, 1729881420932715. [Google Scholar] [CrossRef]

- Kulik, S.D.; Shtanko, A.N. Experiments with neural net object detection system YOLO on small training datasets for intelligent robotics. In Advanced Technologies in Robotics and Intelligent Systems: Proceedings of ITR 2019; Springer International Publishing: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Hurtado, J.V.; Valada, A. Semantic scene segmentation for robotics. In Deep Learning for Robot Perception and Cognition; Academic Press: Cambridge, MA, USA, 2022; pp. 279–311. [Google Scholar]

- Dang, T.-V.; Ngoc-Tam, B. Multi-scale fully convolutional network-based semantic segmentation for mobile robot navigation. Electronics 2023, 12, 533. [Google Scholar] [CrossRef]

- Lahbas, A.; Hadmi, A.; Radgui, A. Scenes Segmentation in Self-driving Car Perception System Based U-Net and FCN Models. In International Conference on Advanced Technologies for Humanity; Springer International Publishing: Cham, Switzerland, 2021. [Google Scholar]

- Kolekar, S.; Gite, S.; Pradhan, B.; Alamri, A. Explainable AI in scene understanding for autonomous vehicles in unstructured traffic environments on Indian roads using the inception U-Net Model with Grad-CAM visualization. Sensors 2022, 22, 9677. [Google Scholar] [CrossRef]

- Kazerouni, I.A.; Dooly, G.; Toal, D. Ghost-UNet: An asymmetric encoder-decoder architecture for semantic segmentation from scratch. IEEE Access 2021, 9, 97457–97465. [Google Scholar] [CrossRef]

- Zhang, C.; Tang, Y.; Zhao, C.; Sun, Q.; Ye, Z.; Kurths, J. Multitask GANs for semantic segmentation and depth completion with cycle consistency. IEEE Trans. Neural Netw. Learn. Syst. 2021, 32, 5404–5415. [Google Scholar] [CrossRef]

- Yan, F. Semantic Scene Understanding for Intelligent Robotics. Ph.D. Thesis, Wichita State University, Wichita, KS, USA, 2023. [Google Scholar]

- Lynen, S.; Achtelik, M.W.; Weiss, S.; Chli, M.; Siegwart, R. A Robust and Modular Multi-Sensor Fusion Approach Applied to MAV Navigation. In Proceedings of the 2013 IEEE/RSJ International Conference on Intelligent Robots and Systems, Tokyo, Japan, 3–7 November 2013; IEEE: Piscataway, NJ, USA, 2013. [Google Scholar]

- Lai, T. A Review on Visual-SLAM: Advancements from Geometric Modelling to Learning-Based Semantic Scene Understanding Using Multi-Modal Sensor Fusion. Sensors 2022, 22, 7265. [Google Scholar] [CrossRef] [PubMed]

- Ovur, S.E.; Demiris, Y. Naturalistic Robot-to-Human Bimanual Handover in Complex Environments Through Multi-Sensor Fusion. IEEE Trans. Autom. Sci. Eng. 2023, 1–12. [Google Scholar] [CrossRef]

- Tang, Q.; Liang, J.; Zhu, F. A Comparative Review on Multi-modal Sensors Fusion Based on Deep Learning. Signal Process. 2023, 213, 109165. [Google Scholar] [CrossRef]

- Yang, M.; Sun, X.; Jia, F.; Rushworth, A.; Dong, X.; Zhang, S.; Fang, Z.; Yang, G.; Liu, B. Sensors and Sensor Fusion Methodologies for Indoor Odometry: A Review. Polymers 2022, 14, 2019. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Gao, J.; Yi, J.; Liu, P.; Xu, C. Environment Perception Technology for Intelligent Robots in Complex Environments: A Review. In Proceedings of the 2022 7th International Conference on Communication, Image and Signal Processing (CCISP), Chengdu, China, 18–20 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 479–485. [Google Scholar] [CrossRef]

- Zheng, S.; Wang, J.; Rizos, C.; Ding, W.; El-Mowafy, A. Simultaneous Localization and Mapping (SLAM) for Autonomous Driving: Concept and Analysis. Remote Sens. 2023, 15, 1156. [Google Scholar] [CrossRef]

- Ge, G.; Zhang, Y.; Wang, W.; Hu, L.; Wang, Y.; Jiang, Q. Visual-Feature-Assisted Mobile Robot Localization in a Long Corridor Environment. Front. Inf. Technol. Electron. Eng. 2023, 24, 876–889. [Google Scholar] [CrossRef]

- Shi, Y.; Jiang, K.; Wang, K.; Li, J.; Wang, Y.; Yang, D. FusionMotion: Multi-Sensor Asynchronous Fusion for Continuous Occupancy Prediction via Neural-ODE. arXiv 2023, arXiv:2302.09585. [Google Scholar]

- Bordvik, D.A.; Hou, J.; Noori, F.M.; Uddin, M.Z.; Torresen, J. Monitoring In-Home Emergency Situation and Preserve Privacy Using Multi-Modal Sensing and Deep Learning. In Proceedings of the 2022 International Conference on Electronics, Information and Communication (ICEIC), Jeju, Republic of Korea, 6–9 February 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Jiang, P.; Ma, J.; Zhang, Z.; Zhang, J. Multi-Sensor Fusion Framework for Obstacle Avoidance via Deep Reinforcement Learning. In Proceedings of the 2022 2nd International Conference on Electrical Engineering and Control Science (IC2ECS), Nanjing, China, 16–18 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 153–156. [Google Scholar] [CrossRef]

- Tayeh, T.; Aburakhia, S.; Myers, R.; Shami, A. An attention-based ConvLSTM autoencoder with dynamic thresholding for unsupervised anomaly detection in multivariate time series. Mach. Learn. Knowl. Extr. 2022, 4, 350–370. [Google Scholar] [CrossRef]

- Kabir, R.; Watanobe, Y.; Islam, M.R.; Naruse, K.; Rahman, M.M. Unknown object detection using a one-class support vector machine for a cloud–robot system. Sensors 2022, 22, 1352. [Google Scholar] [CrossRef] [PubMed]

- Yun, H.; Kim, H.; Jeong, Y.H.; Jun, M.B.G. Autoencoder-based anomaly detection of industrial robot arm using stethoscope based internal sound sensor. J. Intell. Manuf. 2023, 34, 1427–1444. [Google Scholar] [CrossRef]

- Yokkampon, U.; Mowshowitz, A.; Chumkamon, S.; Hayashi, E. Robust Unsupervised Anomaly Detection with Variational Autoencoder in Multivariate Time Series Data. IEEE Access 2022, 10, 57835–57849. [Google Scholar] [CrossRef]

- Mantegazza, D.; Giusti, A.; Gambardella, L.M.; Guzzi, J. An outlier exposure approach to improve visual anomaly detection performance for mobile robots. IEEE Robot. Autom. Lett. 2022, 7, 11354–11361. [Google Scholar] [CrossRef]

- Dulac-Arnold, G.; Levine, N.; Mankowitz, D.J. Challenges of Real-World Reinforcement Learning: Definitions, Benchmarks and Analysis. Mach. Learn. 2021, 110, 2419–2468. [Google Scholar] [CrossRef]

- Kormushev, P.; Calinon, S.; Caldwell, D.G. Reinforcement Learning in Robotics: Applications and Real-World Challenges. Robotics 2013, 2, 122–148. [Google Scholar] [CrossRef]

- Zhu, H.; Yu, J.; Gupta, A.; Shah, D.; Hartikainen, K.; Singh, A.; Kumar, V.; Levine, S. The Ingredients of Real-World Robotic Reinforcement Learning. arXiv 2020, arXiv:2004.12570. [Google Scholar]

- Ibarz, J.; Tan, J.; Finn, C.; Kalakrishnan, M.; Pastor, P.; Levine, S. How to Train Your Robot with Deep Reinforcement Learning: Lessons We Have Learned. Int. J. Robot. Res. 2021, 40, 698–721. [Google Scholar] [CrossRef]

- Tsurumine, Y.; Cui, Y.; Uchibe, E. Matsubara, TDeep reinforcement learning with smooth policy update: Application to robotic cloth manipulation. Robot. Auton. Syst. 2019, 112, 72–83. [Google Scholar] [CrossRef]

- Kobayashi, T. Adaptive and multiple time-scale eligibility traces for online deep reinforcement learning. Robot. Auton. Syst. 2022, 151, 104019. [Google Scholar] [CrossRef]

- Iriondo, A.; Lazkano, E.; Ansuategi, A.; Rivera, A.; Lluvia, I.; Tubío, C. Learning positioning policies for mobile manipulation operations with deep reinforcement learning. Int. J. Mach. Learn. Cyber. 2023, 14, 3003–3023. [Google Scholar] [CrossRef]

- Wang, Q.; Sanchez, F.R.; McCarthy, R.; Bulens, D.C.; McGuinness, K.; O’Connor, N.; Wüthrich, M.; Widmaier, F.; Bauer, S.; Redmond, S.J. Dexterous robotic manipulation using deep reinforcement learning and knowledge transfer for complex sparse reward-based tasks. Expert Syst. 2023, 40, e13205. [Google Scholar] [CrossRef]

- Shahid, A.A.; Piga, D.; Braghin, F.; Roveda, L. Continuous control actions learning and adaptation for robotic manipulation through reinforcement learning. Auton Robot. 2022, 46, 483–498. [Google Scholar] [CrossRef]

- Biemann, M.; Scheller, F.; Liu, X.; Huang, L. Experimental evaluation of model-free reinforcement learning algorithms for continuous HVAC control. Appl. Energy 2021, 298, 117164. [Google Scholar] [CrossRef]

- Aumjaud, P.; McAuliffe, D.; Rodríguez-Lera, F.J.; Cardiff, P. Reinforcement Learning Experiments and Benchmark for Solving Robotic Reaching Tasks; Springer International Publishing: Cham, Switzerland, 2021; pp. 318–331. [Google Scholar]

- Lyu, J.; Yang, Y.; Yan, J.; Li, X. Value activation for bias alleviation: Generalized-activated deep double deterministic policy gradients. Neurocomputing 2023, 518, 70–81. [Google Scholar] [CrossRef]

- Flet-Berliac, Y.; Ouhamma, R.; Maillard, O.-A.; Preux, P. Learning Value Functions in Deep Policy Gradients using Residual Variance. arXiv 2020, arXiv:2010.04440. [Google Scholar]

- Kovalev, V.; Shkromada, A.; Ouerdane, H.; Osinenko, P. Combining Model-Predictive Control and Predictive Reinforcement Learning for Stable Quadrupedal Robot Locomotion. arXiv 2023, arXiv:2307.07752.2023. [Google Scholar]

- Zhang, Z.; Chang, X.; Ma, H.; An, H.; Lang, L. Model Predictive Control of Quadruped Robot Based on Reinforcement Learning. Appl. Sci. 2023, 13, 154. [Google Scholar] [CrossRef]

- Chadi, M.A.; Mousannif, H. Understanding Reinforcement Learning Algorithms: The Progress from Basic Q-learning to Proximal Policy Optimization. arXiv 2023, arXiv:2304.00026. [Google Scholar]

- Gelly, S.; Kocsis, L.; Schoenauer, M.; Sebag, M.; Silver, D.; Szepesvári, C.; Teytaud, O. The grand challenge of computer Go. Commun. ACM 2012, 55, 106–113. [Google Scholar] [CrossRef]

- Koren, M.; Kochenderfer, M.J. Adaptive Stress Testing without Domain Heuristics using Go-Explore. arXiv 2020, arXiv:2004.04292. [Google Scholar]

- Bai, F.; Meng, F.; Liu, J.; Wang, J.; Meng, M.Q.-H. Hierarchical policy with deep-reinforcement learning for nonprehensile multiobject rearrangement. Biomim. Intell. Robot. 2022, 2, 100047. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, B.; Fränti, P. A review of motion planning algorithms for intelligent robots. J. Intell. Manuf. 2022, 33, 387–424. [Google Scholar] [CrossRef]

- Baláž, M.; Tarábek, P. Tensor Implementation of Monte-Carlo Tree Search for Model-Based Reinforcement Learning. Appl. Sci. 2023, 13, 1406. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, H.; Xu, W. Hierarchical Reinforcement Learning By Discovering Intrinsic Options. arXiv 2021, arXiv:2101.06521. [Google Scholar]

- Morimoto, J.; Doya, K. Acquisition of stand-up behavior by a real robot using hierarchical reinforcement learning. Robot. Auton. Syst. 2001, 36, 37–51. [Google Scholar] [CrossRef]

- Chapman, M.; Xu, L.; Lapeyrolerie, M.; Boettiger, C. Bridging adaptive management and reinforcement learning for more robust decisions. arXiv 2023, arXiv:2303.08731. [Google Scholar] [CrossRef]

- Wang, Z.; Meng, H.; Zhou, Z.; Feng, Y.; Gao, Y.; Yu, C. Towards Uncertainty in Decision: A Survey on Recent Advances and Challenges in Bayesian Reinforcement Learning. 2022. Available online: https://www.researchsquare.com/article/rs-1780336/v1 (accessed on 12 September 2023).

- Badings, T.; Simão, T.D.; Suilen, M.; Jansen, N. Decision-Making Under Uncertainty: Beyond Probabilities. Int. J. Softw. Tools Technol. Transf. 2023, 25, 375–391. [Google Scholar] [CrossRef]

- Valverde, G.; Quesada, D.; Larrañaga, P.; Bielza, C. Causal reinforcement learning based on Bayesian networks applied to industrial settings. Eng. Appl. Artif. Intell. 2023, 125, 106657. [Google Scholar] [CrossRef]

- Xu, S.; Liu, Q.; Hu, Y.; Xu, M.; Hao, J. Decision-making models on perceptual uncertainty with distributional reinforcement learning. Green Energy Intell. Transp. 2023, 2, 100062. [Google Scholar] [CrossRef]

- Wu, J.; Shang, S. Managing Uncertainty in AI-Enabled Decision Making and Achieving Sustainability. Sustainability 2020, 12, 8758. [Google Scholar] [CrossRef]

- Tchangani, A.; Networks, B.; Advances, I.D. Bayesian Networks in Risk Informed Decision-Making. Adv. Math. Res. 2023, 29, 31–76. [Google Scholar]

- Celemin, C.; Kober, J. Knowledge- and ambiguity-aware robot learning from corrective and evaluative feedback. NEural Comput. Appl. 2023, 35, 16821–16839. [Google Scholar] [CrossRef]

- Liang, Z.; He, J.; Hu, C.; Pu, X.; Khani, H.; Dai, L.; Fan, D.; Manthiram, A.; Wang, Z. Next-Generation Energy Harvesting and Storage Technologies for Robots Across All Scales. Adv. Intell. Syst. 2023, 5, 2200045. [Google Scholar] [CrossRef]

- Szewczyk, P.K.; Gradys, A.; Kim, S.K.; Persano, L.; Marzec, M.; Kryshtal, A.; Busolo, T.; Toncelli, A.; Pisignano, D.; Bernasik, A.; et al. Enhanced Piezoelectricity of Electrospun Polyvinylidene Fluoride Fibers for Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 13575–13583. [Google Scholar] [CrossRef]

- Pu, X.; Liu, M.; Chen, X.; Sun, J.; Du, C.; Zhang, Y.; Zhai, J.; Hu, W.; Wang, Z.L. Ultrastretchable, transparent triboelectric nanogenerator as electronic skin for biomechanical energy harvesting and tactile sensing. Sci. Adv. 2017, 3, e1700015. [Google Scholar] [CrossRef] [PubMed]

- Mamur, H.; Dilmaç, Ö.F.; Begum, J.; Bhuiyan, M.R.A. Thermoelectric generators act as renewable energy sources. Clean. Mater. 2021, 2, 100030. [Google Scholar] [CrossRef]

- Zhu, S.; Fan, Z.; Feng, B.; Shi, R.; Jiang, Z.; Peng, Y.; Gao, J.; Miao, L.; Koumoto, K. Review on Wearable Thermoelectric Generators: From Devices to Applications. Energies 2022, 15, 3375. [Google Scholar] [CrossRef]

- Verstraten, T.; Hosen, M.S.; Berecibar, M.; Vanderborght, B. Selecting Suitable Battery Technologies for Untethered Robot. Energies 2023, 16, 4904. [Google Scholar] [CrossRef]

- Fichtner, M.; Edström, K.; Ayerbe, E.; Berecibar, M.; Bhowmik, A.; Castelli, I.E.; Clark, S.; Dominko, R.; Erakca, M.; Franco, A.A.; et al. Rechargeable Batteries of the Future—The State of the Art from a BATTERY 2030+ Perspective. Adv. Energy Mater. 2022, 12, 2102904. [Google Scholar] [CrossRef]

- Al-Thyabat, S.; Nakamura, T.; Shibata, E.; Iizuka, A. Adaptation of minerals processing operations for lithium-ion (LiBs) and nickel metal hydride (NiMH) batteries recycling: Critical review. Miner. Eng. 2013, 45, 4–17. [Google Scholar] [CrossRef]

- Duffner, F.; Kronemeyer, N.; Tübke, J.; Leker, J.; Winter, M.; Schmuch, R. Post-lithium-ion battery cell production and its compatibility with lithium-ion cell production infrastructure. Nat. Energy 2021, 6, 123–134. [Google Scholar] [CrossRef]

- Forouzandeh, P.; Kumaravel, V.; Pillai, S.C. Electrode Materials for Supercapacitors: A Review of Recent Advances. Catalysts 2020, 10, 969. [Google Scholar] [CrossRef]

- Citroni, R.; Di Paolo, F.; Livreri, P. A Novel Energy Harvester for Powering Small UAVs: Performance Analysis, Model Validation and Flight Results. Sensors 2019, 19, 1771. [Google Scholar] [CrossRef]

- Nardekar, S.S.; Kim, S.-J. Untethered Magnetic Soft Robot with Ultra-Flexible Wirelessly Rechargeable Micro-Supercapacitor as an Onboard Power Source. Adv. Sci. 2023, 10, 2303918. [Google Scholar] [CrossRef]

- Townsend, A.; Jiya, I.N.; Martinson, C.; Bessarabov, D.; Gouws, R. A comprehensive review of energy sources for unmanned aerial vehicles, their shortfalls and opportunities for improvements. Heliyon 2020, 6, e05285. [Google Scholar] [CrossRef] [PubMed]

- Allioui, H.; Mourdi, Y. Unleashing the Potential of AI: Investigating Cutting-Edge Technologies That Are Transforming Businesses. Int. J. Comput. Eng. Data Sci. IJCEDS 2023, 3, 1–12. [Google Scholar]

- Sun, Y. Neural Network-Based Tracking Control of Uncertain Robotic Systems: Predefined-Time Nonsingular Terminal Sliding-Mode Approach. IEEE Trans. Ind. Electron. 2022, 69, 10510–10520. [Google Scholar] [CrossRef]

- Bhadra, P.; Chakraborty, S.; Saha, S. Cognitive IoT Meets Robotic Process Automation: The Unique Convergence Revolutionizing Digital Transformation in the Industry 4.0 Era. In Confluence of Artificial Intelligence and Robotic Process Automation; Smart Innovation, Systems and Technologies; Bhattacharyya, S., Banerjee, J.S., De, D., Eds.; Springer: Singapore, 2023; Volume 335. [Google Scholar]

- Chryssolouris, G.; Alexopoulos, K.; Arkouli, Z. Artificial Intelligence in Manufacturing Equipment, Automation and Robots. In A Perspective on Artificial Intelligence in Manufacturing. Studies in Systems, Decision and Control; Springer: Cham, Switzerland, 2023; Volume 436. [Google Scholar]

- Tan, Y.; Deng, T.; Xu, L. An Ensemble Energy Consumption Prediction Model for Industrial Serial-Robot. In Proceedings of the 2022 34th Chinese Control and Decision Conference (CCDC), Hefei, China, 15–17 August 2022; pp. 5473–5478. [Google Scholar]

- Bathla, G.; Bhadane, K.; Singh, R.K.; Kumar, R.; Aluvalu, R.; Krishnamurthi, R.; Kumar, A.; Thakur, R.N.; Basheer, S. Autonomous Vehicles and Intelligent Automation: Applications, Challenges and Opportunities. Mob. Inf. Syst. 2022, 2022, 7632892. [Google Scholar] [CrossRef]

- Liu, C.; Lu, J.; Yang, H.; Guo, K. Current State of Robotics in Hand Rehabilitation after Stroke: A Systematic Review. Appl. Sci. 2022, 12, 4540. [Google Scholar] [CrossRef]

- Su, H.; Hou, X.; Zhang, X.; Qi, W.; Cai, S.; Xiong, X.; Guo, J. Pneumatic Soft Robots: Challenges and Benefits. Actuators 2022, 11, 92. [Google Scholar] [CrossRef]

- Xie, D.; Chen, L.; Liu, L.; Chen, L.; Wang, H. Actuators and Sensors for Application in Agricultural Robots: A Review. Machines 2022, 10, 913. [Google Scholar] [CrossRef]

- Dhanya, V.G.; Subeesh, A.; Kushwaha, N.L.; Vishwakarma, D.K.; Nagesh Kumar, T.; Ritika, G.; Singh, A.N. Deep learning based computer vision approaches for smart agricultural applications. Artif. Intell. Agric. 2022, 6, 211–229. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Monsalve, G.; Cardenas, A.; Mousazadeh, H. Off-Road Electric Vehicles and Autonomous Robots in Agricultural Sector: Trends, Challenges and Opportunities. Vehicles 2022, 4, 843–864. [Google Scholar] [CrossRef]

- Barrile, V.; Simonetti, S.; Citroni, R.; Fotia, A.; Bilotta, G. Experimenting Agriculture 4.0 with Sensors: A Data Fusion Approach between Remote Sensing, UAVs and Self-Driving Tractors. Sensors 2022, 22, 7910. [Google Scholar] [CrossRef] [PubMed]

- Arbanas, B.; Petric, F.; Batinović, A.; Polić, M.; Vatavuk, I.; Marković, L.; Bogdan, S. From ERL to MBZIRC: Development of An Aerial-Ground Robotic Team for Search and Rescue. In Automation and Control—Theories and Applications; IntechOpen: Rijeka, Croatia, 2022. [Google Scholar] [CrossRef]

- Megalingam, R.K.; Vadivel, S.R.R.; Rajendraprasad, A.; Raj, A.; Baskar, S.; Marutha Babu, R.B. Development and Evaluation of a Search-and-Rescue Robot Paripreksya 2.0 for WRS 2020. Adv. Robot. 2022, 36, 1120–1133. [Google Scholar] [CrossRef]

- Nguyen, T.; Katila, R.; Gia, T.N. An advanced Internet-of-Drones System with Blockchain for improving quality of service of Search and Rescue: A feasibility study. Future Gener. Comput. Syst. 2023, 140, 36–52. [Google Scholar] [CrossRef]

- Hu, J.; Niu, H.; Carrasco, J.; Lennox, B.; Arvin, F. Voronoi-Based Multi-Robot Autonomous Exploration in Unknown Environments via Deep Reinforcement Learning. IEEE Trans. Veh. Technol. 2020, 69, 14413–14423. [Google Scholar] [CrossRef]

- Sahoo, S.; Lo, C.-Y. Smart Manufacturing Powered by Recent Technological Advancements: A Review. J. Manuf. Syst. 2022, 64, 236–250. [Google Scholar] [CrossRef]

- Luiz, L.E.; Pilarski, L.; Baidi, K.; Braun, J.; Oliveira, A.; Lima, J.; Costa, P. Robot at Factory Lite—A Step-by-Step Educational Approach to the Robot Assembly. In ROBOT2022: Fifth Iberian Robotics Conference; Tardioli, D., Matellán, V., Heredia, G., Silva, M.F., Marques, L., Eds.; ROBOT 2022; Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2023; Volume 589. [Google Scholar]

- Hemavathi, S.; Shinisha, A. A Study on Trends and Developments in Electric Vehicle Charging Technologies. J. Energy Storage 2022, 52 Pt C, 105013. [Google Scholar] [CrossRef]

- Sengun, B.; Iscan, Y.; Ozbulak, G.A.; Kumbasar, N.; Egriboz, E.; Sormaz, I.C.; Aksakal, N.; Deniz, S.M.; Haklidir, M.; Tunca, F.; et al. Artificial Intelligence in Minimally Invasive Adrenalectomy: Using Deep Learning to Identify the Left Adrenal Vein. Surg. Laparosc. Endosc. Percutaneous Tech. 2023, 33, 327–331. [Google Scholar] [CrossRef]

- Haidegger, T.; Speidel, S.; Stoyanov, D.; Satava, R.M. Robot-Assisted Minimally Invasive Surgery—Surgical Robotics in the Data Age. Proc. IEEE 2022, 110, 835–846. [Google Scholar] [CrossRef]

- Farooq, M.U.; Eizad, A.; Bae, H.-K. Power solutions for autonomous mobile robots: A survey. Robot. Auton. Syst. 2023, 159, 104285. [Google Scholar] [CrossRef]

- Ghobadpour, A.; Cardenas, A.; Monsalve, G.; Mousazadeh, H. Optimal Design of Energy Sources for a Photovoltaic/Fuel Cell Extended-Range Agricultural Mobile Robot. Robotics 2023, 12, 13. [Google Scholar] [CrossRef]

- Saviolo, A.; Loianno, G. Learning quadrotor dynamics for precise, safe and agile flight control. Annu. Rev. Control. 2023, 55, 45–60. [Google Scholar] [CrossRef]

- Barzegar, A.; Lee, D.-J. Deep Reinforcement Learning-Based Adaptive Controller for Trajectory Tracking and Altitude Control of an Aerial Robot. Appl. Sci. 2022, 12, 4764. [Google Scholar] [CrossRef]

- Ruan, T.; Wang, H.; Stolkin, R.; Chiou, M. A Taxonomy of Semantic Information in Robot-Assisted Disaster Response. In Proceedings of the 2022 IEEE International Symposium on Safety, Security and Rescue Robotics (SSRR), Sevilla, Spain, 8–10 November 2022; pp. 285–292. [Google Scholar]

- Chen, Z.; Jiao, W.; Ren, K.; Yu, J.; Tian, Y.; Chen, K.; Zhang, X. A Survey of Research Status on the Environmental Adaptation Technologies for Marine Robots. Ocean. Eng. 2023, 286 Pt 2, 115650. [Google Scholar] [CrossRef]

- Arzo, S.T.; Sikeridis, D.; Devetsikiotis, M.; Granelli, F.; Fierro, R.; Esmaeili, M.; Akhavan, Z. Essential Technologies and Concepts for Massive Space Exploration: Challenges and Opportunities. IEEE Trans. Aerosp. Electron. Syst. 2023, 59, 3–29. [Google Scholar] [CrossRef]

| Power Converter | Key Features | Voltage Regulation Range | Efficiency Range | Switching Frequency | Robotics Applications |

|---|---|---|---|---|---|

| Buck Converter [61] | Step-down voltage conversion | Narrow to Moderate | High | Medium to High | Battery-powered robots, sensor nodes |

| Boost Converter [62] | Step-up voltage conversion | Moderate | High | Medium to High | Energy harvesting, charging mobile robots |

| Buck-Boost Converter [63] | Bidirectional voltage conversion | Wide | High | Medium to High | Battery management, variable power demands |

| Resonant Converter [52,53] | Zero-voltage switching, reduced EMI | Wide | Moderate to High | Medium to High | Wireless power transfer, contactless charging |

| Multi-level Converter [54,55] | Reduced harmonics, high voltage capability | Wide | High | Medium to High | High-power robotic arms, electric vehicles |

| Matrix Converter [58,59] | Bi-directional AC–AC conversion | Wide | High | Medium to High | Variable-speed motor drives, robotic actuators |

| Soft-Switching Converters [56,57] | Minimal switching losses | Moderate to Wide | High | High | High-frequency motor drives, precision robotics |

| Dual Active Bridge Converter [60] | Bidirectional AC–DC conversion | Moderate | High | Medium to High | Grid-tied robotics, energy-efficient actuators |

| Learning Method | Application | Advantages | Disadvantages | Possible Advancement |

|---|---|---|---|---|

| Reinforcement Learning | Robot decision-making | Learns from trial and error, Adapts to changing environments | Requires complex algorithms, May converge slowly | Enhanced exploration strategies, Improved sample efficiency |

| Deep Reinforcement Learning | Robotic arm manipulation | Handles complex situations, Utilizes deep neural networks | High computational cost, Prone to overfitting | Hybrid architectures combining RL and symbolic reasoning, Better regularization techniques |

| Trust Region Policy Optimization | Precise task execution | Fine-tuned actions for precision, Stable learning | Limited to small-scale problems, Sensitive to hyperparameters | Scalable TRPO variants, Adaptive hyperparameter tuning |

| Soft Actor-Critic | Fine-tuned actions | Handles precise tasks efficiently, Stable training | Complex to implement, Requires careful tuning | Improved exploration strategies, Real-time implementation |

| Model Predictive Control combined with RL | Legged locomotion | Adapts to unexpected environmental changes, Predictive control | Computationally intensive, Limited to short planning horizons | Efficient approximations for long planning horizons, Better integration with sensor data |

| Monte Carlo Tree Search | Complex decision-making | Effective in complex situations, Strong theoretical foundation | Limited to discrete action spaces, Computationally expensive | Hybrid MCTS with RL for continuous action spaces, Parallelization for faster decision-making |

| Proximal Policy Optimization | Complex decision-making | Stable and straightforward to implement, Good sample efficiency | Can be sensitive to initial conditions, Requires careful hyperparameter tuning | Advanced trust region methods, Adaptive exploration strategies |

| Hierarchical RL | Efficient decision-making | Breaks down complex tasks into manageable steps, Improved efficiency | Complex to design and train, Hierarchical policies may not generalize well | Better automated hierarchy discovery, Transfer learning between hierarchies |

| Bayesian RL | Decision-making under uncertainty | Considers uncertainty and risk, Robust decision-making | Requires probabilistic modeling, Computationally demanding | Improved inference algorithms, Incorporation of domain knowledge |

| Method of Energy Harvesting | Description | Advantages and Applications | Challenges and Considerations | Possible Advancements |

|---|---|---|---|---|

| Solar Energy [89,194,195,196] | Utilizes solar cells (e.g., DSSCs, CIGS, PSCs, OSCs) to convert sunlight into electrical power. | Global availability of sunlight, Suitable for robotic installations, Various material options for flexibility | Efficiency and reliability improvements, Flexible installation options | Enhanced efficiency of solar cells, improved flexibility and advanced installation techniques. |

| Thermoelectrical Generation [197,198] | Harnesses temperature differentials to generate electrical energy using semiconductor elements. | Harvests heat during operation, Potential for energy capture from human body | Power sharing among multiple drivers, Multi-degree of freedom operation considerations | Development of more efficient thermoelectric materials, advanced power management for multi-driver robots. |

| Battery Technology [199,200,201,202] | Evolution of rechargeable batteries (e.g., lead acid, lithium-ion, nickel-metal hydride) for improved robot performance. | Longer-lasting batteries, Enhanced efficiency and durability, Various battery chemistries | Issues with limited lifespan (lead acid), Operating temperature limitations (lithium-ion) | Advancements in battery chemistry, increased energy density and improved temperature tolerance. |

| Super Capacitors [203,205] | Offers fast charging as an alternative to batteries, categorized as electrochemical pseudo-capacitors and double-layer capacitors. | Rapid charge and discharge, Environmentally friendly, Suitable for wearables | Faster charging and discharging, Structural and stretchability advantages | Development of supercapacitors with even faster charging rates and enhanced structural properties. |

| Polymer Electrolyte Membrane Fuel Cells [206] | Employs fuel cells using chemical properties for energy storage, providing high energy density performance. | High energy density, Potential for green energy transition, Economical hydrogen fuel option | Efficient energy storage, Upscaling potential, Promotes green energy transition | Advances in fuel cell technology for increased energy density, efficiency and scalability. |

| Emerging Technology | Integration Details | Advancements | Technical Highlights | Innovations |

|---|---|---|---|---|

| Smart Factory [223,224,225] | Bidirectional converters manage energy based on demand predictions, Robots optimize energy usage via learning. | Reduced costs, efficient production, Adaptive energy allocation. | Real-time power management, Reinforcement learning for optimization. | Agile robotic assembly lines. |